Ricoh A161, A162, A157, A160, A153 Service Manual

...

® |

® |

®

A156/A212...SERIES

SERVICE MANUAL

RICOH GROUP COMPANIES |

PN: RCFM5535 |

®

®

®

MANUAL SERVICE

...A156/A212

SERIES

RICOH GROUP COMPANIES

Rev. 4/98

A156/A153

A160/A157

A162/A161

SERVICE TRAINING

MANUAL

|

LEGEND |

Rev. 4/98 |

|

|

|

||

|

|

|

|

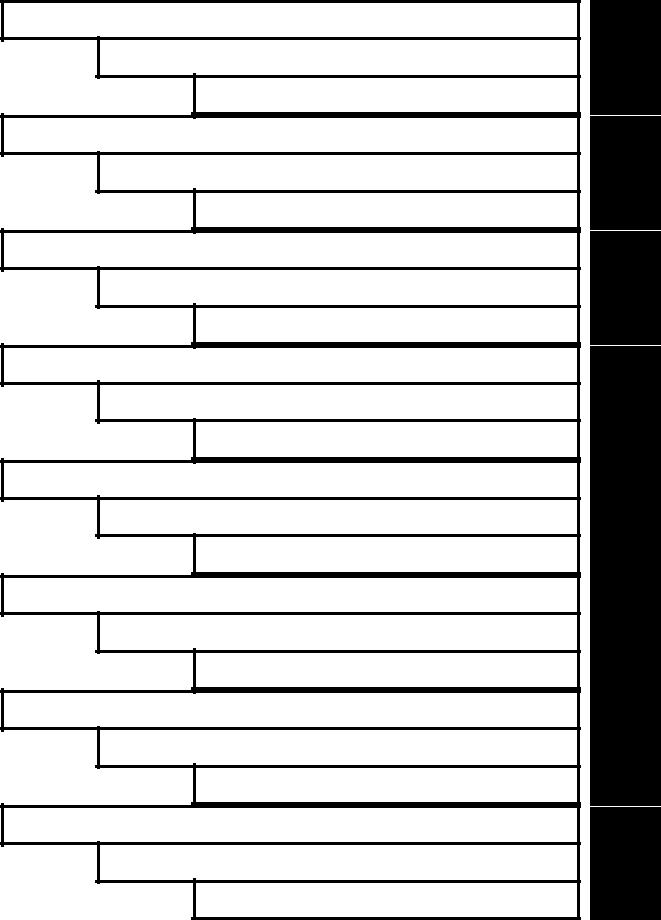

PRODUCT CODE |

|

COMPANY |

|

|

GESTETNER |

RICOH |

SAVIN |

A156 |

2635TD |

FT5535 |

9035DL |

A153 |

2635 |

FT5035 |

9035 |

A160 |

2627TD |

FT4527 |

9027DL |

A157 |

2627 |

FT4027 |

9027 |

A162 |

2822TD |

FT4522 |

9220DL |

A161 |

2822 |

FT4022 |

9220 |

A207 |

CMR402 |

FT5840 |

9400D |

A208 |

CMR321 |

FT5632 |

9032 |

A211 |

CMR322 |

FT5832 |

9032D |

A206 |

CMR401A |

FT5740 |

9400L |

A204 |

CMR401 |

FT5640 |

9400 |

A210 |

CMR321A |

FT5732 |

9032L |

A212 |

— |

FT4622 |

9122 |

A214 |

— |

FT4822 |

9122DL |

|

|

|

|

DOCUMENTATION HISTORY

REV. NO. |

DATE |

COMMENTS |

1 |

3/95 |

Original printing |

2 |

7/95 |

A162/A161 addition |

|

|

|

3 |

5/97 |

A207/A208/A211 Addition |

|

|

|

4 |

12/97 |

A212/A214 Addition |

|

|

|

|

|

|

The A204 copier is based on the A153 copier.

The A206 copier is based on the A155 copier.

The A207 copier is based on the A156 copier.

The A208 copier is based on the A157 copier.

The A210 copier is based on the A159 copier.

The A211 copier is based on the A160 copier.

The A212 copier is based on the A161 copier.

The A214 copier is based on the A162 copier.

Only the differences from the base copiers are described in the following pages. Therefore, this documentation should be treated as an insert version of the base copier’s service manual, although it has a separate binder. It should always be utilized together with the base copier’s service manual.

WARNING

The Service Training Manual contains information regarding service techniques, procedures, processes and spare parts of office equipment distributed by Ricoh Corporation. Users of this manual should be either service trained or certified by successfully completing a Ricoh Technical Training Program.

Untrained and uncertified users utilizing information contained in this service manual to repair or modify Ricoh equipment risk personal injury, damage to property or loss of warranty protection.

