Minolta EDH-5, C-403, C-404, FN-7, FN-115 Service Manual

...

EDH-5

C-403/C-404

FN-7/FN-115

Cover Inserter C

PK-3

ZK-2

TMG-2

Option

Service Manual

Dual references may be used on the following:

Official Options name : Popular Options name

EDH-5 : RADF

C-403/C-404 : LT and LCT

FN-115 : FNS

FN-7 : FNS

Cover Inserte Cr : PI

PK-3 : PU

TMG-2 TU

ZK-2 : PZ

In-System Writer : ISW

RADF

EDH-5

RADF

Refer to the Di850 service manual on page.......... S-1

SAFETY AND IMPORTANT WARNING ITEMS

EDH-5

CONTENTS

RADF

1. OUTLINE

PRODUCT SPECIFICATIONS..................................1-1

CENTER CROSS-SECTIONAL DRAWING..............1-2

DRIVE SYSTEM DIAGRAM ......................................1-3

ORIGINAL CONVEYANCE PROCESS.....................1-4

[1] Single side original copy mode (large) .......1-5

[2] Single side original copy mode (small).......1-6

[3] Double side original copy mode (large)......1-7

[4] Double side original copy mode (small) .....1-8

[5] Mixed original copy mode...........................1-9

2. UNIT EXPLANATION

EXTERNAL SECTION...............................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

ORIGINAL FEED/CONVEYANCE/EXIT SECTION...2-2

[1] Composition ...............................................2-2

[2] Mechanisms ...............................................2-2

[3] Original Fe ed/Conveyance/Scan Control ...2-4

[4] Original Reversal and Conveyance

Control........................................................2-7

[5] Original Exit Control ...................................2-9

[6] Original Size Detection Control ................2-11

RADF

1

RADF

OUTLINE

RADF

EDH-5

1-1

RADF

PRODUCT SPECIFICATIONS

[1] Type

Type

Sheet-through type reversible DF

[2] Functions

Original size:

• Metric area

A3 / B4 / A4 / A4R / B5 / B5R / A5 / A5R

11 x 17 / 8.5 x 14 / F4

• Inch area

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R /

5.5 x 8.5 / 5.5 x 8.5R

A3 / B4 / A4 / B5 / B5R

• All sizes are detected automatically.

• Mixing of original sizes possible.

Original type:

Plain original

50 to 200 g/m

2

or 14 to 45 lbs high quality

paper.

Special original

Original feed and conveyance ability may be

inferior to those of 50 to 130 g/m

2

or 14 to 35

lbs high quality original.

Only SDF mode single-sided passage allowed

for 131 to 200 g/m2 or 35 to 45 lbs thick origi-

nal.

The following types of original cannot be used:

• OHP film

• Blueprint masters

• Label original

•Offset masters

• Bonded originals

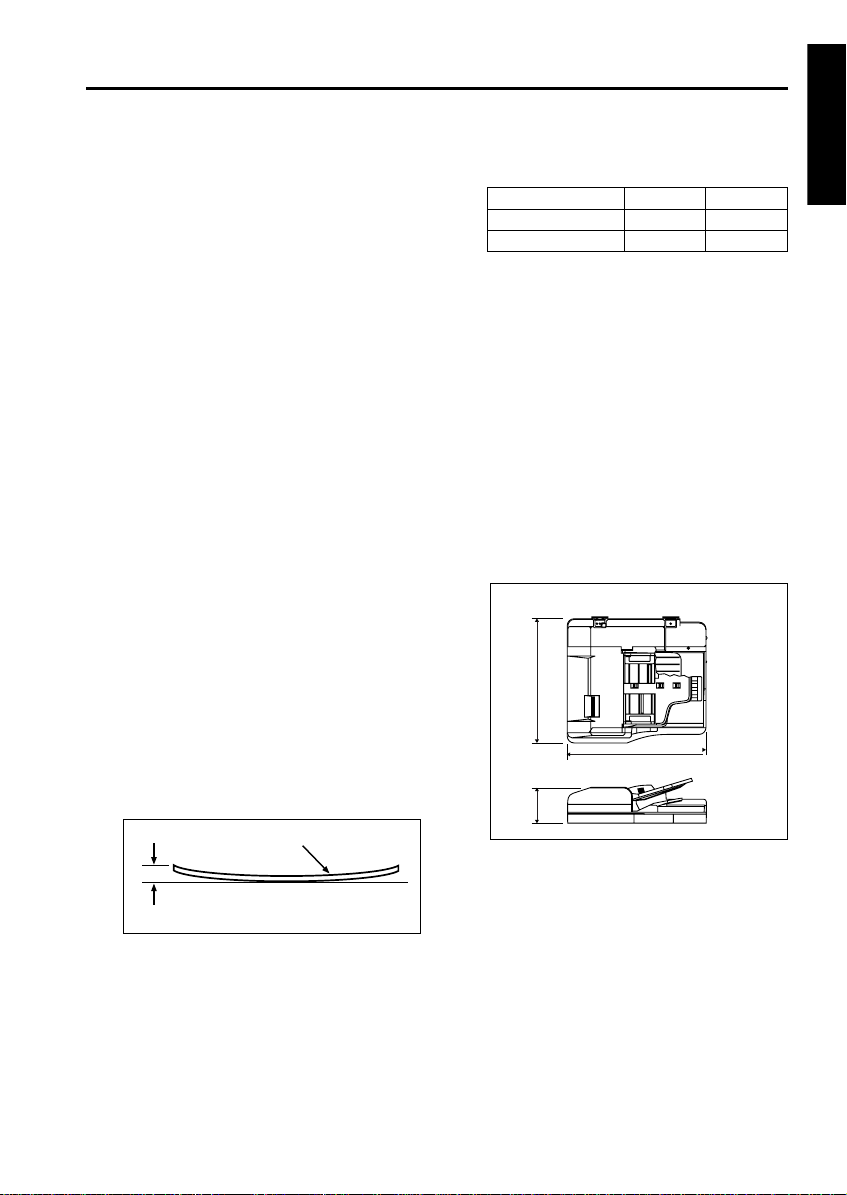

Original curling:

10 mm maximum

Maximum number of stacked originals:

100 sheets maximum (80 g/m

2

or 22 lbs)

Original read speed (copies per minute,

600dpi):

Original feed layout:

Face-up placement, centered, U-turn feed/

straight eject (large size/small size indepen-

dent eject), reversal section placed at ejection

side.

Original image read position:

At the slit glass section

[3] Machine Data

Power source:

DC24 V / 5 V (supplied from the main unit)

Max. power consumption:

Less than 180 VA

Weigh t:

Approx. 21.5 kg

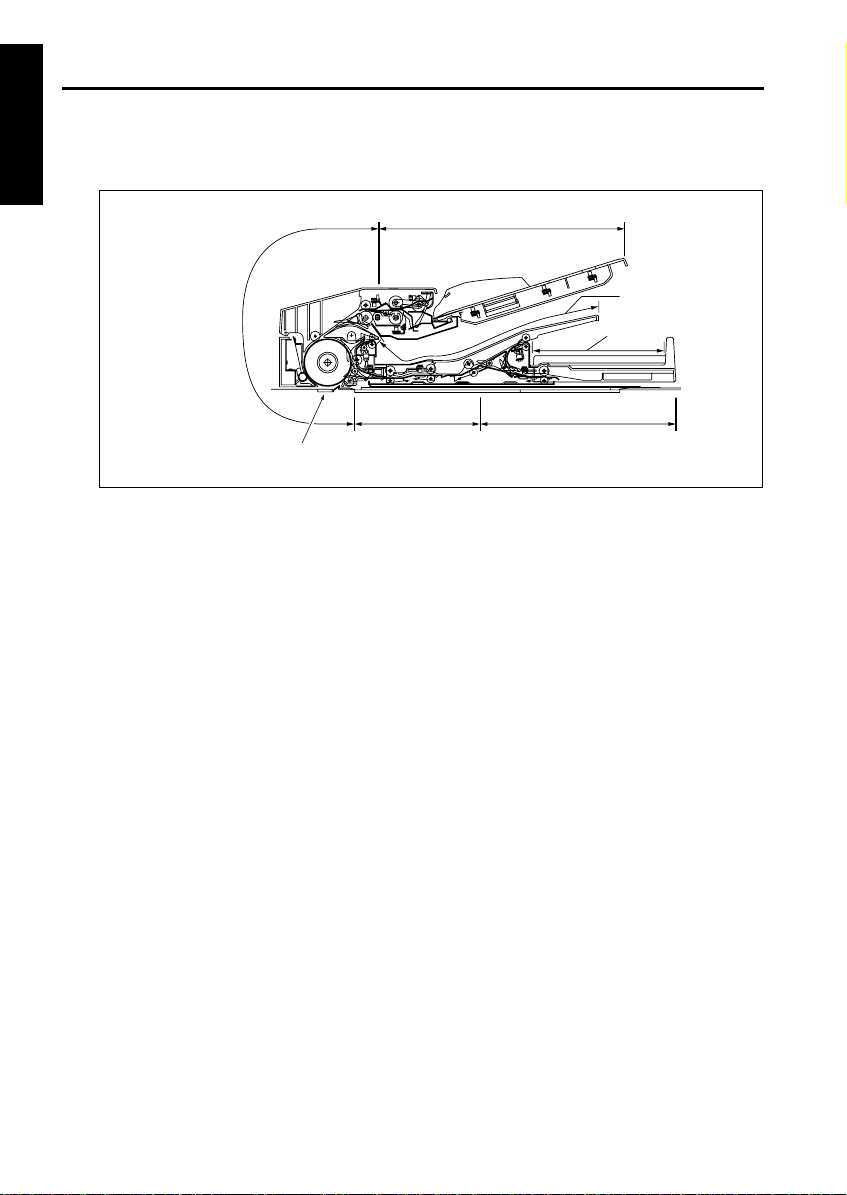

Machine dimensions:

[4] Maintenance

Maintenance : Same as the main body

Service life : Same as the main body

[5] Operating Environment

Temperature:

10 to 30 °C (50 to 86 °F)

Humidity:

10 to 80 % RH

Note: The information herein may be subject to

change for improvement without notice.

