Samsung AC071MN4PKH, AC090MN4PKH, AC140MN4PKH, AC090MXADKH, AC100MXAD*H Service Manual

...

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Reference Sheet

CONTENTSSYSTEM AIR CONDITIONER

INDOOR UNIT OUTDOOR UNIT

SYSTEM AIR

CONDITIONER

CIRCULAR CASSETTE SERIES

AC071MN4PKH

AC090MN4PKH

AC100MN4PKH

AC120MN4PKH

AC140MN4PKH

AC090MXADKH

AC100MXAD*H

AC120MXAD*H

AC140MXAD*H

Section 0

1

Contents

1. Precautions

..............................................................................................................................................................................................

1-1

1-1. Precautions for the Service

.........................................................................................................................................................

1-1

1-2. Precautions related to static electricity and PL

...................................................................................................................

1-1

1-3. Precautions related to product safety

...................................................................................................................................

1-2

1-4. Other precautions

..........................................................................................................................................................................

1-2

2. Product Specifications

....................................................................................................................................................................

2-1

2-1. The Feature of Product

.................................................................................................................................................................

2-1

2-2. Product Specifications

..................................................................................................................................................................

2-2

2-3. Specifications of optional items

...............................................................................................................................................

2-8

2-3-1. Accessories

...........................................................................................................................................................................

2-8

2-3-2. Wireless remote controller (AR-KH0O)

.....................................................................................................................

2-9

2-3-3. Wired remote controller (AWR-WE10N)

..................................................................................................................

2-10

2-3-4. Filter specifications

............................................................................................................................................................

2-11

3. Disassembly and Reassembly

..................................................................................................................................................

3-1

3-1. Necessary Tools

...............................................................................................................................................................................

3-1

3-2. Indoor Unit

........................................................................................................................................................................................

3-2

3-3. Outdoor Unit

.....................................................................................................................................................................................

3-11

4.

Troubleshooting

..........................................................................................................................................................................

4-1

4-1. Setting an indoor unit address and installation option

..................................................................................................

4-1

4-1-1. The procedure of setting option

..................................................................................................................................

4-1

4-1-2. The procedure of setting option

.................................................................................................................................

4-2

4-1-3. Order for Setting Options (Wired Remote Controller)

........................................................................................

4-12

4-1-4. Indoor address(MAIN/RMC)setting

............................................................................................................................

4-13

4-1-5. Set the indoor installation options(Option to set for the installation site conditions)

...........................

4-14

4-1-6. Changing the addresses and options individually

...............................................................................................

4-15

4-2. Model-specific option code

............................................................................................................................................................

4-16

4-3. Diagnostic Checklist ago

..............................................................................................................................................................

4-17

4-3-1. Test operation mode and check mode

....................................................................................................................

4-17

4-3-2. Eco Mode [Power Save Mode]

......................................................................................................................................

4-18

4-3-3.

Error code [indoor]

...........................................................................................................................................................

4-19

4-3-4. Error code [outdoor]

..........................................................................................................................................................

4-20

4-3-5.Wired remote controller

..................................................................................................................................................

4-33

4-4. Troubleshooting by symptoms

...................................................................................................................................................

4-25

4-1-1. When the outdoor unit power is not ON – Initial Diagnosis : 1-phase products

....................................

4-25

4-4-2. Indoor temperature sensor error (E121)

..................................................................................................................

4-26

4-4-3. Indoor heat exchanger temperature sensor error (E122)

..................................................................................

4-27

4-4-4. Indoor Fan error (E154)

....................................................................................................................................................

4-28

4-4-5. Communication error after finishing Tracking (E202)

.........................................................................................

4-29

4-4-6. Indoor unit float sensor error

........................................................................................................................................

4-30

4-4-7. EEPROM circuit failure (E162)

........................................................................................................................................

4-31

4-4-8. The whistling noise from the indoor unit in low wind mode

..........................................................................

4-32

4-4-9. When the outdoor unit power is not ON - Initial Diagnosis : 3-phase products

.....................................

4-33

4-4-10. Indoor/outdoor communication error (1min.) (Error Code : E202)

............................................................

4-37

Section 0

2

Contents

4-4-11. Communication error between outdoor unit INV ׳ MAIN MICOM (1 min.)(Error Code: E203)

...

4-39

4-4-12. Outdoor sensor error(Error Code : E221, E231, E251, E320)

............................................................................

4-40

4-4-13.Reverse phase / Loss phase detection (3-phase outdoor unit) (Error Code : E425 )

..............................

4-41

4-4-14. Compressor down due to freezing control (Error Code : E403)

....................................................................

4-42

4-4-15. Outdoor unit Fan error (Error Code : E458, E475)

...............................................................................................

4-43

4-4-16. Compressor starting error / rotation error (Error Code : E461, E467)

..........................................................

4-44

4-4-17. Full current error / PFC over-current error (Error Code : E462, E484)

...........................................................

4-46

4-4-18. IPM IPM (Over Current) error (Error Code : E464)

................................................................................................

4-47

4-4-19. DC LINK over-current / low-voltage error (Error Code : E466)

H/W DC_Link Over Voltage Error (Error Code : E483)

AC Input Voltage Sensor Error (Error Code : E488)

...................................................................................................................................... 4-50

4-4-20. Gas leakage error(Error Code : E554)

............................................................................................................................................................................. 4-51

4-4-21. Pipe blockage error(Error Code : E422)

....................................................................................................................................................................... 4-53

4-4-22. Smart install mode was not carried out (Error Code : E508 )

........................................................................................................... 4-54

4-4-23. Others

.................................................................................................................................................................................................................................................................... 4-56

5. PCB Diagram and Parts List

........................................................................................................................................................

5-1

5-1. PCB Diagram

....................................................................................................................................................................................

5-1

5-1-1. Indoor Unit Main PBA

.......................................................................................................................................................

5-1

5-1-2 Display PCB

............................................................................................................................................................................

5-3

5-1-3. Outdoor PCB

.........................................................................................................................................................................

5-4

6. Wiring Diagram

....................................................................................................................................................................................

6-1

6-1. Indoor Unit

........................................................................................................................................................................................

6-1

6-2. Outdoor Unit

....................................................................................................................................................................................

6-2

7. SW update

................................................................................................................................................................................................

7-1

7-1. S-net pro Download

......................................................................................................................................................................

7-1

7-2. RS485 VS RS232(UART)

................................................................................................................................................................

7-1

7-3. How to update the Micom(RS485)

.........................................................................................................................................

7-2

7-4. How to update the Micom(UART)

..........................................................................................................................................

7-7

7-5. How to write the EEPROM

..........................................................................................................................................................

7-9

8. Reference Sheet

...................................................................................................................................................................................

8-1

8-1. Index for model name

..................................................................................................................................................................

8-1

8-1-1. Indoor Unit

............................................................................................................................................................................

8-1

8-1-2. Outdoor Unit

........................................................................................................................................................................

8-3

8-1-3. Panel

........................................................................................................................................................................................

8-3

8-2. Refrigerating Cycle Diagram

......................................................................................................................................................

8-4

1-1

1. Precautions

1-1 Precautions for the Service

O Use the standard parts when replacing the electric parts.

– Confirm the model name, rated voltage, rated current of the electric parts.

O When repairing the equipment, connection of the harness parts must be firm and solid.

– A loose connection may cause noise or other malfunction.

O When assembling and disassembling the equipment while it is laid down, lay it on soft cloth.

– Otherwise it may scratch the back of the exterior of the product.

O Remove dust or dirt completely from the housing block, wiring block and service parts during repair.

– This helps prevent the danger of fire caused by tracking or short circuit.

O Fasten the valve caps of service valves and charging valves of outdoor unit as much as possible using adjustable wrenches.

O Check the status of the components’ assembly after repair service.

– The status must be the same as before the repair service.

1-2 Precautions related to static electricity and PL

O The PCB power supply block is susceptible to static electricity. Therefore, care must be taken during repair or measuring

while the power is on.

– Wear insulation gloves for PCB repair or measuring.

O Check whether the installation location is at least two meters away from other electronic products such as TV, video, or

audio.

– Otherwise, the video quality might be degraded or noise might be generated.

O Do not let end users repair the products themselves.

– Unauthorized disassembly might cause electric shock or fire.

1-2

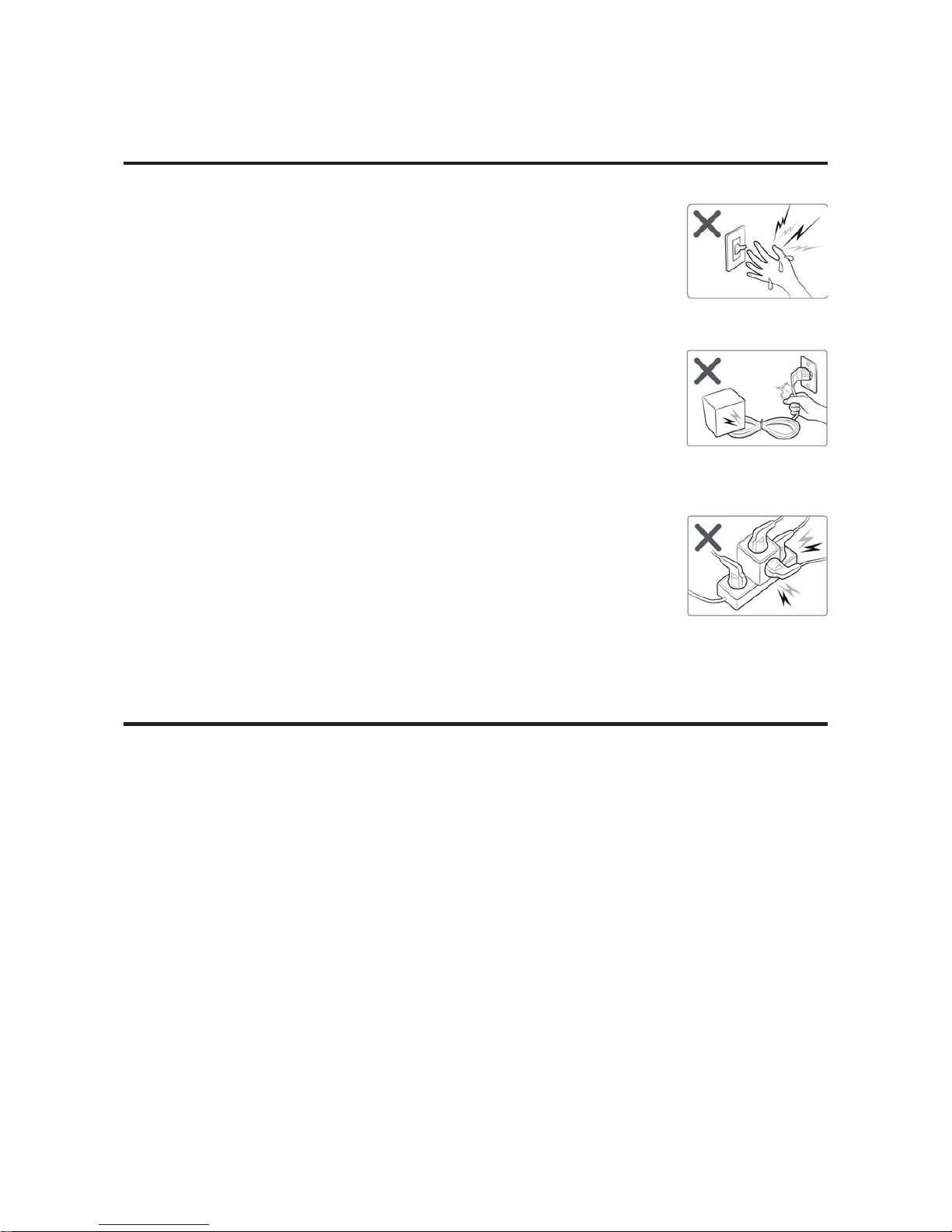

1-3 Precautions related to product safety

O Do not pull the power cord and do not touch the power plug or aux power switch

with wet hands.

– It might cause electric shock or fire.

O A damaged power line or power plug must be replaced to prevent danger.

O Do not bend the power cable with excessive force, and do not place a heavy weight

on the case as it might damage the cable.

– It might cause electric shock or fire.

O Do not use multiple electric outlets.

– This might cause electric shock or fire.

O Connect the ground terminal when necessary.

– Y ou must connect the ground terminal if you determine that there is a danger of electric

leakage due to moisture or water.

O Unplug the power cable or turn off the auxiliary power switch for electric part

replacement and repair service.

– Otherwise it might cause electric shock.

O Instruct end users to separate the batteries from the remote controllers and store

them separately when the product is not used for long time.

– Otherwise leakage from the dry cell may cause problems with the remote controller.

1-4 Other precautions

O The pipes should have no leaks during installation, and the compressor must be stopped before removing connecting

pipes for pump down work. Operating the compressor while the service valve is open and coolant pipe is not properly

connected may cause explosion or injury due to abnormal high pressure created inside the coolant cycle as the air can be

absorbed through the pipe.