Ricoh Corporation

|

Rev. 7/95 |

|

Table of Contents |

|

|

1. OVERALL MACHINE INFORMATION |

|

|

1. SPECIFICATIONS.............................................................. |

1-1 |

|

2. MACHINE CONFIGURATION............................................ |

1-5 |

|

2.1 COPIER ...................................................................................... |

1-5 |

|

2.2 OPTIONAL EQUIPMENT ........................................................... |

1-6 |

|

3. MECHANICAL COMPONENT LAYOUT ........................... |

1-7 |

|

4. PAPER PATH ................................................................. |

1-10 |

|

4.1 NORMAL COPYING .................................................................. |

1-10 |

|

4.2 DUPLEX COPYING ................................................................. |

1-11 |

|

5. ELECTRICAL COMPONENT DESCRIPTIONS .............. |

1-12 |

|

6. DRIVE LAYOUT ............................................................... |

1-17 |

|

6.1 ALL MODELS ........................................................................... |

1-17 |

|

6.2 A153/A156 ............................................................................... |

1-18 |

|

6.3 A157/A160/A161/A162 .............................................................. |

1-18 |

|

2. DETAILED DESCRIPTIONS |

|

|

1. PROCESS CONTROL ....................................................... |

2-1 |

|

1.1 OVERVIEW.................................................................................. |

2-1 |

|

1.1.1 Copy Process around the Drum................................................................ |

2-1 |

|

1.1.2 Factors Affecting Process Control ........................................................... |

2-4 |

|

1.1.3 Process Control Procedures ..................................................................... |

2-5 |

|

1.1.3.1 Copy Image Control ............................................................................... |

2-5 |

|

1.1.3.2 Image Density Control ........................................................................... |

2-5 |

|

1.1.3.3 Drum Potential Control........................................................................... |

2-5 |

|

1.2 COPY IMAGE CONTROL............................................................ |

2-8 |

|

1.2.1 Manual ID Correction ................................................................................ |

2-8 |

|

1.2.2 Reproduction Ratio Correction.................................................................. |

2-9 |

|

1.2.3 ADS Correction ....................................................................................... |

2-10 |

|

STM |

i |

A156/A160/A162 |

Rev. 7/95 |

|

1.3 IMAGE DENSITY CONTROL .................................................... |

2-10 |

1.3.1 Overview ................................................................................................. |

2-10 |

1.3.2 VSP and VSG Detection ......................................................................... |

2-11 |

1.3.3 ID Correction for the VSP Pattern ........................................................... |

2-12 |

1.3.4 Toner Supply Control During Copying .................................................... |

2-14 |

1.3.5 Toner Supply in Abnormal Sensor Conditions ........................................ |

2-16 |

1.4 DRUM POTENTIAL CONTROL................................................. |

2-18 |

1.4.1 VR Pattern Correction ........................................................................... |

2-18 |

1.4.2 VL Pattern Correction ........................................................................... |

2-20 |

1.4.3 T/H Correction ...................................................................................... |

2-23 |

1.5 PROCESS CONTROL DURING ABNORMAL CONDITIONS .. |

2-25 |

1.6 SUMMARY................................................................................. |

2-26 |

1.6.1 Process Control and Sensor Detection Timing ....................................... |

2-26 |

1.6.2 Process Control Checks During Machine Operation .............................. |

2-27 |

2. DRUM ............................................................................. |

2-32 |

2.1 DRUM UNIT ............................................................................... |

2-32 |

2.2 DRIVE MECHANISM ............................................................... |

2-33 |

3. DRUM CHARGE .............................................................. |

2-34 |

3.1 OVERVIEW .............................................................................. |

2-34 |

3.2 DRUM CHARGE ROLLER DRIVE MECHANISM .................. |

2-35 |

3.3 DRUM CHARGE ROLLER CLEANING .................................... |

2-37 |

3.4 TEMPERATURE COMPENSATION ..................................... |

2-38 |

4. OPTICS............................................................................. |

2-39 |

4.1 OVERVIEW ............................................................................. |

2-39 |

4.2 SCANNER DRIVE ................................................................... |

2-41 |

4.3 LENS DRIVE.............................................................................. |

2-41 |

4.4 HORIZONTAL LENS POSITIONING ....................................... |

2-43 |

4.4.1 Original Alignment Position .................................................................... |

2-43 |

4.4.2 Paper Size ............................................................................................. |

2-43 |

4.4.3 Reproduction Ratio ................................................................................ |

2-43 |

4.5 3RD SCANNER DRIVE ........................................................... |