Amount of curl

Original

Mode Original size Feed speed

Single sided original A4/8.5x11 85

Double sided original A4/8.5x11 58

Unit: mm

570

170

650

EDH-5

1-2

RADF

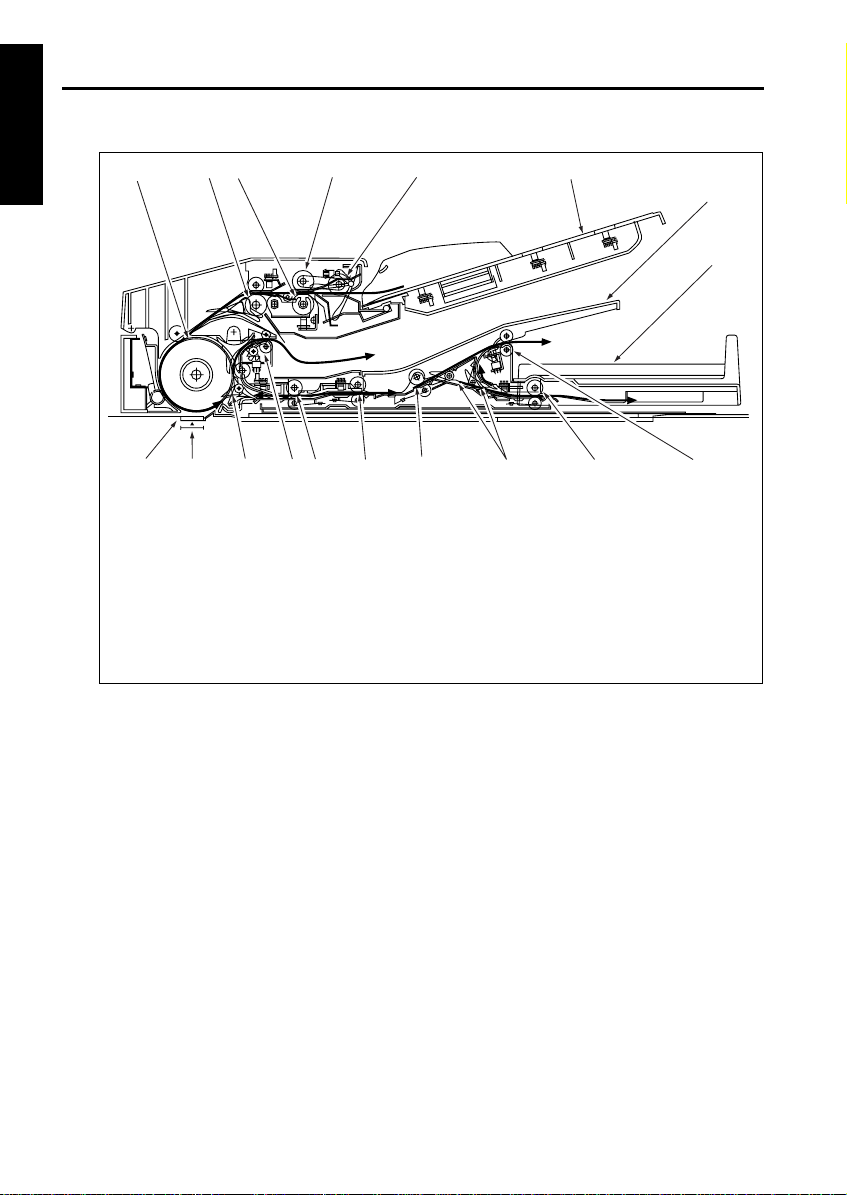

CENTER CROSS-SECTIONAL DRAWING

2

1

12

6

7

5

3

8

9

10

11

18

17

13

14

16

15

4

1. Original conveyance roller

2. Registration roller

3. Double feed prevention roller

4. Separation roller

5. Original feed roller

6. Original feed tray

7. Original exit tray (for large-size original)

8. Original exit section (for small-size original)

9. Original exit roller 2

10. Original exit reversal roller

11. Original exit gate

12. Reversal conveyance roller 2

13. Reversal conveyance roller 1

14. Reversal roller

15. Original exit roller 1

16. Flapper

17. Read position

18. Slit glass

EDH-5

1-3

RADF

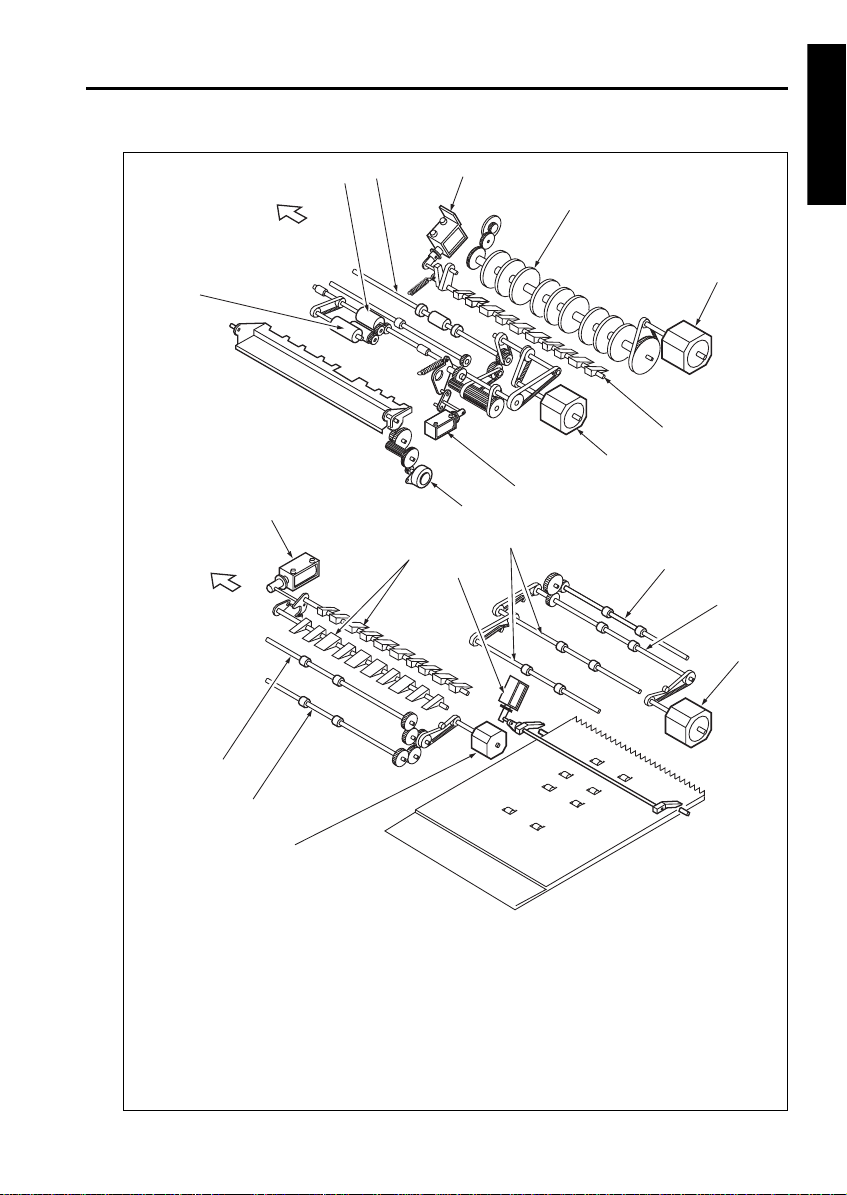

DRIVE SYSTEM DIAGRAM

2

1

12

6

7

5

3

8

9

20

10

11

19

18

17

13

14

16

15

4

1. Separation roller

2. Registration roller

3. Flapper drive SD (SD 301)

4. Original conveyance roller

5. Original conveyance motor (M301)

6. Flapper

7. Original feed motor (M302)

8. SDF switching SD (SD304)

9. Tray up/down drive motor (M303)

10. Original feed roller

11. Original exit gate SD (SD303)

12. Original exit gate

13. Pressure roller release SD (SD302)

14. Reversal conveyance roller

15. Original exit roller 1

16. Reversal roller

17. Original exit motor 1 (M304)

18. Original exit motor 2 (M305)

19. Original exit reversal roller

20. Original exit roller 2

FRONT

FRONT

EDH-5

1-4

RADF

ORIGINAL CONVEYANCE PROCESS

The RADF consists of a original feed section, conveyance section, reversal section, original exit reversal sec-

tion, original exit tray (large), and original exit tray (small).

The original placed faced up on the original feed

tray is fed from the topmost original. The fed orig-

inal is not conveyed to the original glass. Instead,

it is read when it passes the slit glass placed in

the conveyance path.

The RADF operation consists of (a) single side

original copy mode, (b) double side original copy

mode, (c) mixed original copy mode and Z fold

mode. Each has a different conveyance path.

The conveyance path also depends on the orig-

inal size.

