Norgren B74G Installation Instructions

B74G

|

|

|

|

|

|

|

|

|

Filter/Regulator |

|

|

|

|

|

Installation & Maintenance |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instructions |

||||||||||

|

|

|

|

|

|

|

|

|

B74G - - - |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Port |

Thread Form |

Adjustment |

Drain |

Bowl |

Element |

Diaphragm |

Spring (Outlet Pressure Range) * |

Gauge |

|||||||||||||||||

3 .... |

3/8" |

A.... |

PTF |

K.... |

Knob |

A.... |

Automatic |

D....Metal with liquid level indicator |

1 .... |

|

5 µm |

N.... |

Non-relieving |

F .... |

0,3 to 4 bar (5 to 60 psig) |

G.... |

With |

||||||||

4 .... |

1/2" |

B.... |

ISO Rc taper |

T .... |

T-bar |

Q.... |

Manual, 1/4 turn |

P....Transparent with guard |

2 .... |

|

25 µm |

R.... |

Relieving |

M |

...0,3 to 10 bar (5 to 150 psig) |

N.... |

Without |

||||||||

6 .... |

3/4" |

G.... |

ISO G parallel |

|

|

|

|

|

|

|

|

|

|

|

3 .... |

|

40 µm |

|

|

S.... |

0,7 to 17 bar (10 to 250 psig) |

|

|

||

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified ranges.

