Omron FQM1-MMA21, FQM1-MMP21, FQM1-CM001 User Manual

OPERATION MANUAL

Cat. No. O010-E1-01

FQM1 Series

FQM1-CM001

FQM1-MMP21

FQM1-MMA21

Flexible Motion Controller

FQM1 Series

FQM1-CM001

FQM1-MMP21

FQM1-MMA21

Flexible Motion Controller

Operation Manual

Produced November 2004

iv

v

Notice:

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this

manual. Always heed the information provided with them. Failure to heed pre-

cautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also

capitalized when it refers to an OMRON product, regardless of whether or not

it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON

products, often means “word” and is abbreviated “Wd” in documentation in

this sense.

The abbreviation “CM” means Coordinator Module and the abbreviation “MM”

means Motion Control Module.

Visual Aids

The following headings appear in the left column of the manual to help you

locate different types of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is con-

stantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

vii

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Data Backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Outline of FQM1 Flexible Motion Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 FQM1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4 CX-Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-5 Expanded System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1-7 Function Tables Arranged by Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SECTION 2

Specifications and Nomenclature . . . . . . . . . . . . . . . . . . . . . 31

2-1 List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-2 General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3 Coordinator Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-4 Motion Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2-5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-6 Module Current Consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-7 Memory Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-3 Wiring Module Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3-4 Wiring Servo Relay Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

3-5 List of FQM1 Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3-6 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

SECTION 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4-1 Coordinator Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4-2 Motion Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

4-3 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

viii

TABLE OF CONTENTS

4-4 Power OFF Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

SECTION 5

Module Functions and Data Exchange . . . . . . . . . . . . . . . . . 103

5-1 Synchronous Operation between Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5-2 Data Exchange between Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5-3 Cyclic Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5-4 Synchronous Data Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5-5 DM Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5-6 Cycle Time Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

5-7 Operation Settings at Startup and Maintenance Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5-8 Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

SECTION 6

Coordinator Module Functions . . . . . . . . . . . . . . . . . . . . . . . 123

6-1 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

SECTION 7

Motion Control Module Functions . . . . . . . . . . . . . . . . . . . . 137

7-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

7-2 Interrupt Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

7-3 Input Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

7-4 Interval Timer Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

7-5 Pulse Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7-6 Pulse Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

7-7 Functions for Servo Drivers Compatible with Absolute Encoders . . . . . . . . . . . . . . . . . . . . 199

7-8 Virtual Pulse Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

7-9 Analog Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

7-10 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

SECTION 8

Connecting the CX-Programmer . . . . . . . . . . . . . . . . . . . . . 233

8-1 CX-Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

8-2 Connecting the CX-Programmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

SECTION 9

Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

9-1 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

9-2 Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

9-3 Troubleshooting Problems in Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

ix

TABLE OF CONTENTS

SECTION 10

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 259

10-1 Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Appendices

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

A

I/O Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

B

System Setup, Auxiliary Area Allocations, and Built-in I/O Allocations . . . . . . . . . . . . . . . . . . 311

C

Auxiliary Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

x

TABLE OF CONTENTS

xi

About this Manual:

This manual describes the operation of the Coordinator Module and Motion Control Modules of the

FQM1-series Flexible Motion Controller.

Please read this manual and all related manuals listed in the table below and be sure you understand

information provided before attempting to program or use FQM1-series Flexible Motion Controllers in a

control system.

Section 1 describes the features of the FQM1 and its system configuration.

Section 2 provides the specifications of the FQM1 and describes the parts and their functions on the

Coordinator Module and Motion Control Modules.

Section 3 describes how to install and wire the FQM1

Section 4 describes the operation of the FQM1.

Section 5 describes the functions common to both the Coordinator Module and Motion Control Mod-

ules and the methods to transfer data between the Coordinator Module and Motion Control Modules.

Section 6 describes the serial communications functions, which are supported only by the Coordinator

Module.

Section 7 describes the various functions supported by the Motion Control Module.

Section 8 explains how to connect a personal computer running the CX-Programmer to the FQM1.

Section 9 provides information on identifying and correcting errors that occur during FQM1 operation.

Section 10 provides inspection and maintenance information.

The Appendices provide information on programming, I/O Memory, System Setup, and built-in I/O

allocations, and Auxiliary Area allocations.

Name Cat. No. Contents

FQM1 Series

FQM1-CM001, FQM1-MMP21, FQM1-MMA21

Flexible Motion Controller Operation Manual

(this manual)

O010 This manual provides an overview of and describes

the following information for the FQM1-series Flexible

Motion Controller: features, system configuration,

system design, installation, wiring, maintenance, I/O

memory allocation, troubleshooting, etc.

FQM1 Series

FQM1-CM001, FQM1-MMP21, FQM1-MMA21

Flexible Motion Controller

Instructions Reference Manual

O011 Describes the ladder diagram programming instruc-

tions supported by FQM1-series Flexible Motion Con-

troller. Use this manual together with the Operation

Manual (Cat. No. O010).

SYSMAC WS02-CXP@@-E

CX-Programmer Operation Manual Version 5.@

W437 Provides information on how to use the CX-Program-

mer, a Windows-based programming and monitoring

package for OMRON PLCs.

xii

xiii

PRECAUTIONS

This section provides general precautions for using the FQM1-series Flexible Motion Controller and related devices.

The information contained in this section is important for the safe and reliable application of the FQM1-series

Flexible Motion Controller. You must read this section and understand the information contained before attempting

to set up or operate a control system using the FQM1-series Flexible Motion Controller.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

4-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

4-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

4-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

4-5 Relay Output Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . xx

5 Data Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

xiv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifica-

tions described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amuse-

ment machines, safety equipment, petrochemical plants, and other systems,

machines, and equipment that may have a serious influence on lives and

property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

!WARNING It is extremely important that the FQM1 be used for the specified purpose and

under the specified conditions, especially in applications that can directly or

indirectly affect human life. You must consult with your OMRON representa-

tive before applying a FQM1 System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Modules apart while the power is being supplied.

Doing so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Modules. Any attempt to

do so may result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits, i.e., not in the Flexible Motion

Controller (referred to as the “FQM1”), to ensure safety in the system if an

abnormality occurs due to malfunction of the FQM1 or another external factor

affecting the FQM1 operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The FQM1 will turn OFF all outputs when its self-diagnosis function

detects any error or when a severe failure alarm (FALS) instruction is exe-

cuted. As a countermeasure for such errors, external safety measures

must be provided to ensure safety in the system.

• The FQM1 outputs may remain ON or OFF due to destruction of the out-

put transistors. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

xv

Safety Precautions 3

• When the 24-VDC output (service power supply to the FQM1) is over-

loaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!WARNING Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes. Not doing so may

result in serious accidents.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution User programs and parameters written to the Coordinator Module or Motion

Control Module will be automatically backed up in the FQM1 flash memory

(flash memory function). The contents of I/O memory (including the DM Area),

however, are not written to flash memory. Part of the DM Area used as a hold-

ing area when recovering from a power interruption is backed up using a

super capacitor, but correct values will not be maintained if an error occurs

that prevents memory backup. As a countermeasure for such problems, take

appropriate measures in the program using the Memory Not Held Flag

(A404.14) when externally outputting the contents of the DM Area.

!Caution Confirm safety at the destination Module before transferring a program to

another Module or editing the I/O area. Doing either of these without confirm-

ing safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

!Caution Do not touch the Power Supply Unit while the power is ON, and immediately

after turning OFF the power. Touching hot surfaces may result in burning.

!Caution Pay careful attention to the polarities (+/-) when wiring the DC power supply.

A wrong connection may cause malfunction of the system.

3-1 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified

in the specifications

• Locations subject to condensation as the result of severe changes in tem-

perature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

xvi

Safety Precautions 3

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

!Caution The operating environment of the FQM1 System can have a large effect on

the longevity and reliability of the system. Improper operating environments

can lead to malfunction, failure, and other unforeseeable problems with the

FQM1 System. Make sure that the operating environment is within the speci-

fied conditions at installation and remains within the specified conditions dur-

ing the life of the system.

3-2 Application Precautions

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

Ω or less when installing the FQM1.

Not doing so may result in electric shock.

• Always connect to a ground of 100

Ω or less when short-circuiting the

functional ground and line ground terminals of the Power Supply Unit, in

particular.

• Always turn OFF the power supply to the FQM1 before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Unit, Coordinator Module, Mo-

tion Control Module, and End Module

• Assembling the Modules

• Setting DIP switches

• Connecting or wiring the cables

• Connecting or disconnecting the connectors

!Caution Failure to abide by the following precautions could lead to faulty operation of

the FQM1 or the system, or could damage the FQM1. Always heed these pre-

cautions.