O Pump Down work procedure (When uninstalling the product)

– Turn on the air conditioner, select cooling operation, and run the compressor for more than three minutes.

– Release the high pressure and low pressure valve caps.

– Close the high pressure valve completely using an L-wrench

– After about two minutes, close the low pressure valve completely.

– Stop running the air conditioner.

– Separate the connecting pipe.

2-1

□ 360 Cassette

□ Differentiated innovation air cooling

It delivers a cool air evenly with the circular air current and provides a wide and agreeable cooling area than general ceiling

air conditioners.

□ Refreshing and soft wind

It provides a horizontal air current that form natural convection instead of unpleasant direct wind.

It is consumer-friendly product that prevents the sudden effective temperature tumble.

□ High quality circular design

It applied the wind direction control technology (Coanda effect) which uses the booster fan. Epoch-making circular design

that eliminates the blade.

□ Eco-friendly air conditioner

It is eco-friendly air conditioner that is certified a RoHS technology as well as realize high effectiveness, low noise, super

power saving.

□ Electricity savings through S- Inverter System

Apply S-inverter system that change capacity to 10~160% according to circumstance by one compressor and reduce

optimum cooling effect and unnecessary electricity consumption.

□ Clearness function of four seasons high efficiency

Energy consumption and driving noise decrease more because can operate clearness function separately.

Make healthy and clean environment by bacillus exclusion function and active oxygen neutralization function that virus

doctor at air conditioner driving removes air various hazardous substances operating always..

2.

Product Specifications

2-1 The Feature of Product

2-2 2-3

ITEM

Development Model

AC090M N4PKH

AC090MXADKH

AC100MN4P KH

AC100MXA DKH

AC100MN4P KH

AC100MXA DKH

AC120MN4PK H

AC120MXAD KH

AC120MN4PK H

AC120MXAD KH

AC120MN4PK H

AC120MXAD NH

AC071MN4PK H

AC140MN4PK H

AC140MXAD KH

AC140MN4PK H

AC140MXAD NH

Design

Indoor Unit

Outdoor Unit

Remote Controller

Capacity

Cooling[w] 9 10 10 12 12 12 13.4 13.4

Heat ing [ W] 10 11.2 11.2 13 13 13 15.5 15. 5

Power input

Cooling[w] 2820 3400 3400 4700 4700 4700 4450 4450

Heating [W] 2650 3150 3150 4000 4000 4000 4540 4540

EER/COP

Cooling[w] 6.8 6.8 6. 8 5.7 5.7 5.7 3.01 3.01

Heating [W] 4.3 4.3 4.3 4.1 4.1 4.1 3.41 3.41

Voltage / Frequency

1Φ, 220-240V~/50Hz 1Φ, 220-240V~/50Hz 1Φ, 220-240V~/50Hz 1Φ, 220-240V~/50Hz 1Φ, 220-240V~/50Hz 3Φ, 380-415V 3N~/50Hz 1Φ, 220-240V~/50Hz 3Φ, 380-415V 3N~/50Hz

Running

Current

Coo li ng [w] 12.7 15.1 15.1 20. 5 20 .5 7.1 20 7

Heating [W] 12.5 14.6 14.6 17.5 17.5 6.3 19.5 7

Noise

Indoor Unit [dBA] (C/H)

48/48 50/50 50/50 50/50 50/50 50/50 51/51 51/51

Outdoo r Unit [dBA] (C /H) 57/59 58/60 58/60 59/61 59/61 59/61 60/62 60/62

Size (W*H*D)

Net Dimension

(WxHxD)

Indoor Unit [mm]

947*947*365 947*947*365 947*947*365 947*947*365 947*947*365 947*947*365 947*947*365 947*947*365

Outdoor Unit [mm]

990*990*414 990*990*414 990*990*414 990*990*414 990*990*414 990*990*414 990*990*414 990*990*414

Shipping

Dimension

(WxHxD)

Indoor Unit [mm]

940*330*998 940*330*998 940*330*998 940*330*998 940*330*998 940*330*998 940*330*1210 940*330*1210

Outdoor Unit [mm] 995*426*1096 995*426*1096 995*426*1096 995*426*1096 995*426*1096 995*426*1096 995*426*1388 995*426*1388

Weight (kg)

Net

Indoo r Unit [kg ] 24 24 24 24 24 24 26 26

Outdoor Unit [kg] 28.5 28.5 28.5 28.5 28.5 28.5 30.5 30.5

Shipping

Indoor Unit [kg] 72 72 72 80 8 0 80 85 85

Outdoor Unit [kg] 77 77 77 85 85 85 94 94

2-2 Product Specifications

2-4 2-5

ITEM

Development Model

AC090M N4PKH

AC090MXADKH

AC100MN4P KH

AC100MXA DKH

AC100MN4P KH

AC100MXA DKH

AC120MN4PK H

AC120MXAD KH

AC120MN4PK H

AC120MXAD KH

AC120MN4PK H

AC120MXAD NH

AC071MN4PK H

AC140MN4PK H

AC140MXAD KH

AC140MN4PK H

AC140MXAD NH

Harness spec

Indoor fan motor

DB31-00577D DB31-00577D DB31-00577D DB31-00577D DB31-00577D DB31-00577D DB31-00577D DB31-00577D

Compressor UG8T300FUBJUSG UG8T300FUBJUSG UG8T 300FUBJUSG UG5TK1450FJX UG5TK1450 FJX U G5T K1450FJX UG5TK1450 FJX U G5T K1450FJX

Outdoor fan motor

DB31-00579B DB31-00579B DB31-00579B DB31-00579B DB31-00579B D B31-00579B DB31-00658A DB31-00658A

Designed

pressure

High presssure 4.1 Mpa 4.1 Mpa 4.1 Mpa 4.1 Mpa 4.1 Mpa 4.1 Mpa 4.1 Mpa 4.1 Mpa

Low pressure 1.4 Mpa 1.4 Mpa 1.4 Mpa 1.4 Mpa 1.4 Mpa 1.4 Mpa 1.4 Mpa 1.4 Mpa

Refrigerant / Factory charging

3000 3000 3000 3000 3000 3000 3400 3400

Additional refrigerant 50g/m 50g/m 50g/m 50g/m 50g/m 50g/m 50g/m 50g/m

Basic piping length

55555555

Max. piping leng th 50 50 50 50 50 50 75 75

Max. level different 3030303030303030

Option code

01007F-19547C-275A64-370040 01007F-19548C-276470-370040 01007F-19548C-276470-370040 01007F-19549D-277882-370040 01007F-19549D-277882-370040 01007F-19549D-277882-370040 01107F-1954AF-278CA0-370040 01107F-1954AF-278CA0-370040

