Mitsubishi Electronics FR-A800, F800 User Manual

INVERTER

FR-A800/F800

Safety Stop Function Instruction Manual

|

CONTENTS |

|

1. |

GENERAL DESCRIPTION ............................................ |

2 |

2. |

INSTALLATION AND WIRING...................................... |

3 |

3. |

EXAMPLE OF SAFETY SYSTEM CONFIGURATION .... 7 |

|

4. |

TEST AND CHECKING FAILURE ............................... |

10 |

5. |

SAFETY PARAMETERS OF FR-A800/F800 ................ |

11 |

Compliance with the EU Machinery Directive – Functional Safety

WARNING

WARNING

Any misuse of safety function could lead to personal injury or death, property damage, or economic loss. To ensure that the system complies fully with requirement of safety, make a system-level risk assessment. Mitsubishi Electric Co. cannot assume responsibility for any system to comply with safety directive.

CAUTION

CAUTION

The information of this manual is merely a guide for proper installation.

Mitsubishi Electric Co. cannot assume responsibility for the compliance or the noncompliance to any code, national, local or otherwise for the proper installation of this equipment.

A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

WARNING

WARNING

To avoid an electric shock hazard, verify that the voltage on the bus capacitors has discharged before performing any work on the drive. Measure the DC bus voltage at the P(+) and N(-) terminals or test points (refer to your drive’s User Manual for locations and discharging time). The voltage must be zero.

WARNING

WARNING

The safety stop function do not isolate electrically between drive and motor. To avoid an electric shock hazard, disconnect/isolate power to the drive and verify to ensure that the voltage is zero before performing any work on the motor (refer to your drive’s User Manual for discharging time).

1

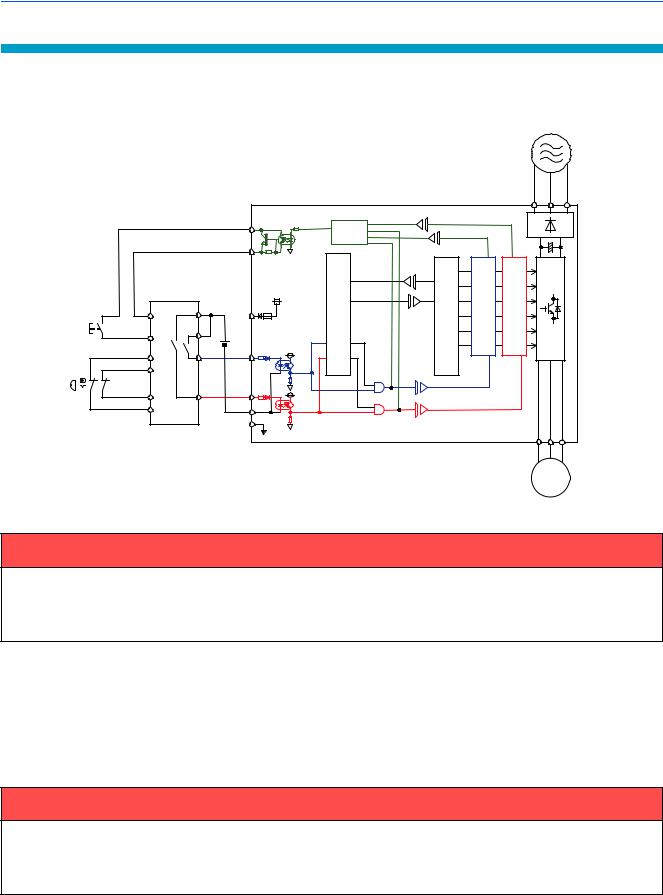

1 GENERAL DESCRIPTION

Features

Mitsubishi FR-A800/F800 safety stop function prevents a drive from supplying rotational energy to motors. Dual safety channels ‘S1’ and ‘S2’ cut off the gate-drive power for IGBT to turn off.

|

|

|

FR-A800/F800 |

|

R/L1 S/L2 T/L3 |

|

|

|

|

|

|

|

SO |

Logic |

|

|

|

|

|

|

|

|

|

|

SOC |

|

|

|

|

|

|

+24V |

|

|

IGBTs |

|

|

|

|

|

|

|

PC |

Fuse |

ASIC |

Gate |

Gate |

|

|

CPU |

Driver |

Driver |

|

|

|

|

|

|

|

RESET |

24VDC |

|

|

|

|

|

|

|

|

|

|

|

S2 |

|

|

G |

G |

Emergency |

S1 |

|

|

|

|

|

|

|

|

|

|

stop button |

SIC |

|

|

|

|

|

SD |

|

|

|

|

|

Safety relay module |

|

|

|

|

|

/ Safety programmable controller |

|

|

|

U V W |

|

|

|

|

|

|

|

|

|

|

|

M |

Fig.1 FR-A800/F800 safety stop function diagram

WARNING

WARNING

Disconnecting the power to the gate driver by the safety stop function does not isolate electrically between drive and motor. To avoid an electric shock hazard, disconnect power to the drive and verify that the main circuit capacitor voltage is zero (across P and N terminals) before performing any work on the motor (refer to your drive’s User Manual for discharging time).

Standards

Mitsubishi FR-A800/F800 safety stop function meets the following directives and categories.

