Navman FUEL 3100, DIESEL 3200 User Manual

Installation and

Operation Manual

NAVMAN

w w w . n a v m a n . c o m

Pilot 3380

A U T O P I L O T

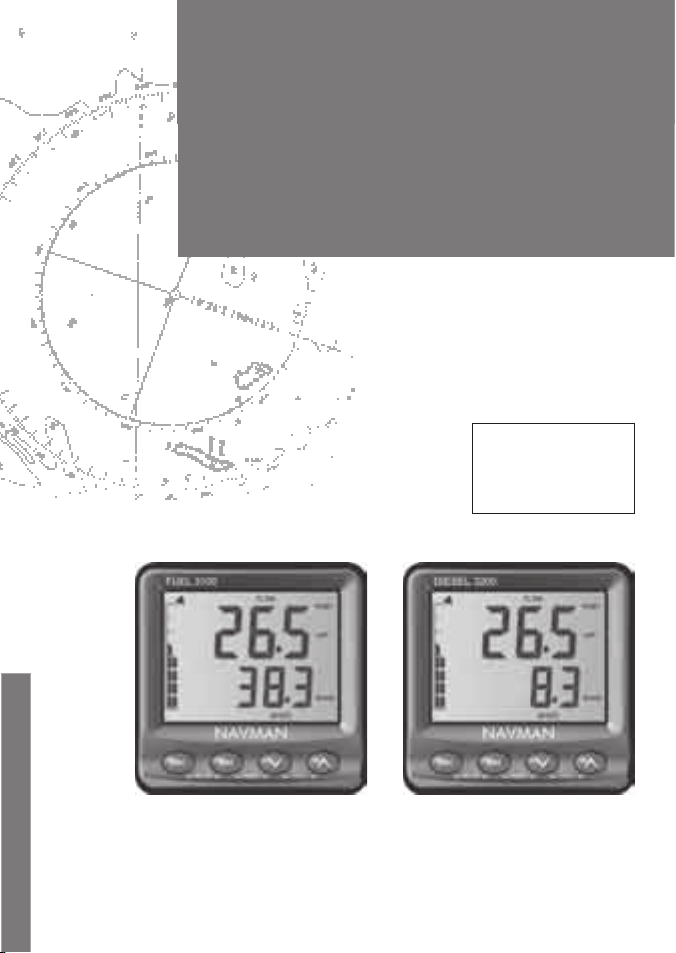

FUEL 3100 (Petrol)

and

DIESEL 3200 (Diesel)

F U E L M O N I T O R S

English ................ 3

Español ............. 27

Português .........51

FUEL 3100 DIESEL 3200

Units

This instrument is set up with units of US Gallons, knots and nautical miles.

Please refer to section 2-7 to change the units.

FCC Statement

Note: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a normal installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation bet ween the equipment and receiver.

• Connect the equipment into an output on a circuit dif ferent from that to which

the receiver is connec ted.

• Consult the dealer or an experienced technician for help.

• A shielded cable must be used when connecting a peripheral to the serial por ts.

Contents

1 Introduction ..........................................................................................................................................6

1-1 Typical Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1-2 How the flow sensors work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Operation ..............................................................................................................................................7

2-1 Turning on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2-2 The Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-3 Setting the backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-4 Upper display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-5 Lower display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-6 Fuel and battery alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2-7 Fuel gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2-8 Changing fuel units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-9 Simulation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2-10 Key reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 The setup menus .................................................................................................................................. 11

3-1 Setup data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-2 Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-3 Setup Menus and data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3-4 Fuel calibration (CAL.F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-5 Fuel flow damping (dAmP.F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-6 Speed input (InPUt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-7 Speed damping (dAmP.S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-8 Speed calibration by log (CAL.L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-9 Speed calibration by boat speed (CAL.S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Installation .......................................................................................................................................... 16

4-1 Tank and engine options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4-2 The display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4-3 The fuel flow sensor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4-4 The speed sensor (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4-5 Power/data cable wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4-6 Systems of several instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-7 Testing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4-8 Resetting to factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5 When you add or remove fuel ...............................................................................................................20

6 Troubleshooting .................................................................................................................................. 21

Appendix A Specifications .......................................................................................................................23

Appendix B Diesel fuel flow sensor hardware ..........................................................................................24

B-1 FUEL 3100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

B-2 DIESEL 3200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

B-3 Other options (FUEL 3100 and DIESEL 3200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Appendix C - Speed through water and over ground ................................................................................26

It is the owner’s sole responsibility to install and use the instrument and its sensor(s) in a manner

that will not cause accidents, personal injury or property damage. The user of this product is solely

responsible for observing safe boating practices.

Fuel type: Navman petrol flow sensors (plastic) and FUEL 3100 instruments have been specifically

developed for use in marine applications with petrol (gasoline) inboard and outboard engines and

are not warranted for any other type of application. These sensors and instruments must NOT be

used with petrol EFI engines with a return line to the tank or with diesel engines.

Navman diesel flow sensors (metal) and DIESEL 3200 instruments have been specifically developed

for use in marine applications with diesel engines and are not warranted for any other type of

application. These sensors and instruments must NOT be used with petrol (gasoline) engines.

Fuel formulation: Every effort has been made by the manufacturer to ensure that the materials

used in the Navman fuel flow sensor(s) will operate reliably with different fuel mixtures. The

manufacturer or its distributors can not be held responsible for fuel formulation or any affect this

may have on the performance and durability of the fuel flow sensor(s).

Back pressure: A fuel flow sensor will create additional back pressure in a fuel system:

• In a petrol system (FUEL 3100): 1/2" of mercury at 19.8 US gallons /hour (75 litres/ hour) and 1"

of mercury at 39.5 US gallons per hour (150 litres/ hour).

• In a diesel system (DIESEL 3200): 0.3" of mercury at 25 US gallons /hour (100 litres/ hour) and

1.5" of mercury at 80 US gallons per hour (300 litres/hour).

It is the owners responsibility to ensure that fitting the fuel flow sensor(s) does not cause fuel

starvation which may lead to poor engine performance.

Fuel Computer: Fuel economy can alter drastically depending on the boat loading and sea

conditions. The fuel computer should not be the sole source of information concerning available

fuel onboard and the electronic information should be supplemented by visual or other

checks of the fuel load. This is necessary due to possible operator induced errors such as forgetting

to reset the fuel used when filling the tank, running the engine with the fuel computer not

switched on or other operator controlled actions that may render the device inaccurate. Always

ensure that adequate fuel is carried onboard for the intended trip plus a reserve to allow for

unforeseen circumstances.

Specific requirements: Your boat’s fuel installation boat might be subject to specific requirements

(such as USCG, NMMA and ABYC guidelines or local laws), particularly if the boat is licensed,

surveyed, charted or inspected. It is the owner’s sole responsibility to install and use the instrument

and its sensor(s) in compliance with these requirements.

NAVMAN NZ LIMITED DISCLAIMS ALL LIABILITY FOR ANY USE OF THIS PRODUCT IN A WAY THAT

MAY CAUSE ACCIDENTS, DAMAGE OR THAT MAY VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals, user guides and other information

relating to the product (Documentation) may be translated to, or has been translated from,

another language (Translation). In the event of any conflict between any Translation of the

Documentation, the English language version of the Documentation will be the official version of

the Documentation.

This manual represents the FUEL 3100 and DIESEL 3200 as at the time of printing. Navman NZ

Limited reserves the right to make changes to specifications without notice.

Copyright © 2004 Navman NZ Limited, New Zealand. All rights reserved. Navman is a registered

trademark of Navman NZ Limited.

Important

6

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

This manual describ es two different Navman

marine fuel instruments:

• The FUEL 3100, which is installed with the

separate petrol/ gasoline flow sensor kit,

and measures petrol consumption.

• The DIESEL 3200, which is installed with

the separate diesel flow sensor kit, and

measures diesel consumption.

This manual describ es how to install, set up and

operate the instruments. For more information,

refer to the separate Flo w Sensor Installation

Manual (for the FUEL 3100 and petrol systems)

and Diesel Fl ow Sensor Installation a nd

Operatio n Manual (for the DIESEL 3200 and

diesel systems); this manual has extensive

information on understanding and optimising

your diesel boat’s performance.

The FUEL 3100 or DIESEL 3200 measures and

displays the fuel flow in real time for a single or

twin engine boat. It can calculate and display

the amount of fuel used, the amount of fuel

remaining and the fuel flow rate.

If an optional speed sensor or speed

instrument is connected, the unit can also

1 Introduction

show the fuel economy, boat speed and the

trip log and total logs.

Knowing the fuel economy can help determine

the optimum throttle settings and maximize

fuel savings. With twin engine boats,

comparison between the flow rates of each

engine can be used to achieve maximum

synchronisation.

It is essential to update the fuel readings in

the FUEL 3100 or DIESEL 3200 after a partial or

full refill, or af ter manually removing fuel, to

maintain accurate readings (see section 5).

The FUEL 3100 and DIESEL 3200 are par t of

the Navman family of instruments for boats,

which includes instruments for speed, depth,

wind and repeaters. These instruments can be

connected together, using NavBus or NMEA , to

form an integrated data system for a boat.

