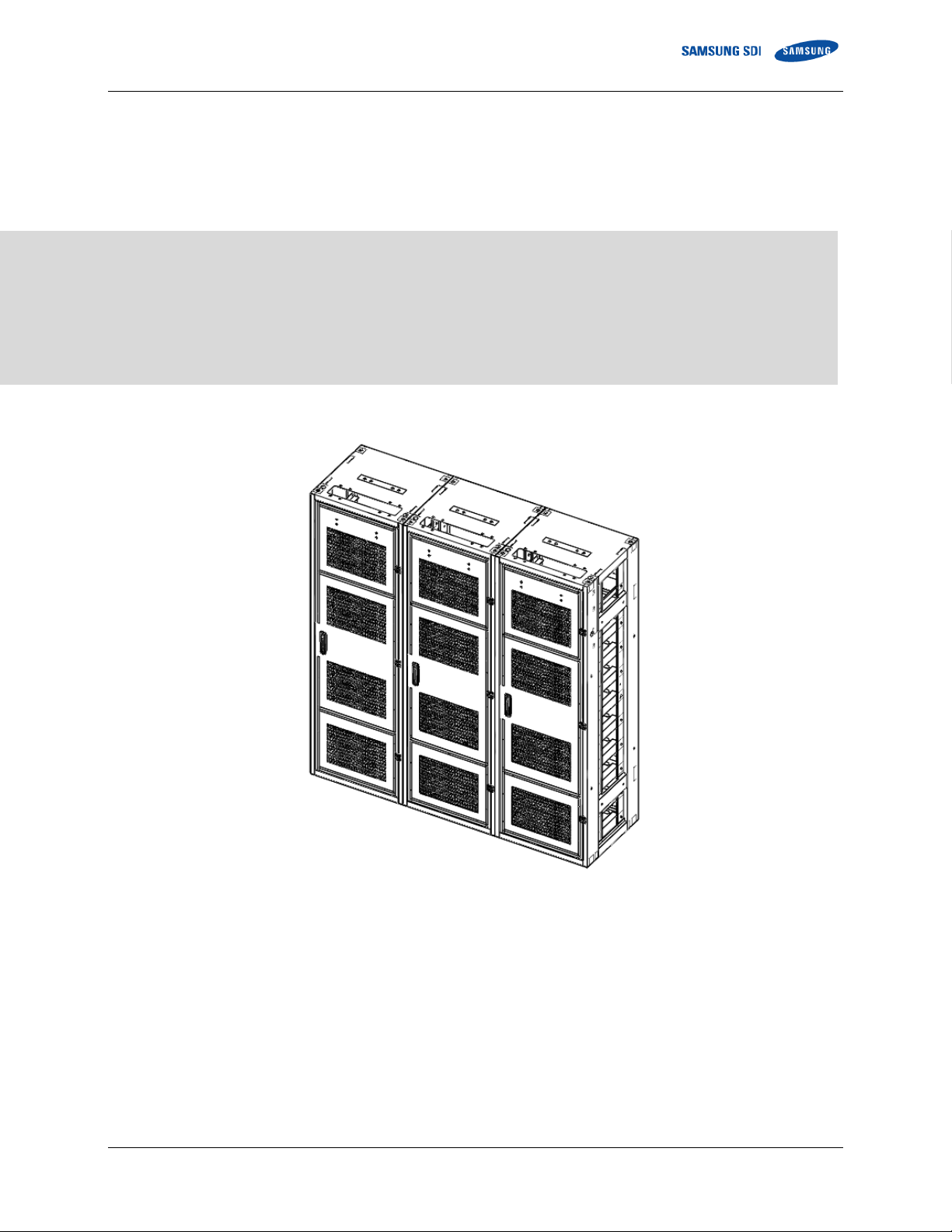

Samsung 136S Installation Manual

Lithium Ion Battery System for UPS

Installation Manual

(136S)

ET003222373 English 4/2018. Rev 0.0

Read this manual carefully before starting to install the battery system.

Keep these instructions for future reference.

ET003222373 English 4/2018. Rev 0.0

Copyright © 2017 SAMSUNG SDI Co., Ltd. All rights reserved.

This document contains information that is the property of SAMSUNG SDI Co., Ltd., and provides

for the sole purpose of the installation, operation, and maintenance of products of SAMSUNG SDI

Co., Ltd. No part of this publication is to be used for any other purpose, and it is not to be

reproduced, copied, disclosed, transmitted, stored in a retrieval system, or translated into any

human or computer language, in any form, by any means, in whole or in part, without prior written

consent of SAMSUNG SDI Co., Ltd.

Although every possible effort has been made to ensure the accuracy of this document, SAMSUNG

SDI Co., Ltd. assumes no responsibility for errors that may appear herein. The information is

subject to change without notice.

