Rinnai V65e (REU-VC2025W-US), V65i (REU-VC2025FFU-US), V75e (REU-VC2528W-US), V75i (REU-VC2528FFU-US) Operation and Installation Manual

Direct Vent Tankless Water Heater

Installa on and Opera on Manual

Installa on and Opera on Manual

FOR INDOOR APPLICATIONS ONLY

V75i....................... |

REU VC2528FFU US |

|

V65i....................... |

REU VC2025FFU US |

|

FOR OUTDOOR APPLICATIONS ONLY |

|

|

V75e...................... |

REU VC2528W US |

|

V65e...................... |

REU VC2025W US |

|

|

|

|

|

|

|

ANS Z21.10.3 ● CSA 4.3

READ ALL OF THE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR OPERATING THIS WATER HEATER.

This manual provides informa on on the installa on, opera on, and maintenance of the water heater. For proper opera on and safety, it is important to follow the instruc ons and adhere to the safety precau ons.

A licensed professional must install the water heater according to the exact instruc ons on pages 4 27.

The consumer must read the en re manual to properly operate the water heater and to have regular maintenance performed.

WARNING If the informa on in these instruc ons is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

WARNING If the informa on in these instruc ons is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instruc ons.

•If you cannot reach your gas supplier, call the fire department.

—Installa on and service must be performed by a licensed professional.

This en re manual must be le for the consumer. The consumer must read and refer to this manual for proper opera on and to maintain the water heater.

Table of Contents

Table of Contents ..................................................... |

|

2 |

Checklist for Gas and Electricity....................... |

20 |

|

Safety Behaviors and Prac ces for the |

|

Installa on of Temperature Controller............ |

21 |

||

Consumer and Installer ............................................ |

|

3 |

Final Checklist .................................................. |

23 |

|

Installa on Instruc ons |

|

Technical Data ........................................................ |

24 |

||

(for the licensed professional) .............................. |

4 |

Specifica ons ................................................... |

24 |

||

Prepare for Installa |

on...................................... |

5 |

Dimensions ...................................................... |

25 |

|

Determine Installa |

on Loca on ........................ |

6 |

Pressure Drop and Water Flow Curves............ |

26 |

|

Checklist to Determine Installa on Loca on... |

12 |

Ladder Diagram................................................ |

27 |

||

Mount to Wall.................................................. |

|

12 |

Opera on Instruc ons........................................ |

28 |

|

Remove the Front Panel .................................. |

12 |

Consumer Opera on Guidelines for the |

29 |

||

Installa on of Ven |

ng (indoor models only) |

13 |

Safe Opera on of your Water Heater.............. |

||

How to Use the Temperature Controller |

30 |

||||

Condensate (indoor models only) |

15 |

||||

How to Set the Temperature |

31 |

||||

Checklist for Ven ng and Condensate |

|

||||

|

Diagnos c Codes |

33 |

|||

(indoor models only)........................................ |

15 |

||||

Installa on of Plumbing................................... |

16 |

Required Maintenance .................................... |

36 |

||

Checklist for Plumbing ..................................... |

18 |

Flushing the Heat Exchanger..................... |

38 |

||

Installa on of Gas Supply ................................ |

18 |

Manual Draining of the Water Heater ...... |

39 |

||

Connect Electricity ........................................... |

|

20 |

State Regula ons.................................................... |

40 |

|

Adjust for High Al tude ................................... |

20 |

Replacement Parts ................................................. |

41 |

||

Adjust for Vent Length (indoor models only) .. |

20 |

Consumer Warranty ............................................... |

42 |

||

|

|

|

French Version........................................................ |

44 |

|

NOTICE: Rinnai some mes shares customer contact informa on with businesses that we believe provide products or services that may be useful to you. By providing this informa on, you agree that we can share your contact informa on for this purpose. If you prefer not to have your informa on shared with these businesses, please contact customer service and ask not to have your informa on shared. We will however, con nue to contact you with informa on relevant to the product(s) you registered and/ or you account with us.

If you have any ques ons or feel that the manual is incomplete contact Rinnai at 1 800 621 9419.

Important Safety Informa on

Safety Defini ons

This is the safety alert symbol. This symbol alerts you to poten al hazards that can kill or hurt you and others.

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

Indicates an imminently hazardous situa on which, if not avoided, will result in death or serious injury.

Indicates a poten ally hazardous situa on which, if not avoided, could result in death or serious injury.

Indicates a poten ally hazardous situa on which, if not avoided, could result in minor or moderate injury. It may also be used to alert against unsafe prac ces.

2 |

Value Series Manual |

Safety Behaviors and Prac ces for the Consumer and Installer

WARNING

WARNING

•Before opera ng, smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will se le on the floor.

•Keep the area around the appliance clear and free from combus ble materials, gasoline, and other flammable vapors and liquids.

•Combus ble construc on refers to adjacent walls and ceiling and should not be confused with combus ble or flammable products and materials. Combus ble and/or flammable products and materials should never be stored in the vicinity of this or any gas appliance.

•Always check the water temperature before entering a shower or bath.

•To protect yourself from harm, before performing maintenance:

◊Turn o the electrical power supply by unplugging the power cord or by turning o the electricity at the circuit breaker. (The temperature controller does not control the electrical power.)

◊Turn o the gas at the manual gas valve, usually located immediately below the water heater.

◊Turn o the incoming water supply. This can be done at the isola on valve immediately below the water heater or by turning o the water supply to the building.

CAUTION

CAUTION

•BURN HAZARD. Hot exhaust and vent may cause serious burns. Keep away from water heater unit. Keep small children and animals away from unit.

California law requires this no ce to be provided:

•Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push in or turn by hand, do not try to repair it; call a licensed professional. Force or a empted repair may result in a fire or explosion.

•Do not use this appliance if any part has been under water. Immediately call a licensed professional to inspect the appliance and to replace any part of the control system and any gas control which has been under water.

•Do not use subs tute materials. Use only parts cer fied with the appliance.

•Should overhea ng occur or the gas supply fail to shut o , turn o the manual gas control valve to the appliance.

•Do not adjust the DIP switch unless specifically instructed to do so.

•Do not use an extension cord or an adapter plug with this appliance.

•Any altera on to the appliance or its controls can be dangerous and will void the warranty.

•Hot water outlet pipes leaving the unit can be hot to touch. In residen al applica ons, insula on must be used for hot water pipes below 36” due to burn risk to children.

California Proposi on 65 lists chemical substances known to the state to cause cancer, birth defects, death, serious illness or other reproduc ve harm. This product may contain such substances, be their origin from fuel combus on (gas, oil) or components of the product itself.

Value Series Manual |

3 |

Installa on Instruc ons

Installer Qualifica ons

A licensed professional must install the appliance, inspect it, and leak test it before use. The warranty will be voided due to improper installa on.

The installer should have skills such as:

•gas sizing

•connec ng gas lines, water lines, valves, electricity,

•knowledge of applicable na onal, state, and local codes.

•installing ven ng through a wall or roof

If you lack these skills contact a licensed professional.

Type of installa on

• For installa on in residen al applica ons.

•Cer fied for installa on in manufactured (mobile) homes.

Installa |

on Steps |

|

|

Prepare for Installa |

on ...................................... |

5 |

|

Determine Installa |

on Loca on ........................ |

6 |

|

Checklist to Determine Installa on Loca on... |

12 |

||

Mount to Wall.................................................. |

|

12 |

|

Remove the Front Panel .................................. |

12 |

||

Installa |

on of Ven |

ng (indoor models only) ... |

13 |

Condensate (indoor models only).................... |

15 |

||

Checklist for Ven ng and Condensate |

|

||

(indoor models only)........................................ |

15 |

||

Installa |

on of Plumbing ................................... |

16 |

|

Checklist for Plumbing ..................................... |

18 |

||

Installa |

on of Gas Supply ................................ |

18 |

|

Connect Electricity ........................................... |

|

20 |

|

Adjust for High Al tude ................................... |

20 |

||

Adjust for Vent Length (indoor models only) .. |

20 |

||

Checklist for Gas and Electricity....................... |

20 |

||

Installa |

on of Temperature Controller............ |

21 |

|

Final Checklist .................................................. |

|

23 |

|

General Instruc ons

DO NOT

•Do not install the V75i or the V65i outdoors.

•Do not install the V75e or the V65e indoors.