020000-100000200000-300000

020000-100000200000-300000

020000-100000200000-300000

020000-100000-

200000-300000

020000-100000200000-300000

020000-100000200000-300000

020000-100000200000-300000

020000-100000200000-300000

030000-100000200000-300000

030000-100000200000-300000

030000-100000-

200000-300000

030000-100000-

200000-300000

030000-100000200000-300000

030000-100000200000-300000

030000-100000200000-300000

030000-100000200000-300000

2-6

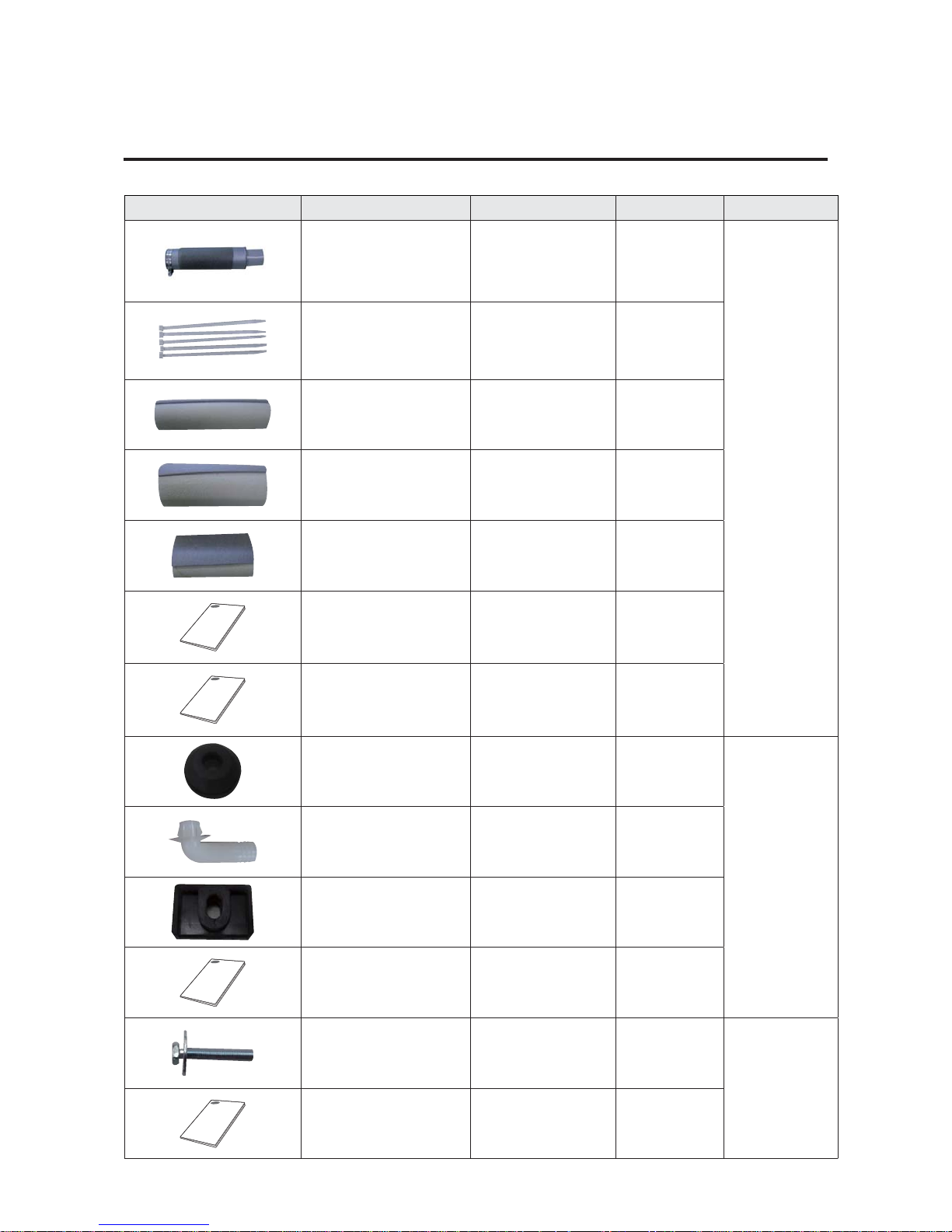

2-3 Specifications of optional items

2-3-1 Accessories

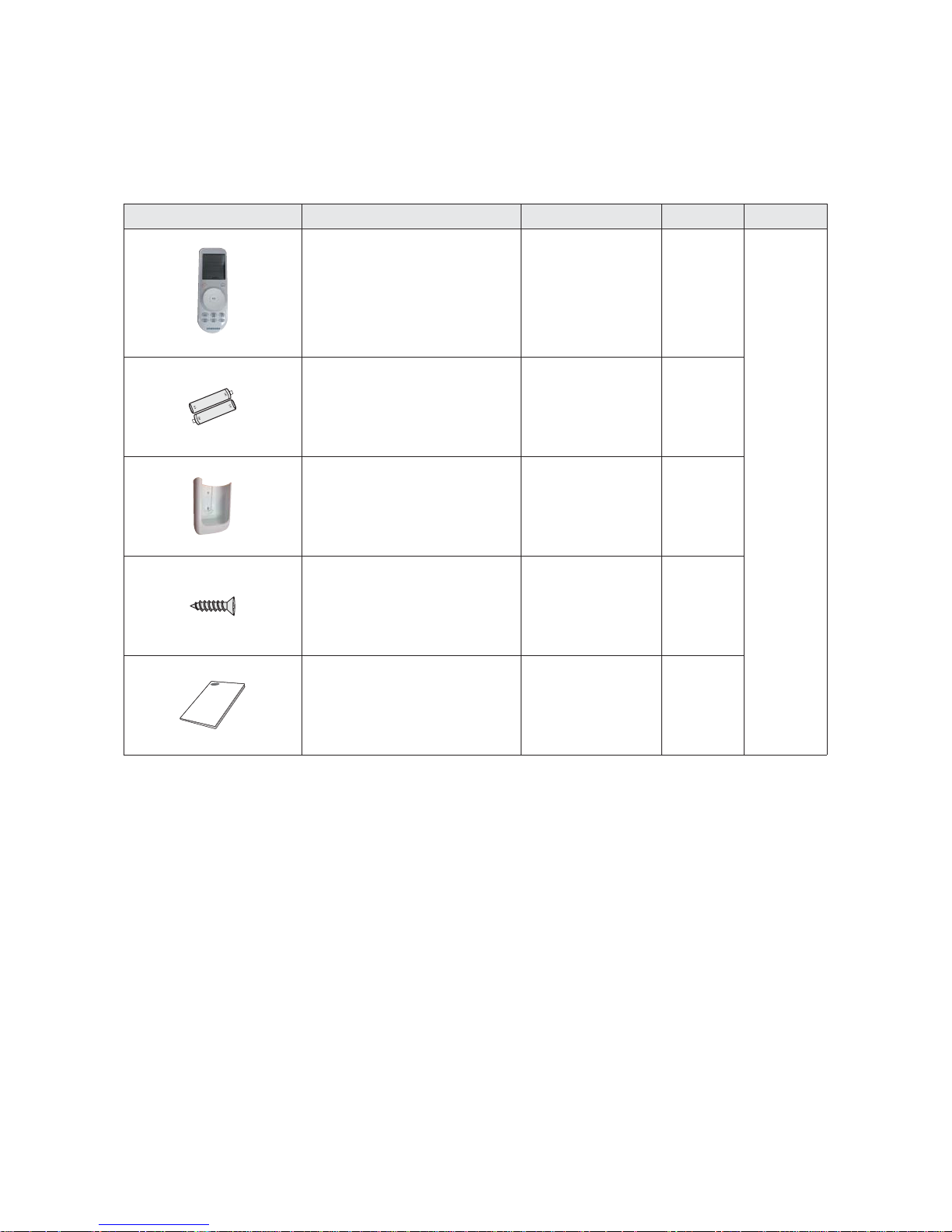

Item Description Code No. Q’ty Remark

ASSY DRAIN- HOSE

DB94-02719B

1

Standard / Indoor unit

Cable tie

DB65-00191A

6

Seal-drain ass'y

DB62-05810A

1

Seal-drain ass'y

DB94-05810F

1

Seal-drain ass'y

DB94-05810G

1

Indoor unit installation manual

DB68-05899A

1

USER MANUAL

DB68-05918A

1

Drain cap

DB63-10355C

3

(AC071KX4DKH : 4)

Standard / Outdoor

unit

Pipe plug

DB67-00806A

1

Rubber Leg

DB73-20134A

(AC071KX4DKH :

DB73-00179A)

4

Outdoor unit installation manual

DB68-05565A

1

Bolt-flange

6009-001435

4

Standard / Panel

INSTALL MANUAL

DB68-05903A

1

Product Specifications

2-7

Item Description Code No. Q’ty Remark

Wireless remote controller

DB93-15771C

1

Optional

Batteries for remote controller

(specification: "AAA" type)

4301-000121

2

Remote controller holder

DB61-06607A

1

M4×16 Screw

6002-000581

2

User’s manual

DB68-05911A

1

2-3-2 Wireless remote controller (AR-KH00E)

Product Specifications

2-8

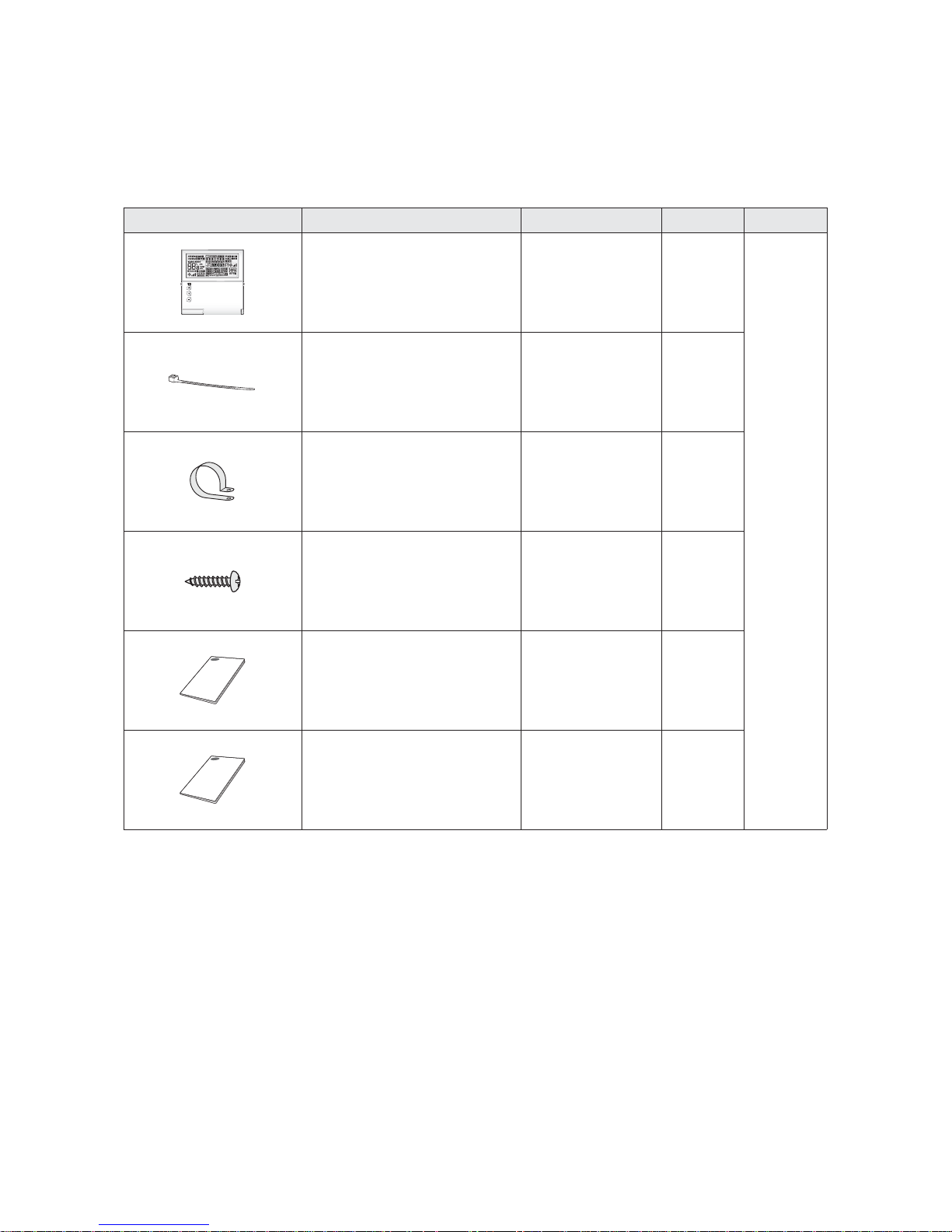

2-3-3 Wired remote controller (MWR-WE10N)

Item Description Code No. Q’ty Remark

Wired remote controller DB93-11251F 1

Optional

Cable tie DB65-10088B

2

Cable clamp DB65-10074E 3

M4×16 Screw 6002-000474 5

User's manual DB68-03732A 1

Installation manual DB68-03716A 1

Product Specifications

2-9

2-3-4 Filter specifications

Item Description Code No. Remark

FILTER-AIR DB63-03764A

3-1

Item Remark

+ Screw Driver

Monkey Spanner

(8mm, 10mm, 13mm)