ET003222373 English 4/2018. Rev 0.0

ET003222373 English 4/2018. Rev 0.0

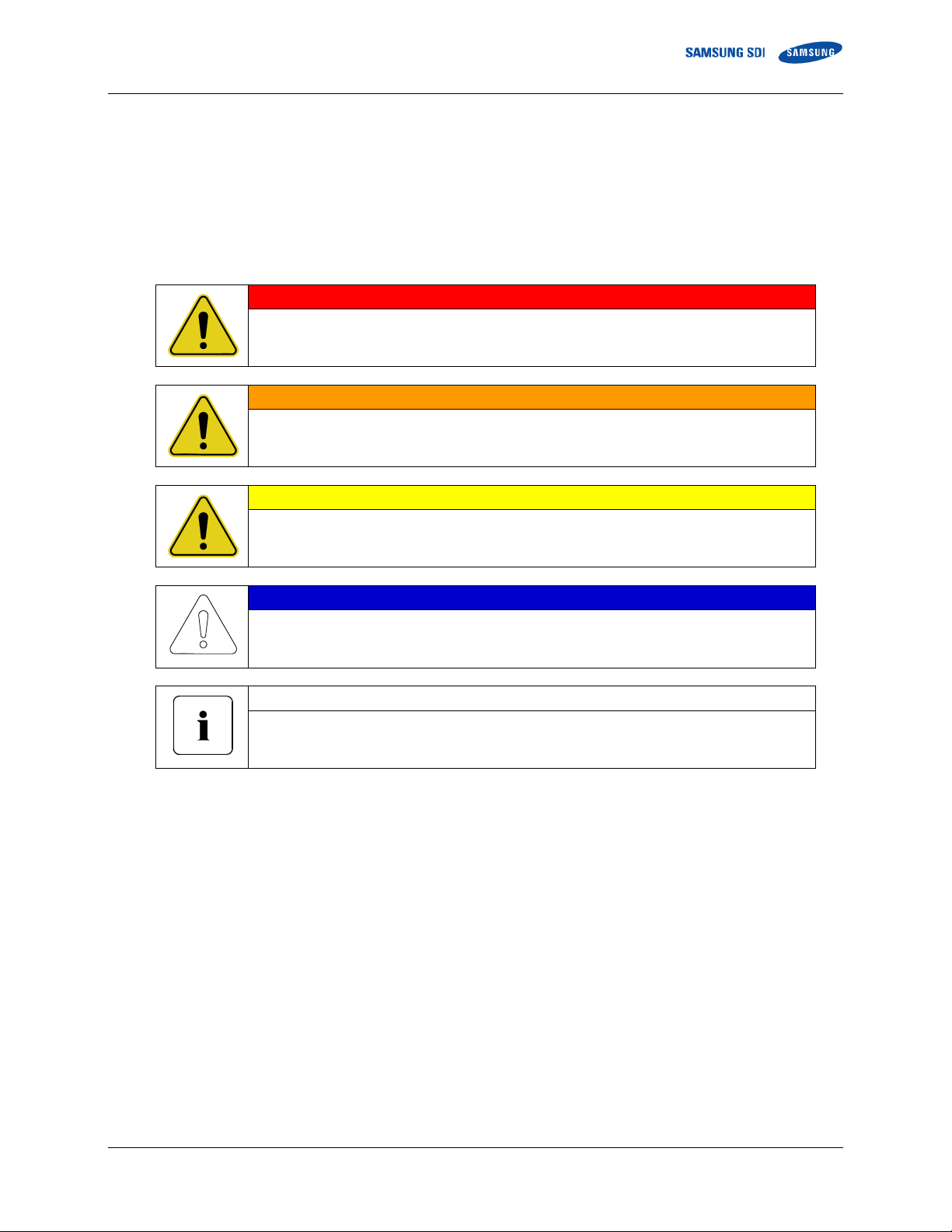

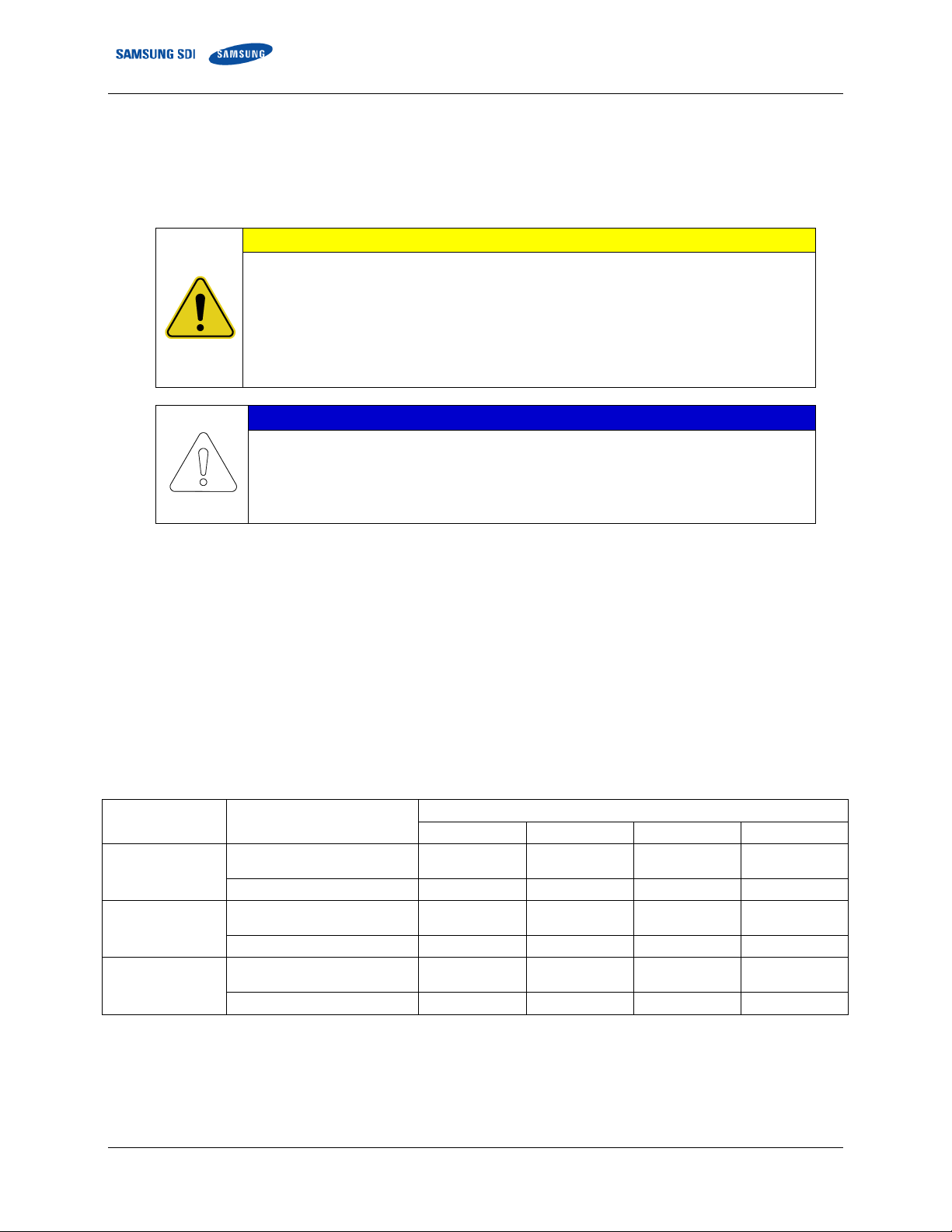

Important Safety Instructions

DANGER

Failure to comply with the instructions with this symbol may result in a serious accident,

causing death or a severe injury.

WARNING

Failure to comply with the instructions with this symbol may result in a serious accident,

causing a severe injury.

CAUTION

Failure to comply with the instructions with this symbol may result in minor or moderate

injury.

NOTICE

Provides information considered important but not hazard-related. The information relates

to property damage.

Important

Indicates valuable tips for optimal installation and operation of the product.

Important Safety Instructions

Read and follow these instructions!

The following precautions are intended to ensure your safety and prevent property damage. Before

installing this product, be sure to read all safety instructions in this document for proper installation.

ET003222373 English 4/2018. Rev 0.0 i

Important Safety Instructions

General Instructions

Please be aware that a battery presents a risk of electrical shock including high short-circuit current.

Follow all safety precautions while operating the batteries.

Remove watches, rings, and other metallic accessories.

Use tools with insulated handles in order to avoid inadvertent short circuits.

Wear rubber gloves and safety boots.

Do not put tools or any metal parts on the top of the batteries.

Disconnect charging source and load before connecting or disconnecting terminals.

Use proper lifting means when moving batteries and wear all appropriate safety clothing and

equipment.

Batteries must be handled, transported and recycled or discarded in accordance with federal, state,

and local regulations. Do not dispose of the batteries in a fire because they can explode.

Do not open or mutilate the batteries.

Only authorized, trained technicians should perform annual preventive maintenance.

Only qualified personnel who are familiar with the batteries and safety precautions should perform

installation or maintenance of the battery.

Do not allow unauthorized personnel to contact the batteries.

Safety Precautions

The following precautions provide general safety guidelines that should be followed when working

with or near the Energy Storage System (ESS). Complete safety parameters and procedures are

site-specific and should be developed by the customer for the installation site.

Review and refer to all safety warnings and cautions in this manual before installation.

Build a clear, permanent, restricted access area around the system.

Only authorized, adequately trained electrical operators should be able to access the system.

The interior design of this equipment must be considered a ―no-go area except for non-qualified

personnel who are familiar with the batteries and safety precautions,‖ depending on the location.

Consult local codes and applicable rules and regulations to determine permit requirements. If

required, mark enclosures appropriately before beginning work.

ii ET003222373 English 4/2018. Rev 0.0

Important Safety Instructions

WARNING—SHOCK HAZARD

Do not contact system connectors or terminals. Do not open the enclosure doors unless proper

lock out/tag out procedures and related trainings are followed in accordance with the local codes

and regulations.

WARNING—ARC FLASH HAZARD

There is an arc flash hazard associated with all electrical equipment. There is a serious risk of

arc flash relating to any equipment modification (e.g. opening doors). Serious injuries can occur

in arc flash incidents. Appropriate training is required in accordance with local codes and

regulations.

WARNING—FIRE HAZARD

Fire may occur under certain fault conditions.

CAUTION—PINCH POINTS

Multiple pinch-points are present in most system components. Be aware that there is a serious

risk of injury while working around and in equipment enclosures.

CAUTION—STATIC SENSITIVE

Electronic appliances can be damaged by electrostatic discharge. Proper handling procedures

are required. Be sure to wear a grounded anti-static wrist strap and to discharge static electricity

by touching a grounded surface near the equipment before touching any system components.

DANGER

The ESS is powered by multiple power sources. Hazardous voltages may be present in the

equipment even when it does not appear operational. Make sure that you completely

understand the cautions and warnings in this installation manual. Failure to do so may result in

serious injury or death. Follow all manufacturer-published safety procedures.

Electrical equipment can present a risk of electrical shock and can cause arc flash. The

following precautions must be observed when working on or around electrical equipment:

Personnel and Equipment Warnings

Personnel in contact with the battery system should be aware of the following hazards:

Dangerous Voltages

Remove watches, jewelry, rings, and other metallic objects.

Use tools with insulated handles.

Safety clothing and shoes must comply with local codes and regulations.

ET003222373 English 4/2018. Rev 0.0 iii

Important Safety Instructions

DANGER

Follow all applicable lock out/tag out procedures at all times. Failure to follow proper lock out/tag

out procedures may result in serious injury or death.

With power applied to the ESS, hazardous voltages are present on some components. To

prevent accidental death or injury, do not touch any components within the enclosure unless you

are specifically directed to do so. To reduce the risk of electrical shock, make sure that all

equipment is properly grounded. For more information, refer to 3.1 Grounding the Battery

System.

WARNING

Enclosure doors must remain closed except when access to the enclosure interior is required. If

possible, personnel should keep a safe distance from enclosures whenever the equipment is

energized. Always comply with local, state, and national lock out/tag out guidelines when working

with or near the ESS. The lock out/tag out procedures must meet or exceed the requirements of

all guidelines presented in SAMSUNG SDI safety documentation. Before entering potentially

hazardous areas or beginning work on the ESS, complete the following tasks:

DANGER

When energized, this equipment presents a potential hazard of electric shock, death, and

burn. Only authorized personnel who are thoroughly familiar with the equipment and

adequately trained should install, operate, or maintain this equipment.

DANGER

To avoid death, personal injury, or damage to the product, follow all safety procedures as

regulated by Environmental Health and Safety (EHS) guidelines.

DANGER

To minimize the hazards of electrical shock, death, and burns, approved grounding

practices and procedures should be strictly followed.

WARNING

To avoid personal injury and damage to equipment, personnel must adhere to the site

protocol concerning working at heights.

WARNING

To avoid personal injury or equipment damage caused by equipment malfunction, only

adequately trained personnel should modify any programmable machine.

WARNING

Always ensure that applicable standards and regulations are followed and only properly

certified equipment is used as a critical component of a safety system. Never assume that

a safety-critical control loop is functioning correctly.

Lock Out/Tag Out Guidelines

Identify and wear protective clothing and shoes.

Identify and isolate all power and stored energy sources.

Apply appropriate lock out/tag out devices. When applying lock out/tag out to the ESS, do not touch

anything within the enclosure except as specifically directed in the work procedures.

Complete the site-specific lock out/tag out procedures and safety checklist before beginning work.

