Miller Electric 350MPa User Manual

Invision 350 MPa System |

Issued Nov. 2007 • Index No. DC/23.5 |

™ |

MIG Welding |

|

|

|

Power Source |

Quick

Specs

Heavy Industrial Applications |

Processes |

|

Invision 350 MPa |

Invision 350 MPa |

|

Railroad |

MIG (GMAW)/Pulsed MIG (GMAW-P) |

|

Truck/Trailer Manufacturing |

Flux Cored (FCAW) |

|

Light Gauge and Tube |

Air Carbon Arc Cutting and Gouging |

|

Lawn and Garden Equipment |

(CAC-A) (1/4 in carbons max.) |

|

Recreational Vehicles |

S-74 MPa |

|

S-74 MPa |

||

MIG (GMAW) |

||

Heavy/Light Manufacturing |

Flux Cored (FCAW) |

|

Metal Fabrication |

Pulsed MIG (GMAW-P) |

Invision 350 MPa

Input Power |

Requires 3- or 1-Phase Power, 50/60 Hz |

Rated Output |

10 – 38 V, 5 – 425 A |

Weight |

Net: 80 lb (36.3 kg) Ship: 89.1 lb (40.4 kg) |

S-74 MPa |

|

Input Power |

24 VAC, 10 A, 50/60 Hz |

Electrode Wire Dia. Capacity .023 –5/64 in (0.6–2 mm)

Wire Speed |

50–780 IPM (1.3–19.8 m/min) |

Weight |

Net: 58 lb (26 kg) |

The Power of Blue®.

Dynamic Pulsed MIG — highly-engineered pulse programs default to give a tight productive pulse arc. The operator can fine tune the arc if desired.

Auto-Line™ Power Management Technology allows for any input voltage hook-up (208 – 575 V) with no manual linking required, providing convenience in any job setting. Ideal solution for dirty or unreliable input power.

Fan-On-Demand™ cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled through machine.

Large, dual digital meters are easy to view and are presettable to ease setting weld output.

Inverter arc control technology provides greater puddle control for outstanding MIG weld performance.

Line voltage compensation keeps welding output constant even if input power varies by +/-10%. XMT 350 models further expand line voltage compensation on 460 VAC to an amazing +37%, -59%.

Invision 350 MPa System

Add the new S-74 MPa feeder for a package that gives you the benefit of Synergic-Pulsed MIG. As you increase/ decrease the wire feed speed, the pulse parameters increase/decrease matching the right amount of power output to the wire speed.

SharpArc™ technology changes welding arc characteristics in Pulsed MIG welding mode.

Lightweight, aerospace-grade aluminum case offers protection with the benefit of reduced weight.

Easy setup for MIG and Pulsed MIG applications.

Power source is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

Gun warranted for 90 days, parts and labor.

|

|

|

|

|

Miller Electric Mfg. Co. |

International Headquarters |

Web Site |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

An Illinois Tool Works Company |

Phone: 920-735-4505 |

www.MillerWelds.com |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1635 West Spencer Street |

USA FAX: 920-735-4134 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Appleton, WI 54914 USA |

Canadian FAX: 920-735-4169 |

|

|

|

|

|

|

|

|

|

|

International FAX: 920-735-4125 |

|

|

|

|

Specifications (Subject to change without notice.)

