Rockwell Automation FactoryTalk Transaction Manager User Manual

USER GUIDE

PUBLICATION RSSQL-UM001H-EN-P-April 2011

Supersedes Publication RSSQL-UM001G-EN-P

●

●

● Copyright

●

●

Contact Rockwell Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support

Copyright Notice © 2011 Rockwell Automation Technologies, Inc. All rights reserved.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation Technologies, Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

Trademark Notices FactoryTalk, Rockwell Automation, Rockwell Software, the Rockwell Software logo are registered trademarks of Rockwell Automation, Inc.

The following logos and products are trademarks of Rockwell Automation, Inc.: RSBizWare, FactoryTalk Metrics, and FactoryTalk Transaction Manager.

Other Trademarks Microsoft, SQL Server, Event Viewer, Windows, Windows Server 2003, and Windows Server 2008 are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other countries.

All other trademarks are the property of their respective holders and are hereby acknowledged.

Warranty This product is warranted in accordance with the product license. The product’s performance may be affected by system configuration, the application being performed, operator control,

maintenance and other related factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this document do not cover all the details or variations in the equipment, procedure, or process described, nor do they provide directions for meeting every possible contingency during installation, operation, or maintenance. This product’s implementation may vary among users.

This document is current as of the time of release of the product. However, the accompanying software may have changed since the release. Rockwell Automation, Inc. reserves the right to change any information contained in this document or the software at anytime without prior notice. It is your responsibility to obtain the most current information available from Rockwell when installing or using this product.

2

Contents

Chapter 1 Welcome To FactoryTalk Transaction Manager |

13 |

What Is FactoryTalk Transaction Manager? ................................. |

13 |

What Can FactoryTalk Transaction Manager Do For Me? ................. |

13 |

Automate Data Logging .................................................... |

13 |

Control the Plant Floor Using Business Rules and Quality |

|

Enforcement ................................................................. |

14 |

Manage Recipes.............................................................. |

14 |

Understanding FactoryTalk Transaction Manager Concepts ............. |

14 |

Transaction Control Manager Service .................................... |

15 |

FactoryTalk Transaction Manager Service and Control Connectors 17 |

|

Control Connectors ......................................................... |

18 |

Enterprise Connectors ...................................................... |

18 |

Configuration Server........................................................ |

18 |

Transactions.................................................................. |

19 |

FactoryTalk....................................................................... |

19 |

FactoryTalk Services Platform Components ............................ |

20 |

Intended Audience .............................................................. |

21 |

Where Can I Go For Help?...................................................... |

22 |

3

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Online Help................................................................... |

22 |

Product Manual .............................................................. |

22 |

Training ....................................................................... |

23 |

Technical Support ........................................................... |

23 |

Get Web Support ............................................................ |

24 |

Get Phone Support .......................................................... |

24 |

Get Consulting Services .................................................... |

24 |

Contact Us .................................................................... |

24 |

Chapter 2 Installing FactoryTalk Transaction Manager |

27 |

Before You Begin ................................................................ |

27 |

Hardware Requirements ................................................... |

27 |

Software Requirements .................................................... |

28 |

Software Compatibility..................................................... |

30 |

Activation..................................................................... |

30 |

Activation Options .......................................................... |

33 |

Installing FactoryTalk Transaction Manager Software .................... |

36 |

Distributed FactoryTalk Transaction Manager Installations ......... |

38 |

Chapter 3 Exploring the FactoryTalk Transaction Manager User Interface |

|

|

41 |

Starting FactoryTalk Transaction Manager ................................. |

41 |

Exploring the FactoryTalk Transaction Manager User Interface ........ |

42 |

Title Bar....................................................................... |

43 |

Menu Bar ...................................................................... |

44 |

Toolbar ........................................................................ |

45 |

Configuration Tree .......................................................... |

46 |

Workspace .................................................................... |

49 |

Status Bar..................................................................... |

50 |

Configuration Checklist ........................................................ |

