Pioneer PDP-V501X, PDP-501MX User Manual

TECHNICAL MANUAL (Ver.1.1A)

TECHNICAL MANUAL (Ver.1.1A)

PLASMA DISPLAY : PDP-501MX/PDP-V501X

TABLE-TOP STAND: PDK-5001

SPEAKER SYSTEM: PDP-S02-LR

This manual provides precautions and information for installation, preparation, and handling of the plasma display and its dedicated mounting hardware.

Before installation and preparation work, choose a safe and appropriate site after thorough consideration of construction, materials used, strength, and surroundings. If the adequate safeguards are not in place, immediately halt the installation process and discontinue marketing activities.

CAUTION

Exclamation marks placed within triangles are intended to alert users to the presence of important safety information. Be sure to read instructions indicated by this symbol.

Exclamation marks placed within triangles are intended to alert users to the presence of important safety information. Be sure to read instructions indicated by this symbol.

PRECAUTIONS

•We accept no responsibility for losses resulting from the use of parts other than those supplied by us.

•We guarantee the performance of our products only when they are assembled and adjusted as described in this manual.

•The specifications and external designs shown in this manual are subject to change without notice.

About Mounting/Installation

•The product is sold under the assumption that installation will be performed by experienced, qualified experts. Refer all mounting and installation work to qualified personnel, or consult the nearest PIONEER dealer for assistance.

•We accept no responsibility for accident or loss resulting from failure to select an appropriate installation site, or for those occurring during assembly, installation, mounting, or operation of this product, or resulting from modifications made to the product, or from natural calamities.

1

Table of Contents |

|

|

|

FEATURES ................................................................................................................................................. |

|

4 |

|

SPECIFICATIONS |

|

|

|

2.1 |

Specifications ..................................................................................................................................................... |

|

6 |

2.2 |

External dimensions ......................................................................................................................................... |

|

10 |

2.3 |

Controls and connectors .................................................................................................................................. |

|

12 |

2.4 |

Remote control unit .......................................................................................................................................... |

|

14 |

INSTALLATION |

|

|

|

3.1 |

Installation site requirements ........................................................................................................................... |

|

16 |

3.2 |

Installation Conditions ...................................................................................................................................... |

|

18 |

|

3.2.1 Heat dissipation ....................................................................................................................................... |

|

18 |

|

3.2.2 Calculating heat quantity .......................................................................................................................... |

|

19 |

|

3.2.3 Product mounting holes ........................................................................................................................... |

|

19 |

|

3.2.4 Mount surface warping ............................................................................................................................ |

|

21 |

3.3 |

Installation Procedures ..................................................................................................................................... |

|

22 |

|

3.3.1 Transportation precautions ...................................................................................................................... |

|

22 |

|

3.3.2 Unpacking ................................................................................................................................................ |

|

22 |

|

3.3.3 Temporary installation using packing materials ....................................................................................... |

|

23 |

|

3.3.4 Re-packing ............................................................................................................................................... |

|

23 |

|

3.3.5 Wiring ...................................................................................................................................................... |

|

24 |

3.4 |

Special Installation ............................................................................................................................................ |

|

26 |

|

3.4.1 Mounting to fittings ................................................................................................................................. |

|

26 |

|

3.4.2 Hanging on the wall ................................................................................................................................. |

|

28 |

|

3.4.3 Embedding in the wall ............................................................................................................................. |

|

30 |

|

3.4.4 Ceiling suspension (with wires) ............................................................................................................... |

|

34 |

HOW TO USE THE STANDARD MOUNT EQUIPMENT |

|

|

|

4.1 |

Standard mount equipment features and characteristics ................................................................................. |

|

36 |

4.2 |

Handling the standard mount equipment ......................................................................................................... |

|

37 |

|

4.2.1 Handling precautions ............................................................................................................................... |

|

37 |

|

4.2.2 Precautions for installation contractors .................................................................................................... |

|

37 |

4.3 |

Table-top Stand: PDK-5001 ................................................................................. |

............................................. |

38 |

|

4.3.1 Specifications .............................................................................................. |

............................................. |

38 |

|

4.3.2 Assembling the stand .............................................................................................................................. |

|

39 |

|

4.3.3 Mounting to the main unit ....................................................................................................................... |

|

40 |

4.4 |

Plasma Display Ceiling Suspension Hardware (one-sided type): PDK-5002 |

NOT AVALABLE IN USA |

42 |

|

4.4.1 Specifications ........................................................................................................................................... |

|

42 |

|

4.4.2 Assembling and installing the mounting hardware and mounting the plasma display ............................ |

44 |

|

4.5 |

Tiltable Plasma Display Wall-Mount Hardware: PDK-5006 |

NOT AVALABLE IN USA |

48 |

|

4.5.1 Specifications ........................................................................................................................................... |

|

48 |

|

4.5.2 Assembling the mounting hardware and mounting the plasma display .................................................. |

|

50 |

4.6 |

Speaker System: PDP-S02-LR .......................................................................................................................... |

|

54 |

|

4.6.1 Specifications ........................................................................................................................................... |

|

54 |

|

4.6.2 Mounting to the main unit ....................................................................................................................... |

|

55 |

|

4.6.3 Mounting with the plasma ceiling-suspension hardware (PDK-5002) ..................................................... |

|

56 |

|

4.6.4 Mounting with PDK-5006 (wall-mounting hardware) ............................................................................... |

|

58 |

ADJUSTMENTS |

|

|

|

5.1 |

Before Beginning Adjustments ........................................................................................................................ |

|

60 |

|

5.1.1 Operating mode ....................................................................................................................................... |

|

60 |

|

5.1.2 Combination use of remote, unit operation panel, and PC ...................................................................... |

|

61 |

|

5.1.3 List of supported input signals ................................................................................................................. |

|

62 |

|

5.1.4 List of adjustable and settable items ....................................................................................................... |

|

65 |

|

5.1.5 Last memory ............................................................................................................................................ |

|

69 |

|

5.1.6 Aging ........................................................................................................................................................ |

|

69 |

5.2 |

Normal Operating Mode ................................................................................................................................... |

|

70 |

|

5.2.1 About the normal operating mode ........................................................................................................... |

|

70 |

5.3 Menu Mode ...................................................................................................................................................... |

|

71 |

|

|

5.3.1 About menu mode ................................................................................................................................... |

|

71 |

|

5.3.2 Example of menu mode operation .......................................................................................................... |

|

72 |

2

|

|

Table of Contents |

5.3.3 Settings in Menu Mode ........................................................................................................................... |

74 |

|

1) |

Setting the three-dimensional Y/C separator ....................................................................................... |

74 |

2) |

ABL On/Off .......................................................................................................................................... |

74 |

3) MP mode On/Off ................................................................................................................................. |

74 |

|

4) |

Auto power off..................................................................................................................................... |

76 |

5) |

Setting up peripheral equipment ......................................................................................................... |

77 |

6) |

Setting the input signal format ............................................................................................................ |

78 |

7) |

Setting the clamp position ................................................................................................................... |

79 |

8) |

Setting the color system...................................................................................................................... |

81 |

5.3.4 Menu Layers ............................................................................................................................................ |

82 |

|

1) |

Adjustments at Menu Layers-1 of 2 .................................................................................................... |

82 |

2) |

Adjustments at Menu Layers-2 of 2 .................................................................................................... |

83 |

5.4 Integrator Mode ............................................................................................................................................... |

85 |

|

5.4.1 About the integrator mode ...................................................................................................................... |

85 |

|

5.4.2 Example of integrator mode operation .................................................................................................... |

86 |

|

5.4.3 Adjustments and settings in the integrator mode ................................................................................... |

88 |

|

1) |

Adjusting the PICTURE parameters..................................................................................................... |

88 |

2) |

Adjusting the WHITE BALANCE parameters ....................................................................................... |

89 |

3) |

Adjusting the SCREEN parameters ..................................................................................................... |

90 |

4) |

Setting the color mode ........................................................................................................................ |

91 |

5) |

Setting the baud rate ........................................................................................................................... |

92 |

6) |

Mirror mode ......................................................................................................................................... |

93 |

7) |

Setting STD-RGB ................................................................................................................................. |

94 |

8) |

Adjusting the side mask ...................................................................................................................... |

95 |

9) |

Initializing adjustments (TOTAL INITIALIZE) ........................................................................................ |

96 |

5.4.4 Integrator mode menu layers .................................................................................................................. |

97 |

|

5.4.5 PICTURE and WHITE BALANCE parameter memory area table ............................................................. |

98 |

|

5.4.6 SCREEN parameter memory area table ................................................................................................ |

100 |

|

5.5 RS-232C Adjustment Mode ........................................................................................................................... |

103 |

|

5.5.1 About the RS-232C adjustment mode ................................................................................................... |

103 |

|

5.5.2 Interface ................................................................................................................................................. |

104 |

|

5.5.3 List of RC-232C commands ................................................................................................................... |

105 |

|

5.5.4 About the GET commands .................................................................................................................... |

107 |

|

5.6 Combination Connection ................................................................................................................................ |

108 |

|

5.6.1 Connections ........................................................................................................................................... |

108 |

|

5.6.2 Assigning IDs ......................................................................................................................................... |

110 |

|

5.7 KEY LOCK/UNLOCK ....................................................................................................................................... |

113 |

|

5.7.1 Functions ............................................................................................................................................... |

113 |

|

5.7.2 How to switch KEY LOCK/UNLOCK ...................................................................................................... |

113 |

|

OPERATING PRECAUTIONS AND RECOMMENDATIONS ................................................................ |

114 |

|

6.1 About pseudo-contour .................................................................................................................................... |

114 |

|

6.2 Cautions ......................................................................................................................................................... |

114 |

|

Maintenance and Cleaning................................................................................................................... |

115 |

|

CAUTION

•To prevent injury and material damage, thoroughly read this manual and all labels found on equipment before attempting to mount, install, move, or adjust the product.