2-45 |

A156/A160/A162 |

ii |

STM |

|

Rev. 7/95 |

4.6 UNEVEN LIGHT INTENSITY CORRECTION ........................ |

2-46 |

4.7 ORIGINAL SIZE DETECTION IN PLATEN MODE ................ |

2-47 |

4.8 AUTOMATIC IMAGE DENSITY CONTROL |

|

SYSTEM (ADS) ......................................................................... |

2-49 |

5. ERASE.............................................................................. |

2-51 |

5.1 OVERVIEW ............................................................................... |

2-51 |

5.2 LEADING EDGE AND TRAILING EDGE ERASE ..................... |

2-52 |

5.3 SIDE ERASE.............................................................................. |

2-52 |

6. DEVELOPMENT .............................................................. |

2-53 |

6.1 OVERVIEW .............................................................................. |

2-53 |

6.2 DRIVE MECHANISM ............................................................... |

2-54 |

6.3 CROSS-MIXING .................................................................... |

2-55 |

6.4 TONER DENSITY SENSOR .................................................... |

2-56 |

6.5 DEVELOPMENT BIAS CONTROL ............................................ |

2-57 |

6.6 TONER SUPPLY ....................................................................... |

2-58 |

6.6.1 Toner Bottle Replenishment Mechanism .............................................. |

2-58 |

6.6.2 Toner Supply Mechanism .................................................................... |

2-59 |

6.6.3 Toner End Detection ............................................................................. |

2-59 |

7. IMAGE TRANSFER AND PAPER SEPARATION .......... |

2-61 |

7.1 PRE-TRANSFER LAMP ........................................................... |

2-61 |

7.2 IMAGE TRANSFER AND PAPER SEPARATION .................... |

2-62 |

7.3 IMAGE TRANSFER AND PAPER SEPARATION |

|

MECHANISM .......................................................................... |

2-63 |

7.4 TRANSFER BELT UNIT LIFT MECHANISM ............................ |

2-65 |

7.5 PAPER TRANSPORTATION AND BELT DRIVE |

|

MECHANISM ........................................................................... |

2-66 |

7.6 TRANSFER BELT CLEANING MECHANISM .......................... |

2-67 |

7.7 TRANSFER BELT UNIT RELEASE MECHANISM .................. |

2-69 |

8. DRUM CLEANING .......................................................... |

2-70 |

8.1 OVERVIEW .............................................................................. |

2-70 |

8.2 DRIVE MECHANISM ................................................................ |

2-71 |

STM |

iii |

A156/A160/A162 |

Rev. 7/95

8.3 CLEANING BLADE PRESSURE MECHANISM AND |

|

SIDE-TO-SIDE MOVEMENT ................................................... |

2-72 |

8.4 TONER COLLECTION MECHANISM ...................................... |

2-73 |

9. TONER RECYCLING ...................................................... |

2-74 |

9.1 OVERVIEW................................................................................ |

2-74 |

9.2 NEW TONER AND RECYCLED TONER MIXTURE................. |

2-75 |

10. QUENCHING ................................................................. |

2-76 |

11. PAPER FEED AND REGISTRATION ........................... |

2-77 |

11.1 OVERVIEW ............................................................................ |

2-77 |

11.2 PAPER FEED MECHANISM [A153/A156] .............................. |

2-78 |

11.2.1 Drive Mechanism ................................................................................ |

2-78 |

11.2.2 Slip Clutch Mechanism ....................................................................... |

2-79 |

11.2.3 Separation Roller Release Mechanism ................................................ |

2-80 |

11.3 PAPER FEED DRIVE MECHANISM [A157/A160] ............... |

2-81 |

11.4 PAPER LIFT MECHANISM .................................................... |

2-82 |

11.5 PAPER END DETECTION ..................................................... |

2-85 |

11.6 PAPER SIZE DETECTION ..................................................... |

2-87 |

11.7 SIDE FENCE DOUBLE STOPPER |

|

MECHANISM [A157/A160] .................................................... |

2-88 |

11.8 LARGE CAPACITY TRAY ....................................................... |

2-89 |

11.8.1 Paper Lift Mechanism .......................................................................... |

2-89 |

11.8.2 Paper Feed Mechanism ....................................................................... |

2-90 |

11.8.3 Paper End Detection ............................................................................ |

2-90 |

11.9 BY-PASS FEED TABLE .......................................................... |

2-91 |

11.9.1 Table Open/Closed Detection .............................................................. |

2-91 |

11.9.2 Feed Mechanism/Paper End Detection .............................................. |

2-91 |

11.9.3 By-pass Feed Paper Width Detection ................................................. |

2-92 |

11.10 PAPER REGISTRATION ...................................................... |

2-93 |

11.11 PAPER FEED AND MISFEED DETECTION TIMING........... |

2-94 |

11.11.1 Paper Feed Tray ................................................................................. |

2-94 |

11.11.2 By-pass Feed ..................................................................................... |

2-96 |

A156/A160/A162 |

iv |

STM |

|

Rev. 7/95 |

11.11.3 (A160/A157) |

........................................................................................2-96 |