General Warnings

iv ET003222373 English 4/2018. Rev 0.0

Table of Contents

Table of Contents

Important Safety Instructions ..................................................................................................... i

General Instructions.............................................................................................................................. ii

Safety Precautions ............................................................................................................................... ii

Personnel and Equipment Warnings .................................................................................................... iii

Dangerous Voltages ............................................................................................................................. iii

Lock Out/Tag Out Guidelines ............................................................................................................... iv

General Warnings ................................................................................................................................ iv

Table of Contents ......................................................................................................................... i

Tables .......................................................................................................................................... iii

Figures ........................................................................................................................................ iv

1. About this Manual ................................................................................................................... 1

1.1 Purpose ....................................................................................................................................... 1

1.2 Target Audience ........................................................................................................................... 1

1.3 Organization ................................................................................................................................ 1

1.4 Revision History ........................................................................................................................... 2

1.5 Acronyms and Abbreviations ....................................................................................................... 2

2. Product Description ............................................................................................................... 3

2.1 Major Components ...................................................................................................................... 3

2.1.1 Battery Module (Type A / Type B) ................................................................................... 4

2.1.2 Switchgear Assembly ..................................................................................................... 5

2.1.3 SMPS Assembly (Type A / Type B) ................................................................................. 6

2.1.4 Rack Frame .................................................................................................................... 7

3. Assembling the Product ........................................................................................................ 8

3.1 Grounding the Battery System ..................................................................................................... 8

3.2 Installation and Assembly Procedure ........................................................................................... 9

3.3 Preparation Stage—Procedure .................................................................................................. 10

3.4 Preparation Stage - Unpacking .................................................................................................. 11

3.5 Preparation Stage - Ground Wire and Tools .............................................................................. 11

3.5.1 Ground Wires ............................................................................................................... 11

3.5.2 Ground Wire Fasteners ................................................................................................ 11

3.5.3 Rack Fasteners (Anchors) ............................................................................................ 11

3.5.4 Multiple Rack Fasteners ............................................................................................... 11

3.6 Preparation Stage—Recommended Tools/Instruments ............................................................. 12

3.7 Preparation Stage - Visual Inspection ........................................................................................ 14

3.7.1 Inspecting the Rack Frame ........................................................................................... 14

3.7.2 Visual Inspection of the Modules .................................................................................. 15

3.7.3 Inspecting the Switchgear ............................................................................................ 15

3.7.4 Inspecting the SMPS assembly .................................................................................... 15

3.8 Rack Anchoring Stage ............................................................................................................... 16

3.9 Rack Installation Stage .............................................................................................................. 21

3.9.1 Switchgear and SMPS Assembly Installation ............................................................... 22

3.9.2 Battery Module Installation ........................................................................................... 26

3.9.3 Busbar Installation ........................................................................................................ 29

3.9.4 Module and Switchgear Signal Cable Connection ........................................................ 63

3.9.5 SMPS Assembly and Switchgear Power Cable Connection ......................................... 75

3.9.6 SMPS Assembly and Switchgear Signal Cable Connection ......................................... 76

ET003222373 English 4/2018. Rev 0.0 i

Table of Contents

3.9.7 SMPS Assembly AC Input Connection ......................................................................... 78

3.9.8 Rack Fuse and Additional Module Signal Cable Connection ........................................ 80

3.9.9 DC Link Cable Connection ........................................................................................... 85

3.9.10 AC Input Commissioning .............................................................................................. 87

4. Performance .......................................................................................................................... 88

4.1 Operating Conditions ................................................................................................................. 88

4.2 Control Power Requirements ..................................................................................................... 88

4.3 Hardware ................................................................................................................................... 88

ii ET003194024 English 5/2017. Rev 0.0

Table of Contents

Tables

Table 3-1: Ground Wire Specifications ......................................................................................................... 11

Table 3-2: Ground Wire Fastener Specification ............................................................................................ 11

Table 3-3: Rack Fastener Specifications ...................................................................................................... 11

Table 3-4: Rack Fastener Specifications (Side by side) ............................................................................... 11

Table 3-5: Recommended Tools and Instruments ........................................................................................ 12

Table 3-6: Module Voltage and Internal Impedance ..................................................................................... 15

Table 3-7: Rack Clearance Distances .......................................................................................................... 16

Table 4-1: Control Power Range of Operation .............................................................................................. 88

Table 4-2: Hardware Description .................................................................................................................. 88

ET003222373 English 4/2018. Rev 0.0 iii

Table of Contents

Figures

Figure 2-1: Battery Modules (Type A and Type B).......................................................................................... 4

Figure 2-2: Switchgear Assembly ................................................................................................................... 5

Figure 2-3: Front View of the Switchgear Assembly ....................................................................................... 5

Figure 2-4: SMPS Assembly (Type A and Type B) ......................................................................................... 6

Figure 2-5: Rack Frame .................................................................................................................................. 7

Figure 3-1: Installation Procedure ................................................................................................................... 9

Figure 3-2: Faulty Cases .............................................................................................................................. 14

Figure 3-3: Clearance Distance for Single Rack Frame ................................................................................ 17

Figure 3-4: Clearance Distance for Multiple Rack Frames ........................................................................... 17

Figure 3-5: Clearance Distance for Multiple Rack Frames Installed Rear-to-Rear ....................................... 18

Figure 3-6: Rack Anchoring Points (4 EA) .................................................................................................... 19

Figure 3-7: Holes on the sides of the rack .................................................................................................... 19

Figure 3-8: Reattaching the Side Panels ...................................................................................................... 19

Figure 3-9: Reattaching the Rear Panels ...................................................................................................... 20

Figure 3-10: Inserting Switchgear ................................................................................................................. 22

Figure 3-11: Attaching a Switchgear Assembly to a Rack Frame ................................................................. 22

Figure 3-12: Ground Cable Connection to the Switchgear Assembly ........................................................... 23

Figure 3-13: Inserting SMPS Assembly ........................................................................................................ 24

Figure 3-14: Attaching the SMPS Assembly ................................................................................................. 24

Figure 3-15: Ground Cable Connection to the SMPS Assembly .................................................................. 25

Figure 3-16: Insertion of Modules on the Ninth Shelf from the Bottom ......................................................... 26

Figure 3-17: Battery Module Arrangement on Eighth and Ninth Shelves...................................................... 27

Figure 3-18: Battery Module Arrangement .................................................................................................... 27

Figure 3-19 : Module Number ....................................................................................................................... 28

Figure 3-20: Insertion of modules on 1st shelf .............................................................................................. 28

Figure 3-21: Removing the Module #1’s Cover and Switchgear B- Terminal Cover ..................................... 30

Figure 3-22: Connect Switchgear B- and Module #1 B- ................................................................................ 30

Figure 3-23: Restore Switchgear’s B- Terminal ............................................................................................ 31

Figure 3-24: Remove Battery Module #2’s Front Cover ................................................................................ 31

Figure 3-25: Connect Battery Module #1 B+ and Battery Module #2 B-. ...................................................... 32

Figure 3-26: Reattach Battery Module #1’s Front Cover ............................................................................... 33

Figure 3-27: Remove Battery Module #2’s Front Cover ................................................................................ 33

Figure 3-28: Connect Battery Module #2 B+ and Battery Module #3 B-. ...................................................... 34

Figure 3-29: Reattach Battery Module #2’s Front Cover ............................................................................... 35

Figure 3-30: Remove Battery Module #4’s Front Cover ................................................................................ 35

Figure 3-31: Connect Battery Module #3 B+ and Module #4 B-. .................................................................. 36

Figure 3-32: Reattach Battery Module #3’s Front Cover ............................................................................... 37

Figure 3-33: Remove Battery Module #5’s Front Cover ................................................................................ 37

Figure 3-34: Connect Battery Module #4 B+ and Battery Module #5 B-. ...................................................... 38

Figure 3-35: Reattach Battery Module #4’s Front Cover ............................................................................... 39

Figure 3-36: Remove Battery Module #6’s Front Cover ................................................................................ 39

Figure 3-37: Connect Battery Module #5 B+ and Battery Module #6 B-. ...................................................... 40

Figure 3-38: Reattach Battery Module #5’s Front Cover ............................................................................... 41

Figure 3-39: Remove Battery Module #7’s Front Cover ................................................................................ 41

Figure 3-40: Connect Battery Module #6 B+ and Battery Module #7 B- ....................................................... 42

Figure 3-41: Reattach Battery Module #6’s Front Cover ............................................................................... 43

Figure 3-42: Remove Battery Module #8’s Front Cover ................................................................................ 43

Figure 3-43: Connect Battery Module #7 B+ and Battery Module #8 B- ....................................................... 44

Figure 3-44: Reattach Battery Modules #7 and #8’s Front Covers ............................................................... 45

Figure 3-45: Remove Front Covers from Battery Modules #9 and #10 ......................................................... 45

Figure 3-46: Connect Battery Module #9 B+ and Battery Module #10 B-. .................................................... 46

Figure 3-47: Reattach Battery Module #9’s Front Cover ............................................................................... 47

Figure 3-48: Remove Battery Module #11’s Front Cover .............................................................................. 47

Figure 3-49: Connect Battery Module #10 B+ and Battery Module #11 B-. .................................................. 48

Figure 3-50: Reattach Battery Module #10’s Front Cover ............................................................................. 49

Figure 3-51: Remove Battery Module #12’s Front Cover .............................................................................. 49

Figure 3-52: Connect Battery Module #11 B+ and Battery Module #12 B-. .................................................. 50

Figure 3-53: Assemble Module #11’s Front Cover........................................................................................ 51

iv ET003194024 English 5/2017. Rev 0.0

Table of Contents

Figure 3-54: Remove Module #13’s Front Cover .......................................................................................... 51

Figure 3-55: Connect Battery Module #12B+ and Battery Module #13 B-. ................................................... 52

Figure 3-56: Assemble Module #12’s Front Cover........................................................................................ 53

Figure 3-57: Remove Battery Module #14’s Front Cover .............................................................................. 53

Figure 3-58: Connect Battery Module #13 B+ and Battery Module #14 B-. .................................................. 54

Figure 3-59: Reattach Battery Module #13’s Front Cover ............................................................................. 55

Figure 3-60: Remove Battery Module #15’s Front Cover .............................................................................. 55

Figure 3-61: Connect Battery Module #14 B+ and Battery Module #15 B-. .................................................. 56

Figure 3-62: Assemble Battery Module #14’s Front Cover ........................................................................... 57

Figure 3-63: Remove Battery Module #16’s Front Cover .............................................................................. 57

Figure 3-64: Connect Battery Module #15 B+ and Battery Module #16 B-. .................................................. 58

