Mercedes-Benz 603, 602 Service Manual

Mercedes-Benz

Mercedes-Benz of North America, Inc. . Montvale, NJ 07645

Q

Mercedes-Benz of North America, Inc., 1991

All rights reserved. Reproduction by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system

or translation in whole or part is not permitted without

written authorization from the publisher.

Published by Mercedes-Benz of North America, Inc.

Printed in U.S.A.

Part number LZ S-2517-091

This service manual is the product of existing technical publications. Special care has been taken

to provide accurate information on removal, disassembly, inspection, installation, and adjustment

procedures, together with the necessary technical data for the particular job.

The material in this manual is divided according to the Mercedes-Benz Component Group System

as outlined on the GROUP INDEX page. This page will quickly direct the reader to the Major

Component Group. Each Major Component Group begins with a JOB INDEX listing all jobs within

that group.

Mercedes-Benz of North America, Inc. recommends that repairs to, and maintenance of

Mercedes-Benz automobiles be performed by

trained Mercedes-Benz personnel

at authorized

Mercedes-Benz dealerships.

The information contained in this special publication is ordinarily issued by Mercedes-Benz of

North America, Inc., in conjunction with supplementary service literature and special tools supplied

only

to its authorized dealers. The repair and maintenance procedures outlined herein are

intended for use by

trained Mercedes-Benz service and dealership personnel.

This manual

can also be useful for Mercedes-Benz owners in diagnosing vehicle systems and performing

repairs.

Supplementary service literature will not be provided with this publication, but may be

contained in reprints of this service manual.

Please note that this manual has been compiled from various sources, some of which cover

models other than the subject of this book.

Always refer to the engine and vehicle identification

table for model and component information.

Special tools required in performing certain service jobs are identified in the manual and are

recommended for use.

Any part numbers given are only used for identification and easier

differentiation between individual components, and are not intended for ordering purposes.

If your Mercedes-Benz model differs from the specifications contained in the manual you select,

consult your authorized Mercedes-Benz dealer.

All procedures, illustrations and specifications contained in this manual were based on the latest

information available at the time of publication. All rights are reserved to make production, design

and specification changes at any time, without notice and without obligation to give notice. Any

such changes will not be contained in this manual.

Caution!

The proper performance of service and repair procedures is essential for both the safety of the

mechanic and the safe and efficient operation of the vehicle. The use of incorrect service

procedures and tools may greatly increase the risk of personal injury and render the vehicle

unsafe. The procedures in this manual are described in such a manner that the service may be

performed safely and accurately.

However, it is a general assumption that the reader is familiar with basic automotive repair

procedures and Mercedes-Benz vehicles. You should not attempt to use this manual if this is not

the case.

Mercedes-Benz of North America, Inc. assumes no liability for any damage to person or property

caused by the utilization of this publication to effect maintenance or repair work on Mercedes-Benz

automobiles.

MERCEDES-BENZ OF NORTH AMERICA, INC.

Service and Parts Literature

Group

Index

General, Technical Data

00

Crankcase

and

Cylinder

head

01

Crankshaft Assembly

03

ngine Timing, Valvetrain

05

Diesel Injection

System

07.1

Air Intake System - Air Filter, Turbocharger

09

elt Drive

13

Intake and Exhaust Manifolds, mission Control System

14

Electrical System, Preglow

15

ngine Lubrication System

18

ngine Cooling System

20

Engine Suspension

22

Accelerator Control

30

Fuel Tank and Lines

47

Exhaust System

49

General, technical data

00

General,

technical

data

00

Job No.

Instructions for use of service manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

00 - 005

Engine and vehicle identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

010

Vehicle identification number locations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

015

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

020

Instructions for use of

servic

00-005

Complete Service Manual coverage for late

model year Mercedes-Benz vehicles requires

four individual manuals:

Service Manual, Engine

Service Manual, Chassis and Body

Service Manual, Automatic Climate Control

Electrical Troubleshooting Manual

Throughout these manuals, the vehicles are

identified by their chassis and engine numbers.

These numbers are made up of the first six digits

of the respective serial number. For the actual

location of chassis and engine numbers, see

page

00-015/l.

In cases where the repair

instructions apply to all versions, only the first

three digits of the respective number are

referenced.

For example, chassis 124 applies to all 124

models. However, chassis

124.128

would apply

only to model 3000 2.5 Turbo.

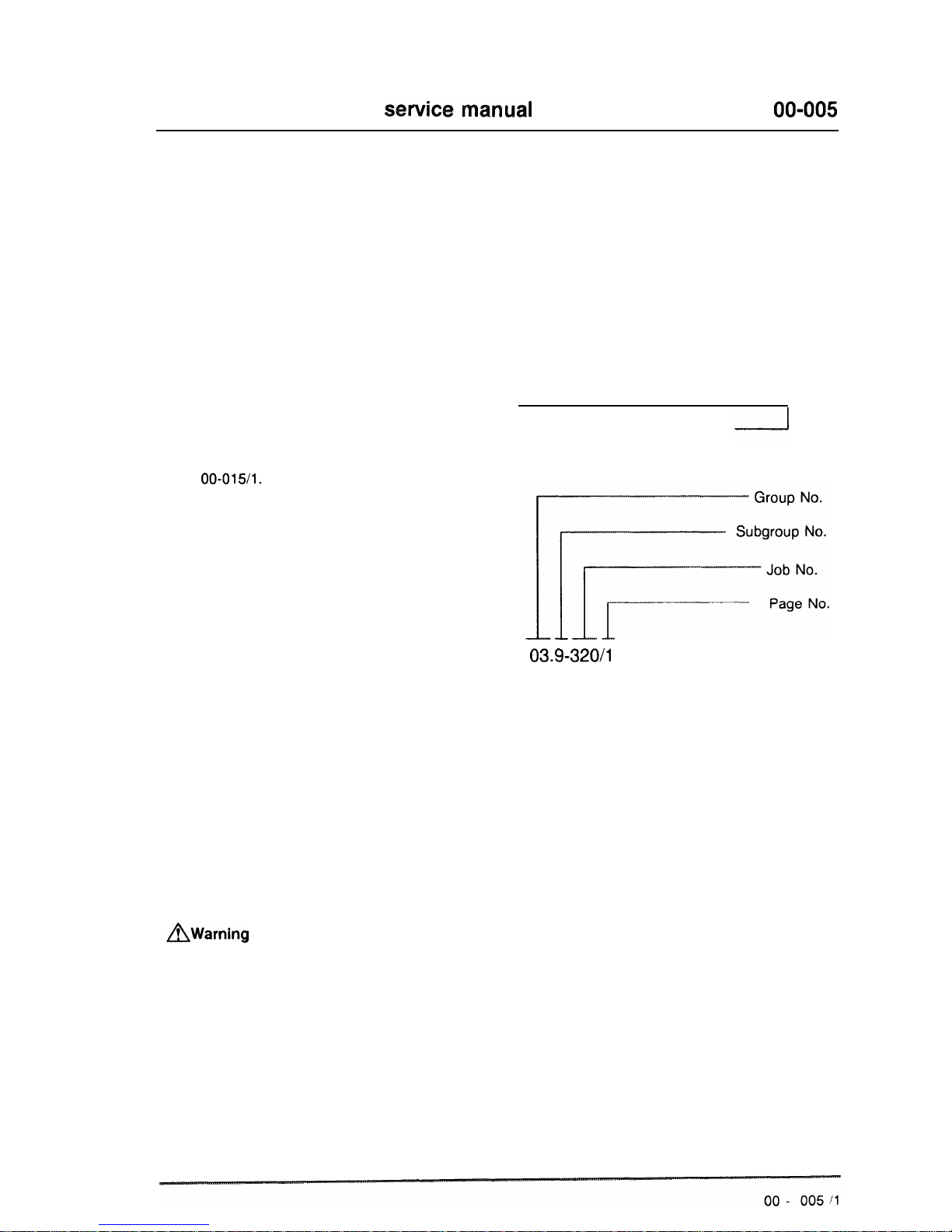

Location of specific repair instructions

First locate the Group No. in the Group Index.

Individual groups are separated by an easily

visible dividing page, which is followed by the job

index page. The exact job required is found in

the job index. The initial page of a typical job

description appears as follows:

03-320 Installation of Crankshaft

Job Title appears on

same line as Group

No.

03.9-320/l

Technical data, tightening torques and tools are

listed at the beginning of each job.

All dimensions are in metric units unless

otherwise indicated. Any part numbers given are

only used for identification and differentiation

between individual components, and are not

intended for ordering purposes.

Special Instructions

AWarning

Appears throughout service instructions indicating the possiblity of personal injury

if procedures are not followed.

Caution!

Indicates possible equipment or vehicle damage if procedures are not followed.

Note

Provides helpful information for the described procedure.

Installation note

Provides detailed information during assembly.

