NILFISK SC2000 53B Installation Manual

SC2000

Instructions for Use - Original Instructions

Instrucciones de Uso

Instructions d’Utilisation

Instruções de Uso

Model: 9087361020

English

Español

Français

Português

01/2015 (1) FORM NO. 9100000386

INSTRUCTIONS FOR USE |

ENGLISH |

TABLE OF CONTENTS |

|

INTRODUCTION............................................................................................................................................................... |

2 |

MANUAL PURPOSE AND CONTENTS........................................................................................................................................... |

2 |

TARGET........................................................................................................................................................................................... |

2 |

HOW TO KEEP THIS MANUAL....................................................................................................................................................... |

2 |

IDENTIFICATION DATA................................................................................................................................................................... |

2 |

OTHER REFERENCE MANUALS................................................................................................................................................... |

2 |

SPARE PARTS AND MAINTENANCE............................................................................................................................................. |

2 |

CHANGES AND IMPROVEMENTS................................................................................................................................................. |

2 |

OPERATION CAPABILITIES............................................................................................................................................................ |

3 |

CONVENTIONS............................................................................................................................................................................... |

3 |

UNPACKING/DELIVERY.................................................................................................................................................. |

3 |

SAFETY............................................................................................................................................................................ |

3 |

VISIBLE SYMBOLS ON THE MACHINE......................................................................................................................................... |

3 |

SYMBOLS THAT APPEAR ON THIS MANUAL............................................................................................................................... |

4 |

GENERAL INSTRUCTIONS............................................................................................................................................................ |

4 |

MACHINE DESCRIPTION................................................................................................................................................ |

6 |

MACHINE STRUCTURE.................................................................................................................................................................. |

6 |

CONTROL PANEL............................................................................................................................................................................ |

8 |

ACCESSORIES/OPTIONS.............................................................................................................................................................. |

9 |

TECHNICAL DATA........................................................................................................................................................................... |

9 |

WIRING DIAGRAM........................................................................................................................................................................ |

10 |

USE................................................................................................................................................................................. |

11 |

BATTERY CHECK/SETTING ON A NEW MACHINE...................................................................................................................... |

11 |

BATTERY INSTALLATION.............................................................................................................................................................. |

11 |

BEFORE MACHINE START-UP..................................................................................................................................................... |

12 |

MACHINE START AND STOP....................................................................................................................................................... |

14 |

MACHINE OPERATION (SCRUBBING/DRYING)......................................................................................................................... |

14 |

TANK EMPTYING.......................................................................................................................................................................... |

17 |

AFTER USING THE MACHINE...................................................................................................................................................... |

17 |

PUSHING/TOWING THE MACHINE.............................................................................................................................................. |

17 |

MACHINE LONG INACTIVITY....................................................................................................................................................... |

17 |

MAINTENANCE.............................................................................................................................................................. |

18 |

SCHEDULED MAINTENANCE TABLE.......................................................................................................................................... |

18 |

BATTERY CHARGING................................................................................................................................................................... |

19 |

SUPER USER KEY (yellow)........................................................................................................................................................... |

20 |

SQUEEGEE CLEANING................................................................................................................................................................ |

22 |

SQUEEGEE BLADE CHECK AND REPLACEMENT..................................................................................................................... |

22 |

CLEANING THE BRUSH............................................................................................................................................................... |

23 |

RECOVERY TANK CLEANING...................................................................................................................................................... |

23 |

WASHING WATER FILTER CLEANING........................................................................................................................................ |

24 |

DETERGENT TANK CLEANING.................................................................................................................................................... |

24 |

DRAINING THE ECOFLEX™ SYSTEM......................................................................................................................................... |

25 |

FUSE CHECK/REPLACEMENT.................................................................................................................................................... |

25 |

SAFETY FUNCTIONS.................................................................................................................................................... |

26 |

EMERGENCY PUSH-BUTTON..................................................................................................................................................... |

26 |

ANTI-SKID SAFETY SYSTEM....................................................................................................................................................... |

26 |

DRIVER’S SEAT MICROSWITCH................................................................................................................................................. |

26 |

ELECTROMAGNETIC BRAKE...................................................................................................................................................... |

26 |

TROUBLESHOOTING.................................................................................................................................................... |

27 |

SCRAPPING................................................................................................................................................................... |

28 |

01/2015 |

9100000386 - SC2000 |

1 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the operator with all necessary information to use the machine properly, in a safe and autonomous way. It contains information about technical data, safety, operation, storage, maintenance, spare parts and disposal.

Before performing any procedure on the machine, the operators and qualified technicians must read this Manual carefully. Contact

Advance in case of doubts concerning the interpretation of the instructions and for any further information.

TARGET

This Manual is intended for operators and technicians qualified to perform the machine maintenance.

The operators must not perform procedures reserved for qualified technicians. Advance will not be answerable for damages coming from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the machine, inside an adequate case, away from liquids and other substances that can cause damage to it.

IDENTIFICATION DATA

The machine serial number and model name are marked on the plate (23). Product number and year of production are marked on the same plate.

This information is useful when requiring machine spare parts. Use the following table to write down the machine identification data.

MACHINE model

PRODUCT code

MACHINE serial number

OTHER REFERENCE MANUALS

––Electronic battery charger Manual, to be considered as integral part of this Manual

––Spare Parts List (supplied with the machine)

––Service Manual (that can be consulted at Advance Service Centers)

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be performed by qualified personnel or by Advance Service

Centers. Only original spare parts and accessories must be used.

Contact Advance for service or to order spare parts and accessories, specifying the machine model, product code and serial number.

CHANGES AND IMPROVEMENTS

Advance constantly improves its products and reserves the right to make changes and improvements at its discretion without being obliged to apply such benefits to the machines that were previously sold.

Any change and/or addition of accessories must be approved and performed by Advance.

2 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

INSTRUCTIONS FOR USE |

ENGLISH |

OPERATION CAPABILITIES

The SC2000 scrubber-dryer is used to clean (scrubbing and drying) smooth and solid floors, in civil or industrial environment, under safe operation conditions by a qualified operator.

The scrubber-dryer cannot be used for fitted carpet and carpet cleaning.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to say on the driver’s seat (12).

UNPACKING/DELIVERY

To unpack the machine, carefully follow the instructions on the packing.

To move the machine manually, see the Pushing/Towing The Machine paragraph.

When the machine is delivered, check that the packing and the machine were not damaged during transportation.

In case of visible damages, keep the packing and have it checked by the carrier that delivered it. Call the carrier immediately to fill in a damage claim.

Please check that the following items have been supplied with the machine:

––Technical documents:

•Scrubber-dryer Instructions for Use Manual

•Scrubber-dryer Spare Parts List

––No. 2 lamellar fuses

––No. 1 splash guard

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments

(such as the State of California, as identified in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any responsibility to advise purchasers of any specifiic requirements that may be applicable to the use of the Products in such environments.