•Do not install the appliance in an area where water leakage of the unit or connec ons will result in damage to the area adjacent to the appliance or to lower floors of the structure. When such loca ons cannot be avoided, it is recommended that a suitable drain pan, adequately drained, be installed under the appliance. The pan must not restrict combus on air flow.

•Do not obstruct the flow of combus on and ven la on air. Combus on air shall not be supplied from occupied spaces.

•Do not use this appliance in an applica on such as a pool or spa heater that uses chemically treated water . (This appliance is suitable for filling large or whirlpool spa tubs with potable water.)

•Do not use subs tute parts that are not authorized for this appliance.

MUST DO

•The installa on must conform with local codes or, in the absence of local codes, with the Na onal Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installa on Code, CSA B149.1. If installed in a manufactured home, the installa on must conform with the Manufactured Home Construc on and Safety Standard, Title 24 CFR, Part 3280 and/or CAN/SCA Z240 MH Series, Mobile Homes.

•The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with the Na onal Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1.

•The appliance and its appliance main gas valve must be disconnected from the gas supply piping system during any pressure tes ng of that system at test pressures in excess of 1/2 psi (3.5 kPa) (13.84 in W.C.).

4 |

Value Series Manual |

•The appliance must be isolated from the gas supply piping system by closing its individual manual shuto valve during any pressure tes ng of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa) (13.84 in W.C.).

•You must follow the installa on instruc ons and those in Care and Maintenance for adequate combus on air intake and exhaust.

INFORMATION

•If a water heater is installed in a closed water supply system, such as one having a backflow preventer in the cold water supply line, means shall be provided to control thermal expansion. Contact the water supplier or local plumbing inspector on how to control thermal expansion.

•Should overhea ng occur or the gas supply fail to shut o , turn o the manual gas control valve to the appliance.

•Keep the air intake loca on free of chemicals such as chlorine or bleach that produce fumes. These fumes can damage components and reduce the life of your appliance.

Prepare for installa on

Parts included

•Tankless water heater

•MC 91 2 temperature controller (integrated into indoor models; provided with outdoor models)

Tools needed

• Pipe wrenches (2) |

• Gloves |

• Adjustable pliers |

• Safety glasses |

• Screwdrivers (2) |

• Level |

• Wire cu ers |

|

Tools that might be needed

•Hammer drill with concrete bits

•Saw

•Threading machine with heads and oiler

Materials needed

•Soap solu on

•Approved ven ng

•Teflon tape (recommended) or pipe

•Core drill with diamond head

•Torch set

•Copper tubing cu er

•Steel pipe cu er

compound

•Pressure relief valve

Materials that may be needed

•Heat tape

•Pipe insula on

•Electrical wire and conduit per local code

•Concrete wall anchors

•Op onal pipe cover

•Op onal temperature controller

•5/8” ID PVC flexible tubing

•2 conductor 22 AWG wire for controller

•Single gang electrical box

•Wire nuts

•Unions, drain valves, isola on valves

Value Series Manual |

5 |

Determine Installa on Loca on

You must ensure that clearances will be met and that the vent length will be within required limits. Consider the installa on environment, water quality, and need for freeze protec on. Requirements for the gas line, water lines, electrical connec on, and condensate disposal can be found in their respec ve installa on sec ons of this manual.

Water Quality

Considera on of care for your water heater should include evalua on of water quality.

Water that contains chemicals exceeding the levels below a ect and damage the heat exchanger. Replacement of the heat exchanger due to water quality damage is not covered by the warranty.

|

|

Maximum Level |

|

|

|

Total Hardness |

|

Up to 200 mg / L |

|

|

|

Aluminum * |

|

Up to 0.2 mg / L |

|

|

|

Chlorides * |

|

Up to 250 mg / L |

|

|

|

Copper * |

|

Up to 1.0 mg / L |

|

|

|

Iron * |

|

Up to 0.3 mg / L |

|

|

|

Manganese * |

|

Up to 0.05 mg / L |

|

|

|

pH * |

|

6.5 to 8.5 |

|

|

|

TDS (Total Dissolved |

|

Up to 500 mg / L |

Solids) * |

|

|

|

|

|

Zinc * |

|

Up to 5 mg / L |

|

|

|

* Source: Part 143 Na |

onal Secondary Drinking Water |

|

Regula ons |

|

|

If you install this water heater in an area that is known to have hard water or that causes scale build up the water must be treated and/or the heat exchanger flushed regularly.

When scale build up in the heat exchanger begins to a ect the performance of the water heater, a diagnos c code “LC#” will display. Flush the heat exchanger to prevent damage to it. Scale build up is caused by hard water set at a high temperature.

Rinnai provides a “Scale Control System” that o ers superior lime scale preven on and corrosion control by feeding a blend of control compounds into the water supply.

Environment

Air surrounding the water heater, ven ng, and vent termina on(s) is used for combus on and must be free of any compounds that cause corrosion of internal components. These include corrosive compounds that are found in aerosol sprays, detergents, bleaches, cleaning solvents, oil based paints/ varnishes, and refrigerants. The air in beauty shops, dry cleaning stores, photo processing labs, and storage areas for pool supplies o en contains these compounds. Therefore it is recommended that outdoor models be used for these loca ons where possible.

The water heater, ven ng, and vent termina on(s) should not be installed in any areas where the air may contain these corrosive compounds. If it is necessary for a water heater to be located in areas which may contain corrosive compounds, the following

instruc ons are strongly recommended.

IMPORTANT CONSIDERATIONS FOR:

Indoor/Internal Water Heaters

•DO NOT Install in areas where air for combus on can be contaminated with chemicals.

•Before installa on, consider where air has the ability to travel within the building to the water heater.

•Where possible, install the water heater in a sealed closet so that it is protected from the poten al of contaminated indoor air.

•Chemicals that are corrosive in nature should not be stored or used near the water heater.

Outdoor/External Water Heaters and Vent Termina ons of Indoor/Internal Water Heaters

•Install the water heater as far away as possible from exhaust vent hoods.

•Install as far away as possible from air inlet vents. Corrosive fumes may be released through these vents when air is not being brought in through them.

•Chemicals that are corrosive in nature should not be stored or used near the water heater or vent termina on.

Damage and repair due to corrosive compounds in the air is not covered by warranty.

6 |

Value Series Manual |

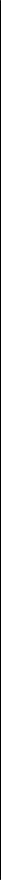

Vent Termina on Clearances

For indoor models, you must install a vent termina on to bring in combus on air and expel exhaust.

TERMINATION |

INSIDE |

|

|

CORNER DETAIL |

|

|

G |

|

Clearance in |

|

|

Ref. A also |

H |

|

applies to |

A |

|

anticipated |

||

|

||

snow line |

|

|

SNOW |

|

|

|

|

|

|

|

|

B |

I M |

|

|

|

|

|

|

|

||

D |

|

B |

FIXED |

|

K |

|

|

|

CLOSED |

|

|

||

|

E |

|

OPERABLE |

|

|

|

|

|

B |

J |

|

|

|

|

|

C |

X AIR SUPPLY INLET |

|||

|

B |

FIXED |

B |

|||

|

CLOSED |

|||||

|

A |

|||||

|

|

OPERABLE |

|

V VENT TERMINAL |

||

|

L |

|

|

|||

|

|

F |

|

|

AREA WHERE TERMINAL |

|

|

|

B |

|

|

IS NOT PERMITTTED |

|

|

|

|

|

|

||

Ref |

Descrip |

on |

Canadian Installa |

ons |

US Installa ons |

|

A |

Clearance above grade, veranda, porch, deck, or balcony |

12 inches (30 cm) |

12 inches (30 cm) |

|||

B |

Clearance to window or door that may be opened |

36 inches (91 cm) |

12 inches (30 cm) |

|||

C |

Clearance to permanently closed window |

* |

|

* |

||

D |

Ver cal clearance to ven lated so t, located above the terminal within a |

* |

|

* |

||

horizontal distance of 2 feet (61 cm) from the center line of the terminal |

|

|||||

|

|

|

|

|||

E |

Clearance to unven lated so t |

|

* |

|

* |

|

F |

Clearance to outside corner |

|

* |

|

* |

|

G |

Clearance to inside corner |

|

* |

|

* |

|

H |

Clearance to each side of center line extended above meter/regulator |

3 feet (91 cm) within a height 15 |

|

|||

feet (4.5 m) above the meter/ |

* |

|||||

assembly |

|

|||||

|

|

regulator assembly |

|

|||

|

|

|

|

|||

I |

Clearance to service regulator vent outlet |

36 inches (91 cm) |

* |

|||

J |

Clearance to nonmechanical air supply inlet to building or the combus on |

36 inches (91 cm) |

12 inches (30 cm) |

|||

air inlet to any other appliance |

|

|||||

|

|

|

|

|

||

K |

Clearance to a mechanical air supply inlet |

6 feet (1.83 m) |

|

3 feet (91 cm) above if within 10 |

||

|

feet (3 m) horizontally |

|||||

|

|

|

|

|

||

L |

Clearance above paved sidewalk or paved driveway located on public |

7 feet (2.13 m) 1 |

* |

|||

property |

|

|||||

|

|

|

|

|

||

M |

Clearance under veranda, porch, deck, or balcony |

12 inches (30 cm) 2 |

* |

|||

[1]A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings.