00

ngine

and vehicle identification

Model

I

Sales designation

I

Engine

201.126 190D2.5

602.911

126.125

300

SDL

Turbo

(Federal)

603.961

126.125

300

SDL

Turbo

(California)

603.961

201.126

190 D

2.5

602.911

201.128 190 D

2.5

Turbo

(Federal)

602.961

124.133

300 D Turbo

603.960

124.193

300TD

Turbo 603.960

126.125

300 SDL

Turbo 603.961

201.126

I

190 D 2.5

(Federal)

I

602.911

201.126

I

190 D 2.5

(Federal)I602.911

124.128

300

D

2.5

Turbo

(Federal)

602.962

126.135

350

SDL

Turbo

(Federal)

603.970

124.128

300

D

2.5

Turbo

(Federal)

602.962

126.134

350

SD

Turbo

(Federal)

603.970

126.135

350

SDL

Turbo

(Federal)

603.970

00 -

010/l

hick

identification number locations

00

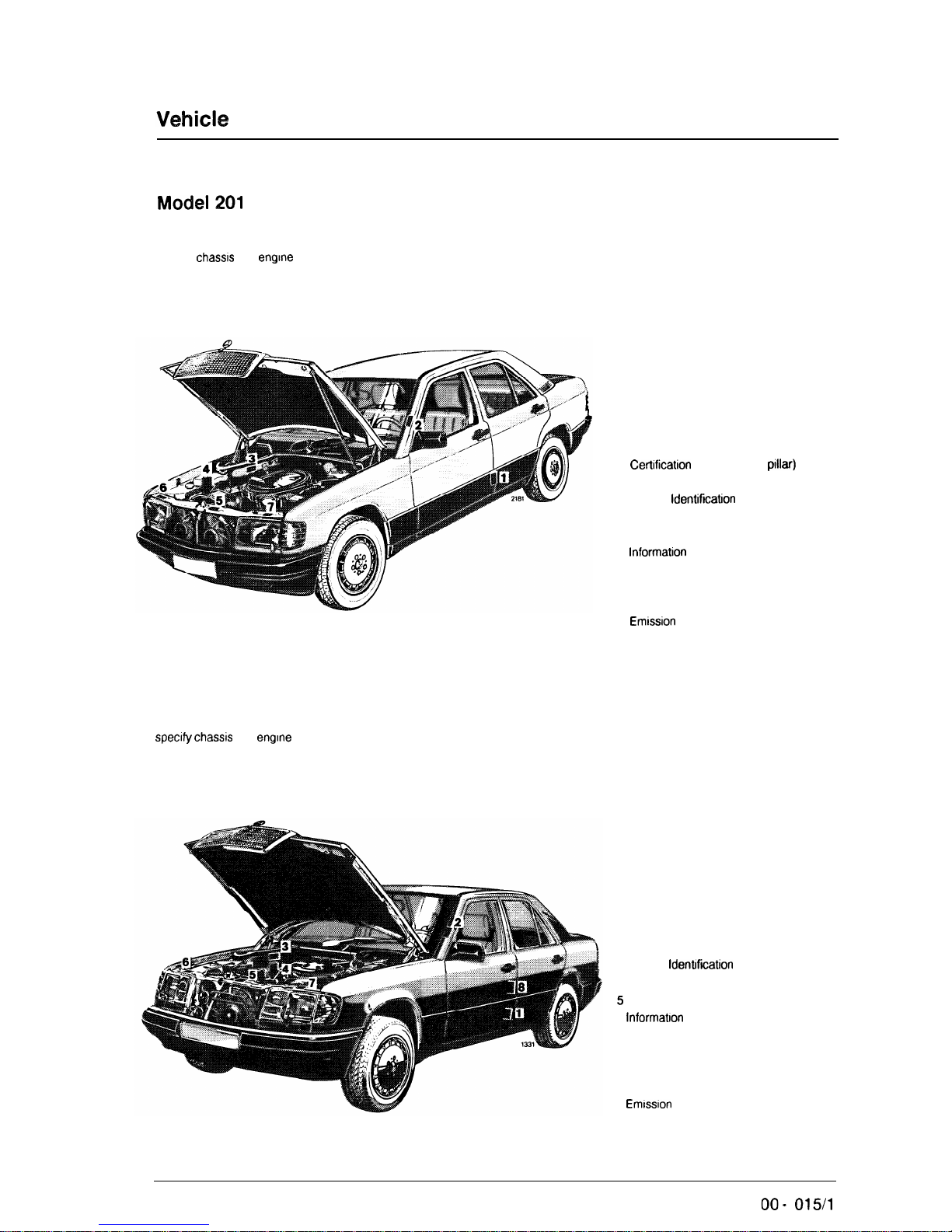

Model

201

When ordering spare parts, please

specify

chassrs

and

engine

numbers.

Model

124

When ordering spare parts, please

specify

chassis

and

engine

numbers.

1

Certrfication

Tag (left door

pillar)

2 Identification Tag (left windshield post)

3 Vehicle

Identificatron

No.

4 Engine No.

5 Body No. and Paintwork No.

6

InformatIon

Tag

California version

Vacuum line routing for emission

control system

7

Emrsslon

Control Tag

1 Certification Tag (left door pillar)

2 Identification Tag (left window post)

3 Vehicle

Idenkficatron

No.

4 Engine No.

5

Body No. and Paintwork No.

6

lnformatron

Tag

California version

Vacuum line routing for emission

control system

7 Emission Control Tag

8

Emrssron

Control Tag

Catalyst Information

00 -

015/l

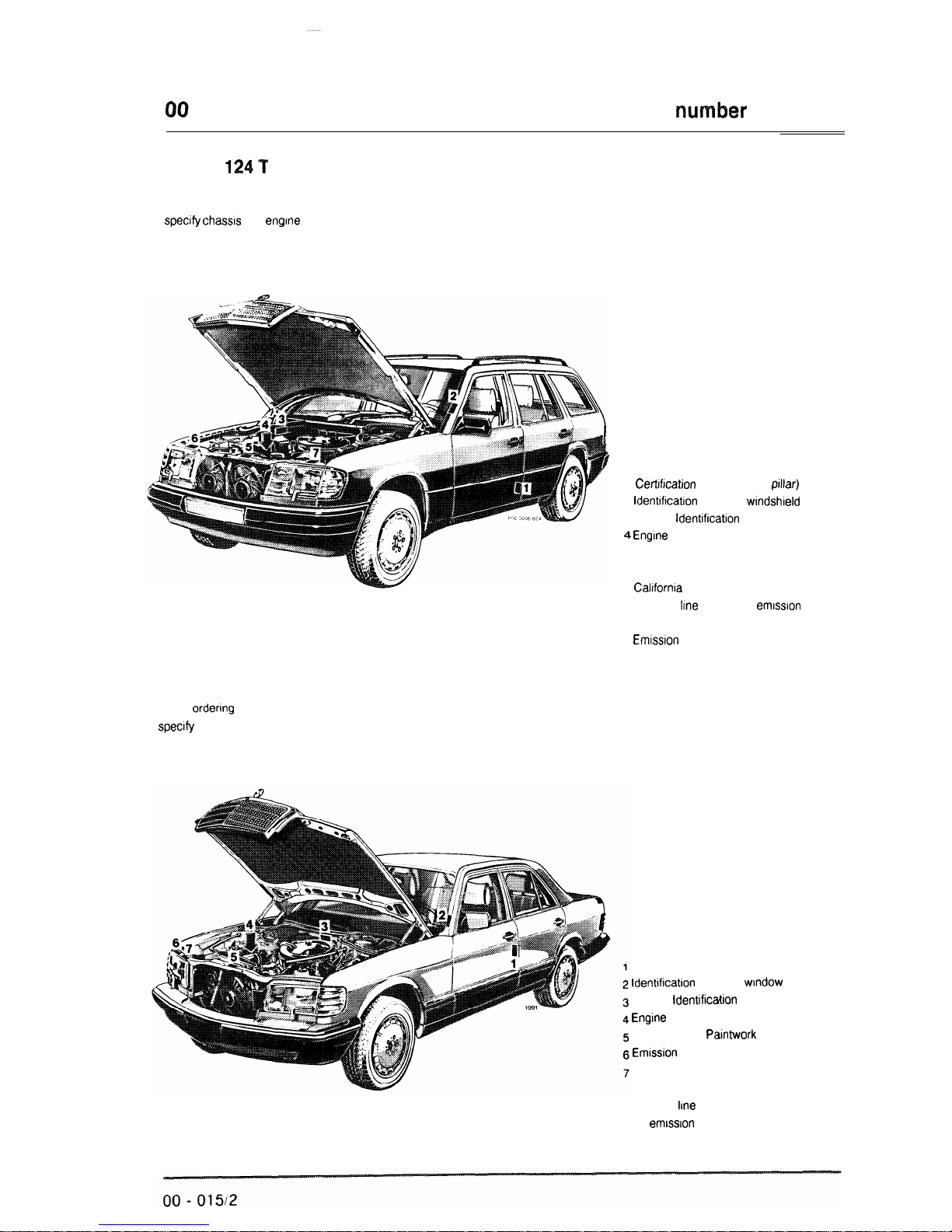

Vehicle identification

number

locations

Model

124

f

When ordering spare parts, please

specify chassrs

and

engine

numbers.

1

Certrfication

Tag (left door

prllar)

2

ldentrftcatron

Tag (left

wrndshreld

post)

3 Vehicle

ldentifrcatron

No.

4

Engine

No.

5 Body No. and Paintwork No.

6 lnformatron Tag

Caltfornia

version

Vacuum

line

routing for

emrssron

control system

7

Emrssron

Control Tag

Model

126

When

ordenng

spare parts, please

specrfy

chassis and engine numbers.

Certification Tag (left door pillar)

ldentlficatron

Tag (left

wrndow

post)

Vehicle

ldentrfication

No.

Engrne

No.

Body No. and PaMwork No.

