Raypak WH3-1262BD Installation Manual

SUPPLEMENTAL INSTALLATION AND OPERATING INSTRUCTIONS

FlexGas™

For Hi Delta Models

302BD–2342BD

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids or other combustible materials in the vicinity of this or any other appliance. To do so may result in an explosion or fire.

NOTE: THIS MANUAL IS SUPPLEMENTAL FOR THE FLEXGAS MODELS OF THE HI DELTA HEATERS. THIS MANUAL ADDRESSES THE SPECIFIC DIFFERENCES BETWEEN THESE HEATERS AND STANDARD HI DELTA MODELS. Please refer to the standard Installation and Operating Instruction manuals

(Catalogs 1000.501 and 1000.511 as appropriate) for installation requirements which are not related to the gas supply.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in another safe place for future reference.

Catalog No. 1000.58C |

Effective: 10-14-14 |

Replaces: 06-24-08 |

P/N 241295 Rev. 4 |

Patent No. 6,904,873; Other patent pending |

|

|

|

Rev. 3 reflects the following: Changes to: Wiring diagram (Fig. 6) on page 9

2

WARNING: Do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the heater and to replace any part of the control system and any gas control which has been under water.

WARNING: Should overheating occur or the gas supply valve fail to shut off, do not turn off or disconnect the electrical supply to the heater. Instead, shut off the gas supply at a location external to the heater.

WARNING: Risk of electrical shock. More than one disconnect switch may be required to de-energize the equipment before servicing.

WARNING: This FlexGas heater is intended for operation on Natural Gas as the primary fuel. DO NOT use this heater on Propane Gas as the primary fuel.

Raypak strongly recommends that this manual be reviewed thoroughly before installing your Hi Delta heater equipped with FlexGas. Raypak also recommends that the appropriate Hi Delta Installation and Operating Instruction manual (1000.501 for 302B902B or 1000.511 for 992B – 2342B) be thoroughly read before attempting to install these heaters. Factory warranty does not apply to heaters that have been improperly installed or operated. (Refer to the warranty at the back of the standard Hi Delta manuals.) Installation and service must be performed by a qualified installer, service agency or gas supplier. If, after reviewing these manuals, you still have questions which these manuals do not answer, please contact the manufacturer or your local Raypak representative.

Thank you for purchasing a Raypak product. We hope you will be satisfied with the high quality and durability of our equipment.

Model Identification

The model identification number and heater serial number are found on the heater rating plate located on the lower right outside jacket of the heater. The model number will have the form H9 1262BD or similar depending on the heater size and configuration. The letter(s) in the first group of characters identifies the application (H = Hydronic Heating, WH = Domestic Hot Water (DHW), P = Pool). The number which follows identifies the firing mode (1 or 4 = on-off, 3 =

2-stage, 8 = 3-stage and 9 = 4-stage). NOTE: Not all these firing options are available on all heaters.

Refer to the Hi Delta manual for available firing options. The second group of characters identifies the size of the heater (four numbers representing the approximate MBTUH input), and, where applicable, a letter, indicating the manufacturing series. The final character is the letter “D” which designates the heater as a FlexGas equipped heater.

|

|

|

|

|

|

Model |

|

Input |

Pipe Size |

|

Pipe Size |

|

(MBTUH) |

(Nat) |

|

(LP) |

|

|

|

|

|||

302BD |

|

300 |

1-1⁄4” |

|

3⁄4” |

402BD |

|

399 |

1-1⁄4” |

|

3⁄4” |

502BD |

|

500 |

1-1⁄4” |

|

3⁄4” |

652BD |

|

650 |

1-1⁄4” |

|

3⁄4” |

752BD |

|

750 |

1-1⁄4” |

|

1-1⁄4” |

902BD |

|

900 |

1-1⁄4” |

|

1-1⁄4” |

992BD |

|

990 |

2” |

|

1-1⁄4” |

1262BD |

|

1260 |

2” |

|

1-1⁄4” |

1532BD |

|

1530 |

2” |

|

1-1⁄4” |

1802BD |

|

1800 |

2” |

|

1-1⁄4” |

2072BD |

|

2070 |

2” |

|

1-1⁄4” |

2342BD |

|

2340 |

2” |

|

1-1⁄4” |

|

Table 1: FlexGas Specifications |

|

|||

Ratings and Certifications |

|||||

Standards:

•ANSI Z21.13 · CSA 4.9 - latest edition, Gas-Fired Hot Water Boilers

•CAN 3.1 - latest edition, Industrial and Commercial Gas-Fired Package Boilers

•ANSI Z21.56 · CSA 4.7 - latest edition, Gas-Fired Pool Heaters

•ANSI Z21.10.3 · CSA 4.3 - latest edition, Gas Water Heaters

3

All Raypak heaters are National Board Approved, and design-certified and tested by the Canadian Standards Association (CSA) for the U.S. and Canada. Each heater is constructed in accordance with Section IV of the American Society of Mechanical Engineers (ASME) Pressure Vessel Code, and bears either the ASME “H” stamp for boilers or “HLW” stamp for water heaters. The heater also complies with the latest edition of ASHRAE 90.1 Standard.

WARNING: Altering any Raypak pressure vessel by installing replacement heat exchangers, tube bundle headers, or any ASME parts not manufactured and/or approved by Raypak will instantly void the ASME and CSA ratings of the vessel and any Raypak warranty on the vessel. Altering the ASME or CSA ratings of the vessel also violates national, state, and local approval codes.

Rated inputs are suitable for up to 4,500 ft elevation without de-rating. Consult the factory for installations at altitudes over 4,500 ft above sea level.