Information in this manual applies to both the

FUEL 3100 and the DIESEL 3200 unless noted. It

is vital to read this document and the Navman

instrument’s installation and operation manual

before installing or using this kit.

Power supply

Sensor wiring

Connection to other

instruments (optional)

Petrol tank

Diesel tank

Diesel engine

Tachometer pickup

Power supply

Sensor wiring

Connection to other

instruments (optional)

Diesel flow

sensor

Diesel flow

sensor

Petrol flow sensor

Petrol engine

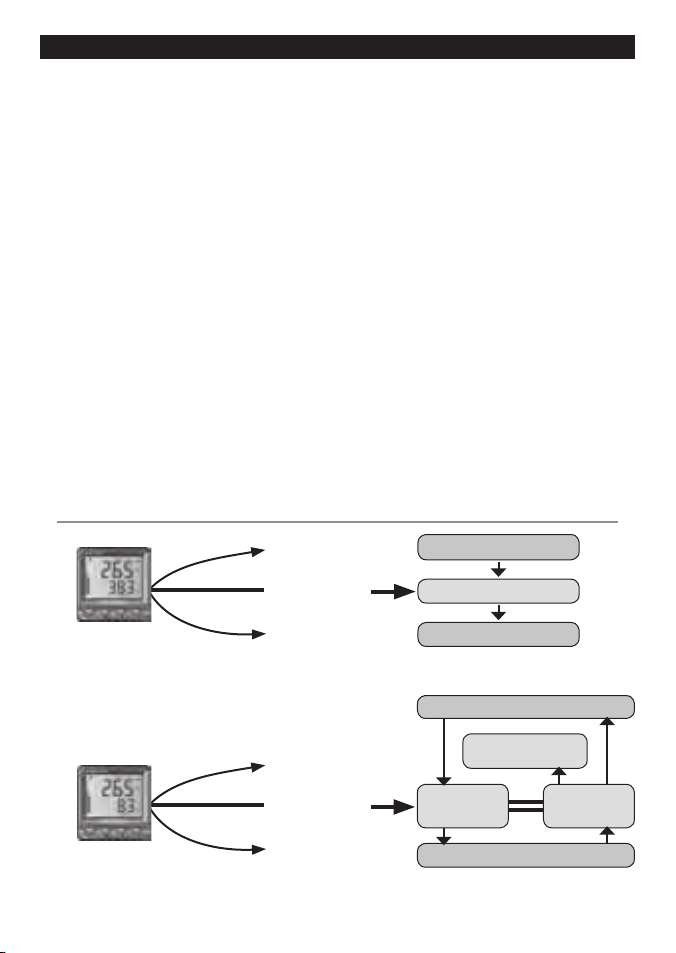

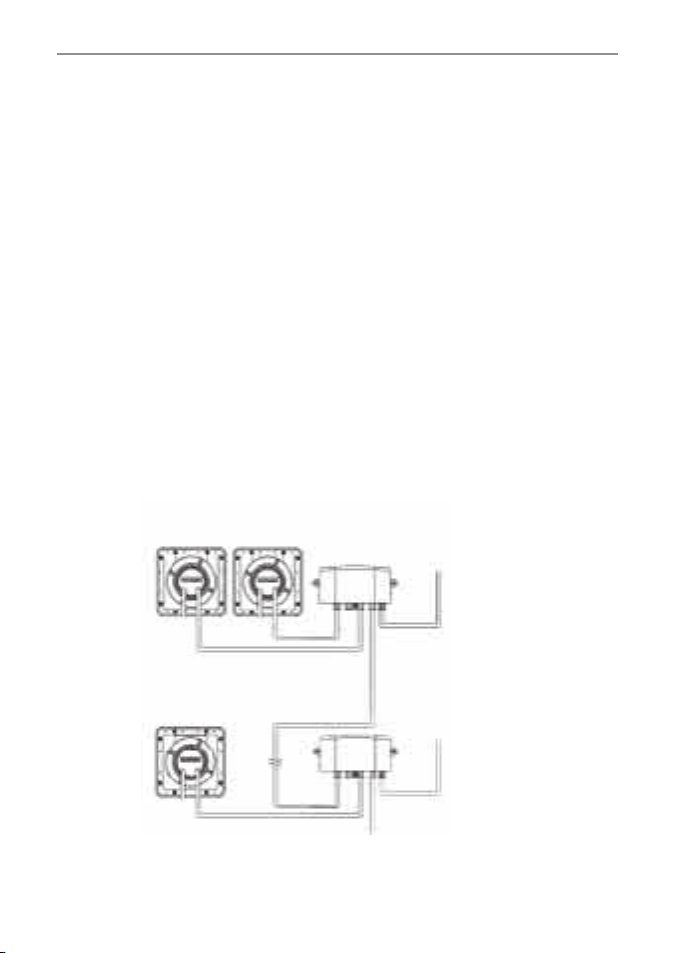

1-1 Typical Installations

FUEL 3100 System

DIESEL 3200 System

In a twin engine system, each

engine has its own sensor(s)

7

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

2 Operation

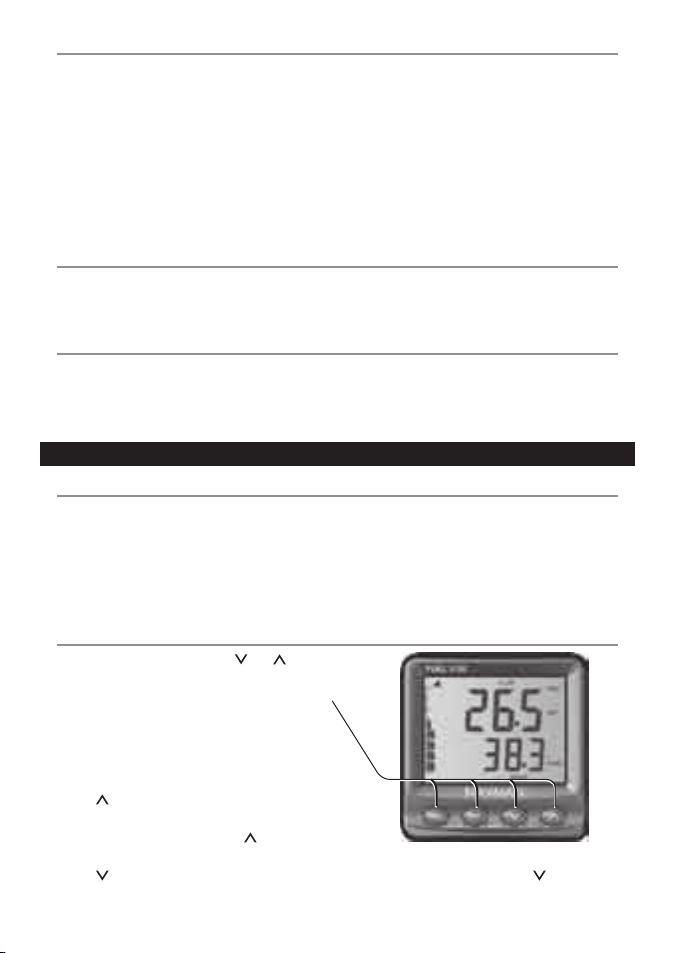

The unit has four keys, ESC , ENT, and .

In this manual:

• Press means push the key for less than one

second.

• Hold means hold the key down until the

display changes.

In general:

• Press to change what is displayed in the

upper display.

In a setup menu, press or hold to

increase the setting.

• Press to change what is displayed in the

lower display.

Petrol flow sensor (FUEL 3100): The petrol

flow sensor is fitted in the fuel line between the

fuel tank and the engine. A small turbine inside

the fuel f low sensor measures the rate of the

fuel flow into the engine. This information is

relayed through the fuel flow sensor cable and

shown electronically on the display unit.

Diesel flow sensor (DIESEL 3200): A diesel

sensor is a positive displacement flowmeter,

with one moving internal part, made of low

friction, fuel proof plastic. There are no fine

pointed shafts and jewelled bearings to get

worn or hammered by diesel pulsing.

Each engine is fit ted with two fuel flow

sensors, to measure fuel supply and return.The

system calculates the engine consumption,

compensating for pulsing from diaphragm

lift pumps, dif ferent fuel temperatures in

the supply and return lines and the flow

characteristic s of the sensors.

Clean the display unit and any plastic sensor

with a damp cloth or mild detergent. Avoid

abrasive cleaners, petrol or other solvents.

1-2 How the flow sensors work

1-3 Cleaning and maintenance

1-4 Calibr ation

Put the protective cover over the display when

it is not being used.

FUEL 3100: It is essential to calibrate the fuel

flow sensors af ter installation and again af ter

the first 100 engine hours to allow moving

parts to wear in (see section 3-4).

DIESEL 3200: The sensors are factor y

calibrated and are highly accurate. They can be

calibrated but this should not be necessary.

2-2 The Keys

2-1 Turning on and off

The display unit does not have its own power

switch, but if possible should be wired so that it

turns on when the engine ignition is turned on

to allow the engine hours counter to function

properly. (See sec tion 4 -5).