• Always use the CX-Programmer (Programming Device for Windows) to

create new cyclic tasks and interrupt tasks.

• The user program and parameter area data in Coordinator Module and

Motion Control Modules is backed up in the built-in flash memory. Do not

turn OFF the power supply to the FQM1 while the user program or param-

eter area data is being transferred. The data will not be backed up if the

power is turned OFF.

• The FQM1 will start operating in RUN mode when the power is turned ON

with the default settings (i.e., if the operating mode at power ON (startup

mode) setting in the System Setup is disabled).

• Configure the external circuits so that the control power supply turns ON

after the power supply to the FQM1 turns ON. If the power is turned ON in

the opposite order, the built-in outputs and other outputs may momen-

tarily malfunction and the control outputs may temporarily not operate cor-

rectly.

xvii

Safety Precautions 3

• Outputs may remain ON due to a malfunction in the built-in transistor out-

puts or other internal circuits. As a countermeasure for such problems,

external safety measures must be provided to ensure the safety of the

system.

• Part of the DM Area (data memory) in the Motion Control Module is held

using the super capacitor. Corrupted memory may prevent the correct

values from being saved, however. Take appropriate measures in the lad-

der program whenever the Memory Not Held Flag (A404.14) turns ON,

such as resetting the data in the DM Area.

• Part of the DM Area in the Coordinator Module is backed up in the built-in

flash memory when transferring data from the CX-Programmer. Do not

turn OFF the power to the FQM1 while data is being transferred. The data

will not be backed up if the power is turned OFF.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the FQM1

• Force-setting/force-resetting any bit in memory

• Changing the present value of any word or any set value in memory

• Install external breakers and take other safety measures against short-cir-

cuiting in external wiring. Insufficient safety measures against short-cir-

cuiting may result in burning.

• Be sure that all the terminal screws and cable connector screws are tight-

ened to the torque specified in the relevant manuals. Incorrect tightening

torque may result in malfunction.

• Mount the Modules only after checking the connectors and terminal

blocks completely.

• Before touching the Module, be sure to first touch a grounded metallic

object in order to discharge any static built-up. Not doing so may result in

malfunction or damage.

• Be sure that the terminal blocks, connectors, and other items with locking

devices are properly locked into place. Improper locking may result in

malfunction.

• Wire correctly according to the specified procedures.

• Always use the power supply voltage specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Leave the dust protective label attached to the Module when wiring.

Removing the label may result in malfunction.

• Remove the dust protective label after the completion of wiring to ensure

proper heat dissipation. Leaving the label attached may result in malfunc-

tion.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Do not apply voltages to the built-in inputs in excess of the rated input

voltage. Excess voltages may result in burning.

xviii

Safety Precautions 3

• Do not apply voltages or connect loads to the built-in outputs in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Wire correctly and double-check all the wiring or the setting switches

before turning ON the power supply. Incorrect wiring may result in burn-

ing.

• Check that the DIP switches and data memory (DM) are properly set

before starting operation.

• Check the user program for proper execution before actually running it on

the Module. Not checking the program may result in an unexpected oper-

ation.

• Resume operation only after transferring to the new Module the contents

of the DM Areas, programs, parameters, and data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• Use the dedicated connecting cables specified in operation manuals to

connect the Modules. Using commercially available RS-232C computer

cables may cause failures in external devices or the Coordinator Module.

• Do not connect pin 6 (+5V) on the RS-232C port on the Coordinator Mod-

ule to any external device other than the NT-AL001 or CJ1W-CIF11 Con-

version Adapter. Doing so may result in damage to the external device

and the Coordinator Module.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• Do not touch the mounted parts or the rear surface of PCBs because

PCBs have sharp edges such as electrical leads.

• When connecting the Power Supply Unit, Coordinator Module, Motion

Control Module, and End Module, slide the upper and lower sliders until a

click sound is heard to lock them securely. Desired functionality may not

be achieved unless Modules are securely locked in place.

• Be sure to mount the End Module supplied with the Coordinator Module

to the rightmost Module. Unless the End Module is properly mounted, the

FQM1 will not function properly.

• Make sure that parameters are set correctly. Incorrect parameter settings

may result in unexpected operations. Make sure that equipment will not

be adversely affected by the parameter settings before starting or stop-

ping the FQM1.

xix

Conformance to EC Directives 4

4 Conformance to EC Directives

4-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

4-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Direc-

tives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61000-6-2

EMI (Electromagnetic Interference): EN61000-6-4

(Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the Motion Controller

(EN61131-2).

4-3 Conformance to EC Directives

The FQM1-series Flexible Motion Controllers comply with EC Directives. To

ensure that the machine or device in which the Motion Controller is used com-

plies with EC Directives, the Motion Controller must be installed as follows:

1,2,3... 1. The Motion Controller must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply and I/O power sup-

plies.

3. Motion Controllers complying with EC Directives also conform to the Com-

mon Emission Standard (EN61000-6-4). Radiated emission characteris-

tics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring,

and other conditions. You must therefore confirm that the overall machine

or equipment complies with EC Directives.

4-4 EMC Directive Conformance Conditions

The immunity testing condition of the Motion Control Modules is as follows:

Overall accuracy of FQM1-MMA21 analog I/O: +4%/

−2%

xx

Conformance to EC Directives 4

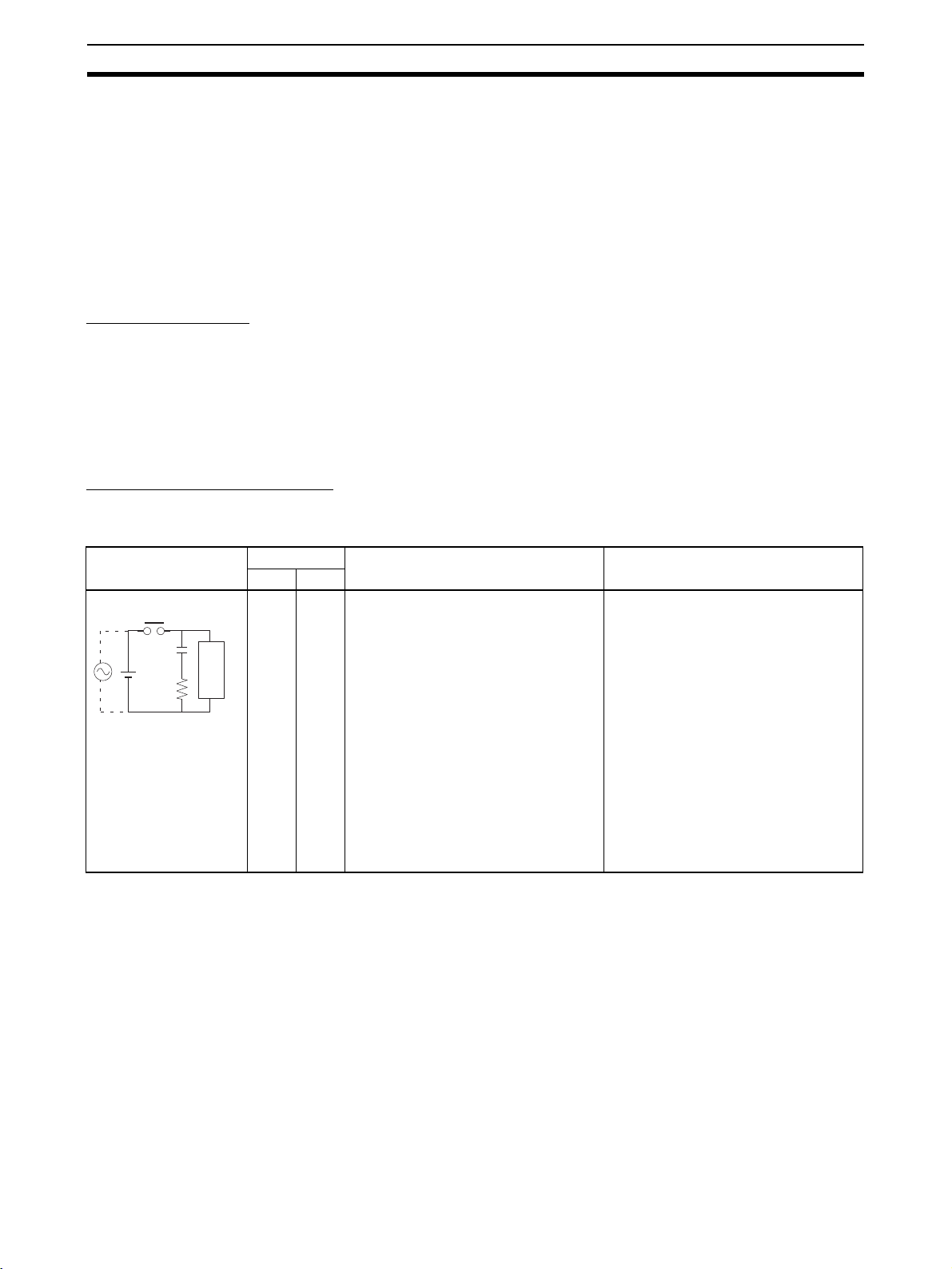

4-5 Relay Output Noise Reduction Methods

The FQM1-series Flexible Motion Controller conforms to the Common Emis-

sion Standards (EN61000-6-4) of the EMC Directives. However, noise gener-

ated by relay output switching may not satisfy these Standards. In such a

case, a noise filter must be connected to the load side or other appropriate

countermeasures must be provided external to the Motion Controller.

