Miller Electric XMT 350 VS User Manual

XMT® 350 Series

Quick

Specs

Heavy Industrial Applications

Construction

Shipbuilding

Railroad

Truck/Trailer Manufacturing

Fabrication

Repair Shops

Rental Fleets

Power Generation Plants

Processes

MIG (GMAW)/Pulsed MIG (GMAW-P)*

Stick (SMAW)

TIG (GTAW)

Flux Cored (FCAW)

Air Carbon Arc Cutting and Gouging (CAC-A)

*XMT-350 MPa; XMT 350 CC/CV with required optional control; not available with XMT 350 VS model.

Issued Nov. 2008 • Index No. DC/18.83

Multiprocess Welding

Power Source

Input Power Requires 3- or 1-Phase Power, 208 – 575 VAC, 50/60 Hz

Rated Output 10 – 38 V, 5 – 425 A

Weight Net: 80 lb (36.3 kg) Ship: 89.1 lb (40.4 kg)

The Power of Blue®.

XMT 350 CC/CV |

XMT 350 MPa with |

|

Built-In Pulse MIG |

|

(see page 4) |

|

XMT 350 VS |

Wind Tunnel Technology™ protects electrical components and PC boards from contamination.

Fan-On-Demand™ cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled through machine.

Lift-Arc™ allows TIG starting without the use of high-frequency. Starts the arc without contaminating the weld with tungsten.

Adaptive Hot Start™ increases the output amperage at the start of a weld if necessary, eliminating electrode sticking.

Lightweight, aerospace-grade aluminum case offers protection with the benefit of reduced weight.

The XMT 350 Series is packed with features to meet the most demanding welding needs.

Please see page 2 to determine which model is right for your application.

Auto-Line™ Power Management Technology allows for any input voltage hook-up (208 – 575 V) with no manual linking required, providing convenience in any job setting. Ideal solution for dirty or unreliable input power.

Inverter arc control technology provides greater puddle control for superior 6010 Stick electrode performance, and outstanding MIG weld performance.

Line voltage compensation keeps welding output constant even if input power varies by +/-10%. XMT 350 models further expand line voltage compensation on 460 VAC to an amazing +37%, -59%.

Process selector switch reduces the number of control setup combinations without reducing any features.

Large, dual digital meters are easy to view and are presettable to ease setting weld output.

Power source is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

Gun warranted for 90 days, parts and labor.

|

|

|

|

|

Miller Electric Mfg. Co. |

International Headquarters |

Web Site |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

An Illinois Tool Works Company |

Phone: 920-735-4505 |

www.MillerWelds.com |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1635 West Spencer Street |

USA FAX: 920-735-4134 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Appleton, WI 54914 USA |

Canadian FAX: 920-735-4169 |

|

|

|

|

|

|

|

|

|

|

International FAX: 920-735-4125 |

|

|

|

|

Which XMT® is Right for You?

Which XMT 350 |

|

Need Pulsed MIG |

NO |

Most often Stick (SMAW) |

NO |

||

|

|

|

|

See XMT 350 CC/CV |

|||

is right for you? |

|

(GMAW-P) |

|

|

or Flux Cored (FCAW) welding |

|

(page 3) |

|

|

|

|

||||

|

|

capability? |

|

|

with a voltage-sensing |

|

|

|

|

|

|

|

feeder? |

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

See XMT 350 MPa |

|

|

|

|

See XMT 350 VS |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

(page 4) |

|

|

|

|

(page 3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Amperage |

Power |

|

|

|

|

|

Remote |

|

Process |

|

|

|

|

|

|

|

|

|

Auxiliary |

For more |

||||||||

Class* |

Processing |

Industrial Inverters |

|

Capability |

|

Capability |

Pulsed MIG Capability |

|

Connectors |

Power |

Information |

|||||||||||||||||

300 A |

Auto-Link® |

XMT 304 CC/CV, 230/460 VAC |

|

Yes |

|

Stick, |

|

Optima™ Pulse Control Required |

Dinse only |

Optional |

Lit. No. DC/18.8 |

|||||||||||||||||

350 A |

Auto-Line™ |

XMT 350 MPa, 208 – 575 VAC |

|

Yes |

|

DC TIG, |

|

Built-In |

|

|

|

Dinse or Tweco |

Optional |

Page 4 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

MIG, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XMT 350 CC/CV, 208 – 575 VAC |

