Rinnai Q85SN, Q85SP, Q175SP, Q205SP, Q175SN User Manual

...

I n s t a l l a t i o n & S e r v i c i n g Instructions

High efficiency condensing gas boiler

Q85SN/Q130SN/Q175SN/Q205SN/Q175CN

Q85SP/Q130SP/Q175SP/Q205SP/Q175CP

Pictured: Q85SN, Q130SN

Q85SP, Q130SP

CAUTION!

Read this manual thoroughly before installing, servicing, putting into operation or using this boiler and vent system.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury (exposure of hazardous materials)* or loss of life. Refer to the user's information manual provided with this boiler. Installation and service must be performed by a licensed professional, service agency or the gas supplier (who must read and follow the supplied instructions before installing, servicing, or removing this boiler).

CAUTION!

The user manual is part of the documentation that is delivered to the installation's operator. Go through the information in this manual with the owner/operator and make sure that they are familiar with all necessary operating instructions.

NOTICE!

Installation and service must be performed by a licensed professional, service technician or the gas supplier.

|

|

|

|

|

WARNING! |

|

|

|

If you do not follow these instructions exactly, a fire or explosion |

|

|

|

may result causing property damage, personal injury or loss of life. |

|

|

|

- Do not store or use gasoline or other flammable vapors and |

|

|

|

liquids in the vicinity of this or any other appliance. |

|

|

|

- WHAT TO DO IF YOU SMELL GAS |

|

|

|

- Do NOT try to light any appliance. |

reserved. |

|

|

- Do NOT touch any electrical switch. |

||

|

|

||

|

- Do NOT use any phone in your building. |

|

|

|

- Immediately call your gas supplier from a neighbor’s phone. |

Changes |

|

|

Follow the gas supplier’s instructions. |

||

|

|

||

|

- If you cannot reach your gas supplier, call the fire department. |

|

|

|

|

|

|

Address: 103 International Drive, Peachtree City, GA, 30269 Toll-free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

8W.51.40.06 / 10.13

8W.51.40.06 / 10.13

These instructions to be retained by user.

Français: voir page 101

Contents of instructions

These installation instructions contain important information for the safe installation, start-up and maintenance of boilers with capacities 85,000 through 205,000 BTU/hr.

These installation instructions are intended for licensed professionals, who have the necessary knowledge and are approved for working on heating and gas systems.

Subject to technical changes

Changes may be made without notice to the illustrations, process steps and technical data as a result of our policy of continuous improvement.

Updating of documentation

Please contact us if you have any suggestions for improvements or corrections.

Find our contact details on the back of this manual.

Installation & Servicing Instructions Rinnai Q-Series

2

Content

1 Safety and general instructions........................................................ |

4 |

||

|

1.1 |

Designated use ................................................................... |

4 |

|

1.2 |

Hazard definitions................................................................ |

4 |

|

1.3 |

Symbol definitions ............................................................... |

4 |

|

1.4 |

The following instructions must be followed ........................ |

5 |

|

1.5 |

Follow these instructions for the space heating water......... |

6 |

|

1.6 |

Tools, materials and additional equipment .......................... |

6 |

|

1.7 |

Relevant Installation, Service and User manuals................ |

6 |

|

1.8 |

Disposal ........................................................................... |

7 |

2 |

Regulations and guidelines.............................................................. |

7 |

|

3 Description of the boiler ................................................................... |

8 |

||

4 |

Packaging and transportation .......................................................... |

9 |

|

|

4.1 |

Scope of delivery................................................................. |

9 |

|

4.2 |

Transportation ..................................................................... |

9 |

5 |

Installation ......................................................................... |

10 |

|

|

5.1 |

Requirements for the installation room............................. |

10 |

|

5.2 |

Fitting the boiler................................................................. |

11 |

|

5.3 |

Dimensions........................................................................ |

12 |

|

5.3.1 |

Plumbing Kits..................................................................... |

15 |

|

5.3.2 |

Clearences from the boiler ................................................ |

16 |

|

5.4 |

Technical specifications..................................................... |

17 |

6 |

Connecting the boiler ..................................................................... |

18 |

|

|

6.1 |

Central heating system...................................................... |

18 |

|

6.1.1 |

Plumbing Kits and installation ........................................... |

20 |

|

6.1.2 |

Side mounting kit for the Low Loss Header....................... |

24 |

|

6.1.3 |

Safety valve....................................................................... |

24 |

|

6.1.4 |

Low water cut off ............................................................... |

24 |

|

6.2 |

Boiler expansion tank ........................................................ |

25 |

|

6.3 |

Underfloor heating system (plastic pipes)........................... |

25 |

|

6.4 |

Gas connection ................................................................. |

26 |

|

6.5 |

Hot water supply (Combi boiler Q175CNQ175CP) ........... |

28 |

|

6.5.1 |

Domestic Water quality...................................................... |

28 |

|

6.5.2 |

Domestic water treatment Accessory ................................ |

29 |

|

6.5.3 |

DHW Expansion Tank........................................................ |

29 |

|

6.5.4 |

Installing a valve kit ........................................................... |

29 |

|

6.5.5 |

Pressure relief Valve for Combi boilers ............................. |

30 |

|

6.6 |

Condensate drain pipe ...................................................... |

30 |

|

6.7 |

Vent system and air supply system ................................... |

31 |

|

6.7.1 |

Intake / Exhaust Guidelines............................................... |

31 |

|

6.7.2a |

Examples vent and air supply systems (concentric) ......... |

32 |

|

6.7.2b |

Examples vent and air supply systems (parallel) .............. |

33 |

|

6.7.3 |

Installation of the vent system ........................................... |

34 |

|

6.7.3.1 |

Boiler conversion from concentric to parallel .................... |

35 |

|

6.7.3.2 |

Installing air filter ............................................................... |

35 |

|

6.7.4 |

Recommended vent/air intake terminal position ............... |

36 |

|

6.7.5 |

Direct vent closet and alcove installation ........................ |

38 |

|

6.7.6 |

Dimensioning of the exhaust and air intake duct ............. |

39 |

|

6.7.7 |

Combustion air and vent piping lengths. ........................... |

40 |

|

6.7.8 |

Calculation of compensation factor ................................... |

41 |

|

6.7.9 |

Room Air System (indoor combustion air)......................... |

42 |

7 |

External domestic hot water tanks ................................................. |

45 |

|

8 |

Electrical connections .................................................................... |

45 |

|

9 |

Boiler controls ......................................................................... |

49 |

|

|

9.1 |

Explanation of the function buttons ................................... |

50 |

10 |

Starting up: Filling and de-aerating the boiler and installation ....... |

51 |

|

|

10.1 |

Requirements of the water system.................................... |

51 |

|

10.2 |

Filling the heating system.................................................. |

52 |

|

10.3 |

Hot water supply (only Q175C) ......................................... |

53 |

11 |

Adjustments ......................................................................... |

55 |

|

|

11.1 |

Altering adjustments.......................................................... |

55 |

|

11.2 |

Activating factory settings (green button function) ........... |

58 |

12 |

Isolating the boiler......................................................................... |

58 |

|

13 |

Commissioning ......................................................................... |

59 |

|

|

13.1 |

Testing for gas leaks.......................................................... |

60 |

|

13.2 |

Testing the Ignition Safety shut off device ......................... |

60 |

|

13.3 |

Checking the O2................................................................. |

61 |

|

13.4 |

Measuring the ionization current ....................................... |

62 |

|

13.5 |

Installing the casing........................................................... |

63 |

14 |

Maintenance ......................................................................... |

63 |

|

|

14.1 |

Periodic examination of venting systems and boiler ......... |

63 |

|

14.2 |

Inspection ......................................................................... |

63 |

|

14.3 |

Maintenance activities ....................................................... |

65 |

|

14.3.1 |

Reset service interval counter ........................................... |

67 |

|

14.4 |

Limited warranty ................................................................ |

67 |

15 |

Parts of the boiler ......................................................................... |

68 |

|

16 |

Blocks and Errors ......................................................................... |

69 |

|

17 |

Spare parts ......................................................................... |

77 |

|

18 |

Parts list vent system ..................................................................... |

89 |

|

19 |

Common venting guidelines........................................................... |

90 |

|

Appendix A - Outoor Reset Sensor Data ............................................. |

91 |

||

Appendix B - Resistance table NTC sensors....................................... |

92 |

||

Installation & Servicing Instructions Rinnai Q-Series

3

Installation & Servicing Instructions Rinnai Q-Series

1 Safety and general instructions

Please observe these instructions in the interest of your own safety.

1.1 Designated use

The boiler is designed for heating water for a central heating system and, if applicable, generating domestic hot water. The boiler is delivered with a burner controller (MCBA) pre-installed.The boiler can be fitted with a modulating outdoor reset sensor ARV12 (included with the boiler) or an On/Off thermostat or relay panel end switch (accessories).

1.2 Hazard definitions

|

The following defined terms are used throughout the documentation to bring attention |

|

to the presence of hazards of various risk levels. Notices give important information |

|

concerning the operation of the product. |

! DANGER |

DANGER: |

|

Indicates the presence of hazards that will cause severe personal injury, death or |

|

substantial property damage. |

!WARNING

!CAUTION

CAUTION

CAUTION

i NOTICE

WARNING:

Indicates the presence of hazards that can cause severe personal injury, death or substantial property damage.