Original feed section

Reversal section

Original exit tray

Slit glass (Read section)

Conveyance section

Original exit tray (small)

Original exit reversal section

EDH-5

1-5

RADF

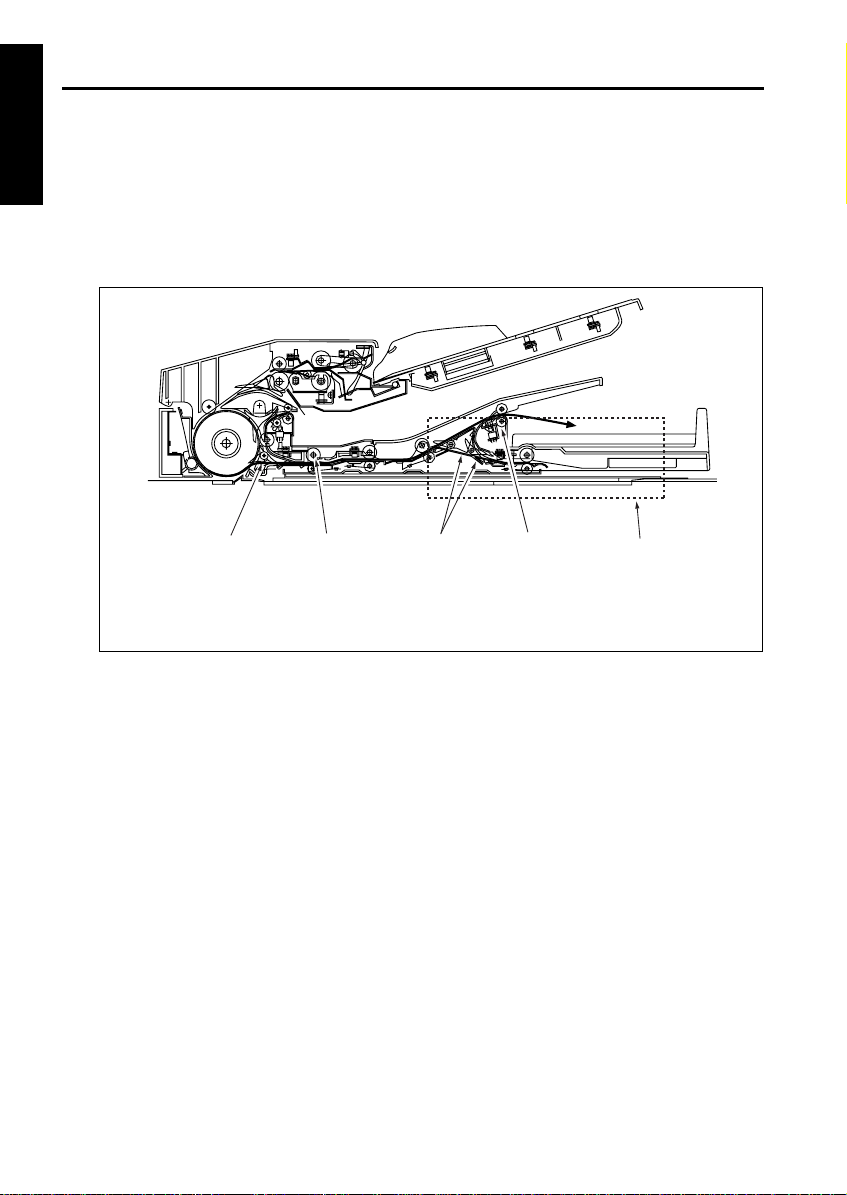

[1] Single side original copy mode (latge)

(single side to single side copy, single side to

double side copy)

The original set in the original feed tray is fed by

the original feed roller and separation roller until

PS306 (original registration detection) turns on.

When PS306 turns on, the registration roller pre-

feeds the original and original is rapidly conveyed

to the conveyance roller. The speed of the con-

veyance roller changes to scan speed at pre-

defined interval after PS306 turns ON and feeds

the original over the slit glass.

At this point, if the next original is present, it is

pre-fed as soon as PS306 detects its leading

edge.

The original is read when it passes over the slit

glass. The original that has been read is con-

veyed along the circumference of the convey-

ance roller by the opening of the flapper, goes

through original exit roller 1, and is exited to the

original exit tray (large).

2

1

3

4

1. Original registration detection PS (PS306

)

2. Separation roller

3. Original feed roller

4. Registration roller

2

1

3

4

1. Original conveyance detection PS (PS308

)

2. Registration roller

3. Original conveyance roller

4. Slit glass

2

1

3

4

1. Next original

2. Original exit roller 1

3. Flapper

4. Slit glass

EDH-5

1-6

RADF

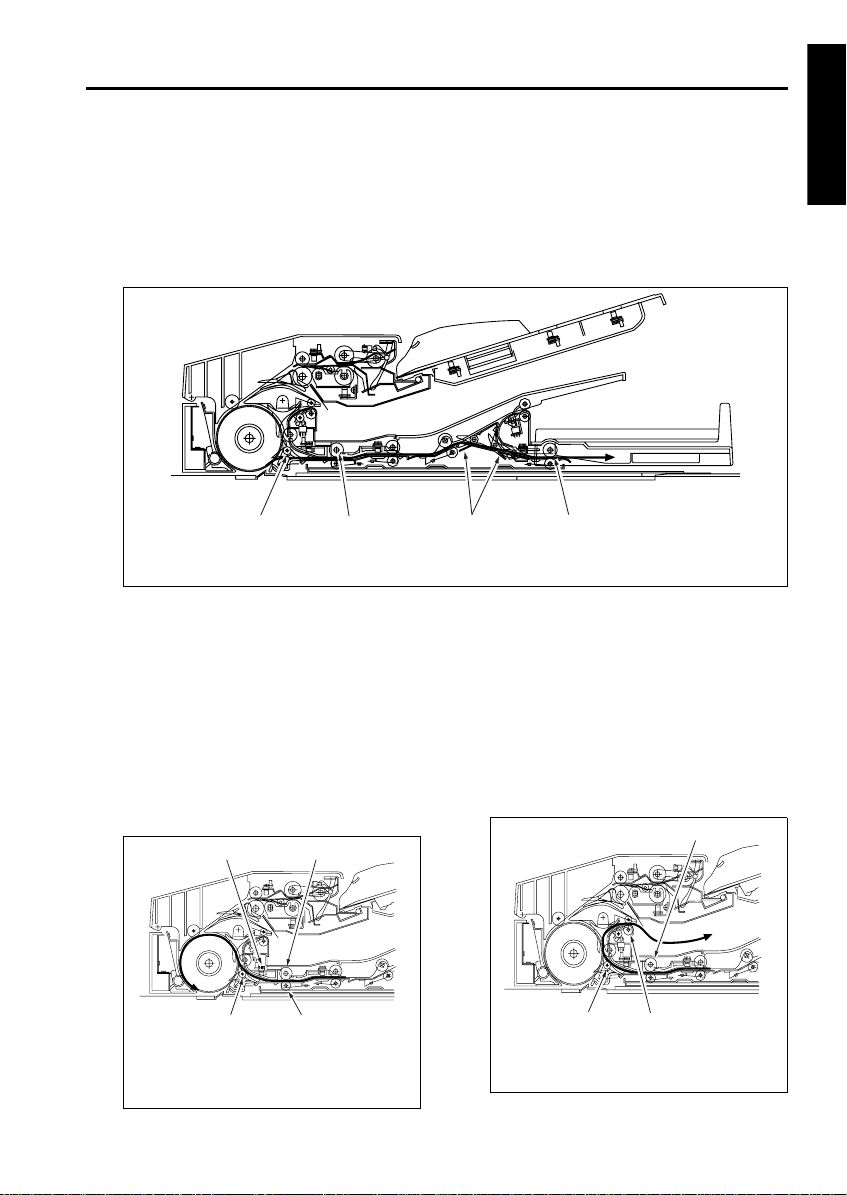

[2] Single side original copy mode (small)

(single side to single side copy, single side to double side copy)

The original feed and conveyance actions up to scanning are performed in the same manner as for single

side original copy mode (large). The original that has been scanned is fed to the original reversal unit by the

reversal roller because the flapper is closed and the paper exit path is blocked. The original fed to the reversal

unit passes through the original exit roller 2 and is exited to the original exit tray (small) since the original exit

gate is closed.

2

1

3

4

Original reversal section

1. Original exit roller 2

2. Original exit gate

3. Reversal roller

4. Flapper

EDH-5

1-7

RADF

[3] Double side original copy mode (large)

(double side to single side copy, double side to double side copy)

The original conveyance action up to the start of scanning of the front side of the first double side original is

the same as for single side original copy mode (large). The original that has been scanned and read on the

front side is fed by the reversal roller to the reversal unit since the flapper is closed and the original exit path

is blocked. The original fed to the reversal unit does not fit in the reversal unit so the original exit gate opens

to feed it to the original exit reversal section.

When the original reversal detection PS (PS309)

detects the trailing edge of the original and turns

off, the reversal roller changes direction and

feeds the original in the reversal section to the

conveyance roller. Since the original is passed

over the surface of the flapper, it is sent to the

conveyance roller with sides reversed. The orig-

inal reaching the conveyance roller does not exit

the reversal roller so the pressure roller is

released. The conveyance roller feeds this orig-

inal over the slit glass for scanning.

The original that has completed scanning of the

back side is fed inside the reversal unit once

again since the flapper is closed. When PS309

detects the trailing edge of the original and turns

off, the reversal roller changes direction and

feeds the original in the reversal unit to the con-

veyance roller. Since the flapper is now opened,

the original is fed along the flapper, passes

through original exit roller 1, and is exited to the

original exit tray (large).

