groov EPIC Chassis

Features

Secure mounting for power supply and processor, with or

>

without groov® I/O modules

Mount on a panel or 35 mm DIN-rail

>>

Modules pivot into place, plug into a module connector, and

>

lock onto the chassis with a single screw

Processor and power supply interlock and are secured with a

>

screw

UL Hazardous Locations approved and ATEX compliant

>>

DATA SHEET

Form 2247-190925

PAGE 1

GRV-EPIC-CHS4

DESCRIPTION

All groov EPIC® I/O mounting chassis are designed to hold an

intelligent groov EPIC processor and power supply, with models

available that can also hold 0, 4, 8, or 16 groov I/O modules.

The GRV-EPIC-CHS4, GRV-EPIC-CHS8, and GRV-EPIC-CHS16 can

hold a mix of groov analog, discrete, and serial I/O modules, because

all modules have the same footprint. Analog and discrete modules

can be placed in any module position on the chassis. Serial modules

can be placed in any of the first four positions and are directly

connected to the groov EPIC processor via the bus on the chassis.

Field devices are wired directly to the top-mounted connectors on the

modules. The module and chassis design allows each module to pivot

into a specific mounting position on the chassis.

The GRV-EPIC-CHS0 mounts the processor and power supply only

(no I/O modules) and is ideal for applications where I/O is not needed

and cabinet space is at a premium.

A Complete I/O Unit Where You Need It

With a GRV-EPIC-CHS4, GRV-EPIC-CHS8, or GRV-EPIC-CHS16, you can

have a powerful I/O unit wherever you need it. From small

applications in a limited physical space, to larger applications with

complex requirements, the three models are designed to meet a large

range of application requirements and physical space limitations.

Beyond a PLC – Processing Power at the Edge

With a GRV-EPIC-CHS0, you can put a groov EPIC processor

(GRV-EPIC-PR1) in tough, industrial locations where typical computers

or networking equipment may not be able to operate. The processor

can provide the computing power and networking connectivity you

need to modernize and extend your applications and systems. To

learn more about the capabilities of the groov EPIC processor, see

groov EPIC Processor Data Sheet (form 2245).

Agency Approvals and Compliance

All groov power supplies, voltage converters, pass-through power

adapters, I/O modules, and processors are UL/cUL listed and

compliant with the ATEX, Low Voltage, and EMC CE directives. Each

module is factory tested twice before shipment and most modules

are guaranteed for life.

Part Numbers

Part Description

GRV-EPIC-CHS0 Processor and power supply only mounting chassis

GRV-EPIC-CHS4 4-module analog/discrete/serial mounting chassis

GRV-EPIC-CHS8 8-module analog/discrete/serial mounting chassis

GRV-EPIC-CHS16 16-module analog/discrete/serial mounting chassis

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

SPECIFICATIONS

All specifications assume the following:

The air temperature 1 inch below the bottom of the chassis vents

does not exceed 70 °C.

The vents are unobstructed.

The chassis is mounted in a horizontal orientation with the back

of the unit mounted on a vertical surface.

Specification GRV-EPIC-CHS16 GRV-EPIC-CHS8 GRV-EPIC-CHS4 GRV-EPIC-CHS0

Number of module slots

Maximum Power Rating

Temperature (operating)

Temperature (storage)

Humidity (non-condensing)

Agency Approvals

Warranty

16840

UL/cUL(Class 1 Div. 2), CE, ATEX(Category 3, Zone 2), RoHS, DFARS; CB Scheme

For a diagram that shows the bottom of the chassis, see “Overall

Dimensions with Power Supply, Processor, and Modules Mounted” on

page 4. For a diagram that shows the chassis in standard orientation,

see “Orientation and Clearances” on page 5.