Figure 3-65: Reattach Battery Module #15’s Front Cover ............................................................................. 59

Figure 3-66: Remove Battery Module #17’s Front Cover .............................................................................. 59

Figure 3-67: Connect Battery Module #15 B+ and Battery Module #16 B-. .................................................. 60

Figure 3-68: Reattach Battery Module #15’s Front Cover ............................................................................. 61

Figure 3-69: Remove Switchgear B+ Terminal Cover .................................................................................. 61

Figure 3-70: Connect Switchgear B+ and Module #17 B+. ........................................................................... 62

Figure 3-71: Reattach Battery Module #16’s Front Cover and Switchgear B+ Terminal Cover .................... 62

Figure 3-72: Rack BMS to Module #1 OUT Signal Cable ............................................................................. 63

Figure 3-73: Opening for Cable Installation .................................................................................................. 64

Figure 3-74: Module #1 to Module #2 Signal Cabling ................................................................................... 64

Figure 3-75: Module #2 to Module #3 Signal Cabling ................................................................................... 65

Figure 3-76: Module #3 to Module #4 Signal Cabling ................................................................................... 65

Figure 3-77: Module #4 to Module #5 Signal Cabling ................................................................................... 66

Figure 3-78: Module #5 to Module #6 Signal Cabling ................................................................................... 66

Figure 3-79: Module #6 to Module #7 Signal Cabling ................................................................................... 67

Figure 3-80: Module #10 to Module #11 Signal Cabling ............................................................................... 67

Figure 3-81: Module #11 to Module #12 Signal Cabling ............................................................................... 68

Figure 3-82: Module #12 to Module #13 Signal Cabling ............................................................................... 68

Figure 3-83: Module #13 to Module #14 Signal Cabling ............................................................................... 69

Figure 3-84: Module #14 to Module #15 Signal Cabling ............................................................................... 69

Figure 3-85: Module #15 to Module #16 Signal Cabling ............................................................................... 70

Figure 3-86: Module #16 to Module #17 Signal Cabling ............................................................................... 70

Figure 3-82: Module #15 to Module #16 Signal Cabling ............................................................................... 71

Figure 3-83: Pre-Punched Hole for Signal Cable .......................................................................................... 72

Figure 3-84: Signal Cabling Examples of Left Alignment of Switchgear ....................................................... 73

Figure 3-85: Openings for Cable................................................................................................................... 73

Figure 3-86: Termination Resistor Setting for Last Switchgear ..................................................................... 73

Figure 3-87: DC Power Cables from SMPS Assembly Type A to Switchgear .............................................. 75

Figure 3-88: DC Power Cables from SMPS Assembly Type B to Switchgear .............................................. 75

Figure 3-89: CAN Signal Cable Connection from SMPS Assembly to Switchgear ....................................... 76

Figure 3-90: TCP/IP Cable Connection to SMPS Assembly ......................................................................... 76

Figure 3-91: Dry Contact Cable Connection to SMPS Assembly ................................................................. 77

Figure 3-92: MCCB Extra Auxiliary Connection ............................................................................................ 77

Figure 3-93: AC Input Terminals ................................................................................................................... 78

Figure 3-94: AC Input Terminals with Cables Attached ................................................................................ 78

Figure 3-95: AC Input Terminals Protective Covers...................................................................................... 79

Figure 3-100: Remove Front Covers from Battery Modules #8 and #9 ......................................................... 80

Figure 3-101: Rack Fuse Busbar Assembly. ................................................................................................ 81

Figure 3-102: Rack Fuse Cover .................................................................................................................... 82

Figure 3-103: Rack Fuse Cover (Fully Assembled; Front View) ................................................................... 82

Figure 3-104: Reattach Front Covers to Battery Modules #8 and #9 ............................................................ 83

Figure 3-105: Battery Module #7 to Battery Module #8 Signal Cabling ........................................................ 83

Figure 3-106: Battery Module #8 to Battery Module #9 Signal Cabling (WIRE ASSY MODULE TO MODULE

#2) ......................................................................................................................................................... 84

Figure 3-107: Battery Module #9 to Battery Module #10 Signal Cabling ...................................................... 84

Figure 3-105: Grounding Points (2 EA) ......................................................................................................... 85

Figure 3-106: Connecting the DC Link High Current Cables ........................................................................ 86

ET003222373 English 4/2018. Rev 0.0 v

1. About this Manual

1. About this Manual

To make sure that you understand the proper procedures for safe operation, this section briefly

describes the purpose, audience, organization, revision history, and acronyms and abbreviations.

1.1 Purpose

The purpose of this manual is to provide information for the safe and successful assembly of the

product.

This product requires configuration by a factory trained service.

The instructions in this manual are based on assembly of a three-cabinet system. Other

configurations are possible and these instructions can be reduced or expanded to accommodate

installation of those systems.

1.2 Target Audience

This installation manual is intended for trades suitable for assembling electrical and electronic

assemblies.

1.3 Organization

This manual is composed of the following chapters:

Chapter 1 ―About this Manual‖ outlines this document.

Chapter 2 ―Product Description‖ describes the major components of the product.

Chapter 3 ―Assembling the Product‖ explains how to install the product.

ET003222373 English 4/2018. Rev 0.0 1

1. About this Manual

Rev.

Description

Author

Date

0.0

2018.04.08

Abbreviations

Full Name

AED

Automated External Defibrillator

BMS

Battery Management System

EHS

Environmental Health and Safety

ESS

Energy Storage System

LOTO

LOCK OUT/TAG OUT

OT

Overtemperature

OVP

Overvoltage Protection

PCS

Power Conversion System

SMPS

Switched Mode Power Supply

SOC

State Of Charge

SOH

State Of Health

SG

Switchgear

UT

Undertemperature

UVP

Undervoltage Protection

UPS

Uninterruptible Power Supply

1.4 Revision History

First Release (customer facing)

1.5 Acronyms and Abbreviations

The following acronyms and abbreviations are used in this manual.

2 ET003222373 English 4/2018. Rev 0.0

2. Product Description

2. Product Description

Before operating the battery system, users must be familiar with its components.

2.1 Major Components

Samsung SDI’s Lithium Ion Battery System has the following components:

Battery Module (Type A / Type B)

Switchgear Assembly

SMPS Assembly (Type A / Type B)

Rack Frame

ET003222373 English 4/2018. Rev 0.0 3

2. Product Description

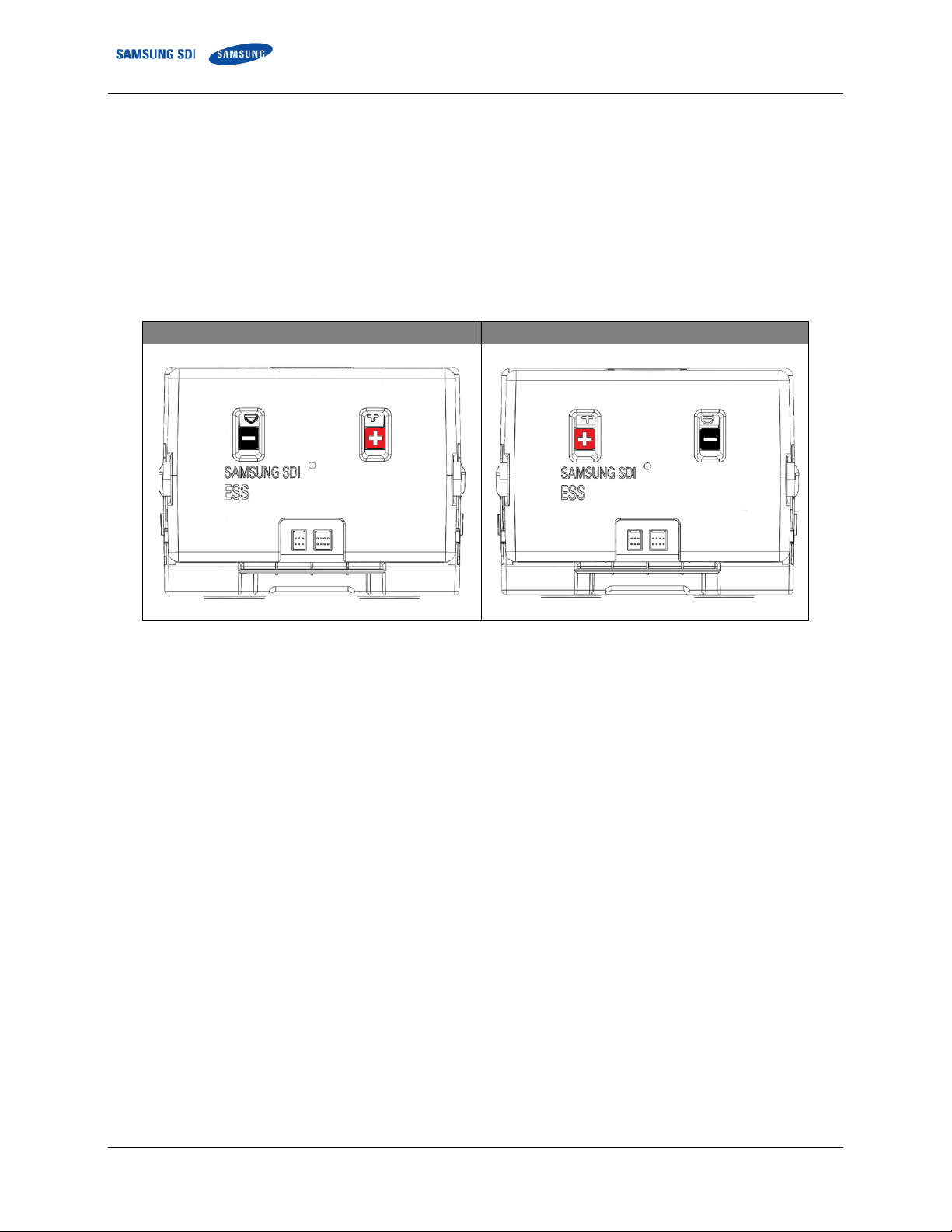

Battery Module Type A (Front)

Battery Module Type B (Front)

2.1.1 Battery Module (Type A / Type B)

The battery module consists of battery cells. Each battery module has a module BMS (Battery

Management System).