TECHNICAL DATA |

INSTALLATION |

|

|

|

|

Fluid: Compressed air |

1. Shut off air pressure. Install filter/regulator in air line - |

|

|

|

|

Maximum pressure: |

● vertically (bowl down), |

1 |

|

|

12 |

Transparent bowl: 10 bar (150 psig) |

● with air flow in direction of arrow on body, |

|

|

|

|

Metal bowl: 17 bar (250 psig) |

● upstream of lubricators and cycling valves, |

|

|

|

|

Operating temperature*: |

● as close as possible to the device being serviced. |

|

|

|

|

Transparent bowl: -20° to +50°C (0° to +125°F) |

2. Connect piping to proper ports using pipe thread sealant |

3 |

|

|

13 |

Metal bowl: -20° to +80°C (0° to +175°F) |

on male threads only. Do not allow sealant to enter |

2 |

|

|

16 |

* Air supply must be dry enough to avoid ice formation at |

interior of unit. |

|

|

|

14 |

temperatures below +2°C (+35°F). |

3. Push bowl, or bowl with guard, into body and turn fully |

|

|

|

|

Particle removal: 5 µm, 25 µm, or 40 µm filter element |

clockwise before pressurizing. |

|

|

|

15 |

Air quality: Within ISO 8573-1, Class 3 and Class 5 |

4. Flexible tube with 3mm (0.125") minimum I.D. can be |

4 |

|

|

|

(particulates) |

connected to the automatic drain. Avoid restrictions in |

|

|

|

|

Typical flow with 10 bar (150 psig) inlet pressure, 6,3 bar |

the tube. |

|

|

|

|

(90 psig) set pressure and 1 bar (15 psig) droop from |

5. Install a pressure gauge or plug the gauge ports. Gauge |

5 |

|

|

|

set: 100 dm3/s (212 scfm) |

ports can also be used as additional outlets for regulated |

|

|

56 |

|

|

|

|

|||

Nominal bowl size: 0,2 litre (7 fluid ounce) |

air. |

|

|

|

|

Manual drain connection: 1/8" |

|

|

|

|

57 |

Automatic drain connection: 1/8" |

ADJUSTMENT |

7 |

|

|

55 |

Automatic drain operating conditions (float operated): |

1. Before applying inlet pressure to filter/regulator, turn |

6 |

|

|

|

Bowl pressure required to close drain: Greater than 0,3 |

adjustment (1 or 7) counterclockwise to remove all force |

|

|

|

|

|

|

|

54 |

||

bar (5 psig) |

on regulating spring. |

|

|

|

|

Bowl pressure required to open drain: Less than 0,2 bar |

2. Apply inlet pressure, then turn adjustment (1 or 7) |

8 |

|

|

Used on |

(3 psig) |

clockwise to increase and counterclockwise to decrease |

|

|

|

models |

Minimum air flow required to close drain: 1 dm3/s |

pressure setting. |

|

|

|

prior to |

9 |

|

|

1998 |

||

(2 scfm) |

3. Always approach the desired pressure from a lower |

|

10 |

||

|

53 |

||||

Manual operation: Depress pin inside drain outlet to |

pressure. When reducing from a higher to a lower |

|

|

||

|

|

|

|||

|

|

|

|

||

drain bowl |

setting, first reduce to some pressure less than that |

|

|

|

52 |

Gauge ports: |

desired, then bring up to the desired pressure. |

|

|

|

|

1⁄4 PTF with PTF main ports |

NOTE |

|

|

|

|

Rc1/4 with ISO Rc main ports |

With non-relieving filter/regulators, make pressure |

11 |

|

|

51 |

Rc1/8 with ISO G main ports |

reductions with some air flow in the system. If |

|

|

||

|

|

|

|||

|

|

|

|

||

Materials: |

made under no flow (dead-end) conditions, the |

|

Current Plastic Bowl |

|

|

Body: Aluminum |

filter/regulator will trap the over-pressure in the |

17 |

|

||

|

|

|

|||

Bonnet: Aluminum |

downstream line. |

|

21 |

|

26 |

Valve: Brass |

4. KNOB ADJUSTMENT. Push knob down to lock pressure |

|

|

|

