Power Innovations Y1112 Datasheet

THE FLUORACTOR® Y1112

FLUORESCENT LAMP STARTER SWITCH

JUNE 1984 - REVISED SEPTEMBER 1997Copyright © 1997, Power Innovations Limited, UK

● V

● I

● I

description

1200 to 1500 V

(BR)

> 175 mA

H

< 2 mA

GT

This product is intended for use as a T8/T12

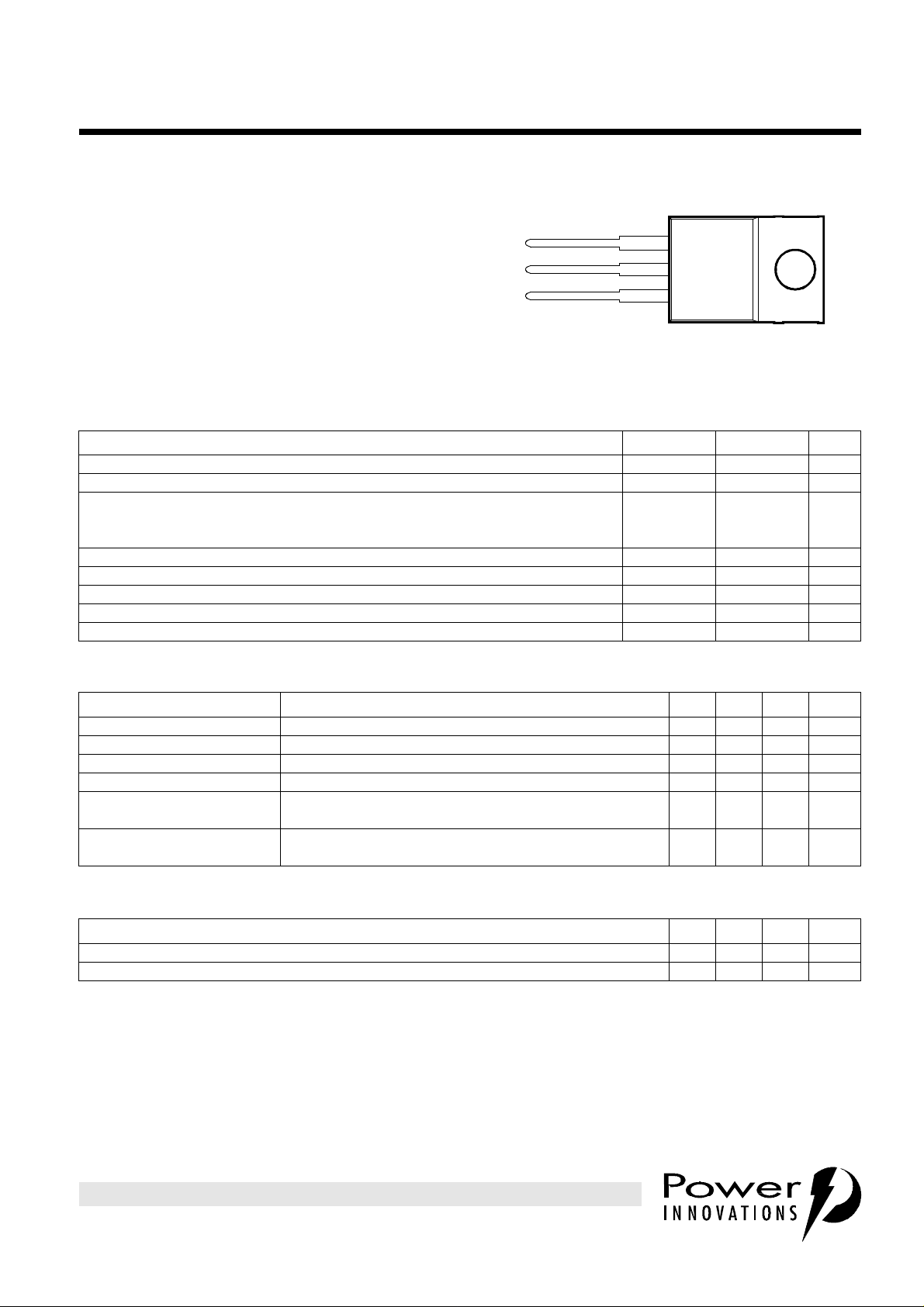

TO-220 PACKAGE

(TOP VIEW)