There are two types of Battery Modules. The model number for each type is determined by the position of

polarity. Type A’s positive (+) terminal is on the right side viewed from the front. The positive terminal for

Type B is on the left.

Following are front and rear views of module assemblies.

Figure 2-1: Battery Modules (Type A and Type B)

4 ET003222373 English 4/2018. Rev 0.0

2. Product Description

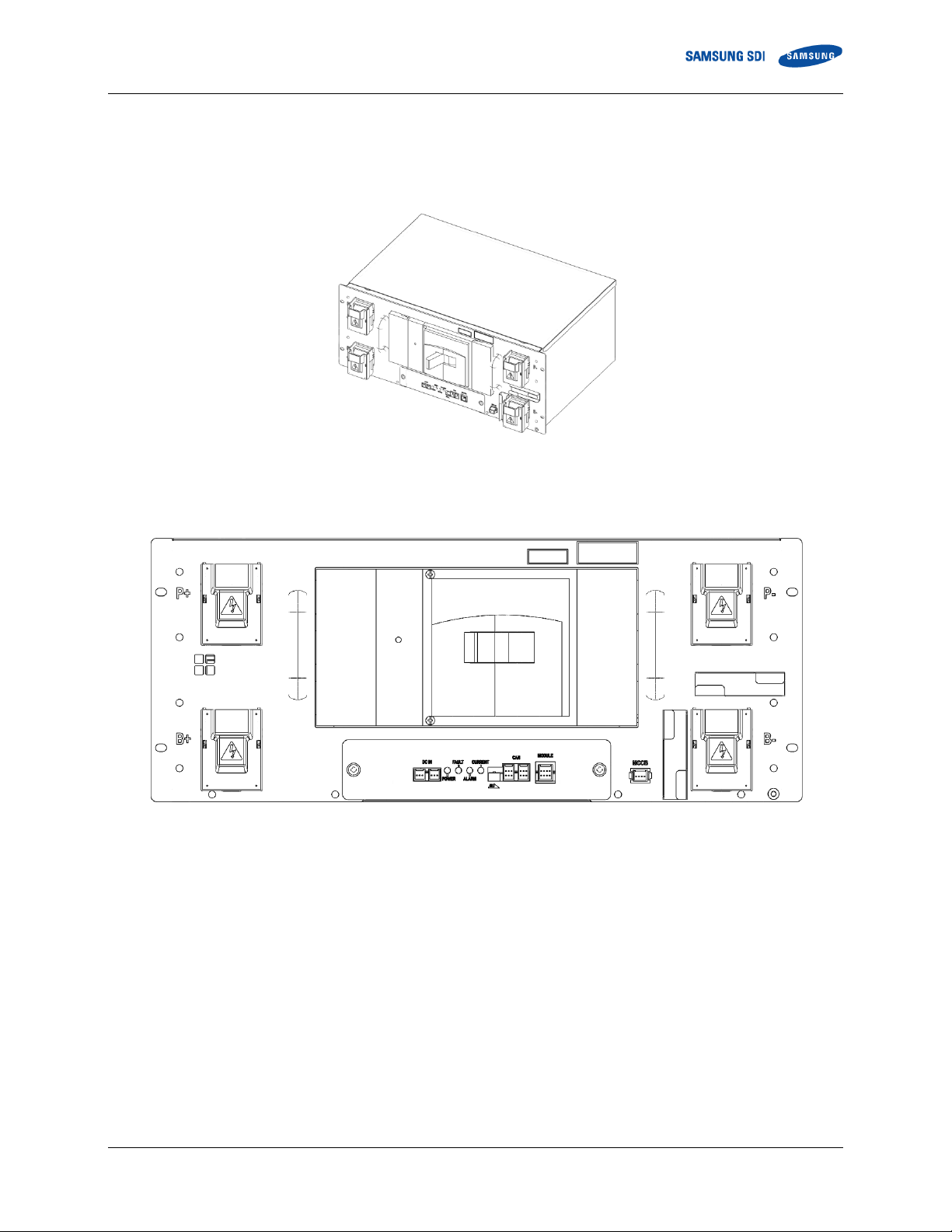

2.1.2 Switchgear Assembly

The Switchgear Assembly consists of a protective circuit and a rack BMS. It is connected to the UPS

using the positive and negative power terminals on the front of switchgear.

Figure 2-2: Switchgear Assembly

The switchgear provides an auxiliary breaker switch that can be connected to an external building

monitoring system.

Figure 2-3: Front View of the Switchgear Assembly

ET003222373 English 4/2018. Rev 0.0 5

2. Product Description

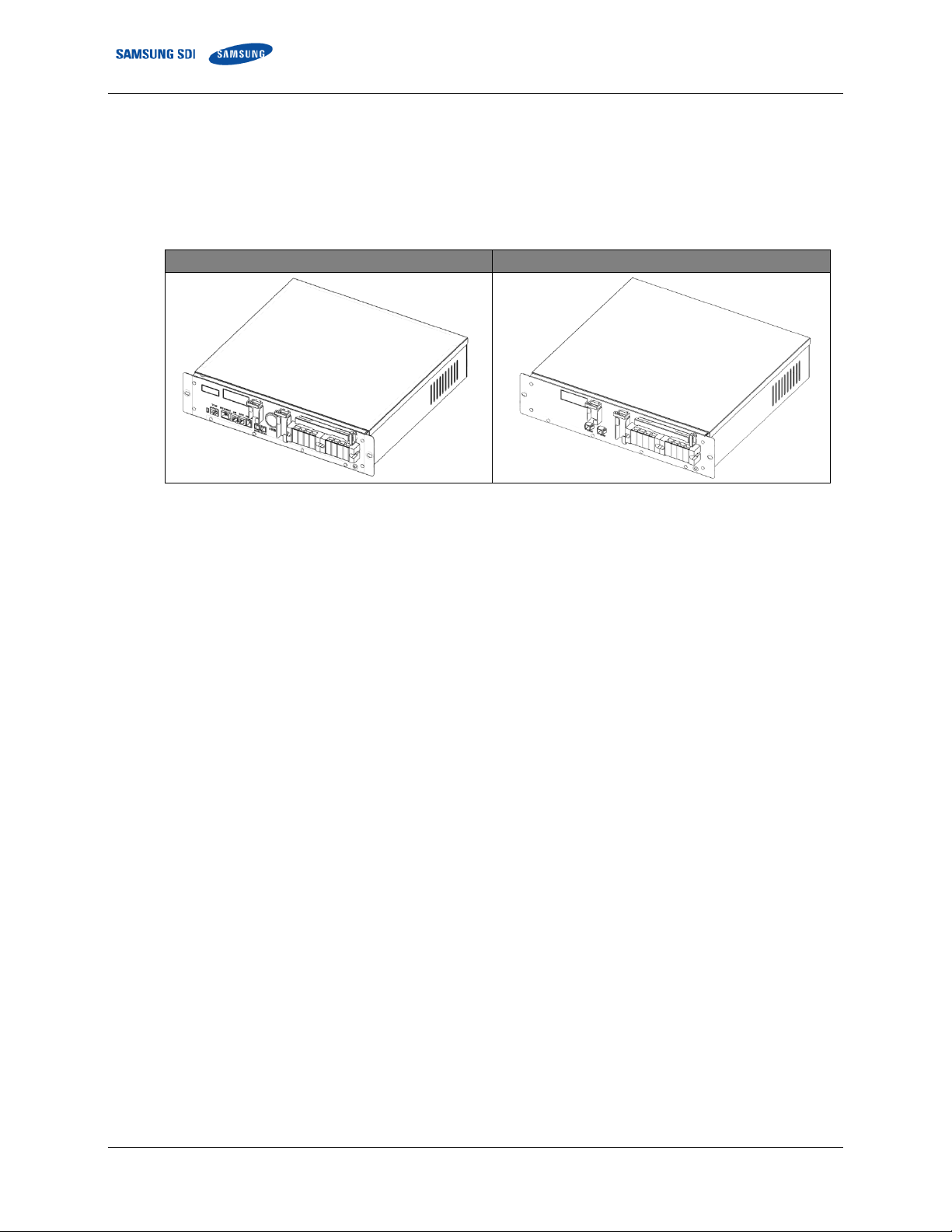

Front SMPS Assembly Type A

Front SMPS Assembly Type B

2.1.3 SMPS Assembly (Type A / Type B)

The SMPS Assembly provides data to the external systems (i.e., building management system, UPS, etc.)

while controlling and monitoring all connected Rack BMS’s.

There are two types of SMPS Assemblies: Type A has a System BMS; Type B does not.

Figure 2-4: SMPS Assembly (Type A and Type B)

The SMPS Assembly provides these communication protocols: RS485, TCP/IP and dry contact.

6 ET003222373 English 4/2018. Rev 0.0

2. Product Description

2.1.4 Rack Frame

The Rack Frame is used to mount the Battery Modules, Switchgear Assembly and SMPS Assembly. It

facilitates grounding of the installed components. Grounding cable/busbar for the rack frame is necessary

for the Switchgear and SMPS Assemblies because they are grounded to the rack frame when installed.