12. DUPLEX ...................................................................... |

2-97 |

12.1 OVERVIEW.............................................................................. |

2-97 |

12.2 DRIVE MECHANISM ............................................................ |

2-98 |

12.3 TURN GUIDE SECTION ......................................................... |

2-99 |

12.4 DUPLEX ENTRANCE TO DUPLEX TRAY ........................... |

2-100 |

12.5 DUPLEX STACKING ......................................................... |

2-101 |

12.6 PAPER FEED FROM THE DUPLEX TRAY ........................ |

2-102 |

12.6.1 Tray Lift Mechanism............................................................................ |

2-102 |

12.6.2 Paper Feed System ........................................................................... |

2-103 |

13. IMAGE FUSING........................................................... |

2-104 |

13.1 OVERVIEW .......................................................................... |

2-104 |

13.2 FUSING DRIVE AND RELEASE MECHANISM .................. |

2-105 |

13.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM ............. |

2-106 |

13.4 PRESSURE ROLLER ........................................................... |

2-107 |

13.5 CLEANING MECHANISM ..................................................... |

2-107 |

13.6 FUSING LAMP CONTROL .................................................. |

2-108 |

13.7 OVERHEAT PROTECTION................................................... |

2-111 |

13.8 ENERGY SAVER FUNCTIONS............................................. |

2-111 |

13.9 MAIN FUSING LAMP INTERCHANGEABILITY.................... |

2-111 |

3. AUTO REVERSE DOCUMENT FEEDER A548 |

|

1. SPECIFICATIONS.............................................................. |

3-1 |

2. COMPONENT LAYOUT..................................................... |

3-2 |

2.1 MECHANICAL COMPONENTS ................................................. |

3-2 |

2.2 ELECTRICAL COMPONENTS .................................................. |

3-3 |

3. ELECTRICAL COMPONENT DESCRIPTION................... |

3-4 |

4. DETAILED DESCRIPTIONS ............................................. |

3-5 |

4.1 ORIGINAL PICK-UP MECHANISM ............................................. |

3-5 |

4.2 SEPARATION AND PAPER FEED MECHANISM ...................... |

3-6 |

4.3 FRICTION BELT DRIVE MECHANISM....................................... |

3-7 |

STM |

v |

A156/A160/A162 |

Rev. 7/95 |

3-8 |

4.4 ORIGINAL SIZE DETECTION .................................................... |

|

4.5 PAPER TRANSPORT MECHANISM ........................................ |

3-9 |

4.6 THICK/THIN ORIGINAL MODES ............................................. |

3-10 |

4.7 ORIGINAL FEED-OUT MECHANISM ..................................... |

3-11 |

4.8 TWO-SIDED ORIGINAL FEED MECHANISM ......................... |

3-12 |

5. TIMING CHARTS ............................................................ |

3-13 |

5.1 A4 SIDEWAYS: 1 SIDED ORIGINAL ........................................ |

3-13 |

5.2 COMBINE 2 ORIGINAL MODE ................................................ |

3-14 |

5.3 A4 SIDEWAYS: DUPLEX ........................................................ |

3-15 |

4. PAPER TRAY UNIT A550/A549 |

|

1. SPECIFICATIONS.............................................................. |

4-1 |

2. COMPONENT LAYOUT..................................................... |

4-2 |

2.1 MECHANICAL COMPONENT LAYOUT ..................................... |

4-2 |

2.2 DRIVE LAYOUT........................................................................... |

4-3 |

2.3 ELECTRICAL COMPONENT DESCRIPTION............................. |

4-4 |

3. OVERVIEW......................................................................... |

4-5 |

4. DRIVE MECHANISM.......................................................... |

4-6 |

5. PAPER FEED AND MISFEED DETECTION TIMING ....... |

4-7 |

5. PAPER TRAY UNIT A553 |

|

1. SPECIFICATIONS.............................................................. |

5-1 |

2. COMPONENT LAYOUT..................................................... |

5-2 |

2.1 MECHANICAL COMPONENT LAYOUT ..................................... |

5-2 |

2.2 DRIVE LAYOUT........................................................................... |

5-2 |

2.3 ELECTRICAL COMPONENT DESCRIPTION............................. |

5-3 |

3. OVERVIEW......................................................................... |

5-4 |

4. DRIVE MECHANISM.......................................................... |

5-5 |

5. PAPER FEED AND MISFEED DETECTION TIMING ....... |

5-6 |

A156/A160/A162 |

vi |

STM |

|

Rev. 7/95 |

|

6. SORTER STAPLER A554 |

|

|

1. SPECIFICATIONS.............................................................. |

6-1 |

|

2. COMPONENT LAYOUT..................................................... |

6-3 |

|

2.1 MECHANICAL COMPONENT LAYOUT ..................................... |

6-3 |

|

2.2 DRIVE LAYOUT........................................................................... |