|

Yes |

|

|

Optima™ Pulse Control Required |

Dinse or Tweco |

Optional |

Page 3 |

|||||||||||||||||

|

|

|

|

|

CAC-A |

|

||||||||||||||||||||||

|

|

|

XMT 350 VS, 208 – 575 VAC |

|

No |

|

|

No |

|

|

|

|

Tweco only |

No |

Page 3 |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

565 A |

Manual |

XMT 456 CC/CV, 230/460 VAC |

|

Yes |

|

|

|

Optima™ Pulse Control Required |

Ring Lug only |

Standard |

Lit. No. DC/18.8 |

|||||||||||||||||

*60% Duty Cycle Rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

XMT® 350 Specifications (Subject to change without notice.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated Output |

|

Voltage |

Amperage |

|

Max. Open- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Input |

|

at 60% |

|

Range in |

Range in |

|

Circuit |

Amps Input at Rated Load Output, 60 Hz, |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Power |

|

Duty Cycle |

|

CV Mode |

CC Mode |

|

Voltage |

208 V |

230 V |

400 V |

460 V |

575 V |

KVA |

KW |

Dimensions |

|

|

Weight |

||||||||||

Three- |

|

350 A at |

|

10–38 V |

5–425 A |

|

75 VDC |

40.4 |

36.1 |

20.6 |

17.8 |

14.1 |

14.2 |

13.6 |

H: 17 in (432 mm) |

|

|

80 lb |

||||||||||

Phase |

|

34 VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W: 12-1/2 in (318 mm) |

(36.3 kg) |

|||||||||

Single- |

|

300 A at |

|

10–38 V |

5–425 A |

|

75 VDC |

60.8 |

54.6 |

29.7 |

24.5 |

19.9 |

11.7 |

11.2 |

D: 24 in (610 mm) |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

Phase |

|

32 VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Certified to both the Canadian and U.S. Standards for welding equipment.

Certified to both the Canadian and U.S. Standards for welding equipment.

Additional Features

Exceptional electrical efficiency. At 400 A, efficiency is 87.24%!

350 A of welding output at 60% duty cycle with superior low-end performance.

Power factor of .95 enables smaller fuses/breakers and primary wiring. Primary amperage draw at rated output is 25% less than the competition.

Ultra-tough, polycarbonate-blended cover for control panel protects front controls from damage.

Optional gas solenoid for TIG welding.

XMT® 350 Performance Data

DUTY CYCLE CHART |

CC VOLT/AMP CURVE |

CV VOLT/AMP CURVE |

|

500 |

|

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

425 |

|

|

|

|

|

|

|

|

|

|

|

90 |

|

|

|

|

|

|

|

90 |

|

|

|

|

|

|

400 |

3-PHASE OPERATION |

|

|

|

|

|

|

|

|

|

80 |

|

|

|

|

|

|

|

80 |

|

|

|

|

|

|

AMPERESWELDING |

350 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

300 |

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VOLTAGE |

|

|

|

|

|

|

|

VOLTAGE |

|

|

|

|

|

|

||

250 |

1-PHASE OPERATION |

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

60 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

6 AWG POWER CORD |

|

|

|

|

|

50 |

|

|

|

|

|

|

|

50 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

SMAW |

|

GTAW |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

200 |

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

MAX |

|

MAX |

|

40 |

|

|

MAX |

|

|

|

|

|

8 AWG POWER CORD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

30 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

GTAW |

SMAW |

|

|

|

|

|

|

|

|

|

|

||

|

150 |

|

|

|

|

|

|

|

|

|

|

|

|

80A |

ARC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

MIN |

0% |

|

|

|

|

20 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTROL |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25% |

