Samsung AC026NNNDKH, AC052NNNDKH, AC035NNNDKH, AC071NNNDKH, AC026MXADKH Service Manual

...

SYSTEM AIR CONDITIONER

Mini 4 WAY CASSETTE SERIES

INDOOR UNIT OUTDOOR UNIT

Model :

AC026NNNDKH

AC035NNNDKH

AC052NNNDKH

AC060NNNDKH

AC071NNNDKH

AC026MXADKH

AC035MXADKH

AC052MXADKH

AC060MXADKH

AC071MXADKH

AIR CONDITIONER CONTENTS

AC026MXADKH

AC035MXADKH

AC071MXADKH

AC026NNNDKH

AC035NNNDKH

AC052NNNDKH

AC060NNNDKH

AC071NNNDKH

AC052MXADKH

AC060MXADKH

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Reference Sheet

Contents

1. Precautions .................................................................................................. 1-1

1-1 Precautions for the Service ........................................................................................................................... 1-1

1-2 Precautions related to static electricity and PL ..................................................................................... 1-1

1-3 Precautions related to product safety ...................................................................................................... 1-2

1-4 Other precautions ............................................................................................................................................. 1-2

2. Product Specifications ................................................................................ 2-1

2-1 The Feature of Product ................................................................................................................................... 2-1

2-2 Product Specifications (cont.) ...................................................................................................................... 2-2

2-2 Product Specifications (cont.) ...................................................................................................................... 2-4

2-3 Accessories .......................................................................................................................................................... 2-5

3. Disassembly and Reassembly .................................................................... 3-1

3-1 Indoor unit ........................................................................................................................................................... 3-2

3-2 Outdoor unit .....................................................................................................................................................3-10

4. Troubleshooting ......................................................................................... 4-1

4-1 Setting an indoor unit address and installation option .................................................................... 4-1

4-1-1 Common steps for setting the addresses and options ........................................................ 4-1

4-1-2 Setting the indoor unit addresses ................................................................................................. 4-6

4-1-3 Setting the installation options in a batch ................................................................................. 4-7

4-1-4 Changing the addresses and options individually ................................................................. 4-9

4-2 Items to check before diagnostics ...........................................................................................................4-10

4-2-1 Four directions cassette type ........................................................................................................4-10

4-2-2 Test run mode and View mode ....................................................................................................4-11

4-2-3 Troubleshooting for outdoor unit ...............................................................................................4-12

4-2-4 Wired remote controller ..................................................................................................................4-14

4-3 Troubleshooting by symptoms .................................................................................................................4-16

4-3-1 Indoor temperature sensor (open/short) .................................................................................4-16

4-3-2 Indoor heat exchanger temperature sensor (open/short) ................................................4-17

4-3-3 Indoor FAN error .................................................................................................................................4-18

4-3-4 Communication error after finishing Tracking.......................................................................4-19

4-3-5 Indoor unit float sensor error ........................................................................................................4-20

4-3-6 EEPROM circuit failure ......................................................................................................................4-21

4-3-7 Outdoor unit is not powered on – Initial diagnosis ............................................................4-22

4-4 Troubleshooting by symptoms ................................................................................................................4-24

4-4-1 Communication error ......................................................................................................................4-24

2 Samsung Electronics

4-4-2 Outdoor temperature sensor error ............................................................................................4-25

4-4-3 Outdoor Coil temperature sensor error ..................................................................................4-27

4-4-4 Outdoor Discharge temperature sensor error .......................................................................4-29

4-4-5 Outdoor Discharge over temperature error ...........................................................................4-31

4-4-6 Outdoor Fan motor error ................................................................................................................4-32

4-4-7 Compressor starting error ..............................................................................................................4-33

4-4-8 Compressor wire missing error/rotation error .......................................................................4-34

4-4-9 O.C(Over Current) error ...................................................................................................................4-35

4-4-10 DC_link voltage sensor error.......................................................................................................4-36

4-4-11 DC_link voltage under/over error,

Over voltage protection error/PFC over load ......................................................................4-37

4-4-12 DC_link voltage sensor error.......................................................................................................4-38

4-4-13 Current sensor error/Input current sensor error .................................................................4-39

4-4-14 Heatsink sensor error/Heatsink over heat .............................................................................4-40

4-4-15 Comp Vlimit error/Comp current limit error ........................................................................4-41

4-4-16 EEPROM error/OTP error ...............................................................................................................4-42

4-4-17 AC zero cross signal error .............................................................................................................4-43

4-4-18 Operation condition secession error .......................................................................................4-44

4-4-19 Capacity miss match error ...........................................................................................................4-45

4-4-20 Gas leak error .....................................................................................................................................4-46

MDS Error Flow chart .....................................................................................................................4-47

4-4-21

5. PCB Diagram ................................................................................................ 5-1

5-1 Indoor Unit ........................................................................................................................................................... 5-1

5-1-1 MAIN PBA ................................................................................................................................................ 5-1

5-1-2 Display PBA ............................................................................................................................................. 5-3

5-2 Outdoor Unit ....................................................................................................................................................... 5-4

5-2-1 MAIN PBA ................................................................................................................................................ 5-4

5-2-2 Display PBA ............................................................................................................................................. 5-6

6. Wiring Diagram ........................................................................................... 6-1

6-1 Indoor Unit ........................................................................................................................................................... 6-1

6-2 Outdoor Unit ....................................................................................................................................................... 6-2

7. Preference Sheet ......................................................................................... 7-1

7-1 Index of Model Name ...................................................................................................................................... 7-1

7-2 Refrigerating Cycle Diagram ........................................................................................................................ 7-3

7-3 Pressure Graph ................................................................................................................................................... 7-4

Samsung Electronics 3

1. Precautions

1-1 Precautions for the Service

■ Use the standard parts when replacing the electric parts.

– Confirm the model name, rated voltage, rated current of the electric parts.

■ When repairing the equipment, connection of the harness parts must be firm and solid.

– A loose connection may cause noise or other malfunction.

■ When assembling and disassembling the equipment while it is laid down, lay it on soft cloth.

– Otherwise it may scratch the back of the exterior of the product.

■ Remove dust or dirt completely from the housing block, wiring block and service parts during repair.

– This helps prevent the danger of fire caused by tracking or short circuit.

■ Fasten the valve caps of service valves and charging valves of outdoor unit as much as possible using adjustable wrenches.

■ Check the status of the components’ assembly after repair service.

– The status must be the same as before the repair service.

1-2 Precautions related to static electricity and PL

■ The PCB power supply block is susceptible to static electricity. Therefore, care must be taken during repair or measuring

while the power is on.

– Wear insulation gloves for PCB repair or measuring.

Check whether the installation location is at least two meters away from other electronic products such as TV, video, or audio.

■

– Otherwise, the video quality might be degraded or noise might be generated.

■ Do not let end users repair the products themselves.

– Unauthorized disassembly might cause electric shock or fire.

Samsung Electronics 1-1

1-3 Precautions related to product safety

■ Do not pull the power cord and do not touch the power plug or aux power switch with wet hands.

– It might cause electric shock or fire.

■ A damaged power line or power plug must be replaced to prevent danger.

■ Do not bend the power cable with excessive force, and do not place a heavy weight on the case as it might damage the cable.

– It might cause electric shock or fire.

■ Do not use multiple electric outlets.

– This might cause electric shock or fire.

■ C onnect the ground terminal when necessary.

– You must connect the ground terminal if you determine that there is a danger of electric leakage due to moisture or water.

■ Unplug the power cable or turn off the auxiliary power switch for electric part replacement and repair service.

– Otherwise it might cause electric shock.

■ Instruct end users to separate the batteries from the remote controllers and store them separately when the product is not

used for long time.

– Otherwise leakage from the dry cell may cause problems with the remote controller.

