Porter-Cable PCB370SS User Manual

16 IN. (406 MM) VARIABLE SPEED SCROLL SAW

SCIE SAUTEUSE 406 MM

(16 PO ) À VITESSE VARIABLE

SIERRA CALADORA DE

VELOCIDAD VARIABLE,

DE 406 MM (16 PULG.)

Instruction Manual

Manuel d’instructions

Manual de instrucciones

www.portercable.com

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

CATALOG NUMBER

PCB370SS

|

TABLE OF CONTENTS |

|

|

SECTION |

|

|

PAGE |

PRODUCT SPECIFICATIONS |

..................................................................................................................... |

|

2 |

CALIFORNIA PROPOSITION 65................................................................................................................. |

|

3 |

|

SAFETY GUIDELINES - DEFINITIONS ...................................................................................................... |

|

3 |

|

GENERAL SAFETY RULES ........................................................................................................................ |

|

|

4 |

SCROLL SAW SAFETY............................................................................................................................... |

|

|

5 |

ELECTRICAL REQUIREMENTS ..........................................................................................AND SAFETY |

|

7 |

|

TOOLS NEEDED FOR ASSEMBLY............................................................................................................. |

|

8 |

|

CARTON CONTENTS.................................................................................................................................. |

|

|

8 |

UNPACKING YOUR SCROLL ...........................................................................................................SAW |

|

9 |

|

KNOW YOUR SCROLL SAW ..................................................................................................................... |

|

|

10 |

GLOSSARY OF TERMS.............................................................................................................................. |

|

|

11 |

ASSEMBLY AND ADJUSTMENTS.............................................................................................................. |

|

12 |

|

OPERATION ............................................................................................................................................... |

|

|

17 |

MAINTENANCE........................................................................................................................................... |

|

|

21 |

ACCESSORIES AND ATTACHMENTS....................................................................................................... |

|

22 |

|

TROUBLESHOOTING GUIDE..................................................................................................................... |

|

|

23 |

PARTS LIST................................................................................................................................................. |

|

|

24 |

WARRANTY................................................................................................................................................. |

|

|

28 |

PRODUCT SPECIFICATIONS |

|||

MOTOR |

|

TABLE |

|

Power Source…………........... ................................. |

120 V AC, 60 HZ, 1.6 Amp |

Size |

12-43/64 in. x 18-1/2 in. |

Speed.................…………...... |

500 - 1500 RPM |

|

(322 mm × 470 mm) |

Speed Control.………............. ................................... |

Electric |

Tilt |

45° Left ; Right |

BLADE |

|

SAWDUST BLOWER |

Yes |

Type…..........…………………. |

Pin - end or Plain - end |

WORK LIGHT |

10 W (maximum) |

Depth of Throat....................... |

16 - 1/16 in. (408 mm) |

|

|

Blade Stroke…......….............. |

11/16 in. (17.5 mm) |

|

|

Depth of 45° Cut…………….... |

1 - 1/16 in. (27 mm) Right ; |

|

|

|

3/4 in. (19 mm) Left |

|

|

Depth of 90° Cut..................... |

2 in. (50.8 mm) |

|

|

! WARNING

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection. Use a separate electrical circuit for your tools.

The scroll saw is wired at the factory for 110-120 Volt operation. It must be connected to a 120V,1.6 AMP branch circuit and use a 1.6 AMP time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is worn, cut or damaged in any way.

2009/10 |

2 |

Printed in China |

CALIFORNIA PROPOSITION 65

! WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

●Lead from lead-based paints,

●Crystalline silica from bricks and cement and other masonry products, and

●Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemical: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

! WARNING

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

SAFETY GUIDELINES - DEFINITIONS

WARNING ICONS

Your power tool and its Instruction Manual may contain “WARNING ICONS” (a picture symbol intended to alert you to and/or instruct you how to avoid a potentially hazardous condition). Understanding and heeding these symbols will help you operate your tool better and safer. Shown below are some of the symbols you may see.