M6, M8 Hex Wrench

Spanner Torque Wrench

3. Disassembly and Reassembly

3-1 Necessary Tools

3-2

3-2 Indoor Unit

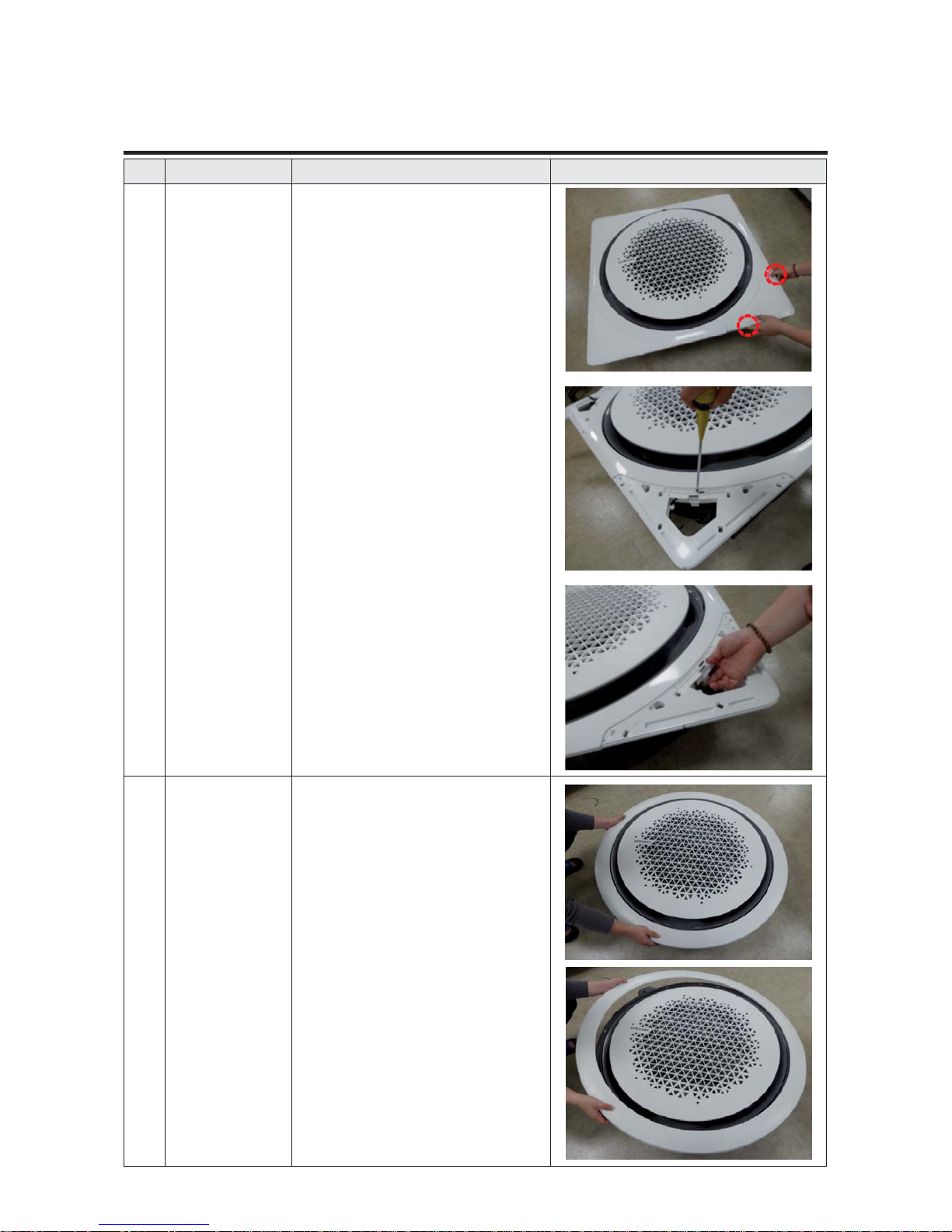

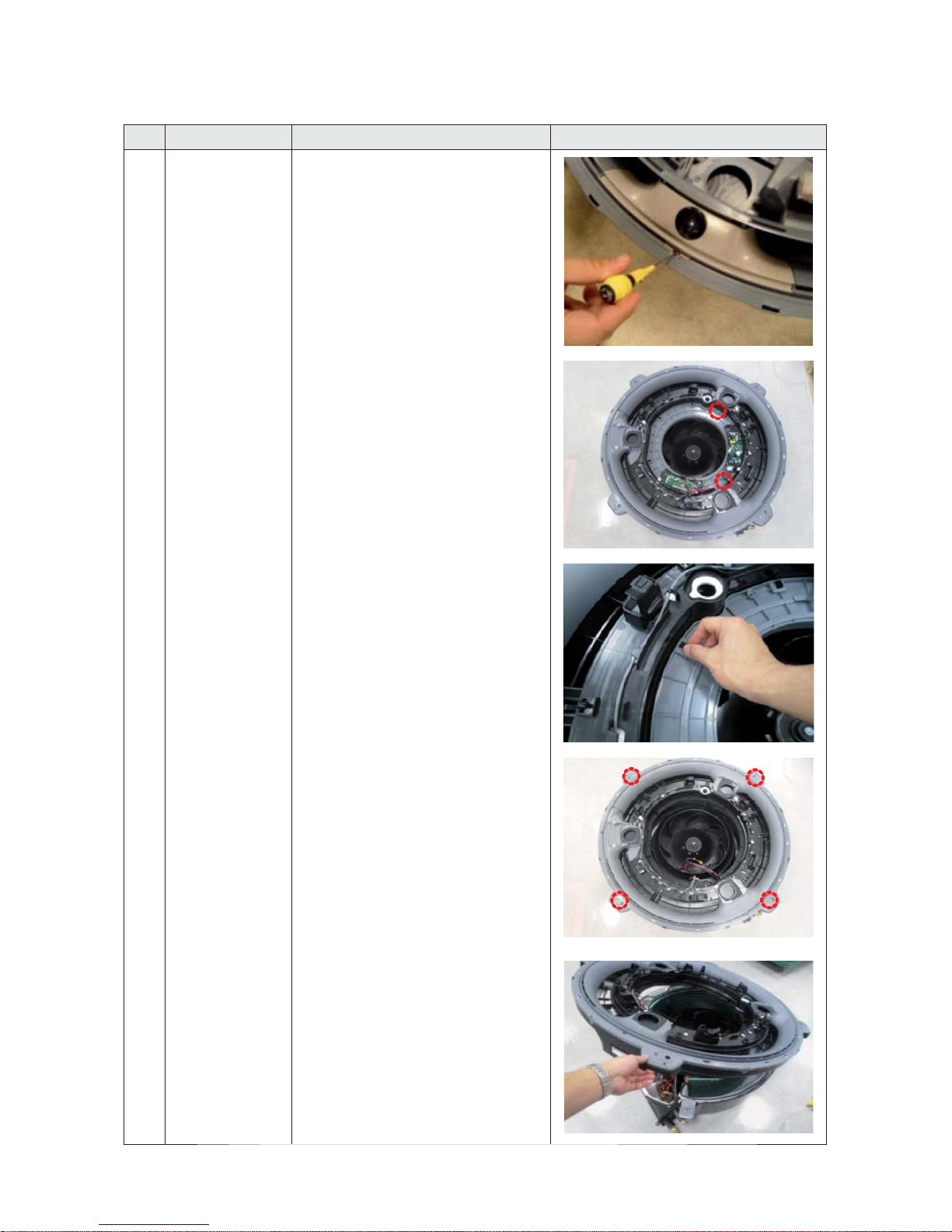

No. Parts Procedure Remark

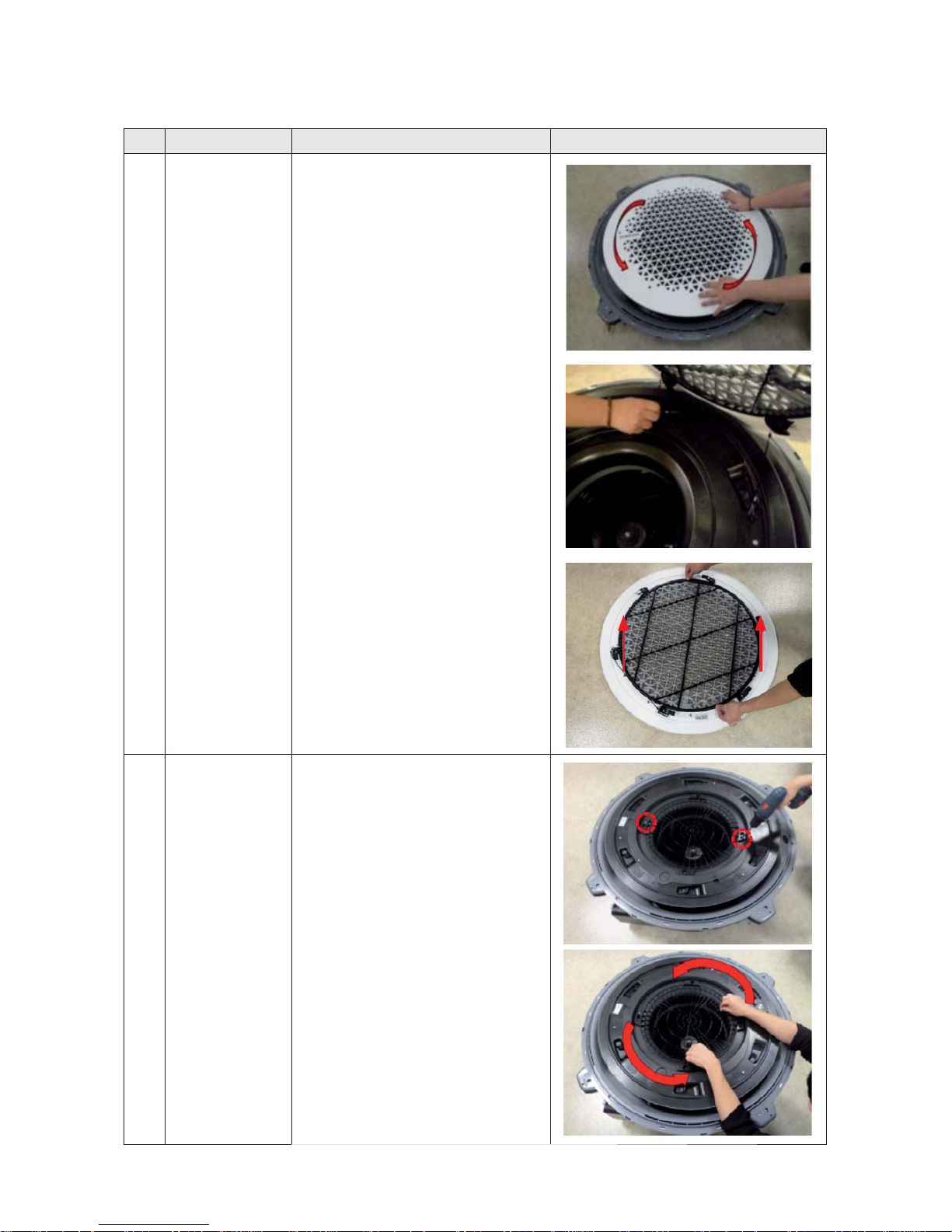

1 Panel

▶ Ceiling type Panel

1) Pull up the corner 4 places of Panel and

separate it.

2) Remove the 4 screws from the corner of

Panel. (Use +Screw Driver)

3) Pull the hook of Panel and then separate the

Panel from the Indoor Unit.

1 Panel

▶ Open type Panel

1) Rotate the outside Panel to counterclockwise

direction and then separate it.

Disassembly and Reassembly

3-3

No. Parts Procedure Remark

1 Panel 2) Rotate the Grille to counterclockwise

direction.

3) Remove the safety clip of Grill inside and then

separate the Panel from the Indoor Unit.

4) Pull up the Filter from the Grill and separate it.

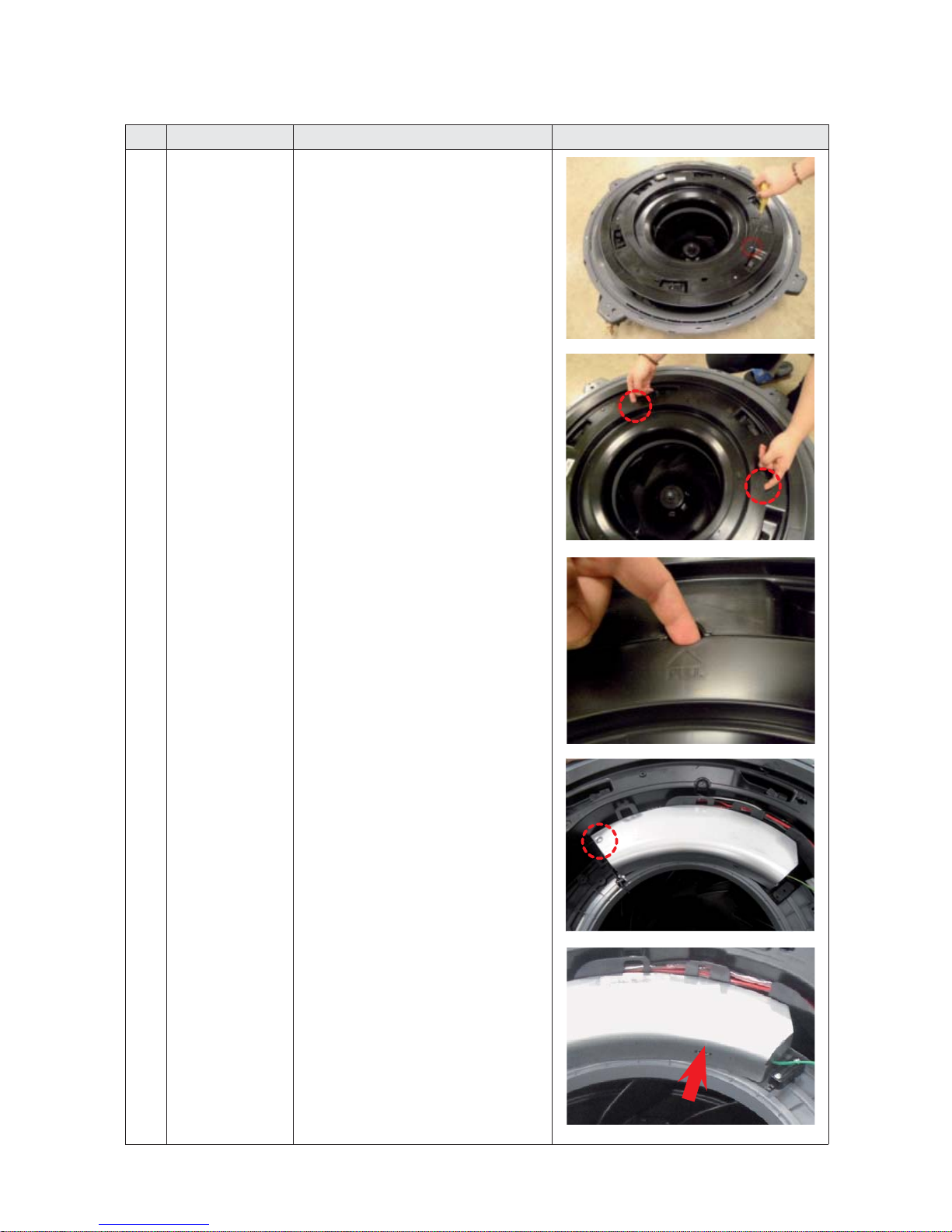

2

Control Box

1) Reomove the 2 screws which is fixed to the

Indoor Unit upper part.(Use +Screw Driver)

2) Rotate the Guard Fan to counterclockwise

direction and separate it

Disassembly and Reassembly

3-4

No. Parts Procedure Remark

2

Control Box

3) Reomove the 1 screw which is fixed to the

Indoor Unit upper part.(Use +Screw Driver)

4) Put finger in the "PULL" marked groove and

then pull up the Cover

5) Put finger in the "PULL" marked groove and

then avoids the hook and it opens the Control

Box Cover

Disassembly and Reassembly

3-5

No. Parts Procedure Remark

2

Control Box

6) Separate the connectors from the Control Box.

7) Remove the ground screw.

(Use +Screw Driver)

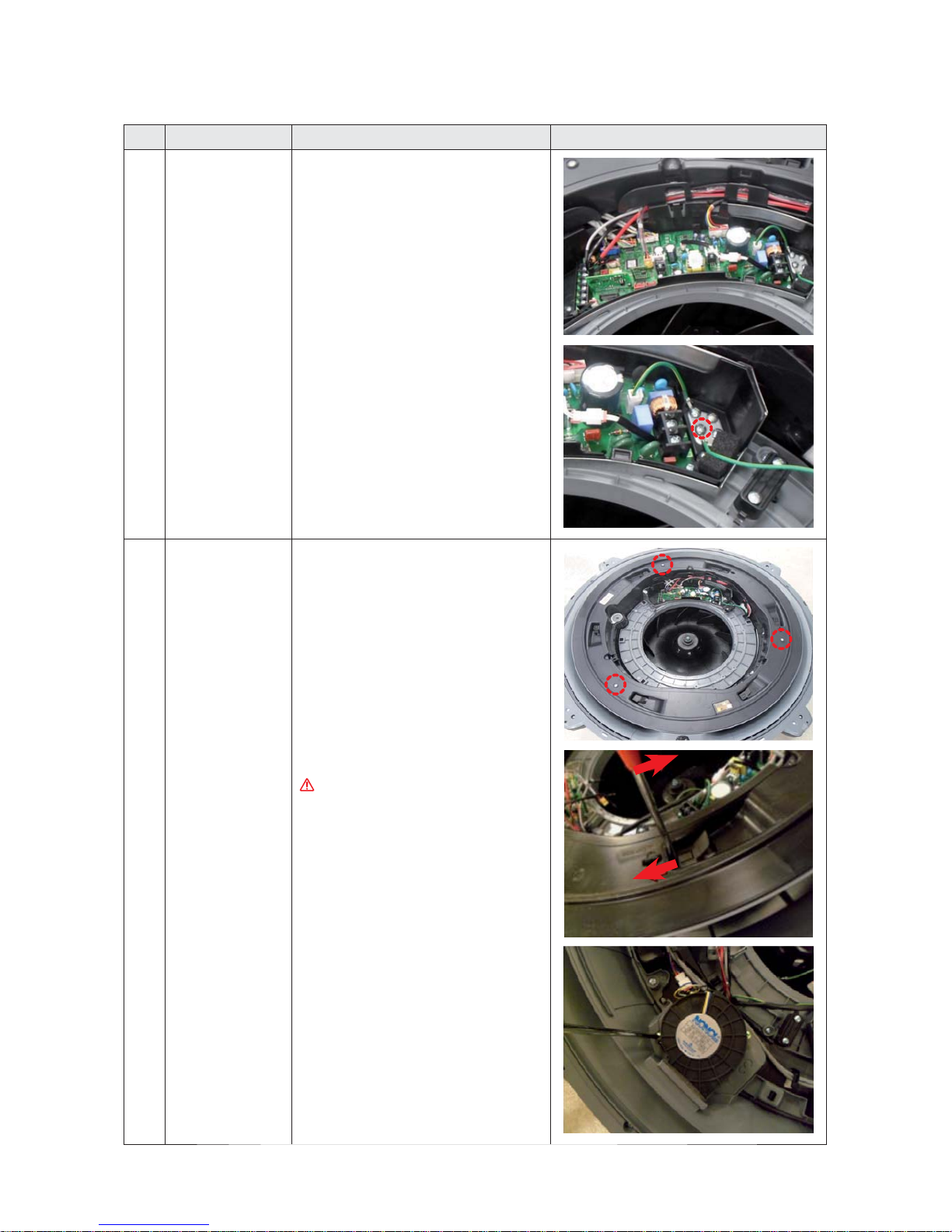

3

Top Cover & Drain Pan

1) Remove the 3 screws. (Use +Screw Driver)

2) Push the hook and separate the Cover.