50 |

4

|

● |

|

● |

●Contents |

|

|

● |

|

● |

|

● |

Step 1: Defining and Naming a New Configuration .................... |

53 |

Step 2: Defining Connectors............................................... |

54 |

Step 3: Defining Data Points .............................................. |

54 |

Step 4: Defining Data Objects ............................................ |

55 |

Step 5: Defining Transactions ............................................. |

55 |

Step 6: Verifying Transactions ............................................ |

56 |

Miscellaneous .................................................................... |

56 |

Viewing Configuration Properties ........................................ |

56 |

Starting Configurations..................................................... |

57 |

Stopping Configurations .................................................... |

58 |

Starting and Stopping Connectors ........................................ |

58 |

Monitoring Configurations ................................................. |

58 |

Understanding FactoryTalk Transaction Manager External Files........ |

60 |

Using the Service Console ..................................................... |

61 |

Chapter 4 Understanding FactoryTalk Transaction Manager Services |

63 |

Introducing FactoryTalk Transaction Manager Services .................. |

63 |

Control Connectors ............................................................. |

63 |

FactoryTalk Live Data ...................................................... |

64 |

DDE ............................................................................ |

64 |

RSLinx Classic OPC .......................................................... |

65 |

RSView32 ..................................................................... |

65 |

Generic OPC.................................................................. |

66 |

Enterprise Database Connectors.............................................. |

66 |

ODBC........................................................................... |

67 |

Oracle OCI .................................................................... |

67 |

Microsoft OLE DB ............................................................ |

67 |

Enterprise Application Connectors ........................................... |

67 |

Microsoft COM+ .............................................................. |

68 |

Time-series Data Compression ............................................ |

68 |

FactoryTalk Metrics ......................................................... |

68 |

Enterprise Connector Options................................................. |

68 |

FactoryTalk Transaction Manager Service .................................. |

69 |

Transaction Control Manager Service........................................ |

70 |

|

5 |

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Configuration Server............................................................ |

70 |

Chapter 5 Defining Data Points |

73 |

Introducing Data Points ........................................................ |

73 |

FactoryTalk Live Data Data Points ........................................... |

75 |

Selecting a Collection Mode ............................................... |

76 |

Consecutive Data Point and Data Block Support....................... |

77 |

Selecting Timeout Properties ............................................. |

78 |

Selecting a Substitution Option........................................... |

80 |

Preventing Stale and Mismatched Data ................................. |

80 |

Specifying Quality ........................................................... |

81 |

OPC Data Points ................................................................. |

82 |

RSLinx Classic OPC Data Points ........................................... |

82 |

Generic OPC Data Points ................................................... |

83 |

RSView32 Data Points ...................................................... |

83 |

DDE Data Points ............................................................. |

84 |

Chapter 6 Defining Data Objects |

87 |

Introducing Data Objects ...................................................... |

87 |

Enterprise Database Objects .................................................. |

89 |

Oracle Call Interface (OCI) Data Objects ............................... |

89 |

Microsoft SQL Server Data Objects........................................... |

89 |

ODBC Data Objects.......................................................... |

89 |

Enterprise Application Objects ............................................... |

90 |

Microsoft COM+ Data Objects ............................................. |

90 |

FactoryTalk Metrics Data Objects ........................................ |

91 |

Enterprise Connector Error Handling ........................................ |

91 |

Inserting and Updating Data Table Records ................................ |

93 |

Stored Procedures............................................................... |

93 |

Chapter 7 Creating Transactions |

95 |

Introducing Transactions....................................................... |

95 |

Transaction Types............................................................... |

96 |

6

|

|

● |

|

|

● |

|

●Contents |

|

|

|

● |

|

|

● |

|

|

● |

Unidirectional Transactions ............................................... |

|

97 |

Bidirectional Transactions ................................................. |

|

97 |

Bidirectional or Unidirectional Transactions With Transaction |

|

|

Bindings ....................................................................... |

|

99 |

Transaction Timeout.......................................................... |

|

101 |

Transaction Completion...................................................... |

|

102 |

Cached Transactions...................................................... |

|

102 |

Real-time Transactions................................................... |

|

102 |

Bidirectional Transactions ............................................... |

|

104 |

Transactions With Bound Transaction Results........................ |

|

104 |

Database Triggers ......................................................... |

|

104 |

Expression Editor .............................................................. |