|

|

|

|

|

|

|

|

MIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

50% |

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

75% |

|

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

100% |

|

|

|

|

0 |

|

|

|

|

|

|

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

70 |

80 |

90 100 |

|

|

0 |

100 |

200 |

300 |

400 |

500 |

|

0 |

100 |

200 |

300 |

400 |

500 |

|

|

|

|

DUTY CYCLE |

|

|

|

|

|

|

|

|

|

AMPS |

|

|

|

|

|

|

AMPS |

|

|

|||

2

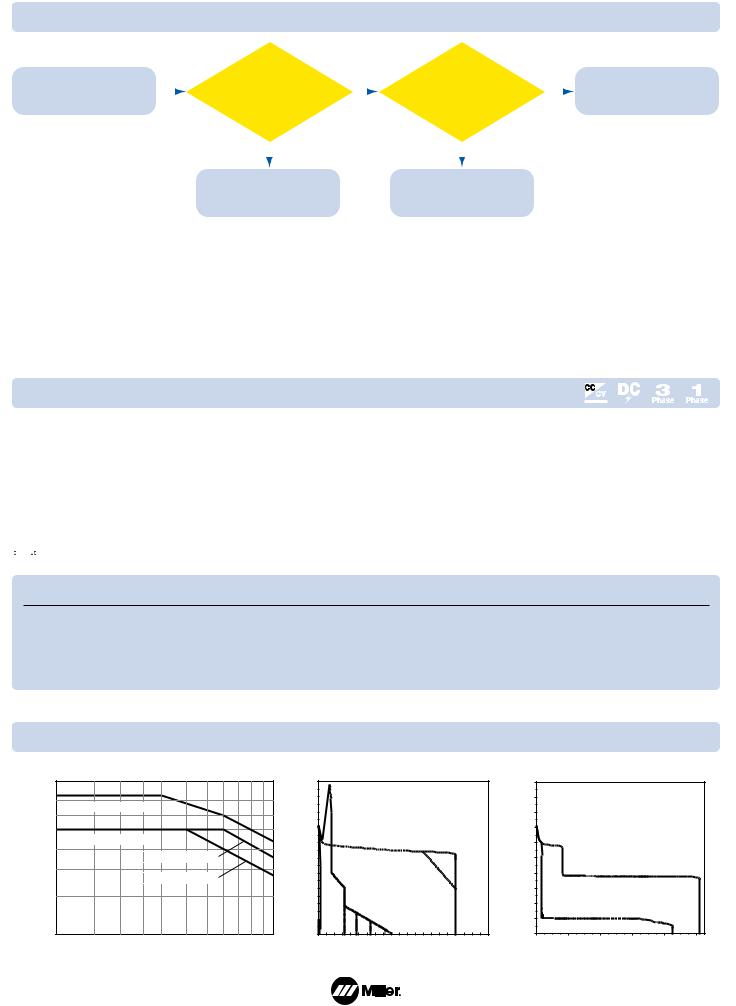

XMT® 350 VS Control Panel |

|

||

Manufactured Under the |

3 |

||

Following US Patents: |

|||

5,601,741 |

5,642,260 |

5,902,150 |

|

6,002,103 |

6,115,273 |

6,193,548 |

|

6,239,407 |

6,266,257 |

6,625,046 |

|

6,611,189 |

6,426,888 |

|

|

Other Patents Pending |

|

||

1 |

|

|

4 |

2 |

5 |

1.Voltmeter

2.Process Selector Switch (Rotary Switch)

3.Ammeter

4.Voltage/Amperage Adjustment Control

5.Arc Control

NOTE: VS model is equipped with Tweco-style output connector.

Additional Features

Low OCV Stick — A built-in, selectable feature, that reduces the Stick mode open-circuit voltage (OCV) to nearly

15 volts when the welding power source is not in use. Eliminates the need for add-on voltage reducers.

Note: VS model is available only with Tweco-style weld cable disconnects. Tweco cable connectors are not supplied with the unit and must be ordered separately.