•Do not install the unit outside or in open air. Doing so will lead to water seepage into the system, resulting in fire or electric shock.

•Be especially careful when working around parts of the system that have sharp edges.

•When performing installation work from a height, take suitable precautions to guard against falling. Set up a barrier around the work site to prevent accidentally-dropped objects from injuring persons standing or walking below.

•Keep all foreign objects out of the unit. Do not tamper with the unit, or fire or electric shock may result.

•Observe the following operating environmental limitations:

Temperature: 0 to 40°C

Humidity: 20 to 80%

• Install the unit only in properly ventilated areas.

3

Features

Features and Functions of the PDP-501MX Plasma Display

• High-definition XGA wide panel

The Display uses a high-definition XGA wide panel, which provides 1280 x 768 resolution with more than 980.000 pixels. This resolution is more than 2.5 times higher than that of conventional panels, and enables multimedia information to be reproduced more vividly and accurately than ever before.

• Clear, high-quality image

Provides 8-bit RGB in 256 gradations/16.77 million colors. A new exclusive technology developed by Pioneer eliminates the pseudo-contour anomaly, that is typically observed in plasma displays.

• Unrivalled brightness

A brightness of 350 cd/m2 (white peak, for panel unit), which is the highest so far for XGA panels, has been achieved by maximizing light-emitting efficiency.

• Flat, lightweight design

The Pioneer plasma display monitor is also unrivalled in compactness: the 50-inch screen is only 98 mm in depth, and weighs only 43.0 kg. It can therefore be mounted at locations where conventional displays are difficult to install.

• Supports a variety of signals from computers

Full specification PC are supported in video modes from VGA (640 x 480 resolution) to XGA (1024 x 762 resolution). The SXGA (1280 x 1024 resolution) mode also accommodates PC signals, although a summary replay approach is employed in this mode. The use of a dedicated video card also allowed access to a display of 1280 x 768 resolution, as well. This monitor also supports HDTV broadcasts*.

Note:

* To display HDTV images on this monitor, an HDTV decoder, additionally.

•Optimized for industrial/public-address use

•An RS-232C interface is provided for control from the exterior

•The combination terminal enables a single PC to control multiple monitor systems

•The integrator mode enables more precise adjustments than ever before

•A color temperature (white balance) switching function is provided for retakes, and a key-lock feature prevents accidental or unauthorized use of the monitor

•Multiple input and output terminals (four inputs and eight outputs) are provided

4

Features

5

Specifications

2.1 Specifications (U.S. Model and Taiwanese Model)

Light-emitting panel: |

...... 50-inch plasma display panel |

|

Aspect ratio: ........................................................... |

|

16:9 |

PEL: ................................. |

|

1280 x 768 (XGA supported) |

PEL pitch: ................ |

0.858 (H·RGB trio) x 0.808 (V) mm |

|

Gradation: ........................ |

|

256/16.77 million full colours |

Intensity: .......... |

350 cd/m2 (white peak, separate panel) |

|

Viewing angle:....... |

Horizontal: more than 160 degrees |

|

|

|

Vertical: more than 160 degrees |

Input/output |

|

|

INPUT 1

Connector type: see NOTE 1 and NOTE 2 RCA jack

(composite video signal, 1 Vp-p/75Ω input) BNC terminal

(composite video signal, 1 Vp-p/75Ω input) Mini-Din, 4-pin/S terminal

(S2 video signal, Y: 1Vp-p; C: 0.286 Vp-p/75Ω input) Output (BNC, under 75Ω output): Yes (see NOTE 3 and NOTE 4)

INPUT 2

Connector type:

RCA jack x 3

(Y: 1 Vp-p; color difference: 0.7 Vp-p/ 75Ω input)

INPUT 3

Connector type:

BNC terminal x 5

(GRB: video section 0.7 Vp-p; sync section 0.3 Vp- p/75Ω input) (HD/CS; VD: TTL level/ 75Ω and 2.2 kΩ inputs switchable)

INPUT 4

Connector type:

Mini D-sub, 15-pin (GBR: video section 0.7 Vp-p; sync section 0.3 Vp-p/75Ω input) (HD/CS; VD: TTL level/2.2 kΩ input)

Output (Mini D-sub, 15-pin; 75Ω output: Yes (see NOTE 4)

* Microsoft Plug & Play (VESA DDC 1/2B) supported

Control Terminal

RS-232C (for control using a PC)

Connector type: D-sub, 9-pin

Baud rate: 1200, 2400, 4800, 9600, 19200 bps (NOTE 5)

Combination In/Out Terminal

For simultaneous control of multiple units Connector type: Mini-Din, 6-pin (NOTE 6)

Power requirements: |

.... AC 120 V, 60 Hz (U.S. Model) |

||

AC 110 V, 60 Hz (Taiwanese Model) |

|||

In-rush: ..................................................... |

|

|

less than 25A |

Power factor: ........................................ |

|

|

more than 0.95 |

Consumption: .......... |

555 W (NOTE 7) (3 W in standby) |

||

External dimensions (WxHxD): |

... |

1218 x 714 x 98 mm |

|

(47-31/32(W) x 28-1/8(H) x 3-7/8(D) inch) |

|||

Weight: ............................................................... |

|

|

43.0 kg |

|

|

|

(94 lbs. 130z.) |

Operating temperature:................. |

|

0 to 40°C (NOTE 8) |

|

|

|

|

(32 to 104°F) |

Operating humidity:..................................... |

|

|

20 to 80% |

Operating atmospheric pressure: |

......... 0.9 to 1.1 atm |

||

Storage limitations |

|

|

|

Temperature: ........................................ |

|

|

–10 to +45°C |

|

|

|

(14to 113°F) |

Humidity: ................................................... |

|

|

20 to 80% |

Atmospheric pressure: ........................ |

|

0.6 to 1.5 atm |

|

Stacking: ................................. |

|

Fewer than three tiers |

|

Standard Accessories |

|

|

|

Power cord ............................................................ |

|

|

x 1 |

AC adapter plug (3p to 2p) |

|

|

|

................................... |

x 1 (Taiwanese Model only) |

||

RCA/BNC conversion adaptor |

|

|

|

................................... |

x 1 (Taiwanese Model only) |

||

Remote control unit |

............................................... |

|

x 1 |

AA battery .............................................................. |

|

|

x 2 |

Wipe cloth ............................................................. |

|

|

x 1 |

Speed clamp .......................................................... |

|

|

x 2 |

Bead band .............................................................. |

|

|

x 2 |

Operation manual .................................................. |

|

|

x 1 |

Warranty card ........................................................ |

|

|

x 1 |

6

Specifications

NOTE 1 To prevent malfunctions and breakdowns, avoid connecting the RCA jack and BNC terminal simultaneously, since they are electrically connected to each other inside the body.

NOTE 2 If the RCA jack or the BNC terminal is connected at the same time as the S terminal, signals received at the S terminal receive priority.

NOTE 3 Signals received at the RCA jack or BNC terminal are sent from this terminal. Signals received at the S terminal are not.

NOTE 4 No signal is sent in power-off or standby status.

NOTE 5 Defaults to 4800 bps. This setting can be changed from the remote or from a PC.

NOTE 6 Connection cables are optional and are not supplied as standard equipment. Use commercially-available Mini-Din 6-pin cables (straight).

NOTE 7 Allow for 600 VA of consumption per unit.

NOTE 8 The correct operating environmental temperature may vary, depending on the installation site. (Refer to Section 3: Installation.)

VESA is a registered trademark of the Video Electronics Standards Association.

Specifications and external designs are subject to change without notice.