2

1

3

4

1. Original exit reversal roller

2. Original exit gate

3. Reversal roller

4. Flapper

2

1

3

4

1. Original reversal detection PS (PS309)

2. Reversal roller

3. Pressure roller

4. Flapper

2

1

3

1. Reversal roller

2. Original exit roller 1

3. Flapper

EDH-5

1-8

RADF

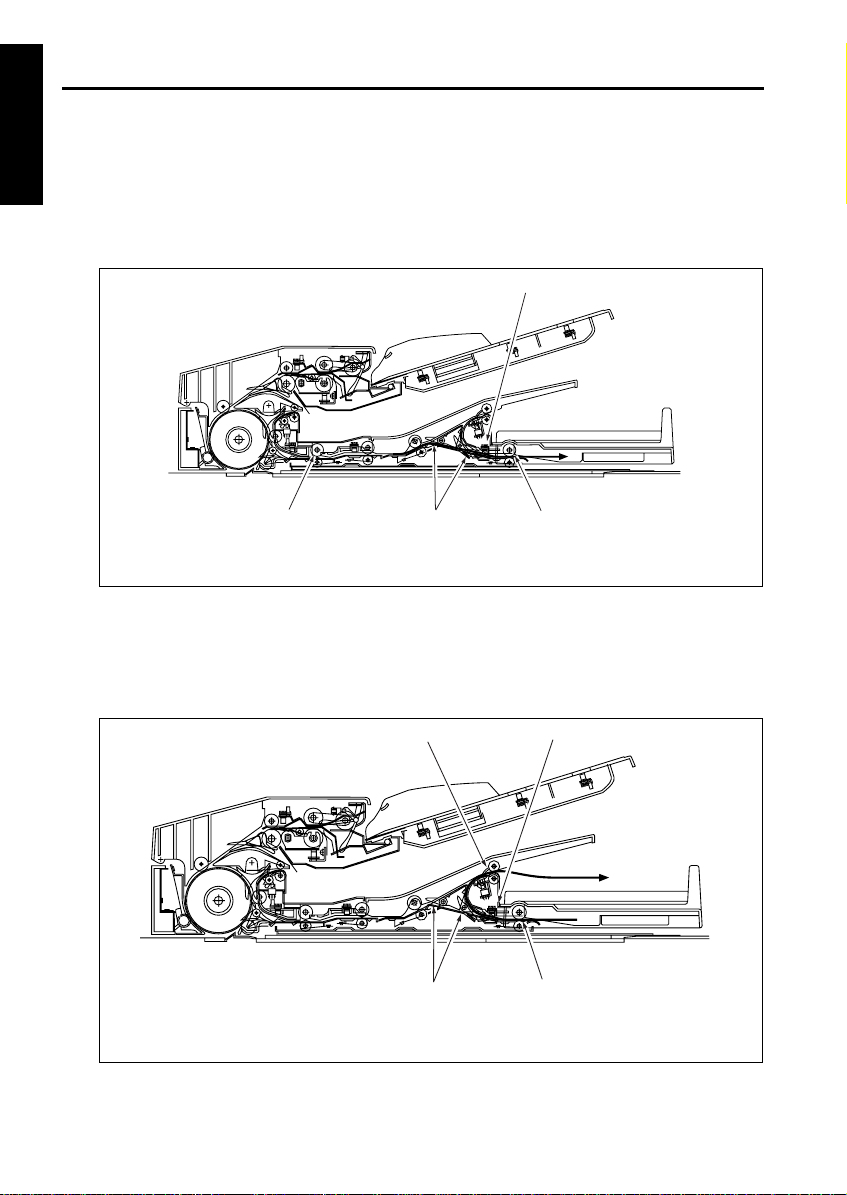

[4] Double side original copy mode (small)

(double side to single side copy, double side to double side copy)

The original conveyance action up to the start of scanning of the back side is the same as double side original

copy mode (large). The original that has been scanned and read on the back side is fed by the reversal roller

to the reversal section since the flapper is closed and the original exit path is blocked. Then the original exit

gate opens and the original is fed to the original exit reversal section.

When PS313 (original exit reverse detection) detects the trailing edge of the original and turns off, the original

exit reversal roller changes direction and feeds the original to the original exit gate. Since the original exit

gate is closed, the original passes over the original exit gate and is exited from the original exit roller 2 to the

original exit section (small) with sides reversed.

2

1

3

4

1. Original exit reverse detection PS (PS313)

2. Original exit reversal roller

3. Original exit gate

4. Reversal roller

2

1

3

4

1. Original exit roller 2

2. Original exit reverse detection PS (PS313)

3. Original exit reversal roller

4. Original exit gate

EDH-5

1-9

RADF

[5] Mixed original copy mode

The mixed original copy mode supports both the

same series originals and different series origi-

nals. However, since the size of the original in the

conveyance direction is determined by the ON

interval of PS306, size detection is performed

prior to scanning.

The subsequent operations are the same as

other copy modes.

For details on size detection, refer to section [6]

Original Size Detection Control in section 2.

UNIT EXPLANATION.

RADF

2

RADF

UNIT EXPLANATION

RADF

EDH-5

2-1

RADF

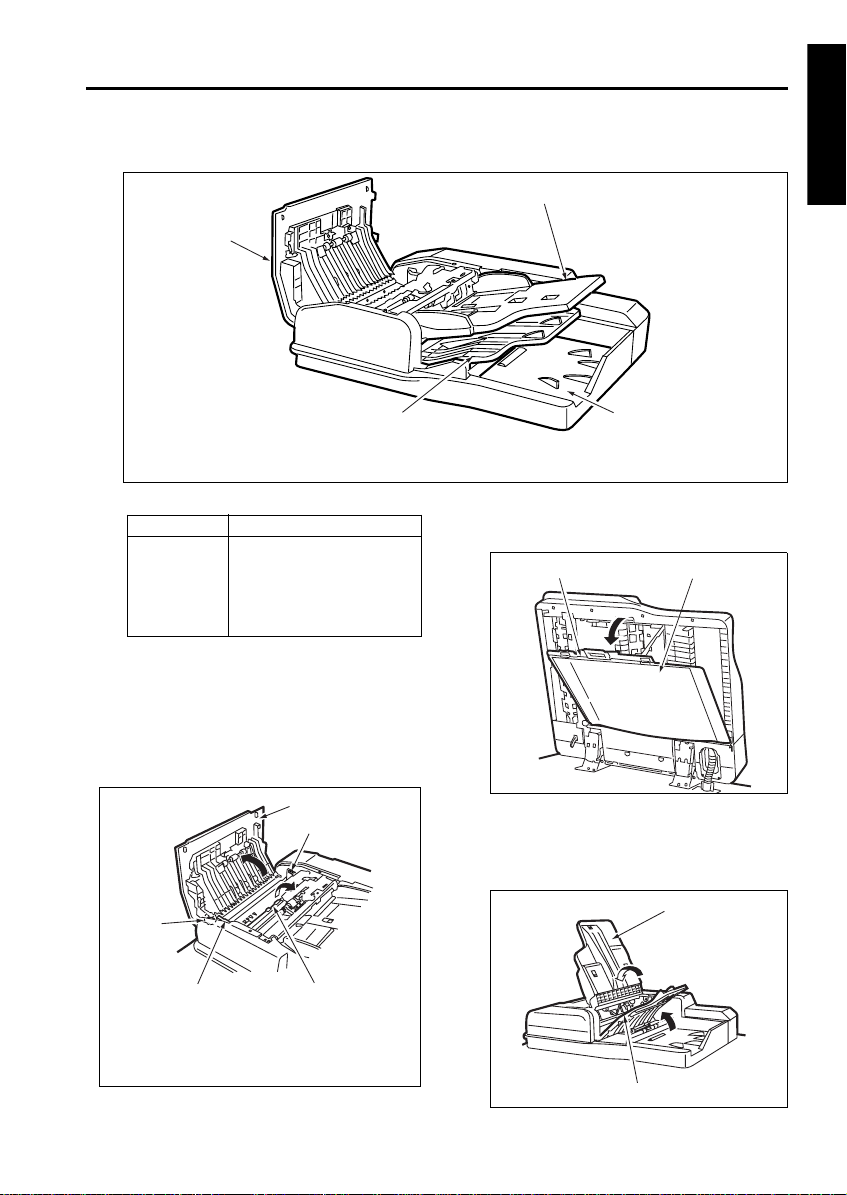

EXTERNAL SECTION

[1] Composition

[2] Mechanism

*1 Jam removal

If an original jam occurs during original feed,

open the Jam access cover and the original con-

veyance guide by releasing the original convey-

ance guide open/close lever, then turn the

jammed original release knob to remove the

jammed original.

If an original jam occurs during original reversal

operation, open the platen guide to remove the

jammed original .

If an original jam occurs during original exit, open

the original feed tray and original exit tray (for

large-size original) to remove the jammed origi-

nal.

2

1

3

4

1. Original feed tray

2. Original exit section (for small-size original)

3. Original exit tray (for large-size original

4. Jam access cover

Mechanism Method

Jam removal

*1

Jam access cover

Jammed original release knob

Original conveyance guide

open/close lever

Platen guide

2

1

3

4

2

1. Jam access cover

2. Original conveyance guide open/close lever

3. Original conveyance guide

4. Jammed original release knob

Lock

Platen guide

Original exit tray (for large-size original)