CAUTION:

Indicates presence of hazards that will or can cause minor personal injury or property damage.

CAUTION:

Risk of electric shock. Indicates presence of hazards due to electric shock.

NOTICE:

Indicates special instructions on installation, operation or maintenance that are important but not related to personal injury or property damage.

1.3 Symbol definitions

The following (safety) symbols may be encountered in these installation instructions and on the unit:

Thissymbolindicatesthattheunitmustbestoredawayfromfreezingconditions.

This symbol indicates that the packaging and/or contents can be damaged as a result of insufficient care taken during transport.

This symbol indicates that, while still in its packaging, the unit must be protected from weather conditions during transport and storage.

4

1.4The following instructions must be followed

-The boiler must only be used for its designated purpose, as described in the Installation Instructions.

-Each unit is fitted with a data plate. Consult the details on this plate to verify whether the boiler is compliant with its intended location, e.g.: gas type, power source and venting classification.

-Only use the boiler with the accessories and spare parts listed.

-Other combinations, accessories and consumables may only be used if they are specifically designed for the intended application and do not affect the system performance and the safety requirements.

-Maintenance and repairs must be performed by a licensed professional.

-Installation of a condensing gas boiler must be reported to the relevant gas utility company and have it approved.

-You are only allowed to operate the condensing gas boiler with the vent system that has been specifically designed and approved for this type of boiler.

-Please note that local permission for the vent system and the condensate water connection to the public sewer system may be required.

You must also respect:

-The local building codes stipulating the installation rules.

-The local building codes concerning the air intake and outlet systems and the chimney connection.

-The regulations for the power supply connection.

-The technical rules established by the gas utility company concerning the connection of the gas connection to the local gas mains.

-The instructions and standards concerning the safety equipment for the water/ space heating system.

-The Installation Instructions for building heating systems.

-The boiler must be located in an area where leakage of the boiler or connections will not result in damage to the area adjacent to the boiler or to lower floors of the structure. When such locations cannot be avoided, it is recommended that a suitable drain pan be installed under the boiler.

-The boiler must be installed in such way that the all components are protected from water (dripping, spraying, rain etc.) during boiler operation and service.

-The boiler must not be installed on or against carpeting.

-Do not restrict or seal any air intake or outlet openings.

-If you find any defects, you must inform the owner of the system of the defect and the associated hazard in writing.

!

!

WARNING

DANGER

In failure to properly commission the boiler as described in section 13 may result unreliable burner operation, reduced component life, and unsafe boiler operation.

DANGER. Gas is flammable and may cause an explosion. Beware if you smell gas: there may be an explosion hazard!

If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

-Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

! |

WARNING |

WHAT TO DO IF YOU SMELL GAS |

|

|

- Do NOT try to light any appliance. |

|

|

- Do NOT touch any electrical switch. |

|

|

- Do NOT use any phone in your building. |

|

|

- Immediately call your gas supplier from a neighbor’s phone. Follow the gas |

|

|

supplier’s instructions. |

|

|

- If you cannot reach your gas supllier, call the fire department. |

! |

WARNING |

Should overheating occur or the gas supply fail to shut off, do not turn off or |

disconnect the electrical supply to the pump. Instead, shut off the gas supply |

||

|

|

at a location external to the boiler. |

Installation & Servicing Instructions Rinnai Q-Series

5

Installation & Servicing Instructions Rinnai Q-Series

i NOTICE |

Chemicals that are corrosive in nature should not be stored or used near the |

boiler or vent termination. |

1.5 Follow these instructions for the space heating water

Unsuitable heating system water can cause the formation of scale or sludge, which affects system efficiency. It can also cause corrosion and reduce life of the heat exchanger.

–You must follow Rinnai guidelines for boiler water quality.

–Thoroughly flush the system prior to filling.

–Follow the Rinnai cleaning instructions.

–Never use water that has been treated by a reverse osmosis, D.I., or distilled water to soften the water to fill the heating system.

–Do not use inhibitors or other additives unless approved by Rinnai for that purpose.

–When freeze protection of the heating system is desired, only use Rinnai-approved antifreezes. The allowed maximum concentration is 50%.

–When using oxygen-permeable pipes, e. g. for under floor heating systems, you must separate the system from the boiler using plate heat exchangers.

–Valve off boiler while flushing system, do not introduce any system cleaner into the boiler loop. Flush system thoroughly to remove all system cleaner before filling boiler.

Approved antifreeze: |

• Rhomar RhoGard Mutli-Metal (AL safe) |

• Sentinel X500 |

(max. concentration 50%) |

• Noble Noburst AL |

• Fernox Alphi 11 |

Approved system cleaner: |

• Noble Noburst Hydronic System Cleaner |

• Fernox F3 Cleaner |

|

• Rhomar Hydro-Solv 9100 |

• Sentinel X400 |

i |

NOTICE |

The system cleaners from NoBurst, Rhomar, and Fernox are not to be used in |

||

the boiler. The boiler must be closed off (valved off) from the rest of the system |

||||

|

|

or not connected while the cleaners are in the system. The system should then |

||

|

|

be drained and then thoroughly flushed with clean water to remove all the |

||

|

|

system cleaner. |

|

|

|

Approved inhibitors: • Rhomar Pro-tek 922 |

• Sentinel X100 |

||

|

|

• Noble Noburst AL inhibitor |

|

|

|

|

|

||

|

|

See the Rinnai Boiler Applications Manual or Chapter 6 and 10 of this manual for |

||

|

|

additional information. |

|

|

|

|

|

||

i |

NOTICE |

If problems occur when using sanitary water with a chlorine content |

||

higher than 150 mg/l, no recourse can be made to the terms of the limited |

||||

|

|

|||

warranty.

1.6 Tools, materials and additional equipment

For the installation and maintenance of the boiler you will need:

–Standard tools for space heating, gas and water fitting

–Digital manometer that is capable of reading both positive and negative pressures

–Combustion analyzer (intended for use with condensing boilers)

–Digital multimeter

–pH digital meter

–Metric Allen wrenches

–Metric socket wrenches

In addition, a handtruck with a fastening belt is useful.

For maintenance of the boiler you will need, apart from standard tools for space heating, gas and water fittings the following items:

-Rinnai toolkit Q and E-Series

6

1.7Relevant Installation, Service and User manuals

–Approved vent system

–Rinnai Boiler Applications Manual

–User manual

1.8Disposal

–Dispose of the boiler packaging in an environmentally sound manner.

–Dispose of components of the heating system (e.g. boiler or control device), that must be replaced in an environmentally responsible manner.

2 Regulations and guidelines

The installation must comply to the requirements of the authority having jurisdiction or, in the absence of such requirements, to the latest edition of the National Fuel Gas Code, ANSI Z223.1/NFPA 54. In Canada, installation must be in accordance with the requirements of CAN/CSA B149.1, Natural Gas and Propane Installation Code.

Where required by the authority having jurisdiction, the installation must comply to the Standard for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ ASME CSD-1.

Install CO detectors per local regulations. Boiler requires an inspection every 2 years or 4000 hours and maintenance every 4 years or 8000 hours. See maintenance section chapter 14.

Operating Limits of the boiler:

Max. boiler temperature: 176 °F (80 °C)

Max. operating pressure: 45 psi (3 bar)

Max. Allowable Working Temperature ASME: 200 °F (93 °C)

Max. Allowable Working Pressure ASME: 45 psi (3 bar)

The hot water distribution system must comply with all applicable codes and regulations. When replacing an existing boiler, it is important to check the condition of the entire hot water distribution system to ensure safe operation.

Installation & Servicing Instructions Rinnai Q-Series

7

3 Description of the boiler

Room sealed boiler

The boiler retreives its combustion air from outside then discharges the flue gasses to the outside.

Condensing

Retrieves heat as much as possible from the flue gasses.

Water condensates on the heat exchanger.

Modulating

Stepless higher or lower burning according to the heat demand.

Different boilertypes:

The Rinnai Q boiler is a room sealed, condensing and modulating central heating boiler, with an optional integrated DHW cylinder (integrated DHW on the Q175C only). The QxxS boiler models have the ability to control a domestic hot water indirect tank.

The boiler is provided with a compact stainless steel heat exchanger with smooth tubes. This design is a well engineered principle using durable materials.

The boiler burns gas for supplying heat. The heat is transferred in the heat exchanger to the water in the central heating system. By cooling down the exhaust gases condensate is formed. This results in high efficiency. The condensate, which has no effect on the heat exchanger and the function of the boiler, is drained through a condensate collector trap.

The boiler is provided with an intelligent control system (CMS Control Management System). The boiler anticipates the heat demand of the central heating system or the domestic hot water facility system.

When an outdoor sensor is connected to the boiler it will operate weather dependantly using outdoor reset. This means that the boiler control measures the outside temperature and supply temperature. With this data the boiler calculates the optimal supply temperature for the installation.