Damage can occur to product in case of use a

sharp tool.

3) Remove the screw which is fixed to Booster

Fan. (Use +Screw Driver)

Disassembly and Reassembly

3-6

No. Parts Procedure Remark

3

Top Cover & Drain Pan

4) Pull the Booster Fan connector and separate

the connector.

5) Remove the 4 screws. (Use +Screw Driver)

6) Push the hook and separate the Cover.

Disassembly and Reassembly

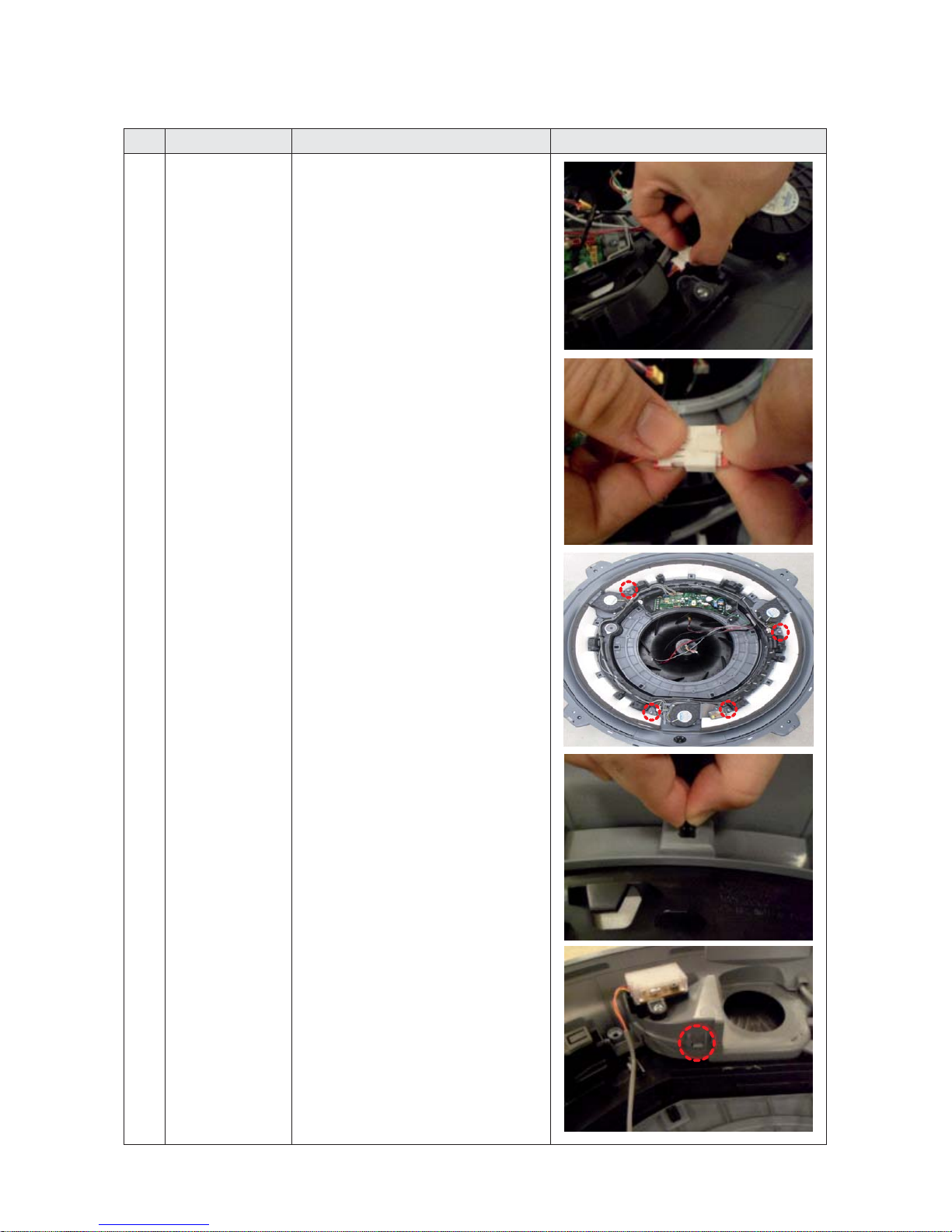

3-7

No. Parts Procedure Remark

3

Top Cover & Drain Pan

7) Remove the screw and separate the Display

Cover. (Use +Screw Driver)

8) ) Remove the 2 screws. (Use +Screw Driver)

9) Push the hook and separate the Cover.

10) Remove the 8 screws. (Use +Screw Driver)

11) Separate the Indoor Unit upper part from

the Body

Disassembly and Reassembly

3-8

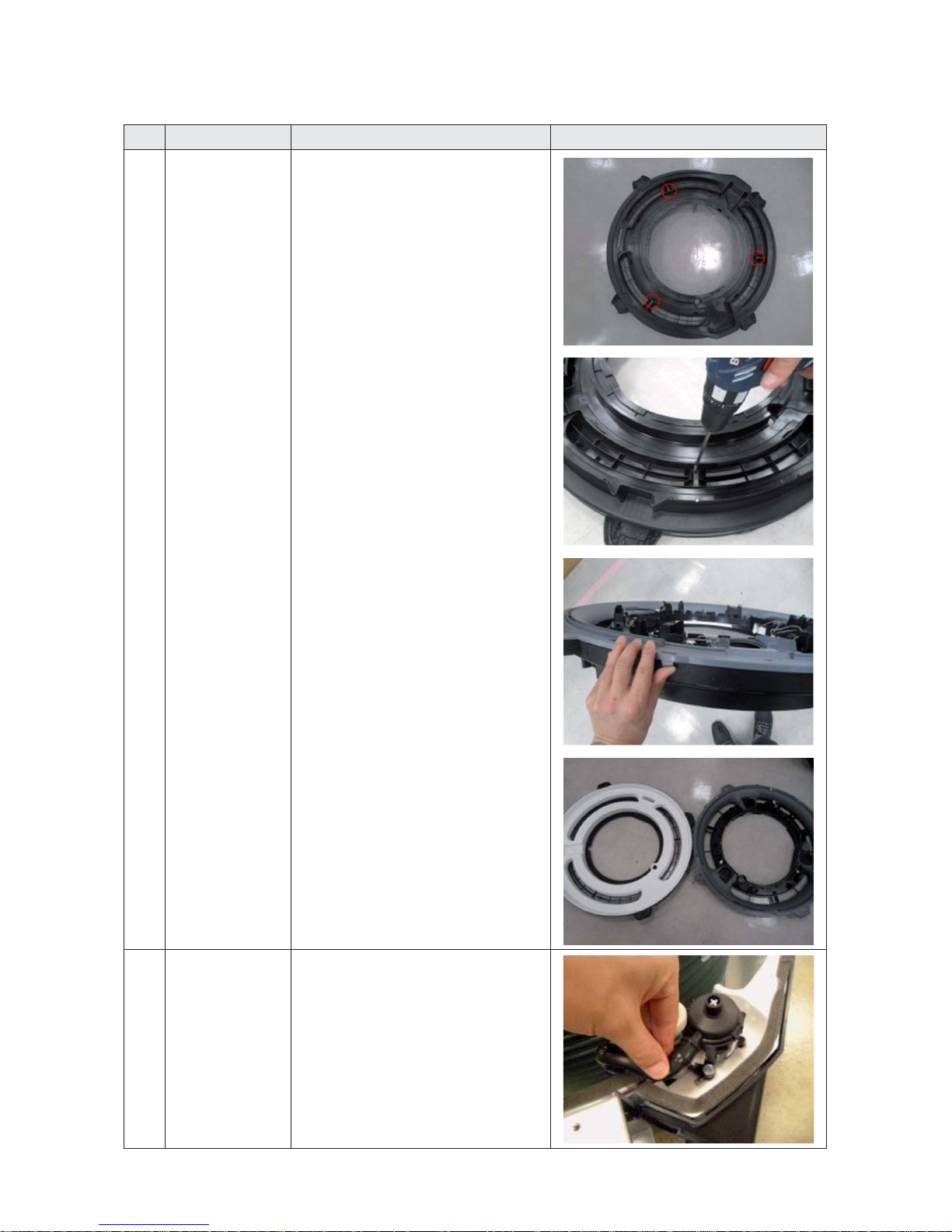

No. Parts Procedure

Remark

3

Top Cover & Drain Pan

12) Remove the 3 screws. (Use +Screw Driver)

13) Pull the hook that is on the side and separate

the Cover.

4

Drain Pump & Hose

1) Separate the Drain Hose from the Drain Pump.

Disassembly and Reassembly

3-9

No. Parts Procedure

Remark

4

Drain Pump & Hose

2) Remove the 2 screws and separate the Drain

Hose that is on the side lower part of Indoor

Unit (Use +Screw Driver)

5

Fan & Motor

1) Remove the hex nut which is fixed to top of

Fan and separate the Fan from the Motor.

(Use Monkey Spanner)

2) Remove the 3 hex nuts which is fixed to Motor

and separate the Motor from the Indoor Unit.

(Use Monkey Spanner)

6

Temperature Sensor

1) Remove the 6 screws which is fixed to

Evaporator and separate the Partition.

2) Separates the Temperature Sensor which is

fixed to Evaporator Pipe with the fixing clip

together by the hand.

Disassembly and Reassembly

3-10

No. Parts Procedure

Remark

4

Evaporator

1) Remove the screws which is fixed to Indoor

Unit and separate the Evaporator fixing

bracket. (Use +Screw Driver)

2) Remove screws which is fixed to Indoor Unit

and pull the hook and then separate the Drain

Cover. (Use +Screw Driver)

When assemble, be careful with the

interference structure of piping

projecting part.

3) Separate the Evaporator from the Indoor Unit.

If you remove the Evaporator withbare hands,

it may injure your hands, gloves must be worn.