Signals supported by INPUT 1

Vertical |

Horizontal |

Signal |

|

||

Frequency |

Frequency |

Remarks |

|||

Format |

|||||

Fv (Hz) |

Fh (kHz) |

|

|||

|

|

|

|||

60 |

15.7 |

Composite |

NTSC |

||

|

|

||||

S video signal |

|||||

|

|

|

|||

|

|

|

|

|

|

Signals supported by INPUT 2 |

|

||||

|

|

|

|

|

|

Vertical |

Horizontal |

Signal |

|

|

|

Frequency |

Frequency |

|

Remarks |

||

Format |

|

||||

Fv (Hz) |

Fh (kHz) |

|

|

||

|

|

|

|||

60 |

15.7 |

Component |

|

|

|

|

|

|

|

||

|

31.5 |

Component |

|

|

|

Signals supported by INPUT 3/4 (video) —1 of 2

Vertical |

Horizontal |

Signal |

|

|

|

Frequency |

Frequency |

Remarks |

|||

Format |

|||||

Fv (Hz) |

Fh (kHz) |

|

|

||

|

|

|

|||

60 |

15.7 |

RGB (Note 9) |

SDTV 480i |

|

|

|

|

Component |

|

|

|

|

|

|

|

||

|

31.5 |

RGB |

SDTV 480p |

||

|

|

|

|

|

|

|

|

Component |

|

|

|

|

|

|

|

||

|

33.8 |

RGB |

HDTV 1080i |

||

|

|

Component |

|

|

|

|

|

|

|

||

|

45.0 |

RGB |

HDTV 720p |

||

|

|

Component |

|

|

|

Signals supported by INPUT 3/4 (PC signals) —2 of 2

Model |

|

Vertical |

Horizontal |

|

Dot x line |

Frequency |

Frequency |

||

Name |

||||

|

Fv (Hz) |

Fh (kHz) |

||

|

|

|||

PC/AT |

640 x 400 |

70.1 |

31.5 |

|

compatibles |

|

|

|

|

640 x 480 |

59.9 |

31.5 |

||

|

|

|

|

|

|

|

72.8 |

37.9 |

|

|

|

|

|

|

|

|

75 |

37.5 |

|

|

|

|

|

|

|

800 x 600 |

56.3 |

35.2 |

|

|

|

|

|

|

|

|

60.3 |

37.9 |

|

|

|

|

|

|

|

|

72.2 |

48.1 |

|

|

|

|

|

|

|

|

75 |

46.9 |

|

|

|

|

|

|

|

1024 x 768 |

60 |

48.4 |

|

|

|

|

|

|

|

|

70.1 |

56.5 |

|

|

|

|

|

|

|

|

75 |

60 |

|

|

|

|

|

|

|

|

87(Note 11) |

35.5(Note 10) |

|

|

|

|

|

|

|

1280 x 1024 |

60 |

64(Note 10) |

|

|

|

|

|

|

Macintosh |

640 x 480 |

66.7 |

35 |

|

|

|

|

|

|

|

832 x 624 |

74.6 |

49.7 |

|

|

|

|

|

|

|

1024 x 768 |

74.9 |

60.2 |

|

|

|

|

|

|

|

1152 x 870 |

75.1 |

68.7(Note 10) |

|

|

|

|

|

|

NEC |

640 x 400 |

56.4 |

24.8 |

|

PC-9800 |

|

|

|

|

|

70.1 |

31.5 |

||

|

|

|

|

|

|

640 x 480 |

59.9 |

31.5 |

|

|

|

|

|

|

|

|

75 |

37.5 |

|

|

|

|

|

|

|

800 x 600 |

60.3 |

37.9 |

|

|

|

|

|

|

|

|

75 |

46.9 |

|

|

|

|

|

|

|

1024 x 768 |

70.1 |

56.5 |

|

|

|

75 |

60 |

|

|

1280 x 1024 |

60 |

64(Note 10) |

NOTE 9 Can be reproduced depending on settings in integrator mode, but primary quality images are not available.

NOTE 10 Simplified reproduction.

NOTE 11 Interlaced signal (frame frequency of 43.5 Hz)

NEC is a trademark of NEC Corp.

PC-9800® is a registered trademark of NEC Corp.

Macintosh® is a registered trademark of Apple Computer, Inc.

7

Specifications

2.1 Specifications (EURO Model)

Light-emitting panel: |

...... 50-inch plasma display panel |

|

Aspect ratio: ........................................................... |

|

16:9 |

PEL: ................................. |

|

1280 x 768 (XGA supported) |

PEL pitch: ............... |

0.858 (H)(RGB trio) x 0.808 (V) mm |

|

Gradation: ........................ |

|

256/16.77 million full colours |

Intensity: .......... |

350 cd/m2 (white peak, separate panel) |

|

Viewing angle:............ |

|

Horizontal 160 degrees or more |

|

|

Vertical: 160 degrees or more |

Inputs/outputs

INPUT 1

Connector type: NOTE 1 and NOTE 2 RCA jack

(composite video signal, 1 Vp-p/75Ω input) BNC terminal

(composite video signal, 1 Vp-p/75Ω input) Mini-Din, 4-pin/S terminal

(S2 video signal, Y: 1Vp-p; C:0.286 Vp-p/75Ω input) Output (BNC, 75Ω output): Yes (see NOTE 3 and NOTE 4)

INPUT 2

Connector type

RCA jack x 3

(Y: 1 Vp-p; color difference: 0.7 Vp-p/ 75Ω input)

INPUT 3

Connector type:

BNC terminal x 5 (GBR:video section 0.7 Vp-p; sync section 0.3 Vp-p/75Ω input) (HD/CS; VD: TTL level/ 75Ω and 2.2 kΩ inputs, switchable)

Control Terminal

RS-232C (for control using a PC)

Connector type: D-sub, 9-pin

Baud rate: 1200, 2400, 4800, 9600, 19200 bps (NOTE 5)

Combination Input/Output Terminal

Used for simultaneous control of multiple units Connector type: Mini-Din, 6-pin (NOTE 6)

Power requirements: ............. |

AC 100-240 V, 50/60 Hz |

|

Electric current: .......................... |

5.6 to 2.3 A (NOTE 7) |

|

In-rush: .................................................... |

|

less than 25 A |

Power factor: ........................................ |

|

more than 0.95 |

External dimensions (WxHxD): ... |

1218 x 714 x 98 mm |

|

(47-31/32(W) x 28-1/8(H) x 3-7/8(D) inch) |

||

Weight: ............................................................... |

|

43.0 kg |

|

|

(94 lbs. 130z.) |

Operating temperature:................. |

|

0 to 40°C (NOTE 8) |

|

|

(32 to 104°F) |

Operating humidity:..................................... |

|

20 to 80% |

Operating atmospheric pressure: |

......... 0.9 to 1.1 atm |

|

Storage limitations |

|

|

Temperature: ........................................ |

|

–10 to +45°C |

|

|

(14 to 113°F) |

Humidity: ................................................... |

|

20 to 80% |

Atmospheric pressure: ........................ |

|

0.6 to 1.5 atm |

Stacking: ................................. |

Fewer than three tiers |

|

Standard accessories

INPUT 4

Connector type:

Mini D-sub, 15-pin (GBR: video section 0.7 Vp-p; sync section 0.3 Vp-p/75Ω input) (HD/CS; VD: TTL level/2.2 kΩ input)

Output (Mini D-sub, 15-pin; 75Ω input: Yes (NOTE 4) * Microsoft Plug & Play (VESA DDC 1/2B) supported

Power cord ............................................................ |

x 1 |

RCA/BNC conversion adaptor ................................ |

x 3 |

Remote control unit ............................................... |

x 1 |

AA battery.............................................................. |

x 2 |

Wipe cloth ............................................................. |

x 1 |

Speed clamp .......................................................... |

x 2 |

Bead band.............................................................. |

x 2 |

Operation manual .................................................. |

x 1 |

Warranty card ........................................................ |

x 1 |

8

Specifications

NOTE 1 To prevent malfunctions and breakdowns, avoid connecting the RCA jack and BNC terminal simultaneously, since they are electrically connected to each other inside the body.

NOTE 2 If the RCA jack or the BNC terminal is connected at the same time as the S terminal, signals received at the S terminal receive priority.

NOTE 3 Signals received at the RCA jack or BNC terminal are sent from this terminal. Signals received at the S terminal are not.

NOTE 4 No signal is sent in power-off or standby status.

NOTE 5 Defaults to 4800 bps. This setting can be changed from the remote or from a PC.

NOTE 6 Connection cables are optional and are not supplied as standard equipment. Use commercially available Mini-Din 6-pin cables (straight).

NOTE 7 Allow for 600 VA of consumption per unit.

NOTE 8 The correct operating environmental temperature may vary, depending on the installation site. (Refer to Section 3: Installation.)

VESA is a registered trademark of the Video Electronics Standards Association.

Specifications and external designs are subject to change without notice.