K

A

G

1

2

3

fluorescent tube starter switch on 200-240 V a.c.

supplies with tube sizes up to 5ft with leading

and lagging ballast circuits.

Pin 2 is in electrical contact with the mounting base.

absolute maximum ratings at 25°C case temperature (unless otherwise noted)

RATING SYMBOL VALUE UNIT

Crest working off-state voltage (Full wave rectified 50 Hz a.c.) V

Peak reverse gate voltage V

On-state current — continuous

— repetitive peak

— non-repetitive peak

Peak gate current I

Average gate power P

Operating case temperature range T

Storage temperature range T

Lead temperature during soldering 1.6 mm from the case for 10 seconds T

DWM

RGM

I

TRM

I

TSM

GRM

G(av)

I

T

C

stg

lead

MDC1ACA

375 V

6 V

1.5

2

10

0.5 A

0.3 W

-5 to +85 °C

-10 to +110 °C

230 °C

A

electrical characteristics at 25°C case temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

I

V

Off-state current VD = V

I

D

On-state voltage IT= 2 A 3.1 V

V

T

Clamping voltage IBR = 5 mA tp< 200 µs, 2% duty cycle 1200 1500 V

(BR)

Holding current See application circuit 175 mA

I

H

Peak gate

GTM

trigger current

Peak gate

GTM

trigger voltage

DWM

= 10 V RL= 10 Ω 2 mA

V

AA

= 10 V RL= 10 Ω 3 V

V

AA

Tj = 65°C 1 mA

thermal characteristics

PARAMETER MIN TYP MAX UNIT

R

R

Junction to free air thermal resistance 62.5 °C/W

θJA

Junction to case thermal resistance 3.5 °C/W

θJC

PRODUCT INFORMATION

Information is current as of publication date. Products conform to specifications in accordance

with the terms of Power Innovations standard warranty. Production processing does not

necessarily include testing of all parameters.