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary precautions to safeguard people and property.

The operator’s cooperation is essential in order to prevent injury. No accident prevention program is effective without the total cooperation of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while working or moving around, are caused by failure to comply with the simplest rules for exercising prudence. A careful and prudent operator is the best guarantee against accidents and is essential for successful completion of any prevention program.

VISIBLE SYMBOLS ON THE MACHINE

WARNING!

Carefully read all the instructions before performing any operation on the machine.

Carefully read all the instructions before performing any operation on the machine.

WARNING!

Do not wash the machine with direct or pressurized water jets.

max.2%

WARNING!

Do not use the machine on slopes with a gradient exceeding the specifications.

01/2015 |

9100000386 - SC2000 |

3 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

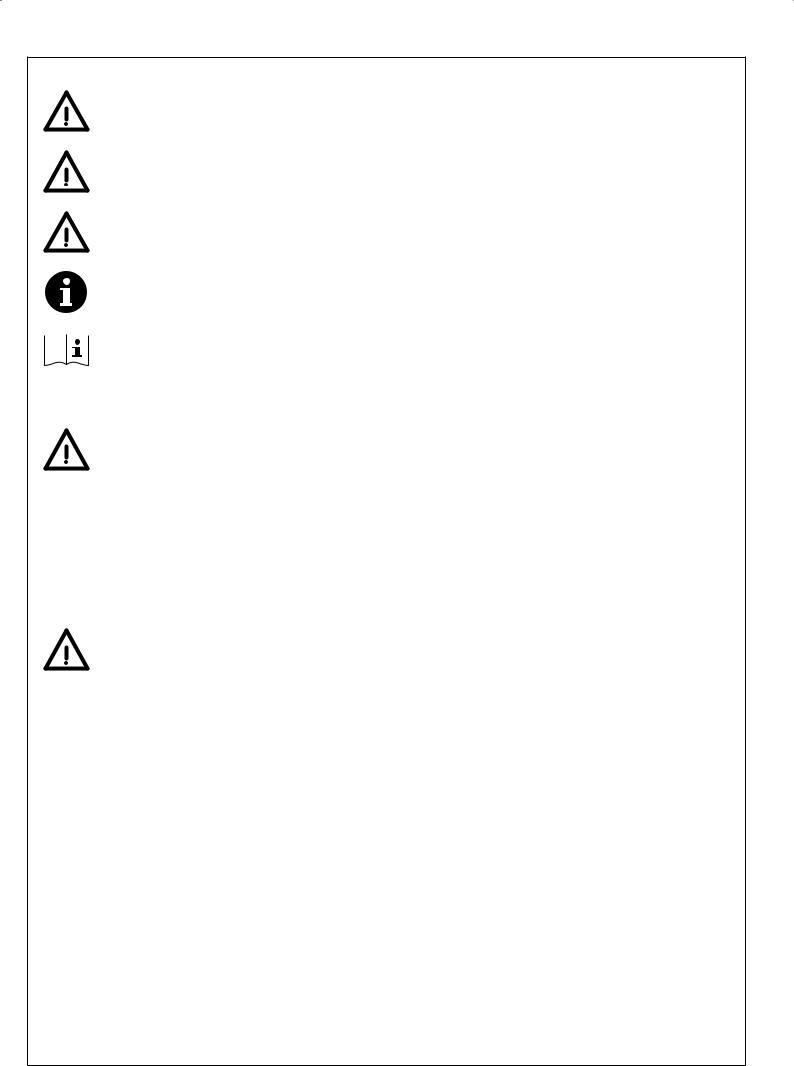

SYMBOLS THAT APPEAR ON THIS MANUAL

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions.

Pay careful attention to the paragraphs marked by this symbol.

NOTE

It indicates a remark related to important or useful functions.

CONSULTATION

CONSULTATION

It indicates the necessity to refer to the Instructions for Use Manual before performing any procedure.

GENERAL INSTRUCTIONS

Specific warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

–– Before performing any maintenance, repair, cleaning or replacement procedure, remove the ignition key and disconnect the battery connector.

–– This machine must be used by properly trained operators only.

–– Do not wear jewels when working near electrical components.

–– Do not work under the lifted machine without supporting it with safety stands.

–– Do not operate the machine near toxic, dangerous, flammable and/or explosive powders, liquids or vapors.

This machine is not suitable for collecting dangerous powders.

–– When using lead (WET) batteries, keep sparks, flames and smoking materials away from the batteries. During the normal operation explosive gases are released.

–– When using lead (WET) batteries, battery charging produces highly explosive hydrogen gas. During battery charging, lift the recovery tank and perform this procedure in well-ventilated areas and away from naked flames.

WARNING!

–– Carefully read all the instructions before performing any maintenance/repair procedure.

–– The machine ignition key has a built-in magnet. Do not place objects having magnetic bands (such as credit cards, electronic keys, phone cards) near the key. The built-in magnet can damage or erase the data stored on the magnetic bands.

–– Before using the battery charger, ensure that frequency and voltage values, indicated on the machine serial number plate, match the electrical mains voltage.

–– Do not pull or carry the machine by the battery charger cable and never use the battery charger cable as a handle. Do not close a door on the battery charger cable, or pull the battery charger cable around sharp edges or corners. Do not run the machine on the battery charger cable.

–– Keep the battery charger cable away from heated surfaces.

–– Do not charge the batteries if the battery charger cable or the plug are damaged.

–– To reduce the risk of fire, electric shock, or injury, do not leave the machine unattended when it is plugged in. Before performing any maintenance procedure, disconnect the battery charger cable from the electrical mains.

–– Do not smoke while charging the batteries.

–– To avoid any unauthorized use of the machine, remove the ignition key.

–– Do not leave the machine unattended without being sure that it cannot move independently.

4 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

INSTRUCTIONS FOR USE |

ENGLISH |

WARNING!

–– Always protect the machine against the sun, rain and bad weather, both under operation and inactivity condition. This machine must be used in dry conditions, it must not be used or kept outdoors in wet conditions.

–– Before using the machine, close all doors and/or covers as shown in the Instructions for Use Manual.

–– This machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

–– Close attention is necessary when used near children. Use only as shown in this Manual. Use only Advance’s recommended accessories.

–– Check the machine carefully before each use, always check that all the components have been properly assembled before use. If the machine is not perfectly assembled it can cause damages to people and properties.

–– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the machine moving parts.

–– Do not use the machine on incline.

–– Do not tilt the machine more than the angle indicated on the machine itself, in order to prevent instability.

–– Do not use the machine in particularly dusty areas.

–– Use the machine only where a proper lighting is provided.

–– If the machine is to be used where there are other people besides the operator, it is necessary to install the pivoting light (optional).

–– While using this machine, take care not to cause damage to people or objects.

–– Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

–– Do not lean liquid containers on the machine, use the relevant can holder.