|

Rated Output |

Voltage |

Amperage |

Max. Open- |

|

|

|

|

|

|

|

|

|

Input |

at 60% |

Range in |

Range in |

Circuit |

Amps Input at Rated Load Output, 60 Hz, |

|

|

|

|||||

Power |

Duty Cycle |

CV Mode |

CC Mode |

Voltage |

208 V |

230 V |

400 V |

460 V |

575 V |

KVA |

KW |

Dimensions |

Weight |

Three- |

350 A at |

10–38 V |

5–425 A |

75 VDC |

40.4 |

36.1 |

20.6 |

17.8 |

14.1 |

14.2 |

13.6 |

H: 17 in (432 mm) |

80 lb |

Phase |

34 VDC |

|

|

|

|

|

|

|

|

|

|

W: 12-1/2 in (318 mm) |

(36.3 kg) |

|

|

|

|

|

|

|

|

|

|

|

|

D: 24 in (610 mm) |

|

Single- |

300 A at |

10–38 V |

5–425 A |

75 VDC |

60.8 |

54.6 |

29.7 |

24.5 |

19.9 |

11.7 |

11.2 |

|

|

|

|

||||||||||||

Phase |

32 VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Certified to both the Canadian and U.S. Standards for welding equipment.

Certified to both the Canadian and U.S. Standards for welding equipment.

Additional Features

Exceptional electrical efficiency. At 400 A, efficiency is 87.24%!

350 A of welding output at 60% duty cycle with superior low-end performance.

Power factor of .95 enables smaller fuses/breakers and primary wiring. Primary amperage draw at rated output is 25% less than the competition.

Ultra-tough, polycarbonate-blended cover for control panel protects front controls from damage.