ISO13849-1:2008 Category 3/PLd

IEC62061:2005 / IEC61800-5-2:2007 / IEC61508 SIL2 IEC60204-1:2010 / IEC61800-5-2:2007 Stop category 0

WARNING

WARNING

The misuse of safety function leads to personal injury or death, property damage, or economic loss. To ensure that the system complies fully with requirement of safety, make a system-level risk assessment. Mitsubishi Electric Co. cannot assume responsibility for any system to comply with safety directive.

2 |

|

GENERAL DESCRIPTION |

|

2 INSTALLATION AND WIRING

CAUTION

CAUTION

The following information is merely a guide for proper installation.

Mitsubishi Electric Co. cannot assume responsibility for the compliance or the noncompliance to any code, national, local or otherwise for the proper installation of this equipment.

A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

CAUTION

CAUTION

Ensure the safety relay unit and the FR-A800/F800 unit is mounted closely in enclosure meeting IP54 and all interconnection wiring is short and protected against open and short circuit faults. Refer ISO/ IEC13849-2.

Installation

Mitsubishi FR-A800/F800 safety stop function should be used under following condition and environment.

Table.1 The condition and environment for using safety stop function

Item |

Condition |

|

Surrounding air |

LD, ND, HD |

-10ºC to +50ºC (non-freezing) |

temperature |

SLD |

-10ºC to +40ºC (non-freezing) |

|

|

|

Storage temperature |

-20ºC to +65ºC |

|

|

|

|

|

|

With circuit board coating (conforming to IEC60721-3-3 3C2/3S2): 95% RH or |

Ambient humidity |

|

less (non-condensing), |

|

|

Without circuit board coating: 90% RH or less (non-condensing) |

|

|

|

Vibration |

|

5.9m/s2 or less at 10 to 55Hz (directions of X, Y, Z axes) |

Altitude |

|

Maximum 2500 above sea level |

|

|

|

Atmosphere |

|

Indoors (free from corrosive gas, flammable gas, oil mist, dust and dirt) |

|

|

|

Over voltage category |

III or less |

|

|

|

|

Pollution degree |

|

II or less |

|

|

|

Mounting |

|

Wall mounting / vertical orientation |

|

|

|

The ND and HD ratings can be selected only for the FR-A800.Temperature applicable for a short time, e.g. in transit.

For the installation at an altitude above 1,000 m (3280.80 feet) up to 2,500 m (8202 feet), derate the rated current 3% per 500 m (1640.40 feet).

INSTALLATION AND WIRING |

|

3 |

|

CAUTION

CAUTION

In order to meet safety stop, an approved safety relay unit to ISO13849-1 safety category 3 or better shall be used in conjunction with FR-A800/F800 as shown in example. In addition, all other components with in the safety stop loop shall be ‘safety approved’ types.

WARNING

WARNING

To avoid an electric shock hazard, insert the magnetic contactor (MC) between power source and drive.

Open the contact of MC and keep away from drive for discharging time (refer to your drive’s User Manual for information) before performing any work on the drive. And verify that the voltage on the bus capacitors has discharged before Measuring the DC bus voltage at the P(+) and N(-) terminals or test points (refer to your drive’s User Manual for locations). The voltage must be zero.

CAUTION

CAUTION

To avoid systematic faults, a test even for faulty demands of the safety function has to be performed in order to check the correct function of the monitor signal. This test shall be carried out at system installation, any software changes, parameterization changes, and/or at least once per year. Refer to ‘4. Test and checking failure’.

●Wiring

The safety related terminals are described in Table.2 and Table.3

Table.2 The safety related terminals

Terminal |

Description |

Rating |

|

symbol |

|||

|

|

||

|

For input of safety stop channel 1. |

|

|

S1 |

S1-SIC is |

|

|

OFF: In safety stop mode. |

|

||

|

Input resistance: 4.7kΩ |

||

|

ON: Non safety stop mode. |

||

|

Input current : 4 to 6 mADC |

||

|

|

||

|

For input of safety stop channel 2. |

||

|

(In case of 24VDC input) |

||

|

S2-SIC is |

||

S2 |

|

||

OFF: In safety stop mode. |

|

||

|

|

||

|

ON: Non safety stop mode. |

|

|

|

|

|

|

SIC |

Common terminal for S1 terminal and S2 terminal. |

|

|

|

|

|

|

|

As output for failure detection and alarm. SO terminal type is |

|

|

|

‘Open collector output’. |

|

|

|

SO-SOC is |

|

|

SO |

OFF: Detect failure or alarm. |

Load: 24VDC/0.1A max. |

|

ON: No failure detected. |

Voltage drop: 3.4V max. |

||

|

Note: This terminal cannot be used to output safety outputs in a |

(In case of ‘ON’ state) |

|

|

|

||

|

safety system. This terminal can be used for alarm or to |

|

|

|

prevent restart only, no other safety function. |

|

|

|

|

|

|

SOC |

Common terminal for SO terminal. |

|

|

|

|

|

Specifications for conforming safety standards.

ON: The transistor is conducted. OFF: The transistor is not conducted.

4 |

|

INSTALLATION AND WIRING |

|

Loading...

Loading...