–– The machine operating temperature must be between +32 °F and 104 °F (0 °C and +40 °C).

–– The machine storage temperature must be between +32 °F and 104 °F (0 °C and +40 °C).

–– The humidity must be between 30 % and 95 %.

–– When using floor cleaning detergents, follow the instructions on the labels of the detergent bottles.

–– To handle floor cleaning detergents, wear suitable gloves and protections.

–– Do not use the machine as a means of transport.

–– Do not allow the brush/pad to operate while the machine is stationary to avoid damaging the floor.

–– In case of fire, use a powder fire extinguisher, not a water one.

–– Do not tamper with the machine safety guards and follow the ordinary maintenance instructions scrupulously.

–– Do not allow any object to enter into the openings. Do not use the machine if the openings are clogged.

Always keep the openings free from dust, hairs and any other foreign material which could reduce the air flow.

–– Do not remove or modify the plates affixed to the machine.

–– To manually move the machine, the electromagnetic brake must be disengaged. After moving the machine manually, engage the electromagnetic brake again. Do not use the machine when the electromagnetic brake handwheel is screwed down.

–– When the machine is to be pushed for service reasons (missing or discharged batteries, etc.), the speed must not exceed 2.5 mi/h (4 km/h).

–– This machine cannot be used on roads or public streets.

–– Pay attention during machine transportation when temperature is below freezing point. The water in the recovery tank or in the hoses could freeze and seriously damage the machine.

–– Use brushes and pads supplied with the machine or those specified in the Instructions for Use Manual.

Using other brushes or pads could reduce safety.

–– In case of machine malfunctions, ensure that these are not due to lack of maintenance. If necessary, request assistance from the authorised personnel or from an authorised Service Center.

–– If parts must be replaced, require ORIGINAL spare parts from an Authorised Dealer or Retailer.

–– To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant chapter of this Manual, must be performed by the authorised personnel or by an authorised Service Center.

–– Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

–– The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries, etc.), which are subject to standards that require disposal in special centres (see Scrapping chapter).

