Samsung RC090-120-140, 160MHXEA Installation And Maintenance Manual

www.samsungehs.co.uk ©G Hendra April 2015 1

Installer

Please

Read

Instructions

Inside

www.samsungehs.co.uk ©G Hendra April 2015 2

www.samsungehs.co.uk ©G Hendra April 2015 3

Air Source Heat Pump

Installation and Maintenance Manual

Model Numbers:

RC090-120-140 and 160MHXEA

www.samsungehs.co.uk ©G Hendra April 2015 4

The outdoor unit (boiler)

Deciding on Where to Install the Outdoor Unit

Choose a location where the noise of the Air to Water Heat Pump when running and the

discharged air do not disturb any neighbours.

Install the outdoor unit on a flat, stable surface with plenty of drainage, gravel or grass is

ideal; make sure the base can support its weight

Position the outdoor unit so that the air flows into an open area, where there are no plants

and animals

If you can see the sea from the position of the outdoor unit you need to apply Blygold, Bronze

glow or equivalent anti-corrosion coating on the whole unit.

The unit will not benefit from being mounted on the North or south of the building, any aspect

is fine, you should avoid very exposed positions to avoid wind blowing into the back or front of

the unit.

The unit needs to be securely

mounted at least 100mm off the

ground on rubber feet. The unit

must be bolted down for security

using 10mm bolts and Zebedee

bolts. If wall brackets are used we

recommend 600mm unistrut

cantilever arms are used. Caution

should be applied when wall

mounting because any vibration

form the unit can be transmitted into the

wall creating noise.