Explanation of the type indication: |

Rinnai Q205SN |

||||||||||||||||||||||||

|

|

|

|

Q = Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

205 = Nominal load in (x1,000) BTU |

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

||||||||||||||||||||||

|

|

|

|

S = System/Solo (C = Combi) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

N = Natural Gas (P = Propane Gas) |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation & Servicing Instructions Rinnai Q-Series

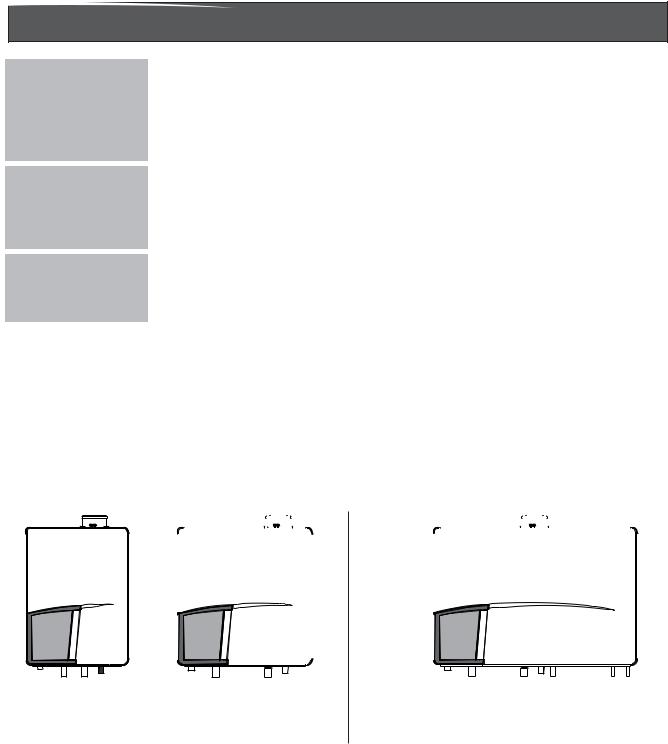

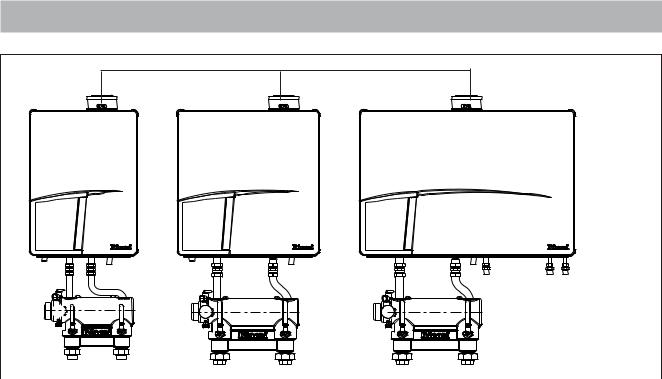

System/Solo boilers: |

|

Q85SN, Q130SN |

Q175SN, Q205SN |

Q85SP, Q130SP |

Q175SP, Q205SP |

Combi boiler with integrated DHW cylinder Q175CN

Q175CP

8

4 Packaging and transportation

4.1 Scope of delivery

The boiler is supplied ready for use.

•Please check if the packaging is intact.

•Check if all the items listed are included in the delivery.

The supply kit contents:

|

Description |

|

Amount |

|

|

|

|

Q85S |

Q175S |

|

|

|

|

Q130S Q205S Q175C |

|

||

|

Boiler with: |

|

|

|

|

|

Outdoor reset sensor ARV12 |

1 |

1 |

1 |

|

|

Compression ring Ø15 brass |

|

|

4 |

|

|

Compression ring Ø22 brass |

|

|

2 |

|

|

Compression ring Ø28 brass |

2 |

|

|

|

|

Compression ring Ø35 brass |

|

2 |

2 |

|

|

Bolt M5X16mm |

1 |

1 |

1 |

|

|

Cover air supply Ø120/Ø80 |

1 |

1 |

1 |

|

|

Gasket vent system ø80 |

1 |

1 |

1 |

|

|

Power cable pull safety Q-Series |

1 |

1 |

1 |

|

|

Flue pipe Ø 80 PP |

1 |

1 |

1 |

|

|

Nut 15mm compression fitting |

|

|

2 |

|

|

Nut W1.1/8x1/14 22 Compression fitting |

|

|

1 |

|

|

Nut W1.3/8"x1/14 28 compression fitting |

2 |

|

|

|

|

Nut W1.610x1/14 35 compression fitting |

|

2 |

2 |

|

|

Screw 6X60mm |

5 |

5 |

5 |

|

|

Lip-ring flue pipe ø80 |

1 |

1 |

1 |

|

|

Feed through + plug flue gas |

1 |

1 |

1 |

|

|

Cap de-aerator |

1 |

1 |

1 |

|

|

Adapter fitting 15mm x 3/4"NPT ext. |

|

|

2 |

|

|

Adapter fitting 22mm x 3/4"NPT ext. |

|

|

1 |

|

|

Flue adapter Ø80/Ø3" pps UL appr. |

2 |

2 |

2 |

|

|

Flow restriction MR01 FG 21,0L red |

|

|

1 |

|

|

Wall mounting suspension bracket |

1 |

1 |

1 |

|

|

Plumbing kit Q85S/Q130S |

1 |

1 |

|

|

|

Plumbing kit Q175S/Q175C/Q205S |

|

|

1 |

|

|

3/4" Gas valve |

1 |

1 |

1 |

|

|

Template on inside of package |

1 |

1 |

1 |

|

|

Installation & Service Instructions |

1 |

1 |

1 |

|

|

User information manual |

1 |

1 |

1 |

|

|

Warranty document |

1 |

1 |

1 |

|

|

ICSL book |

1 |

1 |

1 |

|

|

|

|

|

|

|

4.2 Transportation |

|

|

|

|

|

! CAUTION |

The boiler may be damaged when not secured properly. |

|

|

||

-Only transport the boiler using appropriate transportation equipment, such as a handtruck with a fastening belt or special equipment for maneuvering steps.

-When shipping the boiler must be secured on the transportation equipment to prevent it from falling off.

-Protect all parts against impacts if they are to be transported.

-Follow the transportation markings on the packaging.

•Packaged boilers must always be lifted and carried by two people, or you must use a handtruck or special equipment for transport.

Installation & Servicing Instructions Rinnai Q-Series

9

Installation & Servicing Instructions Rinnai Q-Series

5Installation

5.1Requirements for the installation room

! DANGER |

- The room where the boiler will be placed must always be free from freezing |

conditions. |

-Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

-Never use or store any chlorinated detergents or halogenated hydrocarbons (e.g. in spraycans, solvents and detergents, paints, adhesives) in proximity of the boiler.

-The boiler must be installed in such a way that it is protected from water (dripping, spraying, rain, etc.) during operation and service (circulator replacement, condensate trap, control replacement, etc.)

-This boiler is for intended for indoor installations only.

Products to avoid present in boiler room and/or around combustion air intake

Spray cans containing chloro-/fluorcarbons Ammonium and/or ammonium solutions Permanent wave solutions (hair product) Chlorinated waxes and/or cleaners Swimming pool chemicals based on chlorine Calcium chloride used for thawing

Sodium chloride used for water softening Refrigerant leaks

Paint or varnish removers Hydrochloric acid/muriatic acid Cements and glues

Antistatic fabric softeners used in clothes dryers Chlorine-type bleaches, detergents, and cleaning solvents found in household laundry rooms

Adhesives used to fasten building products and other similar products

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

10

5.2 Fitting the boiler

i

i

!

!

NOTICE

NOTICE

CAUTION

WARNING

-Remove the packaging materials.

-Do not tear the packaging. Take notice of the presence of the mounting template at the inside of the carton wrapper.

-Lay the boiler on its back during unpacking. When unpacking, the casing can be removed from the boiler. This part can be kept apart during installation. It must be placed on the boiler and fixed with the screw behind the door before the boiler is started up.

Turn the boiler to its side and remove the wall bracket from the back of the boiler by removing the 2 screws.

The boiler can be mounted practically to any wall with the suspension bracket and the enclosed mounting equipment.

-The wall must be flat and of sufficient strength in order to be able to securely hold and support the boiler weight with its water content.

-Take note of the necessary space around the boiler for installation of venting system, pipework and servicing. See drawing in section 5.3.

The location of the boiler can be determined by using the template which is printed on the inside the boiler package wrapping. Remember to account for the spacing of the plumbing kit.

-Drill the necessary holes using the template

-Install the mounting bracket to the wall using the supplied mounting materials

Lifting and carrying precautions.

To avoid personal injury please follow these recommendations:

-Always lift the boiler with 2 people or use special equipment.

-When lifting the boiler, bend the knees, and keep the back straight and feet apart.

-Do not lift and twist at the same time.

-Lift and carry the boiler close to the body.

-Wear protective clothing and gloves to protect from any sharp edges.

Lift the boiler only by the boiler's rear wall. Do not lift using the pipes on the bottom of the boiler or the vent connections on the top of the boiler.

-Dispose the packaging materials.