01/2015 |

9100000386 - SC2000 |

5 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

MACHINE DESCRIPTION

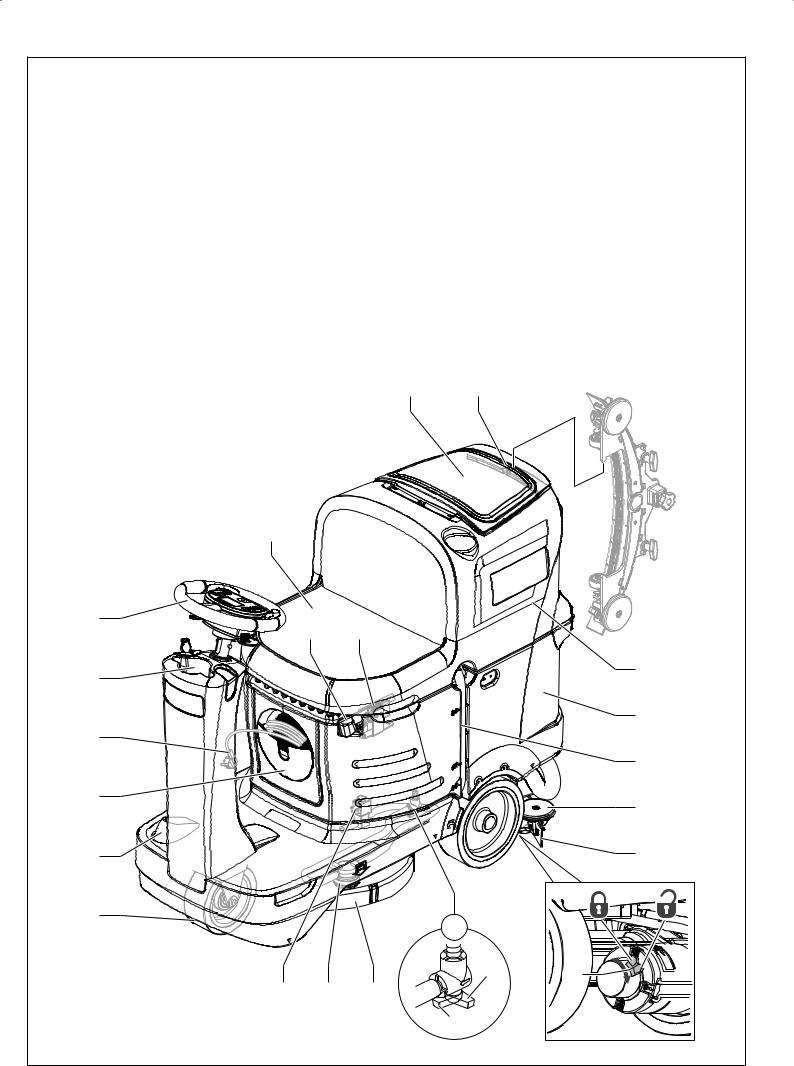

MACHINE STRUCTURE

1. |

Steering wheel with control panel (see the following |

10. |

Solenoid valve |

|

|

paragraph) |

11. |

Squeegee hook |

|

2. |

Drive pedal |

12. |

Seat |

|

3. |

Front steering wheel |

13. |

Squeegee |

|

4. |

Electromagnetic brake locking/unlocking lever |

14. |

Squeegee bumper wheels |

|

5. |

EMERGENCY push-button, to stop immediately all |

15. |

Washing water tank |

|

|

functions |

16. |

Washing water level and drain hose |

|

6. |

Battery connector |

17. |

Dumping recovery tank assembly |

|

7. |

Brush deck |

18. |

Recovery tank cover |

|

8. |

Washing water filter |

19. |

Can holder |

|

9. |

Washing water valve |

20. |

Battery charger cable housing and document holder |

|

|

A) |

Open valve |

21. |

Battery charger cable |

|

B) |

Closed valve |

|

|

18 11

12

1 |

5 |

6 |

|

19 |

|

|

17 |

|

|

|

|

||

21 |

|

|

15 |

|

|

|

|

||

|

|

|

16 |

|

20 |

|

|

14 |

|

|

|

|

||

2 |

|

|

13 |

|

3 |

|

9 |

|

|

|

|

|

||

|

|

B |

4 |

|

10 |

8 |

7 |

||

|

||||

|

|

A |

|

P100859

6 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

|

|

INSTRUCTIONS FOR USE |

|

ENGLISH |

|

|

|

|

|

|

|

MACHINE STRUCTURE (Continues) |

|

|

|

|

|

22. |

Battery charger |

31. |

Squeegee support wheel |

|

|

23. |

Serial number plate/technical data/conformity certification |

32. |

Squeegee mounting handwheels |

|

|

24. |

Rear driving wheels |

33. |

Squeegee adjusting knob |

|

|

25. |

Washing water tank filler |

34. |

Brush deck bumper wheel |

|

|

26. |

Recovery water drain hose |

35. |

Tank assembly and seat lifting handle |

|

|

27. |

Container with debris collection grid |

36. |

Tank assembly and seat support rod |

|

|

28. |

Vacuum grid with automatic shut-off float |

37. |

Batteries (optional) |

|

|

29. |

Recovery water tank cover (open) |

38. |

EcoFlex™ detergent tank |

|

|

30. |

Squeegee vacuum hose |

39. |

Electronic component compartment cover |

|

|

|

|

40. |

Lifted recovery tank assembly and driver’s seat |

|

|

39 38 37

36 40

29

28

27

26

25

30

32

33

32

31

23

35

35

22

34

24

P100860

01/2015 |

9100000386 - SC2000 |

7 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

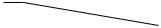

CONTROL PANEL

41. |

Machine ignition key: |

49. Reverse gear activation/deactivation lever |

|||

|

• |

Operator key (grey) |

50. |

EcoFlex™ activation/deactivation lever |

|

|

• Super User key (yellow) (see Maintenance chapter) |

51. |

Multifunction display |

||

42. |

Machine start/stop push-button |

|

Items displayed: |

||

43. |

One-Touch™ Scrub ON/OFF push-button |

|

A) |

Hours worked |

|

|

• Flashing green LED: Brush deck moving up/down |

|

B) |

Battery type |

|

|

• Steady green LED: Ready for work |

|

C) |

Battery charge level |

|

|

• Steady red LED: Extra pressure active (hold for one |

|

D) |

Vacuum mode |

|

|

|

second) |

|

E) |

Brush work mode |

44. |

Vacuum system adjustment/deactivation push-button: |

|

F) |

Detergent solution flow quantity |

|

|

• LED on - solution flow activated |

|

G) |

Detergent quantity |

|

45. |

Brush engage/disengage push-button: |

|

H) |

Percentages of detergent in the washing water |

|

|

• |

Flashing LED - system activated |

|

I) |

EcoFlex™ system override timer |

46. |

Detergent percentage adjustment push-button |

|

J) |

Anti-skid control |

|

47. |

Detergent flow adjustment push-button |

|

K) |

Maximum machine speed setting |

|

48. |

Horn switch |

|

L) |

Auto shut-off timer |

|

|

|

|

|

M) Battery charging with on-board battery charger |

|

|

|

|

|

N) |

EcoFlex™ system drain activation |

A B G I C J K

F

D

D

H

E

E

L M N

51

50

46

47

48

42

42

max.2%

1s

41

49

43

44

45

P100861

8 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

INSTRUCTIONS FOR USE |

ENGLISH |

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according to the machine specific use:

–– |

GEL/AGM batteries |

–– |

Pivoting light |

–– Brushes of different materials |

–– Mop a trash kit |

||

–– Pads of different materials |

–– |

TrackClean system |

|

–– |

Squeegee blades of different materials |

–– |

USB port |

––Filling hose

For further information concerning the optional accessories, contact an authorised Retailer.

TECHNICAL DATA

Model |

SC2000 53 B |

Washing water tank capacity |

18.5 US gal (70 liters) |

Recovery tank capacity |

18.5 US gal (70 liters) |

Machine length |

50 in (1,270 mm) |

Machine width with squeegee |

28.3 in (720 mm) |

Machine width without squeegee |

21.6 in (550 mm) |

Machine height |

40.1 in (1,020 mm) |

Turning space for U-turns |

71 in (1,800 mm) |

Cleaning width |

21 in (530 mm) |

Rear driving wheel diameter |

10 in (254 mm) |

Rear driving wheel specific pressure on the floor |

145 psi (1.0 N/mm2) |

Front steering wheel diameter |

7.9 in (200 mm) |

Front wheel specific pressure on the floor |

188 psi (1.3 N/mm2) |

Brush/pad diameter |

21 in (530 / 508 mm) |

Brush pressure with extra-pressure function turned off |

33 lb (15 kg) |

Brush pressure with extra-pressure function turned on |

66 lb (30 kg) |

Solution flow values |

0.75 cl/m / 1.5 cl/m / 3.0 cl/m / (2.8 l/min, if enabled) |

EcoFlex™ system detergent percentage |

0.25 % - 3 % |

Sound pressure level at workstation (ISO 11201, ISO 4871, EN 60335-2-72) (LpA) |

68 ± 3 dB(A) |

Sound pressure level at workstation in silent mode (LpA) |

62 ± 3 dB(A) |

Machine sound power level (ISO 3744, ISO 4871, EN 60335-2-72) (LwA) |

84 dB(A) |

Vibration level at the operator’s arms (ISO 5349-1, EN 60335-2-72) |

130 in/s2 (3.3 m/s2) |

Vibration level at the operator’s body (ISO 5349-1, EN 60335-2-72) |

35.4 in/s2 (0.9 m/s2) |

Maximum gradient when working |

2 % |

Drive system motor power |

0.53 hp (400 W) |

Drive speed (variable) |

0 - 3.7 mi/h (0 - 6 km/h) |

Vacuum system motor power |

0.4 hp (310 W) |

Vacuum system circuit capacity |

39 in H2O (1,000 mm H2O) |

Brush motor power |

0.6 hp (450 W) |

Brush motor speed |

155 rpm |

Total absorbed power (*) |

26 A (620 W) |

IP protection class |

X4 |

Protection class (electric) |

III (I for the battery charger) |

Battery compartment size |

13.8x14.2x11 in (350x360x280 mm) |

System voltage |

24V |

Standard batteries (2) |

Discover 12V-105Ah |

Battery charger |

100-240Vac 50-60Hz, 24Vdc 13A |

Operating time (standard batteries) (*) |

2.5 hour |

Weight without batteries and with empty tanks |

267 lb (121 kg) |

Gross vehicle weight (GVW) |

754 lb (342 kg) |

Shipping weight |

342 lb (155 kg) |

(*)Values reflect standard operating conditions (EN 60335-2-72)