Disassembly and Reassembly

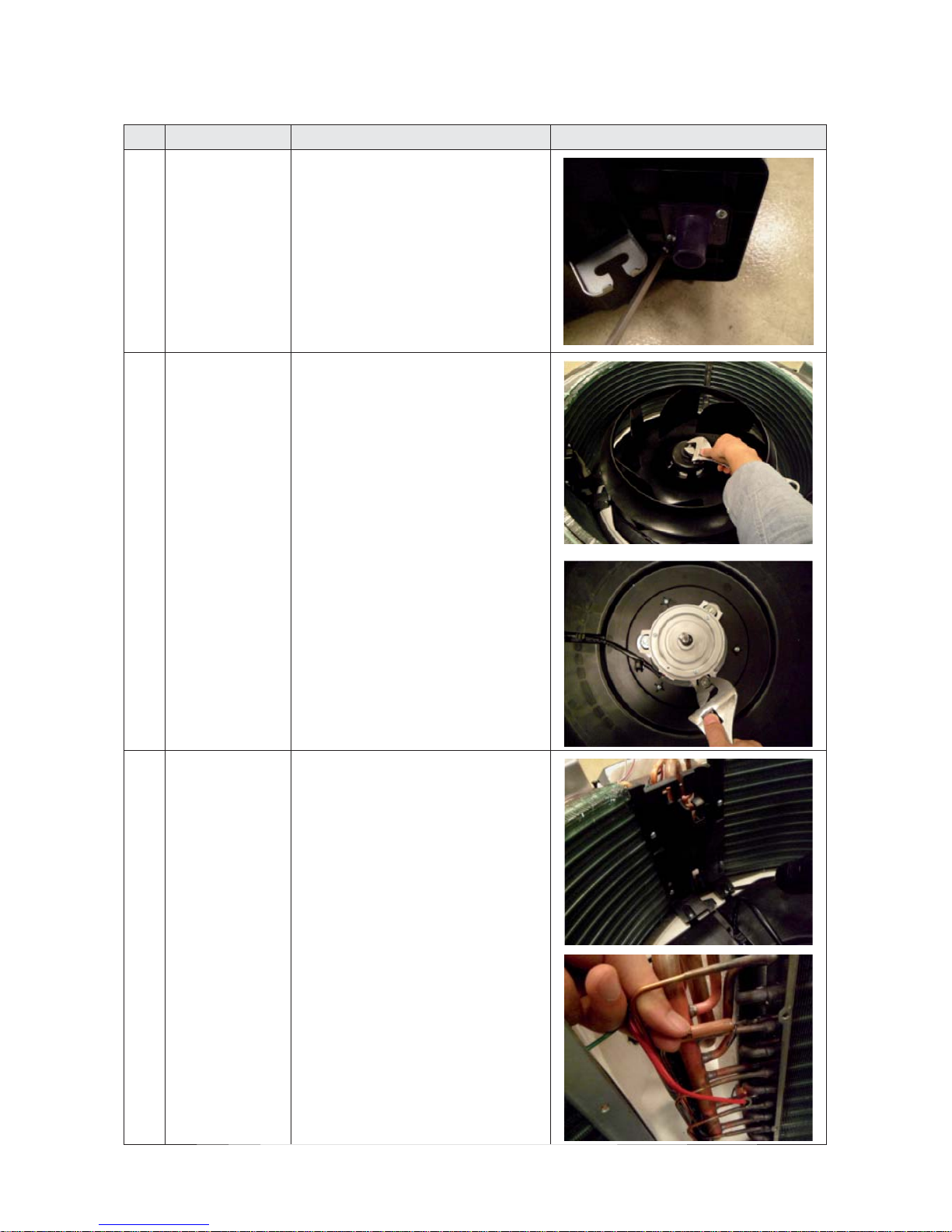

3-11

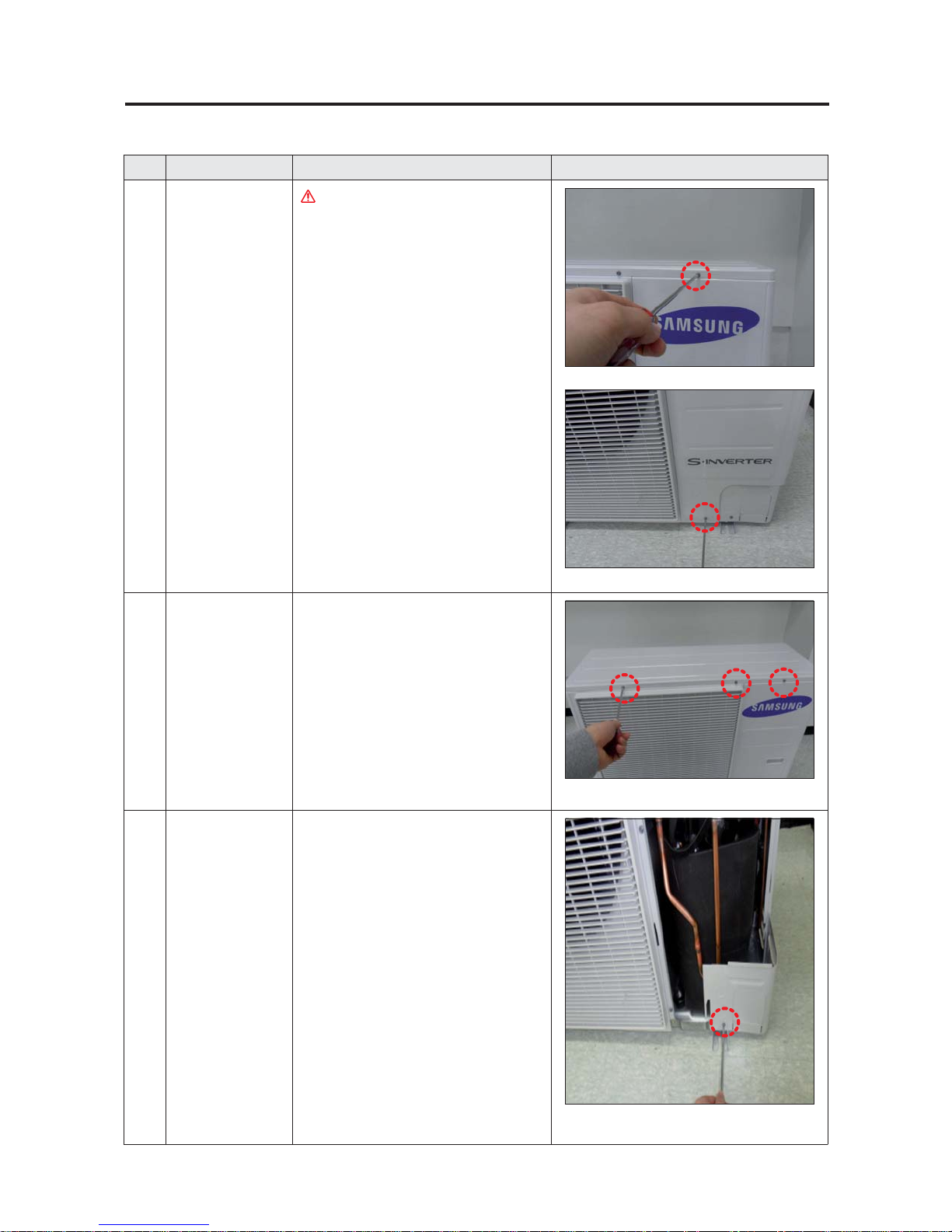

No. Parts Procedure Remark

1

Cabinet Front RH

Turn off the power before disassembly

necessarily.

1) Remove the 2 screws from the Cabinet Front

RH and separate it. (Use +Screw Driver)

2

Cabinet Upper

1) Remove the 9 screws which is fixed to each

side of Cabinet Upper and separate it. (Use

+Screw Driver)

3

Cabinet-Installation

Front Part

1) Remove the 1 screw which is fixed to

Cabinet-Installation Front Part and separate

it. (Use +Screw Driver)

■ AC090/100/120MXAD*H

3-3. Outdoor Unit

Disassembly and Reassembly

3-12

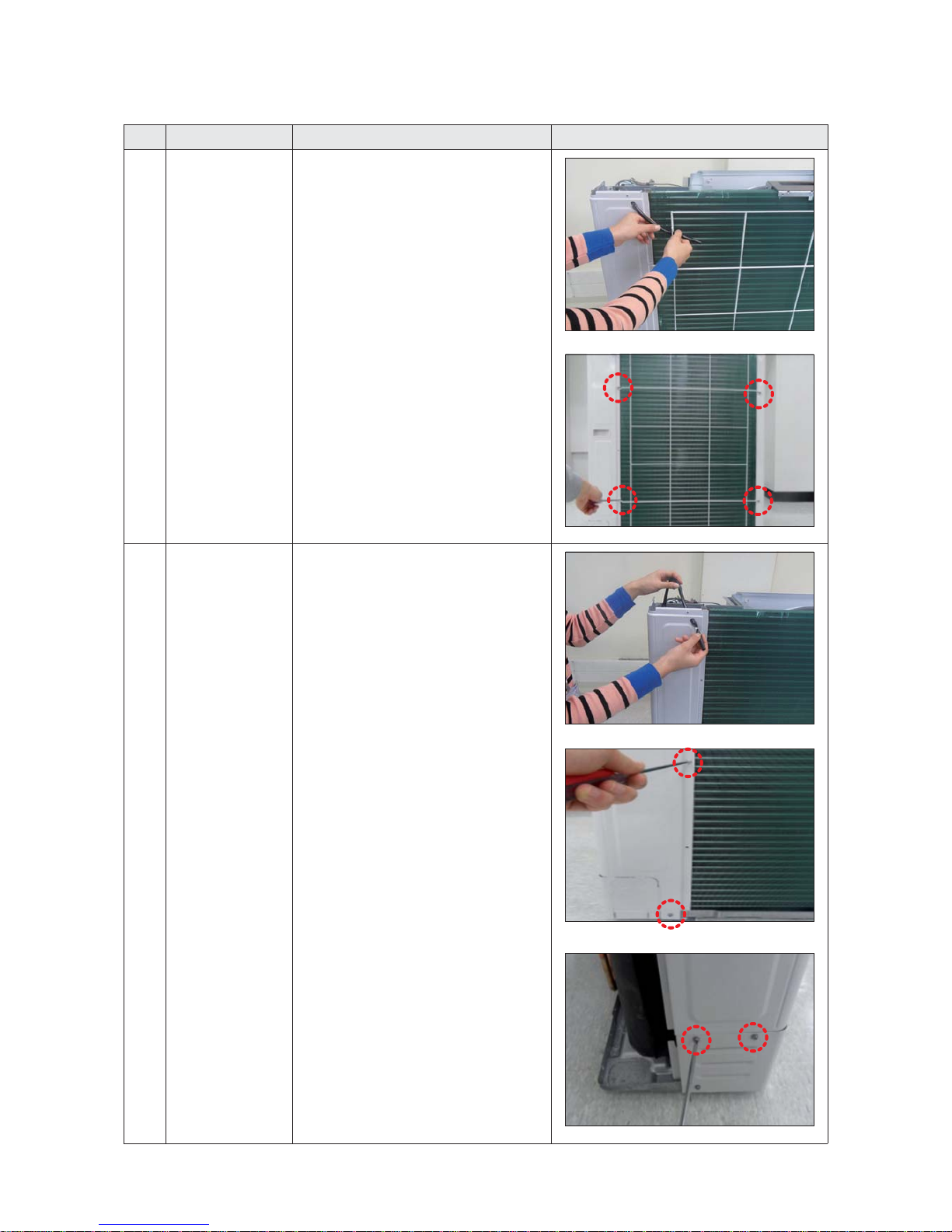

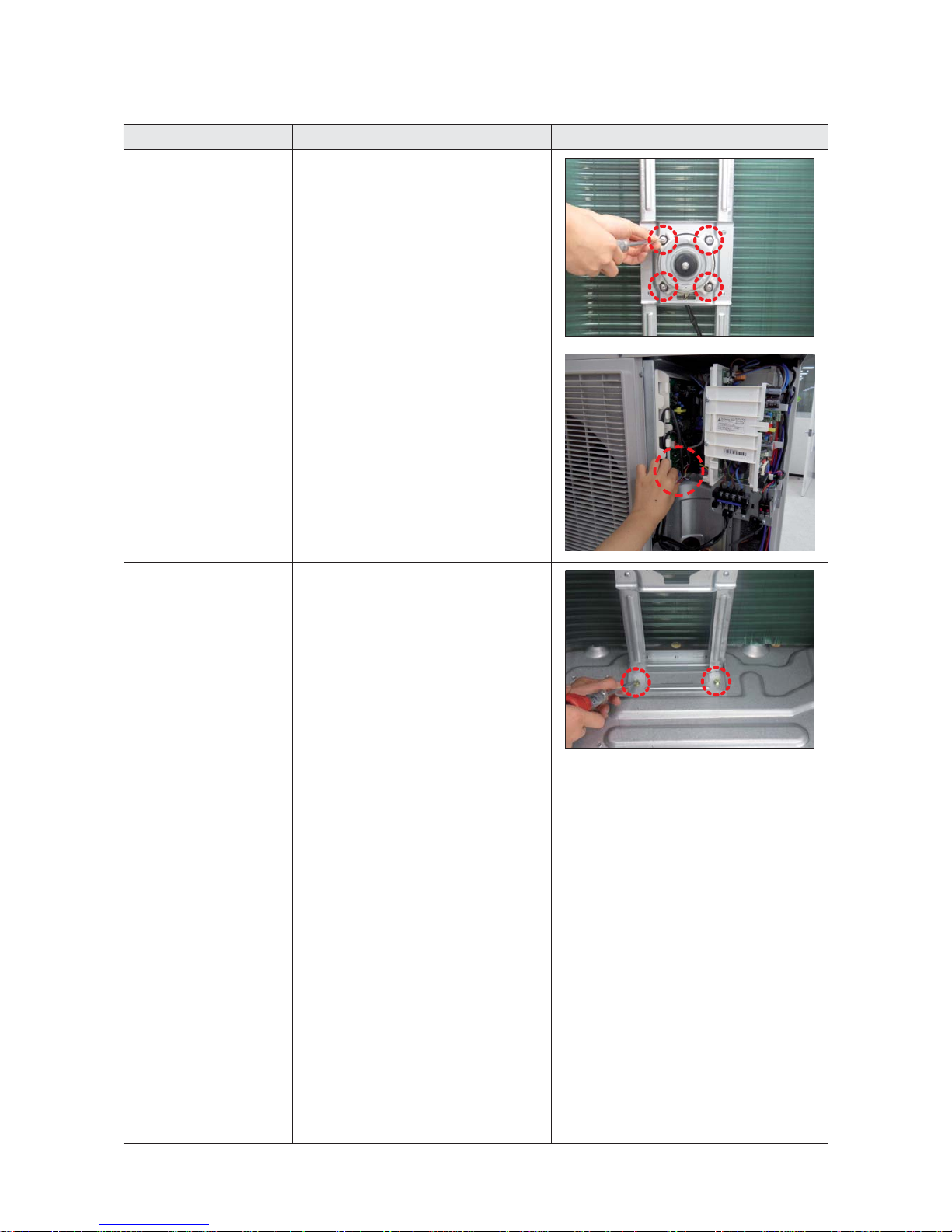

No. Parts Procedure Remark

4

Outdoor Unit Guard

1) Pull out the sensor from the Outdoor Unit

Guard and separate it.