|

104 |

Logical and Mathematical Operations ................................. |

|

105 |

Time Functions ............................................................ |

|

106 |

Data Point Range and Advanced Functions ........................... |

|

106 |

Parse Function ............................................................. |

|

107 |

Chapter 8 Understanding Online Edits |

111 |

|

Introducing Online Edits ..................................................... |

|

111 |

Understanding Online Edit Concepts....................................... |

|

111 |

Online Edits Workflow .................................................... |

|

112 |

Configurations That Use Online Edits .................................. |

|

114 |

Learn More About Current and Pending Edits ........................ |

|

115 |

Assembling Pending Edits ................................................ |

|

116 |

Canceling Pending Edits.................................................. |

|

117 |

Pending Edit Alerts........................................................ |

|

118 |

Creating a Configuration That Uses Online Edits ........................ |

|

121 |

Editing Data Points In a Running Configuration That Uses Online Edits |

||

............................................................................... |

|

121 |

Editing Transactions In a Running Configuration That Uses Online |

|

|

Edits ......................................................................... |

|

124 |

Chapter 9 Exploring Advanced Topics |

131 |

|

Introducing Advanced Topics................................................ |

|

131 |

Remote User Interface ....................................................... |

|

131 |

|

|

7 |

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Configuring the Remote User Interface ............................... |

132 |

Distributed Configurations................................................... |

133 |

Licensing Required For a Distributed Configuration ................ |

133 |

Establishing Microsoft Windows Privileges ............................ |

134 |

Creating a Distributed Configuration .................................. |

134 |

Using UNC Paths ........................................................... |

134 |

Data Point Buffering ...................................................... |

135 |

Increasing Performance ...................................................... |

138 |

Control System............................................................. |

138 |

Database .................................................................... |

138 |

FactoryTalk Transaction Manager ...................................... |

139 |

Hardware and Operating Environment ................................ |

140 |

Appendix A FactoryTalk Transaction Manager Sample Applications |

143 |

External Trigger Sample Application ...................................... |

143 |

Contents .................................................................... |

143 |

Running the Application.................................................. |

144 |

Appendix B FactoryTalk Transaction Manager and Microsoft COM+ Objects147

Introducing FactoryTalk Transaction Manager and Microsoft COM+ |

|

Objects.......................................................................... |