An equipment grounding conductor is required to ground the rack frames together and to the UPS module.

Figure 2-5: Rack Frame

ET003222373 English 4/2018. Rev 0.0 7

3. Assembling the Product

WARNING

The power terminal cap must be left in place on the power terminal of the tray for

insulation.

Be sure to use insulated tools (torque wrench, extension, socket, etc.).

All the instruments must be insulated and no metal articles (e.g. watch, ring) should be

present in the installation area.

All power switches must be turned off in advance.

Prepare a CO2 fire extinguisher, a first aid kit, and an AED (automated external

defibrillator) before installation.

CAUTION

If available, use a mechanical lift for lifting heavy (22 kg [50 lb.]) components. If there is

no lift, two or three workers must move items weighing more than 22 kg (50 lb.).

The ambient temperature range must be 23°C ±5°C during installation.

WARNING—SHOCK HAZARD

Verify with a voltmeter that no power is present on the system before beginning work on the

battery system or other part of the UPS system. Use lock out/tag out procedures to secure the

UPS and batteries Do not contact system connectors or terminals. Follow all applicable safety

measures.

Follow all local and national codes and regulations.

3. Assembling the Product

Because this product has a battery with more than 300V present when fully assembled, you must

follow the general safety Instructions. This system must be installed by qualified, trained workers

familiar with the required instruments. Use appropriate lifting methods when moving the batteries.

3.1 Grounding the Battery System

Grounding methods and wiring must comply with NEC Article 250.

Grounding is required to prevent electric shock hazards and reduce or eliminate damage caused by

electrical noise. Ground connections and ground wire routing vary significantly depending on

system configuration and equipment layout. Samsung provides two grounding strips on each rack,

one on top of the rack and the other on the bottom of the rack. See Figure 3-109: Grounding Points

(2 EA).

8 ET003222373 English 4/2018. Rev 0.0

3. Assembling the Product

1. Preparation

Stage

2. Rack Anchoring

Stage

3. Rack

Installation

Stage

4. System

Installation Stage

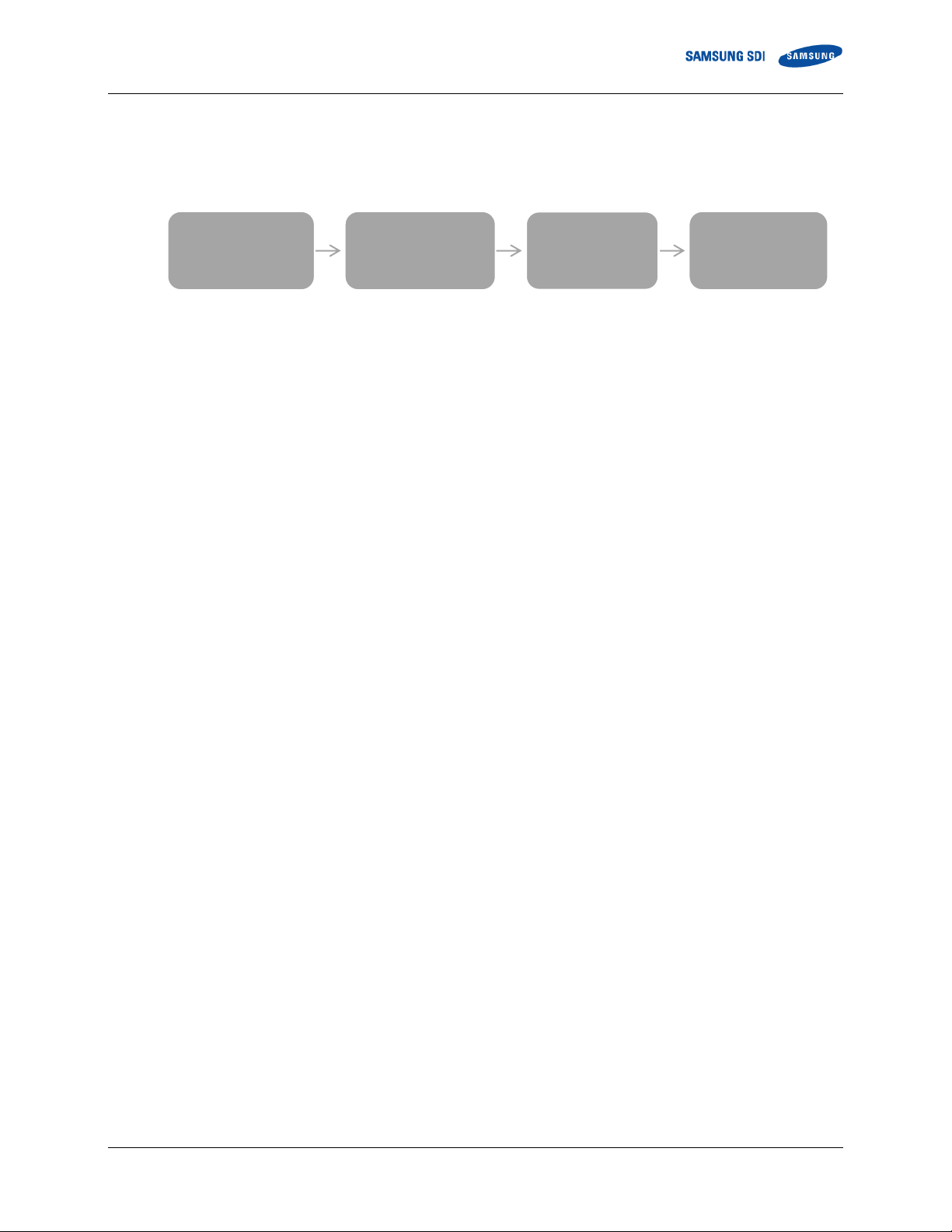

3.2 Installation and Assembly Procedure

This product must be installed and assembled by following the procedure below:

Figure 3-1: Installation Procedure

Preparation Stage

Procedure

Unpacking

Ground wire and tools

Recommended tools and instruments

Appearance inspection

Rack Anchoring Stage

Transport the rack frame to the installation location after unpacking

Arrange the rack frame after checking the positions of holes in the frame and anchoring points

Perform the anchoring and ground connections

Rack Installation Stage

Transport the battery modules to the installation location

Place the battery modules in the rack frame

Insert the Switchgear assembly in the rack frame

Insert the SMPS assembly in the rack frame

After all subassemblies are inserted in the rack frame, attach the subassemblies to the rack frame

Connect the busbars

Connect the signal cables from switchgear to module, and module to module

Connect the signal cables from switchgear to switchgear

System Installation Stage

Connect the SMPS assembly

Perform installation checks

Prepare the items for BMS configuration

Configure the BMS EEPROM settings

ET003222373 English 4/2018. Rev 0.0 9

3. Assembling the Product

WARNING

Do not wear watches, rings, jewelry, or any other metal objects.

Wear electrically insulated gloves and safety shoes.

CAUTION

Store the product in a dust-free place with the moisture level of below 60% and the

temperature level of 23°C ±5°C.

Keep components out of direct sunlight.

3.3 Preparation Stage—Procedure

For the preparation stage, perform the following steps:

1. Create the installation plan and check the equipment and instruments for installation.

2. Check the arrival schedule of the parts required.

3. Unpack the equipment.

4. Inspect the equipment.

10 ET003222373 English 4/2018. Rev 0.0

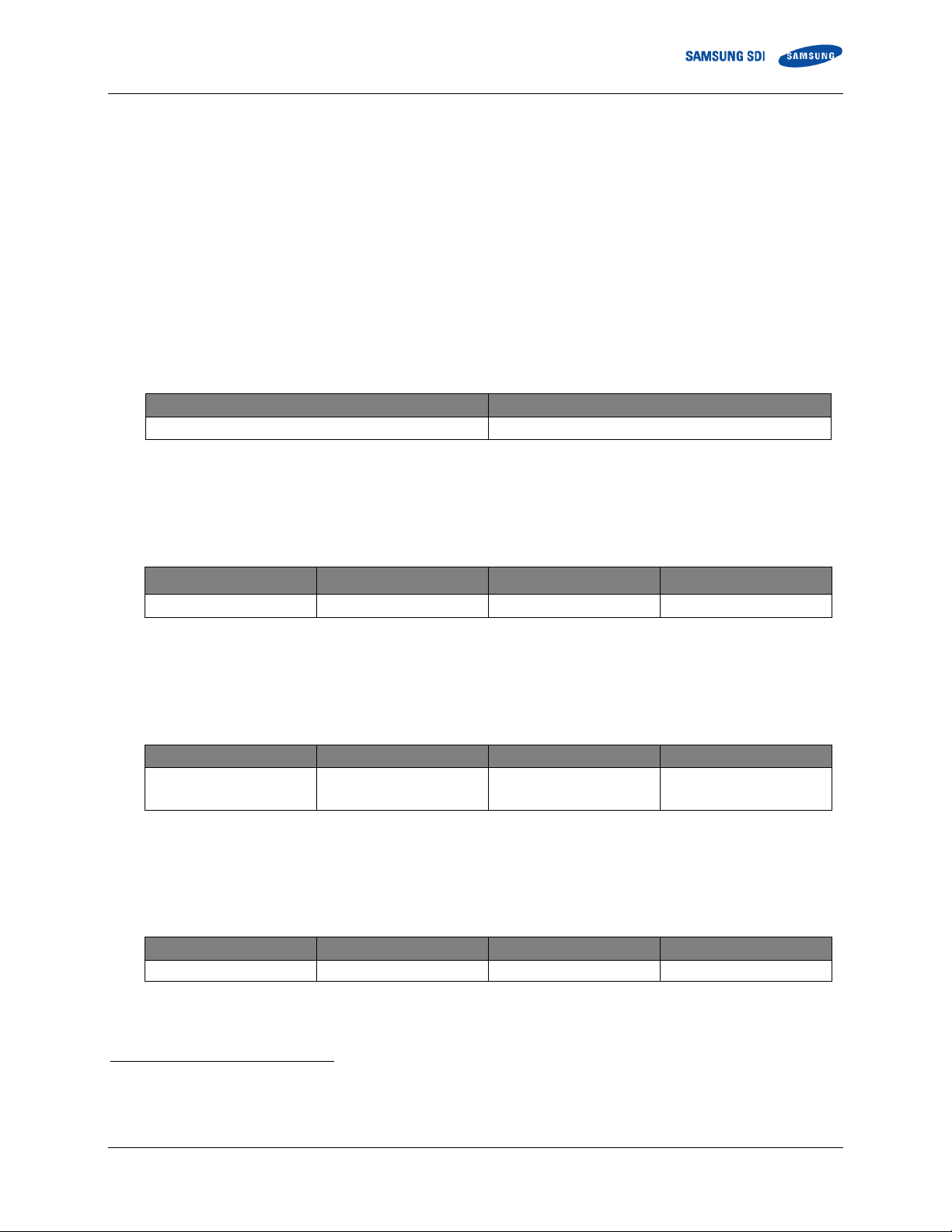

3. Assembling the Product

Wire No.