Emrssron

Control Tag

lnformatron Tag

California version

Vacuum

lrne

routing

for

emrssron

control system

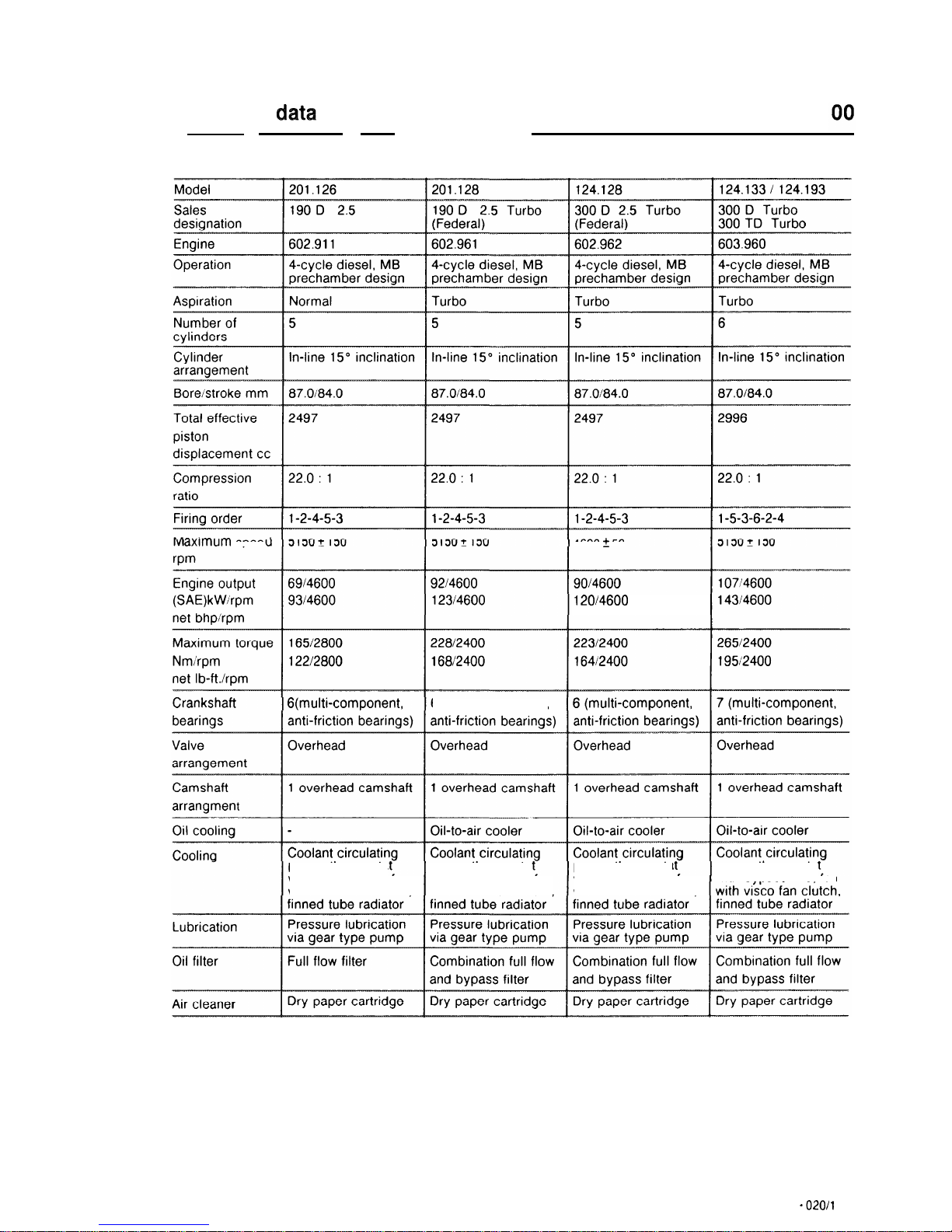

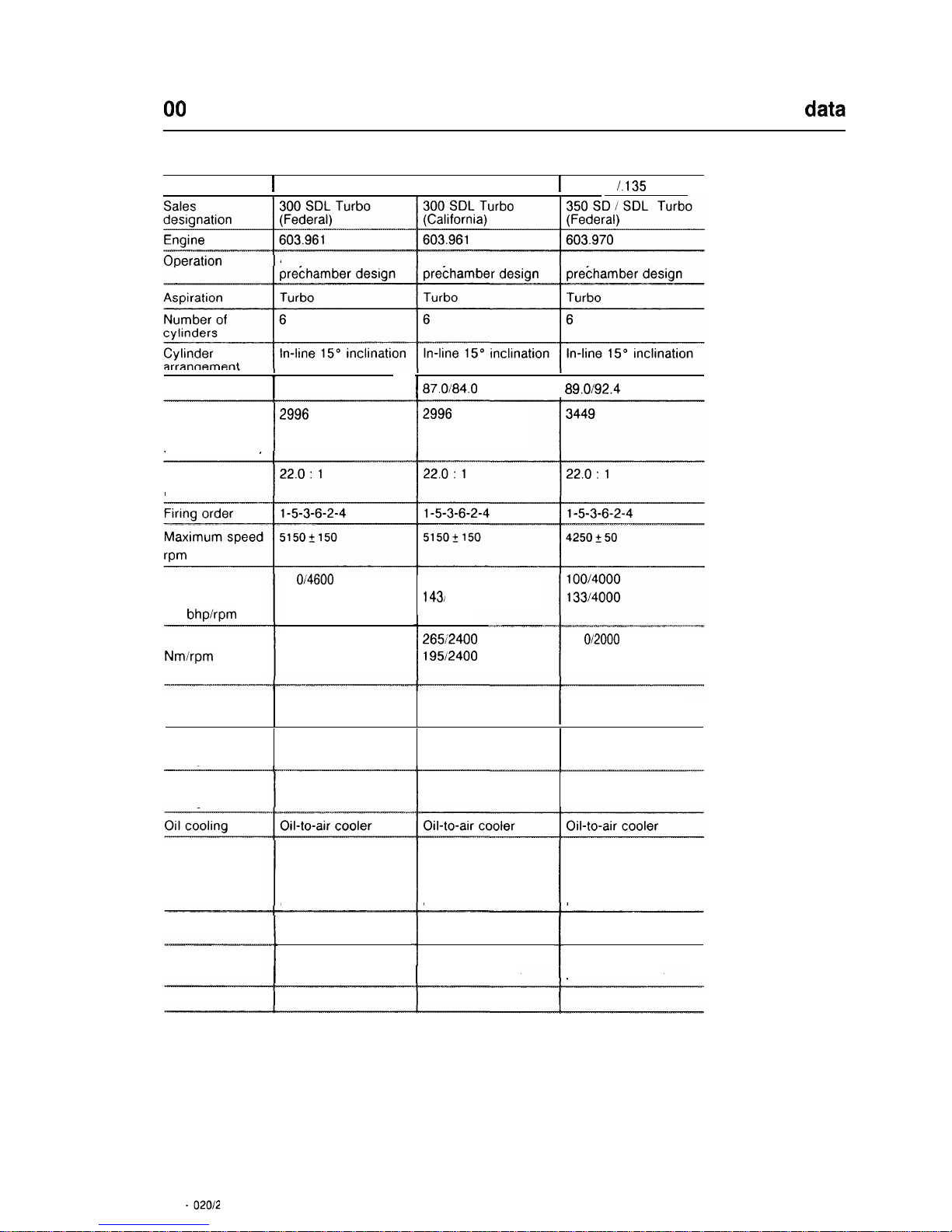

Technical

data

Diesel engines

axlmum spee

G(multi-component, 6 (multi-component,

pump, thermosta pump, thermosta

with bypass line, fan with bypass line,

fan

with

visco fan clutch,

with

visco fan clutch,

4600t 50

120/4600

pump, thermosta

pump, thermosta

with bypass line, fan

with

bypass line, fan

with visco fan clutch,

00 -

020/l

00

Technical

data

Gasoline engines

Model

i

126.125

1126.125

1

126.134

I.135

4-cycle diesel,

MB

4-cycle diesel,

MB

4-cycle diesel,

MB

arranqemen

Bore/stroke mm

I

87.0184.0

I

87.Oi84.0

I

89.0192.4

Total effective

piston

displacement cc

2996

2996

Compression

ratio

Engine output

(SAE)kW/rpm

net bhp/rpm

11

O/4600 1071’4600

14814600

143)

4600

Maximum torque

Nmirpm

net lb-ft./rpm

27312400

20112400

265/2400

195/2400

3 1

o/2000

22812000

Crankshaft

bearings

7 (multi-component, 7 (multi-component,

7 (multi-component,

anti-friction bearings) anti-friction bearings)

anti-friction bearings)

