Norgren 11-002 Installation Instructions

|

11-002 |

Pressure Regulator |

Installation & Maintenance |

|

Instructions |

TECHNICAL DATA |

DISASSEMBLY |

|

|

|

Fluid: Compressed air |

1. Regulator can be disassembled without removal from air |

|

||

Maximum pressure: 400 psig (28 bar) |

line. |

|

|

|

Regulator type: Relieving or non-relieving diaphragm |

2. Shut off inlet pressure. Reduce pressure in inlet and outlet |

|

||

Operating temperature: -30 to +175°F (-34° to +80°C). Air |

lines to zero. |

|

1 |

|

supply must be dry enough to avoid ice formation at |

3. Turn adjustment (1) counterclockwise to remove all force |

|

||

temperatures below +35°F (+2°C). |

on regulating spring (6). |

|

|

|

Main port size: 1/4", 3/8", or 1/2" |

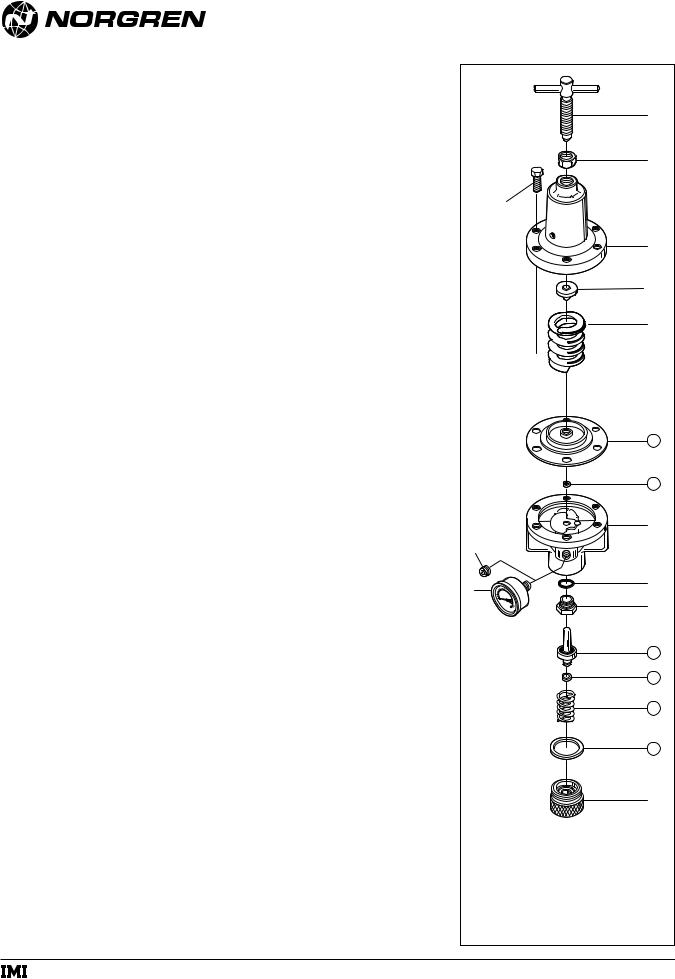

4. Disassemble in general accordance with the item numbers |

|

||

Main port thread form: PTF, ISO Rc, or ISO G |

on exploded view. Do not remove valve seat (14) unless |

2 |

||

Gauge ports: |

replacement is necessary. Remove o-ring (8) using a hook |

|||

|

||||

1⁄8 PTF with PTF main ports |

shaped tool, taking care not to damage o-ring seating |

|

||

Rc1/8 with ISO G and ISO Rc main ports |

surfaces and valve seat. |

|

|

|

Outlet pressure adjustment ranges:** |

CLEANING |

|

3 |

|

5 to 50 psig (0.3 to 3.5 bar) |

|

|||

|

|

|||

5 to 125 psig (0.3 to 8.5 bar) |

1. Clean parts with warm water and soap. |

|

||

5 to 250 psig (0.3 to 17 bar) |

2. Rinse and dry parts. Blow out internal passages in body |

|

||

** Outlet pressure can be adjusted to pressures in excess |

with clean, dry compressed air. |

4 |

||

of, and less than, those specified. Do not use these |

3. Inspect parts. Replace those found to be damaged. |

|||

|

||||

units to control pressures outside of the specified |

ASSEMBLY |

|

|

|

ranges. |

|

|

||

Typical flow with 150 psig (10 bar) inlet pressure, 90 psig |

1. Lubricate o-rings, adjusting screw threads and tip (1), |

5 |

||

(6.3 bar) set pressure, and a 15 psig (1 bar) droop from |

center bore in bottom plug (9), valve stem and body (13), |

|||

|

||||

set: |

with a light coat of good quality o-ring grease. |

|

||

1/4" and 3/8" ports: 110 scfm (52 dm3/s) |

2. Assemble the unit as shown on the exploded view. |

6 |

||

1/2" ports: 260 scfm (123 dm3/s) |

3. Torque Table |

|

||

|

|

|||

Materials: |

Item |

Torque Inch-Pounds (Nm) |

|

|

Body: Zinc |

14 (Valve seat - if removed) |

15 to 20 (1.7 to 2.3) |

|

|

Bonnet: Aluminum |

9 (Bottom plug) |

Hand tighten |

|

|

Valve: Brass and nitrile |

3 (Screw) |

45 to 55 (5.1 to 6.2) in a |

|

|

Valve seat: Brass |

|

diagonal sequence |

|

|

Elastomers: Nitrile |

WARNING |

|

|

|

Bottom plug: |

|

|

||

1/4" and 3/8" ports: Brass |

These products are intended for use in industrial |

|

||

1/2" ports: Nylon |

compressed air systems only. Do not use these products |

|

||

|

where pressures and temperatures can exceed those listed |

7 |

||

REPLACEMENT ITEMS |

under Technical Data. |

|

||

|

|

|||

Service kits (includes items circled on exploded view) |

If outlet pressure in excess of the regulator pressure |

|

||

1/4" and 3/8" Ported Regulators: |

setting could cause downstream equipment to rupture or |