Countermeasures taken to satisfy the standards vary depending on the

devices on the load side, wiring, configuration of machines, etc. Following are

examples of countermeasures for reducing the generated noise.

Countermeasures

(Refer to EN61000-6-4 for more details.)

Countermeasures are not required if the frequency of load switching for the

whole system with the Motion Controller included is less than 5 times per

minute.

Countermeasures are required if the frequency of load switching for the whole

system with the Motion Controller included is more than 5 times per minute.

Countermeasure Examples

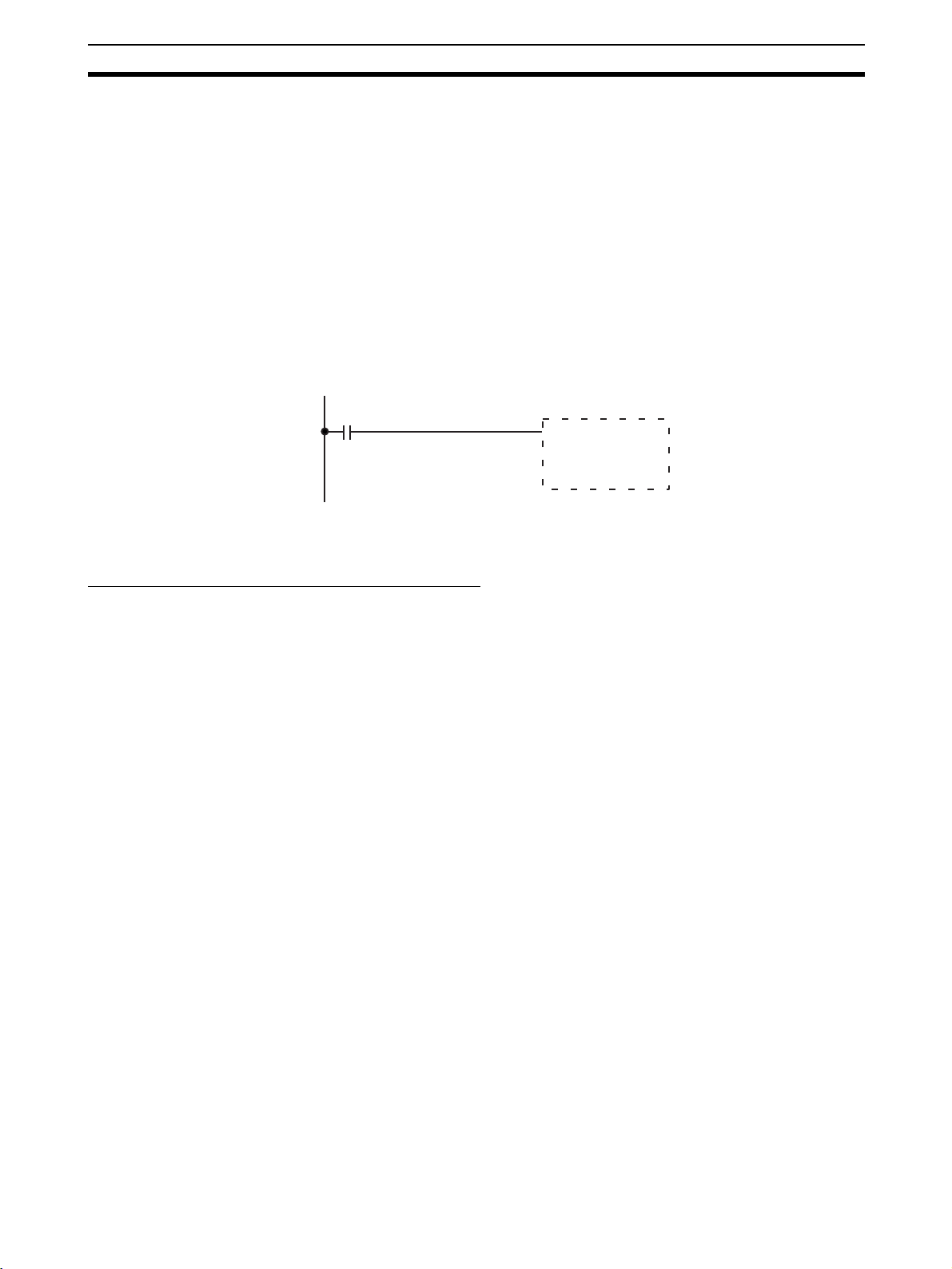

When switching an inductive load, connect an surge protector, diodes, etc., in

parallel with the load or contact as shown below.

Circuit Current Characteristic Required element

AC DC

Yes Yes If the load is a relay or solenoid, there

is a time lag between the moment the

circuit is opened and the moment the

load is reset.

If the supply voltage is 24 or 48 V,

insert the surge protector in parallel

with the load. If the supply voltage is

100 to 200 V, insert the surge protector

between the contacts.

The capacitance of the capacitor must

be 1 to 0.5 µF per contact current of

1 A and resistance of the resistor must

be 0.5 to 1 Ω per contact voltage of 1 V.

These values, however, vary with the

load and the characteristics of the

relay. Decide these values from experi-

ments, and take into consideration that

the capacitance suppresses spark dis-

charge when the contacts are sepa-

rated and the resistance limits the

current that flows into the load when

the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 300 V. If the circuit is an

AC circuit, use a capacitor with no

polarity.