Signals supported by INPUT 1

Vertical |

Horizontal |

Signal |

|

|||

Frequency |

Frequency |

Remarks |

||||

Format |

||||||

Fv (Hz) |

Fh (kHz) |

|

||||

|

|

|

||||

50 |

15.6 |

|

Composite |

PAL, SECAM |

||

|

|

|

|

|

||

|

|

|

S video signal |

|||

|

|

|

|

|||

|

|

|

|

|

|

|

60 |

15.7 |

|

Composite |

NTSC |

||

|

|

|

||||

|

|

|

|

|

4.43 NTSC |

|

|

|

|

S video signal |

|||

|

|

|

|

|||

|

|

|

|

|

|

|

Signals supported by INPUT 2 |

|

|||||

|

|

|

|

|

|

|

Vertical |

Horizontal |

Signal |

|

|

||

Frequency |

Frequency |

|

Remarks |

|||

Format |

|

|||||

Fv (Hz) |

Fh (kHz) |

|

|

|||

|

|

|

||||

50 |

15.6 |

|

Component |

|

|

|

|

|

|

|

|

|

|

|

31.3 |

|

Component |

|

|

|

|

|

|

|

|

|

|

60 |

15.7 |

|

Component |

|

|

|

|

|

|

|

|

|

|

|

31.5 |

|

Component |

|

|

|

|

|

|

|

|

|

|

Signals supported by INPUT 3/4 (video) —1 of 2

Vertical |

Horizontal |

Signal |

|

||

Frequency |

Frequency |

Remarks |

|||

Format |

|||||

Fv (Hz) |

Fh (kHz) |

|

|||

|

|

||||

50 |

15.6 |

|

RGB (Note 9) |

|

|

|

|

|

Component |

|

|

|

31.3 |

|

RGB |

|

|

|

|

|

Component |

|

|

60 |

15.7 |

|

RGB |

|

|

|

|

|

Component |

|

|

|

31.5 |

|

RGB |

|

|

|

|

|

Component |

|

|

|

33.8 |

|

RGB |

|

|

|

|

|

Component |

|

|

|

45.0 |

|

RGB |

|

|

|

|

|

Component |

|

|

Signals supported by INPUT 3/4 (PC signals)—2 of 2

Model |

|

Vertical |

Horizontal |

||

Dot x line |

Frequency |

Frequency |

|||

Name |

|||||

|

Fv (Hz) |

Fh (kHz) |

|||

|

|

||||

|

|

|

|

|

|

PC/AT |

640 x 400 |

70.1 |

31.5 |

|

|

compatibles |

640 x 480 |

59.9 |

31.5 |

|

|

|

|

72.8 |

37.9 |

|

|

|

|

75 |

37.5 |

|

|

|

800 x 600 |

56.3 |

35.2 |

|

|

|

|

60.3 |

37.9 |

|

|

|

|

72.2 |

48.1 |

|

|

|

|

75 |

46.9 |

|

|

|

1024 x 768 |

60 |

48.4 |

|

|

|

|

70.1 |

56.5 |

|

|

|

|

75 |

60 |

|

|

|

|

87(Note 11) |

35.5(Note 10) |

||

|

1280 x 1024 |

60 |

64(Note 10) |

||

Macintosh |

640 x 480 |

66.7 |

35 |

|

|

|

832 x 624 |

74.6 |

49.7 |

|

|

|

1024 x 768 |

74.9 |

60.2 |

|

|

|

1152 x 870 |

75.1 |

68.7(Note 10) |

||

NEC |

640 x 400 |

56.4 |

24.8 |

|

|

PC-9800 |

|

70.1 |

31.5 |

|

|

|

640 x 480 |

59.9 |

31.5 |

|

|

|

|

75 |

37.5 |

|

|

|

800 x 600 |

60.3 |

37.9 |

|

|

|

|

75 |

46.9 |

|

|

|

1024 x 768 |

70.1 |

56.5 |

|

|

|

|

75 |

60 |

|

|

|

1280 x 1024 |

60 |

64(Note 10) |

|

|

|

|

|

|

|

|

NOTE 9 Can be reproduced depending on settings in integrator mode, but primary quality images are not available.

NOTE 10 Simplified reproduction.

NOTE 11 Interlaced signal (frame frequency of 43.5 Hz)

NEC is a trademark of NEC Corp.

PC-9800® is a registered trademark of NEC Corp. Macintosh® is a registered trademark of Apple Computer, Inc.

9

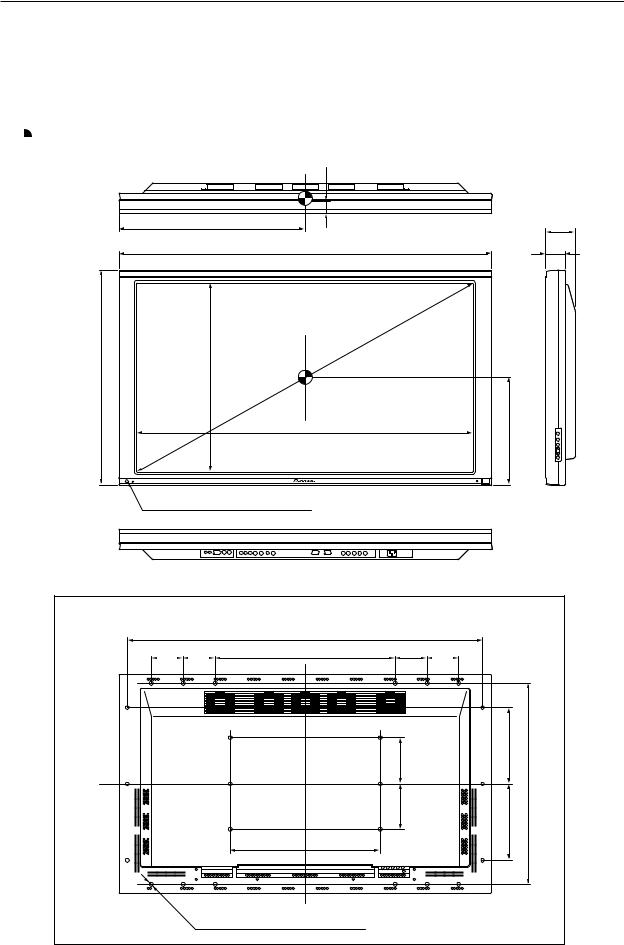

External Dimensions

2.2 External Dimensions

Weight: 43.0 kg

Material: Front: Resin; Rear: Resin

Treatment: Front: Laser-satin gray paint; Rear: Laser-satin gray paint

For packaging information, refer to 3.3.2 Unpacking

: Center of gravity

: Center of gravity

(Unit: mm)

31

609 |

98.5 |

1218 |

65.5 |

714 |

628 |

1108

Light sensor for the remote

357

Rear View

|

|

1162 |

|

|

104 |

104 |

590 |

104 |

104 |

150 |

250 |

150 |

660 |

250 |

496

24-M8 (ø16 mm, with hole rivet)

