Miller Electric Millermatic 212 User Manual

|

|

® |

|

|

|

Issued August 2007 • Index No. DC/12.46 |

||

|

|

|

|

|

MIG Arc Welding |

|||

Millermatic 212 |

|

|

|

|||||

|

|

|

Power Source |

|||||

|

|

|

|

|

|

|||

|

Industrial Applications |

Processes |

Rated Output 160 A at 24.5 VDC, 60% Duty Cycle |

|||||

Quick |

Light Fabrication |

MIG (GMAW) |

Max. Open-Circuit Voltage 34.5 VDC |

|||||

Garages/Body Shops |

Flux Cored (FCAW) |

Amperage Range |

|

30 – 210 A |

||||

Specs |

Farm/Ranch |

Input Power |

|

|||||

Vocational/Technical Schools |

Wire Feed Speed |

|

50 – 700 IPM (1.3 – 17.8 m/min) |

|||||

200(208)/230 V |

|

|||||||

|

|

|

Weight 190 lb (86 kg) |

|||||

|

® |

|

|

|

Comes Complete With: |

|||

The Power of Blue. |

|

|

|

|||||

|

|

|

|

7 ft (2.1 m) power cord and plug |

||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|

|

NEW! 15 ft (4.6 m), 250 amp M-25 |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

Seven taps provide wider welding range |

|

|

|

|

MIG gun for .030/.035 in wire |

|||

|

|

|

|

10 ft (3 m) work cable and clamp |

||||

of 30 – 210 amps with improved high and |

|

|

|

|

||||

|

|

|

|

|||||

|

|

|

|

Argon mix regulator/flow gauge |

||||

low ends to weld materials from 22 gauge |

|

|

|

|

||||

|

|

|

|

|||||

|

|

|

|

and hose |

||||

up to 3/8 in (9.5 mm) thick in a single pass. |

|

|

|

|

||||

|

|

|

|

Extra contact tips |

||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

NEW! Angled, dual-gear driven, cast |

|

|

|

|

NEW! Factory-installed running gear |

|||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

with EZ-Change™ Low Cylinder Rack |

||||

aluminum drive system features |

|

|

|

|

.030/.035 in reversible drive rolls |

|||

|

|

|

|

|||||

no-tool, quick-change reversible drive |

|

|

|

|

||||

|

|

|

|

NEW! Set-up and operation |

||||

|

|

|

|

|||||

rolls and an easy-to-set, scaled tension |

|

|

|

|

||||

|

|

|

|

interactive CD |

||||

knob. See page 3 for more information. |

|

|

|

|

||||

|

|

|

|

|

|

|

||

NEW! Patent-pending EZ-Change™ Low |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

Cylinder Rack allows operators to easily |

|

|

|

|

|

|

|

|

roll cylinders on and off of rack — no |

|

|

|

|

|

|

|

|

need to lift cylinders. See page 3 for |

|

|

|

|

|

|

|

|

more information. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NEW! EZ-Access™ Consumable |

|

Compartment and Parameter Chart — |

|

set weld parameters right the first time with |

|

convenient new flip-down compartment |

|

that provides fast access to parameter |

|

chart and consumables. See page 3 for |

Add the Spoolmate™ 3035 spool gun |

more information. |

|

|

for aluminum welding. Easy to install |

|

with direct hook up. And with Miller’s |

NEW! Larger |

exclusive Gun-On-Demand,™ simply pull |

work area — |

the trigger for either gun and you’re ready |

now with longer |

to weld. No time wasted toggling switches! |

15-ft M-25 gun. |

NEW! Thermal overload protection shuts |

Less weld cleanup with Active Arc |

down unit and activates over temperature |

|

light if airflow is blocked or duty cycle is |

Stabilizer™ — patented Miller design |

exceeded. Automatically resets when fault |

provides excellent starts proven superior |

is corrected and unit cools. |

to the competition. |

|

Welder is warranted for 3 years, parts and labor. |

|

Original main power rectified parts are warranted for 5 years. |

|

Gun warranted for 90 days, parts and labor. |

|

|

|

|

|

Miller Electric Mfg. Co. |

International Headquarters |

Web Site |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

An Illinois Tool Works Company |

Phone: 920-735-4505 |

www.MillerWelds.com |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1635 West Spencer Street |

USA FAX: 920-735-4134 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Appleton, WI 54914 USA |

Canadian FAX: 920-735-4169 |

|

|

|

|

|

|

|

|

|

|

International FAX: 920-735-4125 |

|

|

|

|

Specifications (Subject to change without notice.)

