PVI Industries PV500-2 User Manual

PVI ATMOSPHERIC GAS WATER HEATERS

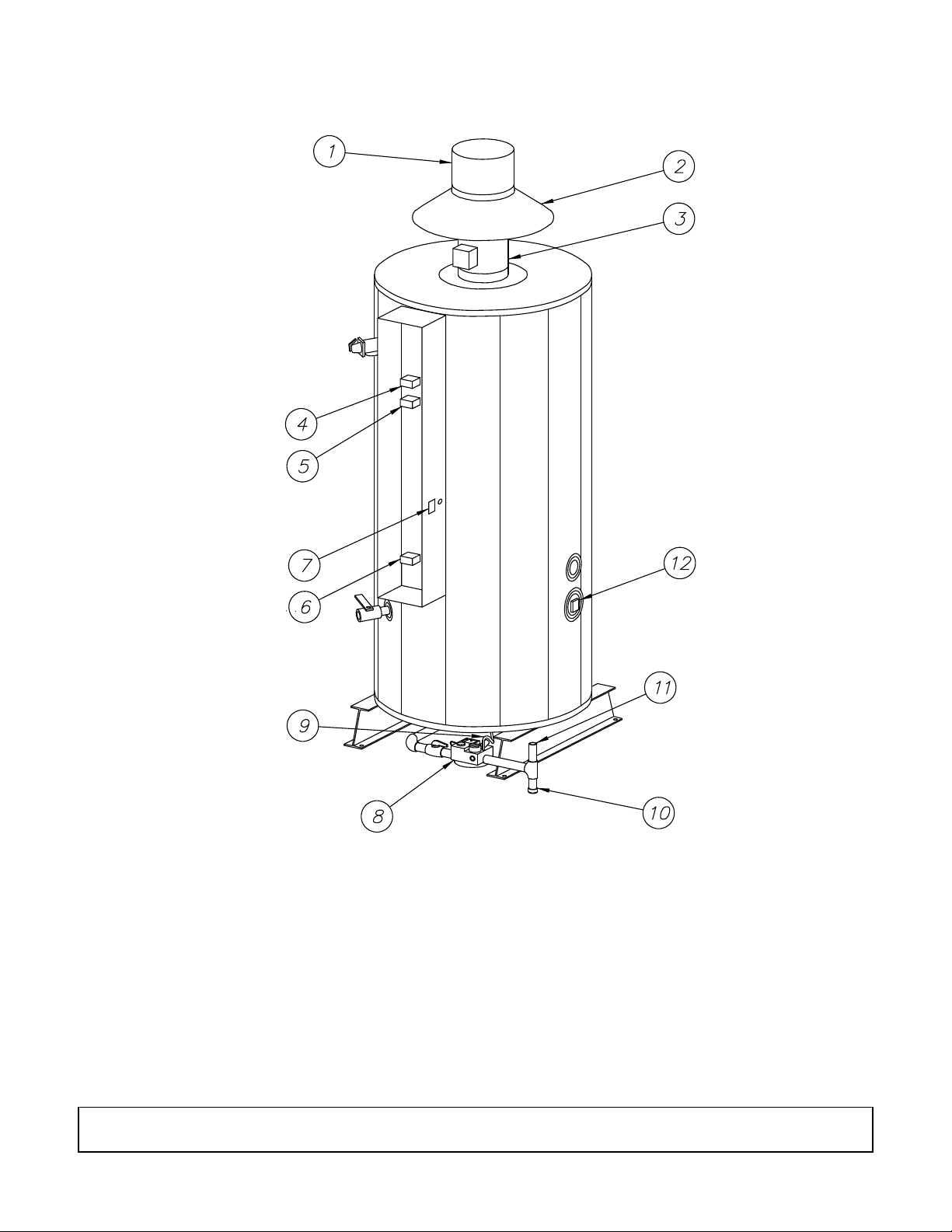

TYPICAL CONSTRUCTION

MANUFACTURED AFTER JANUARY 1, 1994

Figure 2-1

1. Vent stack * 7. Control switch(es) and fuse(s)

2. Draft diverter (hood) 8. Gas valve

3. Flue damper (on some models) 9. Pilot line

4. Temperature limiting device 10. Drip leg *

(set at 200°F) 11. Gas supply line *

5. Upper operating thermostat 12. Handhole cleanout

(set at 130°F)

6. Operating thermostat

(set at 120°F) (* Not furnished by PVI)

CAUTION: TEMPERATURES HIGHER THAN 125°F INCREASE THE RISK OF SCALD INJURY!