Installation & Servicing Instructions Rinnai Q-Series

11

Installation & Servicing Instructions Rinnai Q-Series

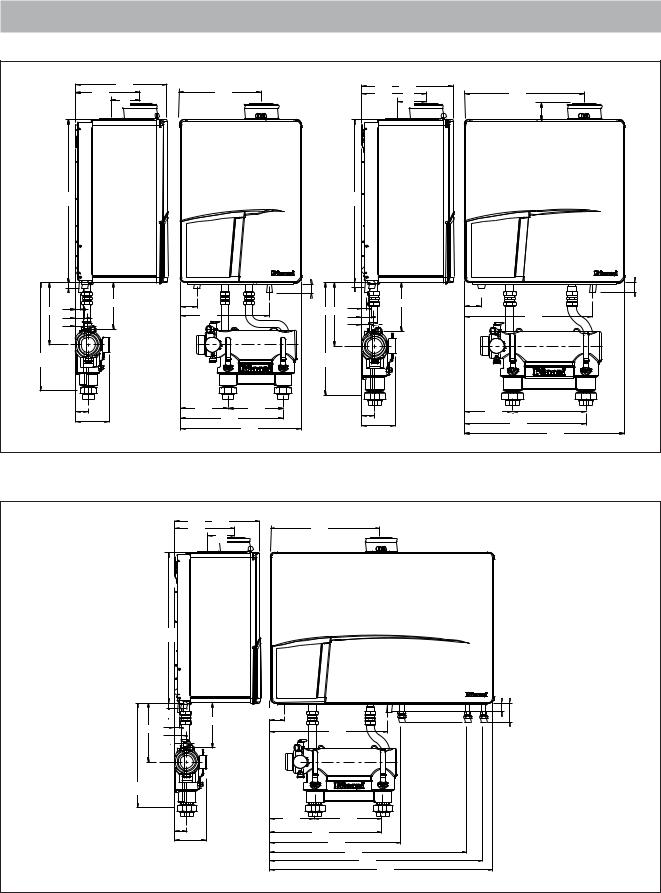

5.3 Dimensions

|

|

F |

C |

|

|

D |

|

|

|

F |

C |

|

D |

|

|

|

|

E |

|

|

|

|

|

E |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

P |

|

|

|

G |

|

|

|

Q |

P |

|

|

G |

|

Q |

|

|

X |

|

|

|

|

|

X |

|

|

|

||||

Y |

T |

|

|

K |

|

|

Y |

T |

|

|

|

||||

U |

|

|

|

|

|

|

U |

|

|

|

|

K |

|||

|

V1 |

|

|

|

|

|

|

|

|

V1 |

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

V2 |

|

|

H |

|

Z |

|

|

V2 |

|

H |

|

|

|

|

|

aa |

|

|

|

|

J |

B |

|

|

aa |

|

J |

|

|

|

|

|

|

|

|

|

|

|

|

B |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

dimensions Q85S, Q130S, Q175S and Q205S |

|

|

|

|

|

|

|

|

figure 1 |

||||||

|

|

|

|

|

F |

C |

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

|

X |

|

G |

|

|

|

|

|

Q S |

|

|

|

|

Y |

T |

|

|

|

K |

|

|

|

|

|

|

|

|

|

|

U |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

V1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V2aa |

|

|

H |

J |

Z |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

L N |

O B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

dimensions Q175C |

figure 2 |

12

Dimensions

|

|

Boiler type |

Solo |

Combi |

|

|

|

|

|

Q85SN/Q85SP |

Q175SN/Q175SP |

|

|

|

|

|

Q130SN/Q130SP |

Q205SN/Q205SP |

Q175CN/Q175CP |

|

|

|

|

inch / mm |

inch / mm |

inch / mm |

|

|

A |

Height |

26.8" / 680 |

26.8" / 680 |

26.8" / 680 |

|

|

B |

Width |

19.7" / 500 |

26" / 660 |

39.4" / 1000 |

|

|

C |

Depth |

15.2" / 385 |

15.2" / 385 |

15.2" / 385 |

|

|

D |

Left side / vent |

13.2" / 335 |

19.5" / 495 |

19.5" / 496 |

|

|

E |

Center to center / vent and air supply |

4.7" / 120 |

4.7" / 121 |

4.7" / 122 |

|

|

F |

Back / vent |

10.6" / 270 |

10.6" / 270 |

10.6" / 270 |

|

|

G |

Left side / gas pipe |

2.6" / 65 |

2.6" / 65 |

2.6" / 65 |

|

|

H |

Left side / supply pipe |

7.8" / 199 |

7.8" / 199 |

7.8" / 199 |

|

|

J |

Left side / return pipe |

16.8" / 428 |

19.8" / 504 |

19.8" / 504 |

|

|

K |

Left side / condensate pipe |

14.6" / 370 |

20.9" / 530 |

20.9" / 530 |

|

|

L |

Left side / expansion pipe |

|

|

23.2" / 590 |

|

|

N |

Left side / cold water pipe |

|

|

34.8" / 885 |

|

|

O |

Left side / hot water pipe |

|

|

37.6" / 955 |

|

|

P |

Pipe length of g* |

0.7" / 18 |

0.7" / 18 |

0.7" / 18 |

|

|

Q |

Pipe length of c* |

2" / 50 |

2" / 50 |

2" / 50 |

|

|

R |

Pipe length of f and r* |

17.7" / 450 |

18.5" / 470 |

18.5" / 470 |

|

|

S |

Pipe length of e, k and w* |

|

|

3.5" /89 |

|

|

T |

Back / Center of pipe c* |

1" / 25 |

1" / 25 |

1" / 25 |

|

|

U |

Back / Center of pipe g* |

1.6" / 40 |

1.6" / 40 |

1.6" / 40 |

|

|

V1 |

Back / Center of pipe f, r, e, k and w* |

2" / 50 |

2" / 50 |

2" / 50 |

|

|

V2 |

Back / Center of pipe f and r* |

2.1" / 54 |

2.1" / 54 |

2.1" / 54 |

|

|

W |

Pipe length vent co-axial |

2.6" / 65 |

2.6" / 65 |

2.6" / 65 |

|

|

|

Pipe length vent parallel |

5.8" / 147 |

5.8" / 147 |

5.8" / 147 |

|

|

X |

Bottom side boiler to center safety valve |

7.7" / 195 |

8" / 200 |

8" / 200 |

|

|

Y |

Bottom side boiler to center header |

10.2" / 260 |

10.4" / 265 |

10.4" / 265 |

|

|

Z |

Center to center of f and r* |

9" / 229 |

12" / 305 |

12" / 305 |

|

|

aa |

Depth plumbing kit |

5.6" / 142 |

5.6" / 142 |

5.6" / 142 |

|

|

|

*) See figure 3 |

|

|

|

|

dimensions |

|

|

table 1 |

|||

Installation & Servicing Instructions Rinnai Q-Series

13

Dimensions

Connection for combustion air supply and vent system

g f1 r1 c |

g f1 |

r1 |

c |

g f1 |

r1 |

c |

e |

k w |

t

f2 |

r2 |

f2 |

r2 |

f2 |

r2 |

|

boiler connections |

|

|

|

|

figure 3 |

|

Installation & Servicing Instructions Rinnai Q-Series

|

|

Boiler type |

Solo |

Combi |

|

|

|

|

|

Q85SN/Q85SP |

Q175SN/Q175SP |

|

|

|

|

|

Q130SN/Q130SP |

Q205SN/Q205SP |

Q175CN/Q175CP |

|

|

|

|

|

|

|

|

|

Vent system / Combustion air supply |

80/125mm |

80/125mm |

80/125mm |

||

|

Gas pipe |

g |

3/4"M-NPT |

3/4"M-NPT |

3/4"M-NPT |

|

|

Supply pipe |

boiler side - f1 |

28mm |

35mm |

35mm |

|

|

|

system side - f2 |

1¼"M-NPT |

1½"M-NPT |

1½"M-NPT |

|

|

Return pipe |

boiler side - r1 |

28mm |

35mm |

35mm |

|

|

|

system side - r2 |

1¼"M-NPT |

1½"M-NPT |

1½"M-NPT |

|

|

Condensate pipe |

c |

0.95" / 24mm |

0.95" / 24mm |

0.95" / 24mm |

|

|

Expansion pipe |

e |

|

|

0.87"x ¾"M-NPT / |

|

|

|

|

22mm |

|||

|

|

|

|

|

||

|

Cold water pipe |

k |

|

|

0.6"x ¾"M-NPT / |

|

|

|

|

15mm |

|

||

|

|

|

|

|

|

|

|

Hot water pipe |

w |

|

|

0.6"x ¾"M-NPT / |

|

|

|

|

15mm |

|||

|

|

|

|

|

||

|

Supply pipe indirect tank. |

|

|

|

|

|

|

In case of optional internal |

t |

1"M-NPT |

|

|

|

|

3 way valve. |

|

|

|

|

|

connection diameters |

|

|

|

table 2 |

||

14

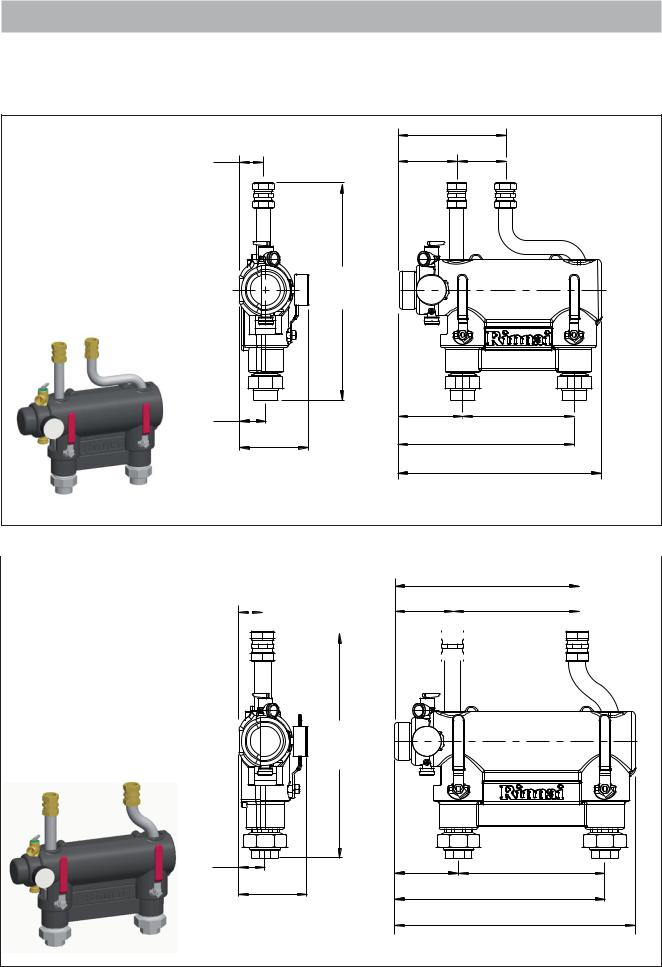

5.3.1Plumbing Kits

Rinnai boilers are supplied with a Plumbing kit from factory. Find below the dimensions.

