Murphy LM2000 User Manual

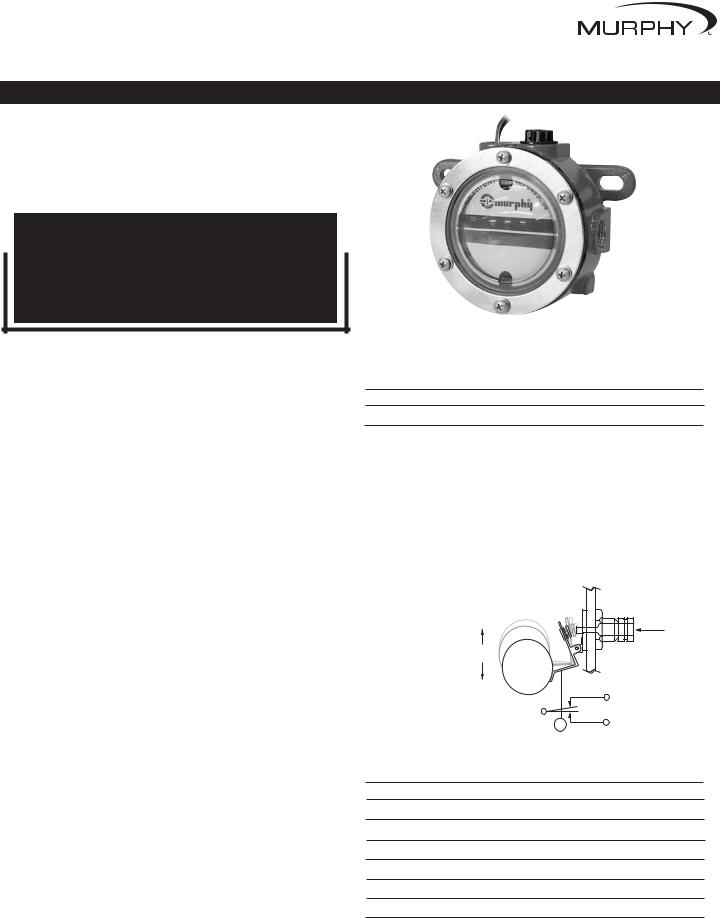

LM2000/LM2000S Lube Level Maintainer

Installation Instructions

LM-00011N

Revised 10-03

Section 15

(00-02-0423)

Please read the following information before installing. A visual inspection of this product for damage during shipping is recommended before mounting. CRANKCASE MUST BE DRAINED BEFORE INSTALLATION.

GENERAL INFORMATION

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

Disconnect all electrical power to the machine.

Make sure the machine cannot operate during installation.

Follow all safety warnings of the machine manufacturer.

Read and follow all installation instructions.

Description |

Optional Hose Kit: 15000355 |

The Murphy LM2000 model maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running-oil-level, the LM2000 will replenish oil as it is used. An integral, low-level switch will alarm and/or shutdown the equipment if supply oil is lost and the equipment continues to use oil.

Specifications

Crankcase Balance Vent Connection: 1/2 NPTF (top).

Inlet Connection: 1/2 NPTF with removable screen (side). Outlet Connection: LM2000 3/4 NPTF (bottom).

LM2000S 2 x 3/8 NPTF (side)

1 x 3/4 NPTF (bottom)

Thumb-ValveTM Material: Viton.

Snap-switch: SPDT rating 10 A, 125 VAC; 0.5 A, 125 VDC; 10 A, 30 VDC. Wire leads: 18 AWG x 24 in.(609 mm) length.

Conduit Connection: 1/2 inch conduit (female, top). Case: Die cast aluminum

Lens: Clear “Frog Eye” non-staining, high impact, high temperature nylon; UV and heat stabilized.

Dial: High visibility white background with green and white “index” lines for normal level indication.

Maximum Inlet Pressure: 9.50 psi/25 ft. oil (head pressure).

Maximum Case Pressure: 15 psi (103 kPa).

Maximum Differential: 2 in. (51 mm) between running and stopped.

Maximum Ambient Temperature: 250°F (121°C). Float: Brass

Flow Rates: SAE 40 motor oil @ 32°F (0°C) with 2 ft. head pressure: 0.5 GPH (1.9 LPH).

NOTE: Friction losses due to piping not considered.