60 W with GRV-EPIC-PSAC

50 W with GRV EPIC PSDC

108 W with GRV-EPIC-PSPT

-20 °C to +70 °C

-40 °C to +85 °C

5–95% RH

30 months

DATA SHEET

Form 2247-190925

PAGE 2

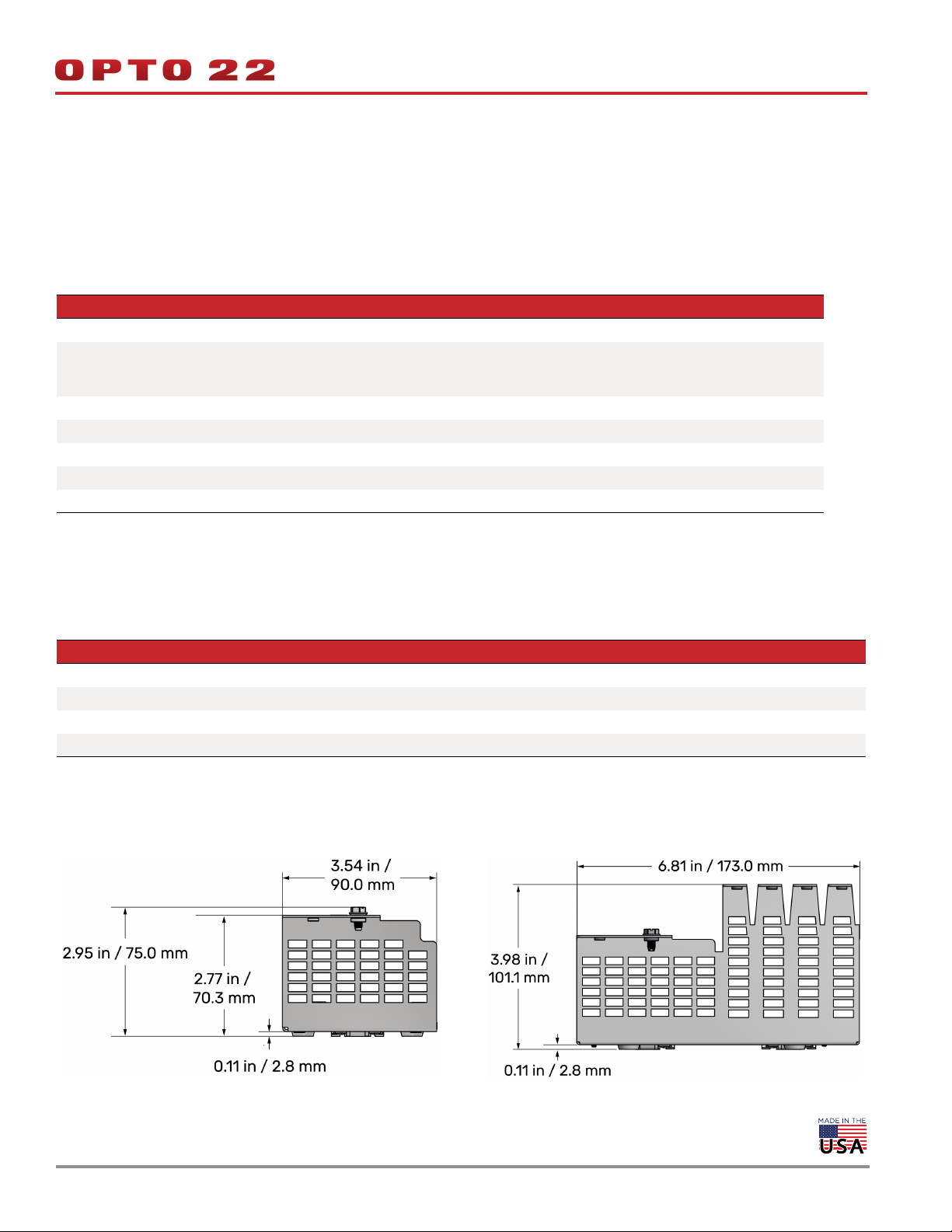

DIMENSIONS: GRV-EPIC-CHS0, GRV-EPIC-CHS4, GRV-EPIC-CHS8, AND

GRV-EPIC-CHS16

If you want to import these dimensions into an AutoCAD software system, go to the Opto 22 website and download CAD Drawings: groov EPIC

chassis.