01/2015 |

9100000386 - SC2000 |

9 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

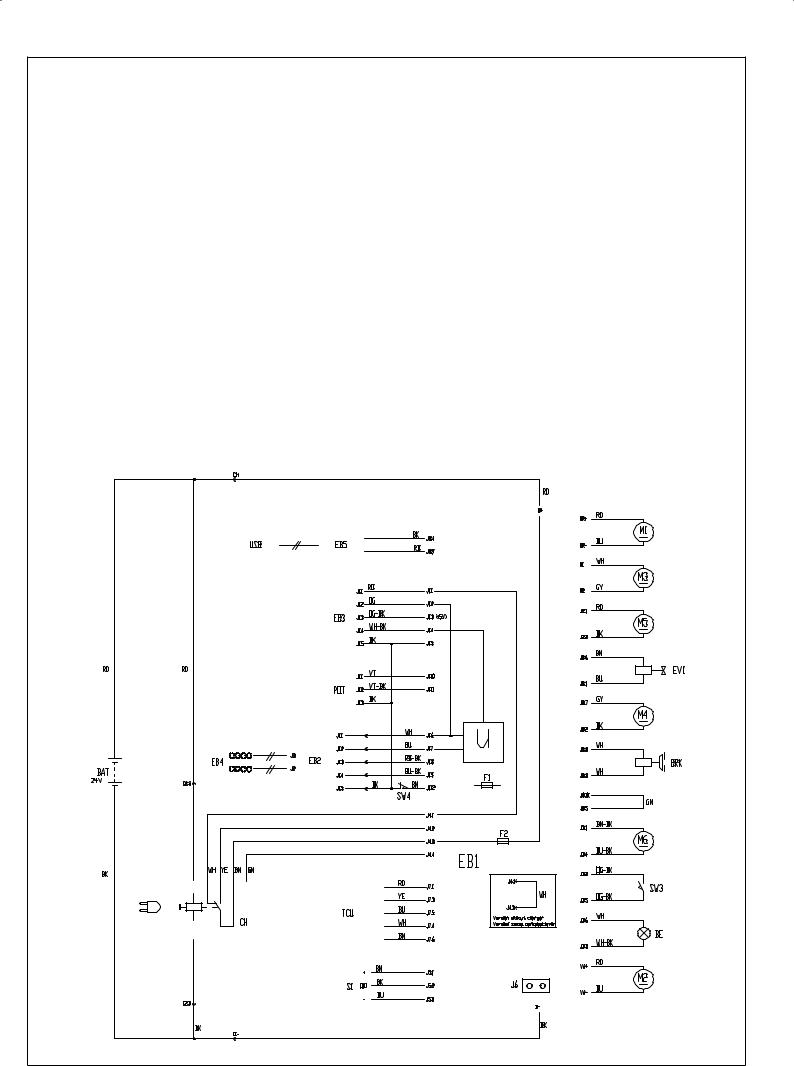

WIRING DIAGRAM

Key

BAT |

24V batteries |

|

|||||||||||||

BE |

Pivoting light (optional) |

|

|||||||||||||

BRK |

Electromagnetic brake |

|

|||||||||||||

C1 |

Battery connector |

|

|||||||||||||

C2 |

Battery charger connector |

|

|||||||||||||

CH |

Battery charger |

|

|||||||||||||

EB1 |

Function electronic board |

|

|||||||||||||

EB2 |

Display electronic board |

|

|||||||||||||

EB3 |

Key electronic board |

|

|||||||||||||

EB4 |

Dashboard instrument electronic board |

|

|||||||||||||

EB5 |

5V power unit (optional) |

|

|||||||||||||

EV1 |

Solenoid valve |

|

|||||||||||||

F1 |

Main electronic board fuse |

|

|||||||||||||

F2 |

Signal circuit fuse |

|

|||||||||||||

M1 |

Brush motor |

|

|||||||||||||

M2 |

Vacuum system motor |

|

|||||||||||||

M3 |

Drive system motor |

|

|||||||||||||

M4 |

EcoFlex™ pump |

|

|||||||||||||

M5 |

Brush deck actuator motor |

|

|||||||||||||

M6 |

Squeegee actuator motor |

|

|||||||||||||

POT |

Drive pedal potentiometer |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

Washing water level sensor |

SW3 |

Seat microswitch |

SW4 |

Anti-skid control sensor |

TCU |

TrackClean™ (optional) |

USB |

USB port (optional) |

Color codes

BK |

Black |

||

BU |

Blue |

||

BN |

Brown |

||

GN |

Green |

||

GY |

Grey |

||

OG |

Orange |

||

PK |

Pink |

||

RD |

Red |

||

VT |

Violet |

||

WH |

White |

||

YE |

Yellow |

||

|

|

|

|

|

|

|

|

P100862

10 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

INSTRUCTIONS FOR USE |

ENGLISH |

USE

WARNING!

On some points of the machine there are some adhesive plates indicating:

–– DANGER

–– WARNING

–– CAUTION

–– CONSULTATION

While reading this Manual, the operator must pay particular attention to the symbols shown on the plates (see Visible Symbols On The Machine paragraph).

Do not cover these plates for any reason and immediately replace them if damaged.

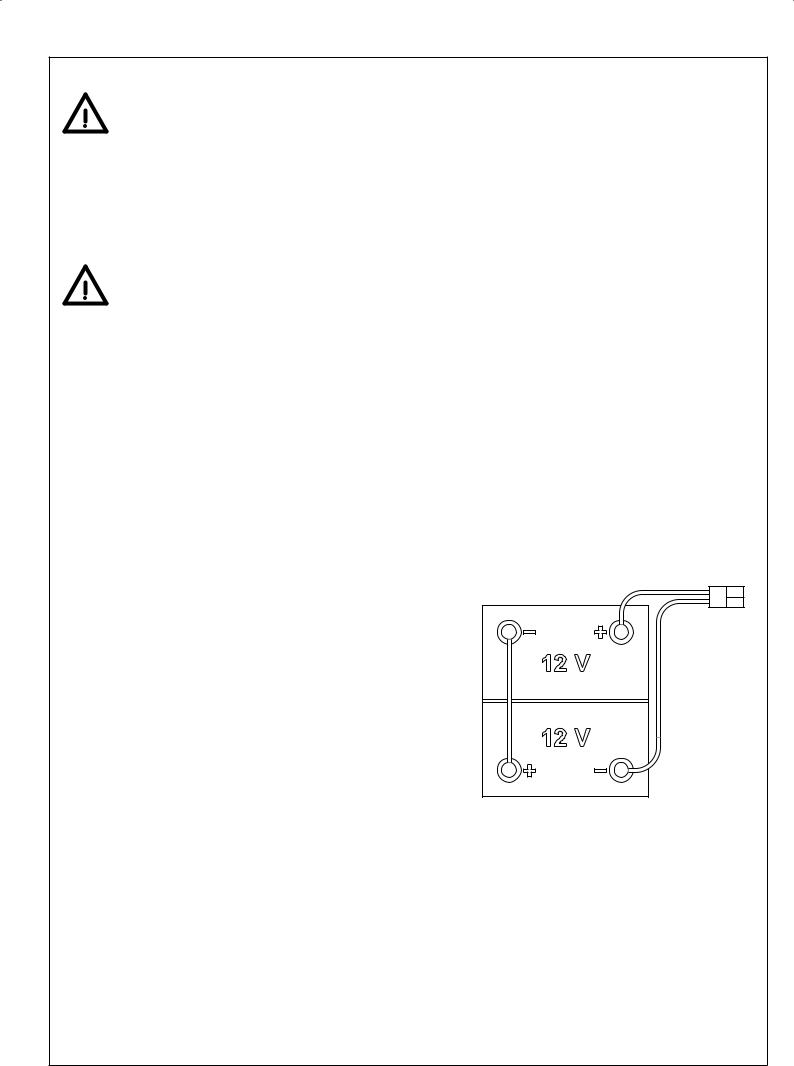

BATTERY CHECK/SETTING ON A NEW MACHINE

WARNING!