CR method

Power

supply

Inductive

load

C

R

xxi

Conformance to EC Directives 4

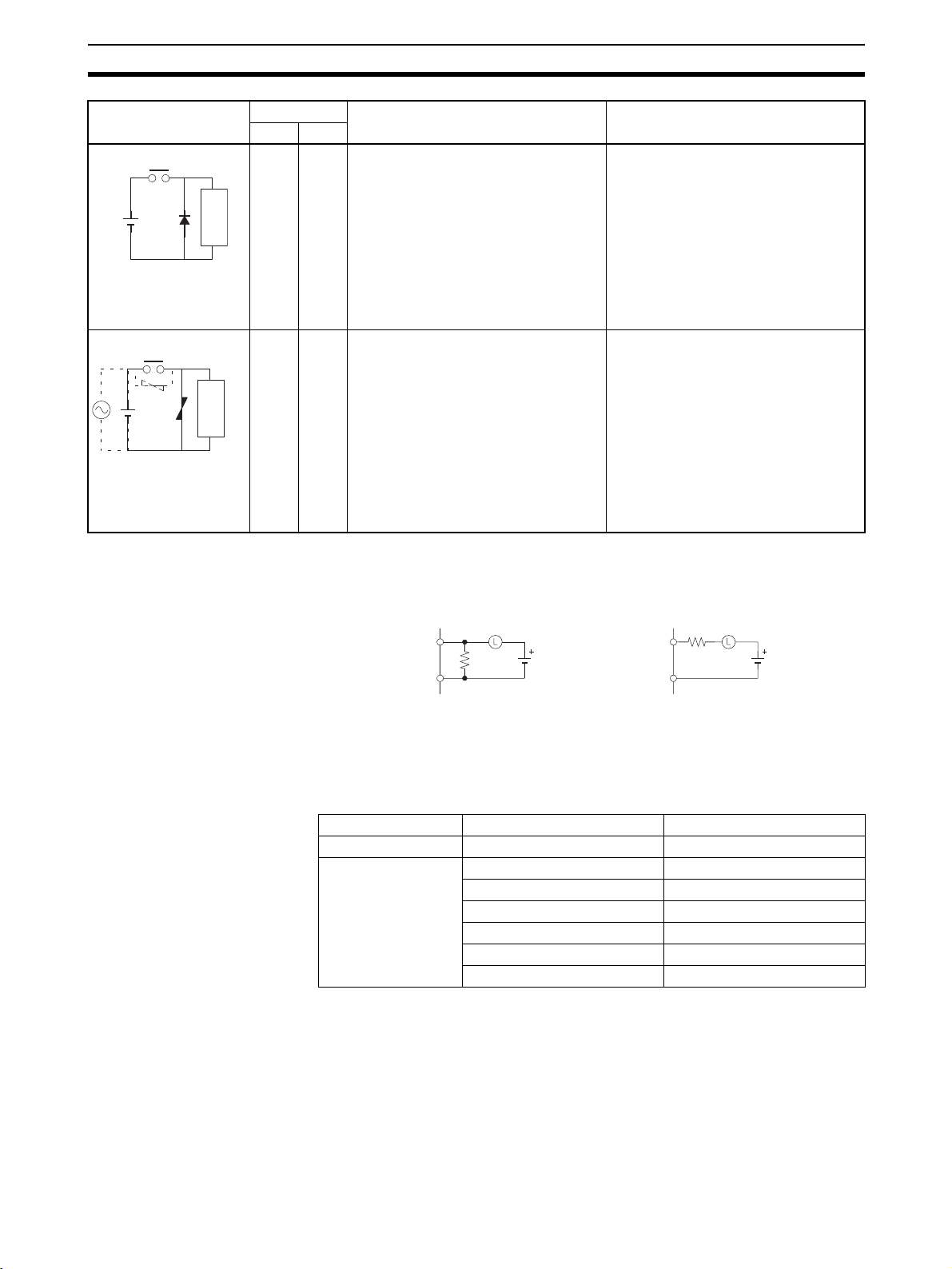

When switching a load with a high inrush current such as an incandescent

lamp, suppress the inrush current as shown below.

The following Unit and Cables can be used with the FQM1-series Flexible

Motion Controller.

No Yes The diode connected in parallel with

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so that the current

will be converted into Joule heat by the

resistance of the inductive load.

This time lag, between the moment the

circuit is opened and the moment the

load is reset, caused by this method is

longer than that caused by the CR

method.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

Yes Yes The varistor method prevents the impo-

sition of high voltage between the con-

tacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the cir-

cuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V,

insert the varistor in parallel with the

load. If the supply voltage is 100 to

200 V, insert the varistor between the

contacts.

---

Circuit Current Characteristic Required element

AC DC

Diode method

Power

supply

Inductive

load

Varistor method

Power

supply

Inductive

load

Name Model Cable length

Relay Unit XW2B-80J7-1A ---

Controller Connect-

ing Cables

XW2Z-050J-A28 0.5 m

XW2Z-100J-A28 1 m

XW2Z-050J-A30 0.5 m

XW2Z-100J-A30 1 m

XW2Z-050J-A31 0.5 m

XW2Z-100J-A31 1 m

OUT

COM

R

OUT

COM

R

Providing a dark current of approx.

one-third of the rated value

through an incandescent lamp

Providing a limiting resistor

Countermeasure 2Countermeasure 1

xxii

Data Backup 5

5Data Backup

The user programs, I/O memories, and other data in the Coordinator Module

and Motion Control Modules is backed up either by a super capacitor or flash

memory, as listed in the following table.

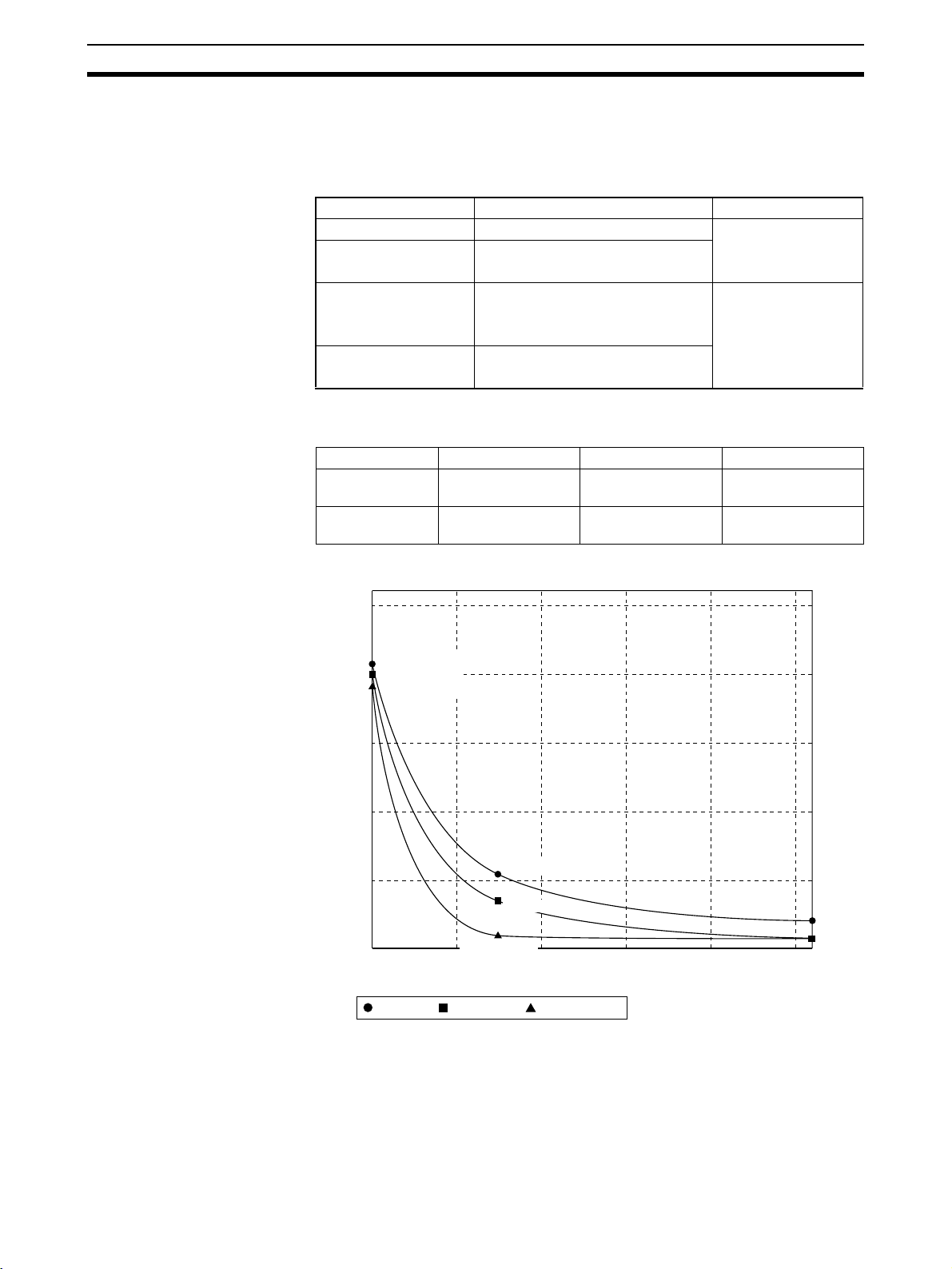

The data backup time of the super capacitor is given in the following table and

shown in the following graph.

Note 1. The times give above assume that the capacitor is completely charged.

Power must be supply to the FQM1 for at least 20 minutes to completely

charge the capacitor.