See chapter 6.1 for additional information.

|

|

8.6” |

||

Plumbing Kit 2 |

2.0” |

219mm |

||

Suitable for: |

4.7” |

3.9” |

||

50mm |

119mm |

100mm |

||

Q85SN / Q85SP |

||||

|

|

|

||

Q130SN / Q130SP |

|

|

|

|

|

17.6” |

|

|

448mm |

|

2.1” |

5.2” |

9” |

54mm |

131mm |

229mm |

142 |

|

14.2” |

[5.6”] |

360mm |

|

|

|

16.4” |

|

|

416mm |

Plumbing kit 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

figure 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15” |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Plumbing Kit 3 |

2.0” |

|

|

|

|

|

4.7” |

|

381mm |

|

|

||||||||||

Suitable for: |

|

|

|

|

|

|

|

|

|

|

|

10.2” |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50mm |

|

|

|

|

|

120mm |

|

|

|

|

|

|

260mm |

|

|

|

|||||

Q175SN / Q175SP |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q175CN / Q175CP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q205SN / Q205SP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18.6” |

|

|

|

Q-Series |

|

|

|

|

RinnaiInstructions |

|

|

474mm |

|

|

|

|

|

|

|

|

|

|

2.1” |

5.2” |

438mm |

19.7” |

|

Servicing& |

54mm |

133mm |

|

305mm |

|

|

[5.6” |

17.2” |

|

|

||

142mm |

|

|

|

|

|

|

|

|

|

Installation |

|

|

|

501mm |

|

||

|

|

|

|

||

Plumbing kit 3 |

|

|

|

figure 5 |

|

15

5.3.2Clearences from the boiler

ceiling |

|

|

|

|

Min. 10" / |

|

|

|

|

250mm |

|

2" |

2" |

|

15.7" |

24" |

|||

50 |

50 |

|||

400 |

600 |

|||

|

|

|||

wall |

|

|

|

Installation & Servicing Instructions Rinnai Q-Series

|

|

|

|

|

|

|

|

|

service clearances to the boiler |

|

|

|

figure 6 |

||||

|

|

|

|

|

|

|

||

|

|

|

Minimum required clearances |

Minimum required clearances |

Recommended |

|||

|

|

|

to combustibles |

|

to non-combustibles |

service clearances |

|

|

|

|

|

All types |

|

All types |

All types |

|

|

|

|

|

inch / mm |

|

inch / mm |

inch / mm |

|

|

Top of boiler |

2" / 50 |

2" / 50 |

10" / |

250 |

|

|||

Back of boiler |

0" |

0" |

0 |

|

|

|||

Front of boiler |

6" / 150 |

6" / 150 |

24" / |

600 |

|

|||

Left side of boiler |

2" / 50 |

2" / 50 |

2" / |

50 |

|

|||

Right side of boiler |

2" / 50 |

2" / 50 |

2" / |

50 |

|

|||

Floor / Ground to |

12" / 300 |

12" / 300 |

30" / |

762 |

|

|||

bottom of boiler |

|

|||||||

|

|

|

|

|

|

|||

Floor/ Ground to |

|

|

|

|

|

|

|

|

bottom Low loss |

|

0" |

0" |

12" / |

300 |

|

||

header |

|

|

|

|

|

|

|

|

Vent |

|

0" |

0" |

0" |

|

|||

clearances to the boiler |

|

|

|

|

table 3 |

|||

For closet installation: clearance is 1” / 25mm from the front.

Low Loss Header

Clearances to combustible and non-combustible is 0 inch for sides, top, front and floor/ground The recommended service clearance to the bottom of the low loss header is 12 inches.

16

5.4 Technical specifications

|

|

|

|

|

|

|

Q-Series |

|

|

|

|

|

|

|

|

|

Combi |

|

|

|

|

|

|

|

|

|

|

|

Q175CN |

Q85SN |

Q130SN |

Q175SN |

Q205SN |

|

|

|

Boiler type |

|

|

Q175CP |

Q85SP |

Q130SP |

Q175SP |

Q205SP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input Hs CH |

BTU/hr |

175,000 |

85,000 |

130,000 |

175,000 |

205,000 |

|

|

||

|

|

|

kW |

|

51 |

25 |

38 |

51 |

60 |

|

|

|

Qn |

Output non-condensing CH |

BTU/hr |

157,000 |

77,000 |

117,000 |

157,000 |

184,000 |

|

|

|

|

|

|

kW |

45.9 |

22.5 |

34.2 |

45.9 |

54.0 |

|

|

|

|

Qn |

Output EN677 efficiency CH |

BTU/hr |

172,400 |

84,000 |

127,600 |

172,400 |

202,200 |

|

|

|

|

|

|

kW |

50.2 |

24.7 |

37.3 |

50.2 |

59.1 |

|

|

|

|

Qn |

Output AFUE CH |

BTU/hr |

167,500 |

82,000 |

124,900 |

167,500 |

196,100 |

|

|

|

|

|

|

kW |

48.8 |

24.1 |

36.5 |

48.8 |

57.4 |

|

|

|

|

Efficiency at 98.6/86°F (36/30°C) part |

% |

98.5 |

98.8 |

98.2 |

98.5 |

98.5 |

|

|

||

|

load, Hs, EN677 CH |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

AFUE according IBR |

% |

|

95.0 |

95.4 |

95.4 |

95.0 |

95.0 |

|

|

|

|

O2 (at full load) |

% |

|

|

Natural gas: 4.4 - 4.7 (Propane: 4.8 - 5.1) |

|

|

|

|||

|

Electr. power consumption max. |

W |

|

210 |

137 |

144 |

210 |

234 |

|

|

|

|

Electr. power consumption stand by |

W |

|

|

|

14 |

|

|

|

|

|

|

Current |

V/Hz |

|

|

|

120Vac/60Hz |

|

|

|

|

|

|

Fuse rating |

A |

|

|

|

5AF & 4AT |

|

|

|

|

|

|

Degree of protection acc. EN 60529 |

|

|

|

|

IPX0D |

|

|

|

|

|

|

Weight (empty) |

lbs / kg |

|

196 / 89 |

110 / 50 |

117 / 53 |

141 / 64 |

141 / 64 |

|

|

|

|

Water content CH |

gallon / liter |

|

1.8 / 7 |

0.9 / 3.5 |

1.3 / 5 |

1.8 / 7 |

1.8 / 7 |

|

|

|

|

Water content DHW |

gallon / liter |

|

3.7 / 14 |

|

|

|

|

|

|

|

|

Water content Plumbing Kit |

gallon / liter |

|

0.74 / 2.8 |

0.58 / 2.2 |

0.74 / 2.8 |

|

|

|||

|

After run time pump CH |

min |

|

|

|

5 |

|

|

|

|

|

|

After run time pump DHW |

min |

|

|

|

1 |

|

|

|

|

|

|

PMS Water pressure min.-max. |

PSI / bar |

|

|

|

14-43 / 1-3 |

|

|

|

|

|

|

PMW Water pressure DHW max. |

PSI / bar |

150 / 10 |

n.a. |

n.a. |

n.a. |

n.a. |

||||

|

Flow temperature max. |

°F / °C |

|

|

|

176 / 80 |

|

|

|

|

|

|

Pump type |

|

|

UPER 20-78 |

UPER 20-58 |

UPER 20-78 |

UPER 20-78 |

UPER 20-78 |

|

|

|

|

Available pump height CH ('T = 25K) |

PSI / kPa |

|

2.9 / 20 |

5.2 / 36 |

3.0 / 21 |

2.9 / 20 |

5.5 / 38 |

|

|

|

|

Approvals |

|

|

ASME, CSA |

ASME, CSA |

ASME, CSA |

ASME, CSA |

ASME, CSA |

|

|

|

|

DHW flow (at 'T50°F) |

gallon/min |

|

6.2 |

|

|

|

|

|

|

|

|

DHW flow (at 'T27.8°C) |

liter/min |

23.5 |

|

|

|

|

|

|

||

|

DHW flow (at 'T75°F) |

gallon/min |

|

4.1 |

|

|

|

|

|

|

|

|

DHW flow (at 'T41.7°C) |

liter/min |

|

15.5 |

|

|

|

|

|

|

|

|

Max. DHW flow rate |

gallon/min |

|

6.2 |

|

|

|

|

|

|

|

|

|

|

liter/min |

|

23.5 |

|

|

|

|

|

|

|

Pressure difference DHW |

PSI / bar |

|

4.3 / 0.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CSA number |

|

|

|

|

2183087 |

|

|

|

|

|

|

CRN number |

|

|

|

|

8101.7CL |

|

|

|

|

|

Technical specifications |

|

|

|

|

|

|

Table 4 |

||||

Installation & Servicing Instructions Rinnai Q-Series

17

Installation & Servicing Instructions Rinnai Q-Series

6 Connecting the boiler

The boiler has the following connection pipes;

-The central heating circuit pipes.