[2]Permi ed only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

For clearances not specified in ANSI Z223.1/NFPA 54, clearances are in accordance with local installa on codes and the requirements of the gas supplier.

Clearance to opposite wall is 24 inches (60 cm).

Value Series Manual |

7 |

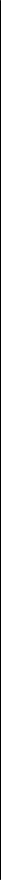

Addi onal clearances V75i, V65i

Check on whether local codes supersede these clearances.

• Avoid termina on loca ons near a dryer vent.

•Avoid termina on loca ons near commercial cooking exhaust.

•You must install a vent termina on at least 12 inches from the ground

Important considera ons for loca ng vent

termina on under a so t (ven lated or unven lated or eave vent; or to a deck or porch)

(1.52 m) |

60" |

|

V |

||

between |

||

|

||

terminals at |

V |

|

di erent levels |

V

•Do not install vent termina on under a so t vent

such that exhaust can enter the so t vent |

|

|

|

(1.52 m) ver cally |

• Install vent termina on such that exhaust and |

|

60" between terminals |

||

|

|

|

|

|

rising moisture will not collect under |

|

|

|

|

eaves. Discolora on to the exterior of the |

V |

|

|

|

|

|

|

||

building could occur if installed too close. |

|

|

|

|

•Do not install the vent termina on too close under the so t where it could present recircula on of exhaust gases back into the combus on air intake part of the termina on

24" (0.61 m) to wall or parapet

|

|

V |

|

|

36" |

12" |

V |

V |

(0.30 m ) to |

||

an inside |

|

12" |

corner |

|

|

(0.30 m) between |

|

|

terminals at same |

12" |

|

level |

(0.30 m) between |

|

V |

V |

terminals at same |

INSIDE |

|

level |

|

|

|

CORNER |

|

|

8 |

Value Series Manual |

Addi onal clearances

V75e, V65e

Local codes supersede these clearances.

• Avoid termina on loca ons near a dryer vent.

•Avoid termina on loca ons near commercial cooking exhaust.

(50 mm) between terminals at same level

12" |

36" |

|

2" |

||

|

(0.30 m) to an inside corner

60"

(0.91 m) to ven lated or unven lated so t or eve vent; or to a deck or porch

(1.52 m) ver cally between terminals

Value Series Manual |

9 |

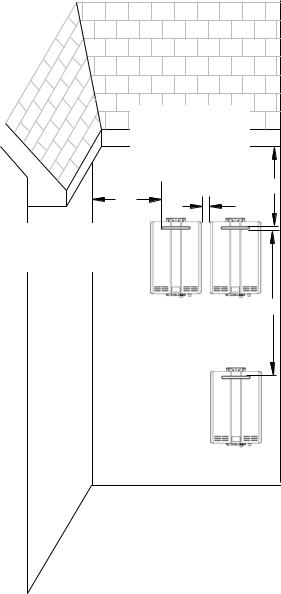

Unit clearances

to top

to side

to front

to ground/bottom

Indoor models: V75i, V65i

|

to Combus bles |

to Non |

|

Combus bles |

|

|

inches (mm) |

|

|

inches (mm) |

|

|

|

|

|

|

|

Top of Heater |

6 * (152) |

2 *(51) |

|

|

|

Back of Heater |

0 (zero) |

0 (zero) |

|

|

|

Front of Heater |

6 (152) |

6 (152) |

|

|

|

Sides of Heater |

2 (51) |

1/2 (13) |

|

|

|

Ground/Bo om |

12 (305) |

12 (305) |

|

|

|

Vent |

0 (zero) |

0 (zero) |

|

|

|

* 0 inches from vent components and condensate drain line.

The clearance for servicing is 24 inches in front of the water heater.

For closet installa on, clearance is 6 inches (152 mm) from the front.

to top

to side

to front

to ground/bottom

Outdoor models: V75e, V65e

|

to Combus bles |

to Non |

|

Combus bles |

|

|

inches (mm) |

|

|

inches (mm) |

|

|

|

|

|

|

|

Top of Heater |

12 (305) |

2 (51) |

|

|

|

Back of Heater |

0 (zero) |

0 (zero) |

|

|

|

Front (Panel) |

24 (610) |

0 (zero) |

|

|

|

Front (Exhaust) |

24 (610) |

24 (610) |

|

|

|

Sides of Heater |

6 (152) |

1/8 (3.2) |

|

|

|

Ground/Bo om |

12 (305) |

2 (51) |

|

|

|

The clearance for servicing is 24 inches in front of the water heater.

10 |

Value Series Manual |

Maximum vent length (indoor models only)

1.Determine the number of 90 degree elbows in the vent system. (Two 45 degree elbows count as one 90 degree elbow.)

2.Refer to the table to find the maximum vent length based on the number of elbows.

Number of |

Maximum vent length |

|

90° Elbows |

|

|

|

|

|

0 |

41 |

(12.5 m) 1 |

|

|

|

1 |

35 |

(10.7 m) 2 |

|

|

|

2 |

29 |

(8.8 m) 3 |

|

|

|

3 |

23 |

(7.0 m) 4 |

|

|

|

4 |

17 |

(5.2 m) 4 |

|

|

|

5 |

11 |

(3.4 m) 4 |

|

|

|

6 |

5 |

(1.5 m) 4 |

|

|

|

3.Adjust switch No. 1 in the SW1 DIP switch (tan switches) if required by the applicable note.

1 If the length is greater than 21 |

(6.4 m) then |

move switch No. 1 (SW1) to OFF. |

|

2 If the length is greater than 15 |

(4.6 m) then |

move switch No. 1 (SW1) to OFF. |

|

3 If the length is greater than 9 |

(2.7 m) then move |

switch No. 1 (SW1) to OFF. |

|

4 Move switch No. 1 (SW1) to OFF.

Example: If you have one elbow then your maximum vent length is 35 feet (10.7 m). If your actual length is greater than 15 (4.6 m) then move switch no. 1 (SW1) to OFF.

NOTICE

If you have a longer vent length (see above), switch No. 1 is required to be in the OFF posi on. This ensures the water heater will run properly. Blocked flue diagnos c codes and shutdowns may result if switch No. 1 is not in the correct posi on.

Freeze Protec on

Make sure that in case of freezing weather that the water heater and its water lines are protected to prevent freezing. Damage due to freezing is not covered by the warranty.

Loss of freeze protec on may result in water damage from a burst heat exchanger or water lines.

With electrical power supplied, the water heater will not freeze when the outside air temperature is as cold as –22°F ( 30°C) for indoor models or is as cold as –4°F ( 20°C) for outdoor models, when protected from direct wind exposure. Because of the “wind chill” e ect, any wind or circula on of the air on the unit will reduce its ability to freeze protect.

The unit may be drained manually. However, it is highly recommended that:

•drain down solenoid valves are installed that will automa cally drain the unit if power is lost. These are available in a kit, 104000059. (The condensate trap drain plug and water drain plug are not a ected by the auto drain down solenoid valves and will have to be manually opened.)

•a surge protector with terminals is installed which allows the solenoid valves to operate if the unit is disabled due to a diagnos c code. This is available as 104000057.

In addi on, the solenoid valves should be connected electrically to a surge protector with terminals. This allows the solenoid valves to operate if the water heater is disabled due to a diagnos c code.