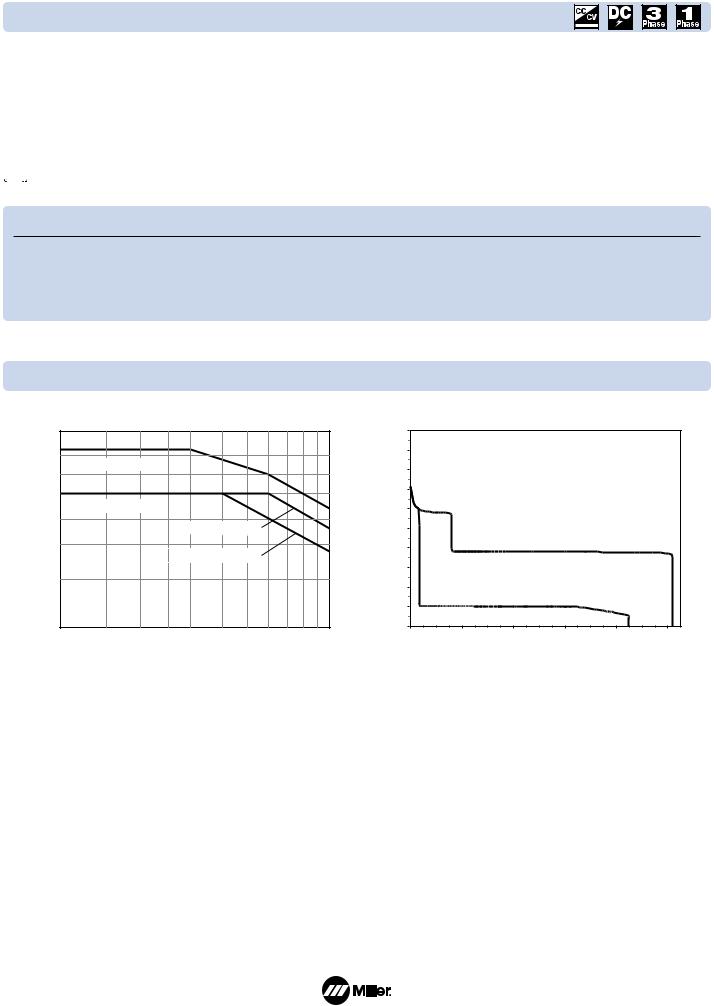

Performance Data

DUTY CYCLE CHART

|

500 |

|

|

|

|

|

|

|

|

|

|

|

100 |

|

425 |

|

|

|

|

|

|

|

|

|

|

|

90 |

|

400 |

3-PHASE OPERATION |

|

|

|

|

|

|

|

|

|

80 |

|

|

350 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WELDING AMPERES |

300 |

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

1-PHASE OPERATION |

|

|

|

|

|

|

|

|

VOLTAGE |

60 |

||

250 |

|

|

|

6 AWG POWER CORD |

|

|

|

|

50 |

||||

|

|

|

|

|

|

|

|

||||||

200 |

|

|

|

8 AWG POWER CORD |

|

|

|

|

40 |

||||

|

|

|

|

|

|

|

|

30 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

150 |

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

100 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

|

DUTY CYCLE

CV VOLT/AMP CURVE

|

|

|

MAX |

|

|

|

|

|

MIN |

|

|

0 |

100 |

200 |

300 |

400 |

500 |

|

|

|

AMPS |

|

|

2

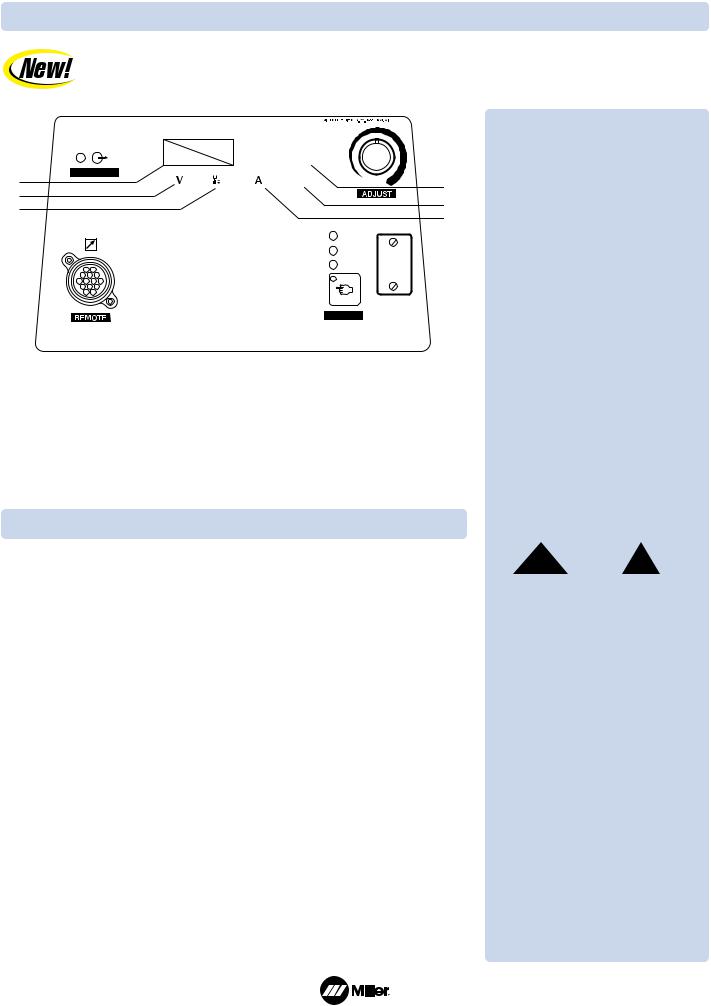

Control Panel

The Invision™ 350 MPa and S-74 MPa combine for a synergic system that simplifies and improves MIG and Pulsed MIG welding applications for industrial manufacturing.

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

MPa |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPa: M (MIG), P (Pulse), a (Advanced |

|||

|

|

|

OUTPUT ON |

|

|

|

|

|

|

|

|||||||

2 |

|

|

Setup |

Arc Control). Advanced arc control |

|||||||||||||

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

7 |

enables an improved pulse welding arc. |

||||||||

|

|

|

|

|

|

|

|

||||||||||

3 |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

8 |

The operator has more control over puddle |

||||||||

4 |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

9 |

™ |

||||||||

|

|

|

|

|

|

|

|

|

and bead characteristics using SharpArc. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