6-4 |

|

2.3 ELECTRICAL COMPONENT DESCRIPTION ............................ |

6-5 |

|

3. BASIC OPERATION .......................................................... |

6-7 |

|

3.1 NORMAL MODE AND SORT/STACK MODE ............................ |

6-7 |

|

3.2 STAPLE MODE ........................................................................ |

6-9 |

|

4. TURN GATE SECTION ................................................... |

6-11 |

|

5. ROLLER DRIVE AND CONTROL ................................... |

6-12 |

|

6. BIN DRIVE AND CONTROL ............................................ |

6-14 |

|

7. JOGGER SECTION ........................................................ |

6-17 |

|

8. GRIP ASSEMBLY ......................................................... |

6-19 |

|

9. STAPLER ......................................................................... |

6-21 |

|

10. JAM DETECTION AND STAPLER ERROR.................. |

6-24 |

|

10.1 SORTER JAMS ....................................................................... |

6-24 |

|

10.2 STAPLER ERROR................................................................... |

6-25 |

|

11. TIMING CHARTS ........................................................... |

6-26 |

|

7. SORTER STAPLER A555 |

|

|

1. SPECIFICATIONS ............................................................. |

7-1 |

|

2. COMPONENT LAYOUT ................................................... |

7-3 |

|

2.1 MECHANICAL COMPONENT LAYOUT .................................... |

7-3 |

|

2.2 DRIVE LAYOUT ......................................................................... |

7-4 |

|

2.3 ELECTRICAL COMPONENT DESCRIPTION............................. |

7-5 |

|

3. BASIC OPERATION ......................................................... |

7-6 |

|

STM |

vii |

A156/A160/A162 |

Rev. 7/95 |

7-6 |

|

|

3.1 NORMAL MODE AND SORT/STACK MODE ............................. |

|

|

3.2 STAPLE MODE .......................................................................... |

7-8 |

|

3.3 BIN DRIVE MECHANISM ......................................................... |

7-10 |

|

3.4 BIN HOME POSITION .............................................................. |

7-11 |

|

3.5 JOGGER MECHANISM ............................................................ |

7-12 |

|

3.6 GRIP ASSEMBLY .................................................................. |

7-13 |

|

3.7 STAPLER UNIT ........................................................................ |

7-14 |

|

3.8 STAPLER SWITCH .................................................................. |

7-15 |

|

3.9 PAPER FEED AND MISFEED DETECTION TIMING ............ |

7-16 |

|

3.10 JAM DETECTION ................................................................... |

7-18 |

|

8. SORTER A556 |

|

|

1. SPECIFICATIONS.............................................................. |

8-1 |

|

2. MECHANICAL COMPONENT LAYOUT ........................... |

8-2 |

|

3. ELECTRICAL COMPONENT LAYOUT............................. |

8-3 |

|

4. ELECTRICAL COMPONENT DESCRIPTIONS ................ |

8-4 |

|

5. BASIC OPERATION .......................................................... |

8-5 |

|

6. EXAMPLE OF SORT MODE OPERATION ....................... |

8-6 |

|

7. BIN DRIVE MECHANISM .................................................. |

8-8 |

|

8. BINS ................................................................................. |

8-10 |

|

9. EXIT ROLLERS................................................................ |

8-11 |

|

10. TIMING CHART.............................................................. |

8-12 |

|

9. SORTER A557 |

|

|

1. SPECIFICATIONS.............................................................. |

9-1 |

|

2. COMPONENT LAYOUT..................................................... |

9-2 |

|

3. ELECTRICAL COMPONENT DESCRIPTIONS ................ |

9-3 |

|

4. BASIC OPERATION .......................................................... |

9-4 |

A156/A160/A162 |

viii |

STM |

|

Rev. 7/95 |

5. EXIT ROLLER DRIVE MECHANISM |

................................. 9-5 |

6. BIN DRIVE MECHANISM .................................................. |

9-6 |

7. MISFEED DETECTION ..................................................... |

9-8 |

STM |

ix |

A156/A160/A162 |

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1.Before disassembling or assembling parts of the copier and peripherals, make sure that the copier power cord is unplugged.

2.The wall outlet should be near the copier and easily accessible.

3.Note that the drum heater and the optional anti-condensation heaters are supplied with electrical voltage even if the main switch is turned off.

4.If any adjustment or operation check has to be made with exterior covers off or open while the main switch is turned on, keep hands away from electrified or mechanically driven components.

5.The inside and the metal parts of the fusing unit become extremely hot while the copier is operating. Be careful to avoid touching those components with your bare hands.