Part Number Description Width (inches) Width (mm) Length (inches) Length (mm) Depth (inches) Depth (mm)

GRV-EPIC-CHS0 0-module chassis 5.36 136.2 3.54 90.0 2.95 101.1

GRV-EPIC-CHS4 4-module chassis 5.36 136.2 6.81 173.0 3.98 101.1

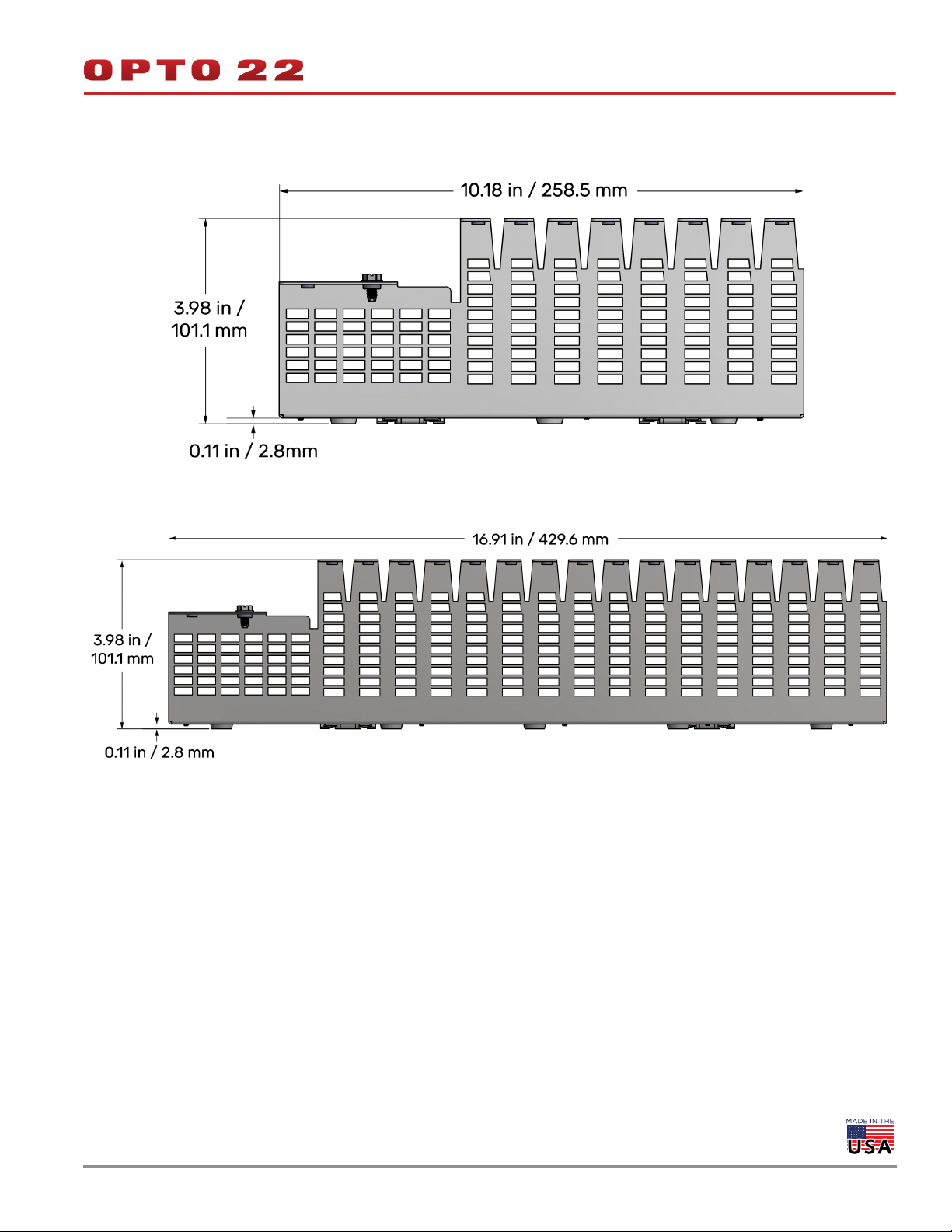

GRV-EPIC-CHS8 8-module chassis 5.36 136.2 10.18 258.5 3.98 101.1

GRV-EPIC-CHS16 16-module chassis 5.36 136.2 16.91 429.6 3.98 101.1

Depth and Length Dimensions

These diagrams show the bottom view of the chassis.