Optional Vent Fittings Kit: 15000954

The 15000943 kit is sold separately. It includes the following items:

Quantity |

Description |

1 |

Tubing vent (15050202). |

1 |

1/4 x 1/4 NPT Connector (85030447). |

Quantity |

Description |

|

|

1 |

1/2 in. (13 mm) I.D. x 3 ft. (914 mm) long hose (89020202) |

11 in. (25 mm) I.D. x 3 ft. (914 mm) long hose (89020203)

21/2 in. (13 mm) worm gear clamp (00003502)

2 |

1 in. (25 mm) worm gear clamp (00003503) |

2 |

1/2 NPT x 1/2 in. (13 mm) barbed fitting (89080801) |

|

|

2 |

3/4 NPT x 1 in. (25 mm) barbed fitting (89081001) |

|

|

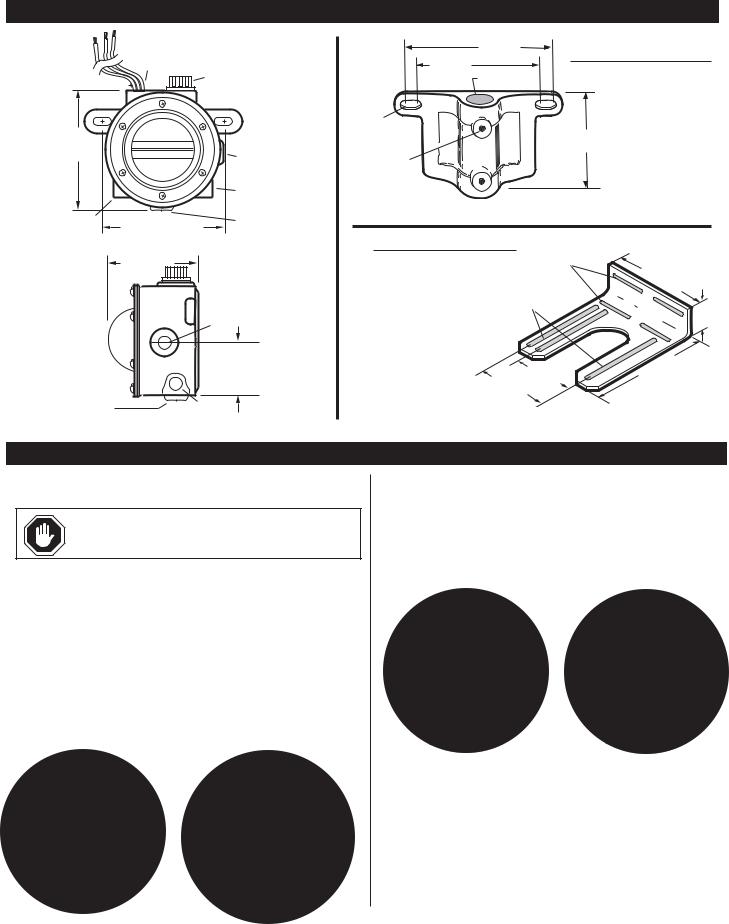

Thumb-Valve™ Operation

As the equipment uses oil, the float falls, providing immediate level compensation. At FULL position, the float holds the valve closed. If the clean oil supply is depleted and oil level continues to fall, the low level switch will operate an alarm or equipment shutdown.