|

SAFETY ALERT: Precautions that involve your safety. |

||

|

PROHIBITION |

||

|

WEAR EYE PROTECTION: Always wear safety goggles or safety glasses with side shields. |

||

|

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury, user and all bystanders |

||

|

must read and understand instruction manual before using this product. |

||

|

KEEP HANDS AWAY FROM THE MOVING PART AND CUTTING SURFACE: Failure to keep your hands |

||

|

away from the moving part and cutting surface will result in serious personal injury. |

||

|

SUPPORT AND CLAMP WORK |

||

|

|

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in |

|

! |

DANGER |

||

|

|

|

death or serious injury. |

|

|

|

|

|

|

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in |

|

! |

WARNING |

||

|

|

|

death or serious injury. |

|

|

|

|

|

|

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor |

|

! |

CAUTION |

||

|

|

|

or moderate injury. |

|

|

|

|

|

|

CAUTION: Used without the safety alert symbol indicates potentially hazardous situation |

|

CAUTION |

|

||

|

|

|

which, if not avoided, may result in property damage. |

|

|

|

3 |

POWER TOOL SAFETY

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combination of common sense, staying alert and knowing how to use your power tool.

! WARNING

To avoid mistakes that could cause serious injury, do not plug the tool in until you have read and understood the following.

1.READ and become familiar with the entire

Instruction Manual. LEARN the tool’s application, limitations and possible hazards.

2.KEEP GUARDS IN PLACE and in working order.

3.REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning ON.

4.KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5.DO NOT USE IN DANGEROUS ENVIRONMENTS. Do not use power tools in damp locations, or expose them to rain or snow. Keep work area well lit.

6.KEEP CHILDREN AWAY. All visitors and bystanders should be kept a safe distance from work area.

7.MAKE WORKSHOP CHILD PROOF with padlocks, master switches or by removing starter keys.

8.DO NOT FORCE THE TOOL. It will do the job better and safer at the rate for which it was designed.

9.USE THE RIGHT TOOL. Do not force the tool or an attachment to do a job for which it was not designed.

10.USE PROPER EXTENSION CORDS. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will result in a drop in line voltage and in loss of power which will cause the tool to overheat. The table on page 6 shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

11.WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

12.ALWAYS WEAR EYE PROTECTION. Any power tool can throw foreign objects into the eyes

and could cause permanent eye damage. ALWAYS wear Safety Goggles (not glasses)

that comply with ANSI Safety standard Z87.1. Everyday eyeglasses have only impact– resistant lenses. They ARE NOT safety glasses. NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could seriously injure you when they break.

13.WEAR A FACE MASK OR DUST MASK. Sawing operation produces dust.

14.SECURE WORK. Use clamps or a vise to hold work when practical. It is safer than

using your hand and it frees both hands to

using your hand and it frees both hands to

operate the tool.

operate the tool.

15.DISCONNECT TOOLS FROM POWER SOURCE before servicing, and when changing accessories such as blades, bits and cutters.

16.REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in the OFF position before plugging the tool in.

17.USE RECOMMENDED ACCESSORIES. Consult this Instruction Manual for recommended accessories. The use of improper accessories may cause risk of injury to yourself or others.

18.NEVER STAND ON THE TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted.

19.CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function

– check for alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

20.NEVER LEAVE THE TOOL RUNNING UNATTENDED. TURN THE POWER “OFF”. Do not walk away from a running tool until the blade comes to a complete stop and the tool is unplugged from the power source.

21.DO NOT OVERREACH. Keep proper footing and balance at all times.

22.MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and changing accessories.

23.DO NOT use power tool in presence of flammable liquids or gases.

24.DO NOT operate the tool if you are under the influence of any drugs, alcohol or medicationn that could affect your ability to use the tool properly.

25.Dust generated from certain materials can be hazardous to your health. Always operate saw in well-ventilated area and provide for proper dust removal.

26.WEAR HEARING PROTECTION to reduce the risk of induced hearing loss.

4

SCROLL SAW SAFETY

SPECIFIC SAFETY INSTRUCTIONS FOR THIS SCROLL SAW

1.READ AND UNDERSTAND all safety instructions and operating procedures throughout the manual.

2.DO NOT OPERATE the Scroll Saw until it is completely assembled and installed according to the instructions.

3.SHOULD any part of Scroll Saw be missing, damaged, or fail in any way, or any electrical component fail to perform properly, shut off the switch and remove the plug from the power supply outlet. Replace missing, damaged, or failed parts before resuming operation.