1-4 Other precautions

■ The pipes should have no leaks during installation, and the compressor must be stopped before removing connecting pipes

for pump down work. Operating the compressor while the service valve is open and coolant pipe is not properly connected

may cause explosion or injury due to abnormal high pressure created inside the coolant cycle as the air can be absorbed

through the pipe.

■ Pump Down work procedure (When uninstalling the product)

– Turn on the air conditioner, select cooling operation, and run the compressor for more than three minutes.

– Release the high pressure and low pressure valve caps.

– Close the high pressure valve completely using an L-wrench

– After about two minutes, close the low pressure valve completely.

– Stop running the air conditioner.

– Separate the connecting pipe.

1-2 Samsung Electronics

2. Product Specifications

2-1 The Feature of Product

■ Built-in Cassette Type

After installed, the air conditioner can be harmonized with a room interior.

■ High Performance & Energy Saving

With the advanced BLDC inverter technology, it makes a room cool with highly energy saving and arises the efficiency of

air conditioner.

■ Long Ambient Operation(In Low Temperature)

It can arise the reliability and the capacity of the air conditioner, especially operated in low temperature.

■ Eco-friendly Product(Lead-Free, RoHS, WEEE)

■ Easy installation of ultra-lightweight indoor unit

Samsung Electronics 2-1

2-2 Product Specifications (cont.)

ITEM

INDOOR UNIT

AC026NNNDKH

AC026MXADKH

Development Model

AC035NNNDKH

AC035MXADKH

IMAGE

Performance

Power

Consumption

Voltage / Frequency

Operating

Current

Noise

Net Dimension

Size

Dimension

Net Weight

Weight

Harness

Specifications

Piping

Factory Charging [g]

Additional Refrigerant (for every 1m) [g]

Basic Piping Length [m]

Max. Piping Length [m]

Max. Level Difference [m]

OUTDOOR UNIT

REMOTE CONTROLLER

Indoor Unit [dBA] (C/H)

Outdoor Unit [dBA] (C/H)

(WxDxH)

Shipping

(WxDxH)

Shipping

Weight

Indoor Fan Motor

Outdoor Fan Motor

High Pressure

PANEL

Refrigerant Type

Option Code

Cooling [W]

Heating [W]

Cooling [W]

Heating [W]

Cooling [A]

Heating [A]

Indoor Unit [mm]

Outdoor Unit [mm]

Indoor Unit [mm]

Outdoor Unit [mm]

Indoor Unit [kg]

Outdoor Unit [kg]

Indoor Unit [kg]

Outdoor Unit [kg]

Compressor

Low Pressure

2,600 3,500

3,400 4,000

680 1,090

900 1,200

1Φ, 220~240V, 50Hz 1Φ, 220~240V, 50Hz

3.8 5.6

4.8 5.8

38/39 41/42

51/51 53/53

575*575*250 575*575*250

790*285*548 790*285*548

623*653*298 623*653*298

926*384*640 926*384*640

11. 4 11. 4

32.8 32.8

13.7 13.7

35.8 35.8

DB31-00578C DB31-00578C

UG9AJ3090FER UG9AJ3090FER

DB31-00642B DB31-00642B

4.1 4.1

1.4 1.4

PC4SUFMAN PC4SUFMAN

R- 410A R- 410A

1,050 1,050

Chargeless Chargeless

5 5

20 20

15 15

01507F-1910C8-271A22-370000

020000-100001-200000-300000

030000-100000-200000-300000

01507F-1930F9-272328-370000

020000-100001-200000-300000

030000-100000-200000-300000

2-2 Samsung Electronics

ITEM

INDOOR UNIT

AC052NNNDKH

AC052MXADKH

Development Model

AC060NNNDKH

AC060MXADKH

IMAGE

OUTDOOR UNIT

REMOTE CONTROLLER

Performance

Power

Consumption

Voltage / Frequency

Operating

Current

Noise

Indoor Unit [dBA] (C/H)

Outdoor Unit [dBA] (C/H)

Net Dimension

(WxHxD)

Size

Shipping

Dimension

(WxHxD)

Net Weight

Weight

Shipping Weight

Harness

Specifications

Piping

Indoor Fan Motor

Outdoor Fan Motor

High Pressure

PANEL

Refrigerant Type

Factory Charging [g]

Additional Refrigerant (for every 1m) [g]

Basic Piping Length [m]

Max. Piping Length [m]

Max. Level Difference [m]

Option Code

Cooling [W]

Heating [W]

Cooling [W]

Heating [W]

Cooling [A]

Heating [A]

Indoor Unit [mm]

Outdoor Unit [mm]

Indoor Unit [mm]

Outdoor Unit [mm]

Indoor Unit [kg]

Outdoor Unit [kg]

Indoor Unit [kg]

Outdoor Unit [kg]

Compressor

Low Pressure

5,000 5,800

5,500 7,000

1,530 2,150

1,520 2,320

1Φ, 220~240V, 50Hz 1Φ, 220~240V, 50Hz

6.9 9.3

6.9 10

43/44 45/46

58/58 58/58

575*575*250 575*575*250

880*310*638 880*310*638

623*653*298 623*653*298

1024*413*73 0 1024*413*730

11. 4 11. 4

43.8 43.8

13.7 13.7

47. 5 47.5

DB31-00578C DB31-00578C

UG9TK3150FE4 UG9TK3150FE4

DB31-00658D DB31-00658D

4.1 4.1

1.4 1.4

PC4SUFMAN PC4SUFMAN

R- 410A R- 410A

1,300 1,300

10 10

5 5

30 30

20 20

01507F-19345D-27343C-370040

020000-100001-200000-300000

030000-100000-200000-300000

01507F-19446E-273C46 -37004 0

020000-100001-200000-300000

030000-100000-200000-300000

Samsung Electronics 2-3

2-2 Product Specifications (cont.)

ITEM

INDOOR UNIT

Development Model

AC071NNNDKH

AC071MXADKH

IMAGE

Performance

Power

Consumption

Voltage / Frequency

Operating

Current

Noise

Net Dimension

Size

Dimension

Net Weight

Weight

Harness

Specifications

Piping

Factory Charging [g]

Additional Refrigerant (for every 1m) [g]

Basic Piping Length [m]

Max. Piping Length [m]

Max. Level Difference [m]

OUTDOOR UNIT

REMOTE CONTROLLER

Cooling [Btu/h]

Heating [Btu/h]

Indoor Unit [dBA] (C/H)

Outdoor Unit [dBA] (C/H)

(WxHxD)

Shipping

(WxHxD)

Shipping

Weight

Indoor Fan Motor

Outdoor Fan Motor

High Pressure

PANEL

Refrigerant Type

Option Code

Cooling [W]

Heating [W]

Cooling [A]

Heating [A]

Indoor Unit [mm]

Outdoor Unit [mm]

Indoor Unit [mm]

Outdoor Unit [mm]

Indoor Unit [kg]

Outdoor Unit [kg]

Indoor Unit [kg]

Outdoor Unit [kg]