Thumb-ValveTM and

Snap-switch |

Thumb-Valve™ |

||

FULL |

Oil Inlet |

||

Schematic |

|||

|

|

||

|

Float |

|

|

|

Action |

LM2000 |

|

|

|

||

|

|

Case |

|

|

LOW |

|

|

|

|

N.C. (red) |

|

|

COM. |

N.O. (black) |

|

|

(white) |

||

|

|

Low Level Switch |

|

Service Parts (Specify part number) |

|||

Description |

|

Part Number |

|

Vent Fittings Kit |

|

15000954 |

|

Hose Kit |

|

15000355 |

|

1/2NPT x 1/2 in. Hose Barbed Fitting |

89080801 |

||

3/4NPT x 1/2 in. Hose Barbed Fitting |

89081001 |

||

3/8NPTF x 1/2 in. Hose Barbed Fitting |

89080601 |

||

Pipe Bracket Kit |

|

15000238 |

|

Universal Flange Kit |

|

15010224 |

|

LM-00011N page 1 of 4

1/2 in. Electrical |

LM2000 |

Female Conduit |

|

Connection |

Crankcase |

|

Balance Vent |

|

1/2 NPTF |

4-5/8 in. |

|

(117 mm) |

Oil Inlet |

|

Connection |

|

1/2 NPTF |

|

3/8 NPTF |

|

LM2000S |

3/8 NPTF |

4-1/2 to 5-3/16 in. |

Oil Outlet |

|

LM2000S |

|||

Connection |

|||

(114 to 132 mm) |

|||

|

3/4 NPTF |

||

|

|

||

|

2-7/8 in. |

|

|

|

(73 mm) |

|

|

|

Oil Inlet |

||

|

Connection |

||

|

1/2 NPTF |

||

|

C |

2-1/4 in. |

|

|

L |

||

|

|

(57 mm) |

|

Oil Outlet |

|

|

|

Connection |

|

|

|

3/4 NPTF |

3/8 NPTF |

||

|

LM2000S |

||

DIMENSIONS

|

5-3/16 in. |

|

|

15000238 |

4-1/2 in. |

(132 mm) |

|

|

|

(114 mm) |

Hole 7/8 in. |

|

Pipe Bracket Kit |

|

|

(22 mm) dia. |

|

Additional Hardware |

|

|

|

|

Supplied |

|

|

|

|

(2) |

1/4-20 x 7/8 inch |

9/32 x 5/8 in. |

|

2-1/2 in. |

|

(22 mm) screws |

(7 x 16 mm) |

|

(2) 1/4-20 x 1 inch |

||

2 places |

|

(63.5 mm) |

||

1/4-20 NC |

|

|

|

(25 mm) screws |

|

|

(4) |

1/4-20 hex nuts |

|

2 places |

|

|

||

|

|

|

(4) |

1/4 inch (6 mm) dia. |

|

|

|

|

split washer |

15010224 |

|

|

|

|

Slot, 29/64 in. (14 mm) |

|||

Universal Flange Kit |

|

|

|

x 2-3/8 in. (60 mm) |

||||

Additional Hardware |

|

|

|

|

4 places |

|||

|

Slot, 29/64 in. (14 mm) |

|||||||

Supplied |

|

|||||||

(2) |

1/4-20 x 1/4 inch |

|

x 4-3/8 in. (111 mm) |

|||||

|

3 places |

|

|

|||||

|

(32 mm) bolts |

|

|

|

||||

|

|

|

|

|

|

|

|

|

(4) |

1/4 inch dia. flat washer |

|

|

|

|

|

|

|

(2) |

1/4-20 hex nuts |

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

(2) |

5/16-18 x 1/4 inch |

|

- |

|

|

- |

|

|

|

(114 |

1/2 |

|

|||||

|

|

|

5 |

|

|

|

in. |

|

|

|

(1323/16 |

|

|

|

|||

(32 mm) bolts |

in. |

mm) |

||||||

(4) |

5/16 dia. flat washer |

|

mm) |

|

|

|

||

|

|

|

|

|

|

|

||

(2) |

5/16-18 hex nuts |

|

|

|

|

|

|

|

6 |

|

|

|

|

- |

|

|

||

|

11/1 |

6 |

|

|

(170 |

|

|

||

|

|

mm) |

in. |

|

|

|

|

|

|

|

in |

. |

1 |

-3/4 |

|

mm) |

||

(44 |

|

|

. inmm) -1/2 7(191

TYPICAL INSTALLATION

Mounting the LM2000

NOTE: Mount the LM2000 as close as possible to the crankcase.

CAUTION: Excessive vibration can cause overfill. Be sure mounting brackets are supported.

The following instructions are based on the usage of the pipe and universal mounting brackets shown above.

Pipe Bracket Mounting (15000238)

1.Mount a nominal 1/2 inch (13 mm) diameter pipe to the base of the engine.

2.Install the pipe bracket to the LM2000 using two 1/4-20 UNC x 1 inch bolts, nuts and lock washers supplied. See Figure 1A.

3.Slip the LM2000 onto the pipe and install the two adjustment bolts. Each bolt consists of a 1/4-20 UNC x 1 in. bolt, nuts and lock washers. See Figure 1B. DO NOT tighten the adjustment screws too tightly because you will have to adjust the LM2000 later in the installation process.

Lock Washer |

|

|

|

|

|

|

|

|

|

|

||||||

Pipe |

|

|||||||||||||||

and Nut |

|

|

|

|

|

|

Bracket |

|

||||||||

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bolt |

Adjustment |

|

Bolts |

LM2000 |

Crankcase |

|

Pipe |

Figure 1A

Figure 1B

Mounting with Universal Bracket (15000370)

The universal bracket has two mounting methods: base mounting or pan mounting.

Base Mounting

1. Install the universal bracket to the base as shown in Figure 2A using two flat washers and two 5/16 inch dia. bolts or others as necessary.

Crankcase |

Lock Washer |

||

and Nut |

Flat |

||

Universal |

|||

|

Washer |

||

Bracket |

|

||

|

|

||

|

|

Adjustment |

|

Base |

|

Bolts |

|

|

|

||

Threaded |

|

|

|

hole |

|

|

|

Figure 2A |

|

Figure 2B |

|

2.Mount the LM2000 to the universal bracket using two 1/4-20 UNC x 1- 1/4 inch (32 mm) bolts, nuts and lock washers supplied (Figure 2B). DO NOT tighten the adjustment screws too tightly. You will have to adjust the LM2000 later in the installation process.

LM-00011N page 2 of 4

Loading...

Loading...