2) Remove the 4 screws which is fixed to

Outdoor Unit Guard and separate it. (Use +

Screw Driver)

5

Cabinet Rear RH

1) Pull out the sensor from the Cabinet Rear RH

and separate it.

2) Remove the 4 screws which is fixed to each

side of Cabinet Rear RH and separate it. (Use +

Screw Driver)

Disassembly and Reassembly

3-13

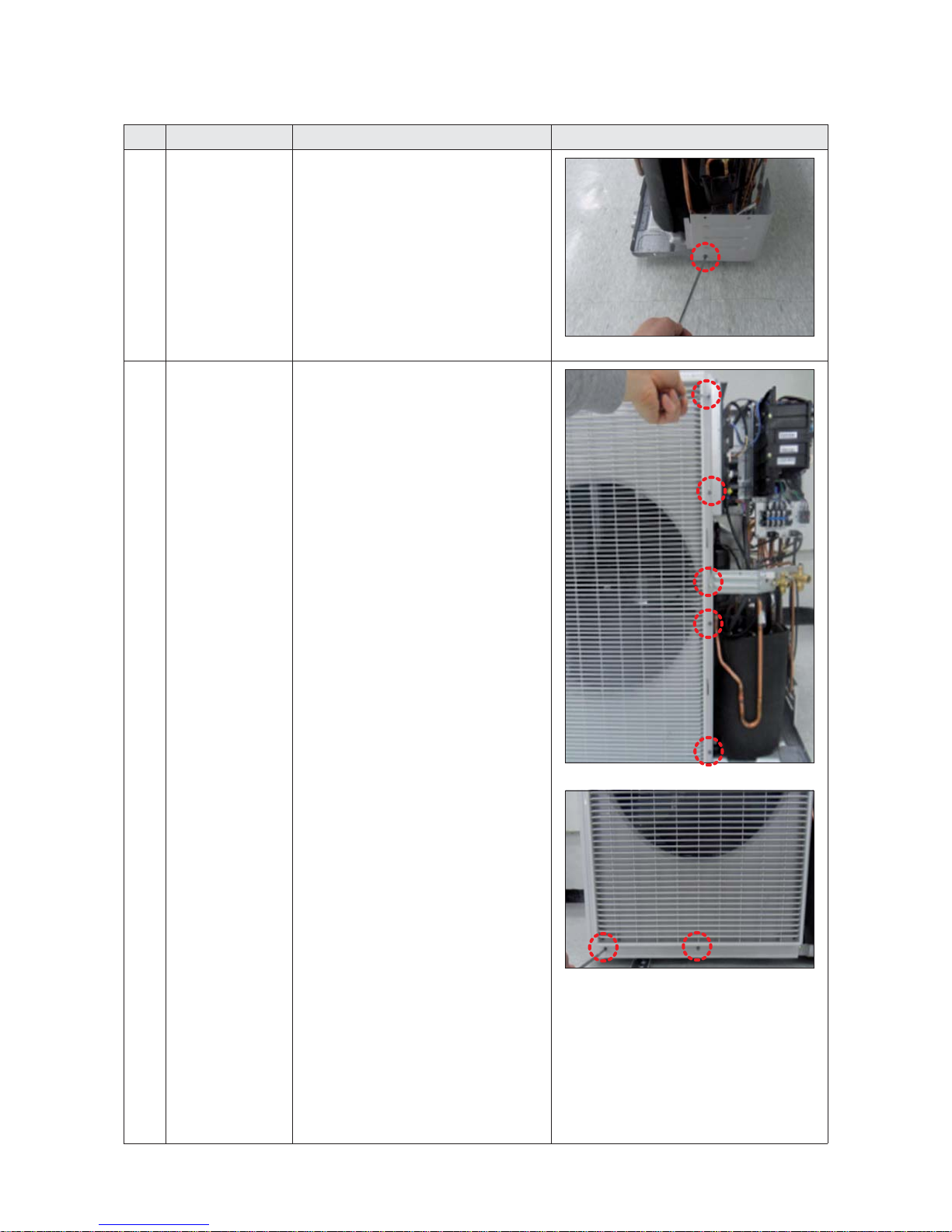

No. Parts Procedure Remark

6

Cabinet-Installation

Rear Part

1) Remove the 1 screw from the Cabinet-

Installation Rear Part and separate it.(Use +

Screw Driver)

7

Cabinet Front LF

1) Remove the 10 screws from the Cabinet

Front LF and separate it. (Use +Screw Driver)

Disassembly and Reassembly

3-14

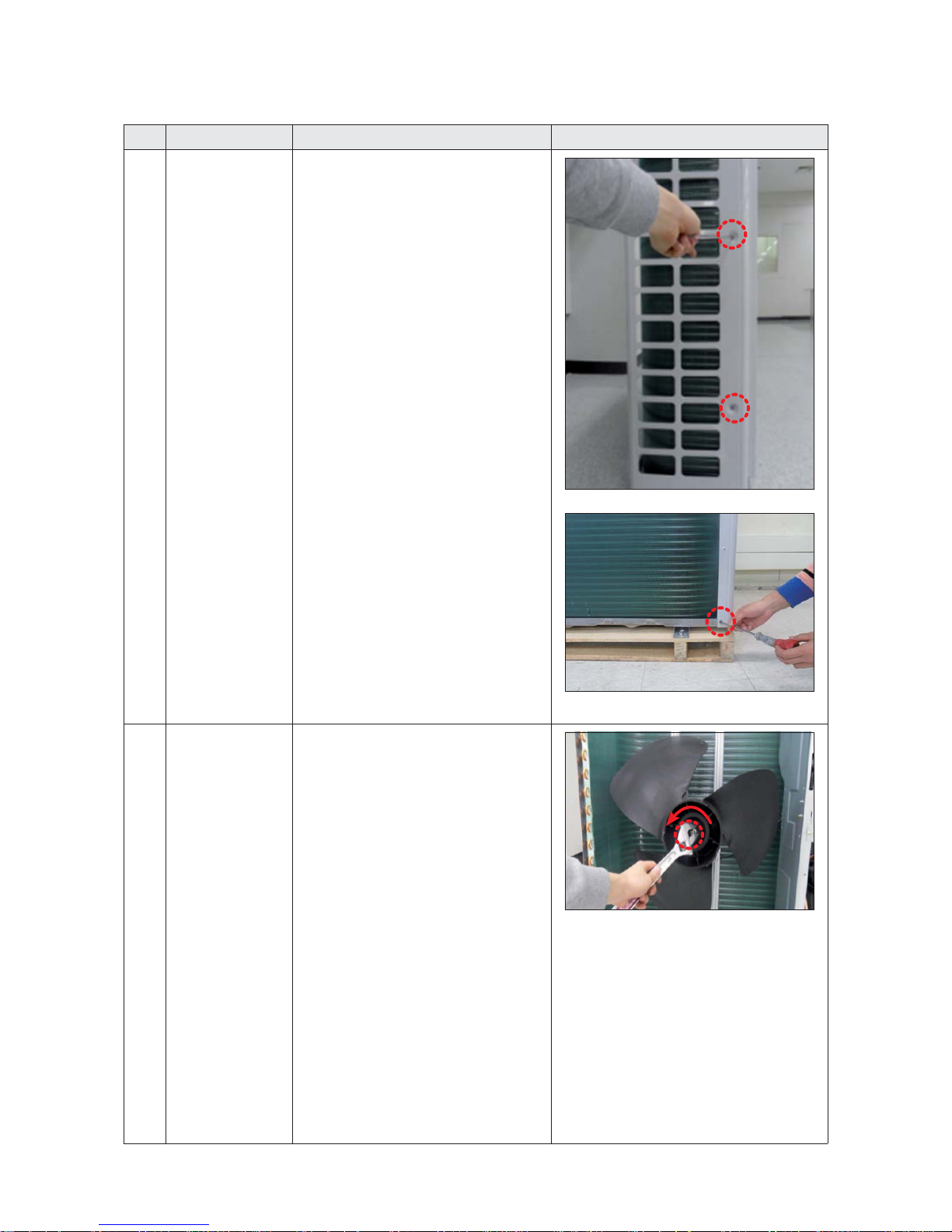

No. Parts Procedure Remark

7

Cabinet Front LF

8

Fan

1) Remove the 2 fixing nuts like the picture

on the right side. (Use Hexagon Wrench,

Monkey Spanner, Hexagon Socket)