GRV-EPIC-CHS0 GRV-EPIC-CHS4

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

GRV-EPIC-CHS8

GRV-EPIC-CHS16

DATA SHEET

Form 2247-190925

PAGE 3

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DATA SHEET

Form 2247-190925

PAGE 4

Overall Dimensions with Power Supply, Processor, and Modules Mounted

The following diagrams show the dimensions of a 16-module chassis with a power supply, processor, and 16 modules mounted on it, with the

touchscreen open in a two different positions. The DIN rail shown is a standard 35 mm DIN rail (not sold by Opto 22). When you are determining

a location for the chassis, ensure you comply with the orientation and clearances indicated in “Orientation and Clearances” on page 5.

End View

The dimensions shown in the diagram to the right show the

touchscreen in two positions:

Open. Those are the dimensions at the top of the diagram.

Closed. Those are the dimensions at the bottom of the diagram.

Back View

The dimensions shown in the following diagram indicate the distance between the DIN rail (if used) and the edges of the chassis and the edges

of the unit (if modules are mounted to the chassis). The view shows the touchscreen open upright, perpendicular to the view.

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Bottom View

The dimensions in the following diagram show the display open in two positions: upright and out to its fullest extension.

DATA SHEET

Form 2247-190925

PAGE 5

ORIENTATION AND CLEARANCES

The diagrams in this section show the orientation and the clearances

recommended to ensure compliance with the specifications.

The diagram below shows a chassis (with modules, power supply, and

groov EPIC processor mounted on the chassis) with arrows indicating

a minimum 2 inch clearance all around the unit.

2 inches

2 inches

2 inches

2 inches

The diagram below shows the chassis mounted in a cabinet in a

horizontal orientation.

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DATA SHEET

Form 2247-190925

PAGE 6

ASSEMBLING AND MOUNTING

Before assembling and mounting your equipment, make sure you have the necessary clearances to ensure good ventilation, and that the area

where you will be installing the equipment does not exceed the specifications listed in “Specifications” on page 2. Check the following:

Ensure that there is a minimum of 2 inches clearance on the top,

bottom, each side, and front of the rack, after the processor,

power supply, and modules are mounted.

Ensure that the vents at the bottom of the chassis are not

obstructed.

Mounting on a DIN Rail

The chassis is built with DIN rail adapters for use on 35 mm DIN rail.

No additional assembly is required.

Mount the empty chassis to the DIN rail before installing the groov

EPIC power supply, processor, or I/O modules.

To mount the chassis to a DIN rail, follow these steps:

1. Hold the chassis so that the module connector numbers are

facing right side up.

2. Hold the chassis at an angle such that the top of the DIN rail

adapter is away from the DIN rail and the bottom of the DIN rail

adapter can slide behind the bottom lip of the DIN rail.

3. Push the bottom part of the chassis upward, making sure that you

feel the clip catch on to the rail, and simultaneously push the top

half of the chassis toward the DIN rail until the top of the DIN rail

adapter engages the top lip of the DIN rail.

Before you release the chassis, verify that the top and bottom of

the DIN rail adapters have engaged the DIN rail.

4. For all chassis models, mount the power supply and the

processor. For the chassis models that also hold groov I/O

modules, mount the modules onto the chassis.

When you choose a mounting location, ensure that the location

complies with the orientation and clearances specified in

“Orientation and Clearances” on page 5.