4.IF YOU ARE NOT thoroughly familiar with the operation of a Scroll Saw, obtain advice from your supervisor, instructor or other qualified person.

5.SERIOUS INJURY could occur if the tool tips over or you accidentally hit the cutting tool. Do not store anything above or near the tool.

6.AVOID INJURY from unexpected saw movement. Place the saw on a firm level surface where the saw does not rock and bolt or clamp the saw to its support.

7.YOUR SCROLL SAW MUST BE SECURELY FASTENED to a stand or workbench. If there is any tendency for the stand or workbench to move during operation, the stand or workbench MUST be fastened to the floor.

8.THIS SCROLL SAW is intended for indoor use only.

9.TENSION BLADE PROPERLY before starting the saw. Recheck and adjust tension as needed.

10.BLADE TEETH MUST POINT downward toward the table.

11.TABLE MUST BE CLEARED of all debris before operating saw. Do not perform lay out, set up or assemble work on the table when the saw is in operation.

12.TO PREVENT INJURIES, avoid awkward hand or finger positions, where a sudden slip could cause a hand to move into the blade when operating the saw.

13.HOLD WORKPIECE FIRMLY against the table top.

14.NEVER CUT MATERIAL that is too small to be held safely.

15.DO NOT USE dull or bent blades.

16.TURN THE SAW OFF AND UNPLUG THE CORD if the blade binds in the saw kerf while being backed out of the workpiece, usually caused by sawdust clogging the kerf. If this happens, turn off the scroll saw and unplug the power cord. Wedge open the kerf and back the blade out of the workpiece.

17.DO NOT feed the material too fast while cutting. Only feed the workpiece at the rate the saw will cut.

18. TURN THE POWER OFF, make sure the scroll saw comes to a complete stop before installing or removing an accessory, and before leaving the work area.

19.DO NOT START the saw with workpiece pressing against the blade. Slowly feed the workpiece into the moving blade.

20.WHEN CUTTING a large workpiece, MAKE SURE the material is supported at table height.

21.EXERCISE CAUTION when cutting workpieces that are round or irregularly shaped, workpieces can pinch the blade.

22.ALWAYS release blade tension before loosening the blade holder screw.

23.MAKE CERTAIN table tilting lock is tightened before starting the machine.

24.NEVER REACH under the scroll saw table when motor is running.

25.CHECK FOR DAMAGED PARTS before each use. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting or any other conditions that may affect operation. Parts that

are damaged should be properly repaired or replaced before using the tool.

26.THINK SAFETY.

5

ELECTRICAL

REQUIREMENTS AND SAFETY

REQUIREMENTS AND SAFETY

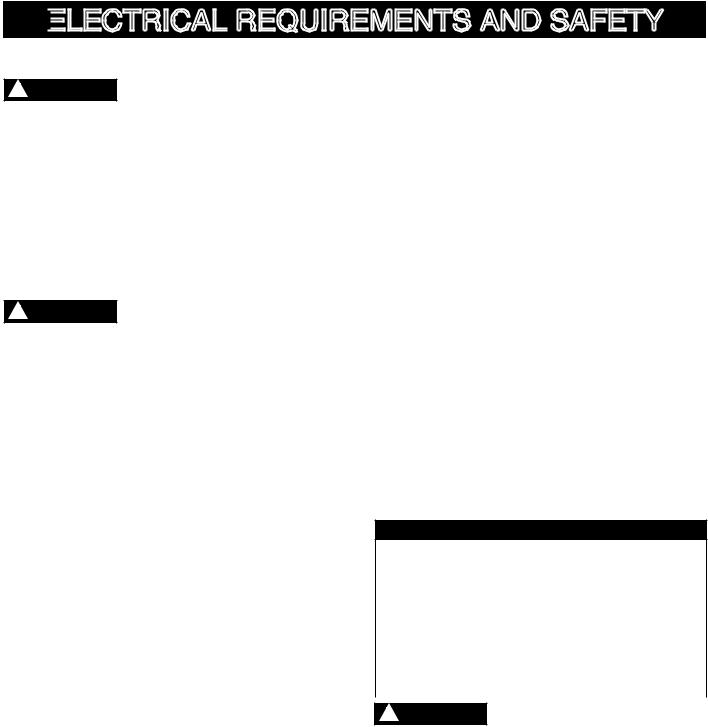

POWER SUPPLY AND MOTOR SPECIFICATIONS

! WARNING

To avoid electrical hazards, fire hazards, or damage to the tool, use proper circuit protection. Use a separate electrical circuit for your tool. Your tool is wired at the factory for 120V operation. Connect to a 120V, 1.6 Amp circuit and use a 1.6 Amp time delay fuse or circuit breaker. To avoid shock or fire, if power cord is worn, cut, or damaged in any way, have it replaced immediately.