These must be connected to the Plumbing Kit by means of adapter fittings. See further chapter 6.1;

-The gas supply pipe.

It is provided with a 3/4" male thread into which the tail piece of the gas valve can be screwed. See further chapter 6.4;

-The condensation drain pipe.

It consists of an oval 1" (24 mm) plastic pipe. The drain pipe can be connected to this by means of an open connection. If the open connection is fitted in a different location, then the pipe can be lengthened by means of a 1 1/4" (32 mm) PVC sleeve. See further chapter 6.6;

-The vent system and air supply system.

It consists of a concentric connection 3"/5" (80/125 mm). The boiler can be converted to a twin pipe connection that will accept 80mm flue and intake air or with the use of the included adapters 3” PVC / CPVC flue and intake. See further chapter 6.7.

-Cold and hot water pipes for domestic hot water (DHW).

Combi boilers only: These consist of 3/4" (15 mm) copper pipe and can be connected to the installation by means of 3/4" M-NPT adapter fittings. See further chapter 6.5;

i NOTICE |

The pipes to be connected to the boiler must be cleaned before connecting in |

order to prevent dirt from entering and damaging the boiler. |

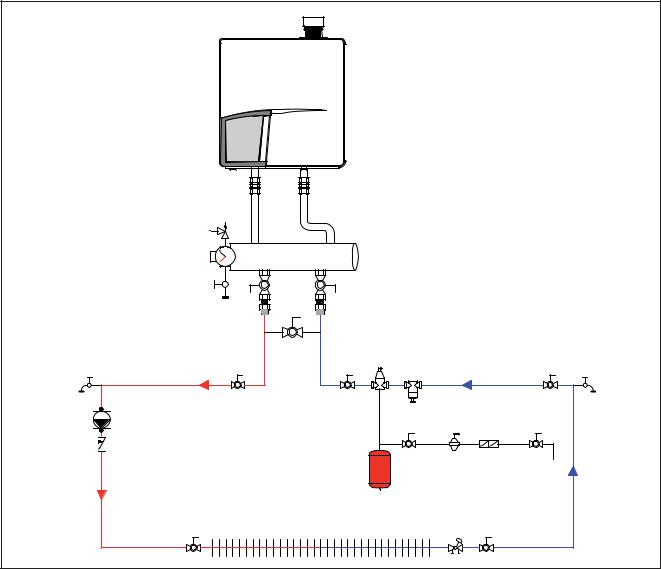

6.1 Central heating system

i i i

i

NOTICE

NOTICE

NOTICE

NOTICE

Connect the central heating system according to its instructions.

The boiler pipes can be connected to the installation by means of compression fittings. Reducers should be used for connecting to thick-walled pipe (welded or threaded).

When removing the plastic sealing caps from the pipes, dirty testing water may drain from the boiler.

A Plumbing Kit must be fitted to the boiler.

The boiler, when used in connection with a refrigeration system, must be installedsothechilledmediumispipedinparallelwiththeboilerwithappropriate valves to prevent the chilled medium from entering the boiler.

The boiler piping system of a hot water boiler connected to heating coils located in air handling units where they may be exposed to refrigerated air circulation must be equipped with flow control valves or other automatic means to prevent gravity circulation of the boiler water during the cooling cycle.

18

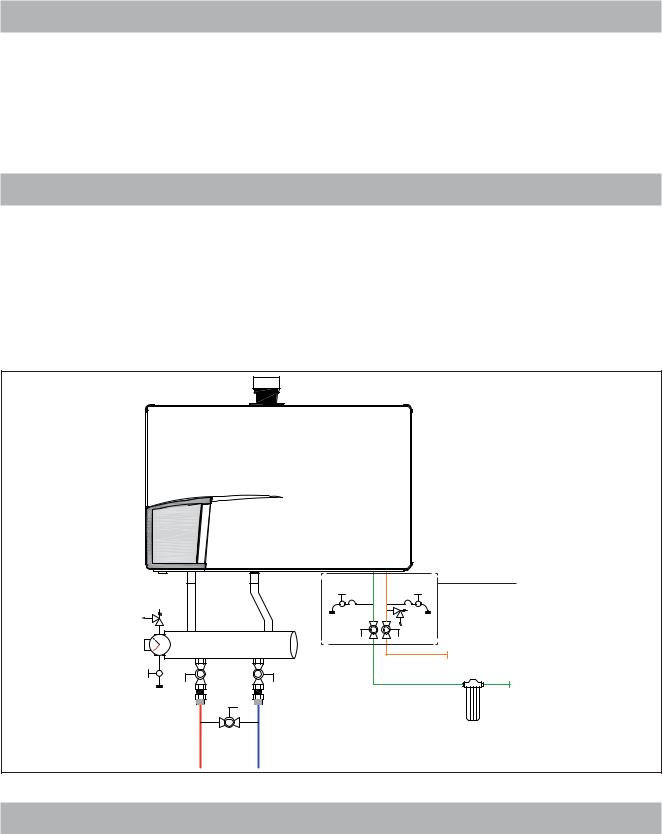

P |

Low Loss Header |

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

V1 |

V2 |

|

|

Service valve |

Service valve |

|

|

|

|

11 |

7 |

|

|

|

1 |

6 |

5 |

|

2 |

|

|

8 |

9 |

3 |

|

|

|

|

|

|

10 |

|

|

|

|

|

4 |

|

Boiler basic piping |

|

|

|

figure 7 |

1.shut off valve

2.system circulator

3.check valve

4.balancing valve

5.boiler drain valve

6.dirt trap

7.air separator

8.automatic fill valve

9.back flow preventer

10.expansion tank

11.bypass for system cleaning

Installation & Servicing Instructions Rinnai Q-Series

19

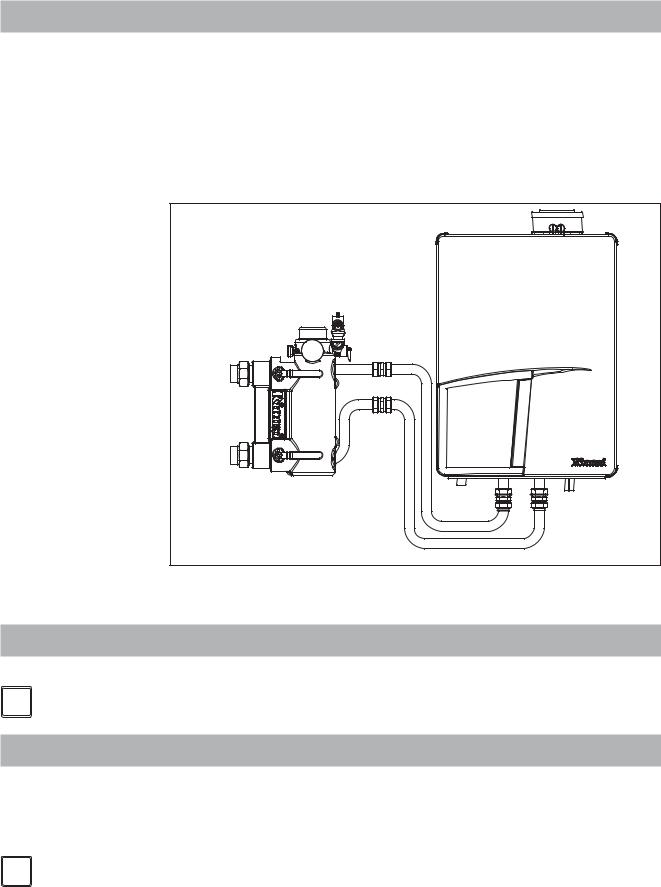

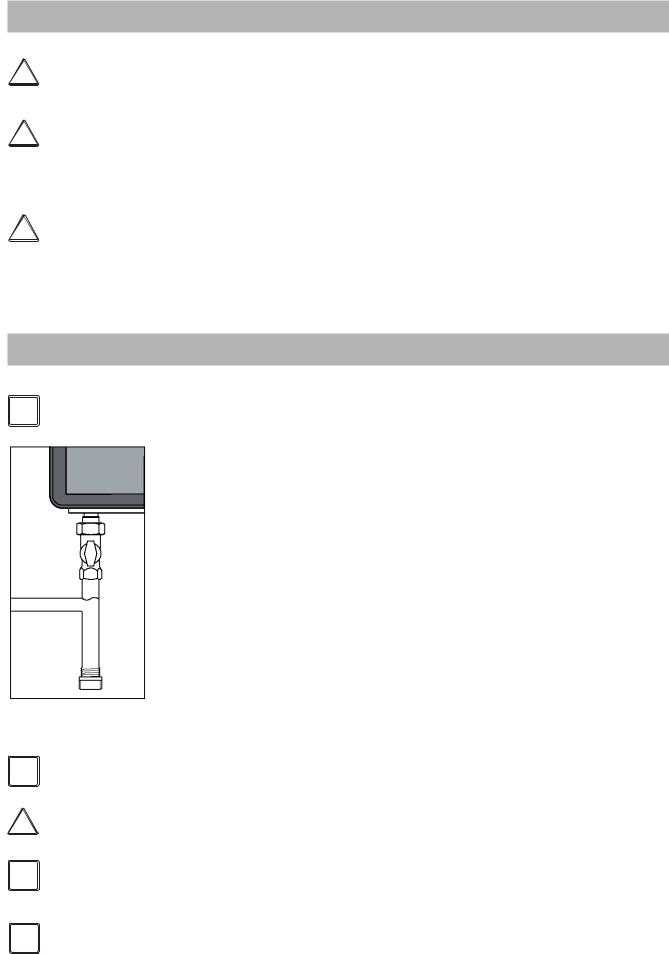

6.1.1Plumbing Kit installation

i

i

i

NOTICE

NOTICE

NOTICE

Rinnai supplies specific Plumbing Kits with each boiler type, which must be fitted directly underneath the boiler on the supply and return pipe. Find in chapter 5.3 the dimensions. Use of the Rinnai boiler without the plumbing kit will void the warranty.