The freeze protec on features will not prevent the external piping from freezing. It is recommended that hot and cold water pipes are insulated. Pipe cover enclosures may be packed with insula on for added freeze protec on.

In the event of a power failure at temperatures below freezing the water heater should be drained of all water to prevent freezing damage. In addi on, drain the condensate trap and drain line.

Value Series Manual |

11 |

Checklist to Determine Installa on Loca on

□The water heater is not exposed to corrosive compounds in the air.

□The water heater loca on complies with the clearances.

□For indoor models, the planned ven ng will not exceed the maximum length for the number of elbows used.

□The planned ven ng termina on/air intake loca on meets the clearances.

□The water supply does not contain chemicals or exceed total hardness that will damage the heat exchanger.

□A standard 3 prong 120 VAC, 60 Hz properly grounded wall outlet (for indoor models) or other 120 VAC, 60 Hz source is available.

□The installa on must conform with local codes or, in the absence of local codes, with the Na onal Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installa on Code, CSA B149.1. If installed in a manufactured home, the installa on must conform with the Manufactured Home Construc on and Safety Standard, Title 24 CFR, Part 3280 and/or CAN/SCA Z240 MH Series, Mobile Homes.

□Leave the en re manual taped to the water heater (indoor models), temperature controller (outdoor models), or give the en re manual directly to the consumer.

Mount to Wall

wall installa on brackets

1.Iden fy the installa on loca on and confirm that the installa on will meet all required clearances.

2.Securely a ach the water heater to the wall using any of the holes in the wall installa on brackets which are at the top and bo om of the water heater. Ensure that the a achment strength is su cient to support the weight. Refer to the weight of the water heater in the Specifica ons sec on.

Use a leveling tool to ensure that the water heater is level. Proper opera on requires that the water heater be level.

NOTE: The water heater should be installed in an upright posi on. Do not install upside down or on its side.

Remove the Front Panel

Slide the plas c trim pieces on each side of the water heater to expose the screws.

Remove the 4 screws and pull o the front panel.

12 |

Value Series Manual |

Installa on of ven ng (indoor models only)

Install the correct ven ng for your model according to the ven ng manufacturer’s instruc ons and the guidelines below.

Refer to the manufacturer’s technical literature for specific part numbers and instruc ons.

Manufacturer |

Listed and Tested Vent Products |

Telephone |

Fax |

Contact |

|

for V75i and V65i |

|||||

|

|

|

|

||

|

|

|

|

|

|

Ubbink |

Rolux Vent System |

800 621 9419 |

678 829 1666 |

www.rinnai.us |

|

|

|

|

|

|

|

Heat Fab |

Saf T Vent SC system |

800 772 0739 |

413 863 4803 |

custsvc@heat fab.com, |

|

www.hea ab.com |

|||||

|

|

|

|

||

|

|

|

|

|

|

Metal Fab |

Corr/Guard Vent/Air Intake System |

800 835 2830 |

316 943 2717 |

info@mtlfab.com, |

|

www.metal fabinc.com |

|||||

|

|

|

|

||

|

|

|

|

|

Ven ng Guidelines

DO NOT

•Do not use PVC, CPVC, ABS or galvanized material to vent this appliance.

•Do not combine vent components from di erent manufacturers.

•Vent diameter must not be reduced.

•Do not connect the ven ng system with an exis ng vent or chimney.

•Do not common vent with the vent pipe of any other water heater or appliance.

INFORMATION

•Refer to the instruc ons of the vent system manufacturer for component assembly instruc ons.

•If the vent system is to be enclosed, it is suggested that the design of the enclosure shall permit inspec on of the vent system. The design of such enclosure shall be deemed acceptable by the installer or the local inspector.

MUST DO

•This water heater is a direct vent water heater and therefore is cer fied and listed with the vent system. You must use vent components that are cer fied and listed with the water heater model.

•The vent system must vent directly to the outside of the building and use outside air for combus on.

•Avoid dips or sags in horizontal vent runs by installing supports per the vent manufacturer’s instruc ons.

•Support horizontal vent runs every four feet and all ver cal vent runs every six feet or in accordance with local codes.

•Ven ng should be as direct as possible with a

minimum number of pipe fi ngs.

•Vent connec ons must be firmly pressed together

so that the gaskets form an air ght seal.

•The vent piece connected to the water heater must be secured with one self tapping screw.

NOTICE

If it becomes necessary to access an enclosed vent system for service or repairs, Rinnai is not responsible for any costs or di cul es in accessing the vent system. The warranty does not cover obtaining access to a vent system in an enclosed environment.

Value Series Manual |

13 |

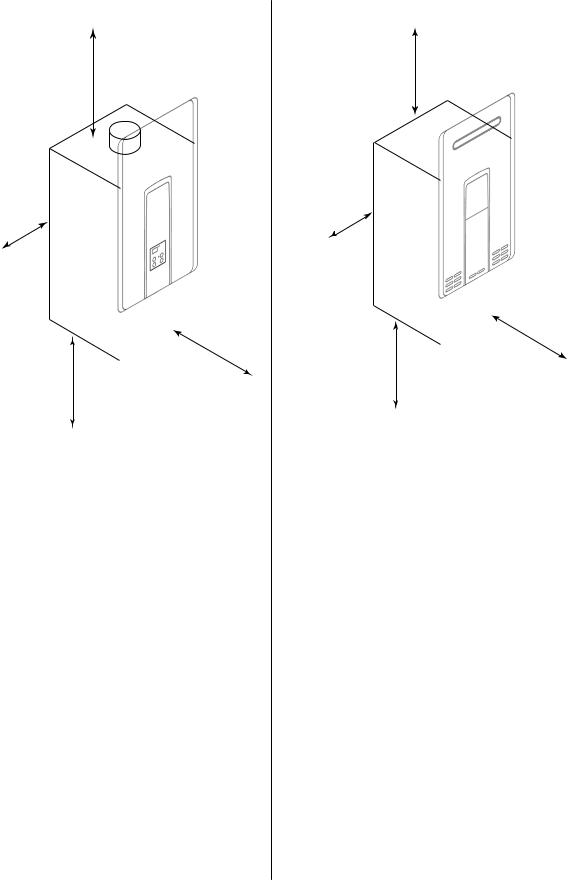

Flue Installa on (indoor models only)

Install the ven ng termina on according to the diagrams and instruc ons below.

Horizontal Termina on without using the Condensate Collector

WARNING |

* The condensate collector must be used in |

If the condensate collector is not used, the drain pipe |

horizontal termina ons if a ver cal rise in |

must be capped to prevent exhaust gases and |

the vent system exceeds 5 . |

|

|

condensate from entering the building. The cap is |

|

supplied on the appliance. |

|

Maximum Height * |

Regions of cold climate will create more |

|

5 feet (1.52 m) |

||

condensate in the vent system. The |

||

|

condensate collector should be used in |

|

|

cold climates. |

|

|

If more than one elbow is used in the |

|

|

ver cal sec on the condensate collector |

|

|

must be used. |

|

Horizontal Termina on using the |

Ver cal Termina on |

Condensate Collector

(condensate collector must be used in all installa ons)

Condensate |

|

|

Trap |

3 in (75 mm) |

|

|

||

|

minimum |

|

3 in (75 mm) |

3 in (75 mm) |

|

minimum |

||

minimum |

||

|

Bracket

Condensate Collector

Securing Screw |

To adjust the condensate collector posi on or to replace the female vent top with a male vent top:

1.Loosen the 4 screws at the rear bracket

2.Slide the bracket away from the female vent top.

3.Remove the 4 screws a aching the female vent top to the water heater.

4. |

Li up the female vent top and reposi |

on as desired |

|

(or replace with a male vent top). |

|

5. |

Install the 4 screws at the vent top and |

ghten the 4 |

|

screws at the bracket. |

|

Secure the first vent component to the water heater with one self tapping screw at the hole located above the condensate collector.

14 |

Value Series Manual |

Condensate

(indoor models only)

Condensate forma on can occur in high e ciency direct vent appliances. Without proper drainage condensate will damage the heat exchanger.

To prevent condensate damage follow these instruc ons.

DO NOT

•Do not allow condensate to enter the water heater.

•Do not connect the condensate drain pipe directly to the rain sewer.

•Do not connect the condensate drain line with an air condi oning evaporator coil drain.

MUST DO

•Use only vent that is approved and iden fied as acceptable for your par cular model.