Turn the unit on and off with the boat ’s ignition

switch. The display unit does not have its own

power switch. When the unit it is turned off,

any settings you have made are retained.

If SIM flashes at the bottom left corner of the

display, the unit is in simulation mode (see

section 2-9).

In a setup menu, press or hold to decrease

the setting.

8

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

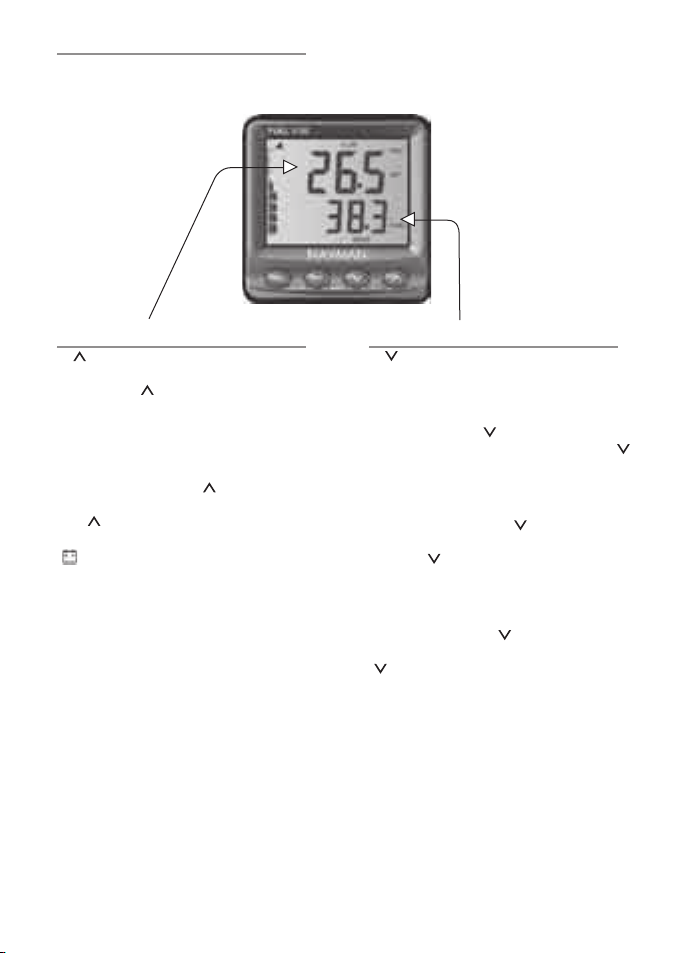

2-4 Upper display

Press one or more times to change what is

displayed (for example, if the display shows

USED then press to change the display to

FLOW):

• REMAINING: Fuel remaining. Update this

when you add or remove fuel (see section 5).

• USED : The fuel used since last reset.

To reset fuel used, press one or more

times until used is displayed, then hold ENT

and together until the reading resets

to zero.

• : Displays supply voltage to the head unit.

• FLOW: Fuel flow rate.

• ECONOMY: Distance travelled per unit of

fuel used (requires optional speed input, see

section 3-6)

• RPM: Engine RPM (DIESEL 3200 only).

PORT RPM: Port engine RPM (displayed on

upper display)

STBD RPM: Starboard engine RPM

(displayed on lower display)

Note:

• If the boat has twin engines, then when

FLOW is displayed, press ENT one or more

times to display PORT, STBD or TOTAL

flow.

• If the boat has a twin fuel tank s, then when

REM AINING or USED is displayed, press

ENT one or more times to display PORT,

STBD or TOTAL data.

2-5 Lower display

Press one or more times to change what

is displayed:

• LOG: Trip distance; the distance travelled

since log was reset.

To reset log, press one or more times

until log is displayed, then hold ENT and

together until the reading resets to zero.

• TOTAL LOG : Total distance; the distance

travelled since total log was reset.

To reset total log, press one or more

times until total log is displayed, then hold

ENT and together until the reading

resets to zero.

• hours: Hours the engine has run since

hours was reset.

To reset hours, press one or more times

until hours is displayed, then hold ENT and

together until the reading resets to zero.

• RANGE: Estimated distance that can be

travelled on the remaining fuel at the

current consumption.

• SPEED: Boat speed.

Note:

• LOG, TOTAL L OG, RANGE and SPEED

require the optional speed input (see

section 3-6).

The display and keys are backlit for easy

reading in dim light. To change the backlight,

change L AmP in the LA mP menu.

(see sec tion 3-3)

2-3 Setting the b acklight

9

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

2-8 Changing fuel units

1 Press until REMAINING, USED, FLOW or

ECONOMY are displayed.

2 Hold one or more times to change fuel

units.

Note:

When “gal” is displayed, this could be US

gallons or imperial gallons. Check the units

menu to conf irm and change if required

(see FUEL UnItS in the UnItS menu,

section 3-3).

Changing distance and speed units

1 Press until LOG, TOTAL LOG, R ANGE

or SPEED are displayed.

2 Hold one or more times to change

distance and speed units.

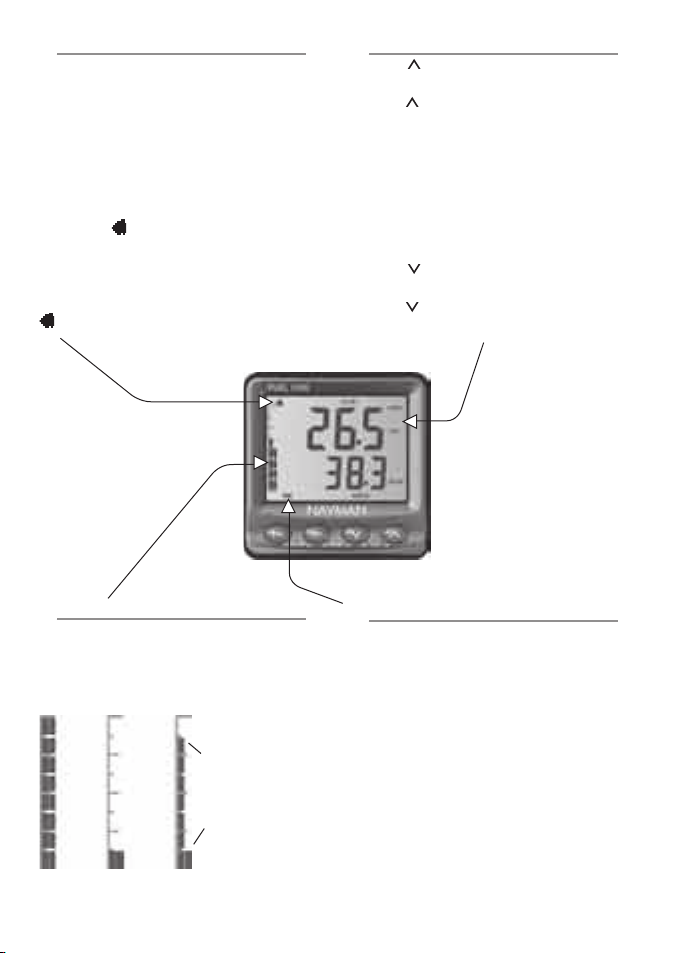

2-7 Fuel gauge

Displays fuel remaining in the tank(s). If the

boat has twin tank s, the gauge shows both

tanks; the left side is the port tank and the right

side the starboard tank:

Single tank Twin tanks

Full

Port tank

almost full

Starboard tank

almost empty

2-6 Fuel and bat tery alarms

The unit has two alarms:

• Low fuel: Alarm sounds when the fuel left

in the tank becomes less than the alarm

value.

• Low battery: Alarm sounds when the

batter y voltage becomes less than the

alarm value.

To turn the alarms on and off and to set the

alarm values, see section 3-3. When an alarm

sounds, the symbol flashes, the internal

beeper sounds and any external beepers or

lights operate. For a low fuel alarm the fuel

gauge flashes.

Press ESC to mute the alarm.

alarm symbol

2-9 Simulatio n mode

Simulation mode allows the user to become

familiar with the FUEL 3100 off the water. In

Simulation mode, the FUEL 3100 generates

data internally and ignores input from the

sensor. The word SIM flashes at the bottom left

corner of the display.