IMPORTANT: Clearances to unprotected combustible material must be 8" minimum at top, sides and rear, and 24" in front.

Clearances for servicing and inspection must be 18" minimum at sides and rear and 24" minimum in front.

PV500-2 06/10 1 Section 2

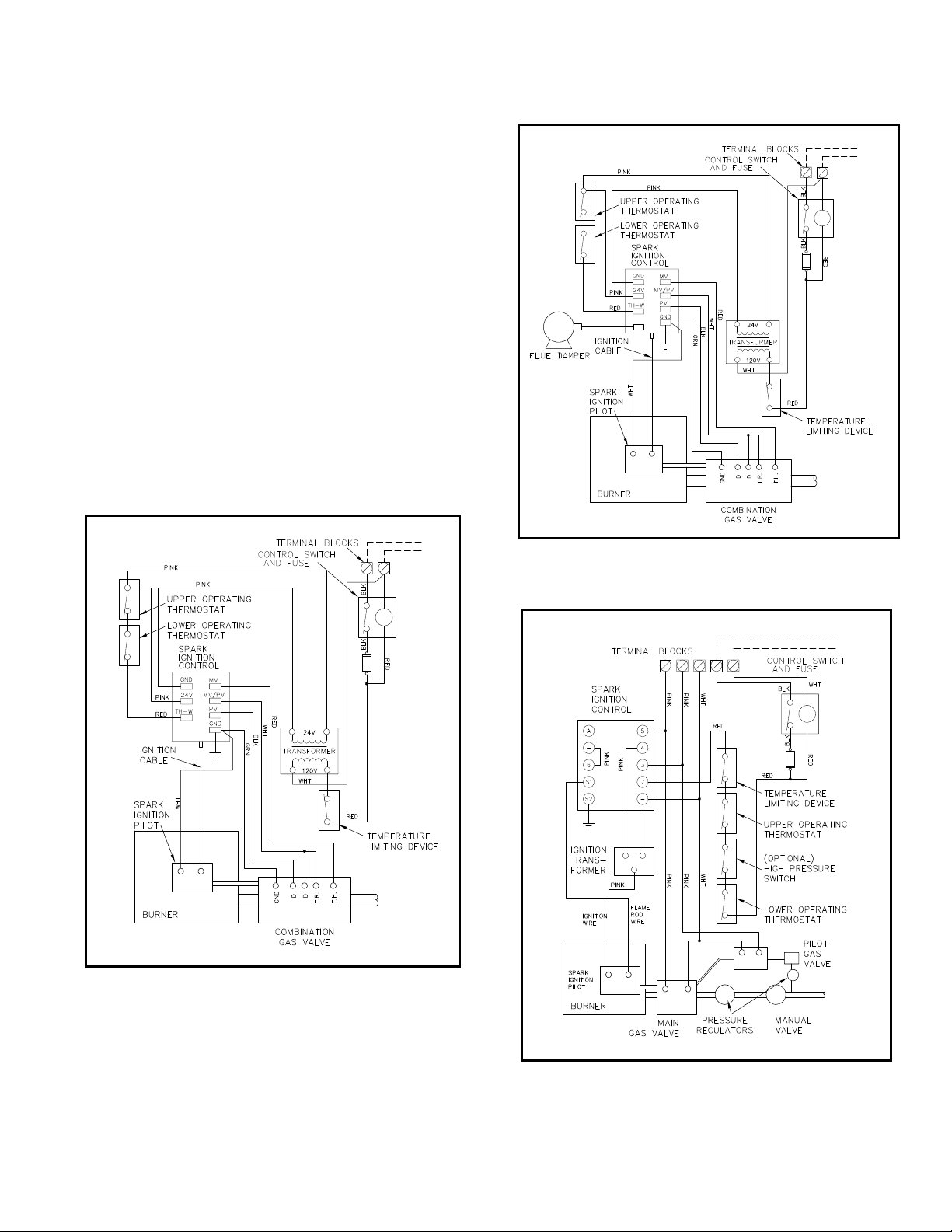

ELECTRICAL

1. Wiring to the unit should conform to the National

Electrical Code or the code legally authorized in your

locality. A fused disconnect switch should be used for

the water heater control. 120V, 1ph, 60 Hz service

wiring is brought to the terminal block in the lower part

of the enclosure on the water heater. See Figures 22, 2-3 and 2-4.