Compressor

Low Pressure

6,800

7,500

2,720

2,800

1Φ, 220~240V, 50Hz

11. 8

12.3

46/46

60/60

575*575*250

880*310*798

623*653*298

1023*413*911

11. 4

43.8

13.7

47. 5

DB31-00578C

UG4T200FUAE4

DB31-00658D

4.1

1.4

PC4SUFMAN

R- 410A

1,500

20

5

50

30

01507F-194581-274750 -37004 0

020000-100031-200000-300000

030000-100000-200000-300000

2-4 Samsung Electronics

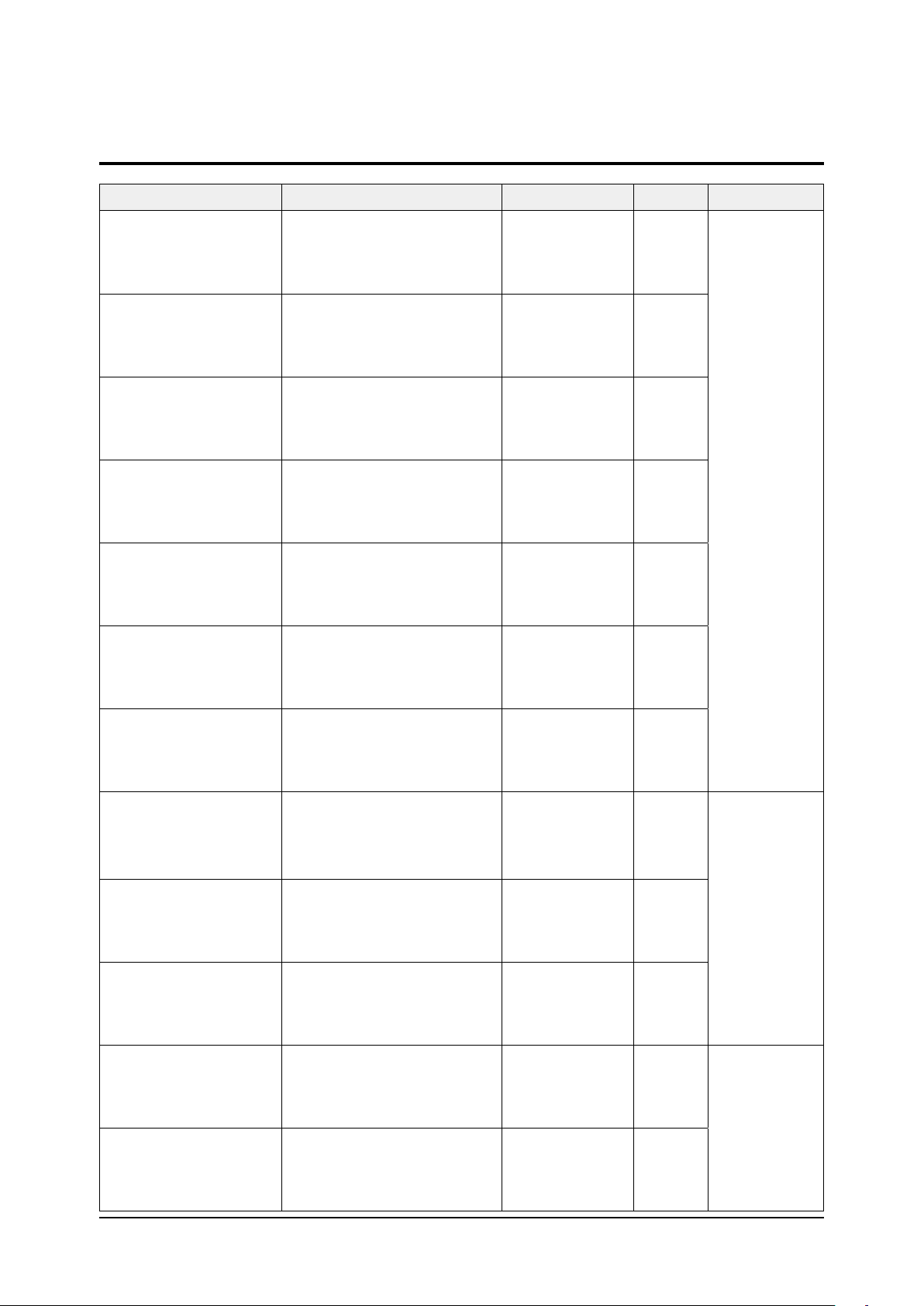

2-3 Accessories

Item Description Code No. Q’ty Remark

Ass'y drain hose DB94 -03287A 1

Cable-tie DB 65-10 088C 6

Seal-drain ass'y DB62-11028A 1

Seal-drain ass'y DB62-11028H 1

Seal-drain ass'y DB62-11028J 1

USER MANUAL

INSTALLATION MANUAL

CARD WARRNATY DB68-02596B

INSTALLATION MANUAL

Drain Plug

DB68-06489A

DB68-06490A

DB68-05688A

DB67-00 477A

Essential Offer

1

1

1

Essential Offer (Outdoor

1

(Indoor Unit)

Unit)

Rubber Leg DB73-20134A 4

BO LT 6011-003975 4

Essential Offer

(Panel)

INSTALLATION MANUAL

DB 68-03837A 1

Samsung Electronics 2-5

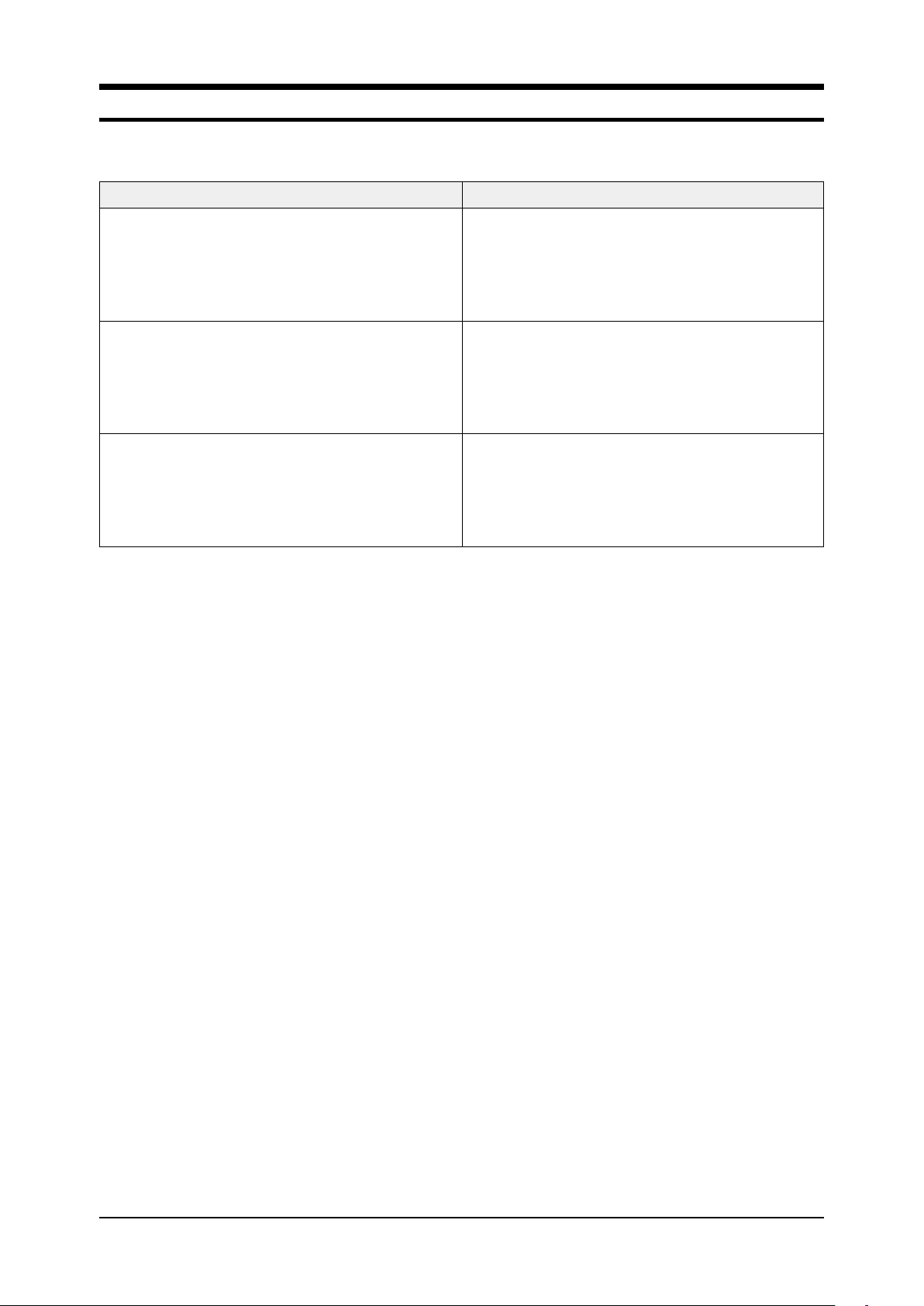

3. Disassembly and Reassembly

■ Necessary Tools

Item Remarks

+SCREW DRIVER

Adjustable Wrench

(8mm, 10mm, 13mm)