2. The backup time of the super capacitor is reduced as the capacitor ages.

It is also affected by the ambient temperature. Use portion of the DM Area

backed up by the super capacitor only for data that is to be held during mo-

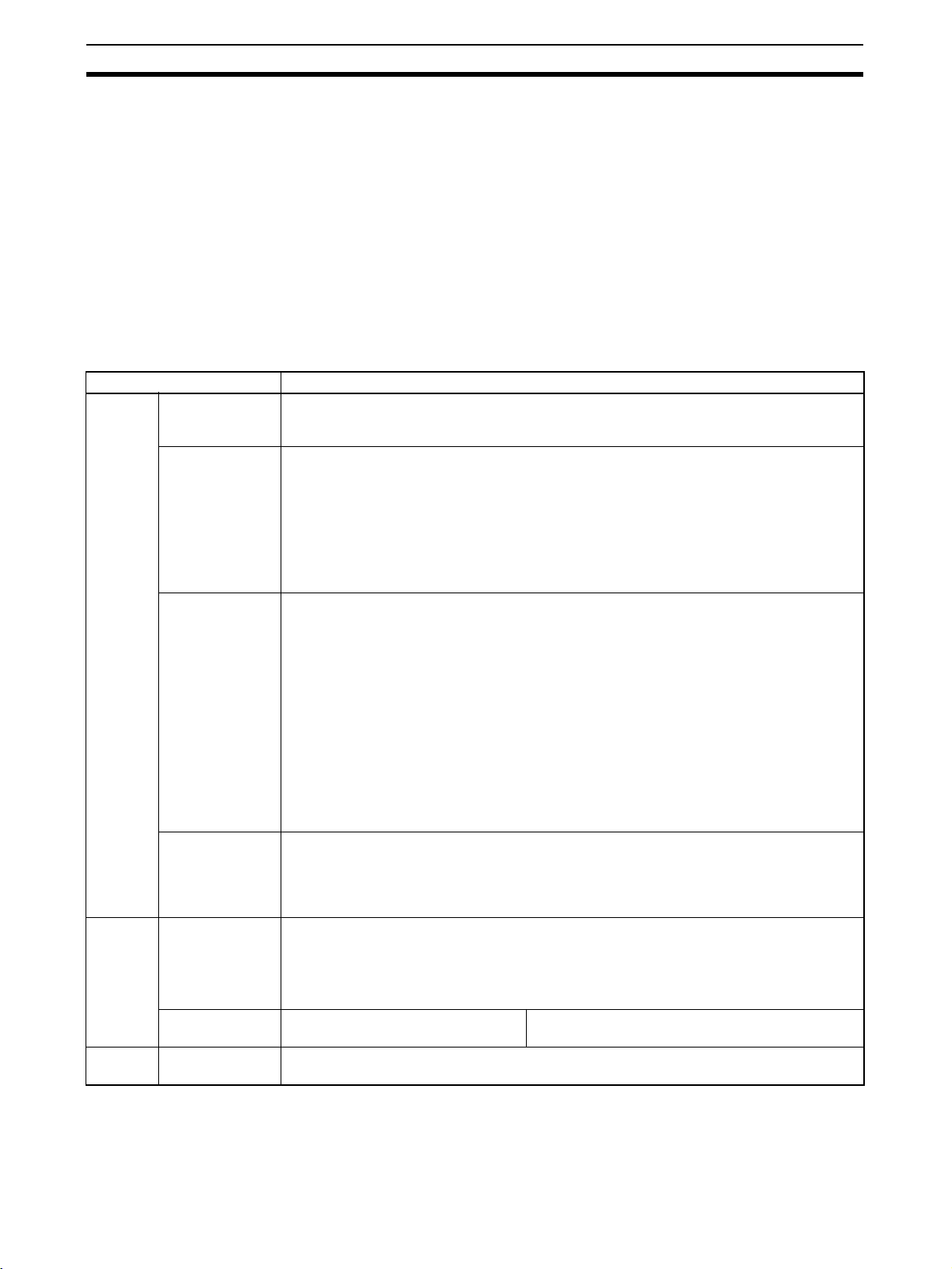

Module Data Data backup

Coordinator Module Error log RAM with super

capacitor

Motion Control Module DM Area words D30000 to D32767

Error log

Coordinator Module User program

System Setup

DM Area words D30000 to D32767

Flash memory

Motion Control Module User program

System Setup

Temperature Initial After 5 years After 10 years

Ta = 2 5°C 101.61 hours

(4.23 days)

96.2 hours

(4.01days)

90.8 hours

(3.78 days)

Ta = 4 0°C 26.39 hours

(1.09 days)

15.28 hours 4.16 hours

25 35 45 55 65 75

0

24

48

72

96

120

Ambient temperature (°C)

Super Capacitor Backup Times

Backup time (h)

25°C: 96.20 h

25°C: 101.61 h

40°C: 26.39 h

Initial value,

40°C: 4.16 h

25°C: 90.80 h

40°C: 15.28 h

After 5 years, After 10 years

xxiii

Data Backup 5

mentary power interruptions. For operating parameters and other long-

term data, use the portion of DM Area stored in flash memory in the Coor-

dinator Module and transfer it to the Motion Control Modules before start-

ing operation.

The data in the DM Area and error log will become unstable or corrupted if the

power to the system is OFF for longer than the backup time.

If the power supply is to be turned OFF for an extended period of time, use

D30000 to D32767 in the Coordinator Module, which is backed up in flash

memory, to store data.

Otherwise, the Memory Not Held Flag (A404.14) can be used as the input

condition for programming using data in areas stored for power interruptions

to perform suitable processing.

A404.14: Turns ON when power is turned ON if data stored for power inter-

ruptions in the DM Area or error log is corrupted.

DM Area words D30000 to D32767 in the Coordinator Module are backed up

in flash memory as described in the next section.

Backing Up DM Area Data in Flash Memory

DM Area words D30000 to D32767 in the Coordinator Module is read from

flash memory when the power supply is turned ON. We recommend using DM

Area words D30000 to D32767 in the Coordinator Module to store operating

parameters and other data required for system operation and then using the

DM transfer function to transfer the data from the Coordinator Module to the

Motion Control Modules at the start of operation.

A404.14

Processing for

corruption of data

backed up for

power interruptions

xxiv

Data Backup 5

1

SECTION 1

Features and System Configuration

This section describes the features of the FQM1 and its system configuration.

1-1 Outline of FQM1 Flexible Motion Controller . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 FQM1 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4 CX-Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-5 Expanded System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5-1 Serial Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5-2 Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6-1 Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-7 Function Tables Arranged by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-7-1 Sync Cycles and Synchronized data. . . . . . . . . . . . . . . . . . . . . . . . . 19

1-7-2 Position and Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-7-3 Measuring Input Pulses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-7-4 High-speed Analog I/O Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-7-5 Controlling Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2

Outline of FQM1 Flexible Motion Controller Section 1-1

1-1 Outline of FQM1 Flexible Motion Controller

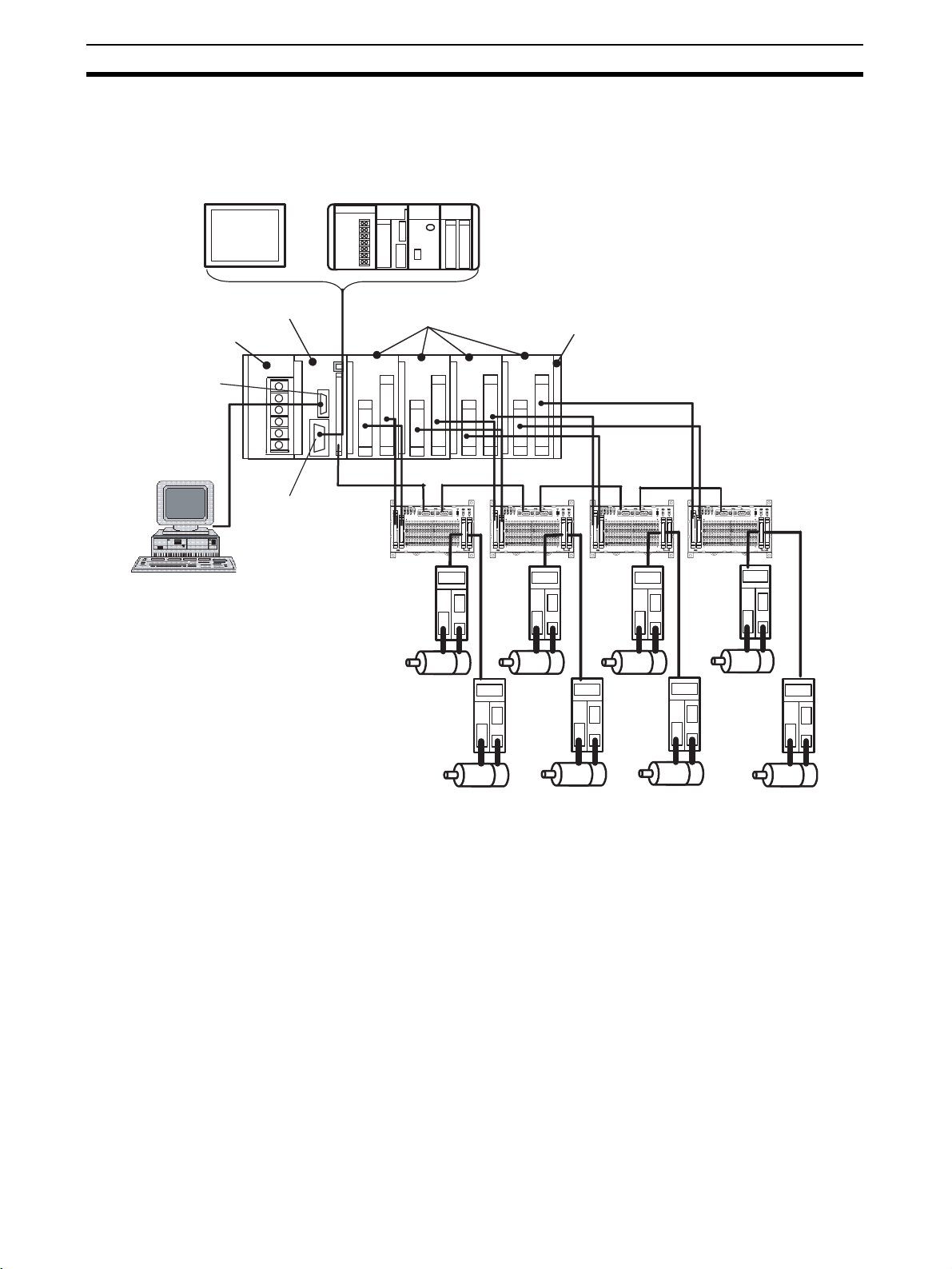

The FQM1 (Flexible Quick Motion) is a stand-alone Flexible Motion Controller

that can be used to create flexible high-speed, high-precision motion control

systems for 2 to 8 axes.