GROUNDING INSTRUCTIONS

! WARNING

This tool must be grounded while in use to protect the operator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides a path of least resistance for electric currents and reduces the risk of electric shock. This tool is equipped with an electrical cord that has an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching receptacle that is properly installed and grounded in accordance with all local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the receptacle, have the proper receptacle installed by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding conductor can result in risk of electric shock. The conductor with the green insulation (with or without yellow stripes) is the equipment grounding conductor. If repair or replacement of the electrical cord or plug is necessary, do not connect the equipment grounding conductor to a live terminal.

CHECK with a qualified electrician or service person if you do not completely understand the grounding instructions, or if you are not certain the tool is properly grounded.

USE only 3-wire extension cords that have three-pronged grounding plugs with three-pole receptacles that accept the tool’s plug. Repair or replace damaged or worn cords immediately.

Use a separate electrical circuit for your tool. This circuit must not be less than #18 wire and should be protected with a 1.6 Amp time lag fuse. Before connecting the motor to the power line, make sure the switch is in the off position and the electric current is rated the same as the current stamped on the motor nameplate. Running at a lower voltage will damage the motor.

GUIDELINES FOR EXTENSION CORDS

USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. Use an extension cord heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power, overheating and burning out of the motor. The table below shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Make sure your extension cord is properly wired and in good condition. Always replace a damaged extension cord or have it repaired by a qualified technician before using it. Protect your extension cords from sharp objects, excessive heat and damp or wet areas.

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(When using 120 volts only)

Ampere Rating |

Total length of Cord |

||||

|

|

|

|

|

|

More Than |

Not More Than |

25 |

50 |

100 |

150 ft. |

|

|

(7.62 15.24 30.48 45.72 m) |

|||

|

|

|

|||

|

|

AWGAmerican Wire Gauge |

|||

|

|

|

|

|

|

0 |

6 |

18 |

16 |

16 |

14 |

|

|

|

|

|

|

6 |

10 |

18 |

16 |

14 |

12 |

|

|

|

|

|

|

10 |

12 |

16 |

16 |

14 |

12 |

|

|

|

|

|

|

12 |

16 |

14 |

12 |

Not Recommended |

|

|

|

|

|

|

|

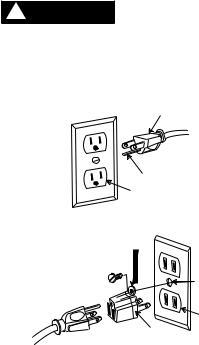

! WARNING

This tool is for indoor use only. Do not expose to rain or use in damp locations.

This tool is intended for use on a circuit that has a receptacle like the one illustrated in Fig. 1. Fig. 1 shows a three-pronged electrical plug and receptacle that has a grounding conductor. If a properly grounded receptacle is not available, an adapter (Fig. 2) can be used to temporarily connect this plug to a two-contact grounded receptacle. The adapter (Fig. 2) has a rigid lug extending from it that MUST be connected to a

6

permanent earth ground, such as a properly grounded receptacle box.

! CAUTION

In all cases, make certain the receptacle is properly grounded. If you are not sure, have a qualified electrician check the receptacle.