The electric components of the machine can be seriously damaged if the batteries are either improperly installed or connected. The batteries must be installed by qualified personnel only.

Set the machine according to the type of batteries used. Check the batteries for damage before installation. Disconnect the battery connector and the battery charger plug. Handle the batteries with great care.

Install the battery terminal protection caps supplied with the machine.

The machine requires 2 12V batteries, connected according to the diagram shown in Figure 1. The machine can be supplied in one of the following modes:

Batteries already installed on the machine

1.Ensure that the battery connector (6) is connected.

2.When first using the machine with new batteries, perform a full charging cycle (see the procedure in Maintenance chapter).

Without batteries

1.Buy appropriate batteries (see “Technical Data” paragraph). For battery choice and installation, apply to qualified battery

Retailers.

2.Set the machine according to the type of batteries installed as shown in the Super User key section of the Maintenance chapter.

BATTERY INSTALLATION

Battery Installation

1.Remove the operator key (41).

2. Disconnect the battery connector by pressing the emergency push-button (5).

3.Lift the cover (18) and check that the recovery tank (17) is empty, otherwise empty it with the drain hose (26).

4. |

Close the cover (18). |

BACK |

FRONT |

5. |

Grasp the handle (35) and carefully lift the recovery tank |

||

|

assembly (17). |

|

|

6. |

The machine is supplied with cables suitable to install 2 |

|

|

|

12V batteries. |

|

|

7. Carefully lift the batteries until the relevant compartment, then place them properly.

8.Route and install the battery cable as shown in Figure 1,

then carefully tighten the nut on each battery terminal. |

Figure 1 |

9. Place the protection cap on each terminal, then connect |

P100863 |

the battery connector (6). |

|

10.Disengage the support rod (36), then grasp the handle (35) and carefully lower the recovery tank assembly (17).

Battery Charging

11.Fully charge the batteries (see the procedure in Maintenance chapter).

01/2015 |

9100000386 - SC2000 |

11 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

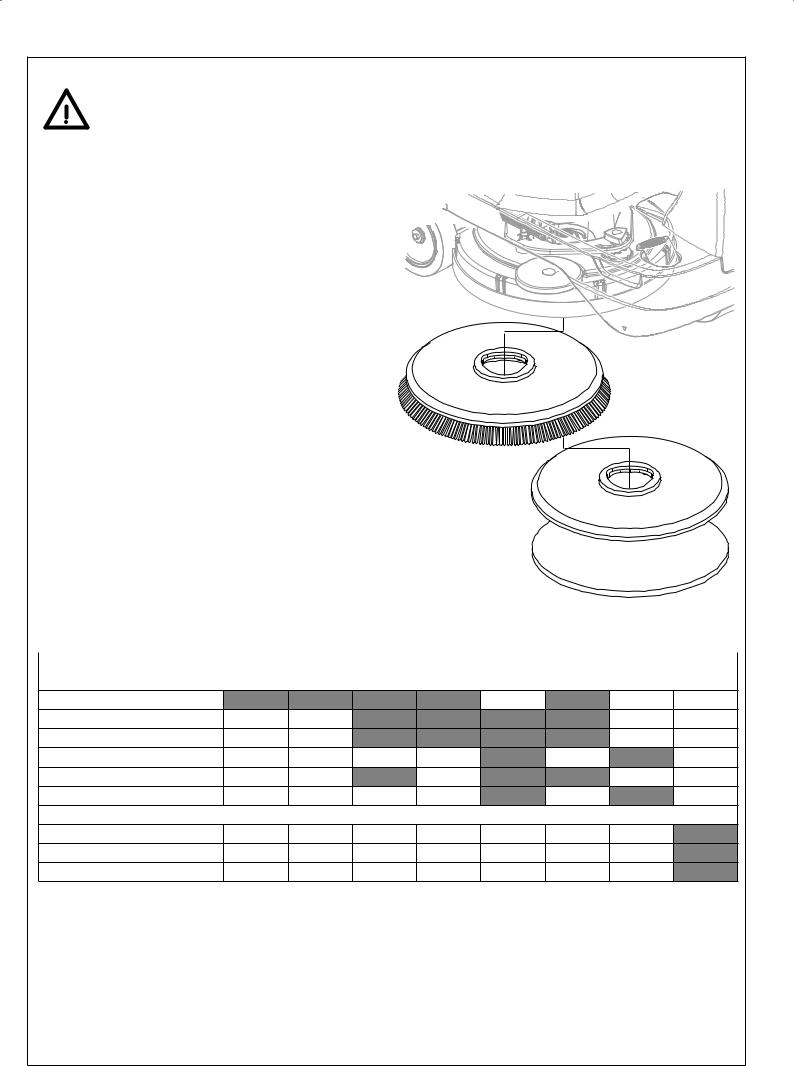

BEFORE MACHINE START-UP

WARNING!

When starting the machine, or before operating the One-Touch™ push-button (43), make sure that there is no foreign material between the deck and the tank assembly which could obstruct the deck movement. If the

machine has been turned off without lifting the deck, the deck would lift automatically at next machine start-up.

Brush or pad-holder removal/installation

1.According to the kind of cleaning to be performed, the machine can be equipped either with the brush (A, Fig. 2) or the pad-holder (B) with pad (C) together with the appropriate deck.

2.Place the brush (A) or the pad-holder (B) under the deck

(7).

3.Insert the operator key (41) in its slot.

4.Press the push-button (43) to lower the deck on the brush.

5.Press the switch (45) to engage the brush.

6.To remove the brush, the deck must be lifted by pressing the push-button (43), then press the release push-button (45).

7.When the display shows the icon (51-K), wait for the brush to fall on the floor.

A

A

B

C

Figure 2

P100864

Available brushes and their relevant application guides (suggestions only)

Models |

46 GRIT |

80 GRIT |

180 GRIT |

240 GRIT |

500 GRIT |

PROLENE |

PROLITE |

UNION MIX |

General cleaning: |

|

|

|

|

|

|

|

|

Concrete

Terrazzo floor

Ceramic tiles/quarrystones

Marble

Vinyl tiles

Rubber tiles

Polishing:

Rubber tiles

Marble

Vinyl tiles

12 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

INSTRUCTIONS FOR USE |

ENGLISH |

Squeegee installation

1.Install the squeegee (A, Fig. 3) and fasten it to the bracket

(C) with the handwheels (B).

2.If necessary, adjust the squeegee with the knob (D) so that the rear blade (E) and front blade (F) touch the floor as shown in the figure.

Washing water tank filling

1.Ensure that the washing water valve (9) is open (9-A).

2.To fill the washing water tank (15) remove the filler neck plug (25).