Flexible Configurations of

Up To 8 Axes

An FQM1 Flexible Motion Controller System is made up of a Power Supply

Unit, a Coordinator Module, one or more Motion Control Modules, and an End

Module.

Motion Control Modules are available with either pulse I/O or analog I/O, and

a mixture of up to four Motion Control Modules can be included in one system

(up to three if only analog I/O Motion Control Modules are used.) A flexible

system ideal for the application can be created because each Motion Control

Module controls two axes, giving total motion control of eight axes when four

Motion Control Modules are connected.

High-speed Processing Each Motion Control Module and Coordinator Module has independent ladder

programming, allowing high-speed independent control of pulse and analog

I/O. Data can be shared between all Modules. The Coordinator Module per-

forms general-purpose I/O control and manages overall system operation.

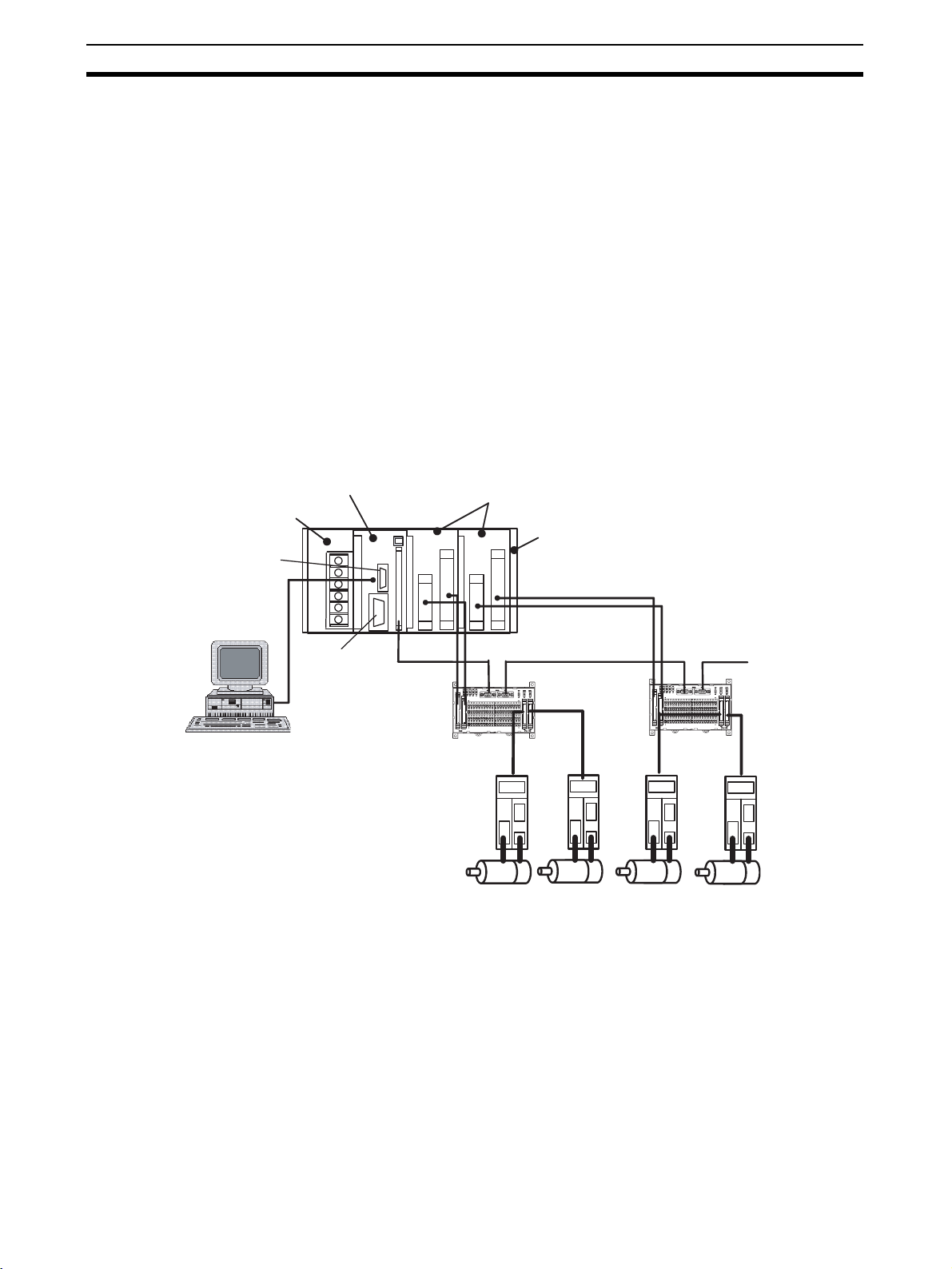

RS-422A

CX-Programmer

PT (Monitor

parameter

settings)

or

Host Controller

Power Supply Unit

Coordinator Module

Motion Control Modules

End Module

Peripheral port

RS-232C port

Servo Relay Units

Servomotors and

Servo Drivers

3

Outline of FQM1 Flexible Motion Controller Section 1-1

Built-in RS-232C Port in

Coordinator Module

A Programmable Terminal (PT) can be connected to the Coordinator Module

to monitor present values on the PT or make parameter settings for Servomo-

tors from the PT.

The RS-232C port is useful for a variety of applications. It can be used, for

example, to connect to a host computer or for a Serial PLC Link connection to

a SYSMAC CJ1M Programmable Controller.

Built-in RS-422A Port in

Coordinator Module

A PT can be connected to the Coordinator Module so that Servo parameters

can be read from and written to Servomotors/Servo Drivers using a Serial

Gateway Function.

Commands can also be sent from the Coordinator Module ladder program to

Servomotors/Servo Drivers.

Motion Control with

Familiar Ladder

Programming

The Coordinator Module and Motion Control Modules each have their own

ladder program, which perform basic I/O and special I/O (pulse I/O and ana-

log I/O).

Built-in General-purpose

I/O in Coordinator Module

The Coordinator Module has 24 built-in I/O (16 inputs and 8 outputs) for com-

munications with host controllers and 12 inputs and 8 outputs for Motion Con-

trol Modules.

Built-in General-purpose

I/O in Motion Control

Modules

Motion Control Modules have 12 contact inputs and 8 contact outputs for I/O

with peripheral devices.

Connections for Absolute

Servomotors

Motion Control Modules can read absolute position data from W-series Abso-

lute Servomotors/Servo Drivers.

High-speed Counter Latch

Function

The high-speed counter latch function latches the high-speed counter's PV

using 2 external signals. Ladder programs can then be used to read the

latched values.

Pulse Input Sampling

Function

The number of pulse inputs within a specified time can be measured.

RS-232C

CX-

Programmer

RS-422A

Coordinator Module

Motion Control

Module #1

Motion Control

Module #4

Motion Control

Module #3

Motion Control

Module #2

Periph-

eral port

Ladder

program

Ladder

program

Ladder

program

Ladder

program

Ladder

program

PT, host

computer,

etc.

Normal I/O

Servo Driver

Special I/O

(pulse or

analog I/O)

Basic I/O

Special I/O

(pulse or

analog I/O)

Basic I/O

Special I/O

(pulse or

analog I/O)

Basic I/O

Special I/O

(pulse or

analog I/O)

Basic I/O

4

FQM1 Configuration Section 1-2

Pulse Input Frequency

Measurement Function

The speed of pulse inputs can be measured at the same time as the number

of pulse inputs is counted.