Valve

arrangement

Overhead

Overhead Overhead

Camshaft

arrangment

1 overhead camshaft 1 overhead camshaft

1 overhead camshaft

Cooling

Coolant circulating

pump, thermostat

with bypass line, fan

with visco fan clutch,

finned tube radiator

Coolant circulating

pump, thermostat

with bypass line, fan

with visco fan clutch,

finned tube radiator

Coolant circulating

pump, thermostat

with bypass line, fan

with visco fan clutch,

finned tube radiator

Lubrication

Pressure lubrication Pressure lubrication

via gear type pump

via gear type pump

Combination full flow Combination full flow

1

and bypass filter

1

and bypass filter

Pressure lubrication

via gear type pump

Combination full flow

and bypass filter

Oil filter

Air cleaner

Dry paper cartridge

Dry paper cartridge Dry paper cartridge

00 -

02012

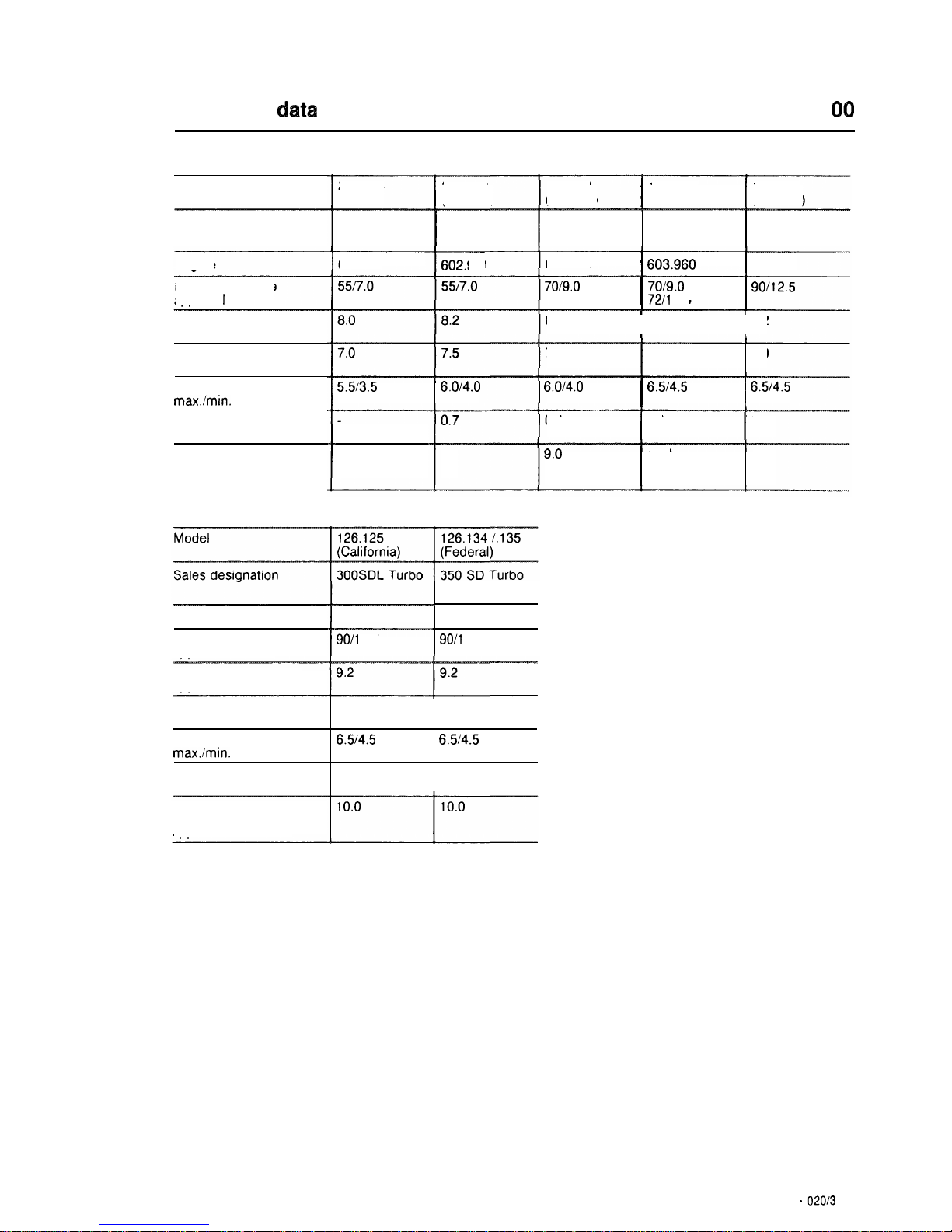

Technical

data

cm

Filling capacities

Model

201.126

I

201.128

(Federal)

124.128

(Federal)

I

124.133,

I

126.125

124.193

(Federal)

Sales designation

190 D 2.5 190 D 2.5

Turbo

300 D 2.5

Turbo

300 D Turbo 300 SDL Turbo

300 TD Turbo

Engine

602.911

-r-m

~

602.961

602.962

I

603.960

I ~~~

603.961

Fuel tank/reserve

aoorox.

I

7019.0

I

7019.0

I

90112.5

72/l

0.0

8.2

I

9.2

I

9.2

Engine oil initial filling

approx. I

During oil and filter

change approx. I

Marks on dipstick

max./min. approx. I

Oil-to-air cooler with

hoses

Cooling system with

heater

approx. I

7.0

I

8.0

I

8.0

6.Oi4.0

I

6.5i4.5

I

6.514.5

5.513.5

6.0/4.0

0.7

I

1.1

I

0.65

8.08.0

9.0

10.0 12.5

Filling capacities (continued)

~ 350 SDL Turbo

603.970

90/l

2.5

603.961

Engine

Fuel tan k/reserve

approx. I

90/l

2.5

Engine oil initial filling

approx. I

During oil and filter

change approx. I

Marks on dipstick

max./min. approx. I

Oil-to-air cooler with

hoses

8.0 7.5

6.514.5

6.514.5

0.65 0.65

Cooling system with

heater

aoorox. I

00 -

02013

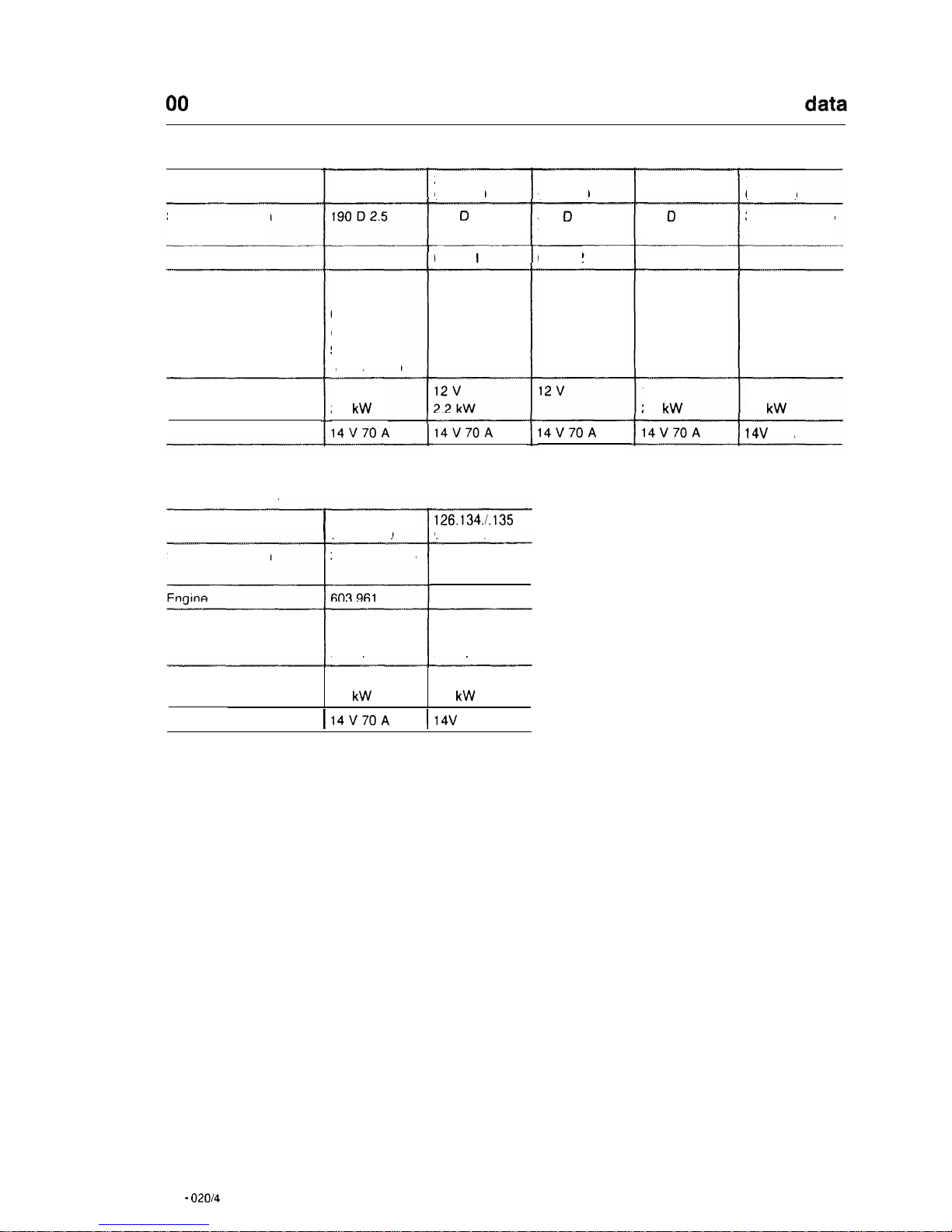

00

Technical

data

Electrical system

Model

201.128

(Federal)

124.128

(Federal)

124.133,

124.193

126.125

(Federal)

201.126

190 0 2.5

Turbo

300 D 2.5

Turbo

300 0 Turbo

300 TD Turbo

Sales designation

300

SDL Turbo

602.962

Engine

602.911

602.961

603.960

603.961

Battery

Voltage

Capacity

12v

62 Ah

(M.Y. 1986)

92 Ah (from

M. Y.

1987)

12 v

92 Ah

12v 12v

92 Ah

12v

92 Ah

12V

2.2

kW

12v

1.5

kW

Starter Bosch 12 v

2.2

kW

14V70A 14V70A

14v 80A

14V70A 14V70A

Alternator

Electrical system

Model

I

126.125

(California)

126.134.1.135

(Federal)

Sales designation 300SDL Turbo 350 SD Turbo

350 SDL Turbo

603.970

Battery

Voltage

Capacity

12v

62 Ah

12v

62 Ah

Starter Bosch

12 v 12v

2.2

kW

1.7

kW

Alternator

I

14V70A

I

14v 80A

00 -

020/4

Crankcase and Cylinder Head 01

01

Crankcase and cylinder

head

Job No.

Engine and model survey

................................................

01 - 001

Removal and installation of noise capsule at bottom of engine compartment

............

01 -

006

Opening hood, setting vertical warnings

...................................... 01 - 008

Testing compression pressure

.............................................

-

010

Checking cylinders for leaks

...............................................

-

015

Evaluating cylinder bores

.................................................

-

020

Removal and installation of engine (oil capacity)

.................................

-

030

Crankcase ventilation - Function

............................................

-

040

Measuring, boring and honing cylinder bores

...................................

-

110

Boring, honing and replacement of cylinder sleeves

..............................

-

115

Planing crankcase parting surface

...........................................

-

120

Removal and Installation of steel balls in main oil duct

............................

-

130

Replacement of freeze plugs in crankcase

.....................................

-

140

Removal and installation of timing cover

......................................

-210

Removal and installation of end cover

........................................

-

222

Removal and installation of oil pan

..........................................

-

310

Repair notes for cylinder heads and cylinder head gaskets

.........................

-

400

Refinishing prechamber sealing surface

.......................................

-

410

Removal and installation of cylinder head

.....................................

-

415

Removal and installation of prechambers

......................................

-

417

Facing cylinder head mating surface

.........................................

-

418

Boring out camshaft bearing bores (repair stage)

................................

-

419

Pressure-testing cylinder head

.............................................