10

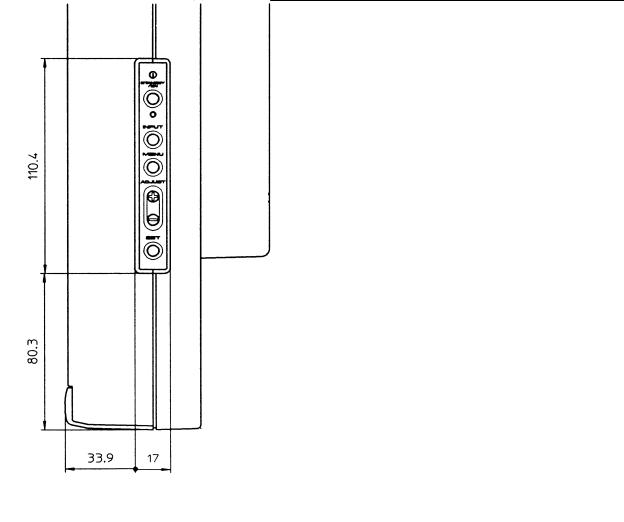

External Dimensions

< Main Switch > |

< Main Unit Operation Panel > |

< Light Sensor for the Remote >

11

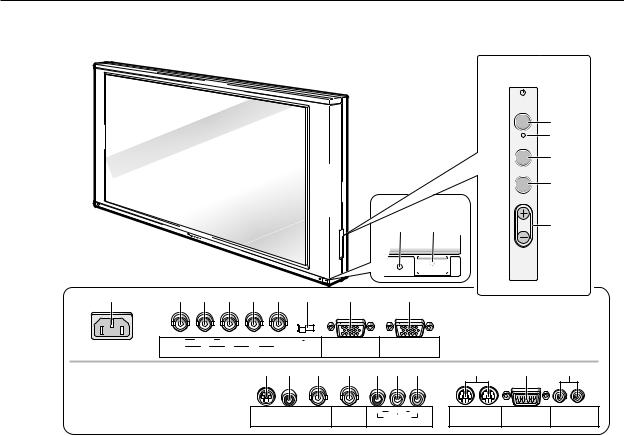

Controls and Connectors

2.3 Controls and Connectors

< Operation Panel >

STANDBY /ON

3

8

|

|

INPUT |

|

|

4 |

|

|

MENU |

|

|

5 |

|

|

ADJUST |

1 |

2 |

6 |

SET

7

7

POWER

9 |

0 |

- |

= |

~ |

! |

@ |

# |

$ |

< Connectors > |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

(at the rear of the main unit) |

|

|

Y |

CB/PB |

CR/PR |

|

|

75Ω 2.2kΩ |

INPUT 4 |

OUTPUT |

|

|

|

G |

B |

R |

HD |

VD |

|

|

|

||

|

|

|

(INPUT 4) |

|

|

|||||

|

(ON SYNC) |

INPUT 3 |

(H/V SYNC) |

|

|

|

|

|||

|

|

|

|

|

|

|||||

|

|

|

|

|

% ^ & * ( ) _ |

+ |

¡ ™ |

|||

|

|

|

|

S - VIDEO |

VIDEO |

OUTPUT |

Y CB/PB CR/PR |

IN OUT |

IN OUT Î |

|

|

|

|

|

|

INPUT 1 |

(INPUT 1) |

C. VIDEO |

|

RS - 232C |

|

|

|

|

|

|

INPUT 2 |

CONBINATION |

CONTROL |

|||

|

|

|

|

|

|

|

|

|||

< Main Power Switch Section >

1STANDBY/ON indicator

Red indicates standby status, green indicates powering

on.

2POWER switch

Turns main power on or off.

< Control Panel >

3Power switch

Toggles unit on or off (standby).

4INPUT switch

Used to select inputs

5MENU switch

Switches the menu screen on or off.

6ADJUST buttons

Used to move the cursor on the menu screen or to

increment/decrement adjustment values

7 SET button

Used to select an adjustment item in the menu screen or to change settings

8KEY LOCK/UNLOCK button (hidden)

Renders the operation panel and remote operative or inoperative.

< Connectors >

9 AC INLET

INPUT 3 Inputs

These RGB inputs are composed of five BNC terminals,

0to !. They also support the component video signal (settings required in the menu screen).

0Green Input: 75Ω

Receives signals of G, G with sync, and Y.

- Blue Input: 75Ω

Receives signals of B, CB, and PB.

= Red Input: 75Ω

Receives signals of R, CR, and PR.

~ Horizontal and Composite Sync Signal Input: 75Ω/ 2.2kΩ

Receives signals of HD, and H/V Sync.

!Vertical Sync Signal Input: 75Ω/2.2 kΩ

Receives a VD signal.

@Sync Signal Input Impedance switch

Used to switch input impedance for items ~ and ! between 75Ω and 2.2 kΩ.

12

Controls and Connectors

INPUT 4 Input

#INPUT 4 input terminal

Mini D-Sub 15-pin terminal for connection of RGB signals

This terminal also supports component signals (settings required in the menu screen).

This terminal supports Microsoft Plug & Play (VESA DDC 1/2B).

(VESA is a registered trademark of the Video Electronics Standards Association.)

INPUT 4 Output

$INPUT 4 output terminal

Signals fed to the INPUT 4 input terminal # are sent from this output terminal. No signal is sent when power is switched off, or in standby status.

NOTE: When the unit is connected in a series using this output terminal, up to five units can be connected including the unit to which signals are first input. If you use separate sync or composite sync signal, over 4.8 Vp-p sync level

is necessary between the video source and the first unit, under the condition of 2.2 kΩ input

impedance.

INPUT 1 Inputs

% S2 Video Input terminal (S terminal)

^ Video Input terminal (RCA jack)

&Video Input terminal (BNC terminal)

To prevent malfunctions and breakdowns, avoid connecting the RCA jack and BNC terminal simultaneously, since they are electrically connected to each other inside the body.

INPUT 1 Output

*Video Output terminal

Signals fed to the INPUT 1 Video Input ^ or & are sent from this output terminal. This terminal does not carry signals received at the S-input terminal %. No signal is available at this output terminal when power is switched off, or in standby status.

NOTE: When the unit is connected in a series using this output terminal, up to five units can be connected including the unit to which signals are first input.

INPUT 2 Input

Component video input terminals composed of three RCA jacks ( to _.

( Y Input: 75Ω

) CB and PB Input: 75Ω

_ CR and PR Input: 75Ω

Control

+Combination Input and Output terminals

Used for simultaneous control of multiple units (Refer to 5.6 Combination Connections)

NOTE: No ABL linkage function is provided. These terminals are incompatible with multi-

projections such as the RM-V4800V.

¡ Control connector (conforming to RS-232C)

Used to make adjustments or settings externally

™SR IN/OUT terminals

For SR connection (refer to the operation manual) to AV units from Pioneer

NOTE: This product does not support RU-V107 wired remote control units.

13

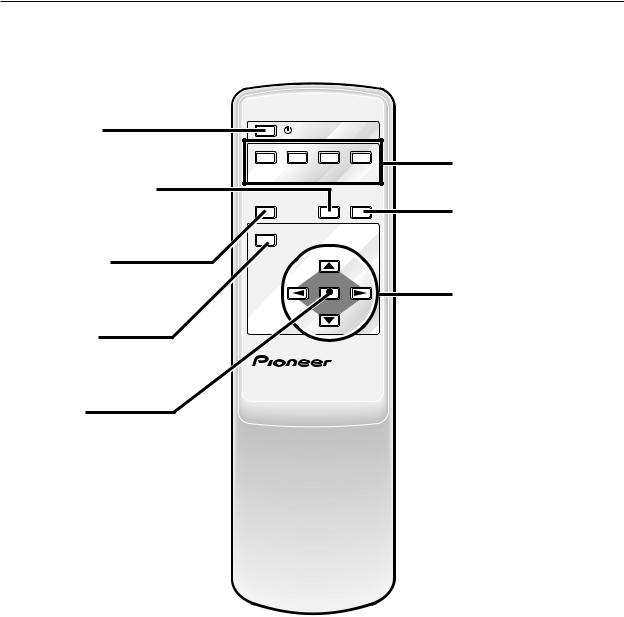

Remote Control Unit

2.4 Remote Control Unit

Power switch |

|

STANDBY/ON |

|

|

|

|

|

|

|

||

Used to turn the system on or off |

INPUT1 |

INPUT2 |

INPUT3 |

INPUT4 |

|

(standby) |

VIDEO |

C.VIDEO |

RGB |

RGB |

Input switches |

|

|||||

|

S-VIDEO |

( RCA ) |

( BNC ) |

( D-sub ) |

Used to select inputs |

Full Auto-Zoom button |

|

|

|

|

|

|

FULL AUTO SCREEN |

|

|||

Used to turn full auto-zoom on or off |

|

|

|||

DISPLAY |

|

ZOOM |

SIZE |

Screen Size switch |

|

|

|

|

|

||

|

|

|

|

|

|

|

MENU |

|

|

|

Used to select screen size |

Display button |

|

|

|

|

|

Used to view status of inputs or |

|

|

|

|

Adjustment buttons |

settings |

|

|

SET |

|

|

|

|

|

|

|

Used to move the cursor in the |

Menu button |

|

|

|

|

menu screen or to adjust various |

|

|

|

|

settings |

|

Used to turn the menu screen on |

|

|

|

|

|

|

|

|

|

|

|

or off |

PLASMA DISPLAY |

Î |

|

||

|

REMOTE CONTROL UNIT |

|

|||

Set button

Used to select adjustment items in the menu screen or to change current settings

14

Remote Control Unit

15

Installation Site Requirements

3.1 Installation Site Requirements

If the site requires modifications or special preparations for installation of the plasma display or its mounting hardware, obtain permission in advance from the building owner or building authorities. To ensure installation safety, it is also important to determine the strength of the installation site with the help of the original building contractor.

Safety Precautions

1) Structure of the installation site

Make sure you thoroughly understand the structure of the installation site before determining the most suitable installation method. Buildings vary in structure and materials, and the appropriate mounting hardware will differ accordingly. When drilling into walls, always remain aware of internal electrical wiring and pipes.

2) Weight capacity of the installation site

Select a location with a weight capacity sufficient to support the total weight of the display and mounting hardware.

3) Horizontal and flat surfaces

Select a flat and surface place for instruction and attach mounting hardware parallel to the pace of installation. Install the unit so that the load is evenly applied to the ceiling or wall, as well as on mounting components such as hang bolts.

4) Sufficient work space

Select a location with sufficient space for installation work. The installation work should be conducted by more than two persons.

5) Nearby equipment

Air conditioning ducts or lamps located near the installation site may be subject to dust, extreme temperatures, humidity, and condensation during installation. Take suitable measures to protect them.

6) Safe locations

Do not install the unit where it may be easily reached or leaned against. Avoid locations subject to high vibration or severe impacts.

7) Lighting conditions

•Consider existing lighting and sunlight angles when creating the installation layout. Extremely bright lighting can reduce the visibility and quality of the display image.