Optional 115 VAC auxiliary power is not available on VS model.

Pulsed MIG (GMAW-P) capability is not available on VS model.

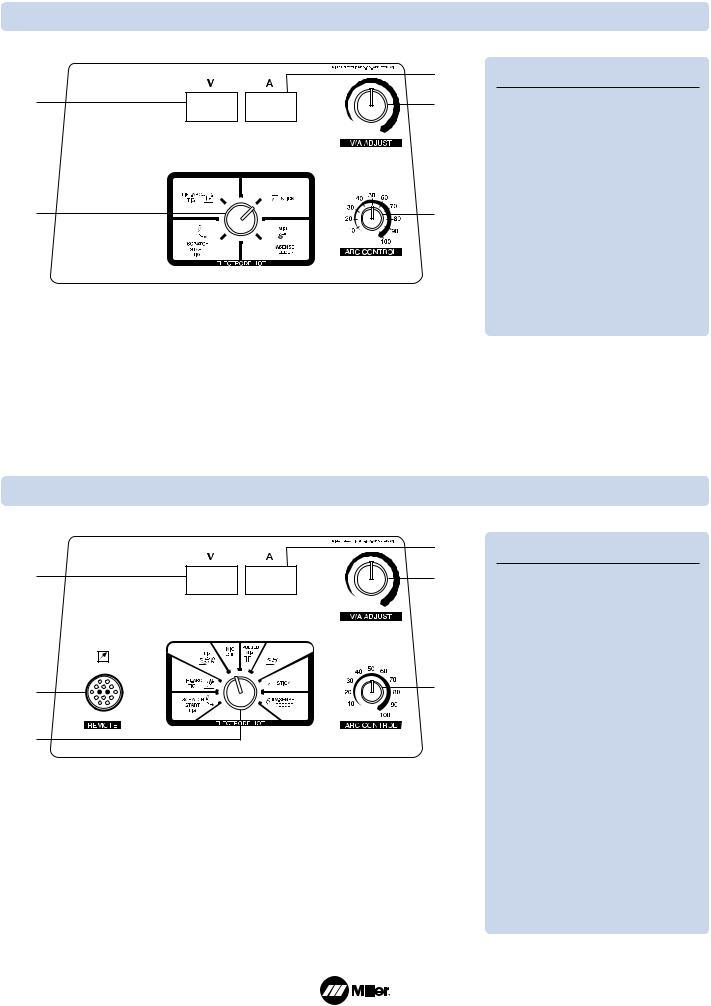

XMT® 350 CC/CV Control Panel |

|

||

Manufactured Under the |

4 |

||

Following US Patents: |

|||

5,601,741 |

5,642,260 |

5,902,150 |

|

6,002,103 |

6,115,273 |

6,193,548 |

|

6,239,407 |

6,266,257 |

6,625,046 |

|

6,611,189 |

6,426,888 |

|

|

Other Patents Pending |

|

||

1 |

|

|

5 |

CC

2 |

6 |

|

3

1.Voltmeter

2.Remote Control Receptacle

3.Process Selector Switch (Rotary Switch)

4.Ammeter

5.Voltage/Amperage Adjustment Control

6.Arc Control

Additional Features

Auto Remote Sense™ enables unit to automatically use remote control if connected to remote control receptacle.

Low OCV Stick — A built-in, selectable feature, that reduces the Stick mode open-circuit voltage (OCV) to nearly

15 volts when the welding power source is not in use. Eliminates the need for add-on voltage reducers.

Dinse International-style weld disconnects provide high-quality weld cable connections. Dinse and Tweco connectors are available. When Dinse connectors are specified, two connectors are supplied with the unit.

Optional 115 VAC auxiliary power provides 10 amps of circuit-breaker-protected power for water circulators, etc.

Pulsed MIG (GMAW-P) capabilities with optional Optima™ control reduces spatter and distortion, allows better out-of-position puddle control, and provides potential reduction of fume particle emission.

3

Loading...

Loading...