-

420

01/l

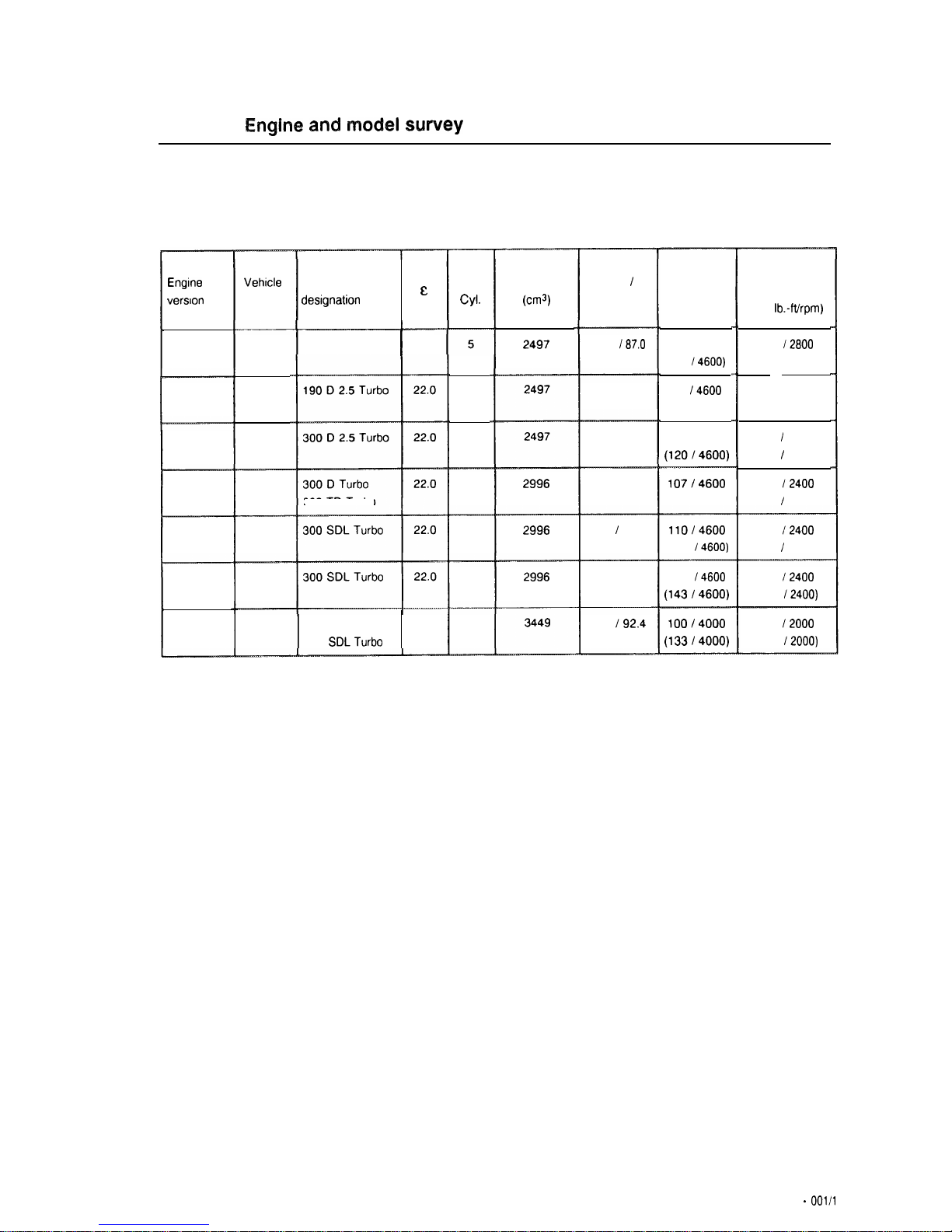

01-001

Engine

and

r?lodel

suwey

output

(SAE)

Kw(hp)/rpm

Torque (SAE)

Nm/rpm

(net

lb.-fthpm)

No.

Cyl.

Displacement

(cm?

Bore

I

Stroke

Engine

version

Vehrcle

model

Sales

&

desrgnation

190 D 2.5

I

22.0

84.0

187.0

201.126

165

12800

(12212800)

22812400

(16812400)

223 / 2400

(164 / 2400)

265

12400

(195 / 2400)

6914600

(93

14600)

92

14600

(12314600)

90 14600

(120/4600)

2497

602.911

84.0 187.0

602.961

Federal

5

201.128

84.0 187.0

602.962

Federal

5

124.128

2996

84.0 187.0

107/4600

(14314600)

603.960

124.133

124.193

6

300 TD

Turbo

87.0 / 84.0

110/4600

(148

/4600)

273

/2400

(201 / 2400)

603.961

Federal

126.125

6

2996

87.0 184.0

107

/4600

(143/4600)

265

12400

(195

12400)

603.961

126.125

6

2996

California

603.970

Federal

310

12000

(228

12000)

6

89.0

192.4

100/4000

(133/4000)

350 SD Turbo

22.0

350 SDLTurbo

126.134

126.135

1.10 -

001/l

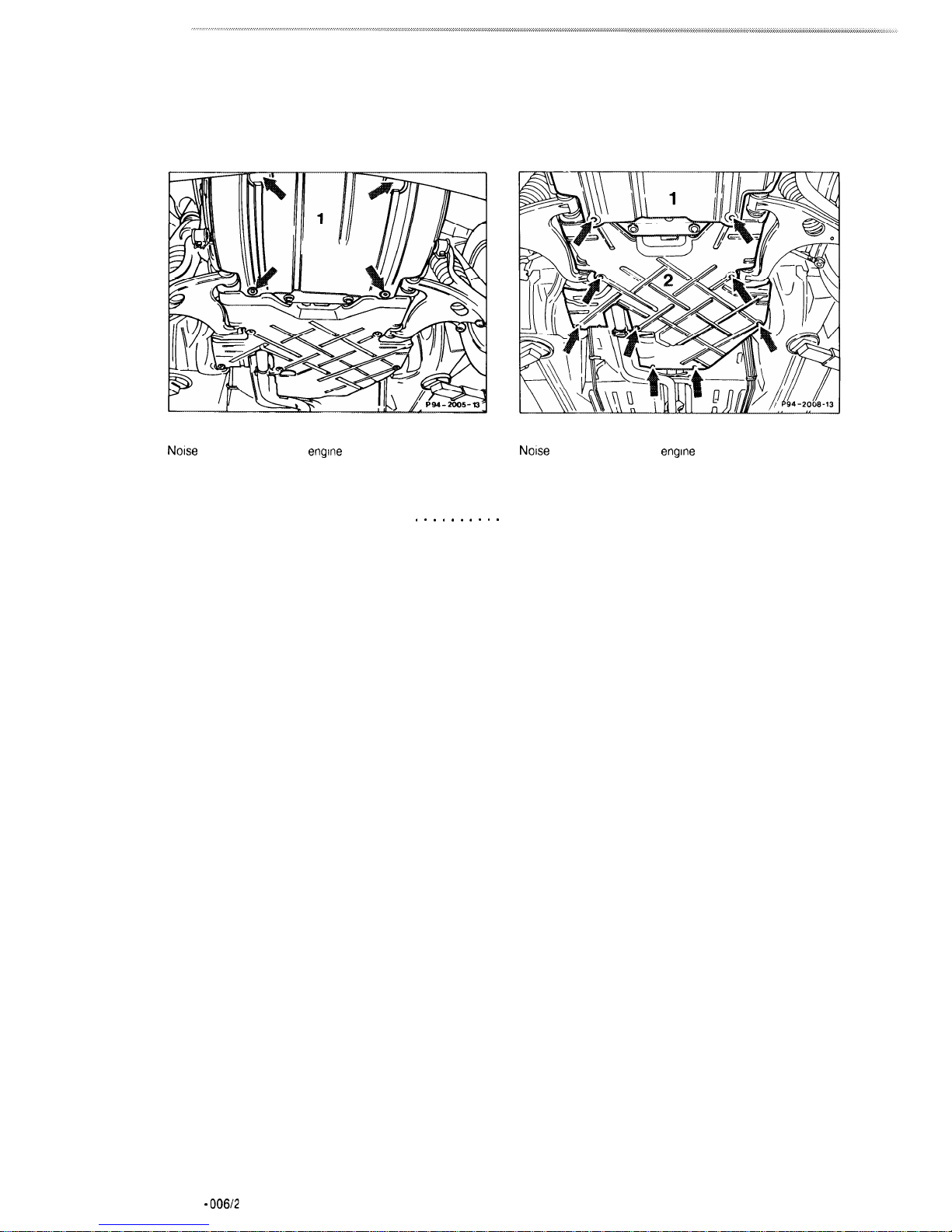

Model

201

Noise

capsule at bottom of

engine

compartment, front (1)

Noise

capsule at bottom of

engine

compartment, rear (2)

Noise capsule, front and rear (1, 2)

. . . . . . . . . .

Remove sheet metal screws (arrows), reinstall

and remove capsule, install.

Note

Install engine compartment capsule so that

edges of side part of capsule engage in bottom

part of capsule.