3.Fill the tank (15) with clean water. If equipped, use the water filler hose (optional) located in the filler neck (25). Do not fill the tank completely, leave a few inches from the edge. Use the level hose (16) as reference.

The water temperature must not exceed 40 °C.

F

C

A

B

D

B

E

E

Figure 3

P100865

EcoFlex™ detergent tank filling

WARNING!

When using floor cleaning detergents, follow the instructions on the labels of the detergent bottles. To handle floor cleaning detergents, wear suitable gloves and protections.

4.Lift the cover (18) and check that the recovery tank (17) is empty, otherwise empty it with the drain hose (26).

5.Close the cover (18).

6.Grasp the handle (35) and carefully lift the recovery tank assembly (17).

7.Fill the tank (38) with a detergent suitable for the work to be performed (highly concentrated detergent).

Do not fill the detergent tank completely, leave a few inches from the edge.

CAUTION!

Use only low-foam and non-flammable detergents, intended for automatic scrubber applications.

NOTE

To accelerate filling of the hoses and system operation (with a new system, if the system has been emptied for cleaning, etc.), it is a good idea to drain the EcoFlex™ system once or several times (see the procedure in the Maintenance chapter).

01/2015 |

9100000386 - SC2000 |

13 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

MACHINE START AND STOP

Starting the machine

1.Prepare the machine as shown in the previous paragraph.

2.To turn on the machine, insert the operator key (41); if the key is already inserted, press the push-button (42).

3.In the first 2 seconds after machine start-up, the multifunction display (51) indicates the machine working hours (51-A) and the type of batteries installed (51-B).

NOTE

Check the battery charge level.

When the multifunction display shows at least one segment of the battery symbol (51-C) which is on but not flashing, the machine is ready for use.

When the battery symbol (51-C) shows just one segment flashing, the batteries have to be charged (see the procedure in

Maintenance chapter).

4.Drive the machine to the working place, by starting it with both hands on the steering wheel (1) and by pressing the drive pedal

(2).

The drive speed can be adjusted from zero to maximum speed according to the pressure on the drive pedal (2).

5.The forward/reverse gear is selected with the relevant lever (49) which is at the right of the steering wheel.

NOTE

The driver’s seat (12) is equipped with a safety sensor, which allows the machine to be driven by pressing the pedal (2) only when the operator is on the driver’s seat.

NOTE

The machine is equipped with an anti-skid safety system (display icon (51-J)) that reduces the speed when turning and when the machine tilts laterally, irrespectively of the pressure on the pedal.

In this case, the reduction of speed is not a malfunction but a characteristic that improves the machine stability and safety in every condition.

Stopping the machine

6.Stop the machine by releasing the drive paddle (2). It is not necessary to lock the machine during stopping or parking, because the electromagnetic brake on the wheels turn on automatically when the drive pedal is not pressed.

7.Turn off the machine by removing the operator key (41), or by pressing the push-button (42).

NOTE

If the machine is on but not working, it automatically turns off after 2 minutes.

CAUTION!

In the event of an emergency, to stop all machine functions immediately, press the push-button (5). To reset the machine functions, connect the connector (6) again.

MACHINE OPERATION (SCRUBBING/DRYING)

1.Start the machine as shown in the previous paragraph.

2.Press the One-Touch™ button (43) to lower the brush deck (7) and the squeegee (13) and start scrubbing and drying.

3.Start scrubbing, by starting it with both hands on the steering wheel (1) and by pressing the drive pedal (2) as necessary.

4.If necessary, to reduce the noise, turn on the vacuum system mute function by pressing the push-button (44).

NOTE

The machine is equipped with a safety system that turns on the brush and vacuum system only when the machine is moving.

14 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

INSTRUCTIONS FOR USE |

ENGLISH |

5.Adjust the solution flow by pressing the push-button (47) as necessary, depending on the type of cleaning to be performed.

NOTE

For the first 3 flow levels (Fig. 4), the amount of solution dispensed is automatically adjusted according to the machine speed, in order to obtain a constant amount of solution per linear meter of cleaning.

Level 4 (when enabled) supplies the maximum possible quantity of detergent solution, regardless of the machine speed (to enable or disable this, see the Super User key section in the Maintenance chapter).

The level 0 closes the solution flow completely.

|

|

|

|

|

|

|

|

|

Lev. |

|

|

|

||

|

|

|

|

|

|

Lev. |

4 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

Lev. |

3 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||

Lev. |

2 |

|

|

|

|

|

|

|

|

Lev. |

||||

|

|

|

|

|

|

|

|

|||||||

1 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

0,75 cl/m |

|

1,5 cl/m |

|

3,0 cl/m |

|

2,8 l/min |

|

OFF |

||||||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

Figure 4 |

|

|

|

|

|

|

|

P100866

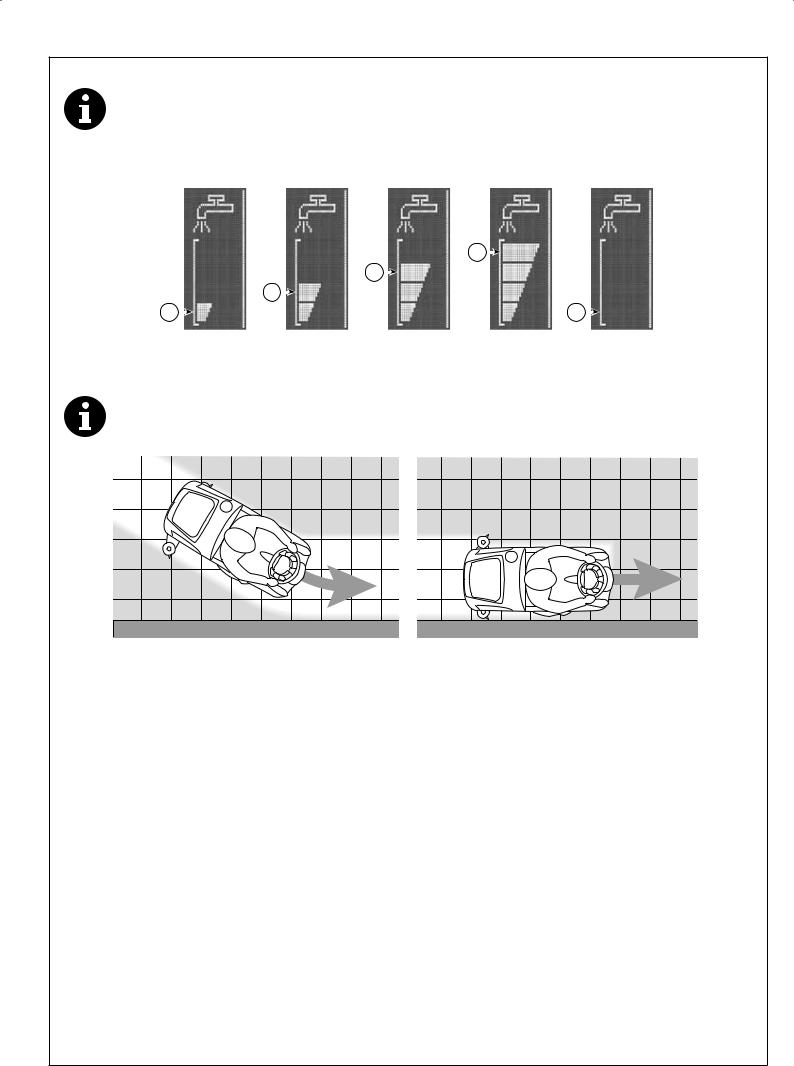

NOTE

For correct scrubbing/drying of floors at the sides of the walls, Advance suggests to go near the walls with the right side of the machine as shown in figure 5.