Original feed tray

EDH-5

2-2

RADF

ORIGINAL FEED / CONVEYANCE / EXIT SECTION

[1] Composition

[2] Mechanism

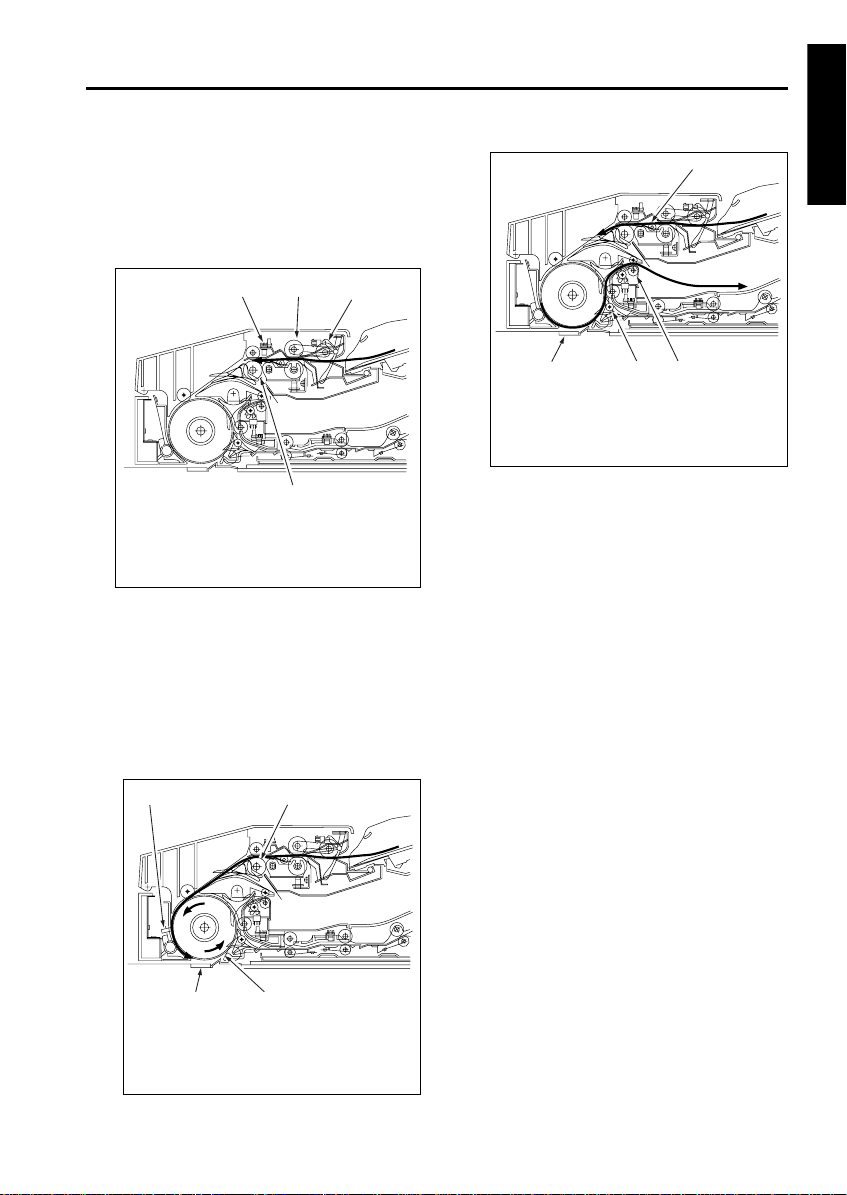

*1 Original conveyance path selection

In the two-sided copy mode, the original convey-

ance path selected after completion of scanning

differs depending on whether the image on the

front surface is to be printed or the image on the

back surface is to be printed. A flapper is used

to switch between these original conveyance

paths. The flapper drive solenoid (SD301) is

turned on/off to switch between the reversal sec-

tion and the original exit section.

2

1

6

7

5

3

8

9

10

4

1. Original exit gate solenoid (SD303)

2. Pressure roller release solenoid (SD302)

3. Flapper drive solenoid (SD301)

4. Original feed tray

5. Jam access cover

6. Original conveyance motor (M301)

7. SDF switching solenoid (SD304)

8. Original feed motor (M302)

9. Original exit motor 1 (M304)

10. Original exit motor 2 (M305)

Mechanism System

Original feed Original feed roller

Double feed preven-

tion

Double feed prevention roller

Separation roller

Original conveyance Original conveyance roller

Original conveyance

path selection *1

Flapper

Original reverse and

feed *2

Reversal roller pressure

Reversal roller rotation

Original exit path

selection *3

Gate 1

Gate 2

FRONT

Flapper

Flapper drive SD

(SD301)

EDH-5

2-3

RADF

*2 Reversed original feed

In the double-side copy mode, the original fed to

the reversal section is fed back by pressing the

the pressure roller against the reversal roller.

The pressure roller is driven by the pressure

roller release solenoid (SD302).

*3 Original exit path switching

Large-size one-side and two-side originals are

exited to the original exit tray (for large-size orig-

inal). On the other hand, small-size one-side and

two-side originals are exited to the original exit

section (for small-size original) through the rever-

sal section. The small-size two-side original fed

to the reversal section is reversed and exited to

the small size original exit section. The original

exit path switching to which the original is exited

is performed by the gate 1 and gate 2, driven by

the on/off contol of the original exit gate solenoid

(SD303).

FRONT

Pressure roller

Pressure roller release solenoid (SD302)

FRONT

Original exit gate

Original exit gate solenoid (SD303)

EDH-5

2-4

RADF

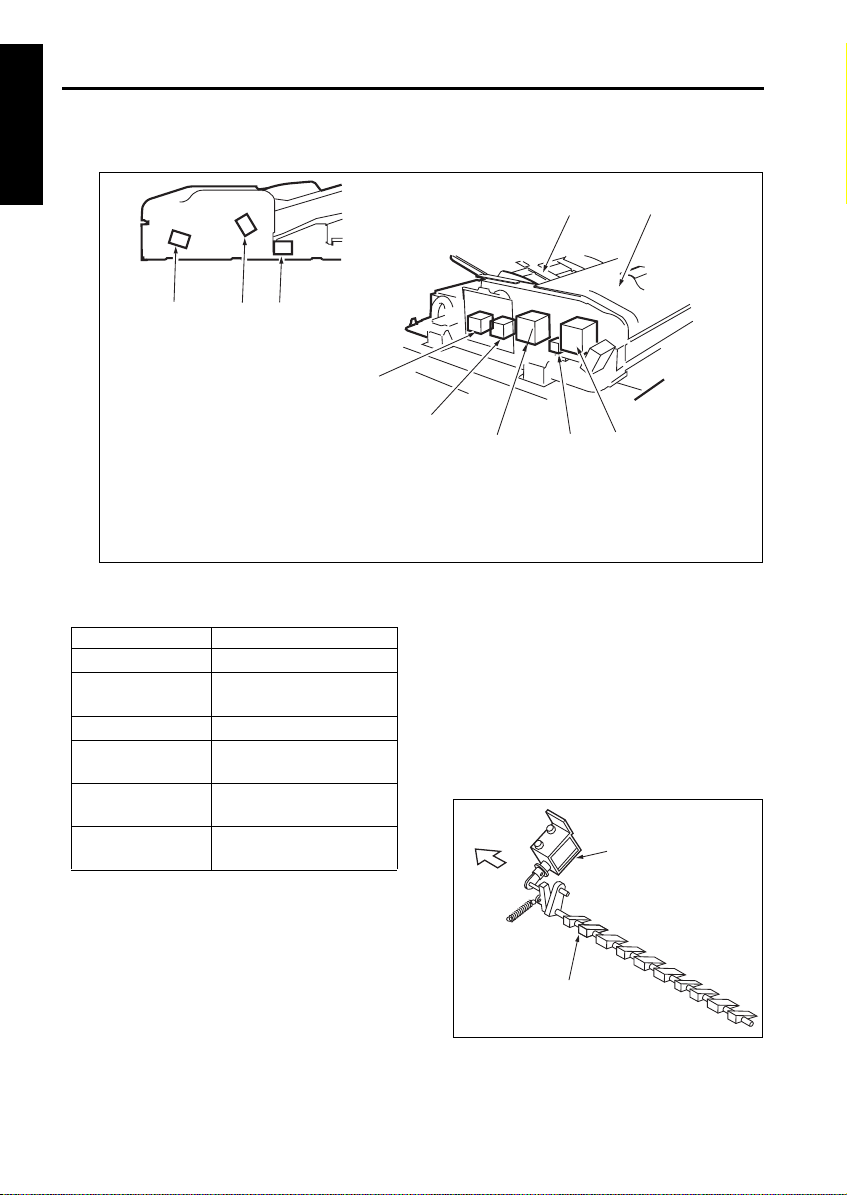

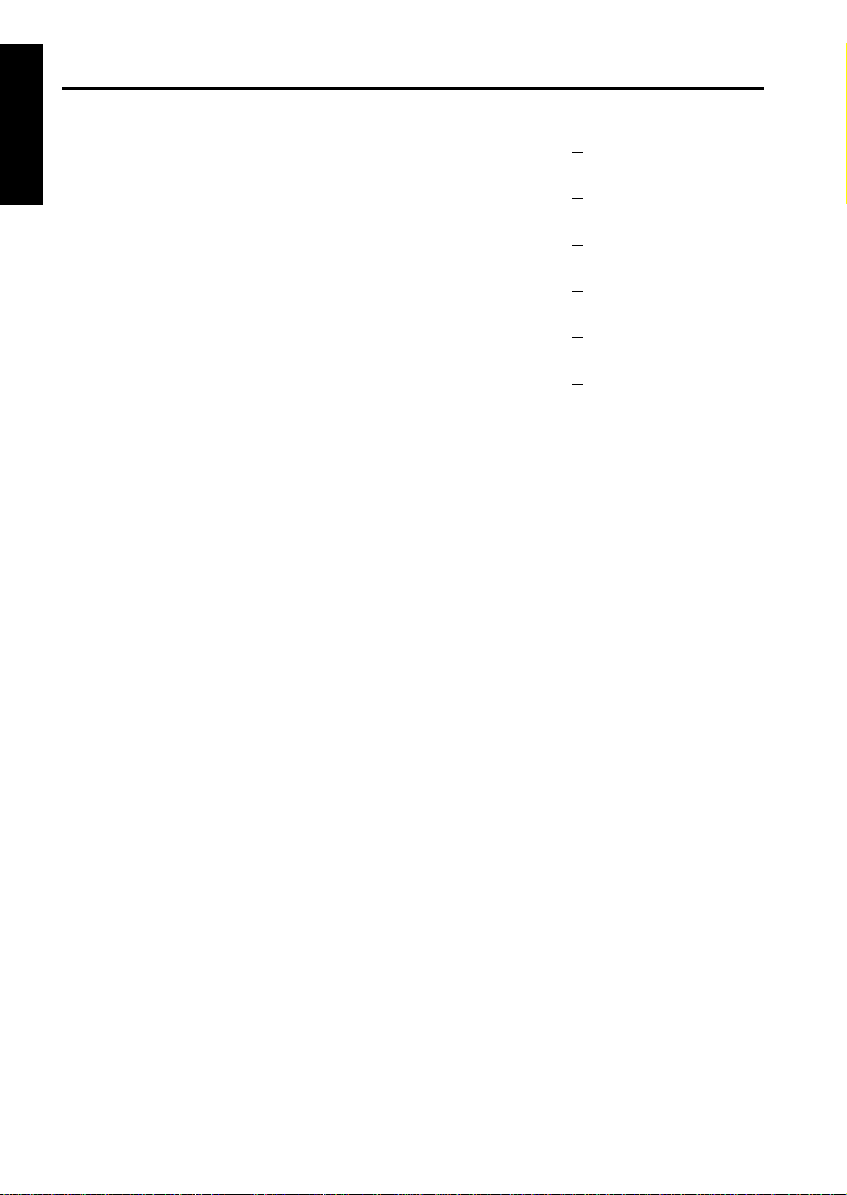

[3] Original Feed / Conveyance / Scan Control

riginal feed is performed by the original feed

roller and separation roller driven by M302 (orig-

inal feed). Original conveyance is performed by

the original conveyance roller driven by M301

(original conveyance).