HEALTH SAFETY CONDITIONS

1.Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1.The copier and its peripherals must be installed and maintained by a customer service representative who has completed the training course on those models.

CAUTION

CAUTION

2.The RAM board has a lithium battery which can explode if handled incorrectly. Replace only with the same type of RAM board. Do not recharge or burn this battery. Used RAM boards must be handled in accordance with local regulations.

STM |

a |

A156/A160/A162 |

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1.Do not incinerate toner cartridges or used toner. Toner dust may ignite suddenly when exposed to open flame.

2.Dispose of used toner, developer, and organic photoconductors in accordance with local regulations. (These are non-toxic supplies.)

3.Dispose of replaced parts in accordance with local regulations.

4.When keeping used lithium batteries (from the main control boards) in order to dispose of them later, do not store more than 100 batteries (from the main control boards) per sealed box. Storing larger numbers or not sealing them apart may lead to chemical reactions and heat build-up.

A156/A160/A162 |

b |

STM |

Rev. 1/98

TAB INDEX

OVERALL MACHINE INFORMATION

SORTER A557

DETAILED SECTION DESCRIPTION

AUTO REVERSE DOCUMENT FEEDER A548

PAPER TRAY UNIT A550/A549

PAPER TRAY UNIT A553

SORTER STAPLER A554

SORTER STAPLER A555

SORTER A556

TAB POSITION 8 TAB POSITION 7 TAB POSITION 6 TAB POSITION 5 TAB POSITION 4 TAB POSITION 3 TAB POSITION 2 TAB POSITION 1

OVERALL MACHINE

INFORMATION

Rev. 7/95

1. SPECIFICATIONS

Configuration: |

Desktop |

|

|

|

|

Copy Process: |

Dry electrostatic transfer system |

|

|||

Originals: |

Sheet/Book |

|

|

|

|

Original Size: |

Maximum A3/11" x 17" |

|

|||

Copy Paper Size: |

Maximum |

|

|

|

|

|

A3/11" x17" (Paper trays) |

|

|||

|

Minimum |

|

|

|

|

|

A5/81/2" x 51/2" sideways (Paper trays) |

||||

|

A4/11" x 81/2" sideways (LCT) |

||||

|

A6/51/2" x 81/2" lengthwise (By-pass) |

||||

Duplex Copying: |

Maximum |

|

|

|

|

|

A3/11" x 17" |

|

|

|

|

|

Minimum |

|

|

|

|

|

A5/81/2" x 51/2" (sideways) |

|

|||

Copy Paper Weight: |

Paper tray: |

|

|

|

|

|

52 ~ 128 g/m2, 14 ~34 lb |

|

|||

|

(A153, A155, and A156 copiers) |

||||

|

64 ~ 90 g/m2, 17 ~ 24 lb |

|

|||

|

(A157, A159, and A160 copiers) |

||||

|

By-pass: |

|

|

|

|

|

52 ~ 157 g/m2, 14 ~42 lb |

|

|||

|

LCT: |

|

|

|

|

|

52 ~ 128 g/m2, 14 ~ 34 lb |

|

|||

|

Duplex copying: |

|

|

|

|

|

64 ~ 105 g/m2, 17 ~ 24 lb |

|

|||

Reproduction Ratios: |

4 Enlargement and 6 Reduction |

|

|||

|

|

|

|

|

|

|

|

A4/A3 Version |

|

LT/DLT Version |

|

|

|

|

200% |

|

200% |

|

Enlargement |

|

141% |

|

155% |

|

|

122% |

|

129% |

|

|

|

|

|

||

|

|

|

115% |

|

121% |

|

Full size |

|

100% |

|

100% |

|

|

|

93% |

|

93% |

|

|

|

82% |

|

85% |

|

Reduction |

|

75% |

|

77% |

|

|

71% |

|

74% |

|

|

|

|

|

||

|

|

|

65% |

|

65% |

|

|

|

50% |

|

50% |

|

|

|

|

|

|

Power Source: |

120V/60Hz: |

|

|

|

|

|

More than 12 A (for North America) |

||||

Information

Overall Machine

STM |

1-1 |

A156/A160/A162 |

Rev. 7/95

Power Consumption:

|

|

|

A153, and A156 copiers |

A157, and A160 copiers |

||

|

|

|

Copier Only |

Full System |

Copier Only |

Full System |

Maximum |

1.45 KW |

1.50 KW |

1.45 KW |

1.50 KW |

||

Copying |

|

1.00 KW |

1.00 KW |

0.80 KW |

0.80 KW |

|

Warm-up |

0.90 KW |

0.92 KW |

0.90 KW |

0.92 KW |

||

Stand-by |

0.16 KW |

0.19 KW |

0.15 KW |

0.17 KW |

||

|

|

1 |

0.15 KW |

0.17 KW |

0.14 KW |

0.16 KW |

Energy |

|

2 |

0.13 KW |

0.15 KW |

0.12 KW |

0.13 KW |

|

3 |

0.12 KW |

0.14 KW |

0.09 KW |

0.10 KW |

|

Saver |

|

|||||

|

4 |

0.11 KW |

0.12 KW |

0.07 KW |

0.08 KW |

|

|

|

|||||

|

|

5 |

0.09 KW |

0.11 KW |

0.05 KW |

0.06 KW |

|

|

6 |

0.07 KW |

0.09 KW |

– |

– |

Auto Off |

|

0.02 KW |

0.04 KW |

0.02 KW |

0.04 KW |

|

|

|

|

|

|

|

|

NOTE: 1) Full System: Copier + ADF + Paper Tray Unit + 20 Bin S/S

2)Energy Saver: See SP1-105-002

3)Auto Off: See SP5-305

A161 and A162 Copiers

|

|

Copier Only |

Full System |

|

Maximum |

|

1.45 KW |

1.50 KW |

|

Copying |

|

0.64 KW |

0.72 KW |

|

Warm-up |

|

0.95 KW |

0.97 KW |

|

Stand-by |

|

0.15 KW |

0.17 KW |

|

|

1 |

0.14 KW |

0.16 KW |

|

Energy Saver |

2 |

0.12 KW |

0.13 KW |

|

3 |

0.09 KW |

0.10 KW |

||

|

||||

|

4 |

0.07 KW |

0.08 KW |

|

|

5 |

0.05 KW |

0.06 KW |

|

Auto Off |

|

0.02 KW |

0.04 KW |

NOTE: 1) Full System: Copier + ADF + Paper Tray Unit + 10 Bin S/S

2)Energy Saver: See SP1-105-002

3)Auto Off: See SP5-305

Noise Emission:

|

A153, and A156 copiers |

A157, and A160 copiers |

||

|

Copier Only |

Full System* |

Copier Only |

Full System* |

1. Sound Power Level |

|

|

|

|

Copying |

66 dB(A) |

68 dB(A) |

61 dB(A) |

67 dB(A) (LWA) |

Warm-up |

41 dB(A) |

41 dB(A) |

39 dB(A) |

40 dB(A) (LWA) |

Stand-by |

41 dB(A) |

41 dB(A) |

39 dB(A) |

40 dB(A) (LWA) |

2. Sound Pressure Level at the operator position |

|

|

||

Copying |

58 dB(A) |

57 dB(A) |

54 dB(A) |

56 dB(A) (LPA) |

Warm-up |

33 dB(A) |

27 dB(A) |

32 dB(A) |

27 dB(A) (LPA) |

Stand-by |

33 dB(A) |

27 dB(A) |

32 dB(A) |

27 dB(A) (LPA) |

|

|

|

|

|

NOTE: The above measurements are to be made according to ISO 7779. * : Full System: Copier + ADF + Paper Tray Unit +10 Bin S/S.

A156/A160/A162 |

1-2 |

STM |

Dimensions: |

|

|

Rev. 7/95 |

||

|

|

|

|

||

|

|

|

|

|

|

|

|

Width |

Depth |

Height |

|

|

A153 copier |

1030 mm (40.6") |

655 mm (25.8") |

606 mm (23.9") |

|

|

A157/A161 copier |

900 mm (35.5") |

655 mm (25.8") |

606 mm (23.9") |

|

|

A156 copiers |

1258 mm (49.6") |

655 mm (25.8") |

606 mm (23.9") |

|

|

A160/A162 copiers |

1128 mm (44.5") |

655 mm (25.8") |

606 mm (23.9") |

|

|

|

|

|

|

|

Measurement Conditions

1)With by-pass feed table closed

2)With platen cover and copy tray attached

3)With LCT cover closed

Weight:

|

|

|

|

|

|

|

|

Weight |

||

|

|

|

FT5035 A153 copier |

|

About 70 kg (154.2 lb) |

|||||

|

|

|

FT5535 A156 copier |

|

About 82 kg (180.7 lb) |

|||||

|

|

|

FT4027 A157 copier |

|

About 67 kg (147.7 lb) |

|||||

|

|

|

FT4527 A160 copier |

|

About 80 kg (176.4 lb) |

|||||

|

|

|

FT4022 A161 copier |

|

About 67 kg (147.7 lb) |

|||||

|

|

|

FT4522 A162 copier |

|

About 80 kg (176.4 lb) |

|||||

|

|

|

|

|

|

|

|

|

|

|

Zoom: |

|

From 50% to 200% in 1% steps |

|

|||||||

Copying Speed (copies/minute): |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A4 sideways/ |