Wide Variety of Interrupt

Functions

The FQM1 can provide high-speed I/O responses because it has a wide vari-

ety of functions for starting interrupt tasks, in addition to input interrupts, inter-

val timer interrupts, high-speed counter interrupts, and pulse output interrupts.

High-speed Analog I/O

Supported

Motion Control Modules with analog I/O support linear (displacement/length

measurement) sensor input, inverter control, and control of Servomotors with

analog-input Servo Drivers. This gives flexibility for a great variety of motion

applications.

Writing and Monitoring

Ladder Programs

The ladder program for each Module is written using CX-Programmer Ver.

5.01 or later (see note) and then written to each Module via the peripheral

port on the Coordinator Module.The ladder program is saved in each Module

and operation of the program can be monitored from the CX-Programmer.

Note FQM1 Patch Software must be installed for CX-Programmer Ver. 5.0.

1-2 FQM1 Configuration

The FQM1 consists of a Power Supply Unit, a Coordinator Module, one or

more Motion Control Modules, and an End Module. Motion Control Modules

are available with either pulse I/O or analog I/O and up to four Motion Control

Modules can be connected in one system. (See note.)

Note The number of Motion Control Modules with Analog I/O that can be connected

is limited by the output capacity of the Power Supply Unit.

RS-422A

CX-Programmer

Power Supply Unit

Coordinator Module

Motion Control Modules

End Module

Peripheral port

RS-232C port

Servo Relay Units

Servomotors/

Servo Drivers

5

FQM1 Configuration Section 1-2

FQM1-CM001 Coordinator

Module

One Coordinator Module is required in an FQM1. The Coordinator Module

provides the following:

I/O: 16 inputs, 8 outputs

Program capacity: 5 Ksteps

DM Area capacity: 32 Kwords (DM)

• The CX-Programmer (Ver. 5.01 or later) is connected to the peripheral

port on the Coordinator Module, and a PT (Programmable Terminal) or

other device is connected to the RS-232C port.

• The Coordinator Module has its own ladder program, which is used to

coordinate Motion Control Module data.

• The Coordinator Module has 24 general-purpose I/O (16 inputs and 8 out-

puts).

• The Coordinator Module has a Cyclic Refresh Bit Area, in which 10 words

are allocated for cyclic refreshing with each Motion Control Module. This

area is refreshed each Coordinator Module cycle.

• The Coordinator Module has a Synchronous Data Link Bit Area, in which

4 words are allocated for sharing with the Synchronous Data Link Bit Area

of each Motion Control Module.

FQM1-MMP21/MMA21

Motion Control Modules

Each Motion Control Module provides the following:

• Rotary Encoders, Linear Sensors, Servos, Inverters, etc., can be con-

nected to the special I/O.

• Each Motion Control Module has a ladder program for executing motion

control and other functions.

• Each Motion Control Module has 20 general-purpose I/O (12 inputs and 8

outputs).

• Each Motion Control Module has 10 words allocated in the Coordinator

Module's Cyclic Refresh Bit Area that is refreshed every Coordinator

Module cycle.

• Each Module cycle, 4 words of Motion Control Module Synchronous Data

Link Bit Area data is shared with the Coordinator Module's Synchronous

Data Link Bit Area.

CJ1W-PA202/PA205R

Power Supply Units

SYSMAC CJ-series Power Supply Units are used.

Select a Power Supply Unit with a capacity greater than the total current con-

sumption of the connected Modules.

Pulse I/O Motion

Control Module

FQM1-MMP21 Program capacity: 5 Ksteps

Pulse inputs: 2

Pulse outputs: 2

General-purpose inputs: 12

General-purpose outputs:8

Analog I/O Motion

Control Module

FQM1-MMA21 Program capacity: 5 Ksteps

Pulse inputs: 2

Analog inputs: 1

Analog outputs: 2

General-purpose inputs: 12

General-purpose outputs: 8

CJ1W-PA202 100 to 240 V AC, output capacity: 5 V DC, 2.8 A, 24 V DC, 0.4 A,

up to 14 W total.

CJ1W-PA205R 100 to 240 V AC, output capacity: 5 V DC, 5.0 A, 24 V DC, 0.8 A,

up to 25 W total.

6

Modules Section 1-3

FQM1-TER01 End Module One End Module is supplied with the Coordinator Module. Always attach the

End Module because it acts as a terminator for the system. A fatal error will

occur if no End Module is attached.

Other Peripheral Devices Special Servo Relay Units are available for connecting the FQM1 Flexible

Motion Control system to OMRON W-series and SMARTSTEP Servo Drivers.

Specific cables suitable for the connected Servomotor/Servo Driver models

and the FQM1 Motion Control Module models are also available.

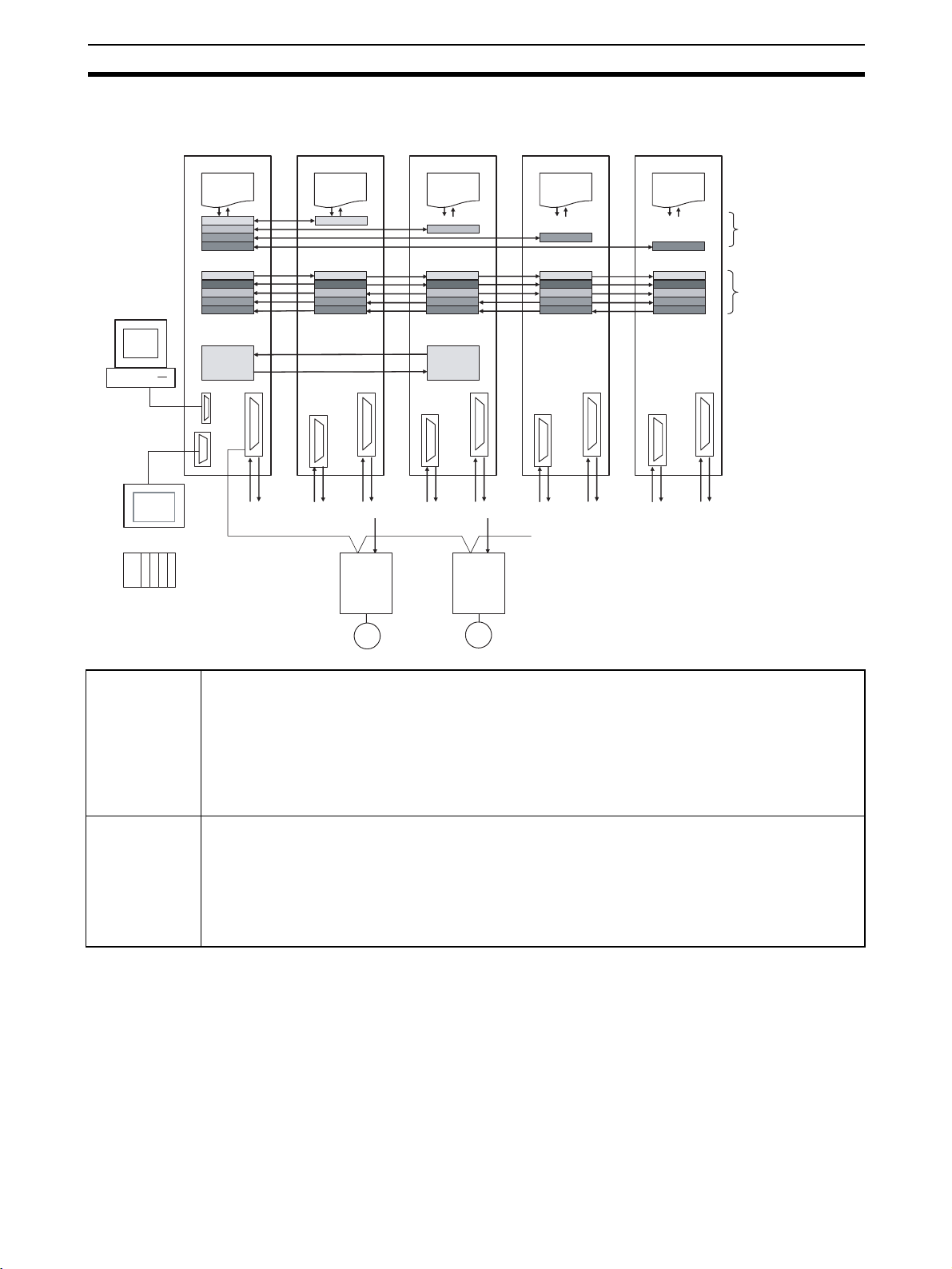

1-3 Modules

The Coordinator Module acts as the interface between the FQM1 system and

peripheral devices, shares data with each Motion Control Module, and syn-

chronizes specific data (e.g., virtual axis data) between Modules.