147 |

Creating the Remote Component .......................................... |

147 |

Creating the Client Application............................................. |

148 |

Installing the Remote Component.......................................... |

149 |

Setting Up the Remote Client............................................... |

150 |

Creating the Microsoft COM+ Setup Program............................. |

150 |

Moving the Client Sample Application ..................................... |

151 |

Including the COM+ Enterprise Application Connector In a FactoryTalk |

|

Transaction Manager Configuration ........................................ |

152 |

Defining the COM+ Enterprise Application Connector .................. |

152 |

Defining the COM+ Data Object ............................................ |

153 |

Code Sample A (ComSampleVB) ............................................ |

154 |

Code Sample B (ClientSampleVB) .......................................... |

155 |

8

|

|

● |

|

|

● |

●Contents |

|

|

|

|

● |

|

|

● |

|

|

● |

Appendix C Securing FactoryTalk Transaction Manager Using FactoryTalk |

||

Security |

159 |

|

About FactoryTalk Security.................................................. |

|

159 |

Considerations When Using FactoryTalk Transaction Manager With |

|

|

FactoryTalk Security.......................................................... |

|

159 |

Specify FactoryTalk Security Permissions That Allow You To Perform |

||

FactoryTalk Transaction Manager Tasks .................................. |

|

162 |

FactoryTalk Transaction Manager Behaviors When the FactoryTalk |

|

|

Security Single Sign-on User Is In Effect .................................. |

|

165 |

Overview.................................................................... |

|

166 |

At FactoryTalk Transaction Manager Start Up ....................... |

|

166 |

When Using FactoryTalk Transaction Manager ....................... |

|

168 |

Writing Product-Specific Security Privileges From a Previous Release |

||

To a File .................................................................... |

|

169 |

Map Old Product-Specific Security Privileges To the New FactoryTalk |

||

Security Permissions ...................................................... |

|

170 |

Appendix D Glossary |

173 |

|

Index .................................................................. |

181 |

|

9

●

●

● FactoryTalk Transaction Manager User Guide

●

●

10

Figures

Figure 1: FactoryTalk Transaction Manager Functions (1) ................... |

16 |

Figure 2: FactoryTalk Transaction Manager Functions (2) ................... |

17 |

Figure 3: FactoryTalk Transaction Manager Functions (3) ................... |

42 |

Figure 4: FactoryTalk Transaction Manager Title Bar ........................ |

43 |

Figure 5: FactoryTalk Transaction Manager Menu Bar ........................ |

44 |

Figure 6: FactoryTalk Transaction Manager Configuration Tree ............ |

47 |

Figure 7: Error Log File View...................................................... |

49 |

Figure 8: Transaction Definition View ........................................... |

50 |

Figure 9: FactoryTalk Transaction Manager Configuration Checklist ...... |

52 |

Figure 10: FactoryTalk Data Point dialog box .................................. |

74 |

Figure 11: Data Object Definition dialog box .................................. |

88 |

Figure 12: Transaction Monitor ................................................... |

92 |

Figure 13: Transaction Definition dialog box................................... |

96 |

Figure 14: Expression Editor dialog box ....................................... |

105 |

Figure 15: Online Edits Workflow diagram ................................... |

113 |

Figure 16: Pending Edit Alerts dialog box..................................... |

120 |

Figure 17: FactoryTalk Transaction Manager Configuration ............... |

121 |

Figure 18: Transaction Definition dialog box................................. |

124 |

Figure 19: Transaction Differences dialog box............................... |

127 |

Figure 20: Communication scheme ............................................ |

132 |

11

●

●

● FactoryTalk Transaction Manager User Guide

●

●

12

Chapter 1

Welcome To FactoryTalk Transaction

Manager

What Is FactoryTalk Transaction Manager?

FactoryTalk Transaction Manager (previously known as RSSql) is an industrial transaction software engine that shares data between your shop floor systems and your enterprise applications (for example, corporate databases) or COM+. FactoryTalk Transaction Manager can interact with the following shop floor systems:

Human Machine Interfaces (HMI)

Programmable Logic Controllers (PLC)

ControlLogix Controllers

Distributed Control Systems (DCS)

What Can FactoryTalk Transaction Manager Do For Me?

FactoryTalk Transaction Manager helps you to manage your manufacturing processes by integrating the data in your control systems with enterprise applications. The following three sections describe examples of FactoryTalk Transaction Manager applications.

Automate Data Logging

FactoryTalk Transaction Manager can move large amounts of data in a fast and robust manner. In addition, the software has built-in fault tolerance and

13

●

●

● FactoryTalk Transaction Manager User Guide

●

●

the ability to optimize reading and writing of both control and enterprise data. You can use the software to automate the following types of processes:

Monitoring performance of control systems such as machine usage.

Tracking product information such as Work in Progress status and raw material availability.

Updating real-time process information such as temperature, pressure, and alarm states.

Control the Plant Floor Using Business Rules and Quality Enforcement

FactoryTalk Transaction Manager provides the interface for a repository of business rules. A business rule can be any logic required to run your plant such as product specifications or quality parameters. By placing business rules in a database or COM+ server in a central location, the rules are easier to manage within an enterprise system. Additionally, the software can assure quality data to meet the requirements of today’s advanced manufacturing companies.

Manage Recipes

FactoryTalk Transaction Manager moves data (for example, recipe information) from a database to an HMI or control system.