To turn Simulation mode on or off:

1 Turn the power off.

2 Hold ESC while turning the power on.

Almost

Empty

10

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

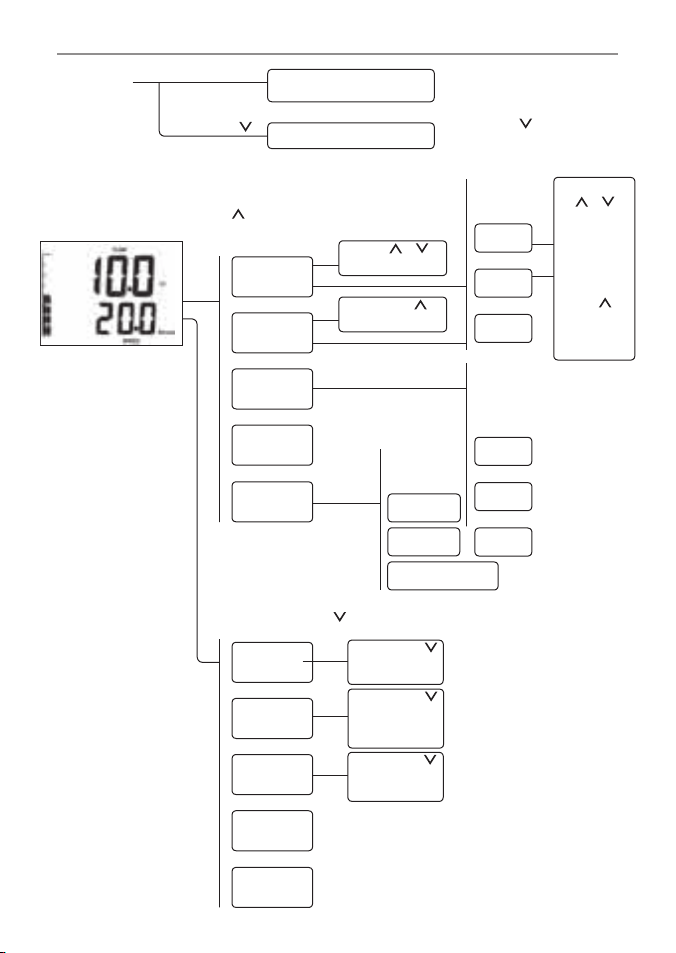

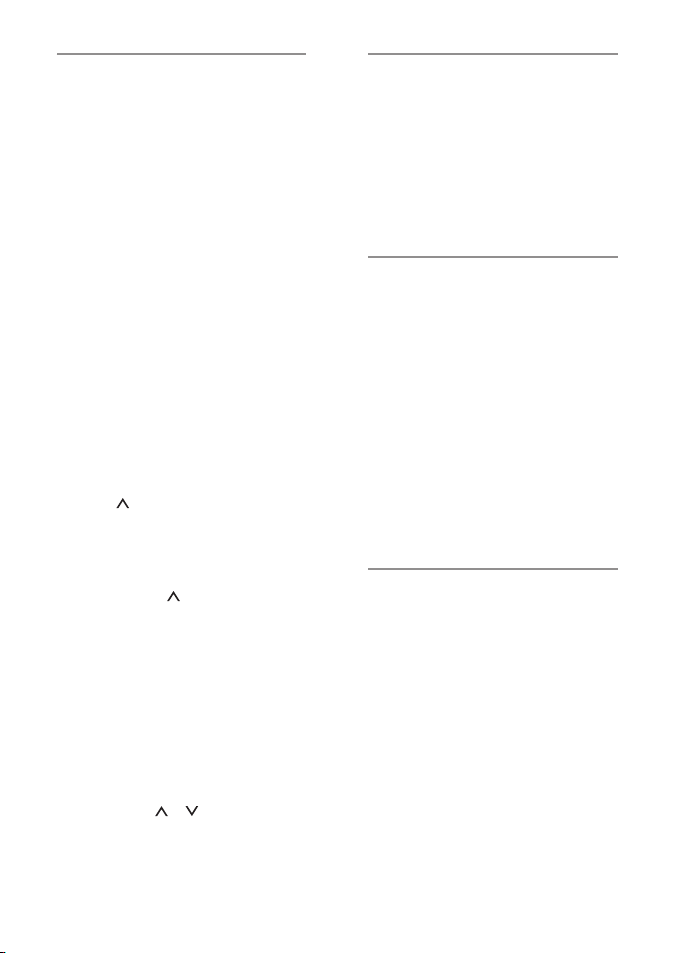

Hold ENT +

for 5 s to reset

TOTAL LOG

Press ENT + to

reset USED

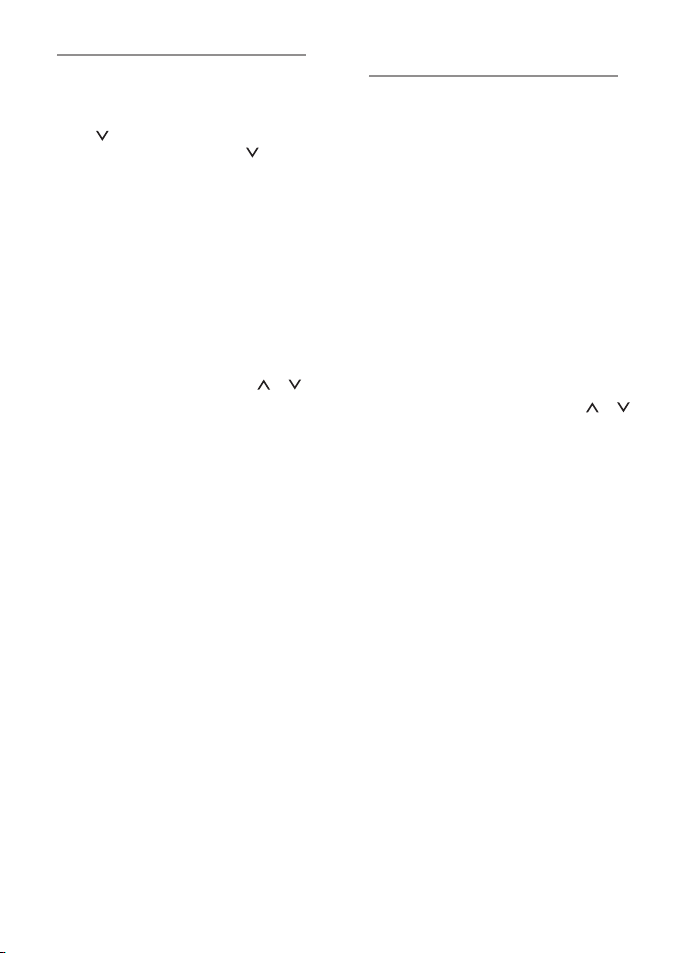

2-10 Key reference

FUEL

REMAINING

FUEL USED

FUEL FLOW

FUEL

ECONOMY*

LOG *

TOTAL

LOG*

hours

RANGE*

SPEED*

Hold ENT +

for 5 s to reset

hours

Press ENT +

to reset LOG

Press +

when tank filled

Press

+

when tank

filled

When USED

displayed,

press

ENT + to

reset USED

Reset to factory defaults

Turn Simulation mode On

or OFF

*Hold ENT +

Upper display

Press to change what is displayed

PORT

STBD

TOTAL

PORT

STBD

TOTAL

Single tank

Hold ESC

Lower display Press to change what is displayed

When unit is

turned on

Main display

RPM PORT

RPM STBD

Twin engines

press ENT to

display:

RPM

Diesel only

PORT and STBD

* denotes must have speed input (see section 3-6)

*Hold ENT + for at

least 5 seconds.

Twin engines

press ENT

to display:

Twin engines

press ENT

to display:

11

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

3 The setup menus

3-1 Setup data

Use the setup menus, shown on the following

pages, to customize the unit to suit your

boat and your own preferences. To display or

change setup data:

1 From the main display, press ESC and ENT

together to start setup mode.

2 Press or one or more times to display

the setup menus.

3 Press ENT to select a setup menu.

4 Press or one or more times to display

the setup data for the setup menu.

5 If the boat has twin engines or twin tanks,

press ENT. Press one or more times to

display the port or starboard setup data.

6 To change the data:

i Press ENT; the data will blink.

ii Press or hold or to change the

value.

iii Press ENT to accept the new value or

press ESC to ignore your changes.

7 To display or change other setup data for

this setup menu, repeat steps 4, 5 and 6.

Then press ESC.

8 To display or change setup data for other

setup menus, repeat steps 2 to 6. Finally,

press ESC to return to the main display.

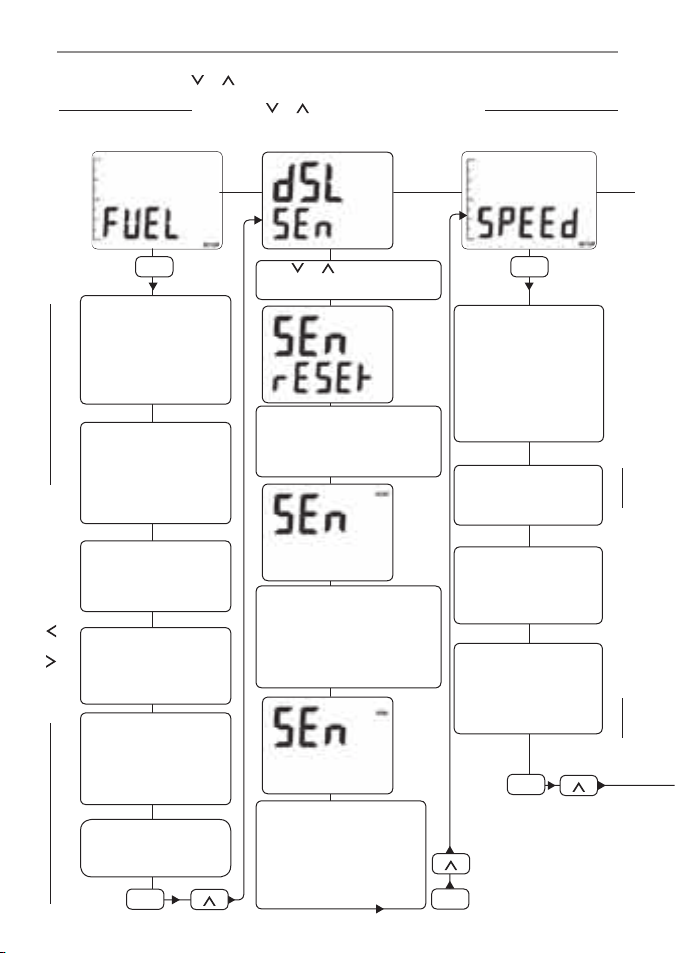

3-2 Initial Setup

1 In the FUEL menu set up the number of

fuel tanks. Select dUA L then Off (1 tank)

or On (2 tank s).Then select the number of

engines. Motor (1 or 2).