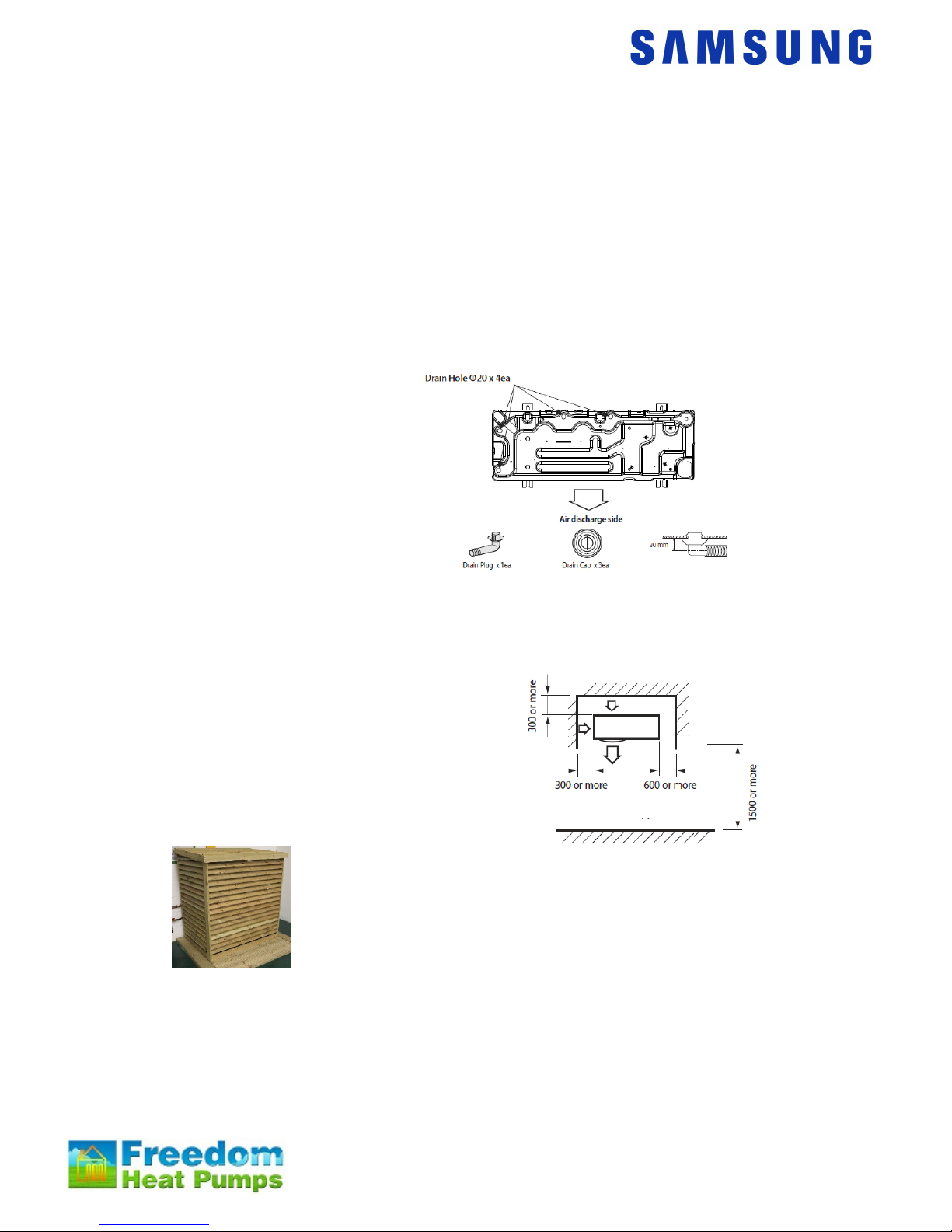

The unit must have adequate drainage away from the unit; it can produce up to 6 L / hour.

There is a drainage kit included which we recommend you don’t use, its best to let the unit

drain into the ground. If a drip tray is used it must be 25mm longer and wider than the base of

the unit to catch all the drips.

Dimensions:

Size 16 - 1420mm (h) 940mm (w) 330mm (d) 103kg

Size 9 - 998mm (h) 940mm (w) 330mm (d) 75kg

The space around the unit is very important, allow:

300mm to the left hand side (facing the front of the

unit), 600mm to the right of the unit, 300mm to the

rear of the unit and 1500mm to the front of the unit.

Wooden enclosures are now available for the units, please contact your

distributor for details.

The Control Box

When the heat pump is delivered it comes with a control box which also contains the flow

switch. Install the control unit indoors as it’s not waterproof.

It needs to be sited less than 15m of the hot water cylinder, 100m of the outdoor unit and as

near as possible to the pump, flow switch and any zone valves.