A |

B |

Figure 5

P100867

6.To stop scrubbing/drying, press the push-button (43) and wait for the brush deck (7) to lift. After 10 seconds, the vacuum system turns off too and the squeegee (13) lifts.

01/2015 |

9100000386 - SC2000 |

15 |

|

|

|

ENGLISH |

INSTRUCTIONS FOR USE |

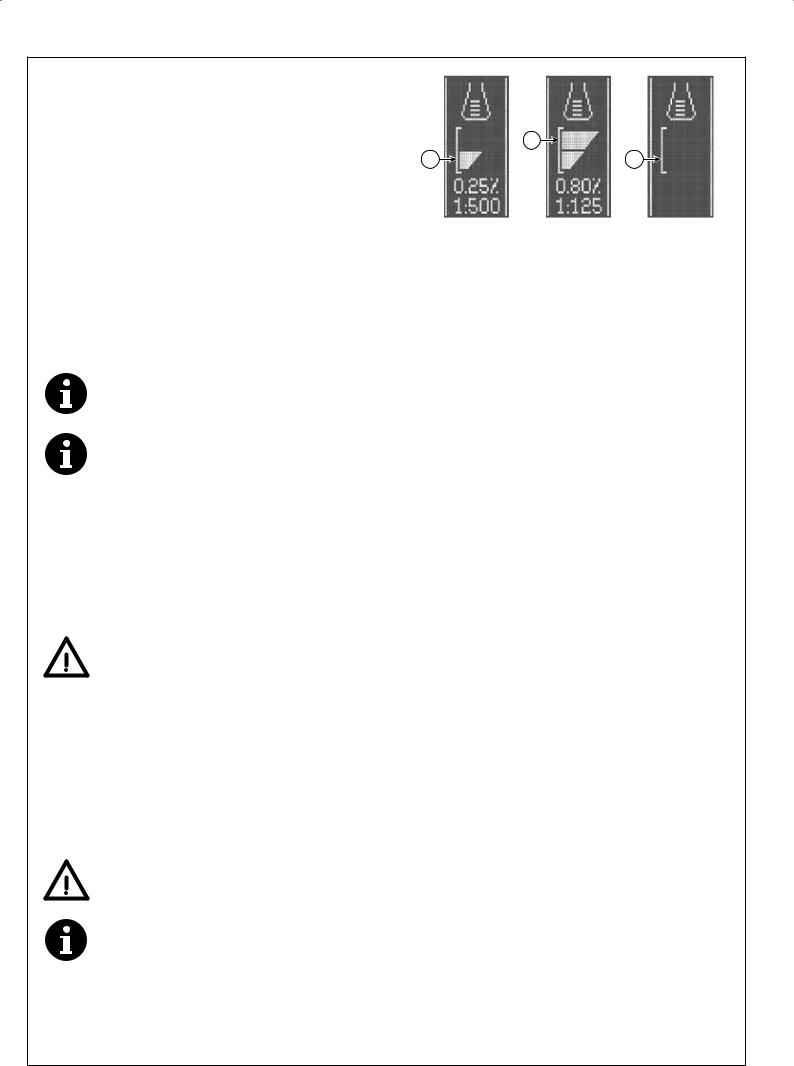

Adjusting of detergent concentration in the washing water

(For machines with EcoFlex™ system)

The system for mixing the detergent in the washing water is automatically activated when the brush is running.

The percentage of detergent added to the washing water is set to level 1 (Fig. 6).

By pressing the push-button (46), it is possible to set the percentage level to 2, or reset it to level 0.

The set percentages are shown on the multifunction display (51-G).

|

Lev. |

|

Lev. |

2 |

Lev. |

1 |

|

0 |

OFF

Figure 6

P100868

EcoFlex™ system

Use the EcoFlex™ lever (50) when a temporary stronger washing power is needed.

With the EcoFlex ™ system activated, increased solution flow, activation of the extra pressure of the brush and an increase in the solution detergent concentration (level 2 if the level was set to 1 - level 1 if the level was set to 0) is obtained.

By using the EcoFlex™ lever (50) again, the original settings (LED on) are restored.

NOTE

If the lever (D) is not used once again, the original settings are restored automatically after 60 seconds.

NOTE

All of the above solution flow and detergent concentration values are factory settings.

To change these settings, see the Super User key section in the Maintenance chapter.

Working with brush extra pressure function turned on

If the floor proves to be particularly difficult to clean, it is possible to turn on the brush extra pressure function, according to the following procedure:

1.Press the push-button (43) to lower the brush deck as shown in “Starting The Machine” paragraph.

2.Press and hold the push-button (43) for more than 1 second. The extra pressure function activation is shown by LED which turns from green to red, and by the icon  on the display (51).

on the display (51).

3.To return to normal pressure, press and hold the push-button (43) for more than 1 second.

4.To lift the brush deck without returning to the normal pressure, press the push-button (43) and release it immediately.

CAUTION!

In case of brush motor overload, due to foreign bodies which prevent them from turning, or to excessively aggressive floors/brushes, the safety system stops the brush after about one minute of continuous overload. If the overload takes place when the extra pressure function is on, the system automatically turns the extra pressure function off.

If the overload persists, the brush stops.

To start scrubbing again after a brush stop due to overload, turn off and then on the machine with the pushbutton (42).

Battery discharge during operation

When there is only one segment turned on and flashing on the battery symbol (51-C), it is advisable to charge the batteries, because the residual autonomy will last for a few minutes (depending on battery characteristics and work to be performed).

When the battery symbol (51-C) is flashing and no segment is turned on, the battery autonomy is over. After a few seconds, the brush is automatically tuned off, while the vacuum system and the drive system stay on, to finish drying the floor and drive the machine to the appointed recharging area.

CAUTION!

Do not use the machine with discharged batteries, to avoid damaging the batteries and reducing the battery life.

NOTE

In case the machine drive system cannot be used in order to move the machine, see Pushing/Towing The Machine paragraph.

16 |

SC2000 - 9100000386 |

01/2015 |

|

|

|

Loading...

Loading...