•In extremely bright surroundings, adjusting screen intensity may not result in perceptibly brighter images. Keep in mind that extreme intensity settings can reduce system service life.

8) Installation partially outdoors

The unit is designed for indoor use and is not suited for open-air use. Installation at locations even just partially exposed to the elements may lead to malfunctions or breakdown caused by any of the following:

•Water and dust

•Change in temperature and humidity

•Salt-bearing wind

Direct sunlight upon the display degrades image quality. In installing the display, avoid sites exposed to direct sunlight.

16

Installation Site Requirements

9) Temperature and humidity conditions

•The installation site should meet the following conditions:

•Operating temperatures: 0 to 40 °C (largely depending on installation conditions)

•Operating humidity: 20 to 80%

•Storage temperature: –10 to +45 °C

•Storage humidity: 20 to 90%

•Operating atmospheric pressure: 0.9 to 1.1 atm

•Storage atmospheric pressure: 0.6 to 1.5 atm

•We recommend against installing electronic products such as this unit in locations subject to high humidity. If the unit is to be installed in a location subject to relatively high humidity, observe the following:

•Never install the unit in locations that fail to meet the conditions specified above

•Make sure the unit is grounded

•Prevent condensation

•Do not allow water or liquids to enter the unit

10) Beware of condensation

One of the chief problem sources during winter is condensation. Rapid temperature fluctuations can deposit airborne water vapor inside the unit or on the screen, degrading performance. If condensation occurs, turn the unit off and leave it off for one hour or so. It is also good practice to increase room temperature gradually.

11) Power requirements

•This unit functions properly when powered at ±10% of its rated voltage. High impedance characteristics of lines at the installation site may distort the voltage output wave form, effectively reducing voltage. If any of the following occurs, inspect the main wiring.

•Significant voltage drop between the switchboard and the plasma display

•Significant changes in voltage when switching unit power on or off

•When calculating heat quantity, allow for 600 VA of consumption per unit

•The in-rush current upon powering up will be approximately 25 A

12) Effectire remote-control distance

This display emits weak infrared radiation. If other products controlled with infrared remote controls are placed nearby, remote control function may be affected. In such cases, move them away from the display.

Depending on installation conditions, the range of the unit’s own remote control may be reduced by infrared emitted by the screen.

The screen’s infrared intensity will vary, depending on the image displayed.

17

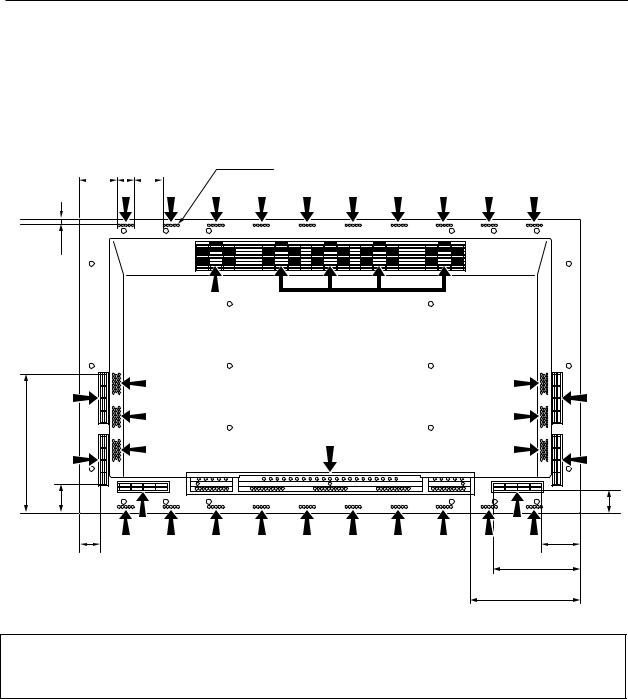

Installation Conditions

3.2 Installation Conditions

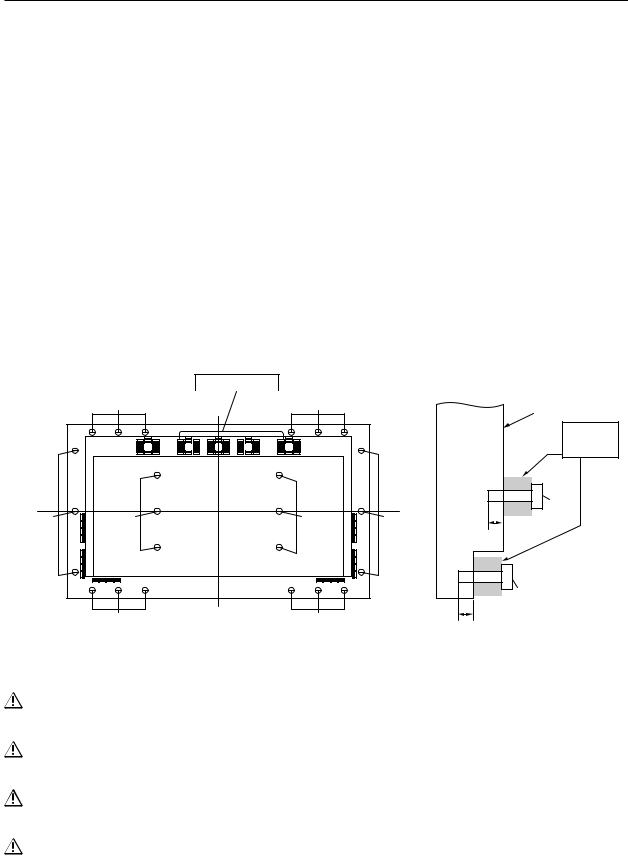

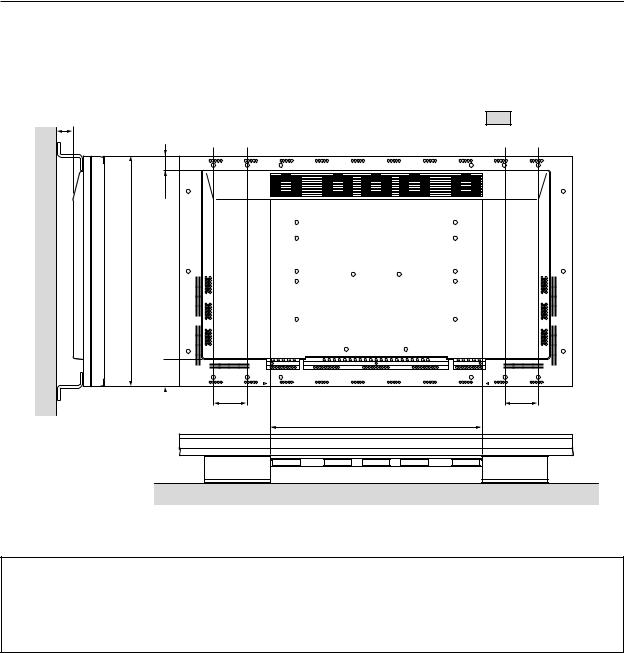

3.2.1 Heat dissipation

This unit has openings for effective ventilation at locations marked by arrows in the illustration below. To allow proper

dissipation of heat from the unit, avoid blocking or covering any of these openings.

96.5 35 75 |

Ø 5 |

||||

|

|

|

|

|

|

10

Fan (4 in number)

345

70 |

|

54 |

|

45 |

85 |

|

|

|

|

|

215 |

|

|

255 |

Air flow through the openings: All four fans exhaust hot air from the unit. All openings not assisted by fans serve as air inlets. If the unit is hung from or embedded into a wall, special operating temperature limits and other limitations may apply. Refer to 3.4 Special Installation.

18

Installation Conditions

3.2.2 Calculating heat quantity

.

For power consumption, allow for 600 VA ( =. 600 W) per unit. Since most of the power consumed is transformed into heat, power consumption may be regarded as roughly equal to generated heat.

1Conversion to calories

[W]x 0.86 = [kcal/h]

Heat generated per display: 600 W x 0.86 = 516 kcal/h

2Conversion to British Thermal Units (BTU)

[W]x 3.41 = [BTU/h] Heat generated per unit: 600 W x 3.41 = 2046 BTU/h

3.2.3 Product mounting holes

We recommend using mounting hardware available from Pioneer. If you use other mounting hardware, attach them to the unit using the M8-bolt holes provided in the unit. Remove the hole rivets, depending on the particular mounting hardware used. Tighten bolts with a torque between 50 and 80 kg.cm. Applying a torque beyond these limits may lead to nut failure.

•Locations of useble mount holes are shown below. (Caps, or plugs, can be removed by turning them with a coin or another device.)