Understanding FactoryTalk Transaction Manager

Concepts

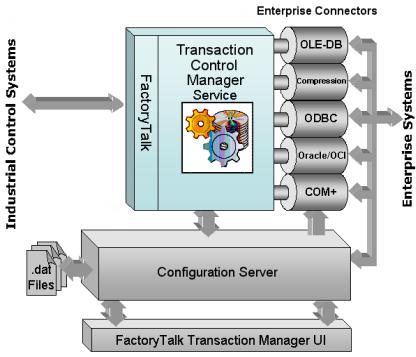

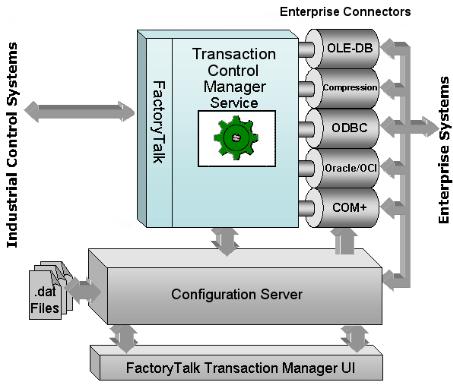

FactoryTalk Transaction Manager consists of several design-time and run-time components. This guide describes the following components in detail: Transaction Control Manager service, FactoryTalk Transaction Manager service, control connectors, enterprise connectors, Configuration Server, and transactions.

14

|

|

● |

|

1 |

●Welcome To FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

Transaction Control Manager Service

The Transaction Control Manager is a service that controls and executes FactoryTalk Transaction Manager transactions contained in a configuration, but with the additional functionality of the FactoryTalk Live Data control connector embedded in it. In an edit enabled configuration, the Transaction Control Manager replaces the separate FactoryTalk Transaction Manager and control connector services.

15

●

●

● FactoryTalk Transaction Manager User Guide

●

●

The Transaction Control Manager service can connect to Rockwell Software products and all OPC servers; therefore, the use of this service is the preferred method for all new FactoryTalk Transaction Manager configurations. For more information on how the Transaction Control Manager service functions, see the following figure.

Figure 1: FactoryTalk Transaction Manager Functions (1)

In a configuration that uses online edits, the Transaction Control Manager service performs the duties of the FactoryTalk Transaction Manager service. For more information on online edits, see Chapter 8, Understanding Online Edits (page 111).

16

|

|

● |

|

1 |

●Welcome To FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

FactoryTalk Transaction Manager Service and Control Connectors

The FactoryTalk Transaction Manager service is used to control and execute FactoryTalk Transaction Manager transactions contained in configurations created prior to CPR 7 or when you have a business reason to not run the Transaction Control Manager service. For more information on how the FactoryTalk Transaction Manager functions, see the following figure.

Figure 2: FactoryTalk Transaction Manager Functions (2)

17

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Control Connectors

The FactoryTalk Transaction Manager service interfaces with the industrial control system device via a control connector. A control connector is a Microsoft Windows 2003/XP/Vista/2008 R2 service that collects data from a controller and sends it to the FactoryTalk Transaction Manager service in the FactoryTalk Transaction Manager. You can use the following types of control connectors: FactoryTalk Live Data, DDE, RSLinx Classic OPC, RSView32, and Generic OPC. Control connectors can be used to reference data points, or memory locations within your control or shop floor system, such as ―tags‖ from an RSView32 application.

Enterprise Connectors

The Transaction Control Manager service and the FactoryTalk Transaction Manager service interface with enterprise systems such as databases via an enterprise connector service. An enterprise connector is a Microsoft Windows 2003/XP/Vista/2008 R2 service that transfers data between the Transaction Control Manager service or the FactoryTalk Transaction Manager service and a database. You can use the following types of enterprise connectors: Open Database Connectivity (ODBC), Oracle Call Interface (OCI), Microsoft OLE DB, Microsoft COM+, Time-series Data Compression, and FactoryTalk Metrics. Enterprise connectors can be used to create data objects that reference elements in your enterprise system, such as tables or stored procedures.

Configuration Server

The Configuration Server is a Microsoft Windows 2003/XP/Vista/2008 R2 service that runs continuously to provide a single interface to the configuration (.dat) files that make up the FactoryTalk Transaction Manager configuration. The Configuration Server simplifies access to configuration files by filtering all changes to the files and interfacing with other FactoryTalk Transaction Manager services. A collection of all changes that affect a configuration are recorded in an audit trail (via either FactoryTalk Diagnostics or the Configuration Server *.log file). For more information, see the FactoryTalk Transaction Manager online help.

