Omron NS10-V2, NS8-V2, NS12-V2, NS5-V2, NS-CXDC1-V1 User Manual

...

Read and Understand this Catalog

Please read and understand this catalog before purchasing the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of the product in the customer's application or use of the product.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

Printed on 100%

Recycled Paper

Note: Do not use this document to operate the Unit.

OMRON Corporation

Control Devices Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530

Japan

Tel:(81)75-344-7109

Fax:(81)75-344-7149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel:(31)2356-81-300/

Fax:(31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg,

IL 60173 U.S.A.

Tel:(1)847-843-7900/Fax:(1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel:(65)6835-3011/Fax:(65)6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120 China

Tel:(86)21-5037-2222/Fax:(86)21-5037-2200

Authorized Distributor:

Note: Specifications subject to change without notice. |

Cat. No. V078-E1-09 |

|

Printed in Japan |

|

0206-1M |

NS12-V2 |

NS10-V2 NS8-V2 |

12-inch Model |

10-inch Model 8-inch Model |

NS5-V2 |

NSH5 |

5-inch Model |

5-inch Hand-held Model |

Programmable Terminals

NS-CXDC1-V1

Ver. 1

NS-series Screen Creation Software

Installing a Navigator: A Totally New Concept in

Programmable Terminals

NSH5 |

NS5-V2 |

NS8-V2 |

NS10-V2 |

NS12-V2 |

|

5-inch |

5-inch Model |

8-inch Model |

10-inch Model |

12-inch Model |

|

Hand-held |

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

NS Series |

|

|

|

Make it More Simple

The NS is moving to the next stage, from a touch screen to an advanced machine management tool.

It's convenient but…

Touch |

Screen |

Operation |

|

||

|

|

Switch |

Operation |

|

It's convenient but…

We are always trying to

Seamless provide solutions that will give the highest added

value to your system. We strive to solve on-site problems with our solutions instead of just providing touch screen functions. That is what OMRON is focused on.

Machine |

Management |

|

Smart

Turning switches into Touch Screens brings enhancements, such as minimum wiring, space savings, and improved local operation efficiency. Moreover, OMRON works to minimize the customer's energy expenditure from machine design to troubleshooting.

OK!