|

||

Relieving.................................................................529-03 |

malfunction, install a pressure relief device downstream of |

8 |

||

Non-relieving ..........................................................529-01 |

the regulator. The relief pressure and flow capacity of the |

|||

|

||||

1/2" Ported Regulators: |

relief device must satisfy system requirements. |

|

||

Relieving.................................................................535-03 |

The accuracy of the indication of pressure gauges can |

|

||

Non-relieving ..........................................................535-01 |

change, both during shipment (despite care in packaging) |

18 |

||

|

and during the service life. If a pressure gauge is to be used |

|||

|

|

|||

PANEL MOUNTING DIMENSIONS - Panel mounting |

with these products and if inaccurate indications may be |

16 |

||

requires optional factory installed threaded bonnet. |

hazardous to personnel or property, the gauge should be |

|||

|

||||

Panel mounting hole diameter: 1.06" (27 mm) |

calibrated before initial installation and at regular intervals |

|

||

Panel thickness: 0.2" to 0.38" (5 to 10 mm) |

during use. |

|

15 |

|

|

Before using these products with fluids other than air, for |

|||

INSTALLATION |

non industrial applications, or for life-support systems |

17 |

||

14 |

||||

1. Shut off air pressure. Install regulator in air line - |

consult Norgren. |

|

||

● with air flow in direction of arrow on body, |

|

|

|

|

● upstream of lubricators and cycling valves, |

|

|

|

|

● as close as possible to the device being serviced. |

|

|

|

|

● at any angle. |

|

|

13 |

|

2. Connect piping to proper ports using pipe thread sealant |

|

|

||

|

|

|

||

on male threads only. Do not allow sealant to enter |

|

|

12 |

|

interior of regulator. |

|

|

||

|

|

|

||

3. Install a pressure gauge or plug the gauge ports. Gauge |

|

|

|

|

ports can also be used as additional outlets for regulated air. |

|

|

11 |

|

4. Install a Norgren general purpose filter upstream of the |

|

|

||

|

|

|

||

regulator. |

|

|

|

|

ADJUSTMENT |

|

|

10 |

|

1. Before applying inlet pressure to regulator, turn |

|

|

|

|

adjustment (1) counterclockwise to remove all force on |

|

|

|

|

regulating spring (6). |

|

|

|

|

2. Apply inlet pressure, then turn adjustment (1) clockwise |

|

|

9 |

|

to increase and counterclockwise to decrease pressure |

|

|

||

setting. |

|

|

|

|

3. Always approach the desired pressure from a lower |

|

|

|

|

pressure. When reducing from a higher to a lower |

|

|

|

|

setting, first reduce to some pressure less than that |

|

|

|

|

desired, then bring up to the desired pressure. |

|

|

|

|

NOTE |

|

|

|

|

With non-relieving regulators, make pressure |

|

|

|

|

reductions with some air flow in the system. If |

|

|

|

|

made under no flow (dead-end) conditions, the |

|

|

|

|

regulator will trap the over-pressure in the |

|

|

|

|

downstream line. |

|

|

|

|

4. Tighten lock nut (2) to lock pressure setting. |

|

|

|

|

© Norgren 2002 |

|

|

|

|

|

|

|

IM-410.207 (2/02) |

|

a subsidiary of IMI plc |

Replaces NIP-202 |

Loading...

Loading...