The box is 323mm wide, 339mm high, 131mm deep

www.samsungehs.co.uk ©G Hendra April 2015 5

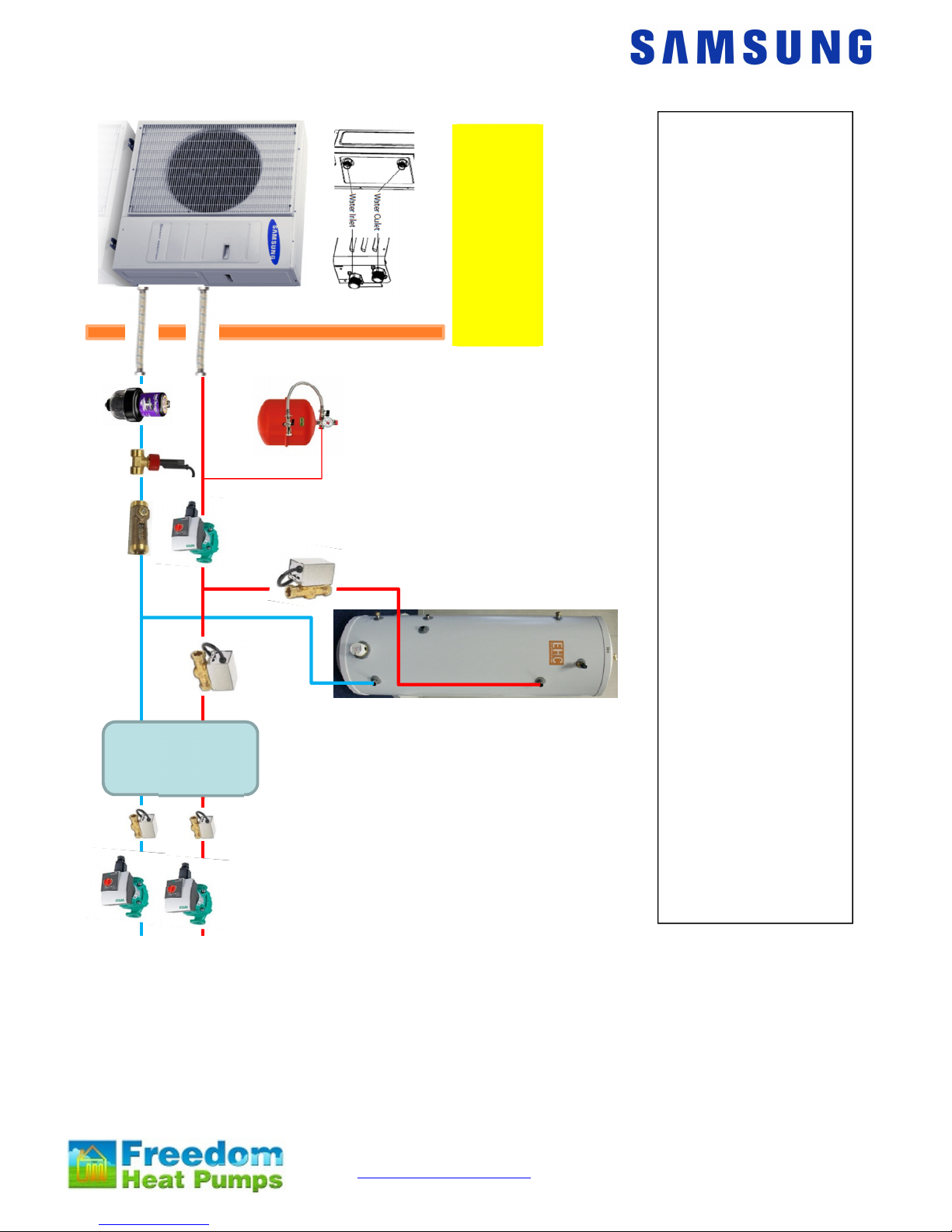

Pipework Schematic size 9 and 16 units

The heat pump has 1 inch

BSP male connections;

these should be

connected to flexi hoses.

The flexi hoses have to be

insulated to conform to

MCS.

To maintain flow rate we

recommend 28mm

pipework is used with this

machine. NEVER use

22mm plastic tube, if you

insist on using plastic use

28mm throughout

You will also need to

install:

High resistance pump,

Expansion vessel,

Pressure gauge,

Pressure relief valve,

Filling loop,

Magnetic filter

Strainer.

Flow meter

Flow switch

2 x 2 port valves

We recommend the

system has a break in it,

you can use a header, a

buffer or a heat exchanger

to do this. This is done to

maintain uninterrupted

flow.

The domestic hot water

cylinder must be

manufactured specifically

for the heat pump and

have a coil with a surface

area of 3m^2 equivalent.

For more details see next

page

Standard System With Header

Or Buffer And 2 Ports

To keep pump sizes

down we recommend

28mm pipework for the

main runs

The header or buffer is in the

heating part of the circuit only.

You can have as many heating

zones as you like, we have only

shown 2. Each zone needs its

own pump and valve.

Pumps 2 and 3 only run when

there is a heating demand, they

are driven by the external run

signal form under floor manifold

or stat.