Mounting on a Panel

Using Chassis as Template

Use this method if you have the chassis on hand to use as a template.

1. Review the mounting hole dimensions on the next page and the

dimensional drawings in previous pages to determine required

product and option clearances.

2. Opto 22 ships the backplane attached to the chassis, so remove

the backplane to gain access to the chassis mounting holes.

Alternate Method: Prefabrication of Panels

If you do not have the chassis on hand, review the diagrams on the next page to determine mounting hole positions.

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

3. Use the chassis as a template to mark holes.

4. After the chassis is securely mounted, attach the backplane with

the retention screws provided.

DATA SHEET

Form 2247-190925

PAGE 7

Mounting Hole Dimensions

The following diagrams show the length measurements from the edges of the chassis to the center positions of the mounting holes. When you

install the chassis, use pan head screws of up to 10-32 in size.

GRV-EPIC-CHS0 GRV-EPIC-CHS4

GRV-EPIC-CHS8

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

GRV-EPIC-CHS16

DATA SHEET

Form 2247-190925

PAGE 8

© 2018-2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

More about Opto 22

PRODUCTS

Opto 22 develops and manufactures reliable, easy-to-use, open

standards-based hardware and software products.

Industrial automation, process control, building automation, industrial

refrigeration, remote monitoring, data acquisition, and industrial

internet of things (IIoT) applications worldwide all rely on Opto 22.

groov EPIC® System

Opto 22’s groov Edge Programmable Industrial Controller (EPIC)

system is the culmination of over 40 years of experience in designing

products for the automation industry.

groov EPIC gives you an industrially hardened system with

guaranteed-for-life I/O, a flexible Linux®-based processor with

gateway functions, and software that meets the needs of your

automation and IIoT applications.

groov EPIC I/O

I/O provides the local connection to

sensors and equipment. groov I/O

offers up to 24 channels on each I/O

module, with a spring-clamp

terminal strip, integrated wireway,

swing-away cover, and LEDs

indicating module health and

digital channel status.

groov I/O is hot swappable, UL

Hazardous Locations approved, and

ATEX compliant. Opto 22 I/O is so

reliable, we guarantee it for life.

Optional access to the Linux operating system through a secure

shell (SSH) to download and run custom applications

groov View for building your own device-independent HMI,

viewable on the touchscreen, PCs, and mobile devices.

Node-RED for creating simple logic flows from pre-built nodes

Ignition Edge® from Inductive Automation®, with OPC-UA drivers

to Allen-Bradley®, Siemens®, and other control systems, and

MQTT/Sparkplug communications for efficient IIoT data transfer

Older products

From solid state relays (our first products) to world-famous G4 and

SNAP I/O, to SNAP PAC controllers, older Opto 22 products are still

supported and still doing the job at thousands of installations

worldwide. You can count on us to give you the reliability and service

you expect, now and in the future.

QUALITY

Founded in 1974, Opto 22 has

established a worldwide reputation

for high-quality products. All are

made in the U.S.A. at our

manufacturing facility in Temecula,

California.

Because we test each product twice

before it leaves our factory rather than

testing a sample of each batch, we

can afford to guarantee most solidstate relays and optically isolated I/O

modules for life.

groov EPIC Processor

The heart of the system is the groov EPIC processor. It handles a wide

range of digital, analog, and serial functions for data collection,

remote monitoring, process control, and discrete and hybrid

manufacturing.

In addition, the EPIC provides secure data communications among

physical assets, control systems, software applications, online services,

and more, both on premises and in the cloud.

Configuring and troubleshooting I/O and networking is easier with

the EPIC’s integrated high-resolution color touchscreen. Authorized

users can manage the system locally on the touchscreen or on a

monitor connected via the HDMI or USB ports.

groov EPIC Software

Software included in the groov EPIC controller:

PAC Control engine to run PAC Control strategies and PAC Display

projects

CODESYS Runtime engine to run IEC61131-3 compliant programs

built with CODESYS Development System

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Form 1335-190917

Loading...

Loading...