M301 and M302 are controlled by DFCB (RADF

control board).

1. Operation

a. Sensor activation at power ON

When SW1 (main) is ON, a sensitivity adjust-

ment for PS306 (original registration detection),

PS308 (original conveyance detection), PS311

(original skew detection 1) and PS312 (original

skew detection 2) are performed. However,

automatic adjustment is not performed when the

RADF jam access cover is opened and MS301

(cover open/close MS) is OFF or when there is

original inside the RADF.

b. Pressing original against roller

(1) First original

When a control signal is received from the main

body, M303 (tray up/down drive) turns forward to

raise the original feed tray. By this moment, the

original is raised and pressed against the original

feed roller.

After PS315 (tray upper limit detection) turns

ON, M303 stops after a predefined interval and

leaves the original feed tray raised in standby

state.

After M302 feeds the first original, M303 rotates

backward after a predefined time has elapsed

since it stopped, lowering the original feed tray,

and the pressure on the originals is released.

M303 continues to rotate backward for a pre-

defined interval and then stops and remains in

standby state. At this point the original feed tray

waits without lowering to the bottom.

(2) Second and subsequent originals

When PS308 (original conveyance detection)

detects the leading edge of the first original and

turns ON, M303 that was in standby turns for-

ward to raise the original feed tray and presses

the original against the original feed roller.

Subsequent operations are the same as for the

first original.

PS312 LED CONT

PS312

5VDC

PS311 LED CONT

PS311

5VDC

PS308 LED CONT

PS308

5VDC

PS301

SGND

5VDC

PS316

SGND

5VDC

5VDC

PS315

SGND

5VDC

PS305

SGND

PS306 LED CONT

PS306

5VDC

MS301

24VDC

DF VALID

DF CTS

DF DTR

DF RXD

24VDC

SD304 DRIVE

PGND

FM301 LD

FM301 DRIVE

M302 DRIVE B

M302 DRIVE B

M302 DRIVE A

M302 DRIVE A

24VDC

24VDC

24VDC

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

M303 DRIVE B

M303 DRIVE B

M303 DRIVE A

M303 DRIVE A

24VDC

24VDC

5VDC

SGND

24VDC

PGND

DF RTS

DF DSR

DF TXD

DFCB

MAIN BODY

PS312 PS311 PS308 PS301 PS316 PS315 PS305 PS306

SD304

FM301 M302 M301 M303

MS301

EDH-5

2-5

RADF

c. Original feed

M302 drives the original feed roller and separa-

tion roller.

When a control signal from the main body is

received, M302 rotates forward at low speed,

stops, and goes into standby.

When the original feed tray is raised and PS315

turns ON, M302 turns backward after a pre-

defined interval to start original feed operation.

Then, when PS306 (original registration detec-

tion) detects the leading edge of the original and

turns ON, M302 switches to high speed forward

after a predefined interval to complete the origi-

nal feed operation. After completing original feed

at high speed forward, M302 returns to low

speed forward and stops and goes into standby

when PS308 (original conveyance detection)

turns ON.

d. Original conveyance operation

When feeding the first original, M302 transports

the original to the conveyance roller by continu-

ing to rotate at high and low speed.

During this time, M301 (original conveyance)

starts rotating forward at low speed at predefined

time after PS306 turns ON. The original reached

to the conveyance roller is then conveyed to the

scan position.

After starting conveyance of the first original,

M301 continues to rotate forward at low speed

until the last original is scanned.

e. Scan operation

The original is passed over the slit glass of the

optics unit by the low speed forward rotation of

M301 and read (scanned). While the original is

being scanned, original feed and conveyance

operations continue, triggered by the turning ON

of PS308.

f. Original mis-centering detection control

PS311 (original skew detection 1) and PS312

(original skew detection 2) are provided to detect

the inclined leading edge of the original during

conveyance.

PS311 and PS312 are placed at the front and

back of the pre-scan conveyance path and deter-

mine the inclination of the original by measuring

the difference in interval at which the leading

edge of the original turns these switches ON. A

skewed image caused by original inclination is

corrected through image processing so that the

image on the original is copied to a copy paper as

it is on the original.

g. SDF (Single Document Feeder) control

When SDF mode is selected, SD304 (SDF

switching SD) cut the drive force to the double

feed prevention roller to facilitate original feed-

ing.

(1) ON timing

At the start of original feed

(2) OFF timing

When PS306 turns OFF

h. FM301 (ADF fan) operation

FM301 is used to cool M301 so that M301 does

not overheat during operation.

(1) ON timing

At the start of original feed

(2) OFF timing

When original ejection completed.

i. Jammed original ejection control

Upon receiving a control signal from the main

body, M301 rotates at high speed forward,

attempting to eject a jammed original in the

RADF.

2. Signals

a. Input signal

(1) MS301 (MS301 to DFCB)

Jam access cover open/close detection signal.

[L]: Cover opened

[H]: Cover closed

(2) PS301 (PS301 to DFCB)

RADF open/close detection signal.

[L]: RADF closed

[H]: RADF opened

(3) PS305 (PS305 to DFCB)

No original on original feed tray detection signal.

[L]: Original present

[H]: No original

(4) PS306 (PS306 to DFCB)

Original feed over original conveyance roller

detection signal.

[L]: Original present

[H]: No original

(5) PS308 (PS308 to DFCB)

Pre-scan position original detection signal.

[L]: Original present

[H]: No original

EDH-5

2-6

RADF

(6) PS311 (PS311 to DFCB)

Front side original skew detection signal.

[L]: Original present

[H]: No original

(7) PS312 (PS312 to DFCB)

Rear side original skew detection signal.

[L]: Original present

[H]: No original

(8) PS315 (PS315 to DFCB)

Original feed tray upper limit detection signal.

[L]: Tray at upper limit

[H]: Tray not at upper limit

(9) PS316 (PS316 to DFCB)

Original feed tray lower limit detection signal.

[L]: Tray at lower limit

[H]: Tray not at lower limit

(10) FM301 LD (FM301 to DFCB)

Goes [L] when FM301 reaches predefined

speed.

(11) DF TXD (MAIN BODY to DFCB)

Serial data for transmitting main body PRCB

operating status to RADF.

(12) DF RTS (MAIN BODY to DFCB)

Send the Request To Send signal from main

body PRCB to RADF.

(13) DF DSR (MAIN BODY to DFCB)

Send the Data Set Ready signal from main body

PRCB to RADF.

b. Output signals

(1) PS306 LED CONT (DFCB to PS306)

Reflective sensor PS306 LED ON/OFF control

signal.

[L]: PS306 LED ON

[H]: PS306 LED OFF

(2) PS308 LED CONT (DFCB to PS308)

Reflective sensor PS308 LED ON/OFF control

signal.

[L]: PS308 LED ON

[H]: PS308 LED OFF

(3) PS311 LED CONT (DFCB to PS311)

Reflective sensor PS311 LED ON/OFF control

signal.

[L]: PS311 LED ON

[H]: PS311 LED OFF

(4) PS312 LED CONT (DFCB to PS312)

Reflective sensor PS312 LED ON/OFF control

signal.

[L]: PS312 LED ON

[H]: PS312 LED OFF

(5) M301 DRIVE (DFCB to M301)

M301 A phase drive signal.

(6) M301 DRIVE (DFCB to M301)

M301 B phase drive signal.

(7) M302 DRIVE (DFCB to M302)

M302 A phase drive signal.

(8) M302 DRIVE (DFCB to M302)

M302 B phase drive signal.

(9) M303 DRIVE (DFCB to M303)

M303 A phase drive signal.

(10) M303 DRIVE (DFCB to M303)

M303 B phase drive signal.

(11) FM301 DRIVE (DFCB to FM301)

FM301 ON/OFF drive signal.

[L]: FM301 ON

[H]: FM301 OFF

(12) DF TXD (DFCB to MAIN BODY)

Serial data for transmitting RADF operating sta-

tus to main body PRCB.

(13) DF DTR (DFCB to MAIN BODY)

Send the Data Terminal Ready signal from

RADF to main body PRCB.

(14) DF CTS (DFCB to MAIN BODY)

Send the Clear To Send signal from RADF to

main body PRCB.

(15) DF VALID (DFCB to MAIN BODY)

Image forming start signal.