A3/11" x 17" |

|

B4/81/2" x 14" |

|||

|

|

|

|

11" x 81/2" |

|

|||||

|

|

|

|

|

|

|

|

|

||

|

A153, and A156 |

|

35 |

|

20/19 |

|

|

22 |

||

|

copiers |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

A157, and A160 |

|

27 |

|

15/14 |

|

|

17 |

||

|

copiers |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

A161, and A162 |

|

22 |

|

12 |

|

|

- |

||

|

copiers |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

Warm-Up Time |

|

A153, and A156 copiers: |

|

|||||||

|

|

|

|

Less than 110 seconds (20°C) |

||||||

|

|

|

|

A157, and A160 copiers: |

|

|||||

|

|

|

|

Less than 80 seconds (20°C) |

||||||

|

|

|

|

A161 and A162 copiers: |

|

|||||

|

|

|

|

Less than 60 seconds (20°C) |

||||||

First Copy Time: |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

Paper Feed Station |

|

A4/11" x 81/2" (sideways) |

|

|||||||

|

A153, and A156 |

|

A157, and A160 |

|

A161, and A162 |

|||||

|

|

|

|

copiers |

|

copiers |

|

copiers |

||

|

1st Tray |

|

5.2 s (except for |

|

5.9 s (except for |

|

|

5.9 s (except for |

||

|

|

A156) |

|

|

A160) |

|

|

A162) |

||

|

|

|

|

|

|

|

||||

|

2nd Tray |

|

5.7 s |

|

|

6.6 s |

|

|

6.6 s |

|

|

By-pass |

|

4.8 s |

|

|

5.6 s |

|

|

5.6 s |

|

|

LCT |

|

5.0 s |

|

|

5.9 s |

|

|

5.9 s |

|

|

|

|

|

|

|

|

|

|

|

|

Note: In A156, A160 and A161 copiers, the 2nd tray in the above table is called the 1st tray (see Installation - Paper Feed Station Definition).

Information

Overall Machine

STM |

1-3 |

A156/A160/A162 |

Rev. 7/95 |

Ten-key pad, 1 to 999 (count up or count down) |

Copy Number Input: |

|

Manual Image Density |

7 steps |

Selection: |

|

Automatic Reset: |

1 minute is the standard setting; it can be |

|

changed to a maximum of 999 seconds or no |

|

auto reset by SP mode. |

Copy Paper Capacity:

|

Paper Tray |

By-pass Feed |

LCT |

A153 copier |

About 500 sheets x2 |

About 40 sheets |

– |

A156 copier |

About 500 sheets x1 |

About 40 sheets |

About 1000 sheets |

A157 copier |

About 250 sheets x2 |

About 40 sheets |

– |

A160 copier |

About 250 sheets x1 |

About 40 sheets |

About 1000 sheets |

A161copier |

About 250 sheets x2 |

About 40 sheets |

– |

A162 copier |

About 250 sheets x1 |

About 40 sheets |

About 1000 sheets |

|

|

|

|

Duplex Tray Capacity |

50 sheets (30 sheets for A3/11"x17" |

|

|

[A156/A160/A162]: |

81 ~ 105g/m2, 21.5 ~ 27.9 lb paper) |

|

|

Toner Replenishment: |

Cartridge exchange (415 g/cartridge) |

|

|

Toner Yield: |

17K Copies/cartridge |

|

|

Developer Replenishment: Type 1 (1kg bag) |

|

||

Developer Yield: |

A153/A156 @ 120K copies |

|

|

|

A157/A160 @ 100K copies |

|

|

|

A161/A162 @ 100K copies |

|

|

Optional Equipment: |

∙ |

Platen cover |

|

|

∙ |

Document feeder |

|

|

∙ Paper tray unit with two paper trays |

|

|

|

∙ Paper tray unit with three paper trays |

|

|

|

∙ 10 bin micro sorter |

|

|

|

∙ 20 bin mini sorter |

|

|

|

∙ 10 bin sorter stapler |

|

|

|

∙ 20 bin sorter stapler (Not used with A161 and A162) |

||

|

∙ Sorter adapter (required when installing 20 |

||

|

|

bin mini sorter, 10 bin sorter stapler, or 20 bin |

|

|

|

sorterstaplerforA157, A160,A161,andA162 copiers) |

|

|

∙ |

Key counter |

|

|

∙ |

Tray heater |

|

|

∙ Optical anti-condensation heater |

|

|

|

∙ Original length sensor for 11" x 15" size |

|

|

|

|

paper (only for LT/DLT version) |

|

|

∙ ADS sensor for particular types of red original |

||

|

∙ Zoom (10 Key) Function Decal * |

|

|

|

∙ Margin Adjustment Function Decal * |

|

|

|

|

* Not used on FT4022/4522 (A161/A162 copiers) |

|

A156/A160/A162 |

|

1-4 |

STM |

Loading...

Loading...