Fig. 1 |

Three-Pronged Plug |

||

|

|

|

|

|

|

Grounding Prong |

|

|

Properly Grounded |

||

|

Three-Pronged Receptacle |

||

Fig. 2 Grounding Lug |

|

Make sure this is |

|

|

|

|

connected to a |

|

|

|

known ground. |

|

|

|

Two-Pronged |

|

Adapter |

Receptacle |

|

|

|

||

7

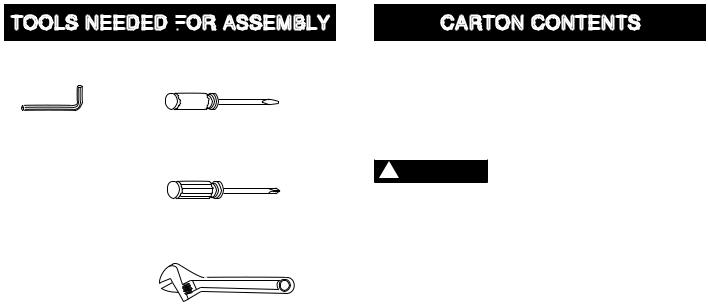

TOOLS NEEDED FOR ASSEMBLY

ASSEMBLY

Supplied |

|

Not Supplied |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 mm hex key |

Medium screwdriver |

#2 Phillips screwdriver

Adjustable wrench

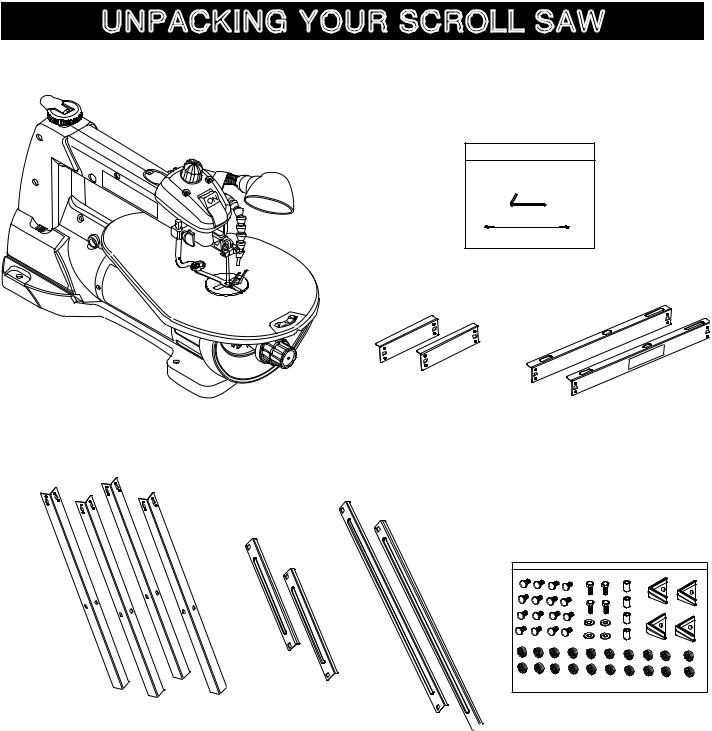

CARTON CONTENTS

UNPACKING AND CHECKING CONTENTS

Carefully unpack the scroll saw and all its parts, and compare against the list below and the illustration on the next page. With the help of an assistant place the saw on a secure surface and examine it carefully.

!WARNING

•To avoid injury from unexpected starting or electrical shock, do not plug the power cord into a source of power during unpacking and assembly. The cord must remain unplugged whenever you are adjusting/ assembling the scroll saw.

•The scroll saw is heavy and should be lifted with care. If needed, get the assistance of someone to lift and move the scroll saw.

•If any part is missing or damaged, do not attempt to assemble the scroll saw, or plug in the power cord until the missing or damaged part is correctly replaced.

TABLE OF LOOSE PARTS |

|

|

ITEM |

DESCRIPTION |

QUANTITY |

A. |

Scroll saw assembly |

1 |

B.Hardware bag assembly

|

Blade |

1 |

|

Hex key |

1 |

STAND |

|

|

C. |

Short upper support |

2 |

D. |

Long upper support |

2 |

E. |

Leg |

4 |

F. |

Short bottom support bracket |

2 |

G. |

Long bottom support bracket |

2 |

H. |

Stand hardware bag |

|

|

Cushion |

4 |

|

Serrated toothed |

20 |

|

Hexagon flange nut |

|

|

|

|

|

Cap hd. sq.neck bolt |

16 |

|

Hex. hd. bolt |

4 |

|

Flat washer |

4 |

|

Spacer |

4 |

8

UNPACKING YOUR SCROLL SAW

|

F |

F |

|

O |

|

B

A C D

E F G

H

H

9

Loading...

Loading...