1

THE FLUORACTOR® Y1112

FLSCCT1

FLUORESCENT LAMP STARTER SWITCH

JUNE 1984 - REVISED SEPTEMBER 1997

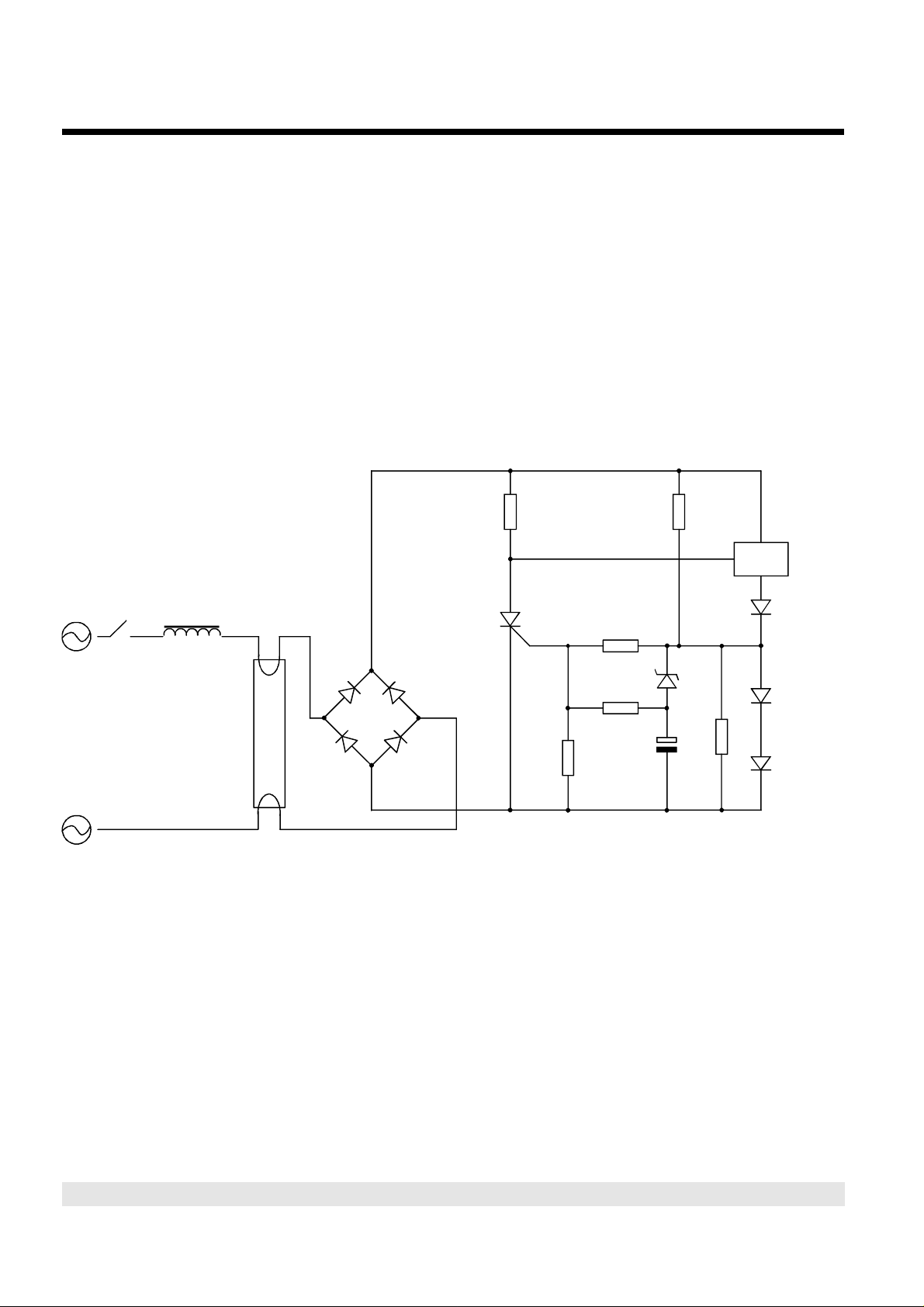

applications data

The conventional method of starting fluorescent tubes employs the use of an electromechanical canister. This

consists of a bimetallic strip which opens as it cools and in conjunction with the ballast inductor, provides the

tube striking voltage. However, the random nature of the pulsing results in repeated striking attempts and

degradation of both the tube and starter. The tube degradation is illustrated by its progressively blackening

ends and ultimately required tube replacement.

®

The Y1112, “Fluoractor

offers the lighting industry an opportunity to develop electronic starters small enough to be retrofit

replacements for the established electromechanical canisters. Its double thyristor structure with integrated

zener clamp diode and current mirror provides the technology for a starter with enhanced features such as

controlled flicker free start up, automatic tube shutdown at end of tube life and reduced degradation of tube

ends leading to extended life. The increased functionality, lifetime and reliability of these starters has led in

some cases to them being embodied in the ballast itself, a development not feasible with the old

electromechanical canisters.

”, has been specifically introduced for use in electronic starters. This unique device

D1 to 4 (see Note A)

4 x 1N4007

Figure 1. Two terminal starter circuit

NOTE 1: These rectifiers need to be voltage selected for VR ≥ V

(BR)max

+ 150 V

150 k

ΩΩ

Y1112

R2

68 k

R3

6.8 k

ΩΩ

ΩΩ

D5

D5 to 7

3 x 1N4001

D6

D7

PRODUCT INFORMATION

2

Loading...

Loading...