01.10 - 006/2

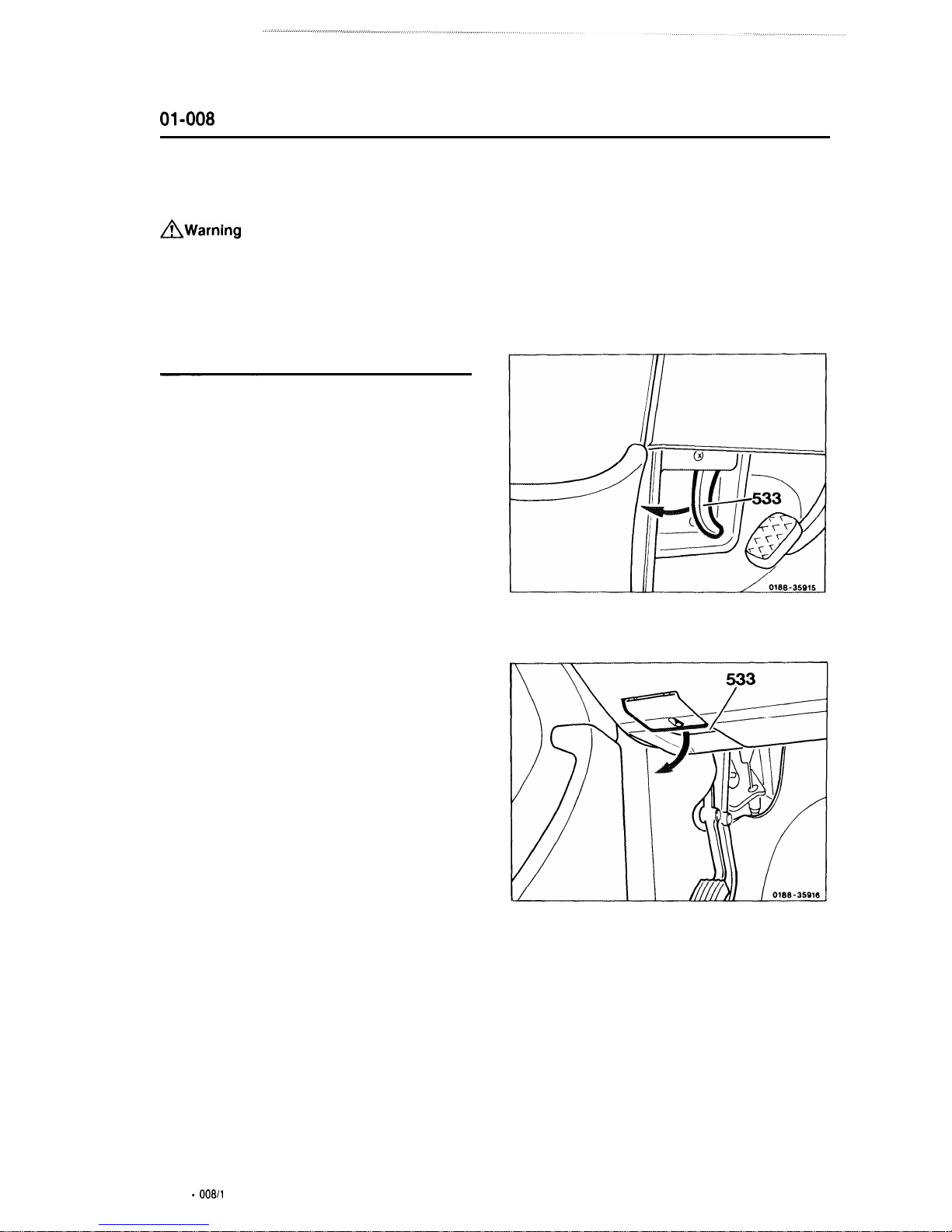

01-008

Opening

hood,

setting vertical,

warnings

AWarning

There is risk of injury whenever the engine is

running and the hood is open.

Opening hood

1

To unlock the hood, pull the lever (533) on

the left below the instrument panel in the

direction of the arrow. The hood opens to the

safety hook stop.

Model126

Model 124

01.10 -

008/l

2

Close hood by pushing down forcibly.

Model201

Model 124, 126, 201

3

Pull the handle (535) extending from the

grille as far as the stop and open hood (it may

be necessary to lift the hood slightly to release

the handle).

Note

Do

not attempt to lift the hood with handle (535).

The windshield wiper arm must not be pivoted

forward when the hood is lifted.

Moving hood into vertical position

Model 124 (production up to August 1988)

4

Push lock lever (537) on the left hood

support (536) in direction of arrow. Lift hood

slightly upward to keep the lock lever (537) from

reengaging again.

Repeat the preceding at the right hood support

and set the hood in a vertical position.

5

To close the hood, push in lock lever at the

right hood support, and close the hood by

pushing down forcibly.

1.10 -

00812

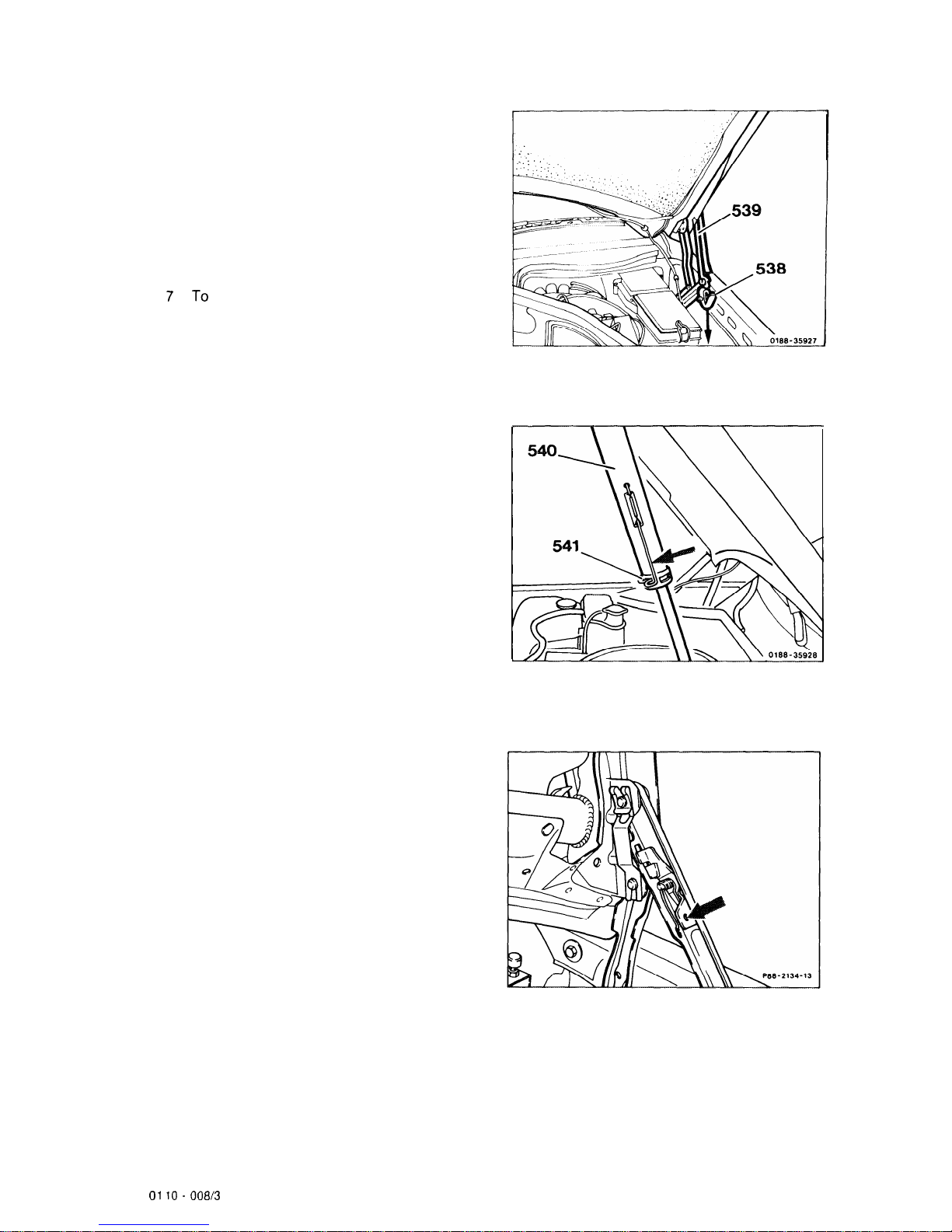

Model 126

6

Push hood down slightly. Push lock lever

(538) on the left hood support (539) down in the

direction of the arrow. Push hood up slightly to

keep the lock lever (538) from reengaging.

Repeat the preceding at the right hood support

and set the hood in a vertical position.

7

To

close the hood, push the lock lever (538)

at the left hood support in the direction of the

arrow, and close the hood by pushing down

forcibly.

Model 201

8

Pull lock (541) on hood damper (540) in

direction of arrow and set the hood in a vertical

position.

9

When the hood is set vertical, a lock

engages on the left hood support.

10 Close hood. Push in the lock lever (arrow)

and close the hood by pushing down forcibly.