2 In the dSL SEn Menu identify the motors

by:

i Reset to single engine installation.

ii Select one motor (port or starboard),

then remove p ower from the

other motor’s diesel f low sensor

by unplugging the white coloured

connector.

iii Press and hold ENT for 2 seconds to

configure the motor, a beep will sound

when complete.

Repeat ii and iii for the other motor.

3 In the SPEEd menu identif y the speed

input.None, GPS or Sen.

4 To reset all data to the factory defaults see

section 4-8

5 For single engine/ single tank diesel

installation fac tory defaults will work.

12

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

FUEL

Set fuel in tank(s) when

you add or remove fuel

(see section 5)

Twin tanks: section 3-1

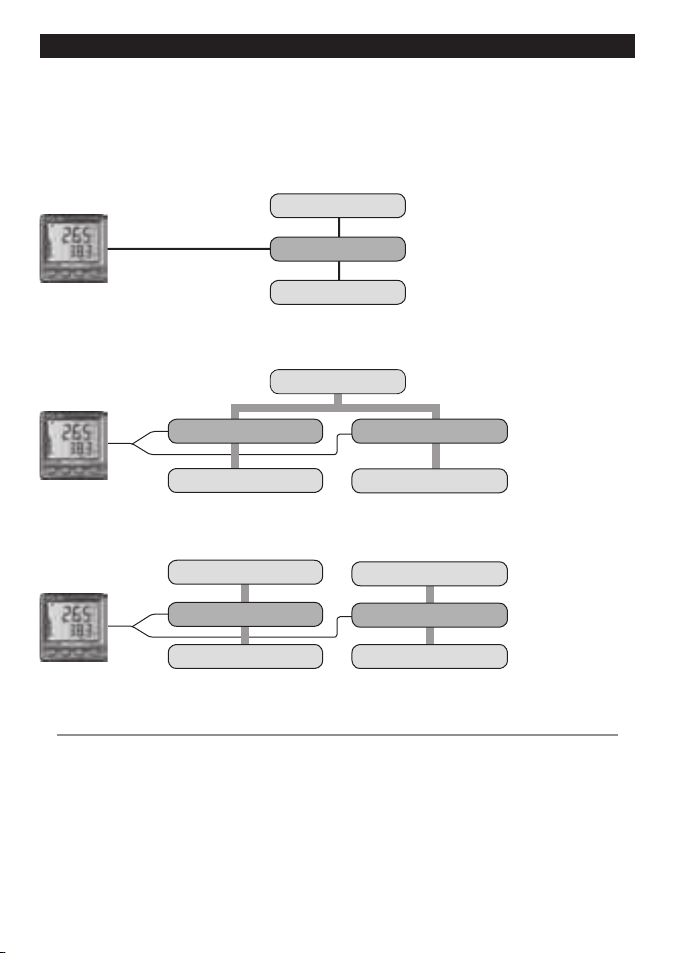

3-3 Setup Menus a nd data

From the main display, press ENT + ESC together

to start setup mode. Press or until desired

menu is desplayed then press ENT to select it.

Press ESC again to return to the main menu.

Speed menuFuel menu

dUAL

Set number of fuel tanks

Off: 1 tank

On: 2 tanks

See section 3-2

SIZE

Set capacity of fuel

tank(s)

See section 3-3

motor

Set number of engines,

1 or 2

See section 3-1

CAL .F

Calibrate fuel sensor(s)

(see section 3-4)

Twin engines:

See section 3-3

dA mP.F

Set fuel damping

see section 3-5)

InPUt

Select speed input:

No: None

GPS: GPS/NMEA

SEn: Paddlewheel

sensor (see section3-6)

dA mP.S

Set speed damping (see

section 3-7)

CAL .L

Calibrate speed sensor

from log (see section

3-8)

CAL .S

Calibrate speed sensor

from boat speed

(see section 3-9)

Press or to select a setup menu

Press or to select setup data

Only available if InPUt = SEn

See also section 4-1

Select port or starboard engine

Press ENT for 2 secs to reset

to single engine installation.

A BEEP will sound when

complete.

Power port sensor only.

See section 3-2.

Press and hold ENT for

2 seconds to configure port

screen to port sensor. A BEEP

will sound when complete.

Press or to view

screens below.

Power starboard sensor

only. See section 3-4.2.

Press ENT for 2 seconds to

configure starboard screen

to starboard sensor. A BEEP

will sound when complete.

ENT

ENT

ESC

ESC

ESC

13

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

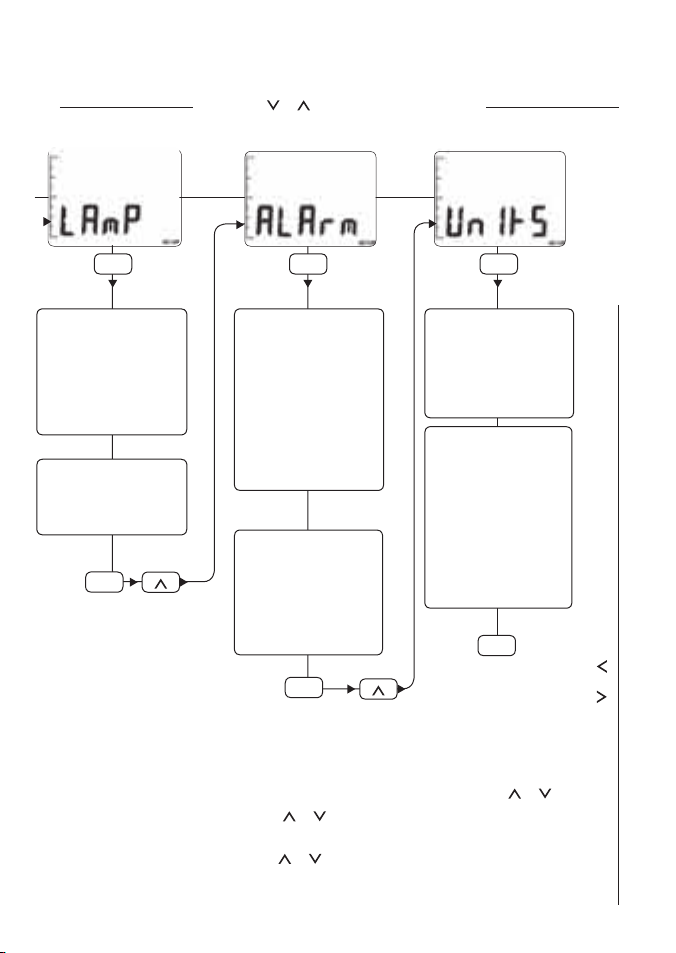

Start setup mode press ENT + ESC together

Move to the desired menu by using or

Select the menu by pressing ENT

Move to the desired page by using or

Select the page press ENT

Units menuAlarm menu

Low .F

Set low fuel alarm:

0: Alarm off

Greater than 0: Set alarm

value

(see section 2-6)

Twin tanks:

see section 3-1

Low .b

Set low battery alarm:

0: Alarm off

Greater than 0: Set alarm

value

(see section 2-6)

Press or to select setup data

FUEL UnItS

Set fuel units:

GAL US, or

GAL ImP, or

LItrE

dISt UnItS

Set distance units:

nAUt mILES, or

StAT mILES

Distance units are used

for the log and for

the speed, eg setting

units to nAUt mILES

displays speed in knots

Lamp menu

LAm P

Set backlight for keys

and display:

0: Off

1: Dimmest

4: Brightest

GrouP

Set backlight group

number: 0 to 4

(see section 4-6

ENT

ENT

ENT

Press or to select a setup menu

Change the data press or

Accept the change press ENT

Leave the page press ESC

Return to the main display press ESC

Sequence of key strokes

ESC

ESC

ESC

14

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

3-4 Fuel calibration (CAL.F)

To calibrate a fuel flow sensor, select CAL.F in

the FUEL menu. Calibrate the sensors if you are

doubtful of their performance.

FUEL 3100: It is essential to calibrate the fuel

flow sensors af ter installation and again af ter

the first 100 engine hours to allow moving parts

to wear in.

DIESEL 3200: The sensors are factory calibrated

and are highly accurate. They can be calibrated

but this should not be necessary.