•For ver cal termina ons, install a condensate drain and trap as close as possible to the appliance.

•Slope the ven ng toward the appliance according

to the vent manufacturers installa on instruc ons.

•All condensate must drain and be disposed of according to local codes.

•Use only PVC or CPVC pipe for the condensate drain line.

•The condensate drain pipe (along its en re length) must be at least the same diameter as the drain line, (5/8 inch NPT).

•The end of the condensate drain pipe should be open to the atmosphere. The end should not be under water or other substances.

•To minimize freezing of the condensate, run the condensate drain line through an interior wall or between insula on and an interior wall.

•The condensate collector should be used for all hydronic hea ng applica ons.

INFORMATION

•A condensate trap is available, P/N 222053.

•Regions of cold climate will create more condensate in the vent system. The condensate collector should be used in cold climates.

•The condensate drain pipe should be as short as possible and have a downward pitch.

Checklist for Ven ng and Condensate (indoor models only)

□Verify proper clearances around the vents and air intakes.

□Ensure you have used the correct ven ng products for the model installed and that you have completely followed the ven ng manufacturer’s installa on instruc ons and these installa on instruc ons.

□Verify that the vent pipe has a downward slope or grade to the outside of 1/4 inch per foot (1.2°) OR if the vent pipe is sloped toward the water heater (as some local codes require), that a condensate collector is installed to allow condensa on to drain away from the water heater to a proper drain source.

□Verify that condensate will not be allowed to drain back into the water heater.

□Verify that the vent system does not exceed the maximum length for the number of elbows used.

Value Series Manual |

15 |

Installa on of Plumbing

Pressure Relief Valve Requirements

Install the pressure relief valve according to local plumbing codes and these instruc ons.

An approved pressure relief valve is required by the

American Na onal Standard (ANSI Z21.10.3) for all water hea ng systems, and shall be accessible for servicing.

DO NOT

•Do not plug the relief valve and do not install any reducing fi ngs or other restric ons in the relief line. The relief line should allow for complete drainage of the valve and the line.

•Do not place any other type valve or shut o device between the relief valve and the water heater.

MUST DO

•The relief valve must comply with the standard for

Relief Valves and Automa c Gas Shuto Devices for Hot Water Supply Systems ANSI Z21.22 and /or the standard Temperature, Pressure, Temperature and Pressure Relief Valves and Vacuum Relief Valves, CAN1 4.4.

•The relief valve must be rated up to 150 psi and to at least the maximum BTU/hr of the appliance.

•The discharge from the pressure relief valve should be piped to the ground or into a drain system to prevent exposure or possible burn hazards to humans or other plant or animal life. Follow local codes. Water discharged from the relief valve could cause severe burns instantly, scalds, or death.

•The pressure relief valve must be manually operated once a year to check for correct opera on.

•The relief valve should be added to the hot water outlet line and near the hot water outlet according to the manufacturer’s instruc ons. DO NOT place any other type valve or shut o device between the relief valve and the water heater.

INFORMATION

•If a relief valve discharges periodically, this may be due to thermal expansion in a closed water supply system. Contact the water supplier or local plumbing inspector on how to correct this

situa on. Do not plug the relief valve.

•The American Na onal Standard (ANSI Z21.10.3) does not require a combina on temperature and pressure relief valve for this appliance. However, local codes may require a combina on temperature and pressure relief valve.

Isola on Valves

Rinnai strongly recommends the installa on of isola on valves on the cold and hot water lines because they provide the ability to isolate the water

heater from the structure’s plumbing and allow quick access to flush the heat exchanger. Flushing the heat exchanger regularly is required as part of the proper maintenance for this water heater.

Piping Requirements

A manual water control valve must be placed in the water inlet connec on to the water heater before it is connected to the water line. Unions may be used on both the hot and cold water lines for future servicing and disconnec on of the unit.

DO NOT

•Do not introduce toxic chemicals such as those used for boiler water treatment to the potable water used for space hea ng.

MUST DO

•The piping (including soldering materials) and components connected to this appliance must be approved for use in potable water systems.

•Purge the water line to remove all debris and air. Debris will damage the water heater.

•If the appliance will be used as a potable water source, it must not be connected to a system that was previously used with a nonpotable water hea ng appliance.

•Ensure that the water filter on the water heater is clean and installed.