01 10 -

008/3

01-010

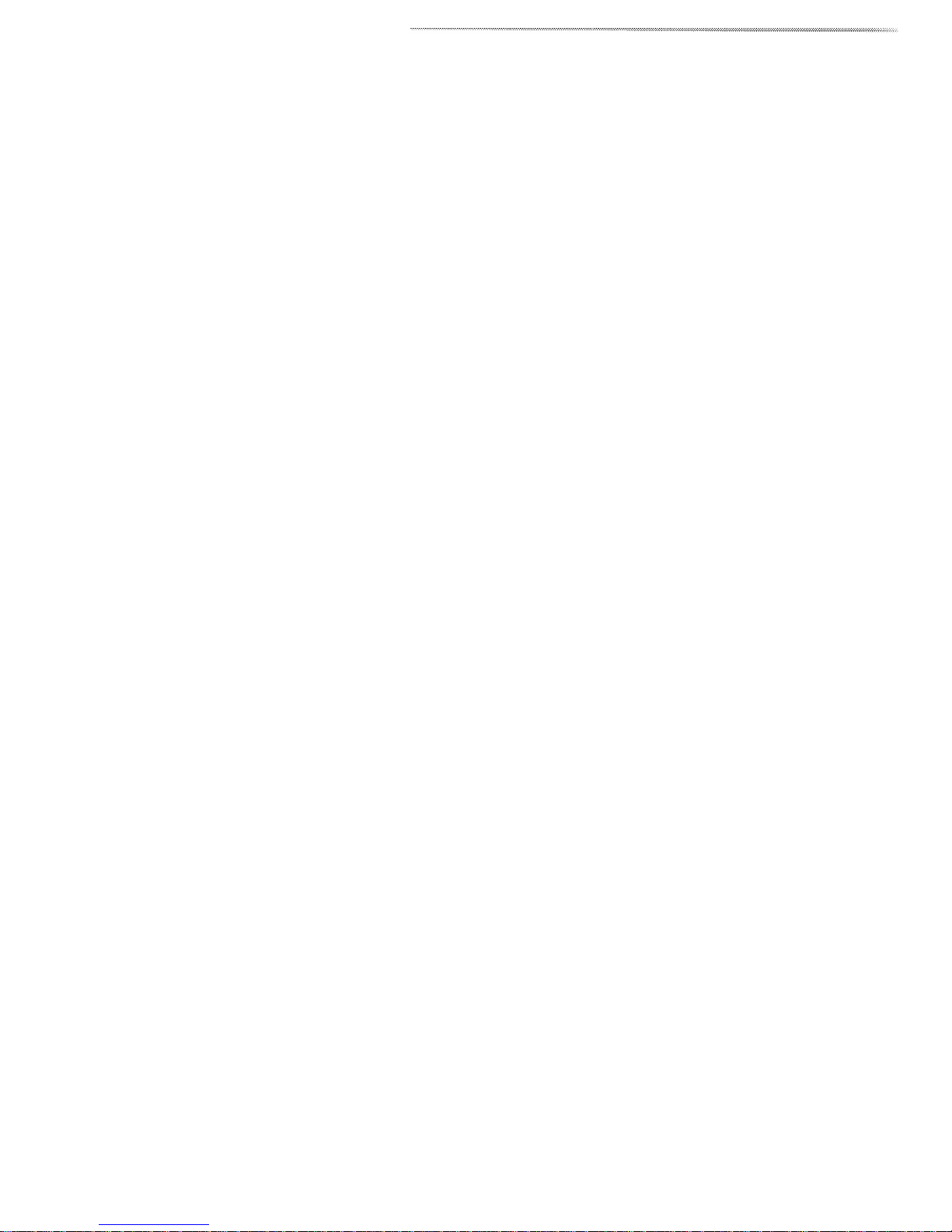

Testing compression pressure

Engine

,..............................

warm up to operating temperature

(approx. 80

“C)

(item

1).

Note

Check compression only with engine at

operating temperature.

Nozzle holder (1)

. . . . . . . . . . . . . . . . . . . . . . .

remove, install (07-230).

Plug connector (X27)

. . . . . . . . . . . . . . . . . . . .

for starter harness, disconnect, reconnect

(items 3 - 4).

Note

The plug connector (X27) illustrated in the figure

is installed on model 124. The installation point

and version of the plug connector differs

depending on the model.

01.10 -

010/l

Contact handle . . . . . . . . . . . . . . . . . . . . . . . .

.

for compression pressure recorder

001 589 78 21 00, connect, adapter line

124 589 36 63 00 (items 3 - 5).

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

turn over a number of times to clean out; the

transmission must be in neutral and the shutoff

lever on the injection pump pressed to “stop”

(item 6).

Compression pressure recorder (01)

. . . . . . . . .

bolt appropriate adapter (03) and flexible

connector (02) into precombustion chamber of

cylinder to be checked (item

7).

Compression. . . . . . . . . . . . . . . . . . . . . . . . .

.

check; shift transmission to neutral and turn

engine over at least 9 revolutions with the

shutoff lever on the injection pump pushed to

“stop” (items 8 - 9).

Note

Check compression in remaining cylinders in

same manner.

Measured compression values . . . . . . . . . . . . . .compare with specified test values (item 10).

Note

If

one or more cylinders do not have the

minimum compression, determine cause.

Test values with engine at operating temperature (approx. 80

“C)

bar

Compression pressure, normal

26 - 32

Minimum compression pressure approx. 18

Permissible difference between individual cylinders

max. 3

Tightening torques

Nm

Union nuts on injection lines (reference value) 10-20

Nozzle holders in prechambers

70+10

Nozzle holders for angular injection

30

01.10 -

01012

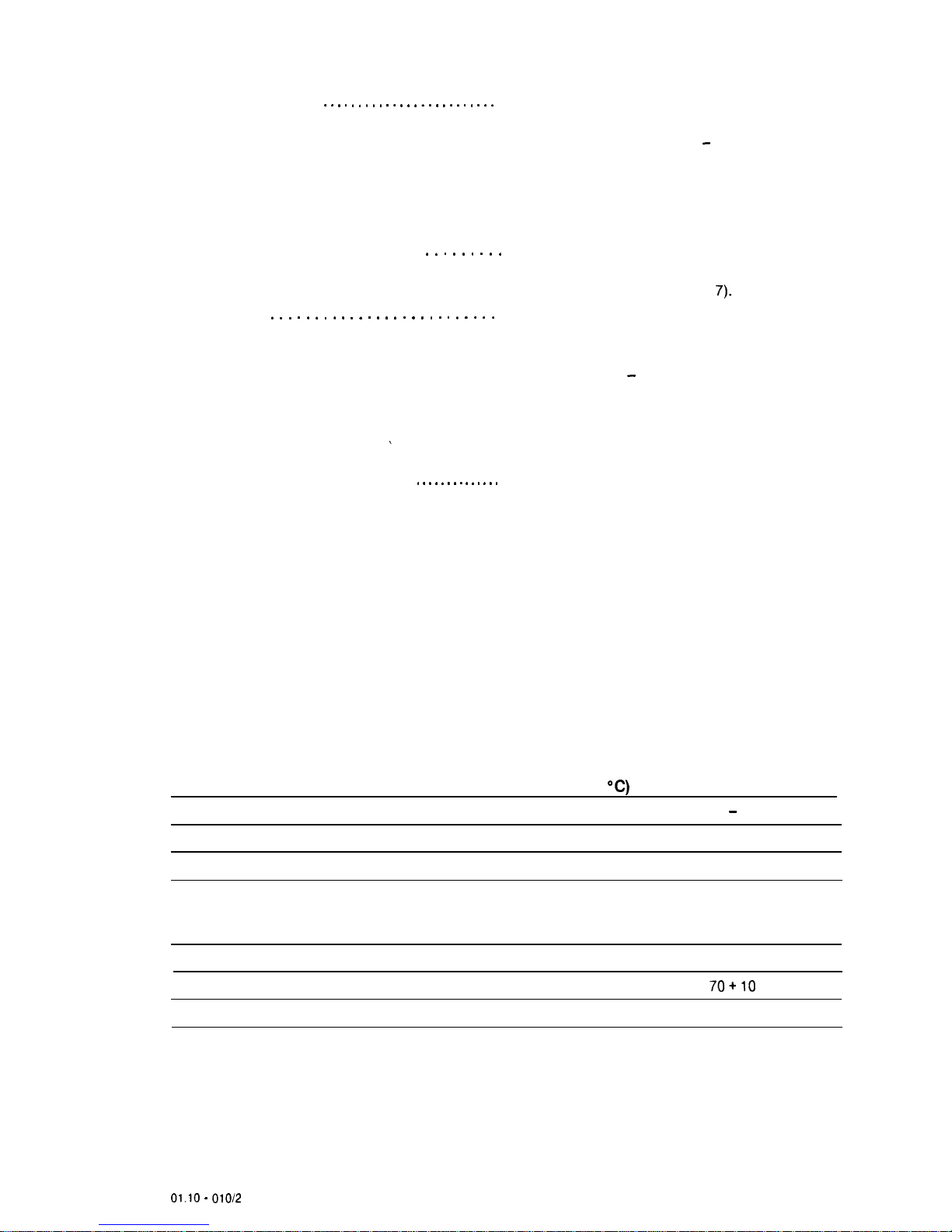

Special tools

Testing

1

Warm engine up to operating temperature

(approx.

80

“C).

Note

Check compression only with engine at

operating temperature.

2

Remove all nozzle holders

(07-230).

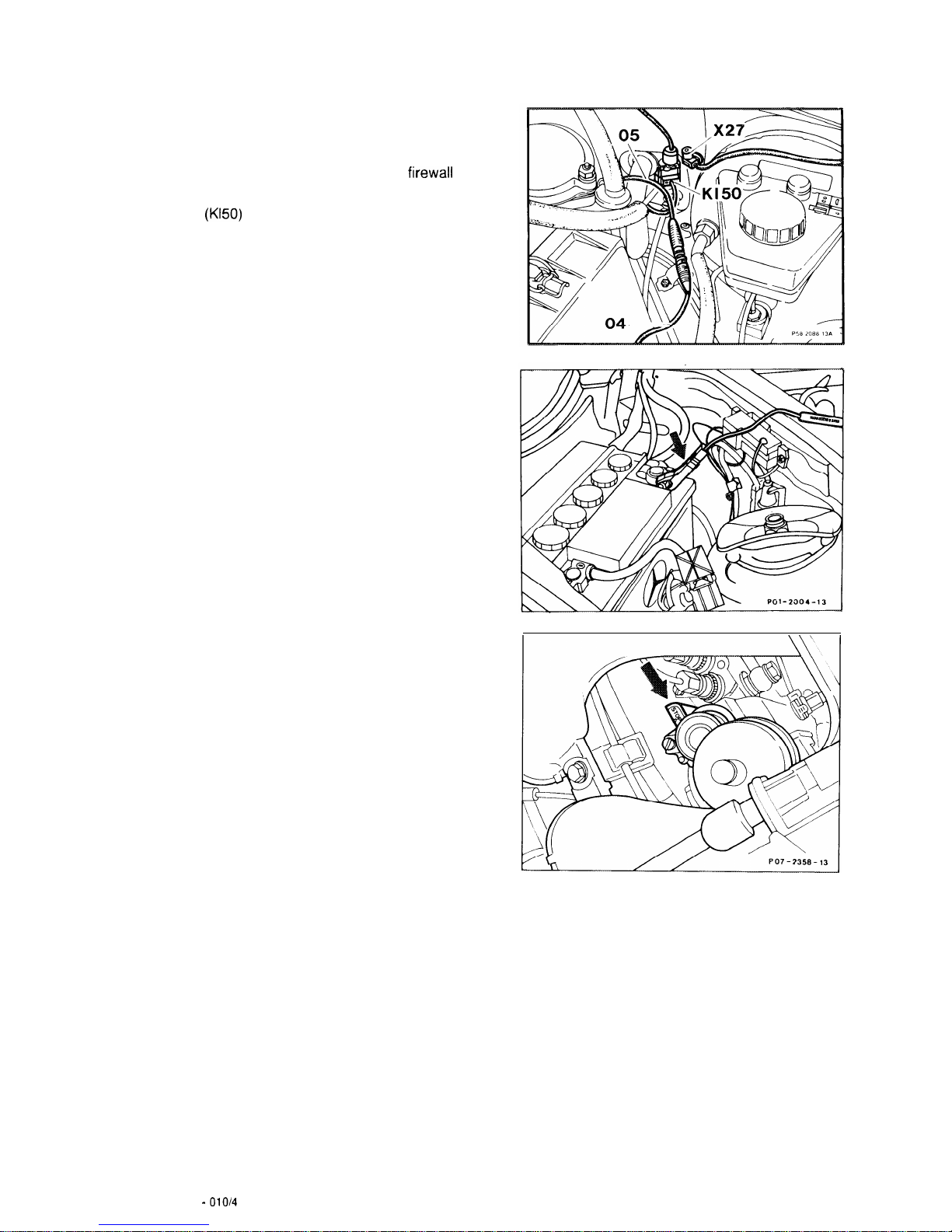

Models 124 and 126

3

Connect contact handle for compression

pressure recorder 001 589

78

21 00; disconnect

plug connector

(X27)

on left side of engine

compartment and connect connection line

(04)

of contact handle to plug

(Kl50)

with adapter line

(124 589 36 63 00 (05).