18

|

|

● |

|

1 |

●Welcome To FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

Transactions

FactoryTalk Transaction Manager creates transactions, or discrete operations that transfer data from your control system to/from the enterprise system. For example, a single transaction can download data from an Oracle database, via a stored procedure, to tags in a ControlLogix processor. Alternately, a transaction can send multiple data points from a distributed control system to a Microsoft SQL Server database to be logged for reporting. Transactions can be modified at runtime; for more information, see Chapter 8, Understanding Online Edits (page 111).

The transaction model organizes the task of data management. FactoryTalk

Transaction Manager’s flexibility provides many options for customizing all aspects of a transaction. The software can manage many transactions at once, allowing for sophisticated manufacturing data collection and control applications. Using the software, you can also monitor, modify, and enable or disable individual transactions, making the development and implementation of an application easier.

FactoryTalk

FactoryTalk is a manufacturing information platform that integrates plant-wide control systems and connects the enterprise with the production facility.

Integrate - FactoryTalk eliminates both functionality gaps and overlaps by providing common services (such as diagnostics and access to real-time data) and by sharing plant resources (such as tags and graphic displays) throughout a production facility.

Communicate - FactoryTalk transforms plant-floor data into useful information and delivers it to the people who need it, from maintenance engineers to enterprise planners.

Collaborate - FactoryTalk allows defining plant-floor resources once, and then allows simultaneous access to those resources across system boundaries.

19

●

●

● FactoryTalk Transaction Manager User Guide

●

●

FactoryTalk Services Platform Components

With each coordinated release, additional Rockwell Software products build on the FactoryTalk platform and integrate more of the FactoryTalk components. All of the FactoryTalk components install together as a platform, integrated into each FactoryTalk-enabled product's install process. The following sections discuss the FactoryTalk Services Platform components.

FACTORYTALK DIRECTORY

FactoryTalk-enabled products use the FactoryTalk Directory to share a common address book, which automatically finds and provides access to plant-floor resources, such as data tags and graphic displays. Unlike a single database, FactoryTalk Directory provides searchable references to resources stored anywhere across an automation system, offering the benefits of central data storage without the risk of a single point of failure. Changes made to the automation system automatically update across all participants in a FactoryTalk-enabled application.

FACTORYTALK LIVE DATA

FactoryTalk Live Data manages connections between FactoryTalk-enabled products and data servers. It notifies clients when a connection is lost, automatically reconnects, and combines data from multiple controllers and servers into a single group with a single data server connection. This results in faster real-time data transfer and more reliable, efficient connections to data servers. It also assists in redundancy support for data servers by automatically handling detection and failovers for all FactoryTalk-enabled products.

FACTORYTALK ADMINISTRATION CONSOLE

The FactoryTalk Administration Console is a stand-alone tool that allows you to configure and manage FactoryTalk-enabled applications.

20

|

|

● |

|

1 |

●Welcome To FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

FACTORYTALK AUDIT AND FACTORYTALK DIAGNOSTICS

FactoryTalk Audit and FactoryTalk Diagnostics provides the ability to log errors, warnings, and other status messages generated throughout a FactoryTalk-enabled system to either local logs or a central location.

FACTORYTALK SECURITY

FactoryTalk Security is intended to improve the security of your automation system by limiting access to those with a legitimate need. FactoryTalk Security authenticates user identities and authorizes user requests to access a FactoryTalk-enabled system. These security services are fully integrated into the FactoryTalk Directory and are included as part of the FactoryTalk Services Platform that installs with many Rockwell Software products.

FactoryTalk Security replaces all of the product-specific privilege configuration that was available in previous releases of FactoryTalk Transaction Manager. For more information about using FactoryTalk Transaction Manager with FactoryTalk Security, refer to Appendix C,

Securing FactoryTalk Transaction Manager using FactoryTalk Security

(page 159).

Intended Audience

We assume that you are a control engineer or database administrator and that you are familiar most of the following:

Intel personal computers

Microsoft Windows 2003/XP/Vista/2008 R2 operating systems

DDE or OPC servers (for example, RSLinx Classic or RSView32)

Configuration of database connections such as ODBC, OCI, or Microsoft OLE DB

Microsoft COM+

RSLinx Enterprise

21

●

●

● FactoryTalk Transaction Manager User Guide

●

●

FactoryTalk View SE

Where Can I Go For Help?