A, A

B, B

A, A

B, B

A, A

B, B

EDH-5

2-7

RADF

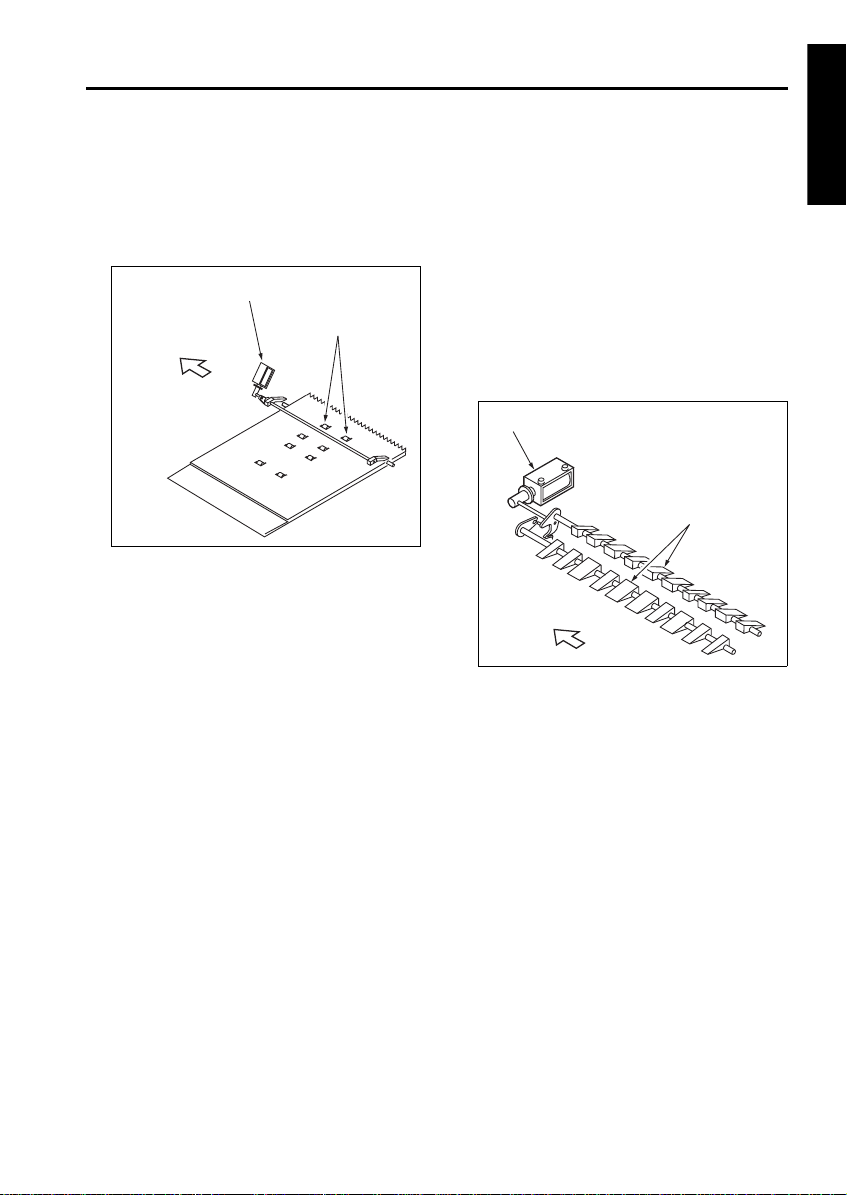

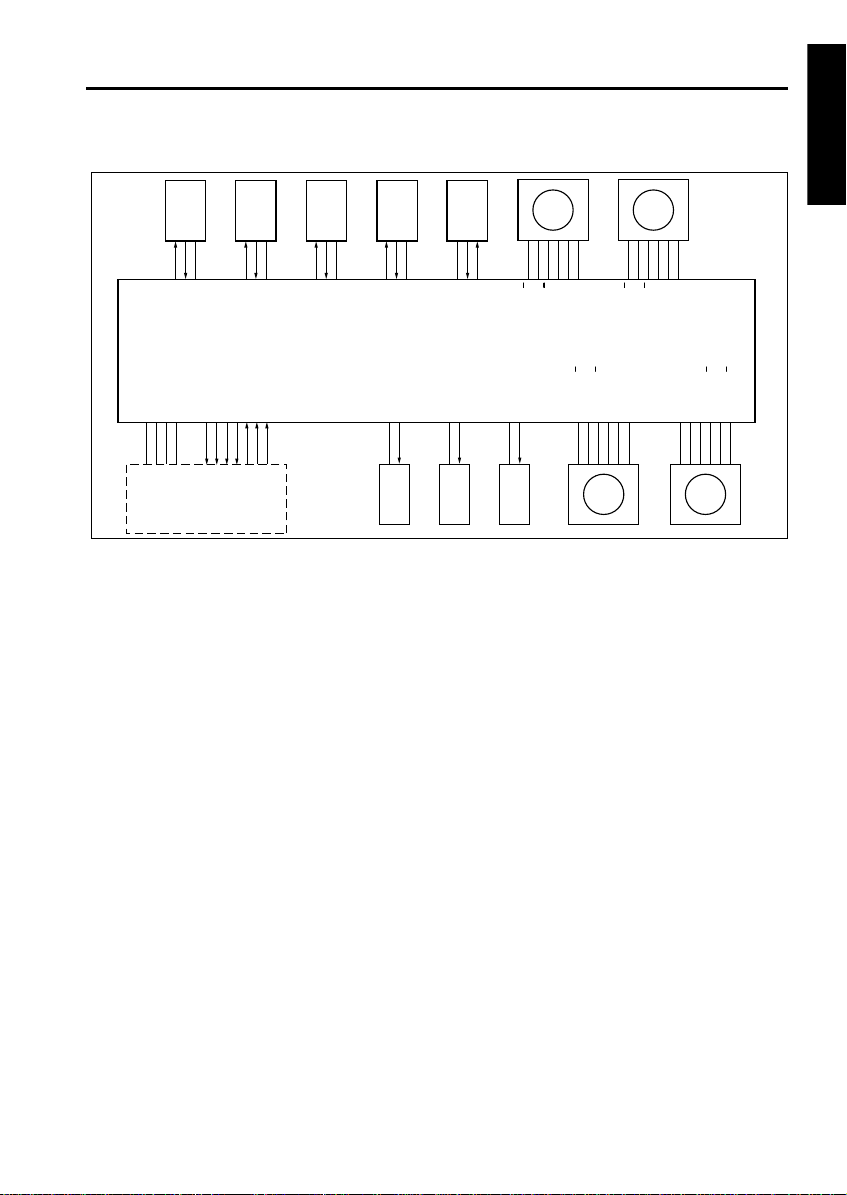

[4] Original Reversal and Conveyance Control

In two side copy mode, an original that has been

scanned on the front side is conveyed to the orig-

inal reversal section to be reversed and then res-

canned.

At entrance to the original reversal section, there

is a flapper to switch the original conveyance

path. The flapper is driven by SD301 (flapper

drive). The reversal roller, which reverses and

conveys front-side-scanned original to the origi-

nal reversal section and feeds that original to the

scan section again, is driven by M304 (original

exit 1). The original reversal roller which conveys

original to the original reversal section is driven

by M305 (original exit 2). When reversing and

feeding large originals, the pressure roller is

released by SD302 (pressure roller release).

M304, M305, SD301, and SD302 are controlled

by DFCB (RADF control board).

1. Operation

a. Sensor activation during power ON

When SW1 (main) is turned ON, a sensitivity

adjustment for PS309 (original reversal detec-

tion) and PS313 (original exit reverse detection)

are performed. However, automatic adjustment

is not performed when the RADF jam access

cover is opened and MS301 (cover open/close

MS) is OFF or when there is original inside the

RADF.

b. Original conveyance path switching/reversal

and original feed operation

(1) Small size original

SD301 is always OFF and the flapper is closed.

Therefore, the scanned original, whether it is sin-

gle side or double side, is conveyed to the rever-

sal section by M304 rotating at low speed

forward.

When copying the back side of a double-side

original, at predefined interval after PS309 (orig-

inal reversal detection) detects the trailing edge

of original and turns OFF, M304 rotates back-

ward at low speed and then at high speed to

reverse and feed the original. The reversed orig-

inal is conveyed through the flapper and the

guides to the conveyance roller.

PS308 LED CONT

PS308

5VDC

PS309 LED CONT

PS309

5VDC

PS304 LED CONT

PS304

5VDC

PS306 LED CONT

PS306

5VDC

5VDC

PS313

PS313 LED CONT

M305 DRIVE B

M305 DRIVE B

M305 DRIVE A

M305 DRIVE A

24VDC

24VDC

M304 DRIVE B

M304 DRIVE B

M304 DRIVE A

M304 DRIVE A

24VDC

24VDC

DF VALID

DF CTS

DF DTR

DF RXD

24VDC

SD301 DRIVE

24VDC

SD302 DRIVE

24VDC

SD303 DRIVE

M302 DRIVE B

M302 DRIVE B

M302 DRIVE A

M302 DRIVE A

24VDC

24VDC

24VDC

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

5VDC

SGND

24VDC

PGND

DF RTS

DF DSR

DF TXD

DFCB

MAIN BODY

PS308 PS309 PS304 PS306

PS313

SD301 SD302 SD303

M302 M301

M304M305

EDH-5

2-8

RADF

(2) Large size original

The scanned-single side original is conveyed to

the original exit tray (large) by the original con-

veyance roller since SD301 is ON and the flapper

is opened.

In the case of large double-side original, the orig-

inal is conveyed to the reversal section when

SD301 turns OFF after scanning the front side of

a double-side original . The original reaching the

reversal section does not fit in the reversal sec-

tion so it is fed to the large-size original exit tray

side by the large original reversal roller, which is

driven by M305 (original exit 2). During this time,

SD303 (original exit gate) turns ON and the orig-

inal exit gate is closed.

The original conveyed to the reversal section is

reversed and fed to the scan section again in the

same manner as small originals. Since the orig-

inal reaching the conveyance roller does not exit

the reversal roller, SD302 is turned ON at pre-

defined interval after high speed backward rota-

tion of M304 to release the pressure roller for the

reversal roller. This enables original conveyance

using the conveyance roller. SD302 turns OFF

when it detects an image scan complete signal

from the main unit.

c. Two side original next original feed operation

(1) Small size original

During front-side scanning of two-side original,

the original feed of the next one is started by the

rotation of M302 (original feed) when PS306

(original registration detection) detects the trail-

ing edge of the previous original and turns OFF.

The next original stops and waits in standby at

predefined interval after the turning ON of PS306

by its own leading edge.

When the back side of the first original is

scanned and PS308 (original conveyance detec-

tion) turns ON, M302 turns ON after a predefined

interval to resume original feed to scan the front

side of the next original. Thereafter, the same

operation is repeated.

(2) Large size original

During front-side scanning of double-side origi-

nal, the original feed of the next original is started

when PS306 (original registration detection)

detects the trailing edge of the previous original

and turns OFF. The next original stops and waits

in standby at predefined interval after the turning

ON of PS306 by its own leading edge.

During ejection of previous original by reverse

and exit operation, when PS309 (original rever-

sal detection) detects the trailing edge of the pre-

vious original and turns OFF, M302 turns ON

after a predefined interval to resume original

feeding to scan the front side of the next original.

Thereafter, the same operation is repeated.

Note: See [5] Original Exit Control for informa-

tion on reverse and exit operation.

d. Jammed original ejction control

Upon receiving a control signal from the main

unit, M304 and M305 rotate at high speed for-

ward, attempting to eject a jammed original in the

RADF.

2. Signals

a. Input signals

(1) PS304 (PS304 to DFCB)

Reversal section original detection signal.