M6, M8 Hex Wrench

Samsung Electronics 3-1

3-1 Indoor unit

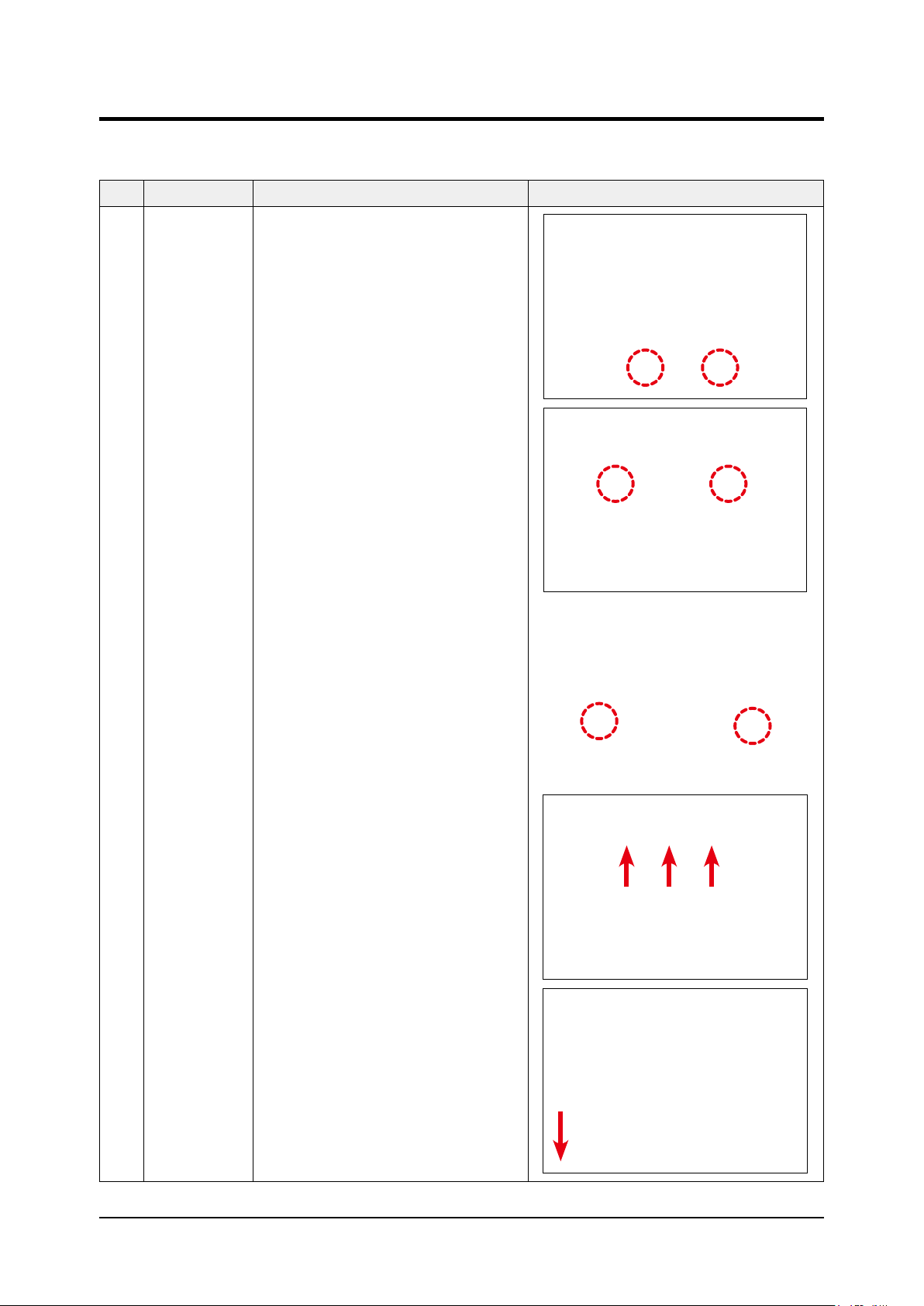

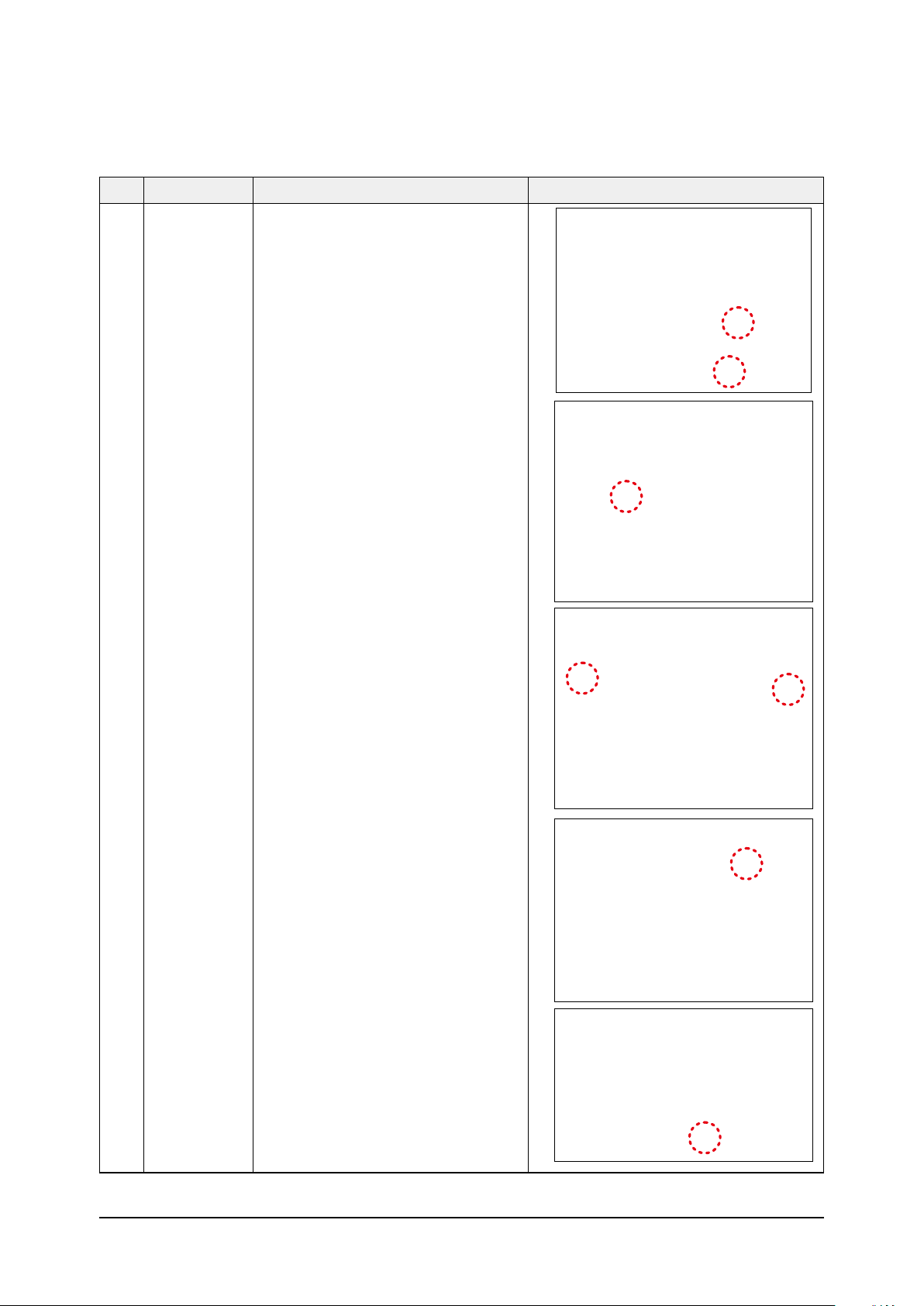

■ AC026NNNDKH, AC035NNNDKH, AC052NNNDKH, AC060NNNDKH, AC071NNNDKH

No Parts Procedure Remark

1 Panel 1) Pull both hooks and take the grille downward.

Two safety clips are mounted to the front grille

to prevent it from dropping.