Terminal Type

#1AWG or thicker

M12 2 Hole Ring Terminal

Size

Hardness

Thread Pitch

Material

M12–30mm

70 (Grade 7)

1.25 mm (0.05 in)

SS304

Size

Hardness

Thread Pitch

Material

M16–L

(Bottom Anchor)

70 (Grade 7)

2.0 mm (0.08 in)

SS304

Size

Hardness

Thread Pitch

Material

M10–25mm (Side)

70 (Grade 7)

1.5 mm (0.06 in)

SS304

1

2

3

3.4 Preparation Stage - Unpacking

Check the parts during unpacking:

3.5 Preparation Stage - Ground Wire and Tools

Ground wires for the racks must be provided by the installer. Installer-supplied ground wires must

meet the specifications below.

3.5.1 Ground Wires

Use ground wire that is #1AWG. The ground wire specifications are:

Table 3-1: Ground Wire Specifications1

3.5.2 Ground Wire Fasteners

Specifications for the ground wire fastening screws are:

Table 3-2: Ground Wire Fastener Specification2

3.5.3 Rack Fasteners (Anchors)

Specifications for the rack fastener screws for anchoring the rack frame to the floor are:

Table 3-3: Rack Fastener Specifications3

3.5.4 Multiple Rack Fasteners

Specifications for the rack fastener screws for installing multiple rack frames side-by-side are:

Table 3-4: Rack Fastener Specifications (Side by side)

Not provided. Must be provided by the installer or customer.

Not provided. Must be provided by the installer or customer.

Not provided. Must be provided by the installer or customer.

ET003222373 English 4/2018. Rev 0.0 11

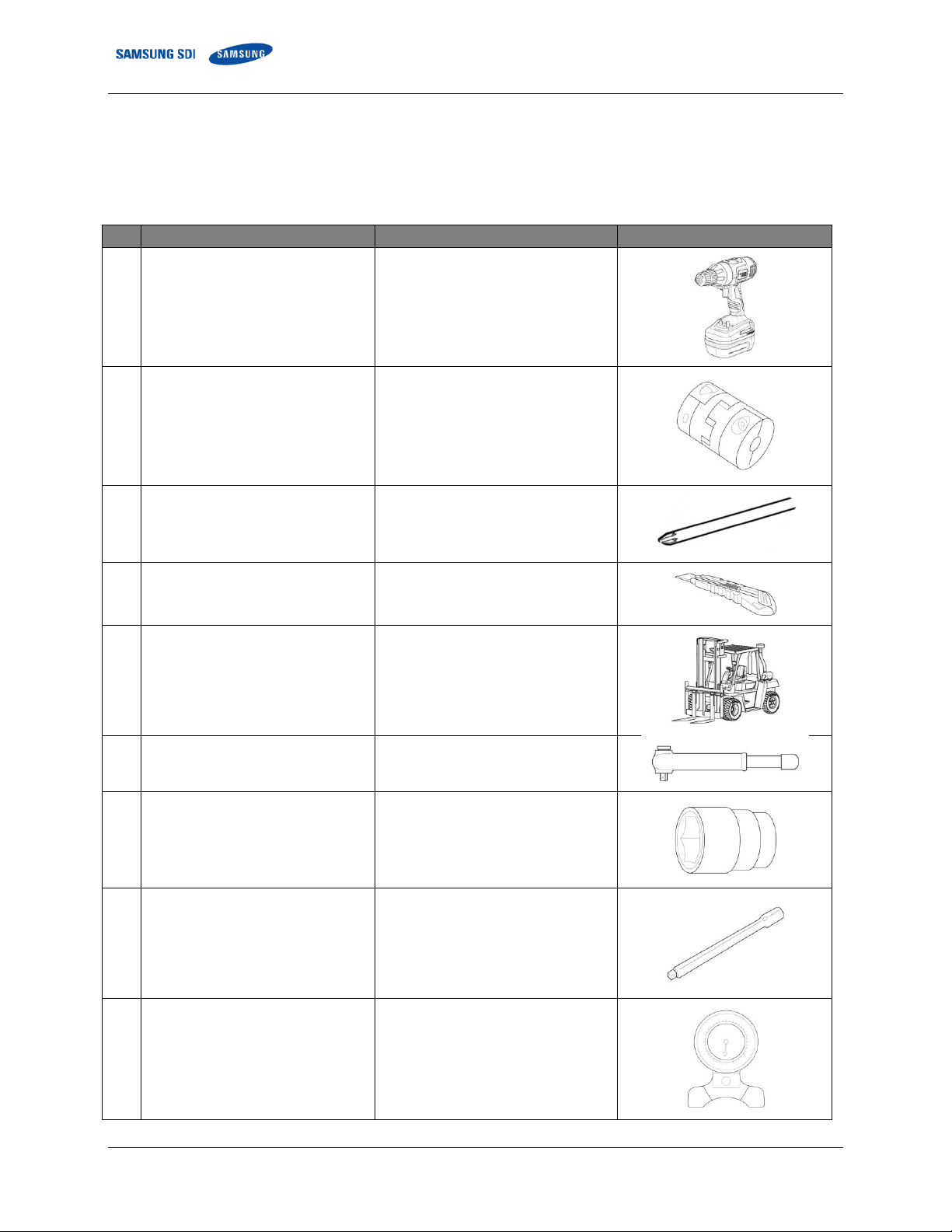

3. Assembling the Product

No.

Items

Usage

Appearance

1

Power Screwdriver/Drill

(Max torque: 26Nm/270 kgf/cm)

To fasten switchgear and SMPS

assemblies to the rack frames

(5.1–6.1Nm/50–60 kgf/cm)

2

Torque Limiter

For use with torque wrench

3

Phillips Screwdriver or Bit

To fasten switchgear and SMPS

assemblies to the rack frames

(M5 Tip)

4

Box Cutter

Opening boxes

5

Forklift

Moving rack frames and pallets

containing modules and switchgear

6

Insulated Torque Wrench

Installing a high-current cable

8.16–30 Nm (72–265 in lbs)

7

Insulated Sockets

(13 mm, 17mm and 19mm)

Installing power cables and busbars

8

Insulated Extension for Socket

Installing a power cable

9

Inclinometer/Level

Installing a rack frame

3.6 Preparation Stage—Recommended Tools/Instruments

Installers must provide these tools for installing the battery:

Table 3-5: Recommended Tools and Instruments

12 ET003222373 English 4/2018. Rev 0.0

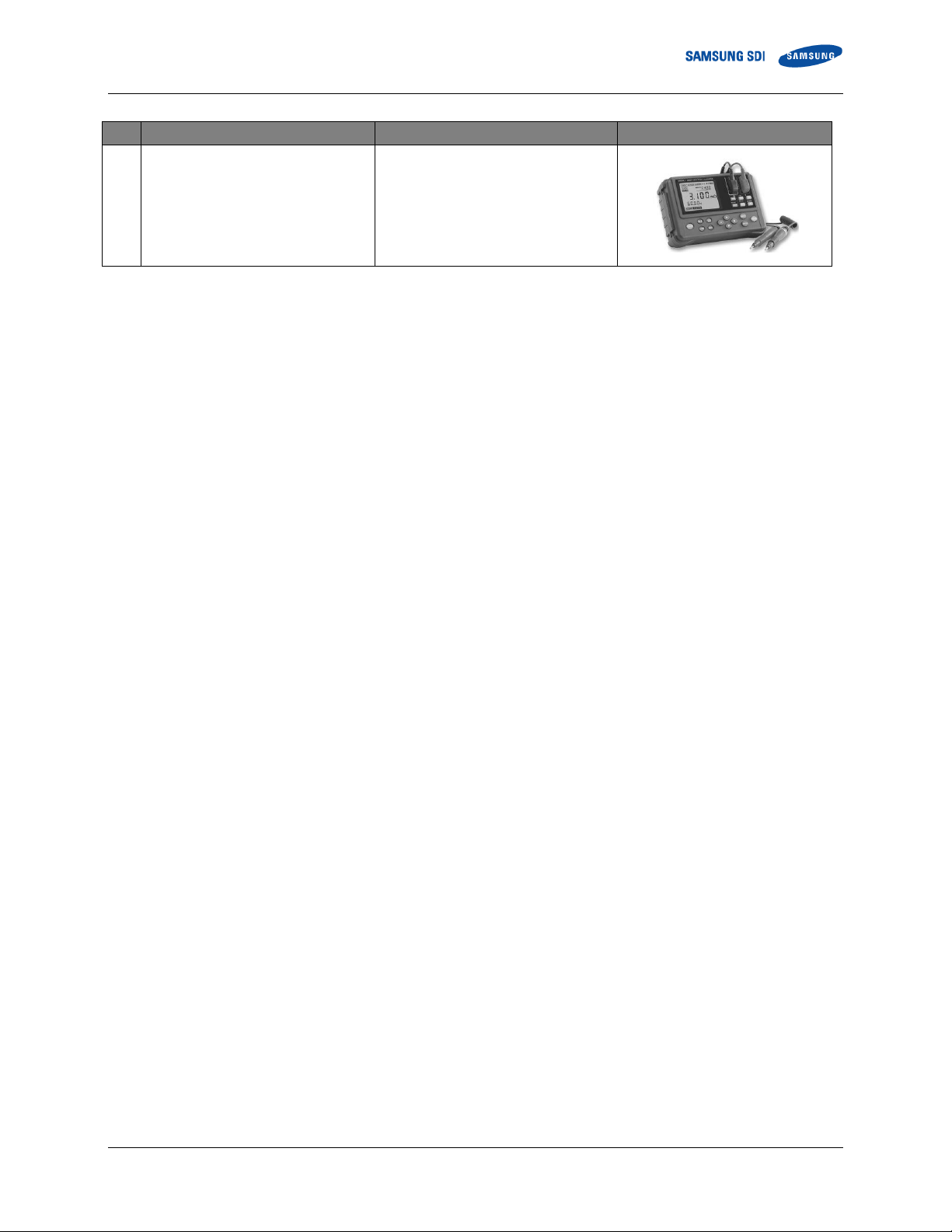

3. Assembling the Product

No.

Items

Usage

Appearance

10

Battery Tester

Measure battery module’s voltage

and internal impedance

ET003222373 English 4/2018. Rev 0.0 13

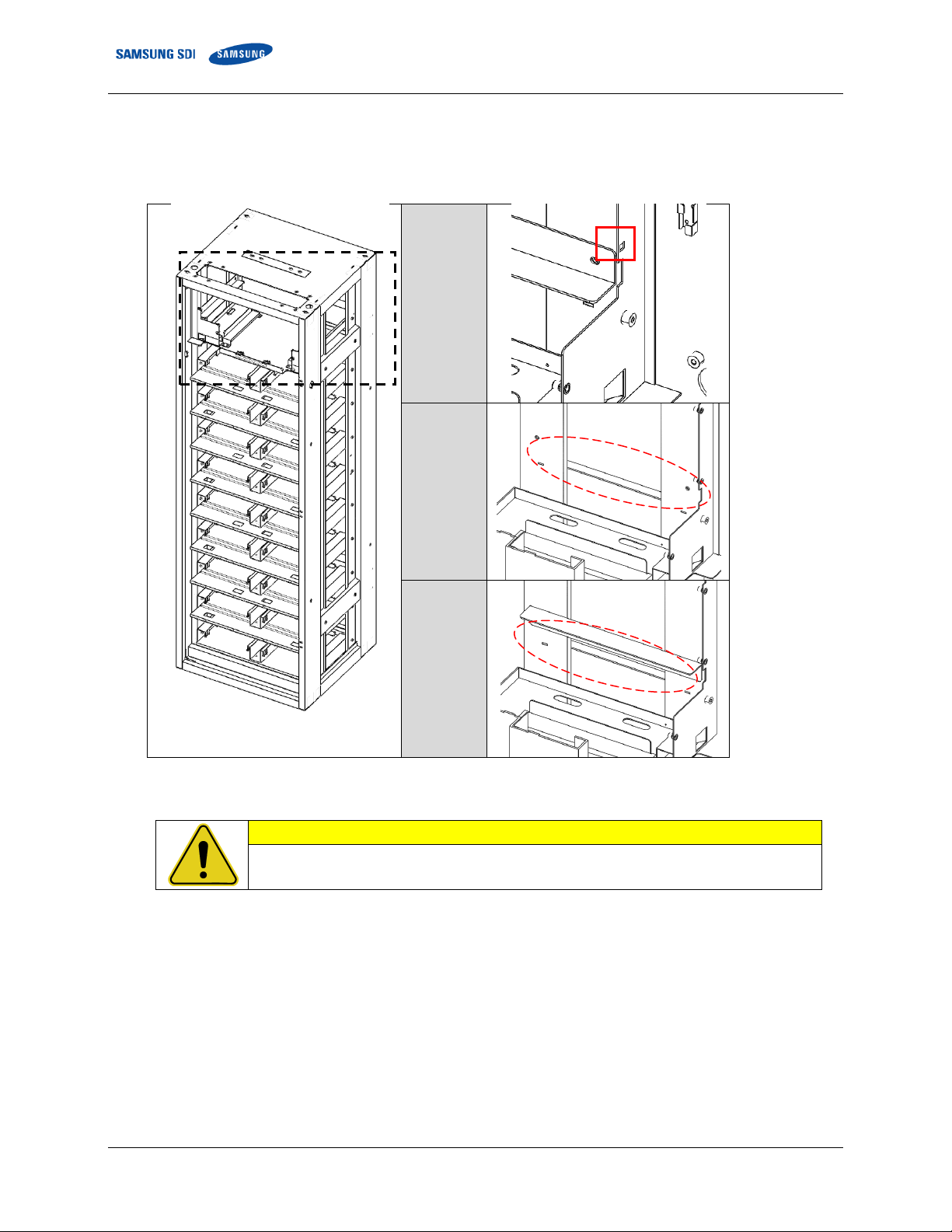

3. Assembling the Product

CAUTION

If any defects are found during the inspection, contact the SAMSUNG SDI customer

service department.

Missing

Cage

Nut

Missing

Guide

Rail

Guide Rail

Incorrect

Orientation

3.7 Preparation Stage - Visual Inspection

During visual inspection, the inspector should check for:

Figure 3-2: Faulty Cases

3.7.1 Inspecting the Rack Frame

After transporting the rack frame to the installation location, check for:

Structural damage

Paint peeling

Damaged or protruding screws.

After completion, install or package the rack for protection during storage.

14 ET003222373 English 4/2018. Rev 0.0

3. Assembling the Product

No.

Items

Value

1

Voltage Check

28.712 ~ 29.104V

2

Internal Impedance Check

3.0 ~ 4.3 mΩ

3.7.2 Visual Inspection of the Modules

After transporting the modules to the installation location, check for:

Physical damage to the exterior

Damaged or protruding screws

Proper voltage and internal impedance of the battery modules using the battery tester.

Table 3-6: Module Voltage and Internal Impedance

After completion, install the battery module in the previously installed rack or return the battery

module to its original packing for protection during storage.

3.7.3 Inspecting the Switchgear

After transporting the Switchgear to its installation location, check for:

Physical damage

Paint peeling

Damaged or protruding screws.

After completion, install the switchgear in the previously installed rack or return the switchgear to its

original packing for protection during storage.

3.7.4 Inspecting the SMPS assembly

After transporting the SMPS Assembly to its installation location, check for:

Physical damage

Paint peeling

Damaged or protruding screws.

After completion, install the SMPS in the previously installed rack or return the SMPS to its original

packing for protection during storage.

ET003222373 English 4/2018. Rev 0.0 15

3. Assembling the Product

CAUTION

Use a proper transportation method considering the weight of the rack frame.

Ensure that the safety of the working place is maintained.

When using a forklift, lift the rack frame from the front.

When a forklift cannot be used, use a mechanical lift or move it by hand with three or

more people.

Use lock washers to prevent bolts from loosening.

Use an inclinometeror carpenter’s level to ensure that the rack frame is plumb.

NOTICE

Battery rack type A will be used for SMPS type A. External communications will

connect to the SMPS in this rack.

Failure to anchor the rack frame on a flat and level surface may distort the rack frame

after installing the racks side-by-side.

Frame distortion may make the rack doors difficult or impossible to open.

Configuration

Anchor points per rack

Clearance Distance (mm)

Side (end)

Side (adjacent)

Rear

Front

Single Rack

2 (Front)

not rated for seismic event

0

n/a 0 1000

4 (All) – Telcordia Zone 3

800

n/a

800

1000

Multiple Racks

(Side-to-Side)

2 (Front)

not rated for seismic event

0 0 0

1000

4 (All) – Telcordia Zone 3

800 0 800

1000

Multiple Racks

(Side-to-Side and

Rear-to-Rear)

2 (Front)

not rated for seismic event

0 0 0

1000

4 (All) – Telcordia Zone 3

800 0 800

1000

3.8 Rack Anchoring Stage

Install the rack frame on a flat, level surface.

To attach the rack and perform the related works

In order to anchor the racks in all four points, racks are recommended to be placed according to the

clearance distances listed in the figures below. In seismically active areas, all four anchor points of the

rack must be installed.

To reduce the product footprint, the racks can be installed side-by-side and rear-to-rear against a wall or

next to another rack. In this case, only two anchor points on the front side of each rack can be installed.

Proper cooling and ventilation of the installed area is recommended for racks installed with no side and

rear clearance. Front side of the rack must be cleared for installation, maintenance, service access, and

ventilation and cooling.

Clearance from the top of the rack frame is not required and the top of the rack frame can be covered to

prevent any foreign objects from falling into the battery rack frame.

Table 3-7: Rack Clearance Distances

16 ET003222373 English 4/2018. Rev 0.0

Loading...

Loading...