Item Details

Functions Interfaces for

peripheral

devices

Connection with the CX-Programmer (peripheral port)

Connection with PT for monitoring and parameter settings (RS-232C port)

Connections with Servo Drivers (RS-422A port)

Sharing data with

each Motion

Control Module

(each Coordina-

tor Module cycle)

The 10 words are allocated for each Motion Control Module in the Cyclic Refresh Bit Area

of the Coordinator Module (CIO 0100 to CIO 0139), based on the Motion Control Module

slot number. These words correspond to CIO 0100 to CIO 0109 in the Cyclic Refresh Bit

Area of each Motion Control Module.

• Coordinator Module to Motion Control Module: 5 words (General-purpose output)

• Motion Control Module to Coordinator Module: 5 words (General-purpose input: 4 words,

program RUN, fatal errors, non-fatal errors)

This cyclic refresh data is refreshed every Coordinator Module cycle.

Synchronized

sharing of special

data between

Modules (broad-

cast at specified

sync cycle)

User-specified synchronous data (see following list) can be allocated to CIO 0200 to CIO

0219 in the Synchronous Data Link Bit Area of the Coordinator Module and each Motion

Control Module, 4 words at a time (2 types of data × 2 words). The allocations are fixed,

starting with the Coordinator Module and followed by Motion Control Modules in order of

slot number.

• Any ladder program data

• High-speed counter PV

• Pulse output PV

• Analog input PV

• Analog output PV

• Built-in I/O input values

The synchronous data is broadcast each specified sync cycle and all other Modules

receive this data in essentially real-time.

DM data transfer

with specific

Motion Control

Modules (as

required)

DM data (499 words max.) can be transferred in the specified direction between the speci-

fied words in the DM Area in the specified Motion Control Module and the specified DM

Area words in the Coordinator Module when the DM Write Request Bit (A530.00) or DM

Read Request Bit (A530.01) in the Auxiliary Area of the Coordinator Module turns ON.

I/O Serial communi-

cations

• Peripheral port: Peripheral bus (for CX-Programmer)

• One RS-232C port: NT Link (for OMRON PTs), Host Link (for host computers), or no pro-

tocol (for PLCs)

• One RS-422A port (Same connector as general-purpose I/O): 1:N communications with

Servo Drivers (for transferring parameters to Servo Drivers)

General-purpose

I/O

General-purpose inputs: 16

General-purpose outputs: 8

40-pin connector (including RS-422A)

Programs Program capacity 5 Ksteps (for data exchange with host computer, coordination of Motion Control Modules,

and other peripheral programming)

7

Modules Section 1-3

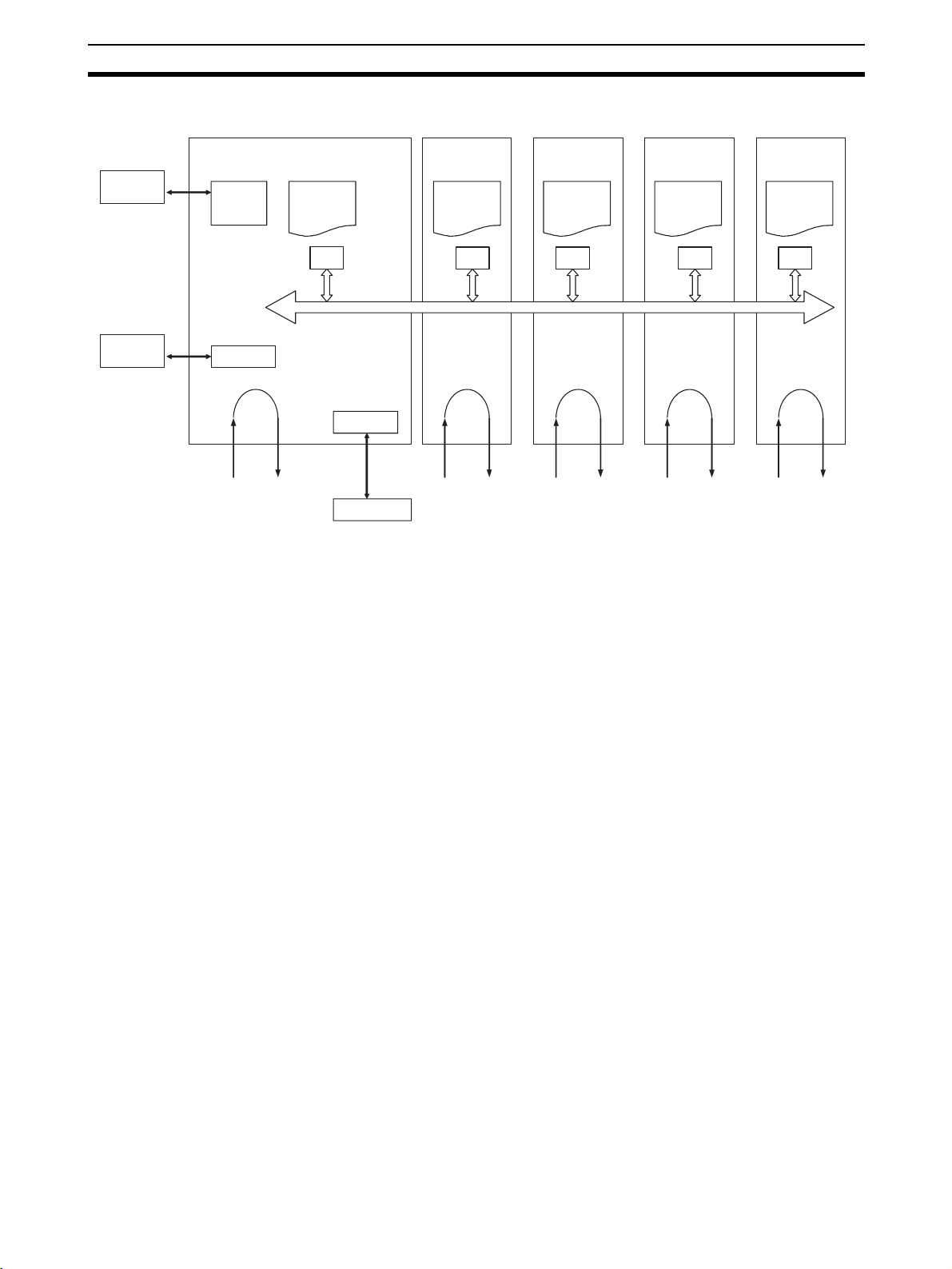

Outline of Internal Data Exchange and I/O

PT

CX-Programmer

DM DM

RS-232C

PLC

RS-422A

Coordinator

Module

Motion Control

Module #1

Motion Control

Module #2

Motion Control

Module #3

Motion Control

Module #4

Ladder program Ladder program Ladder program Ladder program Ladder program

Cyclic Refresh Bit

Area (refreshed each

Coordinator Module

cycle)

Sync Data Link Bit

Area (Broadcast

each Motion

Control Module

cycle)

DM data transfer

(as required)

Peripheral port

16 inputs

8 outputs

12 inputs

8 outputs

Special I/O 12 inputs

8 outputs

Special I/O 12 inputs

8 outputs

Special I/O 12 inputs

8 outputs

Special I/O

(for parameter settings)

W-series/

SMART

STEP

Servo

Driver

W-series/

SMART

STEP

Servo

Driver

Coordinator

Module

• Peripheral port for connecting CX-Programmer and RS-232C port for connecting PTs and other

devices

• Ladder program for coordinating Motion Control Module data and other functions

• 24 general-purpose I/O

• 10 words of cyclic refresh data for each Motion Control Module allocated in Cyclic Refresh Bit Area,

which is refreshed each Coordinator Module cycle

• 4 synchronous data link words allocated for each Motion Control Module in Coordinator Module's Syn-

chronous Data Link Bit Area, which is shared each Module cycle

Motion Control

Modules

• Linear Sensors, Servo Drivers, Inverters, etc., connected to special I/O

• Ladder program for executing motion control and other functions

• 20 general-purpose I/O

• 10 words of cyclic refresh data for each Motion Control Module allocated in its Cyclic Refresh Bit Area,

which is refreshed each Coordinator Module cycle

• 4 synchronous data link words allocated for each Motion Control Module in Coordinator Module's Syn-

chronous Data Link Bit Area, which is shared each Module cycle

Loading...

Loading...