Hole “a”: in 6 locations

Hole “b”: in 18 locations

|

Air outlet (Fan) |

|

|

Hole “b” |

|

Hole “b” |

|

|

Mounting Surface |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mount |

|

|

|

|

|

|

hardware, |

|

|

|

|

|

The main |

etc. |

|

|

|

|

|

|

|

|

|

|

|

|

unit |

Hole “a” |

|

|

|

|

Center |

|

Bolt |

Hole “b” |

|

|

|

line |

|

|

Hole “a” |

|

Hole “a” |

Hole “b” |

|

10 to 17mm |

|

|

|

|

|

|

|

Hole “b” |

|

|

|

|

|

|

Bolt |

|

Hole “b” |

Center line |

Hole “b |

|

10 to 23mm |

|

|

|

|

Rear View |

|

Side View |

|

Always use a minimum four mounting holes, evenly distributed on opposite sides of both the horizontal and vertical center lines.

Use bolts that can be driven 10 to 17-mm into holes “a” or 10 to 23-mm into holes “b,” as shown in the Side View above.

Do not block or cover air outlets and openings for ventilation on the rear panel. Take precautions to prevent fouling walls behind the product with exhaust air discharged from the air outlets.

This unit incorporates glass components. Install only on flat surfaces.

19

Installation Conditions

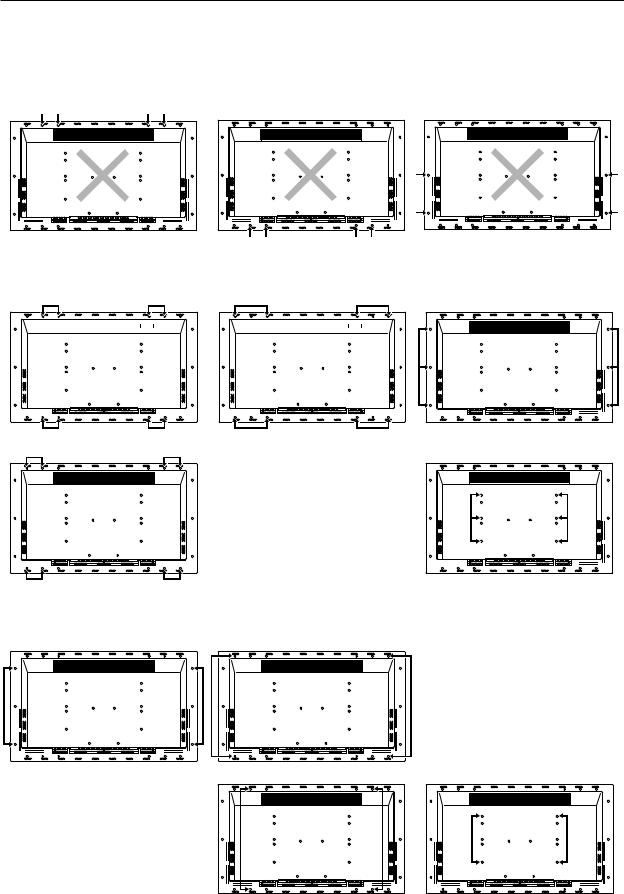

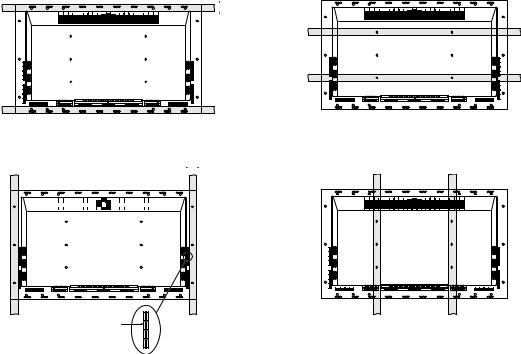

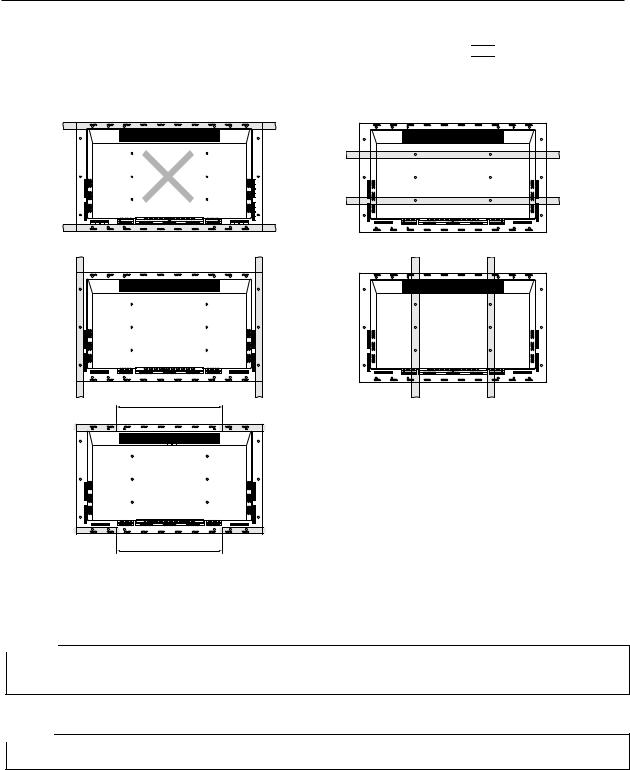

This unit is designed to be mounted using four bolt holes. For additional safety, we recommend securing it at six to eight points on opposite sides of the horizontal and vertical center lines, as shown in the illustration below. Do not secure the unit at four points arranged in a single row, as shown below.

Methods for securing — Unfavorable examples

Methods for securing — Favorable examples

A. Secured at eight points |

|

|

|

|

|

|

|

|

|

|

|

B. Secured at six points |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C.Secured at four points

(with mounting hardware attached to the sides)

20

Installation Conditions

D. Secured at four points (with mounting hardware attached horizontally)

(Take proper precautions to prevent pinching the power cord or signal cables)