2) Detach the safity clip and take up the grille.

3) Remove the 2 fixed screws to remove the

Control-Box Cover. (Use +Screw Driver)

4) Remove the remote control-receiver , blade

conector and humidity sensor wires from the

PBA. (4EA)

5) Push the 4 panel corners and cover downwards

to remove it.

3-2 Samsung Electronics

No Parts Procedure Remark

6) Disassemble the bolts that are assembled with

the indoor unit at the 4 panel corners.

7) Press the Hangers at both sides of the panel

inwards, to remove it from the indoor unit’s

hook.

Remove the panel from the indoor unit.

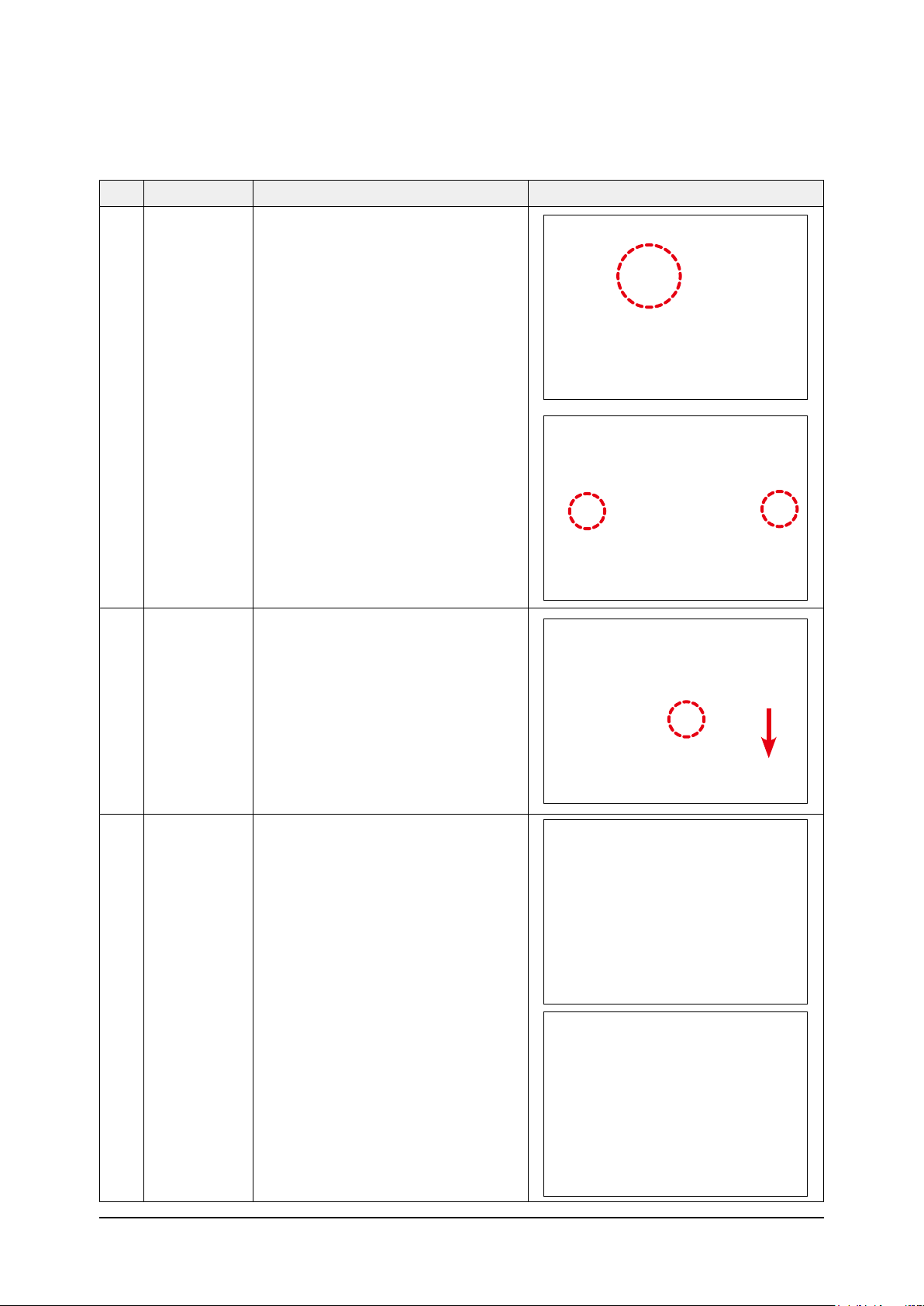

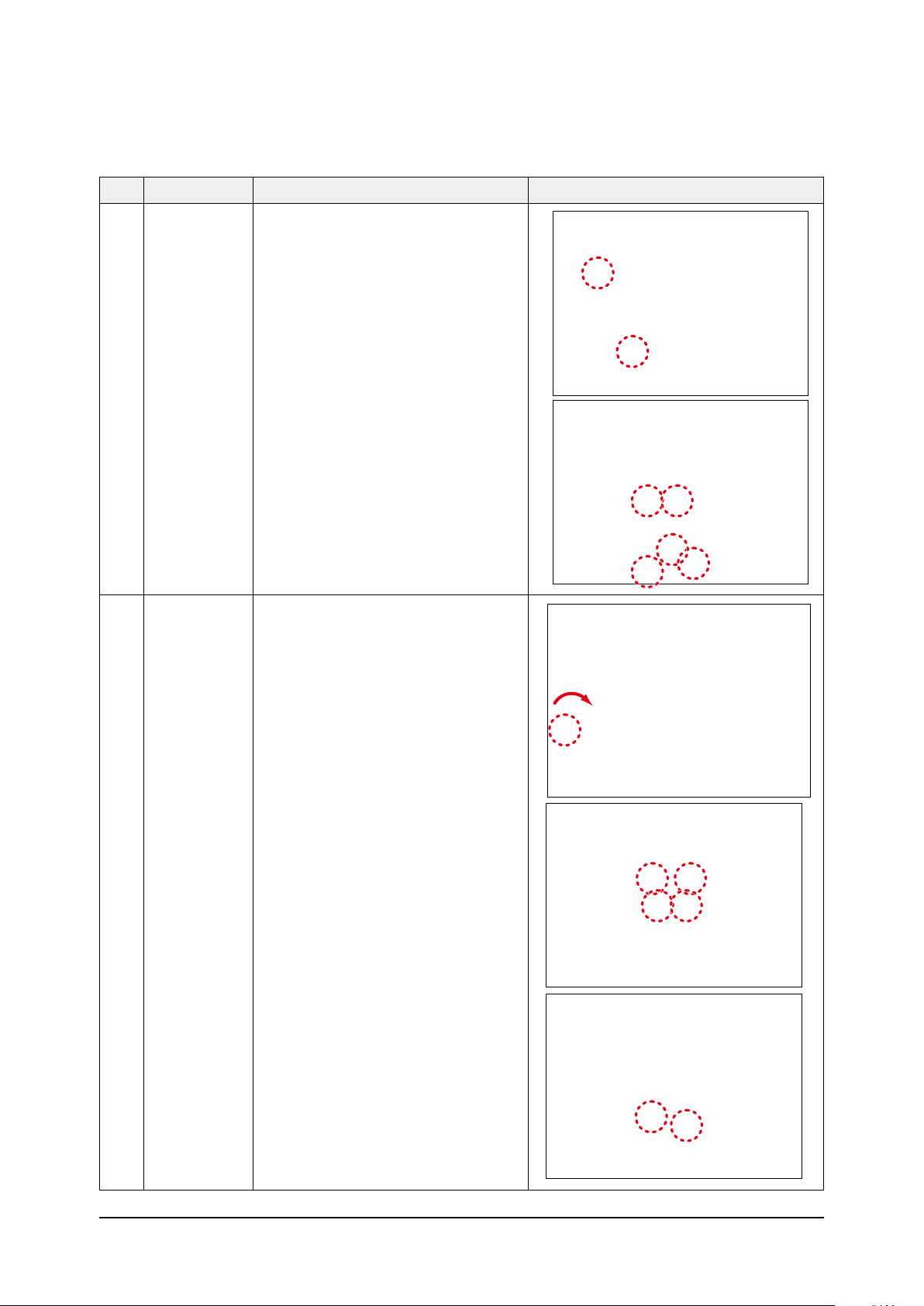

2

3 Display PBA

Blade 1) Remove the hinge-blade and blade.

1) Remove the cover display.

2) Remove the cover PBA from the cover display.

Samsung Electronics 3-3

No Parts Procedure Remark

3) Disconect the conector wire from the PBA.

Humidity Sensor 1) Remove the humidity sensor from the panel.

4

5

Step motor 1) Unscrew 2 screws on cover motor. (Use +Screw

Driver

2) Remove 2 cover motor.

Remove the 2 fixed screws and disassemble the step

3)

motor. (Use +Screw Driver)

3-4 Samsung Electronics

No Parts Procedure Remark

6 Control-Box 1) Disconnect the Connector Wire that is

connected to the indoor unit’s PBA

2) Unscrew the 2 fixed screws on both sides of the

Control Box, and disassemble the Control Box

from the indoor unit.(Use +Screw Driver)

Samsung Electronics 3-5

No Parts Procedure Remark

7 Bell-Mouth 1) Unscrew the screw fixed on the Bell-Mouth.

(Use +Screw Driver)

2) Push the Bell-Mouth in the direction