[L]: Original present

[H]: No original

(2) PS309 (PS309 to DFCB)

Reversal section entrance original detection sig-

nal.

[L]: Original present

[H]: No original

(3) PS313 (PS313 to DFCB)

Original ejection reversal section original detec-

tion signal.

[L]: Original present

[H]: No original

b. Output signal

(1) M304 DRIVE (DFCB to M304)

M304 A phase drive signal.

(2) M304 DRIVE (DFCB to M304)

M304 B phase drive signal.

(3) M305 DRIVE (DFCB to M305)

M305 A phase drive signal.

(4) M305 DRIVE (DFCB to M305)

M305 B phase drive signal.

A, A

B, B

A, A

B, B

EDH-5

2-9

RADF

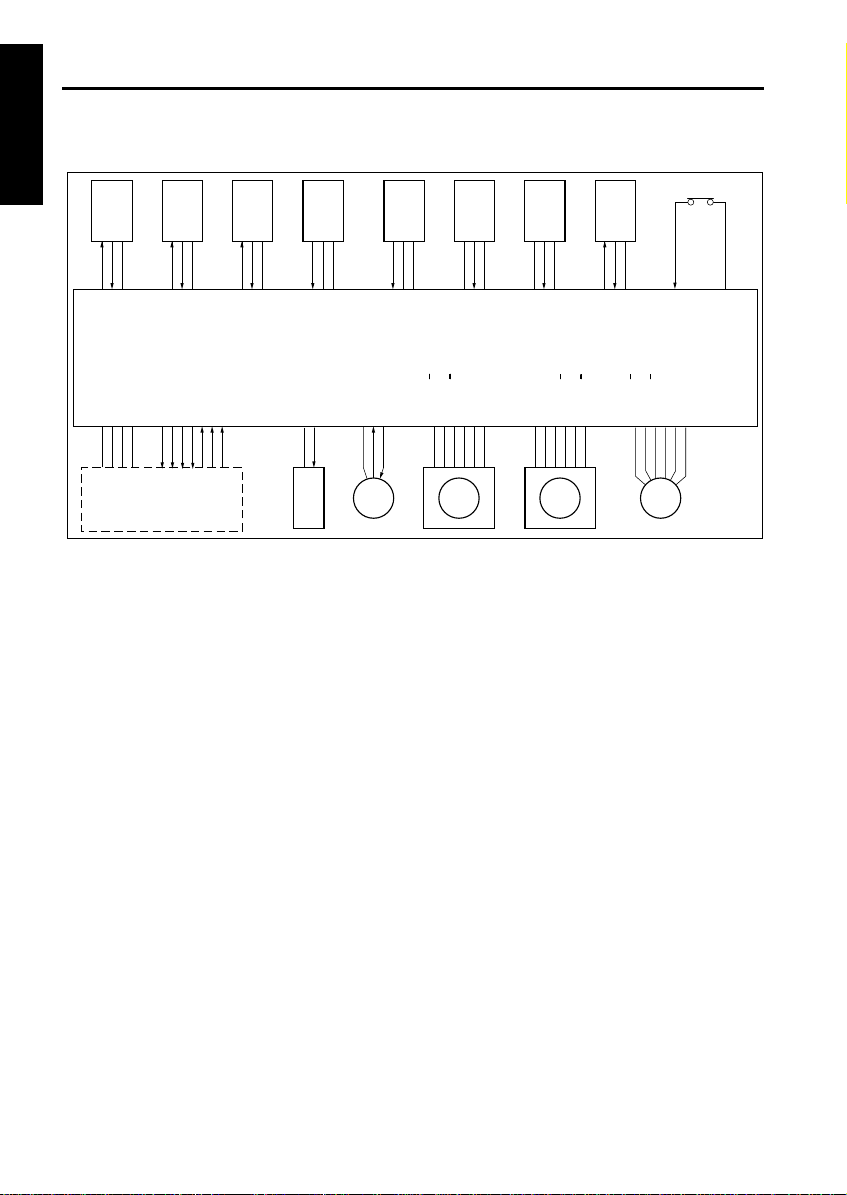

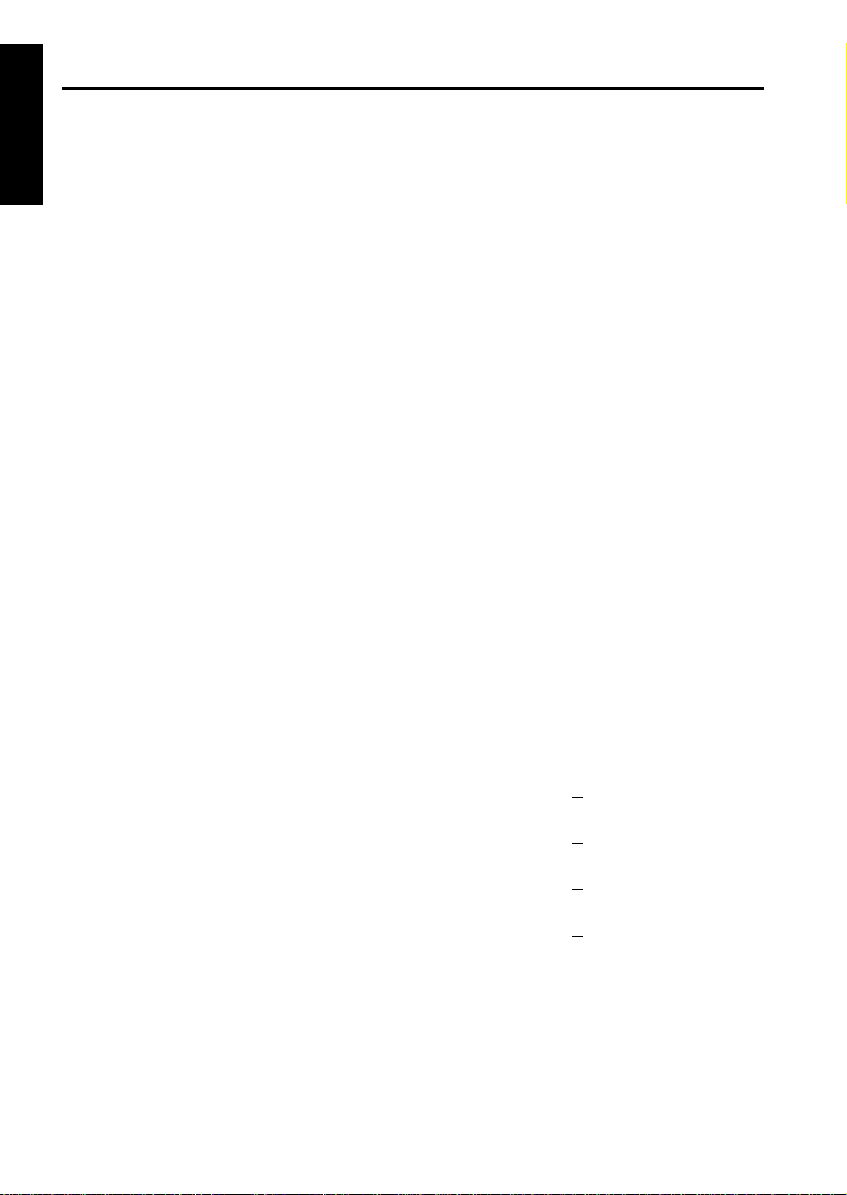

[5] Original Exit Control

The ejection destination of the original that has

been scanned depends on the size of original.

The original exit roller 1 which conveys the orig-

inal to the original exit tray (large) is driven by

M304 (original exit 1). The original exit roller 2

which conveys the original to the original exit

section (small) is driven by M305 (original exit 2).

The flapper which switches the original exit path

and the original exit gate are driven by SD301

(flapper drive) and SD303 (original exit gate)

respectively.

M304, M305, SD301, and SD303 are controlled

by DFCB (RADF control board).

1. Operation

a. Small size original exit operation

(1) Single-side original

Scanned original is conveyed to the reversal sec-

tion since SD301 is OFF and the flapper is

closed.

Original conveyed to the reversal section is con-

veyed to the original exit gate by the reversal

roller which is driven by M304. During this time,

M304 drives the conveyance roller with low

speed forward rotation.

The original is conveyed to the original exit roller

2 since SD303 is OFF and the original exit gate

is opened. M305 drives the original exit roller 2

with low speed forward rotation and ejects the

original to the original exit section (small) with the

original surface facing down.

(2) Two-side original

A original that has been scanned on the back

side is conveyed to the original exit gate in the

same manner as single-side original. During this

time, SD303 is ON and the original exit gate is

closed. Therefore, the original is passed through

the original exit reversal roller, which is driven by

the low speed forward rotation of M305, and con-

veyed to the original exit reversal section.

M305 turns OFF when PS313 ( original exit

reverse detection) is turned OFF by the con-

veyed original. When SD303 turns OFF and the

original exit gate opens, M305 starts high speed

backward rotation after a predefined interval and

reverses the direction of the conveyed original.

Since the original exit gate is opened, the original

is conveyed to the original exit section (small)

rather than returning to the reversal section.

As a result, the two-side original is ejected with

the front side facing down.

PS307

SGND

5VDC

PS309 LED CONT

PS309

5VDC

PS304 LED CONT

PS304

5VDC

5VDC

SGND

PS314

5VDC

PS313

PS313 LED CONT

M305 DRIVE B

M305 DRIVE B

M305 DRIVE A

M305 DRIVE A

24VDC

24VDC

M304 DRIVE B

M304 DRIVE B

M304 DRIVE A

M304 DRIVE A

24VDC

24VDC

DF VALID

DF CTS

DF DTR

DF RXD

24VDC

SD301 DRIVE

24VDC

SD302 DRIVE

24VDC

SD303 DRIVE

24VDC

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

5VDC

SGND

24VDC

PGND

DF RTS

DF DSR

DF TXD

DFCB

MAIN BODY

PS307 PS309 PS304

PS314 PS313

SD301 SD302 SD303

M301

M305 M304

Loading...

Loading...