Our commitment to your success starts with the suite of learning aids and assistance we provide with FactoryTalk Transaction Manager. Consult the following resources for additional information:

Online help

Product manual

Training

Technical support

Online Help

The online help provides general overview information, comprehensive step-by-step procedures, quick start topics, and context-sensitive control definitions (for example, text boxes, drop-down lists, and option buttons) for working with all of the features in FactoryTalk Transaction Manager. You can view online help in FactoryTalk Transaction Manager by using any of the following methods:

select Help > FactoryTalk Transaction Manager Help on the main FactoryTalk Transaction Manager user interface.

click Help on any FactoryTalk Transaction Manager dialog box.

click the What's This? icon in the upper-right corner of a FactoryTalk Transaction Manager dialog box, then click any control to open a definition of that control.

Product Manual

You can gain immediate access to product documentation by selecting Help

> Product Manuals > FactoryTalk Transaction Manager User Guide from within FactoryTalk Transaction Manager. Throughout this document, a number of style conventions are used to help identify material. File menu

22

|

|

● |

|

1 |

●Welcome To FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

paths are in bold with a (>) separating the entries (e.g., go to File > New); text you are asked to type is shown in Courier Bold (e.g., in this field, type Work Week), and button names are shown in bold (e.g., click OK).

Training

One of the best ways to increase your proficiency at using Rockwell Software products is to attend Rockwell Software training programs. Our training programs can help you master the basics and show you how to unleash the full potential of our software.

We offer a wide range of training programs, from regularly scheduled classes conducted at Rockwell Automation facilities to custom-tailored classes conducted at your enterprise. The size of each class is kept small intentionally to maximize student engagement.

If you would like more information about our training programs, visit the Rockwell Software site on the World Wide Web or contact the Rockwell Software Training Coordinator. Our World Wide Web address and telephone numbers appear on the inside front cover of this document.

Technical Support

Rockwell Automation’s support team of outstanding professionals provides top-notch technical support-monitoring and tracking your experience with our products to pave the road to your success in understanding and improving your factory performance.

Rockwell Automation provides full support for FactoryTalk Transaction Manager. Questions concerning installation and the use of the software are handled by the Rockwell Automation Customer Support Center, staffed every day - except U.S. holidays - from 8 AM to 5 PM in your time zone for calls originating within the U.S. and Canada.

To reach the Customer Support Center, call 1 (440) 646-3434 and follow the prompts. For calls originating outside the U.S./Canada, locate the number in your country by visiting http://www.rockwellautomation.com/locations.

23

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Get Web Support

For web-based product support, and for detailed information on technical support resources, please visit http://www.rockwellautomation.com/support/.

Access the Rockwell Automation Knowledge base for 24/7 technical information and assistance. You can also download software patches and new software versions, ask questions via email, participate in user forums, and access other useful problem-solving tools.

The support resources available vary depending upon the product purchased. The latest information can be obtained from the Rockwell Automation Technical Support website.

A current TechConnect Support contract may be required to use some online features.

Get Phone Support

To speak with a Technical Support representative in North America, call 1-440-646-3434.

For information on how to contact Technical Support in other locations worldwide, please visit http://www.rockwellautomation.com/support/.

A current TechConnect Support contract may be required to obtain phone support.

Get Consulting Services

Rockwell Automation provides expert consulting and turnkey implementation of this product. Please contact your local representative for more information.

Contact Us

We strive to help all of our customers become successful in their manufacturing improvement efforts. Toward this objective, we invite you to contact your local representative or Rockwell Automation at any time that we may be of service to you.

24

|

|

● |

|

1 |

●Welcome To FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

25

Chapter 2

Installing FactoryTalk Transaction Manager

Before You Begin

You should know about the following prerequisites before you install FactoryTalk Transaction Manager:

hardware requirements

software requirements

software dependencies

activation

activation options

See the following sections for more information.

Hardware Requirements

To use FactoryTalk Transaction Manager v10.10 effectively, your personal computer must meet the following hardware requirements:

Intel Pentium processor (1 GHz or faster recommended) - single, dual, or quad processors.