Header

, buffer

or heat

exchan

ger

Pump 1

Pump 2 Pump 3

www.samsungehs.co.uk ©G Hendra April 2015 6

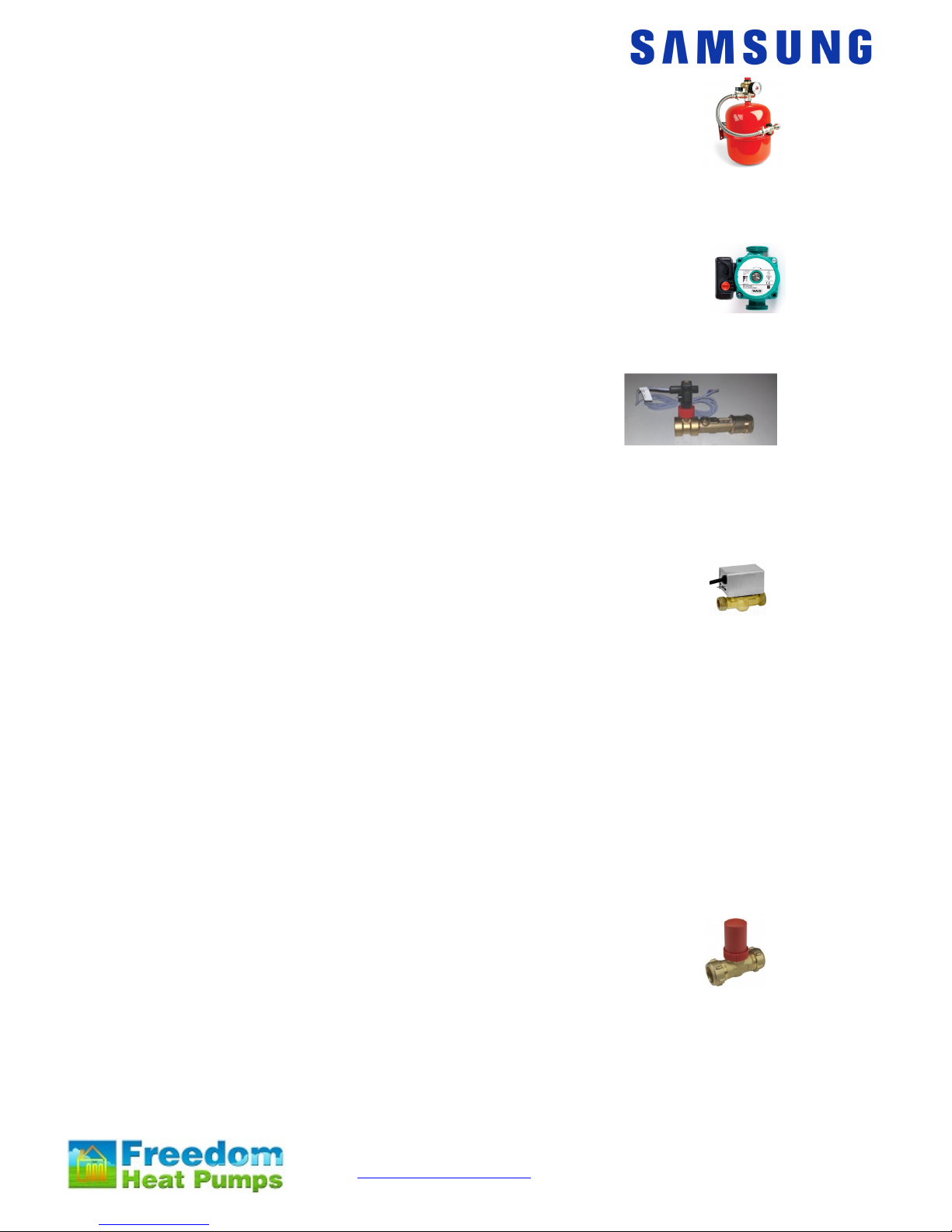

Other components you need to supply and fit:

An expansion vessel, pressure gauge, pressure relief valve and filling

loop

Most heating engineers use a robokit with the appropriate size expansion

vessel; this is sized exactly the same way as when using a boiler.

Pump

Your pump needs to supply 20l/min for the 9kW and 30l/min for the 16kW unit.

The static resistance through the unit is 10kPa for the 9kW and 15kPa for the

16kW unit. The flow meter has a resistance of around 5kPa

The cylinders (Gledhill) have a static resistance of 5kPa for the heat pump coil

and 19kPa for the solar coil.

The total resistance of the components will be approximately 39kPa for the size

9 unit and if the cylinder is piped using both coils and approximately 44kPa for the size 16

unit.

Flow switch and flow meter

The unit requires 17L / min flow at all times, if you don’t achieve this

E911 error will occur to check this flow switch is installed. The flow

switch comes with the control box.

The flow Switch MUST be installed in either horizontally or vertically

with at least 150mm of straight pipe either side, connection is 1” female BSP. The wire is 2m

long and needs to connect into the wiring station. This wire can be extended to suit. We

recommend a flow meter is installed into the flow side of the flow switch as per the photo.

Adaptors may be required to enable this join. The flow switch is not IP65 rated (weatherproof)

and so must not be installed externally.

Diverter valves

If you require domestic hot water and heating, diverter valves are required, you

need to supply these.

Water Filter

In all cases a filter with strainer needs to be installed in the return to the heat pump. A

magnetic filter must also be installed in the return to the unit. The filters ensure that

debris/foreign materials do not cause damage to the heat exchanger in the unit voiding

warranties.

Glycol

A propylene glycol mixture must be utilized to prevent freezing of the water within the system.

It is important that the glycol concentration is adequate to protect the unit in case of power

failure in very cold conditions. If the unit freezes up there will be no warranty. Manufacturer

dependant, a mix of around 25% should suffice.

Buffer vessels, heat exchangers and low loss headers

You don’t have to use a buffer vessel on a Samsung but we do need a minimum flow rate of

17l/min and have a circulating volume of over 20 Litre. To achieve this is much easier if you

break the system in two with a header, a buffer or a heat exchanger.

Bypass Valve

If you don’t use a header buffer or heat exchanger you must install a bypass

valve in the heating circuit as far away from the heat pump as possible. The

bypass valve enables flow to be maintained as the trv’s shut down at all times to

prevent unit flow fault.

The Cylinder:

The cylinder needs to be installed less than 15m from the control box to allow for the

temperature sensor cable. Note the size and weight of the cylinder. Full installation

instructions are included with the cylinder.