Calibrating a fuel flow sensor requires accurate

measurement of the fuel consumption. This is

best done using a small portable tank. At least 4

gallons (15 litres) of fuel should be used to ensure

an accurate calibration. The more fuel used, the

more accurate the calibration.

Twin engine boats require both engines to

be calibrated. Do these together with t wo

portable tanks, or at different times using one

portable tank.

To calibrate an engine’s fuel flow sensor:

1 Connect the portable tank to the

engine through the fuel flow sensor.

2 Reset USED:

i Press one or more times

until USED is displayed.

ii If your boat has twin tanks,

press ENT one or more times

to display PORT or STBD.

iii Hold ENT and together until

the reading resets to zero.

3 Run the engine at normal cruising

speed until a known amount of

fuel, at least 15 litres (4 gallons),

has been used per engine.

4 Select the FUEL setup menu, then

select CAL.F; if your boat has twin

engines, select the PORT or STBD engine

to be calibrated (see section 3-1).

5 If the value of CAL.F does not match

the known amount of fuel used, press

ENT, then press or and change

CAL.F until it does match. Then press

ENT to save the correct value (otherwise

press ESC to ignore the calibration).

3-5 Fuel flow damping (dAmP.F)

Waves and rocking of the boat cause the fuel

flow to fluctuate slightly. To give a stable reading,

the instrument calculates flow by taking several

measureme nts over a period of time and

averaging them. This is called damping.

Set d Am P.F to between 1 to 99 seconds. Small

values will give more accurate readings but

will show fluctuations. Large values will give

more stable readings, but will ignore some

true fluctuations.

3-6 Speed input (InPUt)

Select the optional speed input:

No : No speed input is available.

GPS: Use GPS speed received via

NMEA. This is speed over ground.

SEn : The optional paddlewheel

sensor connected directly to the

unit, or through the Navbus system.

This is speed through water.

Note:

A speed input is required to disp lay L OG ,

TO TA L LOG, RA N G E and SPE ED (see

section 2-5).

Speed over ground and speed through water

can give different values for some displayed data

(see appendix C).

3-7 Speed damping (dAmP.S)

(Only available if an optional paddlewheel sensor

is connected to the unit and InPUt = SEn .)

Waves and rocking of the boat cause the speed

to fluctuate slightly. To give a stable reading,

the instrument calculates speed by taking

several measurements over a period of time and

averaging them. This is called damping.

Set d Am P.S to 1 (6 sec), 2 (12 sec), 3 (18 sec), 4

(24 sec) or 5 (30 sec). Small values will give more

accurate readings but will show fluctuations.

Large values will give more stable readings, but

will ignore some true fluctuations.

15

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

3-8 Speed ca libration by log (CAL.L)

(Only available if an optional paddlewheel

sensor is connecte d to the unit and InPUt

= SEn.) Select CA L.L to calibrate the

paddlewheel speed sensor using the trip log.

1 Press until LOG is displayed in the lower

part of the screen. Press ENT + to reset

LOG to 0.

2 Travel a known distance in a straight line

at a speed between 5 and 20 knots. Best

results are achieved in calm conditions

and with minimal current (best at high or

low tide). Tidal ef fects can be reduced by

making the trip once in each direc tion,

parallel to the current, to average the

distance.

3 Select the SPEED setup menu, then select

CAL.L, the distance travelled.

4 If the value of CAL.L does not match the

known distance, press ENT then or

and change the value until it does match.

Then press ENT to save the correct value

(otherwise press ESC to exit).

3-9 Speed calibration by boat speed

(CAL.S )

(Only available if an optional paddlewheel

sensor is connecte d to the unit and InPUt

= SEn.) Select CA L.S to calibrate the

paddlewheel speed sensor using boat speed.

You need an accurate way of knowing boat

speed, such as another boat with a calibrated

paddlewheel sensor or a GPS receiver.

For accurate calibration:

• The spee d from another paddlewheel

sensor should be between 5 and 20 knots.

• Conditions should be calm, with little

current (best at high or low tide).

To calibrate:

1 Travel at a constant, known speed.

2 Select the SPEED setup menu, then select

CAL.S, the boat speed.

3 If the value of CAL.S does not match the

known boat speed, press ENT then or

and change the value until it does match.

Then press ENT to save the correct value

(otherwise press ESC to exit).

Note:

After you press ENT, it does not matter if the

boat’s speed changes.

16

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

Single fuel tank, twin engines (requi res twin engine kit)

Two fuel

consumption

measurements

Fuel tank

Starboard engine

Port engine

Flow sensor Flow sensor

Twin fuel tanks, twin engines (requires twi n engine kit)

Port fuel tank

Starboard fuel tank

Flow sensor

Starboard enginePort engine

Flow sensor

Two fuel

consumption

measurements

Single fuel tank, single engine

Fuel tank

Flow sensor

Engine

Single fuel

consumption

measurement

4 Installation

There are three options for the FUEL 3100 and

the DIESEL 3200.

A FUEL 3100 uses one sensor to measure fuel

consumption. The DIESEL 3200 uses t wo

sensors to measure fuel consumption, a sensor

in the supply line and a sensor in the return line

(see sec tion 1-1).

To configure the unit for different tank and

engine options, set dUAL and m otor in the

FUEL menu and for twin motors identif y each

engine in the dSL SEn menu by alternately

removing p ower from the flow sensors as

described

in this sec tion.

Note:

Twin fuel tanks connected by an open balance

pipe should be configured as a single fuel tank.

4-1 Tank and engine options

Correct installation is critical to the performance

of the unit. It is vital to read the entire

installation section of this manual, and the

documentation that comes with any optional

other parts, before starting the installation.

For more information, refer to the installation

instruc tions supplied with the sensor, or

consult your Navman dealer.

17

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

Warnings

1. The display unit is waterproof from the

front. Protect the rear from water, otherwise

water might enter the breathing hole and

damage the display unit. The warranty does

not cover damage caused by moisture or

water entering the back of the display unit.

2. Ensure that any holes cut for the

installation will not weaken the boat’s

structure. If in doubt, consult a qualif ied boat

builder.

50 mm (2") minimum

clearance for cables

20 mm (0.75")

maximum thickness

Fixing nutFixing hole

50 mm (2")

Side view of display unit mounting

4-2 The display unit

1 Choose a location for the display unit that:

•

is easily seen and protected from

damage

•

is at least 100 mm (4") from a compass

and at least 500 mm (19.5") from a radio

or radar antenna

•

is away from engines, f luorescent lights,

power inver ters and radio or radar

transmit ters

•

is accessible from the back; a minimum

clearance of 50 mm (2") is required at

the back (see mounting diagram)

•

protects the back of the unit from

moisture and water.

2 The unit must be mounted on a flat panel

less than 20 mm (0.75") thick . Stick the

mounting template in place. Drill a 50 mm

(2") fixing hole through the centre hole

in the template. Note that the template

allows space around the display unit for the

protective cover.

3 Remove the fixing nut from the back of

the display unit. Insert the stud at the back

of the display unit through the mounting

hole. Hand tighten the fixing nut.

4-3 The fuel f low sensor(s)

Install the fuel flow sensor(s) following the

instruc tions in the manual supplied with the

petrol fuel or diesel flow sensor(s). Note the

warning about fuel types in appendix B.

FUEL 3100: Plug the sensor cable into the

FUEL 3100 cable with a white connector and do

up the locking collar. For a twin engine or twin

tank boat, follow the instruc tions in the Fuel

Sensor Instal lation Manual.

DIESEL 3200: Connect the white sensor

cable to the DIESEL 3200. For a twin engine

installation install the white T connector and

then connect the sensor cables to this.

4-4 The speed sensor (optional)

If required, install the optional paddlewheel

speed sensor following the instructions in

the manual supplied with the sensor. Plug the

sensor cable into the FUEL 3100 cable with a

blue connector and do up the locking collar.

If a NavBus or NMEA speed source is used,

connect it to the power/data cable (see nex t

page).