In addition, the unit provides a more robust |

||||

|

|

|

|

|

|

|

|

|

|

Arc Control |

|

||||||

|

|

|

|

|

|

|

|

|

|

Process |

|

and stable arc at very low arc length, reducing |

|||||

|

|

|

|

|

|

|

|

|

|

Wire/Gas |

|

heat input, and providing the ability to weld |

|||||

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

on a wider range of material thickness. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

Synergic pulsing is available only with the |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

SETUP |

|

S-74 MPa dedicated wire feeder. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

What are some benefits of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Synergic-Pulsed MIG? |

|

1. |

Output ON Indicator Light |

8. Setup Indicator |

1. Easier to set up |

||||||||||||||

2. No more changing wire speed, and |

|||||||||||||||||

2. |

Left Display |

9. Amperage Indicator |

|||||||||||||||

then having to go back to reset the |

|||||||||||||||||

3. |

Voltage Indicator |

10. Setup Indicator Lights |

|||||||||||||||

welding output. |

|||||||||||||||||

4. |

Arc Length Indicator |

|

• Arc Control Indicator |

||||||||||||||

|

|

||||||||||||||||

5. |

Wire Feeder Receptacle |

|

• Process Indicator |

Additional Features |

|||||||||||||

6. |

Adjustment Control |

|

• Wire/Gas Type Indicator |

||||||||||||||

7. |

Right Display |

|

• Setup Button |

|

|||||||||||||

|

|

||||||||||||||||

SharpArc™

Changes welding arc characteristics in

Pulsed MIG (GMAW-P) welding mode.

Built-In Pulsed MIG Programs

The Invision 350 MPa has built-in dynamic Pulsed MIG capabilities. See the table below for the wide range of Pulsed MIG (GMAW-P) welding applications the Invision 350 MPa can handle.

|

Wire Types |

|

Gas Types |

|

Steel |

|

.035 |

STL |

ARGN CO2 (Argon/Carbon Dioxide) |

|

|

.045 |

STL |

ARGN OXY (Argon/Oxygen) |

Metal Core |

|

.035 |

MCOR |

ARGN CO2 (Argon/Carbon Dioxide) |

|

|

.045 MCOR |

|

|

|

|

.052 MCOR |

|

|

Stainless Steel |

|

.035 |

SSTL |

TRI MIX (Tri-gas mixture) |

|

|

.045 |

SSTL |

ARGN OXY (Argon/Oxygen) |

|

|

|

|

ARGN CO2 (Argon/Carbon Dioxide) |

Aluminum |

|

.035 |

AL4X (4000 Series) |

ARGN (Argon) |

|

|

3/64 AL4X (4000 Series) |

|

|

|

|

.035 |

AL4X (5000 Series) |

|

|

|

3/64 AL4X (5000 Series) |

|

|

Nickel |

|

.035 |

NI |

ARGN HE (Argon/Helium) |

|

|

.045 |

NI |

|

Silicon Bronze |

|

.035 |

SIBR |

ARGN (Argon) |

|

|

|

|

|

Copper Nickel |

|

.045 |

CUNI |

HE ARGN (Helium/Argon) |

|

|

|

|

|

|

(0 setting) |

|

(50 setting) |

||

|

|

||||

|

|

|

|

|

|

Low Setting |

High Setting |

||||

Note: Setting has a subtle effect on arc that is exaggerated in graphic for visual emphasis.

If a gas is used other than what is listed on the Pulsed MIG welding program chart (below left), the SharpArc™ can be adjusted to help customize your arc to the gas being used.

Lower SharpArc™ settings widen the arc cone, increase puddle fluidity and flattens the weld bead.

Auto Remote Sense™

Enables unit to automatically use remote control if connected to remote control receptacle.

Dinse International-style weld disconnects

Provide high-quality weld cable connections. Dinse and Tweco connectors are available. When Dinse connectors are specified, two connectors are supplied with the unit.

Optional 115 VAC auxiliary power

Provides 10 amps of circuit-breaker- protected power for water circulators, etc.

3

Loading...

Loading...