Cylinders can be used IF the coil area is more than 2.5m^2. Smaller coils are not acceptable

and cannot be used. Please do not attempt to utilize a standard central heating, non-heat

pump optimized cylinder. Cylinders can be pressurised or open vented.

www.samsungehs.co.uk ©G Hendra April 2015 7

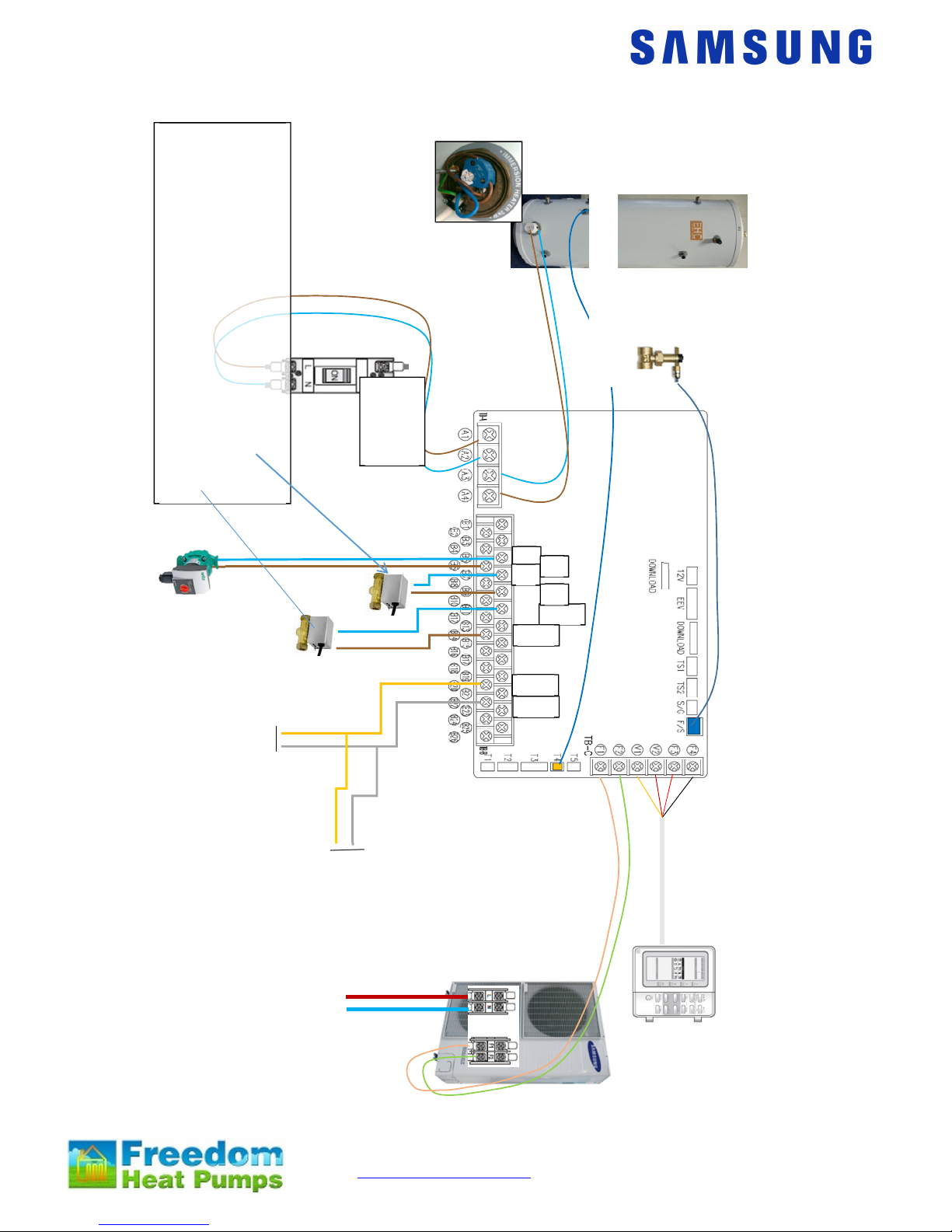

Wiring diagram for heating and HW heat pump:

Flow switch 2m long

you can extend this

Standard System

With Header Or Buffer

and 2 Ports

Power

input

16Amps

Power supply

240V

20A for size 9

32A for size 16

Communication

cable 2 core 1mm

(16Vdc)

12m long

Hot

water

valve

Valve

zone 1

How the valves work

The HW valve is only open (B9 live) when the system is in

HW mode (coke can symbol showing in status on controller)

it is closed (B10 live) at all other times.

Heating valve 1 is open at all times (B14 live) except when

HW is operating and when thermostat 2 only is made, (B13

live).

Pump 1

Fl

ow switch 2m long

you can extend this

Run signal

from

heating

zone

valves

Run signal

from

heating

zone

valves

5

6

1

1

9

1

4

2

0

2

2

7

Tank sensor 15m long DON

’

T cut this

Loading...

Loading...