16 |

Value Series Manual |

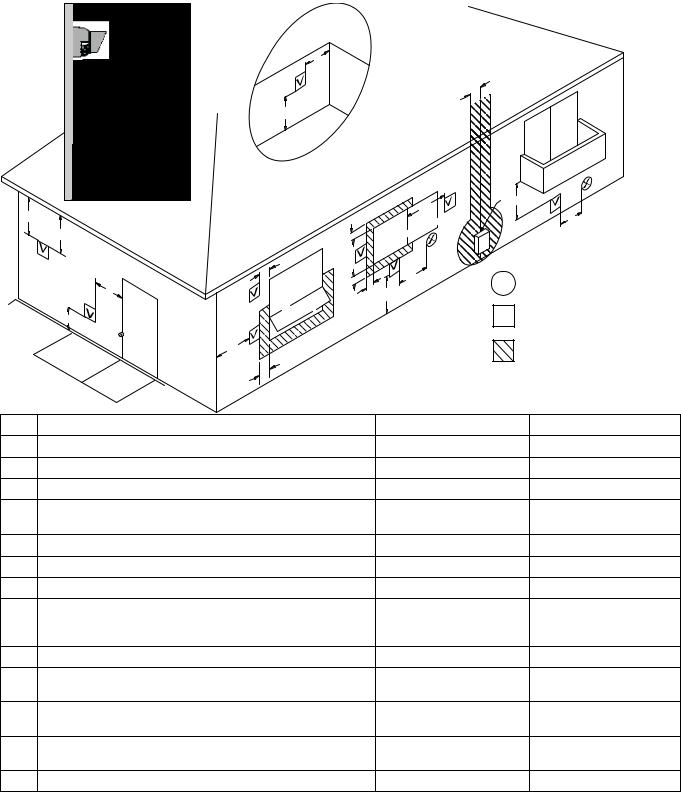

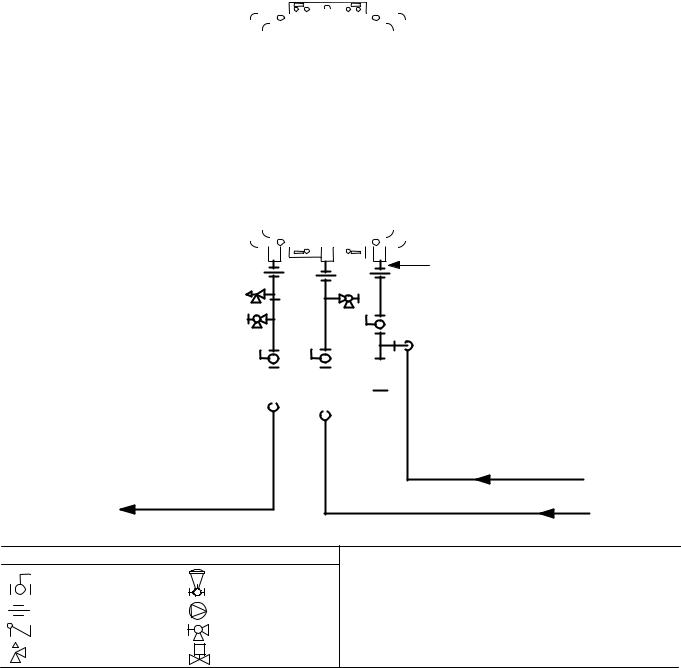

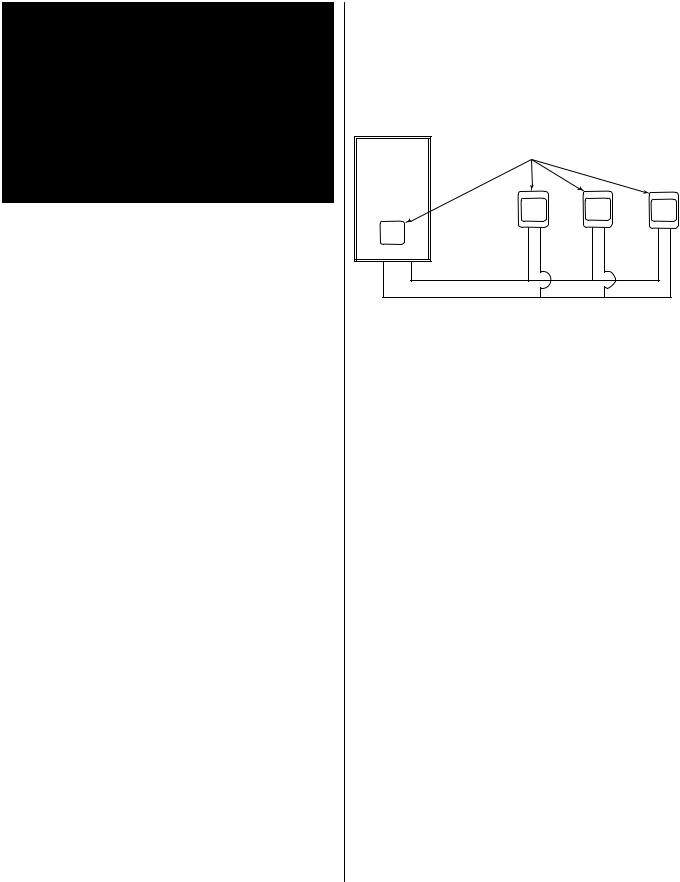

Piping Diagram for Basic Installa on

Rinnai

Water Heater

Rinnai |

|

|

Equipment List |

QTY |

|

Rinnai |

|

|

Water Heaters |

1 |

|

RIK-KIT (Optional) |

1 |

|

(3/4" Fittings Include: |

|

|

2 |

Unions, 2 Ball Valves, |

|

2 |

Drain Valves and |

|

1 |

Pressure Relief Valve.) |

|

|

|

|

3/4" Gas Connection

3/4" Hot Water Supply Line |

|

For Building Fixtures |

|

|

KEY |

3/4" Ball Valve |

Pressure Regulator |

|

|

3/4" Union |

Circulating Pump |

Check Valve |

Boiler Drain Valve |

Pressure Relief Valve |

S Solenoid Valve |

Gas Supply

3/4" Cold Water Supply Line

This is not an engineered drawing. It is intended only as a guide and not as a replacement for professionally engineered project drawings. This drawing is not intended to describe a complete system. It is up to the contractor/engineer to determine the necessary components and configuration of the particular system being installed. This drawing does not imply compliance with local building code requirements. It is the responsibility of the contractor/engineer to ensure installation is in accordance with all local building codes. Confer with local building officials before installation.

Value Series Manual |

17 |

Connect Water Heater to Water Supply

Water connec ons to the tankless water heater should follow all state and local plumbing codes.

If this is a standard installa on, refer to the Piping Diagram for Basic Installa on.

1.Plumb water supply to the tankless water heater on the 3/4” MNPT connec on at the bo om of the unit marked “Water Inlet”, which is the cold water supply.

2.Plumb the building hot water supply to the 3/4” MSPT connec on marked “Water Outlet”, which is the hot water supply.

If a pipe cover will be installed, make sure water lines to the water heater fit.

Checklist for Plumbing

□Purge the water line of all debris and air by closing the hot isola on valve and opening the cold isola on valve and its drain. Debris will damage the water heater. Use a bucket or hose if necessary.

□Ensure that hot and cold water lines are not crossed to the unit and are leak free.

□Ensure that a pressure relief valve is installed with a ra ng that exceeds the BTU input of the water heater model. Refer to the ra ng plate on the side of the water heater for BTU input.

□Clean the inlet water filter by closing the cold and hot water inlet isola on (shut o ) valves. Put a bucket under the filter at the bo om of the water heater to catch any water that is contained inside the unit. Unscrew the water filter. Rinse the filter to remove any debris. Install the filter and open the isola on valves.

□Check for proper water pressure to the water heater. Minimum water pressure is 50 psi. Rinnai recommends 60 80 psi for maximum performance.

Installa on of Gas Supply

WARNING

WARNING

1.If you are not knowledgeable or qualified to install gas lines or connec ons, then contact a licensed professional to install the gas supply.

2.Turn o 120v power supply.

3.Turn o the gas.

4.Gas is flammable. Do not smoke or provide other igni on sources while working with gas.

5.Do not turn on the water heater or gas un l all fumes are gone.

General Instruc ons

MUST DO

•A manual gas control valve must be placed in the gas supply line to the water heater. A union can be used on the connec on above the shut o valve for the future servicing or disconnec on of the unit.

•Check the type of gas and the gas inlet pressure before connec ng the water heater. If the water heater is not of the gas type that the building is supplied with, DO NOT connect the water heater. Contact the dealer for the proper unit to match the gas type.

•Check the gas supply pressure immediately upstream at a loca on provided by the gas company. Supplied gas pressure must be within the limits shown in the Specifica ons sec on with all gas appliances opera ng.

•Before placing the appliance in opera on all joints including the heater must be checked for gas

ghtness by means of leak detector solu on, soap and water, or an equivalent nonflammable

solu on, as applicable. (Since some leak test solu ons, including soap and water, may cause corrosion or stress cracking, the piping shall be rinsed with water a er tes ng, unless it has been determined that the leak test solu on is non corrosive.)

•Use approved connectors to connect the unit to the gas line. Purge the gas line of any debris before connec on to the water heater.

18 |

Value Series Manual |

•Any compound used on the threaded joint of the gas piping shall be a type which resists the ac on of liquefied petroleum gas (propane / LPG).

• The gas supply line shall be gas ght, sized, and so installed as to provide a supply of gas su cient to meet the maximum demand of the heater and all other gas consuming appliances at the loca on without loss of pressure.

INFORMATION

•Refer to an approved pipe sizing chart if in doubt about the size of the gas line.

Size the gas pipe

The gas supply must be capable of handling the en re gas load at the loca on. Gas line sizing is based on gas type, the pressure drop in the system, the gas pressure supplied, and gas line type. For gas pipe siz ing in the United States, refer to the Na onal Fuel Gas Code, NFPA 54. The below informa on is provided as an example. The appropriate table from the applica ble code must be used.

1.For some tables, you will need to determine the cubic feet per hour of gas required by dividing the gas input by the hea ng value of the gas (available from the local gas company). The gas input needs to include all gas products at the lo ca on and the maximum BTU usage at full load when all gas products are in use.

2.Use the table for your gas type and pipe type to

Cubic Feet Gas Input of all gas products (BTU / HR)

per Hour = |

Hea ng Value of Gas (BTU / FT 3 ) |

(CFH) |

|

find the pipe size required. The pipe size must be able to provide the required cubic feet per hour of gas or the required BTU/hour.

Example:

The hea ng value of natural gas for your loca on is 1000 BTU/FT3. The gas input of the V75i is 180,000 BTU/HR. Addi onal appliances at the loca on require 65,000 BTU/hr. Therefore the cubic feet per hour = (180,000 + 65,000) / 1000 = 245 FT3/HR. If the pipe length is 10 feet then the 3/4 inch pipe size is capable of supplying 273 FT3/HR of natural gas.

Pipe Sizing Table Natural Gas

Schedule 40 Metallic Pipe

Inlet Pressure: less than 2 psi (55 inches W.C.) Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

cubic feet per hour

Length |

|

Pipe Size (inches) |

|

||

|

|

|

|

||

3/4 |

1 |

1 1/4 |

1 1/2 |

||

|

|||||

|

|

|

|

|

|

10 |

273 |

514 |

1060 |

1580 |

|

|

|

|

|

|

|

20 |

188 |

353 |

726 |

1090 |

|

|

|

|

|

|

|

30 |

151 |

284 |

583 |

873 |

|

|

|

|

|

|

|

40 |

129 |

243 |

499 |

747 |

|

|

|

|

|

|

|

50 |

114 |

215 |

442 |

662 |

|

|

|

|

|

|

|

60 |

104 |

195 |

400 |

600 |

|

|

|

|

|

|

|

70 |

95 |

179 |

368 |

552 |

|

|

|

|

|

|

|

80 |

89 |

167 |

343 |

514 |

|

|

|

|

|

|

|

90 |

83 |

157 |

322 |

482 |

|

|

|

|

|

|

|

100 |

79 |

148 |

304 |

455 |

|

|

|

|

|

|

|

Pipe Sizing Table Propane Gas

Schedule 40 Metallic Pipe

Inlet Pressure: 11.0 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

Capacity in Thousands of BTU per Hour

Length |

|

Pipe Size (inches) |

|

||

|

|

|

|

||

1/2 |

3/4 |

1 |

1 1/4 |

||

|

|||||

|

|

|

|

|

|

10 |

291 |

608 |

1150 |

2350 |

|

|

|

|

|

|

|

20 |

200 |

418 |

787 |

1620 |

|

|

|

|

|

|

|

30 |

160 |

336 |

632 |

1300 |

|

|

|

|

|

|

|

40 |

137 |

287 |

541 |

1110 |

|

|

|

|

|

|

|

50 |

122 |

255 |

480 |

985 |

|

|

|

|

|

|

|

60 |

110 |

231 |

434 |

892 |

|

|

|

|

|

|

|

80 |

101 |

212 |

400 |

821 |

|

|

|

|

|

|

|

100 |

94 |

197 |

372 |

763 |

|

|

|

|

|

|

|

Value Series Manual |

19 |

Connect Electricity

WARNING

WARNING

Do not use an extension cord or an adapter plug with this appliance.