18

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

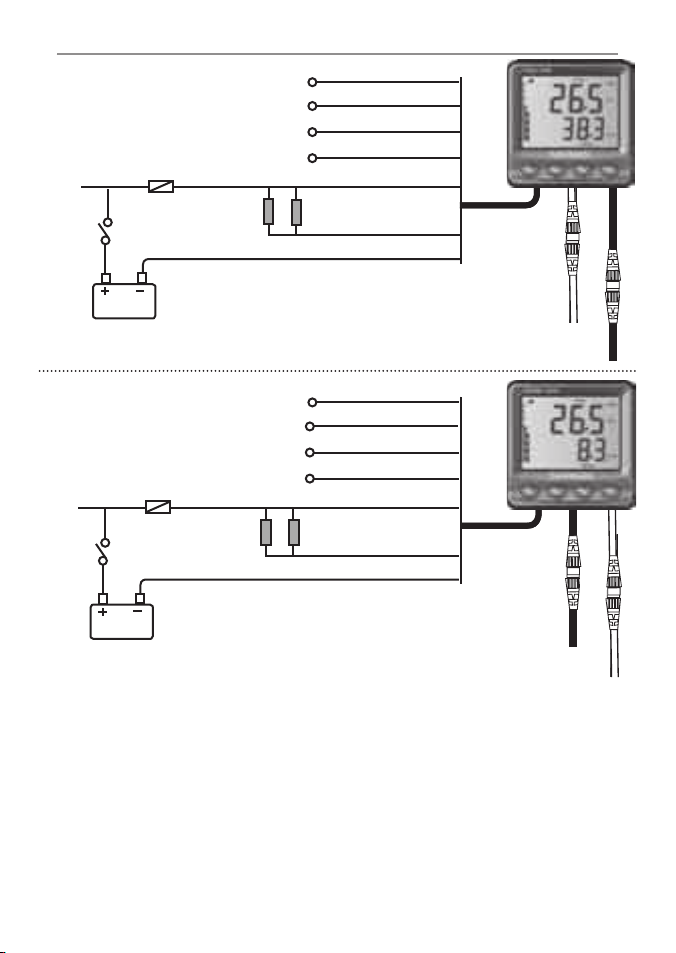

4-5 Power/data c able wiring

Fuse 1 A

12 V DC

Alarm beepers and

lights (optional)

Power to

engine

Engine

ignition

switch

FUEL 310 0

NMEA ground

Notes for both FUEL 3100 and DIESEL 3200:

Use a Navman junction box or any simple wire

to wire connector system to wire the power/data

cable. Tape or cover any unused wires or

connectors to protect them from water and keep

them from shorting together. The unit requires

between 9 and 30 V DC power. To allow the

engine hours counter to function properly the

unit should be powered only when the engine’s

igniton switch is turned on. With twin engines

the unit ideally needs to work when either one

or both engines are running. If acceptable power

is available wire the unit through each ignition

system seperately using an On/On switch.

Alternatively wire it through a seperate switch to

the vessels 12 V power supply. The units must

not be powered from both ignition systems

simultaneously.

If a Navman connector box is not used a 1 A fuse

must be fitted in the power supply (+ ) line.

The instrument’s alarm output is switched to

ground to sound the alarm, 30 V DC and 250 mA

maximum. If the external alarms require more

than 250 mA DC total, fit a relay.

Yellow

White

Orange

Blue

Red

Green

Black

NMEA in (optional)

NMEA out (optional)

NavBus, to other

instruments (optional)

Power/

data cable

Petrol fuel sensor

cable, white plug

Optional paddlewheel

speed sensor, blue plug

Fuse 1 A

12 V DC

Alarm beepers and

lights (optional)

Power to

engine

Engine

ignition

switch

NMEA ground

Yellow

White

Orange

Blue

Red

Green

Black

NMEA in (optional)

NMEA out (optional)

NavBus, to other

instruments (optional)

Power/

data cable

Optional paddlewheel

speed sensor, blue plug

Diesel fuel sensor

cable, white plug

DIESEL 3200

19

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

However, changing the backlight setting in

an instrument in group 0 will not af fect any

other instrument.

To assign the FUEL 3100 or DIESEL 3200 to

a group, set GrouP in the LAmP menu

(see sec tion 3-3).

• If an alarm sounds, mute it by clearing the

alarm on any instrument which can display

that alarm.

• NavBus junction boxes simplify wiring.

For more information, refer to the NavBus

Installatio n and Operation Manu al.

NMEA

NMEA is an industry standard for marine

instrument connec tions. The FUEL 3100 and

DIESEL 3200 :

• Can read speed data (RMC) from a

compatible NMEA GPS instrument (see

section 3-6)

• Transmit PTTKV, VHW, XDR, VLW .

Several Navman instruments can be connected

together to share data, either by using NavBus

or NMEA.

NavBus

NavBus is a Navman proprietary system that is

high speed and allows a wide range of data to

be shared by the instruments.

When instruments are connec ted by NavBus:

• Data from a sensor connected to one

instrument is available to all instrument s.

• If the units, alarms or calibration are

changed in one instrument, then the values

will automatically change in all instruments

of the same t ype.

• Each instrument can be assigned to a group

of instruments by setting a group number

between 0 and 4. Then, if the back light

is changed in an instrument in groups 1,

2, 3 or 4, it will automatically change in

all the other instruments in that group.

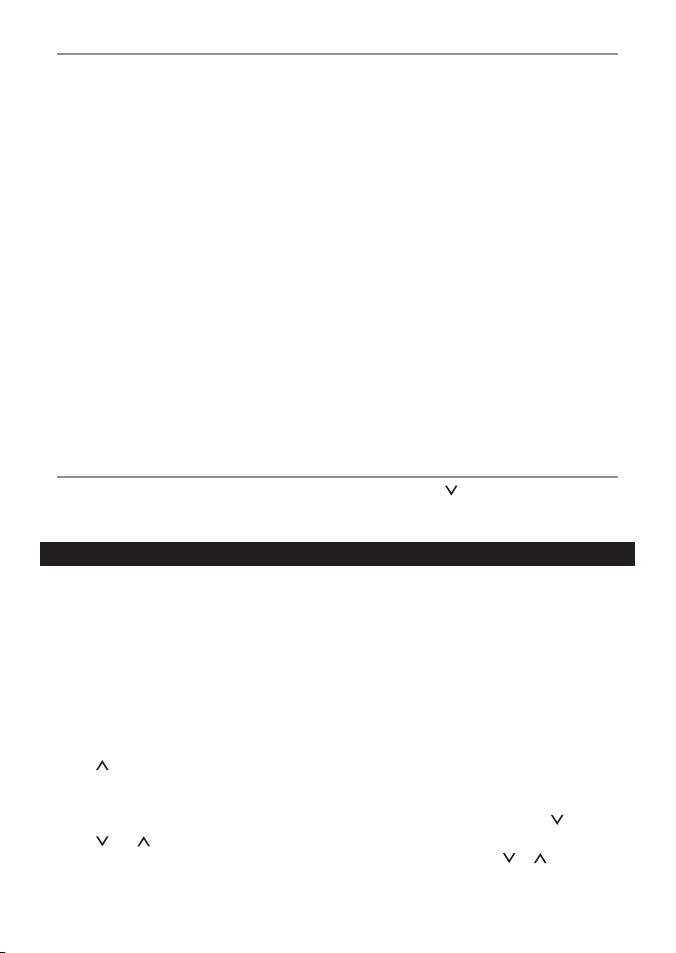

4-6 Systems of severa l instruments

Power/data cables

Junction box

Power and data

connections

Power/data cables

NavBus cable

Group 1

Group 2

A typical NavBus system

Power and data

connections

20

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

To check out the installation:

1 Power on the boat and any other

instruments. Check the instruments work

properly.

2 Enter the setup data (see section 3).

Set d UAL, motor , and InPUt first, then

enter the rest of the setup data.

For boats with t win tanks or twin engines,

remember to enter port and starboard data

separately where required.

3 Fill the fuel tank (s) and set the fuel in the

tank(s) in the FUEL 3100 or DIESEL 3200 (see

section 5).

4 On boats with twin engines, check the

installation of the port and starboard fuel

sensors:

• DIESEL 3200: Star t the port engine. Check

the LED lights under the sensors are

blinking. This indicates the sensors are

operating correc tly. Confirm the fuel flow is

being displayed as port engine fuel usage

on the instrument. (If it is being displayed

as starboard engine fuel usage, swap

over the fuel flow sensor connectors on

the ‘T’ connector.) Repeat the check with

starboard engine.

• FUEL 3100: Star t the port engine. Confirm

the fuel f low is being displayed as port

engine fuel usage on the instrument. If it is

being displayed as starboard engine fuel

usage, reconfigure the set tings (see section

3-3).

5 FUEL 3100 only: Calibrate the fuel sensor(s)

(see sec tion 3-4).

6 If a paddlewheel speed sensor is

connected, calibrate it (see sections 3-8

and 3-9).

7 Take the boat for a trial run and check the

unit is displaying the correct data.

FUEL 3100: Recalibrate the FUEL 3100’s fuel

sensor(s) after the first 100 engine hours (see

section 3-4).

When you add or remove fuel from a tank, you

must enter into the FUEL 3100 or DIESEL 3200

how much fuel you have added or removed.

Otherwise REMAINING, RA NGE and the low

fuel alarm will be meaningless. Twin tanks

connected by an open balance pipe should be

trated as a single fuel tank.

When you add or remove fuel from a tank:

a When you fill a tank

1 Fill the tank.

2 Press until REMAINING is displayed.

3 If the boat has twin tanks, press ENT until

the display shows the name of the tank you

have filled, PORT or STBD.

4 Press and together.

5 If the boat has twin tanks and you are filling

the other tank as well, repeat the ab ove

steps.

Note:

It is often very difficult to refill underfloor

fuel tanks to the same level twice, due to air

pockets. Because of this, owners of boats with

underfloor fuel tanks should:

• Ensure the boat is trimmed to sit at

the same angle in the water each time

procedure a above is followed.

• Mostly use procedure b below when filling

the tank, but use procedure a above about

every tenth fill.

b When you fill or part fill a tank

1 Before adding or removing fuel, press ESC

and ENT together, then press until the

FUEL setup menu is displayed.

2 Press ENT, then press or until the

FUEL data is displayed.

