Neumann KM 84 User Manual

neumann.berlin

the microphone company

the microphone company

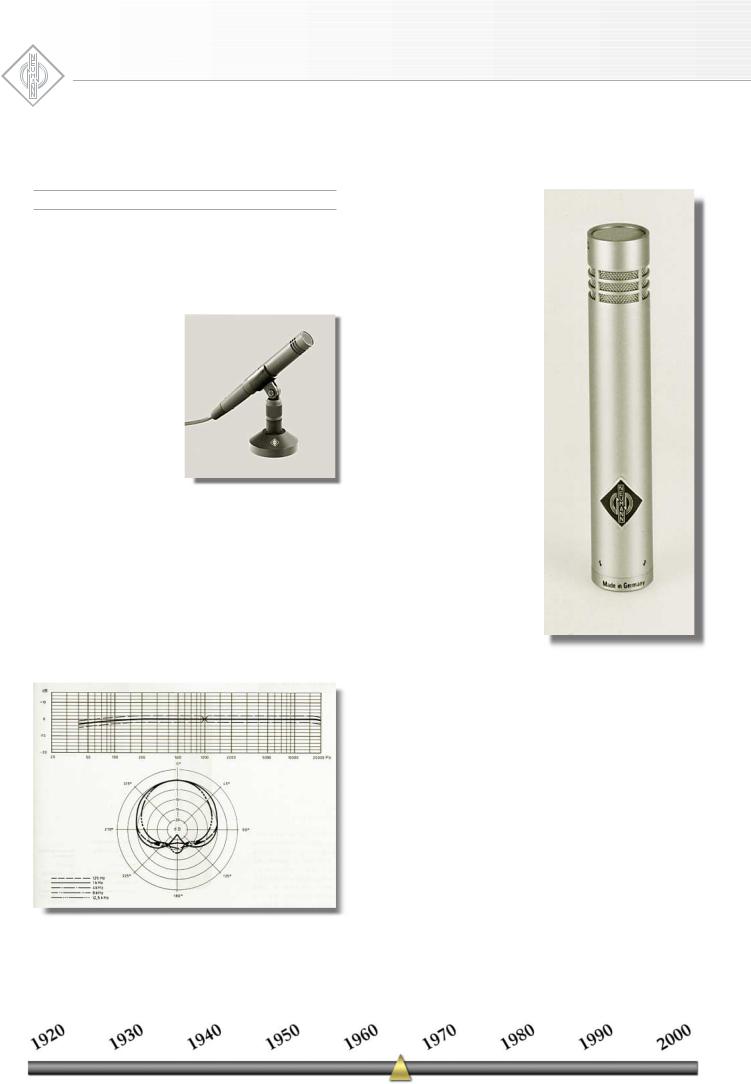

KM 84 - 48 Volt Phantom Powered

From the very start, Neumann has maintained close relations with the people using its products. The suggestions, wishes and demmands of these important customers often lead to the development of new standards and the introduction of novel techniques. One particularly important development began with a

visit by Neumann staff to Oslo, Norway, in 1966.

Norwegian State Television planned to outfit a new station which would use transistor-based microphones. Instead of using the German 12 Volt wire circuit system, the engineers wished to use the station’s existing central 48 Volt DC system. Neu-

mann suggested a circuit in which the microphone could be operated with this 48 Volt supply by dividing the voltage across the two modulation pins and developing the necessary current in reference to the cable shield.

This system is devised by using two matching 6.8 kOhm resistors where the positive pole of both modulation wires are fed to these resistors and recovered in the microphone. Due to the high degree of balance (because of the carefully matched resistors), no potential difference voltage exists between the modulation wires. Thus the term “Phantom Power” has come to be understood as a powering sys-

tem where no voltage is developed between the modulation pins of the microphone and thus “does not appear” unless used with a corresponding microphone.

This type of powering system has several advantages, one being particularly important in standard applications. Phantom powering allows for the connection of dynamic and ribbon mics without damage. All microphones with a symmetrical, ungrounded output can also be used with this powering scheme. Even tube microphones, with their separate power supplies, can be connected to a Phantom supply without problems.

The first microphone made with this technology was the Neumann KM 84, a miniature microphone with a near perfect cardioid characteristic

(due |

to the |

excellent |

|

KM 64 |

capsule |

it |

con- |

tains). |

The circuit |

was |

|

made quite small so that the mic could be made with a diameter of only 21 mm and a length of 110 mm. With phantom powering, a truly “minia-

ture microphone” was now possible!

The KM 84 was designed with a 10 dB attenuation switch, therefore allowing the microphone to be used up close with loud instruments. By placing the pad at the gate of the fieldeffect transistor (FET), this “pre-attenuation” prevents the hot capsule signal from overloading the front end of the amplifier. With the switch on, a sound pressure level of 130 dB can pass through without distortion.

What began as a modest interest in this new type of powering (and using a new connector for microphones) in 1966 resulted with the KM 84 as being one of the great success stories in Neumann’s history. Following its introduction, all microphone manufacturers began to produce or modify models for 48 volt phantom powering and this system has since become the world standard for condenser microphone powering.

Loading...

Loading...