opposite to where it’s installed on the

Control-Box to remove it.

8 Drain Pan 1) Unscrew the screws on the 4 corners

of the indoor unit. (Use +Screw Driver)

2) Remove the Drain Pan from the indoor unit.

3-6 Samsung Electronics

No Parts Procedure Remark

9 Drain Pump

&

Hose

1) Remove the 2 fixed screws and

disconnect the white drainage hose from

the Drain Pump. (Use +Screw Driver)

2) Remove the 2 screws and take the

Drain-Hose out from the indoor unit to

disassemble the transparent Drain-Hose

fixed on the side of the indoor unit.

(Use +Screw Driver)

10 Evap.

Temperature

Sensor

1) Use your hand to remove the temperature

sensor attached to the Evap Pipe along with

the fixing clip.

Samsung Electronics 3-7

No Parts Procedure Remark

11 Fan

&

Motor

1) Turn the hexangular nut attached to the

top of the Fan counterclockwise to remove it.

Take the Fan out of the Motor.

2) Turn the three hexangular nuts on the

Motor counterclockwise to remove the nuts.

Take the Motor Wires attached to these

three locations out with your hands prior to

removing the Motor.

12 Evaporator 1) Remove the screws of the Steel Holder Evaps

that are used to fix the Heat Exchanger, and

then remove it. (Use +Screw Driver)

2) Remove the 2 fixing screws of the Partition

Evap at the Heat Exchanger’s In/Out Pipe.

(Use +Screw Driver)

3-8 Samsung Electronics

No Parts Procedure Remark

3) Remove the screw of the Cover Pipe

that is used to fix the In/Out Pipe.

Remove the In/Out Pipe. (Use +Screw Driver)

4) Remove the Heat Exchanger from the

indoor unit’s cabinet.