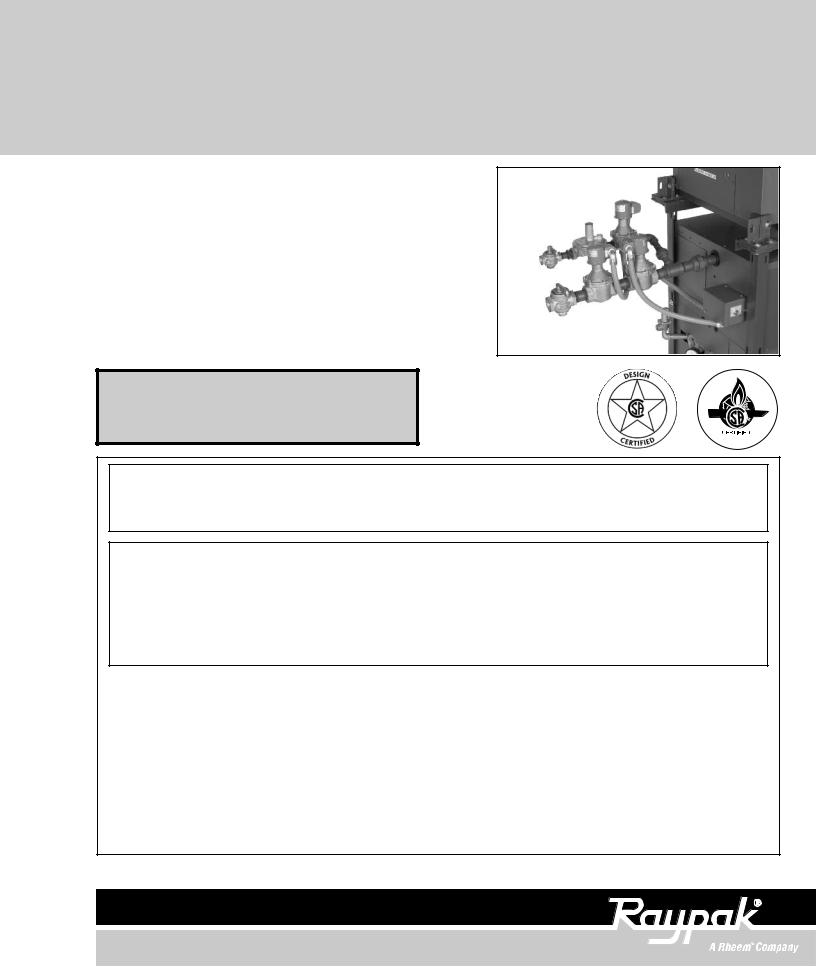

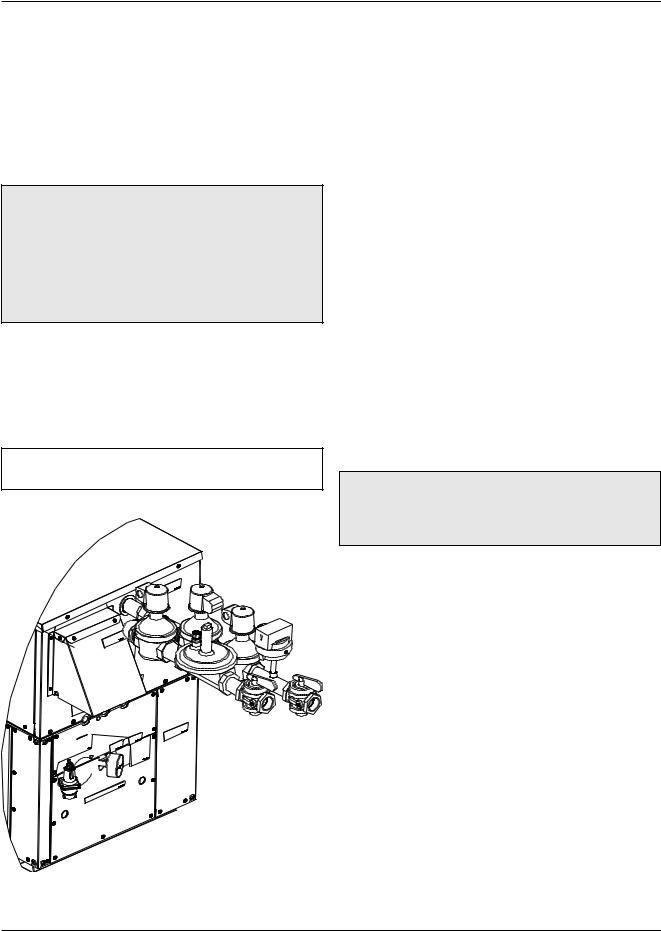

Component Locations

NOTE: Maintain upright orientation of all components as shown in Fig. 1.

Installation Codes

Installations must follow these codes:

•Local, state, provincial, and national codes, laws, regulations and ordinances

•National Fuel Gas Code, ANSI Z223.1/NFPA 54 – latest edition (NFGC)

•National Electrical Code, ANSI/NFPA 70 - latest edition (NEC)

For Canada only: CAN/CGA B149 Installation Code (B149.1) and CSA C22.1 C.E.C. Part 1 (C22.1)

Gas Supply

This heater will be connected to 2 different gas supplies (Natural Gas and Propane Gas).

Each gas piping must have a separate sediment trap ahead of the gas controls. Pounds-to-inches regulators must be installed to reduce the gas supply pressure to a maximum of 10.5 in. WC for natural gas and 13.0 in. WC for propane gas. The regulator should be placed a minimum distance of 10 times the pipe diameter upstream of the heater gas controls.

CAUTION: The heater must be disconnected from the gas supply during any pressure testing of the gas supply system at test pressures in excess of 1/2 psi (3.45 kPa).

The heater must be isolated from the gas supply piping system by closing the manual shut-off valves during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.45 kPa). Relieve test pressure in the gas supply line prior to reconnecting the heater and its manual shut-off valves to the gas supply lines. FAILURE TO FOLLOW

THIS PROCEDURE MAY DAMAGE THE GAS VALVES. Over-pressurized gas valves are not covered by warranty. The heater and its gas connections shall be leak-tested before placing the appliance in operation. Use soapy water for leak test. DO NOT use an open flame.

FlexGas cover not shown for clarity

Fig. 1: Component Locations – Back

4

Loading...

Loading...