To protect the entire heating system we recommend installing a dirt particle trap in the return circuit. When the boiler is installed to an existing heating system this trap is required. Use of a Y strainer is not permitted as a substitute for a dirt trap.

-Install shut-off valves immediately before and after the dirt particle filter to allow the trap to be cleaned.

-Position 3 (figure 8) is a garden hose thread boiler drain that can be used to drain the boiler or add water treatment additives to the system such as inhibitors or glycol.

-Position 4 (figure 8) is the supply connection for an indirect tank when used with the optional 3-way valve kit.

-For information on locating the expansion tank and system fill, please see the Rinnai Boiler Applications Manual.

Thoroughly flush all pipes and radiators. We recommend the use of a Rinnai approved system cleaner. Please refer to the list of approved Rinnai system cleaners in this chapter.

-Refer to the installation template and chapter 5.3 for the pipe connection dimensions.

The plumbing kit is not intended to support the weight of the piping. Appropriate piping supports should be used to support all attached piping to the boiler and plumbing kit.

Installation & Servicing Instructions Rinnai Q-Series

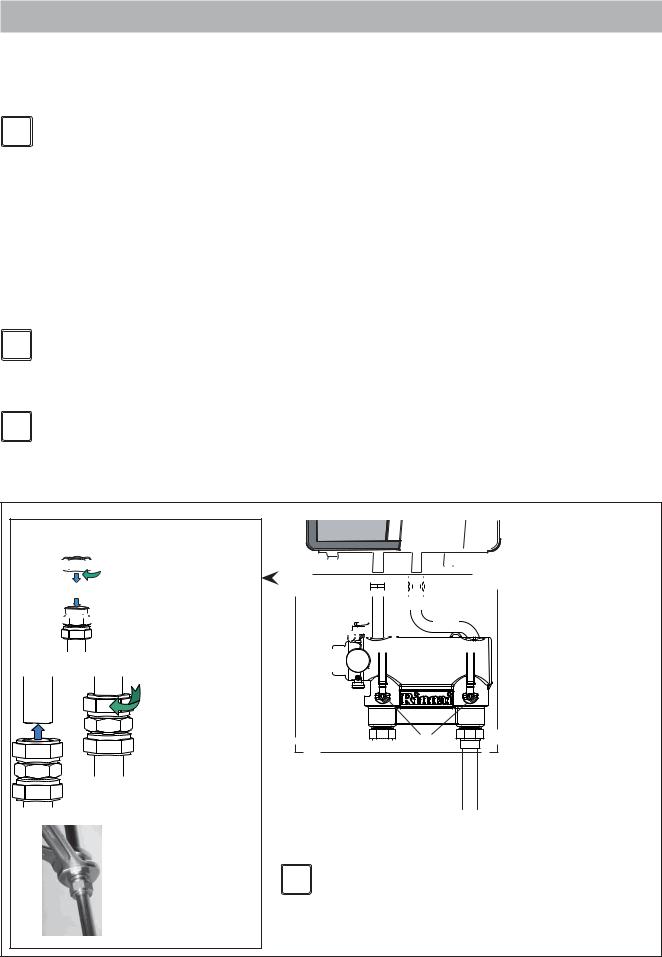

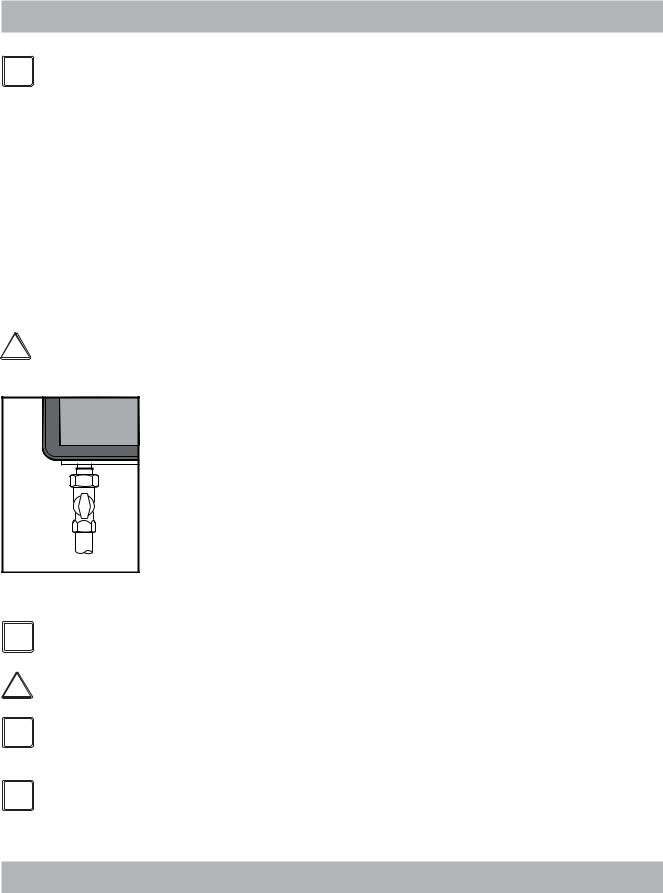

Compression fittings.

Parts:

1. Nut

1. Nut

2. Ferrule

2. Ferrule

3. Fitting

3. Fitting

Fitting instructions: |

|

|

1 |

2 |

1. Push the complete |

fitting over the pipe as |

||

|

|

far as possible. Ferrule |

|

|

should be over the |

|

|

pipe completely. |

|

|

2. Turn the nut handtight |

|

|

clockwise. |

3

3. Use 2 wrenches, one to hold the fitting on its place, the other for tighten the nut clockwise in 3/4 turn.

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

4

9

9

3

6

|

|

|

|

|

7 |

|

8 |

||

|

||||

1.Plumbing kit

2.Safety valve

3.Drain and Purge connection

4.DHW flow connection in case of optional internal 3 way valve

5.Bronze adapter fittings

6.Service valves*

7.Flow

8.Return

9.Pressure gauge*

* After installation of the plumbing kit to i NOTICE the boiler the pressure gauge and both

handles of the service valves must be mounted. Be sure the gauge is fitted leak free and that the handles are secured with the supplied nuts.

Plumbing Kit installation |

figure 8 |

20

-Boiler system flushing (Not Boiler heat exchanger)

When replacing an existing boiler the heating system should be flushed with the old boiler in place before the new boiler is added to the system. If the old boiler has already been removed a bypass must be piped in when the new boiler is installed in order to facilitate the flushing of the system.

The boiler must be valved off from the system, while the system is flushed. No system cleaner should ever enter the boiler heat exchanger due to its caustic nature which could damage the heat exchanger.

1.Close the shutoff valves on both the supply and return connections on the plumbing kit (V1 and V2).

2.Open the bypass valve (V4).

3.Connect pump outlet hose (H1) to the supply side purge station (BD1)

4.Connect drain hose (H3) to the return side purge station (BD2).

5.Pour the system cleaner into a pail and follow the system cleaner instructions on circulation time and volume to be added to the system.

6.Operate the charging pump (CP) and charge the system with the required volume of system cleaner

7.Close the supply side purge station (BD1)

8.Turn on the system pump(s) (SP) and circulate the cleaner through the system for required time as established by the cleaner manufacturer.

9.Once the time required by the system cleaner manufacturer has been met place the drain hose (H3) in a drain.

10.Turn off the system pump(s) (SP)

11.Close the main valve on the system return (V3) and open the return side purge station (BD2).

12.Open the auto feed on the system (F1) and allow water to rinse the system for whichever is greater; 10 minutes or the required rinse time by the system cleaner manufacturer.