Samsung Electronics 3-9

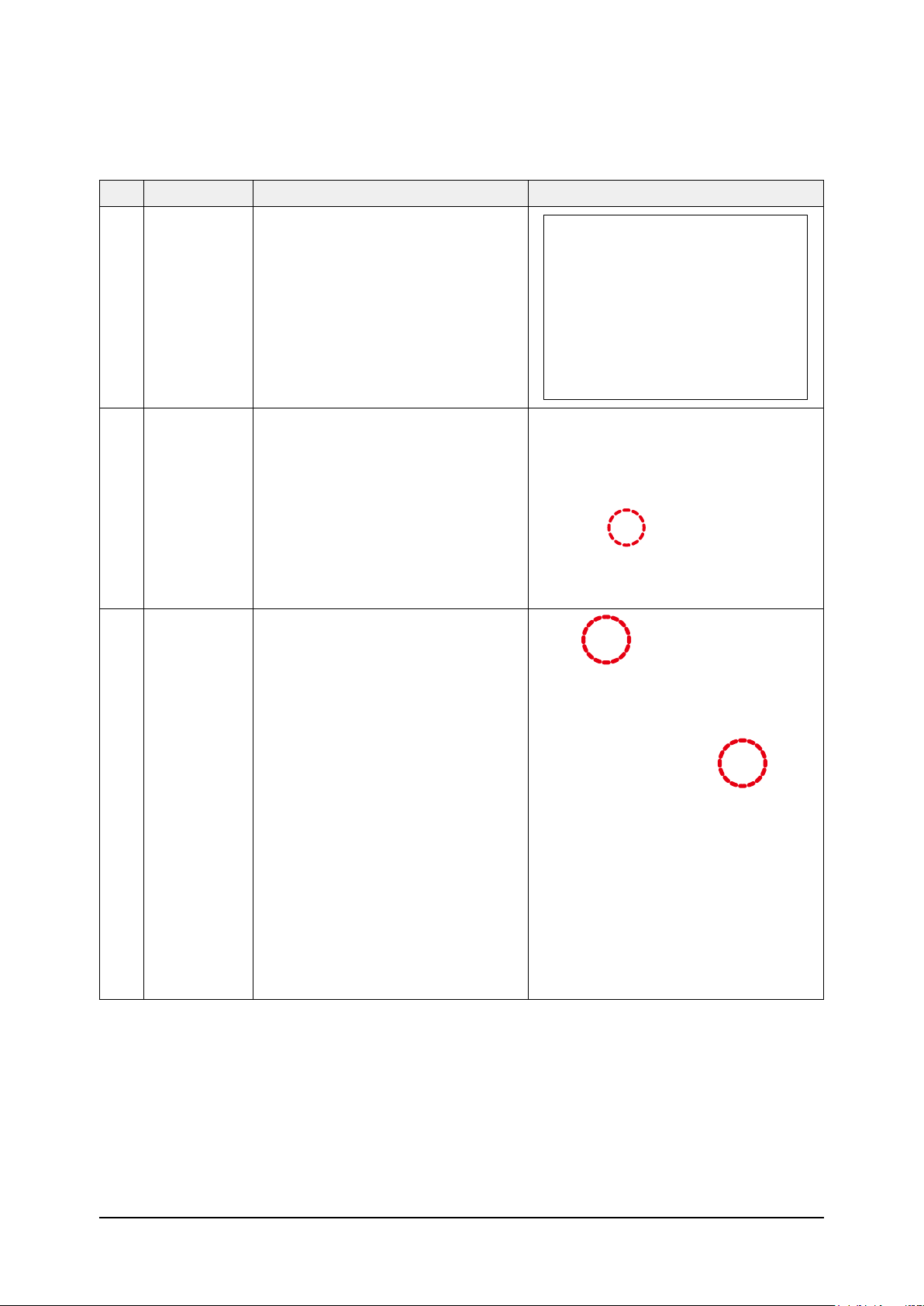

3-2 Outdoor unit

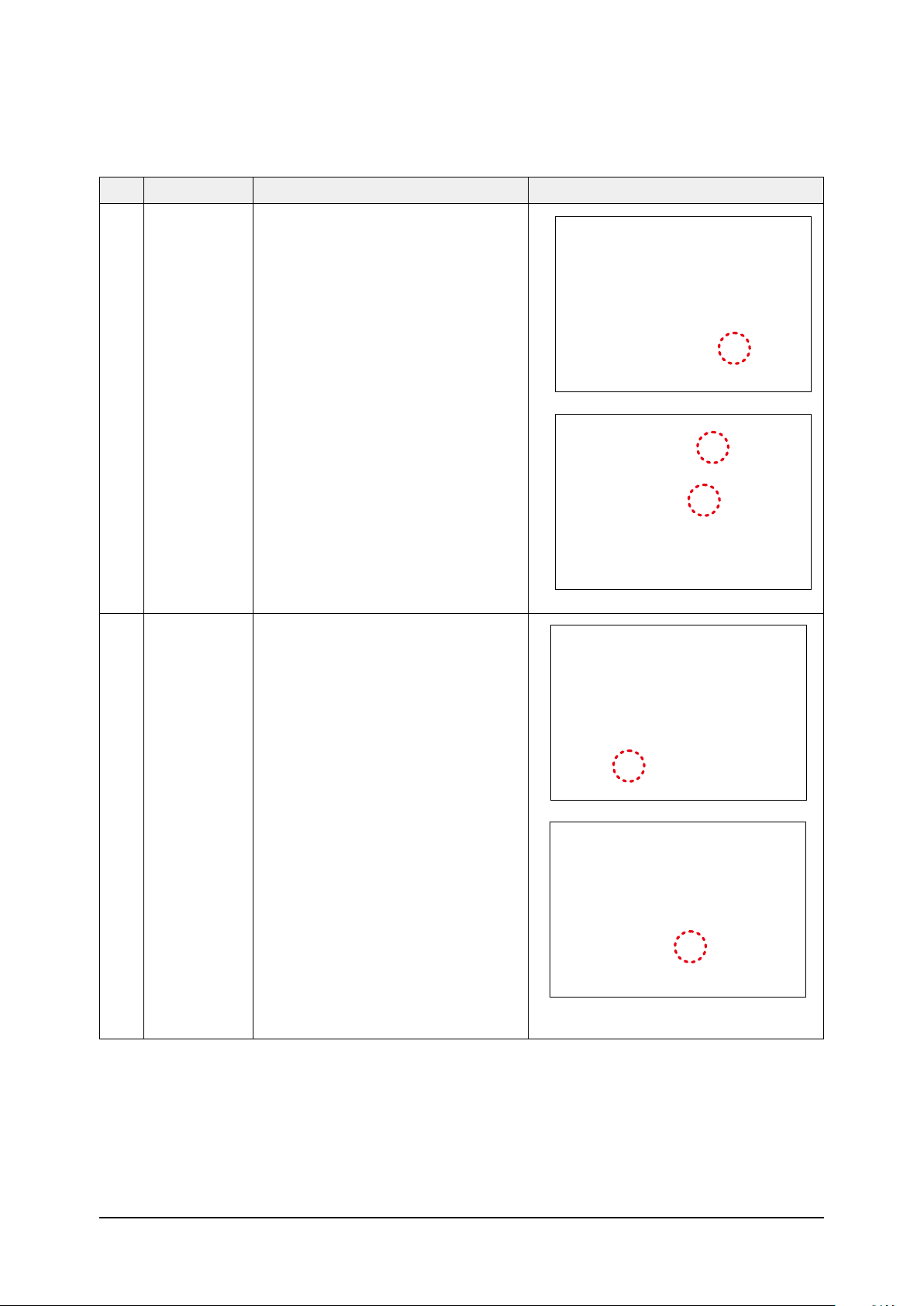

■ AC026MXADKH / AC035MXADKH

No Parts Procedure Remark

1 common work You must turn off the Power

CAUTION

before disassembly.

1) loosen 1 pcs screw of cover control,and

detach it.

2) loosen 5 pcs screws on both right and

left cabniet side edges and to detach the

cover-top

3) Loosen 7 screwsfixed to disassemble

cabi-front , and detach it.

3-10 Samsung Electronics

No Parts Procedure Remark

common work

4) loosen 2 screws to disassemble steel-bar.

5) Loosen 2 screws to disassemble the cabi left

and detach it.

Samsung Electronics 3-11

No Parts Procedure Remark

common work 6) Loosen 7 screws to disassemble the cabi right

and detach it.

2 fan&motor 1) loosen 1 screw as indication and detached

the fan.

2) loosen 4 pcs motor screws and disconnect

the wire betwwen assy control out and motor.

3) loosen 2 pcs bracket-motor screw and

detach it.

3-12 Samsung Electronics

No Parts Procedure Remark

3 assy control out 1) lossen fixing 1 screw from cover -control

2) detach several connections from assy control

out, take out assy control out.

4 Heat exchanger 1) Release the refrigerant at first

2) Looosen fixing screw on both side.

3) disaessembly the pipes in both inlet and

outlet with welding torch.

4) detach the heat exchanger.