NS Enters a New Zone

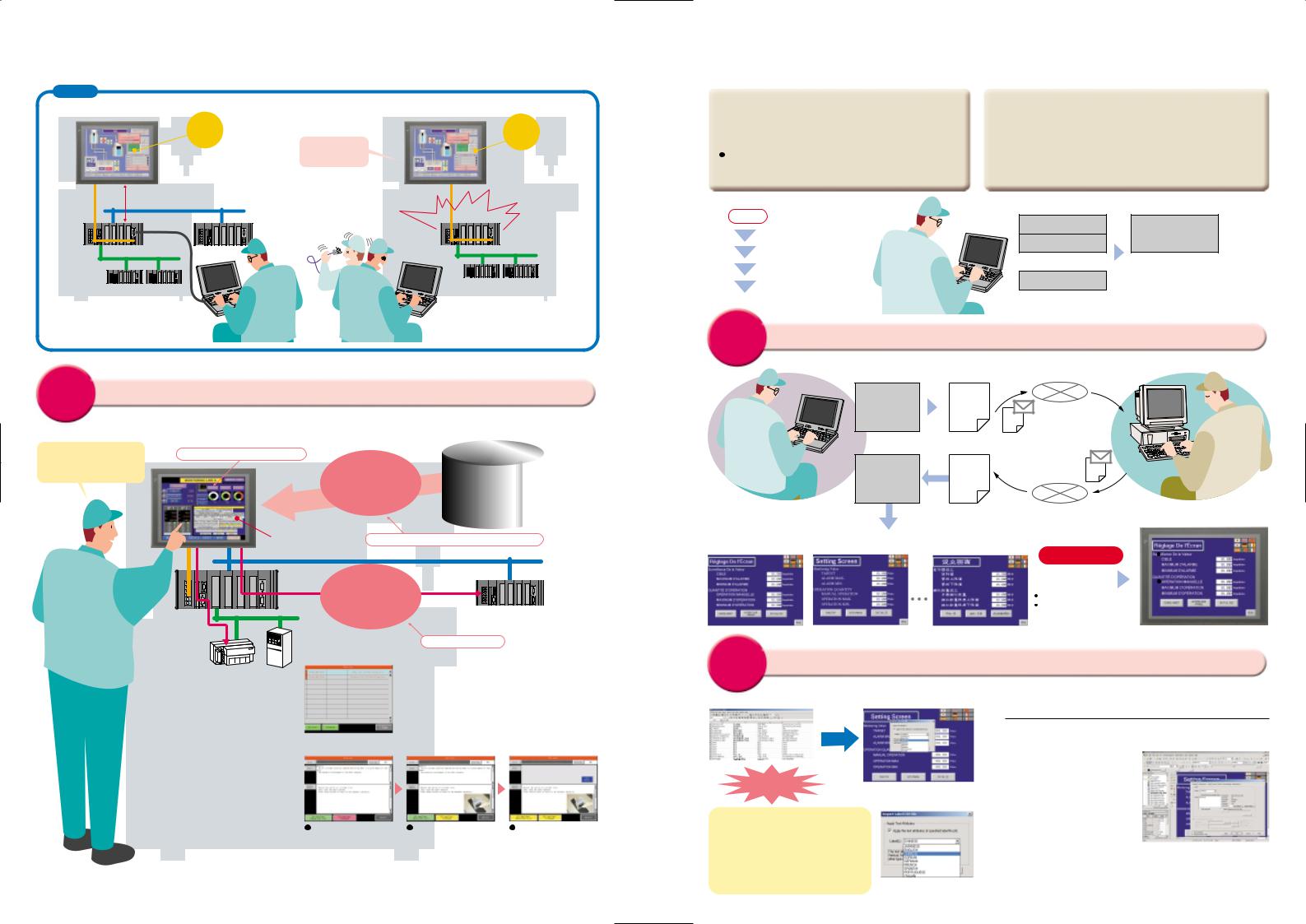

From PLC Memory Allocation to Device Access

Previous PTs shared data that was allocated in advance to specific words in the CPU Unit, and they were used to assist with device operations, and to display error locations, and countermeasures.

Previous

Previous

PT

PT

Previous

Previous

zone

zone

New

New

zone

zone

PT

PLC |

CPU Unit |

Allocated data

Sharing allocated data with CPU Unit

NS Series

PLC |

Special I/O Units |

|

Network |

|

Example: DeviceNet |

The NS Series achieves flexible data access to a variety of devices. It enables operators to reach the devices on the network including Special I/O Units, intelligent devices, and PLCs.

|

It's time for |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

switch inspection. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The cylinder |

Intelligent devices |

|

|

||||||||||||

Smart Active Parts |

|

|

||||||||||||||

speed is strange. |

Example: DRT2-series Smart Slave |

|

|

|||||||||||||

(Functional software parts) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Example: Monitoring maintenance information

for various DeviceNet Smart Slave models

2 |

3 |

PTs as a Machine Navigator

NS--seriesi PTs navigatei allll areas off machinei operation,i , fromf dailyily operationi to error recovery..

The PT is traditionally a terminal that exchanges data in

allocated areas with the PLC's CPU Unit. The internal and external control of a PLC with only this type of data exchange is, however, difficult.

A NS-series PT, however, uses communications functions and Smart Active Parts to incorporate

software computer functions to operate as a Device Navigator.

Previous |

NS Series |

Device operations |

|

|

PT |

|

NS: Device Navigator |

Displaying device error locations

Personal computer tool

Displaying countermeasures

Internal device monitoring and resetting

(Supporting recovery methods)

With version 2 PTs (V2 suffix in model number), hardware functions are upgraded.

Large Capacity |

Increased Visibility |

NS8-V2/NS10-V2/NS12-V2: 60 MB |

NS8-V2: Increased from 8.0 to 8.4 inches |

(-V1: 20 MB, same as before) |

NS5-V2(STN)/NS12: Wider field of vision |

NS5-V2: 20 MB |

|

Note: The NS5-V1 has a capacity of 6 MB.