The water heater must be electrically grounded in accordance with local codes and ordinances or, in the absence of local codes, in accordance with the

Na onal Electrical Code, ANSI/NFPA No. 70.

Indoor water heaters are equipped with a three prong (grounding) plug for your protec on against shock hazard and should be plugged directly into a properly grounded three prong receptacle. Do not cut or remove the grounding terminal from this plug.

Do not rely on the gas or water piping to ground the water heater. A screw is provided in the junc on box for the grounding connec on.

The water heater requires 120 VAC, 60 Hz power from a properly grounded circuit.

If using the 5 foot long power cord, plug it into a standard 3 prong 120 VAC, 60 Hz properly grounded wall outlet.

On outdoor models, a disconnect switch must be provided and installed for the incoming 120 VAC power. It should be a type that is suitable for outdoor use. Check the Na onal Electrical Code, ANSI/NFPA 70 and your local codes for a proper switch type to use in your area.

The wiring diagram is located on the Technical Sheet a ached to the inside of the front cover.

Adjust for High Al tude

For the V75i/e, on the SW1 DIP switch (tan switches), set switches 2 and 3 to the values shown in table below for your al tude. The default se ng for the appliance is 0 2000 (0 610 m) with switches No. 2 and No. 3 in the OFF posi on. When the DIP switch is adjusted, it is not necessary to adjust the gas pressure se ng for high al tude.

|

|

SW1 |

SW1 |

Al |

tude |

Switch No. |

Switch No. |

|

|

2 |

3 |

|

|

|

|

0 2000 |

(0 610 m) |

OFF |

OFF |

|

|

|

|

2001 5200 |

(610 1585 m) |

OFF |

ON |

|

|

|

|

5201 7700 |

(1585 2347 m) |

ON |

OFF |

|

|

|

|

7701 10200 |

(2347 3109 m) |

ON |

ON |

|

|

|

|

The V65i/e is not approved for high al tude opera on.

Adjust for Vent Length

(indoor models only)

Adjust switch No. 1 in the SW1 DIP switch (tan switches) if required. Refer to the sec on “Maximum vent length”.

Checklist for Gas and Electricity

□A manual gas control valve is placed in the gas line to the water heater.

□Check the gas lines and connec ons for leaks.

□Confirm that the gas inlet pressure is within limits.

□Confirm that the water heater is rated for the gas type supplied.

□Confirm that the electricity is supplied from 120 VAC, 60 Hz power source and is in a properly grounded circuit.

□An extension cord or an adapter plug has not been used with the water heater.

□For indoor models verify that switch No. 1 in the SW1 DIP switch (tan switches) has been adjusted for vent length if necessary. Refer to the sec on on Maximum Vent Length.

20 |

Value Series Manual |

Installa on of Temperature Controller

WARNING

WARNING

Turn the power o . Do not a empt to connect the temperature controllers with the power on. Although the controller is a low voltage device, there is 120 volt poten al next to the temperature controller

connec ons inside the unit.

Do not connect the temperature controller to the 120VAC terminals provided for the op onal solenoid drain valves.

Indoor models have their controller built into the front panel. Addi onal controllers can be installed.

Controller Loca on

•The controller should be out of reach of small children.

•Avoid loca ons where the controller may become hot (near the oven or radiant heater).

•Avoid loca ons in direct sunlight. The digital display may be di cult to read in direct sunlight.

•Avoid loca ons where the temperature controller could be splashed with liquids.

•Do not install in loca ons where it can be adjusted by the public.

Cable Lengths and Sizes

The cable for the temperature controller should be a non polarized two core cable with a minimum gauge of 22 AWG. The maximum cable length from each controller to the water heater depends on the total number of wired controllers connected to the water heater.

Number of Wired |

Maximum Cable Length for each |

|

Controllers |

Controller to Water Heater |

|

|

|

|

1 |

328 |

(100 m) |

|

|

|

2 |

164 |

(50 m) |

|

|

|

3 or 4* |

65 |

(20 m) |

|

|

|

* Only 3 addi onal controllers can be wired to the indoor water heater.

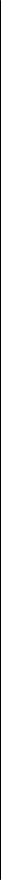

Configura ons

A maximum of 4 temperature controllers can be installed for a water heater or bank of water heaters. This includes the controller built into an indoor water heater. Controllers can only be wired in parallel. Controllers cannot be wired in series.

Rinnai |

Maximum 4 Controllers |

Water |

|

Heater |

|

Wire controllers in parallel

The 4 temperature controllers can consist of mul ple MC 91 2 or MCC 91 2 but only one BC 100V and only one MC 100V.

The clock func on on the BC 100V will only be available if an MC 100V is also connected.

If 4 MC 91 2’s are installed, simultaneously press the Priority and On/O bu ons on the fourth controller un l a beep sounds.

Value Series Manual |

21 |

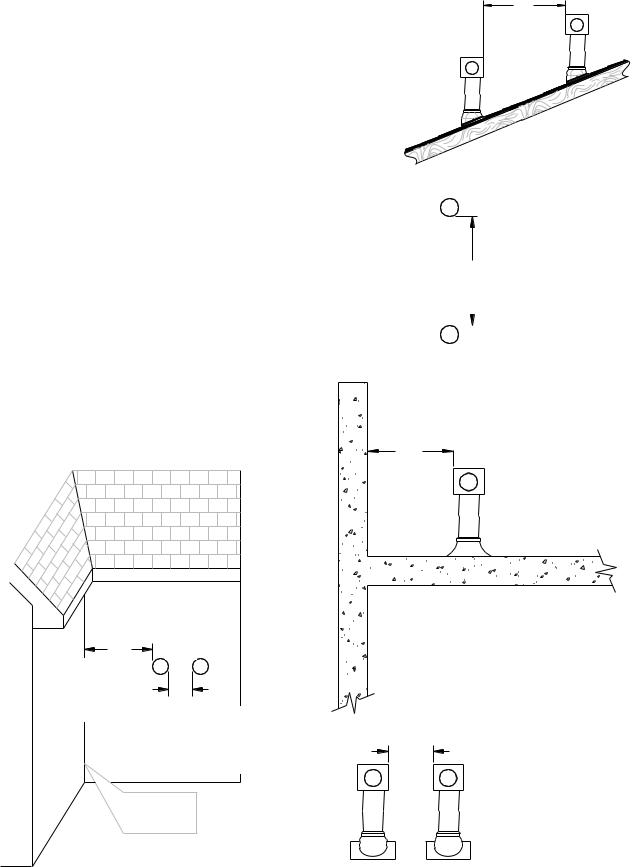

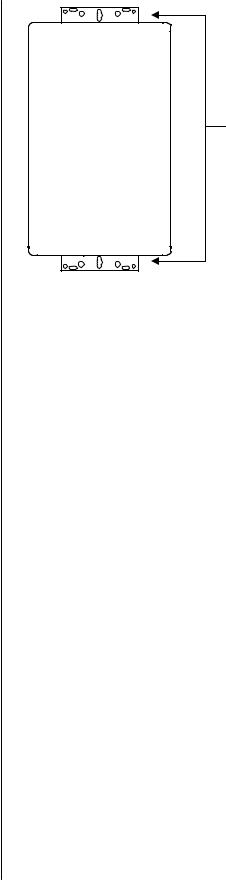

Moun ng the controller

1. Make three holes in the wall as shown.

Outline of Remote

securing screw

1-21/32"

1-21/32"

wiring hole

3-5/16"

securing screw

2.Run the cable between the controller and the water heater or the controller and another controller.