|

|

Max. |

|

|

|

|

|

|

Max. |

|

|

|

Amperage |

Open-Circuit |

Amps Input at Rated Output, 60 Hz |

Wire Type and |

Wire Feed |

Spool |

|

Net |

|||

Rated Output |

Range |

Voltage |

200(208) V |

230 V |

KVA |

KW |

Diameter |

Speed |

Size |

Dimensions |

Weight |

|

|

|

|

|

|

|

|

|

|

|

|

160 A, 24.5 VDC |

30 –210 A |

34.5 |

31.2 |

27.1 |

6.36 |

5.45 |

Solid/Stainless Steel: |

50 –700 IPM |

12 in |

H: 30 in |

190 lb |

at 60% Duty Cycle |

|

|

2.1* |

1.8* |

0.51* |

0.26* |

.023 – .035 in |

(1.3 –17.8 |

(305 mm) |

(762 mm) |

(86 kg) |

210 A, 23 VDC |

|

|

|

|

|

|

(0.6 – 0.9 mm) |

m/min) |

|

W: 19 in |

|

at 30% Duty Cycle |

|

|

|

|

|

|

Flux Cored: |

|

|

(483 mm) |

|

|

|

|

|

|

|

|

.030 – .045 in |

|

|

D: 40 in |

|

|

|

|

|

|

|

|

(0.8 – 1.2 mm) |

|

|

(1016 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

*While idling.

Note: Operating Temperature Range: -4˚ to +104˚ F (-20 to +40˚ C) Storage Temperature Range: -22˚ to +122˚ F (-30 to +50˚ C)

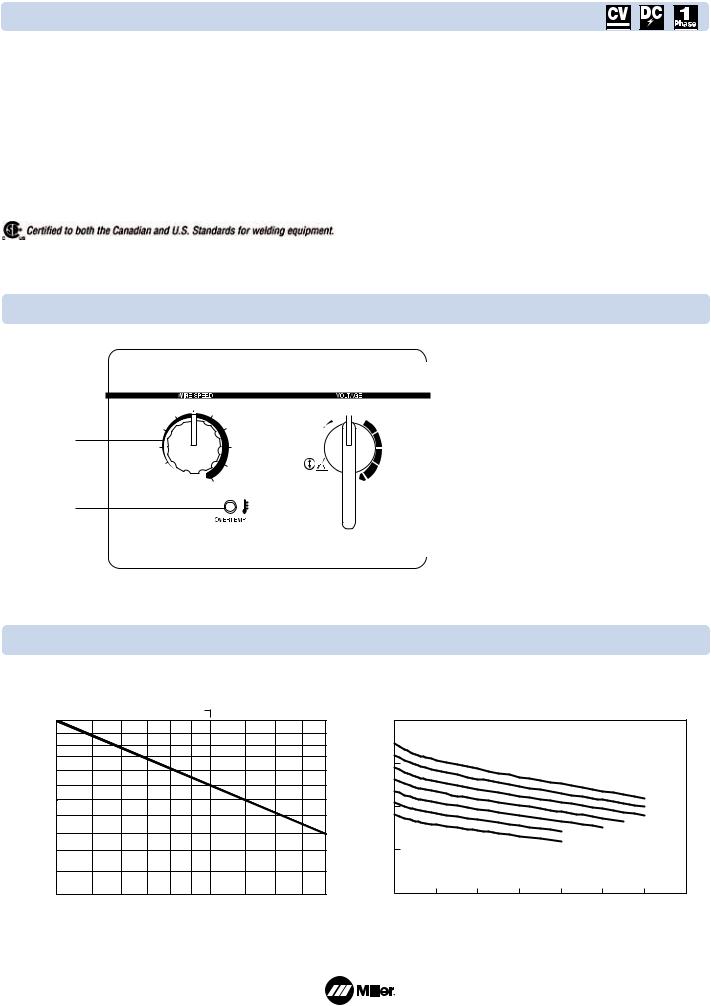

Control Panel

1

2

|

50 |

40 |

60 |

30 |

70 |

20 |

80 |

10 |

90 |

|

|

|

100 |

2

1 3

3

DO NO T SWITCH

WHILE WELDING

7

4 |

|

3 |

1. |

Wire Feed Speed Control |

|

|

2. |

Overtemp Light |

|

5 |

|

|||

|

|

3. |

Voltage Control |

|

|

|

|

||

6 |

|

|

|

|

|

|

|

|

|

Performance Data

WELD AMPS

DUTY CYCLE CHART |

VOLT/AMP CURVES |

210 |

|

RATED OUTPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

160 |

|

|

|

|

|

|

|

VOLTSDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

|

0 |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

|

|

% DUTY CYCLE |

|

|

|

|

|

|

|

|

DC AMPERES |

|

|

|

||

2

Standard Fully Loaded Features

EZ-Change™ Low Cylinder Rack

NEW! Patent-pending design — operators no longer need to lift cylinders. Cylinders now easily roll on and off our EZ-Change™ Low Cylinder Rack.

Angled Wire Drive

Angled industrial aluminum dual-gear drive system significantly improves wirefeeding and runs large spools of wire.

Allows quick change of drive rolls without tools.

Drive roll storage — no more lost drive rolls, extra drive rolls are conveniently stored next to drive motor.

Operators no longer bump into and bend

MIG gun and gun liner.

Dual Front Handles

Exclusive split handle with rubber grips designed to move machine easily and allow work lead and MIG gun to be stored independently.

Handles provide protection for front panel and MIG gun during transportation.

EZ-Access™ Consumable

Compartment and Parameter Chart

Convenient flip-down compartment holds parameter chart and storage for consumables.

3

Loading...

Loading...