512 MB of RAM recommended (or more based on application requirements).

34 MB of free hard disk space (or more based on application requirements).

CD-ROM compatible drive.

256-color VGA graphics adapter (1024 x 768 or greater resolution).

27

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Software Requirements

To use FactoryTalk Transaction Manager v10.10 effectively, the software installed on your server computer must meet the following minimum requirements.

One of the supported operating systems:

Microsoft Windows XP (Service Pack 3)

Microsoft Windows Server 2003 R2 Standard Edition (Service Pack 2)

Microsoft Windows Vista Business (Service Pack 2)

Microsoft Windows Server 2008 R2

In order to use control connectors, you need one or more of the following:

DDE server and/or OPC server software.

If you use the RSView32 control connector, you must have RSView32 v7.40.00 or later.

RSView32 is not supported on Windows Server 2008 R2.

If you use the RSLinx Classic OPC control connector, you must have RSLinx Classic v2.52.00 or later.

RSLinx Classic must be configured to start as a Microsoft Windows service.

In order to use enterprise connectors, you need one or more of the following:

If you use an ODBC enterprise connector, you must have ODBC Manager and ODBC drivers version 2.x or later.

If you use an Oracle OCI enterprise connector, you must use one of the following types of Oracle databases:

28

|

|

● |

|

2 |

●Installing FactoryTalk Transaction Manager |

● |

|

● |

|||

|

|

●

●

Oracle 9i, with ODBC driver version 9.2.1.0, and Net client driver version 9.2.0.1.0.

Oracle 10g, with ODBC driver version 10.2.0.1.0, and Net client driver version 10.2.0.1.0.

Oracle 11g, with ODBC driver version 11.1.0.6.0, and Net client driver version 11.1.0.6.0.

Oracle 10g and later supports all three types of client installations (Instant client, Runtime and Administrator install).

Oracle databases created in version 10.2.0.1.0 and later are recommended. The use of the Oracle ODBC drivers is not recommended.

If you use a Microsoft OLE DB enterprise connector, you must have one of the following types of Microsoft SQL Server databases:

SQL Server 2000 (Service Pack 4), with ODBC driver SQLSRV32.DLL version 2000.85.1117.0

SQL Server 2005 (Service Pack 3), with ODBC driver SQLSRV32.DLL version 2000.86.3959.0 and Net client driver SQLNCLI.dll version 2005.90.4035.0.

SQL Server 2008 R2 with ODBC driver SQLSRV32.DLL version 6.1.7600.16385 and Net client driver SQLNCLI.dll version 2005.90.1399.0.

If you use Microsoft COM+, your Microsoft COM+ connector and the FactoryTalk Transaction Manager configuration using it must reside on a computer running one of the supported systems:

Microsoft Windows XP (Service Pack 3)

Microsoft Windows Server 2003 R2 Standard Edition (Service Pack 2)

Microsoft Windows Vista Business (Service Pack 2)

29

●

●

● FactoryTalk Transaction Manager User Guide

●

●

Microsoft Windows Server 2008 R2

Microsoft COM+ objects must be built using Microsoft Developer Studio 6.0.

Microsoft Windows 2003/XP/Vista/2008 R2 simple TCP/IP services must be configured.

Microsoft Data Access Components (MDAC) is updated to version 2.8 during the FactoryTalk Transaction Manager installation.

Minimum video resolution of 1024 x 768.

Software Compatibility

FactoryTalk Transaction Manager v10.10 has been tested, and is compatible, with the latest Rockwell Software release of the following products:

FactoryTalk Services Platform (v2.30.01)

FactoryTalk Activation (v3.30.00)

RSView32 (v7.50.00)

FactoryTalk View SE (v5.20.00)

RSLinx Enterprise (v5.30.00)

RSLinx Classic (v2.56.00)

Activation

Rockwell Software's Windows-based software products are copy protected and require an activation key, located in an activation file, to run the software.

FactoryTalk Transaction Manager v10.10 supports the following activation tools:

FactoryTalk Activation: If you are a new user, you will need to activate your software using FactoryTalk Activation.

30

Loading...

Loading...