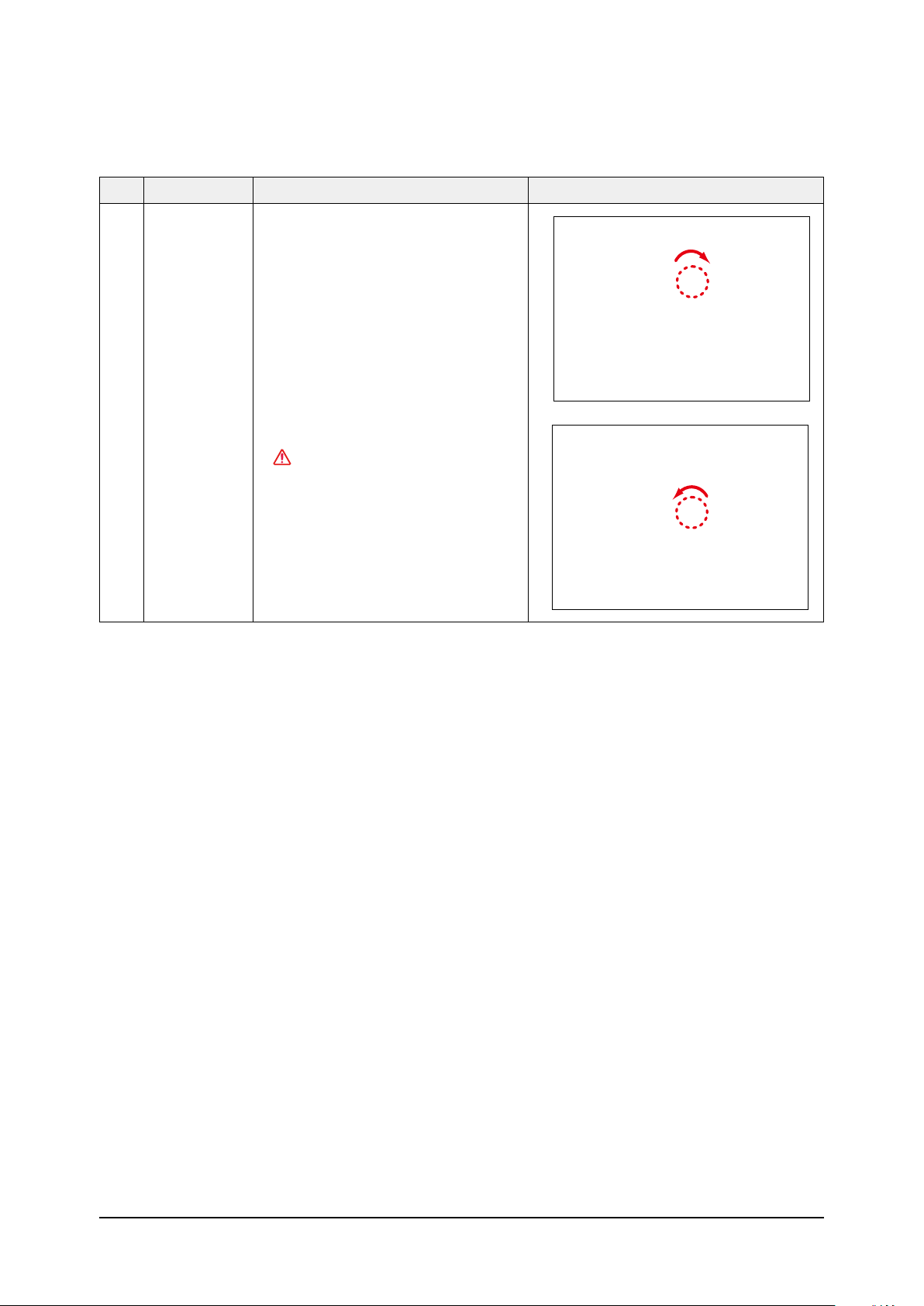

Samsung Electronics 3-13

No Parts Procedure Remark

CAUTION

5 compressor 1) disconnect the compressor lead wire .

2)disassembly the felt comp sound.

loosen the 3 bolts at the bottom .

When removing the compres-

sor, Heat Exchanger, and Pipe, purge the

Coolant inside the Compressor completely

and remove the pipe with a welding flame.

3-14 Samsung Electronics

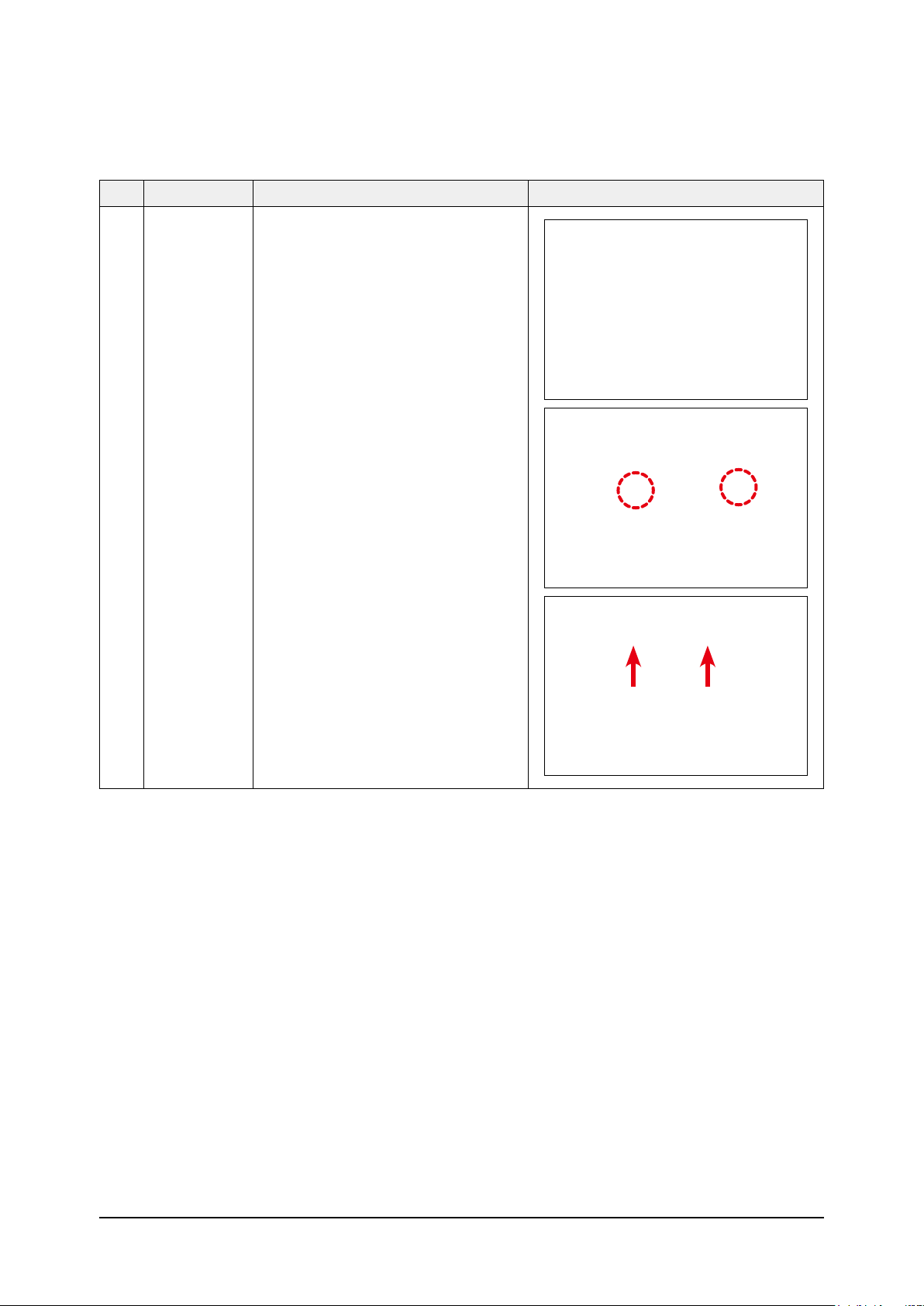

■ AC052MXADKH / AC060MXADKH

No Parts Procedure Remark

1 common work You must turn off the Power before

CAUTION

disassembly.

1) Loosen 1 pcs screw of cover control

2) Loosen 8 pcs screw of the cabi top

cover.

3) Loosen 4 pcs screw of the bar steel.

4) Loosen 10 pcs screw of the cabi side

front.

Samsung Electronics 3-15

No Parts Procedure Remark

1 common work

2 Fan& motor 1) Loosen the fan screw according the indi

-

cation and detach the fab propeller

2)Disconnect the wire between assy control out

and motor.

3-16 Samsung Electronics

No Parts Procedure Remark

2

3) Loosen 4 pcs motor screw.

4) Loosen 2 pcs screw of bracket motor.

3 Assy control out

1)Loosen the screws that connected partition

and case control then get the control out.

2) Loosen the screw of the cover termimal

Samsung Electronics 3-17

No Parts Procedure Remark

3

3) Loosen 2 screws , disassemble the Coil

Harmonic.

4) Loosen the screw of the cover terminal.

3-18 Samsung Electronics

No Parts Procedure Remark

CAUTION

4 Heat exchanger 1) Release the refrigerant at first

2) Loosen fixing screw on both side..

3) Disassemble the pipes in both inlet and

outlet with welding torch.

4) Detach the heat exchanger.

When removing the compres-

sor, Heat Exchanger, and Pipe, purge the

Coolant inside the Compressor completely

and remove the pipe with a welding flame.

5 Compressor

1)Loosen the 3 bolts at the bottom of compres-

sor.

Samsung Electronics 3-19

Loading...

Loading...