Don't you have these problems?

The Smart Active Parts are the solution.

Using all of the device-specific |

Previous |

|

personal computer tools at startup is |

Various device-specific tools |

|

okay, but using the personal |

|

|

|

Peripheral Devices for PLC |

|

computer tools for error recovery |

|

Network control |

|

Temperature settings and |

|

during operation is overly difficult. |

|

|

Personal computer tools |

monitoring tools |

|

|

Setting tool for position control |

|

Wouldn't it be simpler to use the PT instead?

OMRON |

With an NS-series PT, just drag and drop Smart Active Parts to customize the interface |

||

ORIGINAL |

for your machine. |

|

|

|

|

|

|

|

Only with NS! |

NS-series PTs provide Smart Active Parts that allow direct data access |

|

|

to a variety of devices. |

|

|

|

|

|

|

|

|

|

PLC System Objects |

|

|

Just |

Previously |

|

|

|

a CX-Programmer |

attach to |

was required. |

|

a screen. |

||

|

|

|

|

|

Position Control Objects |

|

|

|

|

Ensures easy |

|

|

|

|

screen settings |

Colors and |

Example: RS-232C |

NS Series |

|

in the NCF. |

|

|

|||

sizes can be |

Example: Ethernet |

|

|

|

changed. |

|

|

|

|

|

|

|

Parts |

|

|

Devices accessed without a program. |

Active |

DeviceNet Objects |

|

|

Previously |

|||

|

Example: DeviceNet |

|||

|

a DeviceNet |

|||

|

|

|

Smart |

|

|

|

|

Configurator was |

|

|

|

|

|

|

|

|

|

|

required. |

Temperature Controller Parts

ThermoTool was required in the past.

Refer to page 15 of this catalog to see the wide variety of Smart

The Smart Active Parts are accessed by selecting Tools Active Parts. Use Library from the menu bar of the CX-Designer.

4 |

5 |

Do you have the following problems when starting the system or when errors occur?

Previous

|

When the System is Started |

|

When an Error Occurs during Operation |

|

|

PT used for operation after startup.

An error occurs, and…

Data exchange is the main function.

Special personal computer tool

A PT mainly exchanges data with a PLC.

A PT mainly exchanges data with a PLC.  Dedicated PC software is required to gain access to other devices.

Dedicated PC software is required to gain access to other devices.

There is no way for the PT to recover following an error. (Creating a screen is quite troublesome.)

Error |

Use a dedicated computer, and you have to wade through functionality that is not being used or that does not need to be reset.

Use a dedicated computer, and you have to wade through functionality that is not being used or that does not need to be reset.

Recovery can only be performed by a specialist (i.e., an engineer).

Recovery can only be performed by a specialist (i.e., an engineer).

Only |

With the Smart Active Parts |

|

|

|

with |

|

|

||

|

|

|

|

|

NS! |

The PT can be customized according to the specifications of the device manufacturer to optimize |

|||

|

||||

|

operation as a tool. This enables equipment maintenance by personnel other than engineers. |

|||

Minor maintenance |

Customizing and optimizing PT |

|

|

|

|

|

|||

can be performed on |

Simply paste one of |

|

|

|

the PT during operation. |

the Smart Active |

|

|

|

|

|

Parts! Then make only |

|

|

|

|

a few device node |

Smart Active Parts |

|

|

|

settings. |

|

|

|

|

|

|

|

Setting specified |

Improved efficiency in creating maintenance screen |

parameters and checking status |

|

|

Smart Active Parts |

|

access data without |

|

any special |

|

programming. |

Create a screen like this as a device troubleshooter.

When an error occurs, rapid recovery is critical. With the NS Series, the following type of screen can be easily prepared to guide on-site workers to carry out the operations required for recovery.

Display explanations of error contents and methods for recovery. (Text file direct specification)

Display explanations of error contents and methods for recovery. (Text file direct specification)

Use diagrams to show error locations and methods for recovery. (Bit map file direct specification)

Use diagrams to show error locations and methods for recovery. (Bit map file direct specification)  Display only the buttons required for recovery operations.