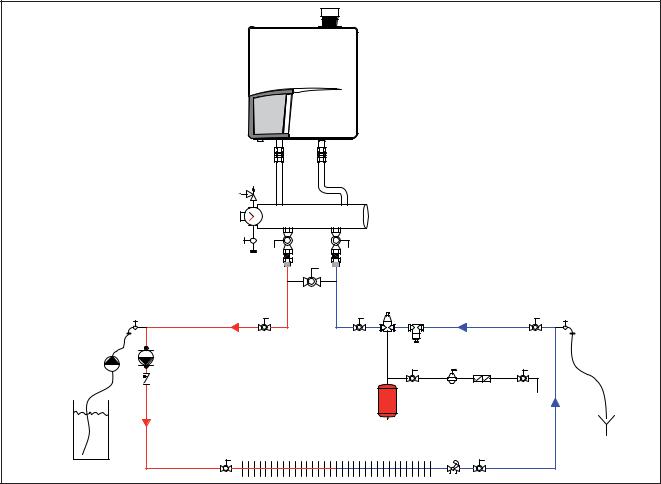

P

Low Loss Header

T

V1 |

V2 |

V4

|

BD1 |

|

H1 |

CP |

SP |

|

|

|

H2 |

System cleaner

Boiler system flushing

V3 |

BD2 |

F1 |

H3 |

|

|

|

Drain |

figure 9

Installation & Servicing Instructions Rinnai Q-Series

21

Installation & Servicing Instructions Rinnai Q-Series

13.If the installation is a zone system be sure to purge out each zone individually

14.Close the auto feed on the system (F1)

15.Close the return side purge station (BD2) and disconnect the hose (H3).

16.Open the main valve on the system return (V3)

17.Close the bypass valve below the plumbing kit (V4).

18.Open shutoff valves on both the supply and return connections on the plumbing kit (V1 and V2).

19.Clean out the dirt trap

20.Test the pH of the water that will be used for filling the system

21.Test the water hardness of the water that will be used for filling the system

22.Use the proper water treatment to ensure the pH and water hardness are within the Rinnai boiler water quality guidelines

23.The boiler and system may now be filled

|

The following is a list of approved system cleaners, inhibitors, and antifreeze. |

|

|

Approved antifreeze: |

|

|

• Rhomar RhoGard Mutli-Metal (AL safe) |

• Sentinel X500 |

|

• Noble Noburst AL |

• Fernox Alphi 11 |

|

Approved system cleaner: |

|

|

• Noble Noburst Hydronic System Cleaner |

• Fernox F3 Cleaner |

|

- Rhomar Hydro-Solv 9100 |

• Sentinel X400 |

i NOTICE |

The system cleaners from NoBurst, Rhomar, and Fernox are NOT to be used in |

|

the boiler. The boiler must be closed off (valved off) from the rest of the system |

||

|

or not connected while the cleaners are in the system. The system should then |

|

|

be drained and then thoroughly flushed with clean water to remove all the |

|

|

system cleaner. |

|

|

Approved inhibitors: |

|

|

- Rhomar Pro-tek 922 |

• Sentinel X100 |

|

- Noble Noburst AL inhibitor |

|

|

|

|

- Connect the expansion tank to the system. See chapter 6.2. - Connect the pipes so that they are free from strain.

Connecting boiler with DHW tank

-Connect the external DHW tank according to the installation instructions of the DHW tank and fittings concerned. See chapter 7 and the Rinnai Boiler Applications Manual for additional information.

The boiler has a self-adjusting and self-protecting control system for the load and the pump capacity. By this means, the temperature difference between the supply and return water is checked.

22

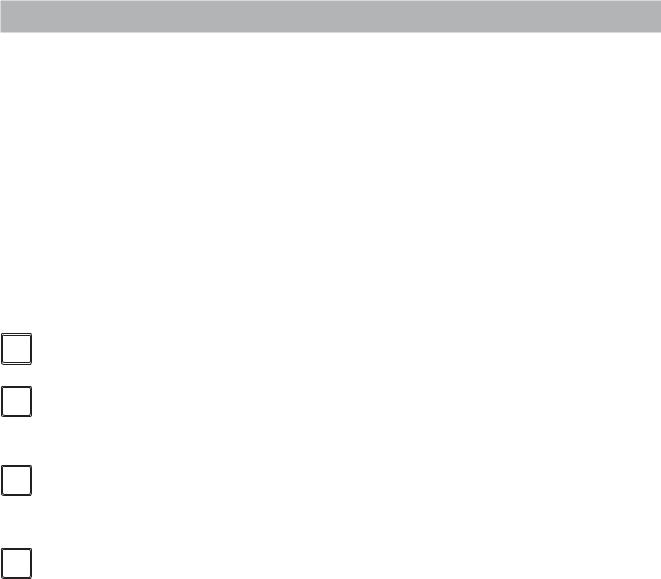

Water filter |

figure 10 |

|

i |

NOTICE |

|

If the installation resistance is over the stated value; the pump will rotate at maximum capacity and the load will be adjusted until an acceptable temperature difference between supply and return water has been obtained. If, after this, the temperature difference is still not acceptable then the boiler will switch off and wait until an acceptable temperature has arisen.

If an unacceptable temperature is detected, the control will repeatedly try to achieve water flow over the boiler. If not the boiler will switch off.

The electrical side of the external circulation pump (fig. 6, pos. 2) can be connected to the Control Tower. This pump thus switches simultaneously to the boiler pump. The maximum absorbed current consumption of the external circulation pump may not exceed 120V, 2 Amp. If a pump with a larger current draw is required an isolation relay must be used. See the Rinnai Boiler applications manual for further information. The extra external pump must be selected according to the installation resistance

and required flow.

As standard the boiler is provided with a water filter in the return pipe of the boiler (fig. 10), so that debris from the central heating water is prevented from affecting the boiler.

The boiler is designed to be used on pressurized heating systems only (closed loop).

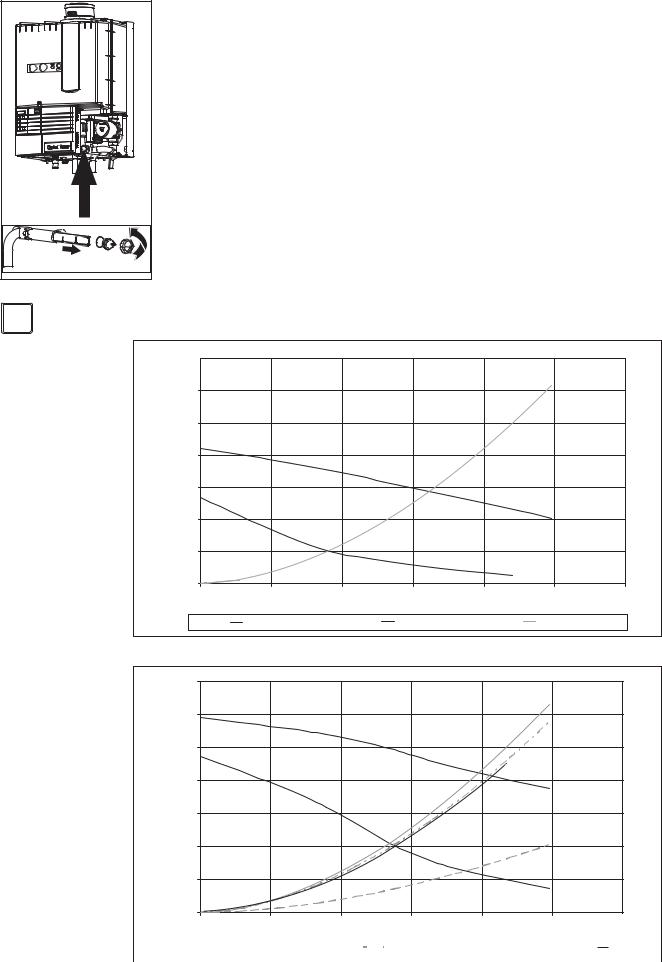

Q85S |

14 |

|

|

|

|

|

32.3 |

|

12 |

|

|

|

|

Q85S |

27.7 |

|

10 |

|

|

|

|

23.0 |

|

|

8 |

|

|

|

|

|

18.5ofhead |

|

PSI |

|

|

|

|

|

Feet |

|

6 |

|

|

|

|

|

13.8 |

|

4 |

|

|

|

|

|

9.2 |

|

2 |

|

|

|

|

|

4.6 |

|

0 |

|

|

|

|

|

0 |

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

|

|

|

|

Q [gallons/min] |

|

|

|

|

|

UPER 20-58 |

25% |

UPER 20-58 |

100% |

Resistance Q85S |

|

pump index lines UPER 20-58 |

|

|

|

|

graph 1a |

||

Q130S 14 |

|

|

|

|

|

32.3 |

|

Q175S |

|

|

|

|

|

|

|

Q175C 12 |

|

|

|

Q175S |

|

27.7 |

|

Q205S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

Q175C |

|

23.0 |

|

|

8 |

|

|

|

Q130S |

|

head |

|

|

|

|

|

18.5 |

||

PSI |

|

|

|

|

|

|

Feetof |

|

6 |

|

|

|

|

|

13.8 |

|

4 |

|

|

|

|

|

9.2 |

|

|

|

|

|

Q205S |

|

|

|

2 |

|

|

|

|

|

4.6 |

|

0 |

|

|

|

|

|

0 |

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

|

|

|

|

Q [gallons/min] |

|

|

|

|

|

|

UPER 20-78 |

|

UPER 20-78 |

|

Restistance |

|

Resistance |

|

|

|

Resistance |

Resistance |

|

|

|

|

|

|

|

|

|

||||||||

|

25% |

|

100% |

|

Q175S |

|

Q175C |

|

|

|

Q205S |

Q130S |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

pump index lines UPER 20-78 |

|

|

|

|

|

|

|

|

|

graph 1b |

|

||||

Installation & Servicing Instructions Rinnai Q-Series

23

Installation & Servicing Instructions Rinnai Q-Series

6.1.2Side mounting kit for the Low Loss header