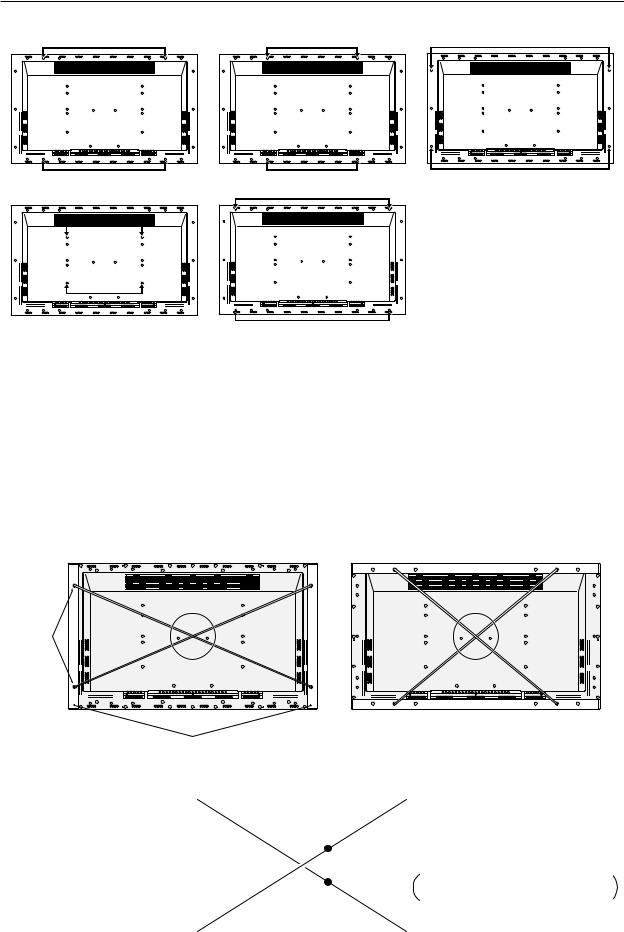

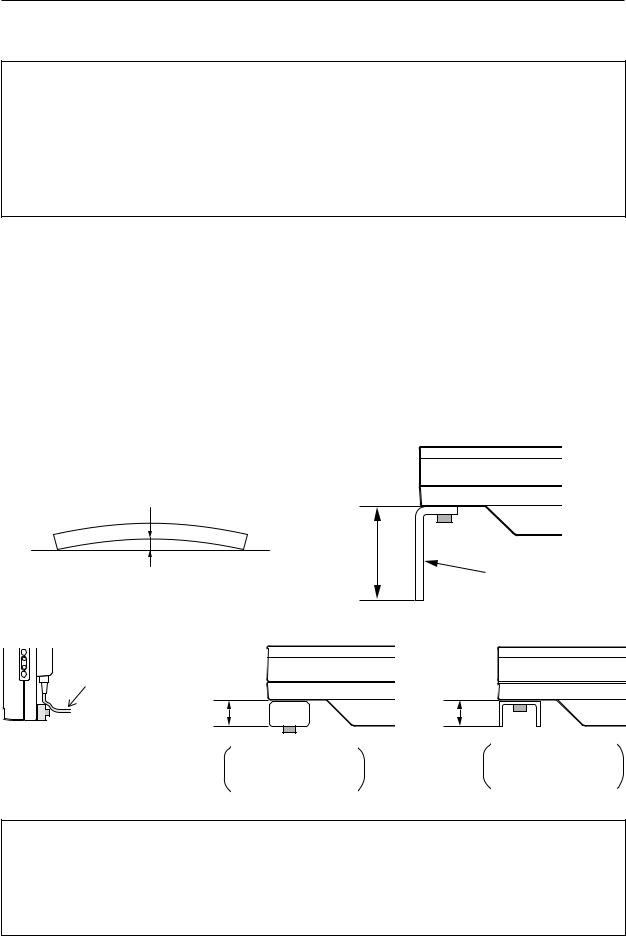

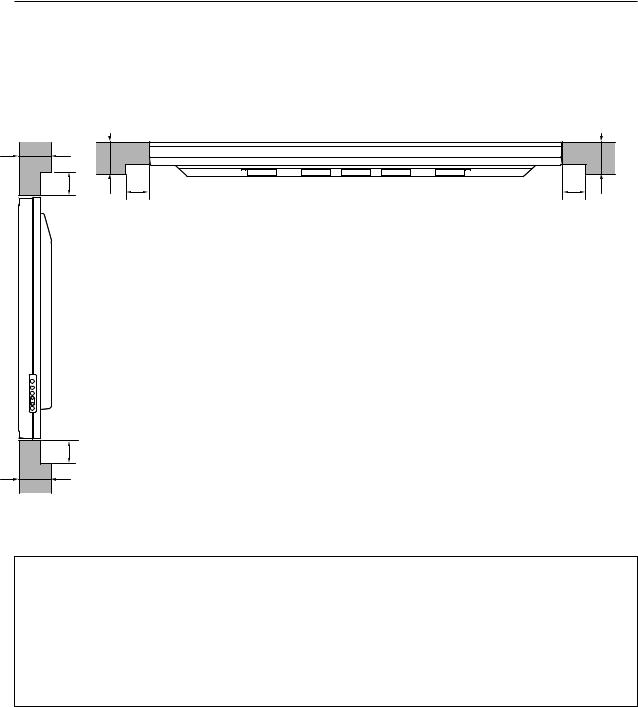

3.2.4 Mounting surface warping

The display section incorporates glass. Before mounting the product, perform the following to confirm that the display is free of warps exceeding 1 mm.

1Referring to the illustration below, diagonally extend string of maximum 0.1-mm diameter through the bolt mount openings. Strings thus arranged should be completely free of slack.

2Measure the clearance (L) between the strings at their point of intersection. Distortion is expressed by: Distortion = L x 2.

3If L is found to be 0, pass the strings through the other bolt mount openings and repeat the measurements. Any value of L greater than 0 indicates the presence of distortion. If the measured values in both cases is 0, the distortion is negligible.

A

Mount

bolt

holes

Plasma Display Mount

Surface (Mount Brackets)

A

String

F

E

String

C

Magnified veiw of section A

A

DPoint E is the center point of string segment A-B.

Point F is the center point of string segment C-D.

Clearance between points E and F = L points E and F shown displaced for illustrative purposes

B

21

Installation Procedures

3.3 Installation Procedures

3.3.1 Transportation precautions

1 Any transportation of the unopened unit in its packaging should be done by more than two persons. To avoid breakage, do not lift the package by the packing bands.

2 When transporting or storing the unit, always position it vertically - never horizontally. Horizontal transportation or storage invalidates the product warranty.

3 In transportation or storage, never stack more than three units. This warning is also indicated on the upper face of the carton.

4 For transportation or storage, observe the warnings and instructions found on the upper surface of the carton.

5 The front of the display is glass-bearing. Always take precautions to prevent sharp objects from striking this side.

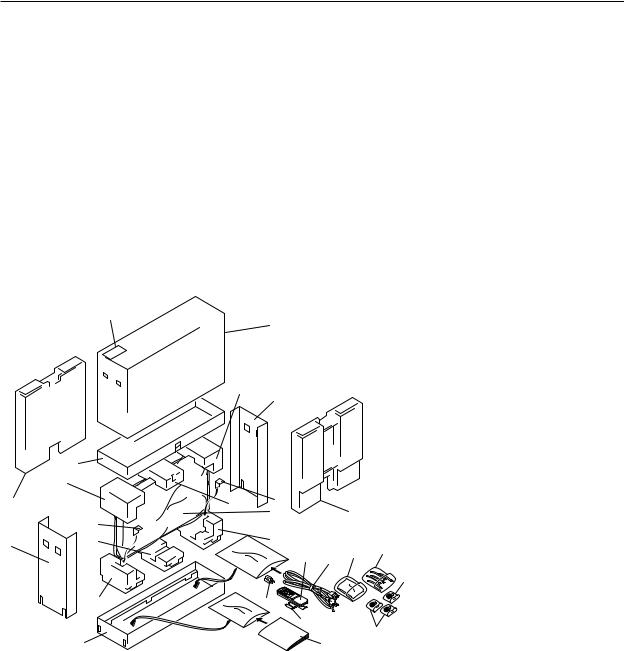

3.3.2 Unpacking

1) Package specifications: 1382 (W) x 888 (H) x 454 (D), 58.0 kg

17

|

2 |

|

5 |

22 |

|

|

11 |

3 |

9 |

|

8

4

|

|

Ref.No. |

Terms: |

|

|

1 |

1 |

Upper face of the carton |

|

|

|

|||

|

|

2 |

Carton cover |

|

|

|

3 |

Side carton |

|

7 |

3 |

4 |

Lower face of the carton |

|

5 |

Upper pad L |

|||

|

||||

|

|

6 |

11 |

|

12 |

||

|

||

|

10 |

23

6Upper pad C

7Upper pad R

8Under pad L

9Under pad C

|

|

21 |

|

10 |

Under pad R |

|

|

|

|

|

|

14 |

13 |

19 |

18 |

11 |

Carton spacer |

|

12 |

Miller mat |

|||

|

|

|

20 |

||

|

|

|

13 |

Power cord |

|

|

|

|

|

14 |

Remote control (CU-PDP002) |

15 |

|

|

|

15 |

2 manganese AA batteries, R6P |

|

|

|

|

|

20

16

16Operating manual

17Warrantee card

18Binder assembly

19Wiping cloth

20Adapter plug

(EURO Model, Taiwanese only)

21Front carton

22Rear carton

23AC conversion plug (Taiwanese only)

22

Installation Procedures

2)Unpacking procedures

1 Remove the packing bands.

2 Slowly lift and remove the upper carton [“top portion of the packaging”].

3 Lift and remove the reinforcement packaging. (Upper protective pad C is held in place by adhesive tape)

4 Remove the L and R upper cartons.

5 Remove the side, front, and rear cartons.

(At this stage, the product is supported by packing materials)

6 Remove the operating manual and accessories, which are secured to the lower carton by adhesive tape.

7 Remove the unit. (This should be performed by more than two persons)

3)Transportation of the unpacked unit

If it needs to be moved, the unit should be lifted by more than two persons.

•Avoid moving the unit by dragging it on the floor.

•Move the unit slowly, taking care to prevent scraping or striking the delicate front protective panel.

•Remove the protective film only after all work and preparations for the installation site, including clean-up following unpacking, are complete.

3.3.3 Temporary installation using packing materials

The lower carton and pads may be used as a temporary stand for the unit.

Connections to and from the unit can be made after the side, rear, and front cartons are removed. At this point, the power switch and remote control may also be operated, but this installation should be regarded as temporary. Always secure the unit to the mounting hardware after pre-installation wiring and adjustments are complete. Never attempt to move the unit while supported only by cartons.

Cutout allowing control

of using the remote

Cutout providing access to

the power switch

3.3.4 Re-packing

If the unit needs to be re-packed, observe the following guidelines:

•Pack by performing the steps described in 3.3.2 Unpacking in reverse order. The mirro mat must be positioned so that the shiny film surface faces outward and its soft surface faces inward (toward the unit).

•Restore all accessories to their original locations. Secure with adhesive tape to prevent damage during transportation.

•Check that no carton spacer is dislodged. Rearrange dislodged carton spacers so they are securely positioned between the unit and the lower pads, and secure with adhesive tape. This guards against instability during packaging or transportation.

23

Installation Procedures

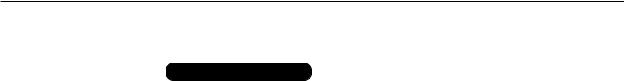

3.3.5. Wiring

1)Connecting the power cable

•Refer to the section on Power Cord Connection on page 26 of the operating manual.

•For power source specifications, refer to 3.1 Installation Conditions, paragraph 11.

2)Connecting signal cables

(1) Connection to PCs

•Refer to the section with this heading in the operating manual, on pages 21 to 22.

(2) Connection to video units

•Refer to the section with this heading in the operating manual, on pages 23 to 25.

(3) Important Notes