FOR YOUR SAFETY

USE ONLY COPPER WIRE OF PROPER SIZING

FOR INCOMING SERVICE. DAMAGE RESULTING

FROM USE OF ALUMINUM WIRING WILL BE

EXCLUDED FROM COVERAGE UNDER THE

WARRANTY OF THIS UNIT.

Typical 24 Volt Control System

Typical 24 Volt Control System

with Damper

Figure 2-3

Typical 120 Volt Control System

Figure 2-2

Figure 2-4

PV500-2 06/10 2 Section 2

START-UP PROCEDURES AND OPERATION

V

V

1. Some PVI atmospheric gas-fired water heaters are

designed to operate with a flue damper that is

shipped with the water heater for installation in the

field. If your water heater was shipped with a flue

damper, it must be attached to the flue collector and

interconnected to the ignition control module before

proceeding with start-up.

Flue Damper Installation

a. Set the flue damper over the flue collector opening

and align the damper drive housing to the front of

the heater.

b. Secure the flue damper to the flue collector at three

locations using the fasteners provided.

c. Remove the damper drive housing cover, feed the

damper interconnect cable through the access hole

and attach the female connector to the four-pin

receptacle. Secure the access hole cover, check to

make sure the test switch is in the "NORMAL"

position, and reattach the damper driver housing

cover.

CAUTION: BE SURE THERE IS NO FOREIGN MATTER

IN THE DAMPER HOUSING BEFORE ATTACHING

THE DRAFT DIVERTER.

Draft Diverter Installation

The draft diverter (provided) is designed to mount on top

of the flue damper. Set the draft diverter on top of the flue

damper and secure in three locations using the fasteners

provided.

Venting

Type B galvanized vent pipe, of the same diameter as the

draft diverter outlet, must be installed to route combustion

products either to existing overhead breeching or to an

appropriate outside location.

1. The control manufacturer's installation and service

manual and start-up procedures for the control

system on your water heater are shipped with the

unit. Study the information carefully and follow the

manufacturer's recommendations.

2. Fill the water heater tank with water. Open the relief

valve or a nearby hot water faucet to allow air in the

tank to escape. Be sure all connections into the tank

are tight as leaks at tank fittings will damage the

insulation.

3. Remove the control box cover to access the control

thermostats and other electrical devices needed to

operate the water heater. The thermostats are labeled

as to their function. The temperature limiting device is

set at 200°F. The thermostats are factory set at

130°F. (the upper operating thermostat) and 120°F

(the operating thermostat). Adjustment may be made

by turning the thermostat dial to the desired

temperature.

CAUTION: BE SURE TO REATTACH THE

CONTROL BOX COVER TO HELP PREVENT

UNAUTHORIZED ACCESS TO CONTROLS.

CAUTION: DO NOT OVERTIGHTEN

COMPRESSION FITTINGS ON THERMOSTAT

BULBS AS CALIBRATION WILL BE CHANGED.

CAUTION: TEMPERATURES HIGHER THAN 125°F

INCREASE THE RISK OF SCALD INJURY!

Gas Train Safety Inspection

CAUTION: ALL VENTED GAS CONTROLS MUST

BE VENTED TO THE OUTSIDE USING TUBING

SIZED IN ACCORDANCE WITH THE

FOLLOWING TABLE:

ENT LINE SIZING

Fuel Line Size,

Nominal Pipe Size,

Inches

Up to 1 1/2 3/4

21

2 1/2 1 1/4

31 1/4

42

52

62 1/2

83

ent Line Size,

Nominal Pipe Size,

Inches

PV500-2 06/10 3 Section 2

Loading...

Loading...