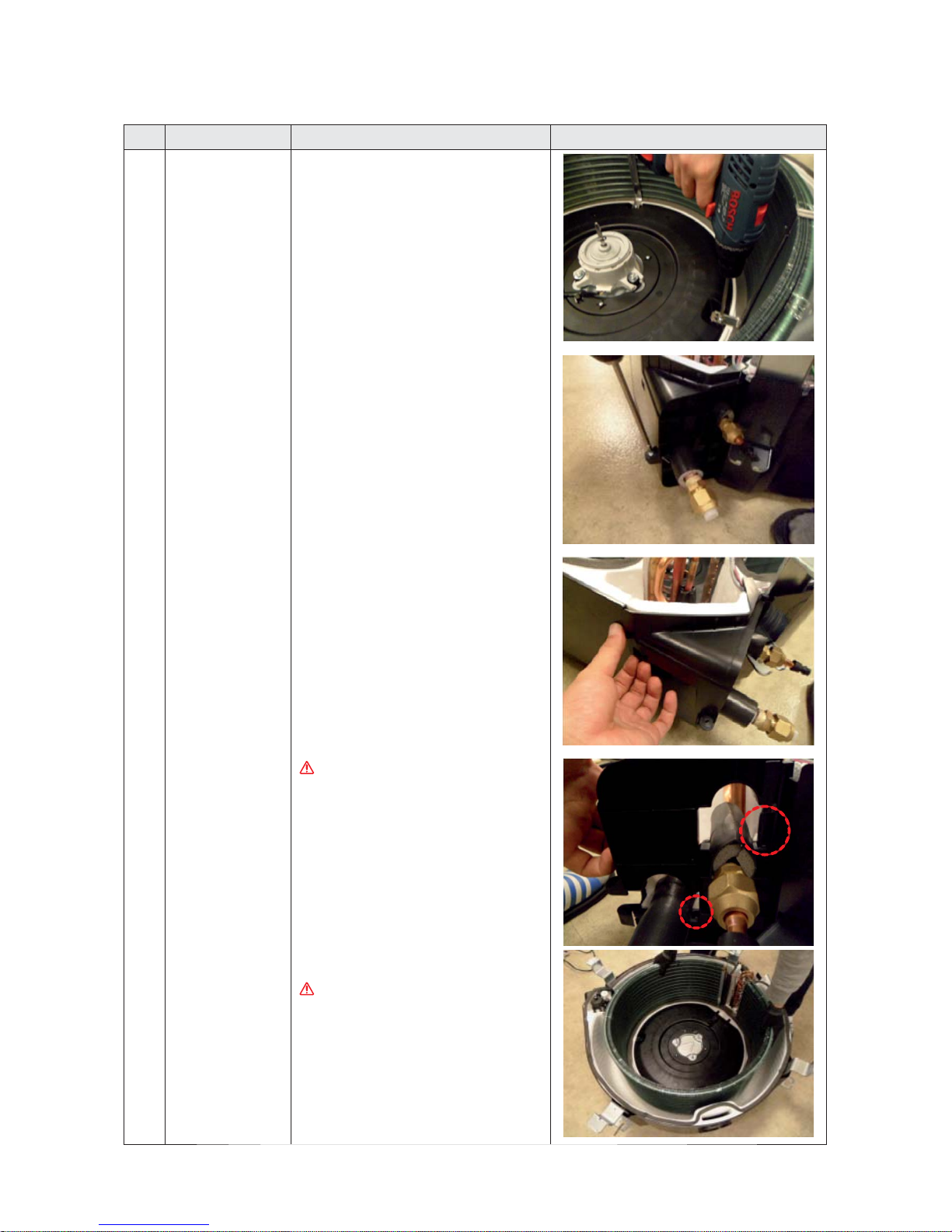

Disassembly and Reassembly

3-15

No. Parts Procedure Remark

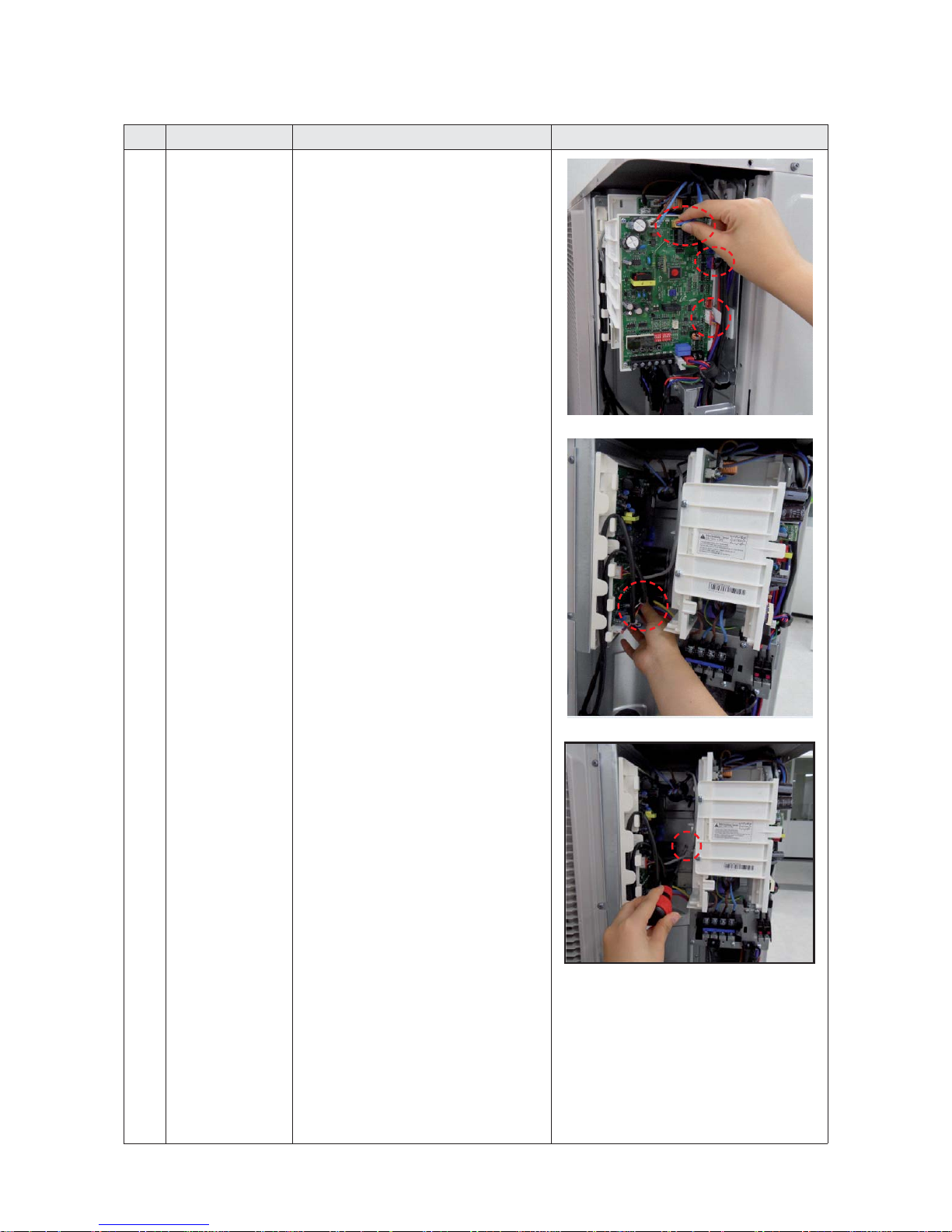

9 Motor 1) Separate the Fan Propeller.

2) Remove the 8 screws which is fixed to

Motor. (Use +Screw Driver)

3) Separate the Motor Wire connector from the

Outdoor Unit Control Part.

10

Bracket Motor

1) Remove the 2 screws from the Bracket Motor

and separate it. (Use +Screw Driver)

Disassembly and Reassembly

3-16

No. Parts Procedure Remark

11

Control Part

1) Separate the 4 connectors from the Outdoor

Unit Control part.

2) Remove the 1 screw which is fixed to Control

Part. (Use +Screw Driver)

3) Separate the Control Part.

Disassembly and Reassembly

3-17

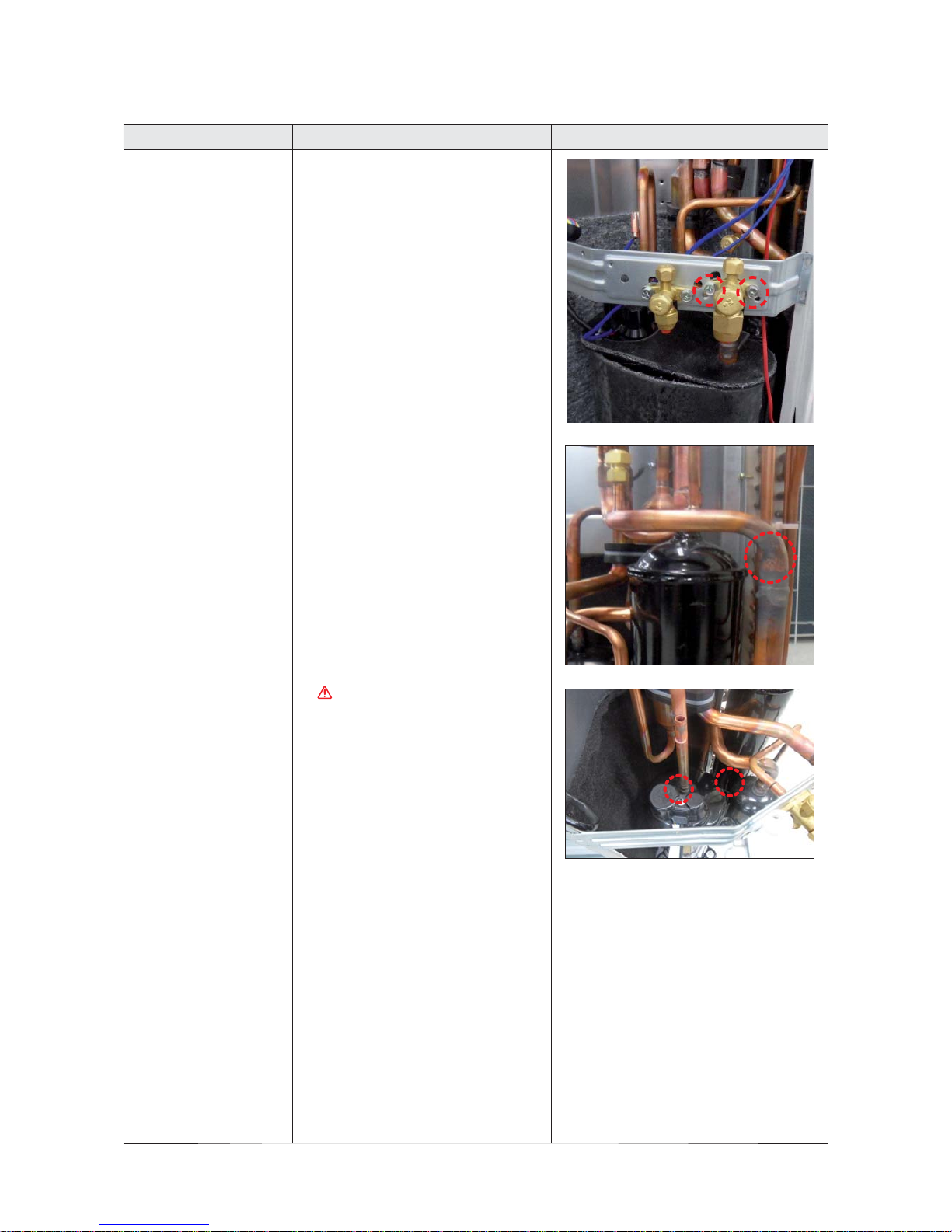

No. Parts Procedure Remark

12

4 Way Valve

1) First, discharge the refrigerant.

2) Remove the 2 screws which is fixed to

Service Valve and separate it. (Use +Screw

Driver)

3) Separate the inlet and outlet pipes by

welding torch.

If you separate the Compressor, Heat

Exchanger or Pipe, please fully discharge

refrigerant in the Compressor and then

separate the Pipe by welding torch.

Disassembly and Reassembly

3-18

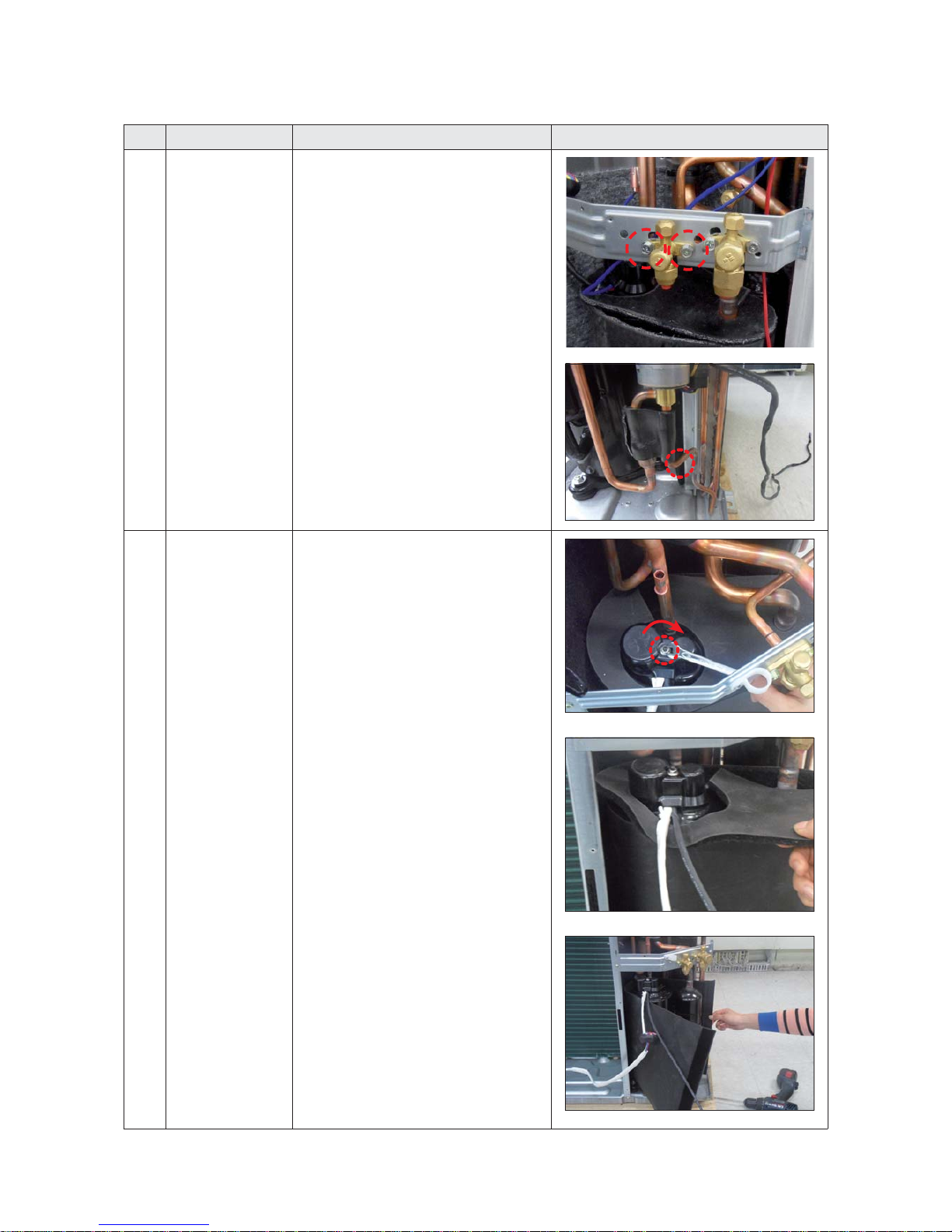

No. Parts Procedure Remark

13

EEV Valve

1) Remove the 2 screws which is fixed to

Service Valve and separate it. (Use +Screw

Driver)

2) Separate the inlet and outlet pipes by

welding torch.

14

Compressor

1) Remove the 1 fixing nut from the end of

Cover and separate it. (Use Hexagon Wrench,

Monkey Spanner, Hexagon Socket)

2) Separate the Felt Compressor.

Loading...

Loading...