5 When you add or remove fuel

4-7 Testing the inst allation

4-8 Resetting to factor y defaults

To reset to factory defaults:

1 Turn the power off.

2 Hold ENT + while turning on the power

and for at least five seconds af ter.

21

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

6 Troubleshooting

This troubleshooting guide assumes that this

manual has been read and understood.

It is possible in many cases to solve difficulties

without having to send the unit back to the

manufac turer for repair. Please follow this

troubleshooting section before contacting the

nearest Navman dealer.

There are no user ser viceable parts. Specialized

methods and testing equipment are required

to ensure that the unit is reassembled correctly

and is waterproof. Repairs to the unit must only

be carried out by a ser vice centre approved by

Navman NZ Limited. Users who ser vice the unit

themselves will void the warranty.

More information can be found on our website:

www.navman.com

1 Instrument will not turn on:

a Power/data cable is damaged or

disconnected. Perform a visual check.

b Fuse is blown or circuit breaker has tripped.

Replace the fuse or reset the circuit breaker.

c Battery voltage is outside the range 9 to

30 V DC. Check the battery voltage using a

multimeter.

2 The word SIM flashes at bot tom left

corner o f screen, values displayed are

unexpected :

a The instrument is in simulation mode (see

section 2-9).

3 Fuel read ing is wrong or erratic:

a Check for leak s in the fuel line or in the fuel

pickup in the tank.

b Fuel sensor cable is unplugged or damaged.

Perform a visual check. DIESEL 3200: check

the LED light on the underneath of flow

sensor blinks when the engine draws fuel.

c The fuel R EMA INING reading is incorrect.

The fuel tank capacity (SIZE) may be

incorrect, or the fuel RE MAINING setting

may not have been updated after a refill.

See section 5.

d Sensors require calibration (see sec tion 3-4;

diesel sensors do not normally need to be

calibrated).

e The fuel flow sensor may have been

mounted too close to the fuel pump, or

may be subject to excessive vibration. Refer

to the installation instructions supplied

with the fuel sensor.

f The fuel f low sensor damping (dA mP.F)

value is not suitable for the engine. Check

that the value is not set to zero and then try

increasing the value until a steady flow rate

is shown (see section 3-5)

4 Speed reading is wrong or erratic:

a Speed readings require the optional speed

sensor to be installed and setup (see

section 3-6).

3 If the boat has twin tanks, press ENT. Then

press until the display shows the name of

the tank to be filled, PORT or STBD.

4 Write down the number displayed, FUEL,

which is the amount of fuel now in the tank.

5 Add fuel to the tank , writing down how

much you add.

6 Add together the two figures you have

written down, to calculate the amount of

fuel now in the tank. Press ENT. Then press

or hold to change FU EL to the amount

of fuel now in the tank.

7 Press ENT, then press ESC to return to the

main display.

8 If the boat has twin tanks and you are

adding fuel to the other tank as well, repeat

the above steps.

Note:

If you follow procedure b above ever y time you

add fuel, then a small error will accumulate,

because it is hard to measure exac tly how

much fuel you add. To avoid this, about every

ten tankfulls of fuel, fill the tank and follow

procedure a.

c When you remove fuel from a tank

Repeat the steps for procedure b above, but:

i This time subtract the fuel you have

removed from the original amount of fuel

in the tank to calculate the amount of fuel

now in the tank.

ii Press or hold to change FUEL to the

amount of fuel now in the tank.

22

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

b Speed sensor cable is unplugged or

damaged. Perform a visual check.

c Speed calibration is incorrect (see sections

3-8 and 3-9).

d Interference from electrical noise may be

affec ting the measurements. Review the

installation.

5 Low Fuel Alarm sounds when fuel not

low:

a The fuel REMAINING reading is incorrec t.

The fuel tank capacity (SIZE) may be

incorrect, or the fuel RE MAINING setting

may not have been updated after a refill.

See sections 2-6. and 5.

6 The display unit fogs:

a Moist air has entered the breathing tube at

the rear of the unit. Air the boat or run the

instrument with backlight fully on.

b Water has entered the breathing tube.

Return the instrument for ser vicing.

7. Flow indicates no fuel or low fuel

a FUEL 3100 : Check that the fuel cable

connectors are securely plugged in and

the collar is locked in place. The collar must

be locked in place to give a watertight

connection.

b A fuel sensor may be clogged. If so, remove

the sensor from the fuel line and gently

blow through it in the opposite direction to

the fuel f low. A fuel filter between the fuel

sensor and the fuel tank must be installed

as per the fuel installation guide. Failure to

do so will void the warranty.

c Inspect the fuel cable from end to end for

damage such as cuts, breaks, squashed or

trapped sections.

d Check that the fuel filter is clean.

8 Fuel used or remaining seem inaccurate:

a In rough seas, fuel may surge back and

forth through the fuel sensor, resulting in

incorrect readings. Try installing a one-way

valve bet ween the fuel sensor and the fuel

tank.

b The amount of fuel must b e reset after

every refuelling (see sec tion 5 ).

c The fuel tank may not ref ill to the same

capacit y each time due to air pockets. This

is particularly noticable with underfloor

tanks (see section 5).

d Petrol fuel sensors wear out over time and

should be replaced after every 500 0 litres

of fuel.

9 A twin engine installation shows only

one flow rate:

a Check that the number of engines is set to 2

(motor in the FUEL menu, see sec tion 3).

10 There is no reading for fuel economy:

a The boat must be travelling through the

water to generate an economy reading.

b If an optional paddlewheel sensor is fitted,

check that the paddlewheel spins freely.

23

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

Appendix A Specifications

Physical

• Case size 113 mm (4.4") square.

• LCD display 82 mm (3. 2") wide, 61 mm (2.4")

high; twisted nematic.

• LCD digits 30 mm (1.2" ) high on top line,

20 mm (0.8") high on bottom line.

• Four operator keys, laser etched.

• Backlighting for display and keys, amber,

four levels and off.

• Operating temperature 0 to 55°C (32 to

131°F).

• Power/data cable 1.1 m (3.25 ft).

Electrical

• Power supply 10.5 to 16.5 V DC, 30 mA

without backlighting, 80 mA with full

backlighting.

• External alarm : Output is switched to

ground to sound the alarm, 30 V DC and

250 mA maximum.

Fuel

Displays fuel used, fuel remaining, rate of

fuel flow and the fuel economy.

Range 0 to 9999 with resolution of 0.1 unit

for the first 999 units, thereafter resolution

of 1.0 unit.

Log

Displays trip log and total log.

• Range 0 to 9999 miles or nautical miles.

Engine Hours

• Displays 0.0 to 9999.

Engine RPM (DIESEL 3200 only)

• Displays 0 to 9999.

Speed (if optional speed sensor or input is

installed)

• Range 0 to 100 knots (0 to 115 mph).

• Speed resolution of 0.1 unit.

• Adjustable damping for speed and log

gives stable readings in all sea conditions

by averaging the readings. Damping values

available are: 1 (6 sec), 2 (12 sec), 3 (18 sec),

4 (24 sec) or 5 (30 sec).

Calibration

• Fuel sensors can be calibrated (diesel

flow sensors do not normally need to be

calibrated). Speed can also be calibrated if

the optional speed sensor is installed.

Interfaces

• NavBus connection to other Navman

instruments.

• NMEA 0183: Input: RMC.

Outputs: PTTK V, VHW, XDR, VLW

Standards compliance

• EMC compliance

USA (FCC):

Par t 15 Class B.

Europe(CE):

EN50081-1,EN50082-1, EN55024, EN55022,

ISO7637-1.

New Zealand and Australia (C Tick) :

AS-NZS 3548.

• Environment:

IP66 from front when correctly mounted on

the bulkhead.

Power / data cable

Wire Signal

Red Power positive, 12 V DC,

100 mA maximum

Black Ground/Shield (NMEA common)

Green External alarm, switched to

ground, 30 V DC and 250 mA max.

Orange NavBus +

Blue NavBus -

White NMEA output

Yellow NMEA input

24

FUEL 3100 / DIESEL 3200 Installation and Ope ration Manual

NAVMA N

What comes with your FUEL 3100?

Also: Warranty card, mounting template, this manual and the Fuel Sensor Installation Manual.

FUEL 310 0 options:

•

Additional FUEL 3100 display units to repeat the data. These do not require flow sensors.

•

FUEL 3100 twin engine upgrade kit.

B-2 DIESEL 3200

What comes with your DIESEL 3200?

Also: Warranty card, mounting template and

this manual.

DIESEL 3200 options:

•

Additional DIESEL 3200 display

units to repeat the data. These

do not require flow sensors.

•

A second diesel flow sensor

kit, for twin engines.

Appendix B Diesel fuel flow sensor hardware

DIESEL 3200

display unit

Protective cover

Diesel flow sensor kit, with two fuel sensors,

tachometer pickup, cables, two straight

through pipes, Diesel Fuel Flow Sensor

Installation and Operation Manual.

FUEL 3100 display unit Protective cover Fuel flow sensor and

cable,

8 m (26¼ ft)

Two stainless steel

clips

B-1 FUEL 3100

Loading...

Loading...