Display only the buttons required for recovery operations.

Notification that an error has occurred

1Error contents and recovery methods are displayed.

No ladder program

Error Recovery Screen Example

Text and BMP files can be directly specified, so operations such as correcting contents for recovery and replacing diagrams and photographs can be executed without requiring any special tools. For example, if the recovery operation procedure is changed by system improvements, screens can be changed by simply replacing text and BMP files, allowing for rapid implementation of improvements and countermeasures.

Note: Transfer tools must be used for transfers.

2 Error location and |

3 Recovery operation screen |

explanations of recovery |

is displayed. (Only the |

methods can be further |

buttons required for |

displayed by bit maps. |

operations are shown.) |

Note: In addition to the Troubleshooter for the machine above, there is a PLC troubleshooter for CS/CJ-series PLCs. Contact your OMRON representative for information on Troubleshooters.

Multi-language Terminal

Machine Localization with PTs

A Multi-language Input Environment Using Excel

No special PT tools are required for translation operations.

No special PT tools are required for translation operations.

Translations can be requested using e-mail attachments.

Previous Either a single screen data file was divided between Japanese and English screens, or else multiple screen data files

had to be created.

Label Switching Function for Up to 16 Languages

Devices can be started with Japanese-language screens, and then operated with screens in other languages.

Devices can be started with Japanese-language screens, and then operated with screens in other languages.

The languages can be switch to the one preferred by the device operators.

The languages can be switch to the one preferred by the device operators.

English and Japanese screen data

Japanese-language

screen

English-language

screen

Chinese screen data

Chinese-language

screen

Dual-language screen data

NS project

Because multiple labels can be set, screen data needs to be set only once. Multi-language capability is simply a matter of switching labels.

Only |

You can get multi-language support in Excel. Switching to as many as 16 languages is as |

||

with |

easy as switching labels. |

|

|

NS! |

Language A screen |

Language A |

Dual-language input in Excel by translation |

|

|||

|

companies and local |

||

|

data |

Excel data |

|

|

companies |

||

|

|

|

|

|

NS project |

CSV |

|

|

|

CSV Attachment |

|

|

Dual-language |

Language A and B |

|

|

screen data |

Excel data |

|

CSV or

NS project Unicode text

Note: Windows 2000 or XP is required for multi-language support.

16 languages max.

Label 0 |

|

Label 1 |

Label 15 |

|

|

|

CSV Attachment

NS Series

Only with NS! |

Multi-Language PT |

||

Asian Languages |

|||

|

|

Japanese, Simplified Chinese (see note |

|

|

|

1), Korean, and Traditional Chinese |

|

|

|

(see note 2) |

|

|

|

European Languages |

|

|

|

||

Support for 17 languages |

English, French, German, Italian, |

||

Portuguese, Spanish, Swedish, Dutch, |

|||

Switching to as many as |

Finnish, Norwegian, |

||

Basque, Catalan, and Danish |

|||

16 languages by simply |

|||

|

|||

|

|||

switching the labels |

|

||

With |

Multi-language conversion has become much easier! |

|

-Designer |

||

|

||

CX |

|

Multi-language CSV data

Import

Convenient!

When importing screen data, the text attributes of user-specified labels can be applied to all other imported text. With this function, entire Japanese text attributes (e.g., MS Gothic in blue or other colors) can be used in Chinese labels. Furthermore, by using the just-fit function, long labels in English will fit within the frame limits after automatic font adjustment.

Creating Chinese, Korean, or Other Language Screens in Any Language Version of Windows

Multi-language Input (When Windows 2000 or XP is Used)

When Windows 2000 or XP is being used, Simplified Chinese (see note),

Traditional Chinese (see note), Korean, and other language text can be input in CX-Designer. Select the desired language with Global IME to input a different language.

Note: Simplified Chinese: Chinese with partially simplified characters, mostly used in Mainland China.

Traditional Chinese: Chinese with traditional characters, mostly used in Hong Kong and Taiwan.

6 |

7 |

Loading...

Loading...