|

Bowl: |

setting. Pull knob up to release. Install tamper resistant |

18 |

|

|

25 |

Transparent with guard: Polycarbonate, steel guard |

cover (see Replacement Items) to make setting tamper |

|

|

||

|

|

|

|

||

Metal: Aluminum |

resistant. |

|

|

|

|

Metal bowl liquid level indicator lens: Transparent |

5. T-BAR ADJUSTMENT. Tighten lock nut (8) to lock |

|

|

|

24 |

nylon |

pressure setting. |

|

23 |

|

|

Element: Sintered polypropylene |

|

|

|

|

|

|

|

|

|

|

|

Elastomers: Neoprene and nitrile |

SERVICING |

|

20 |

|

|

|

1. Open manual drain to expel accumulated liquids. Keep |

|

|

|

|

REPLACEMENT ITEMS |

19 |

|

|

|

|

liquids below baffle (51). |

|

|

|

||

|

|

|

|

||

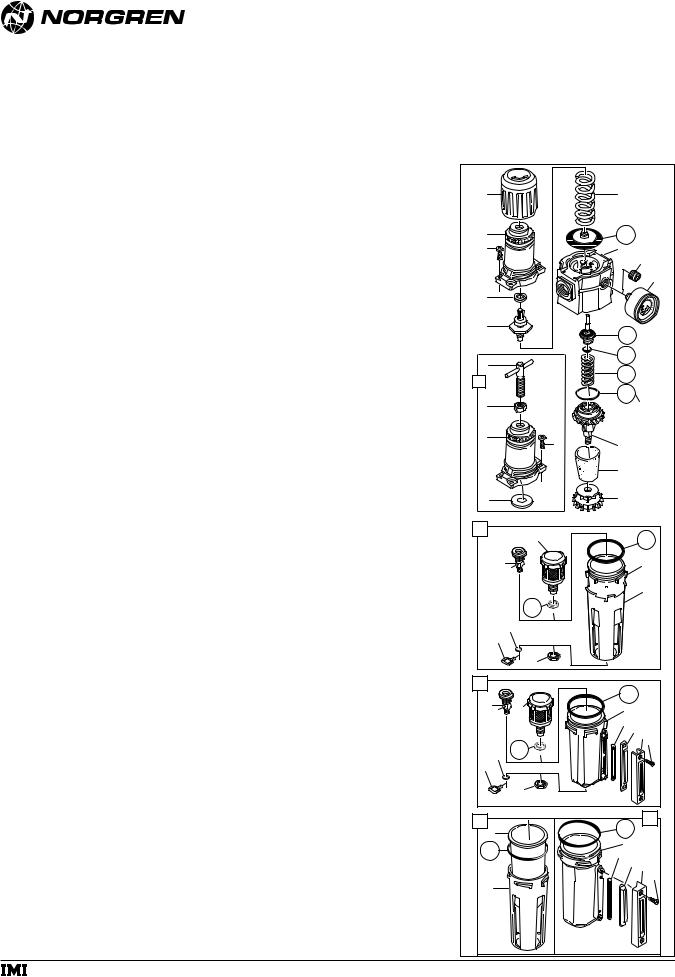

Service Kit (includes items circled on exploded view): |

2. Clean or replace filter element when dirty. |

|

22 |

|

|

Relieving.............................................................4383-700 |

|

|

|

|

|

Nonrelieving .......................................................4383-701 |

DISASSEMBLY |

27 |

Current Metal Bowl |

|

|

Liquid level lens kit (34, 36, 37, 38) ......................4380-050 |

1. Filter/regulator can be disassembled without removal |

|

|

|

|

|

|

|

38 |

||

Filter element, 5µm, red speckles (52).....................4338-04 |

from air line. |

28 |

|

|

|

Filter element, 25µm, blue speckles (52) .................4338-07 |

2. Shut off inlet pressure. Reduce pressure in inlet and |

31 |

|

39 |

|

|

|

||||

Filter element, 40µm, no speckles (52)....................4338-05 |

outlet lines to zero. |

|

|

|

3736 35 |

Manual drain (18, 19, 20) (28, 29, 30) ......................619-50 |

3. Turn adjustment (1 or 7) fully counterclockwise. |

|

|

|

|

Automatic drain (21, 22, 23) (31, 32, 33) |

4. Remove bowl - push into body and turn |

|

33 |

|

34 |

1/8 NPT outlet ......................................................3000-10 |

counterclockwise. |

30 |

|

|

|

|

|

|

|||

G 1/8 outlet ..........................................................3000-97 |

5. Disassemble in general accordance with the item |

29 |

|

|

|

Tamper resistant cover (knob adjustment only).......4355-51 |

numbers on exploded view. Do not remove the drains |

|

|

|

|

|

|

|

|

||

PANEL MOUNTING DIMENSIONS |

unless replacement is necessary. Remove and replace |

|

32 |

|

|

only if they malfunction. |

|

|

|

||

|

|

|

|

||

Panel mounting hole diameter: 52 mm (2.06") |

|

Early Plastic Bowl |

Early Metal Bowl |

|

|

Panel thickness: 2 to 6 mm (0.06" to 0.25") |

CLEANING |

44 |

|||

|

1. Clean plastic bowl (25, 42) with warm water only. Clean |

40 |

|

|

49 |

|

42 |

|

|

||

|

other parts with warm water and soap. |

|

|

|

|

|

|

|

|

50 |

|

|

2. Rinse and dry parts. Blow out internal passages in body |

43 |

|

|

|

|

|

48 |

|||

|

(16) with clean, dry compressed air. Blow air through |

|

|

||

|

|

|

|

47 46 |

|

|

filter element (52) from inside to outside to remove |

|

|

|

|

|

surface contaminants. |

|

|

|

45 |

|

41 |

|

|

|

|

|

3. Inspect parts. Replace those found to be damaged. |

|

|

|

|

|

Replace plastic bowl with a metal bowl if plastic bowl |

|

|

|

|

|

shows signs of cracking or cloudiness. |

|

|

|

|

© Norgren 1998 |

|

|

|

|

|

|

|

|

|

IM-200.300.01 (9/98) |

|

a subsidiary of IMI plc |

Supersedes 4/98 |

Loading...

Loading...