3.Remove the face plate from the temperature controller using a screwdriver.

4.Connect the cable to the temperature controller.

5.Mount the controller to the wall using the holes drilled in step 1.

6.Disconnect the power from the water heater.

7.Remove the plas c cover from the PCB and electrical connec ons.

8.Thread the cable through the access hole at the base of the unit and connect the wires to the controller terminals on the right hand side bo om of the PCB.

9.Secure the controller cable using the clamp provided.

10.Replace plas c cover over PCB and then replace the cover of the water heater.

22 |

Value Series Manual |

Final Checklist

□The water heater is not subject to corrosive compounds in the air.

□The water supply does not contain chemicals or exceeds total hardness that will damage the heat exchanger.

□Clearances from the water heater unit are met.

□Clearances from the vent termina on / air intake are met.

□For indoor models, ensure you have used the correct ven ng products for the model installed and that you have completely followed the

ven ng manufacturer’s installa on instruc ons and these installa on instruc ons.

□For indoor models, verify that the vent system does not exceed the maximum length for the number of elbows used.

□For indoor models verify that switch No. 1 in the SW1 DIP switch (tan switches) has been adjusted for vent length if necessary. Refer to the sec on on Maximum Vent Length.

□For indoor models, verify that the vent pipe has a

downward slope or grade to the outside of 1/4 inch per foot (1.2°) OR if the vent pipe is sloped toward the water heater (as some local codes require), that a condensate collector is installed to allow condensa on to drain away from the water heater to a proper drain source.

□For indoor models, verify that condensate will not be allowed to drain back into the water heater.

□Purge the water line of all debris and air by closing the hot isola on valve and opening the cold isola on valve and its drain. Debris will damage the water heater. Use a bucket or hose if necessary.

□Ensure that hot and cold water lines are not crossed to the unit and are leak free.

□Clean the inlet water filter by closing the cold and hot water inlet isola on (shut o ) valves. Put a bucket under the filter at the bo om of the water heater to catch any water that is contained inside the unit. Unscrew the water filter. Rinse the filter to remove any debris. Install the filter and open the isola on valves.

□Ensure that a pressure relief valve is installed with a ra ng that exceeds the BTU input of the water heater model. Refer to the ra ng plate on the side of the water heater for BTU input.

□A manual gas control valve has been placed in the gas line to the water heater.

□Check the gas lines and connec ons for leaks.

□Confirm that the gas inlet pressure is within limits.

□Confirm that the water heater is rated for the gas type supplied.

□Confirm that the electricity is supplied from a 120 VAC, 60 Hz power source, is in a properly grounded circuit, and turned on.

□Verify the temperature controller is func oning properly.

□For the V75i/e, verify that switches No. 2 and No. 3 in the SW1 DIP switch (tan switches) is set correctly for your al tude.

□Verify the system is func oning correctly by connec ng your manometer to the gas pressure test port on the water heater. Operate all gas appliances in the home or facility at high fire. The inlet gas pressure at the water heater must not drop below that listed on the ra ng plate.

□If the water heater is not needed for immediate use, then drain the water from the heat exchanger.

□Install the front panel.

□Explain to the customer the importance of not blocking the vent termina on or air intake.

□Explain to the customer the opera on of the water heater, safety guidelines, maintenance, and warranty.

□The installa on must conform with local codes or, in the absence of local codes, with the Na onal Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installa on Code, CSA B149.1. If installed in a manufactured home, the installa on must conform with the Manufactured Home Construc on and Safety Standard, Title 24 CFR, Part 3280 and/or CAN/SCA Z240 MH Series, Mobile Homes.

□Leave the en re manual taped to the water heater (indoor models), temperature controller (outdoor models), or give the en re manual directly to the consumer.

Value Series Manual |

23 |

Technical Data

Specifica |

ons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V75i |

|

V65i |

|

|

V75e |

|

V65e |

|

|

|

|

|

|

|

|

|

|

||

Minimum Gas Consump on Btu/h |

|

10,300 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

Maximum Gas Consump on Btu/h |

180,000 |

|

150,000 |

|

|

180,000 |

|

150,000 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

Hot water capacity (Min Max) * |

0.26 7.5 GPM |

|

0.26 6.6 GPM |

|

0.26 7.5 GPM |

|

0.26 6.6 GPM |

||||

(1.0 28.5 L/min) |

|

(1.0 25.0 L/min) |

|

(1.0 28.5 L/min) |

|

(1.0 25.0 L/min) |

|||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

Temperature Se |

ng (no controller) |

|

|

120° F (49° C) or 140° F (60° C) |

|

||||||

|

|

|

|

|

|

||||||

Maximum Temp Se |

ng (residen al) |

|

|

Selectable at 120° F (49° C) or at 140° F (60° C) |

|

||||||

|

|

|

|

|

|

|

|

||||

Minimum Temperature Se |

ng |

|

|

98° F (37° C) |

|

|

|

||||

|

|

|

|

|

|

|

|||||

Weight |

|

|

|

45.6 lb (20.7 kg) |

|

|

43.6 lb (19.8 kg) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

Energy Factor |

|

|

|

|

0.82 |

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

Noise level |

|

|

|

|

|

49 dB (excluding start up or shutdown) |

|

||||

|

|

|

|

|

|

|

|

|

|||

|

|

Normal |

76 W |

|

76 W |

|

|

57 W |

|

57 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical |

|

Standby |

|

|

2 W |

|

|

|

|

||

Consump on |

|

|

|

|

|

|

|

|

|

|

|

|

An frost |

|

120 W |

|

|

104 W |

|

||||

|

|

|

|

|

|

||||||

|

|

Protec |

on |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

By Pass Control |

|

|

|

|

|

Fixed |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Gas Supply Pressure |

Natural Gas |

|

|

5.0 10.5 inch W.C. |

|

||||||

|

|

|

|

|

|

|

|

|

|

||

Propane |

|

|

8.0 13.5 inch W.C. |

|

|||||||

|

|

|

|

|

|||||||

|

|

|

|

|

|||||||

Type of Appliance |

|

|

Direct Vent, Tankless, Temperature controlled con |

nuous flow gas hot water system |

|||||||

|

|

|

|

|

|||||||

Connec ons |

|

|

|

Gas Supply: 3/4" MNPT, Cold Water Inlet: 3/4" MNPT, Hot Water Outlet: 3/4" MNPT |

|||||||

|

|

|

|

|

|

|

|

|

|||

Igni on System |

|

|

|

|

|

Direct Electronic Igni |

on |

|

|||

|

|

|

|

|

|

|

|

||||

Electric Connec |

ons |

|

|

|

|

Appliance: AC 120 Volts, 60Hz. |

|

||||

|

|

|

|

Temperature Controller: DC 12 Volts (Digital) |

|

||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

||||||

Water Temperature Control |

|

|

|

Simula on Feedforward and Feedback |

|

||||||

|

|

|

|||||||||

Water Supply Pressure |

|

Minimum Water Pressure: 50 PSI (Recommended 60 80 PSI for maximum performance) |

|||||||||

|

|

|

|

|

|

|

|

||||

Maximum Water Supply Pressure |

|

|

150 PSI |

|

|

|

|

||||

|

|

|

|

|

|||||||

Temperature Control Cable |

|

|

Non Polarized Two Core Cable (Minimum 22 AWG) |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||

Energy Star Qualified |

|

|

|

|

Yes |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Cer fied for installa |

on in |

|

|

|

Yes |

|

|

|

|

||

manufactured (mobile) homes |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|||||||

NOx |

|

|

|

Complies with South Coast Air Quality Management District 14 ng/J or 20 ppm NOx emission |

|||||||

|

|

|

levels |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* Minimum flow may vary slightly depending on the temperature se ng and the inlet water temperature. Minimum ac va on flow is 0.4 GPM (1.5 L/min).

Our products are con nually being updated and improved; therefore, specifica ons are subject to change without prior no ce.

The maximum inlet gas pressure must not exceed the value specified by the manufacturer. The minimum value listed is for the purpose of input adjustment.

24 |

Value Series Manual |

Loading...

Loading...