602 589 00 6300

ol

!

Model124

Model126

01.10 -

010/3

Model 201

4

Connect contact handle of compression

pressure recorder 001 589

78 21 00;

disconnect

plug connector (X27) on left side of

firewall

and

connect connection line (04) of contact handle to

plug

(Kl50)

with adapter line 124 589 36 63 00.

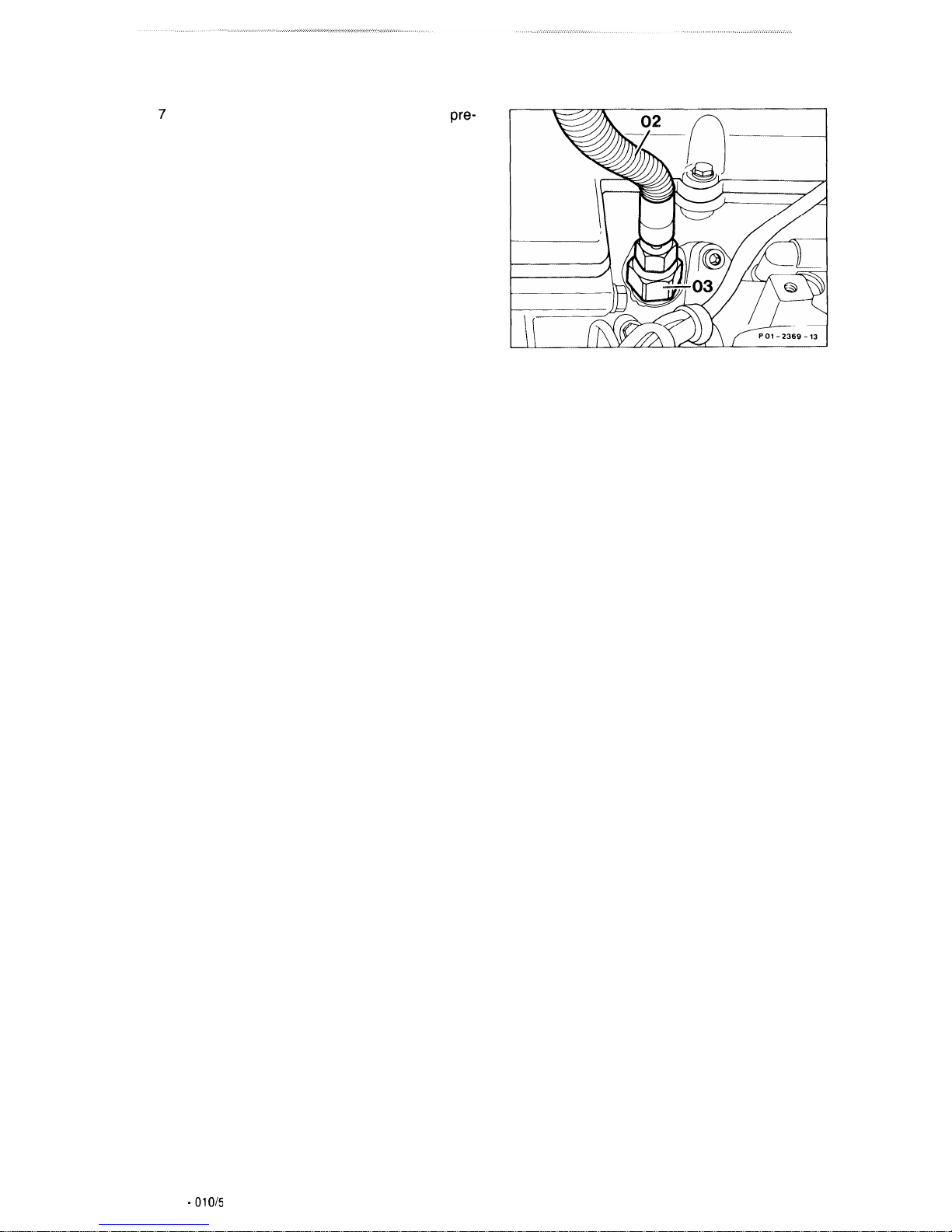

5

Connect second connection line from

contact handle to positive pole (K130) on battery

(arrow).

6

Crank engine a number of times with starter

with transmission in neutral and shutoff lever on

injection pump (arrow) pressed to “stop” to

remove combustion residues in the

precombustion chamber of the cylinder.

Note

Always hold shutoff lever on injection pump

depressed when cranking engine. This prevents

fuel from being pumped and therefore running

out of the disconnected injection lines.

01.10 -

01014

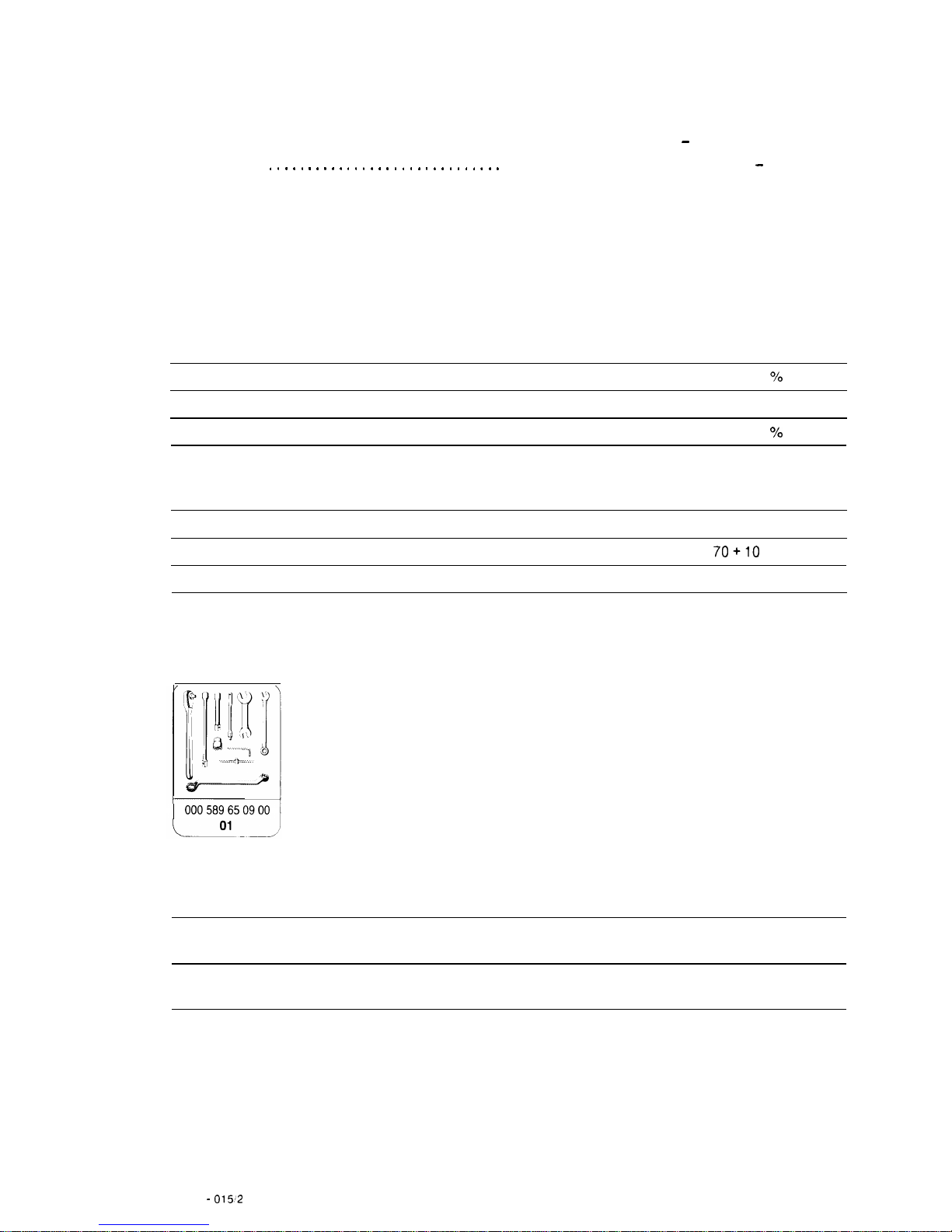

7

Bolt compression pressure recorder into

pre-

chamber of cylinder to be tested with appropriate

adapter (03) and flexible connector (02).

Note

On engines with angular injection use adapter

602 589 00 63 00.

8

Crank engine at least 8 revolutions to test

compression.

9

Perform test on remaining cylinders in same

manner.

10 After completing the compression test

compare pressures measured with specified

values.

Note

If one or more cylinders do not have the

minimum compression pressure, check cylinder

for leakage (01-015) and determine cause.

11 Install in reverse order.

01.10 -

OlO&

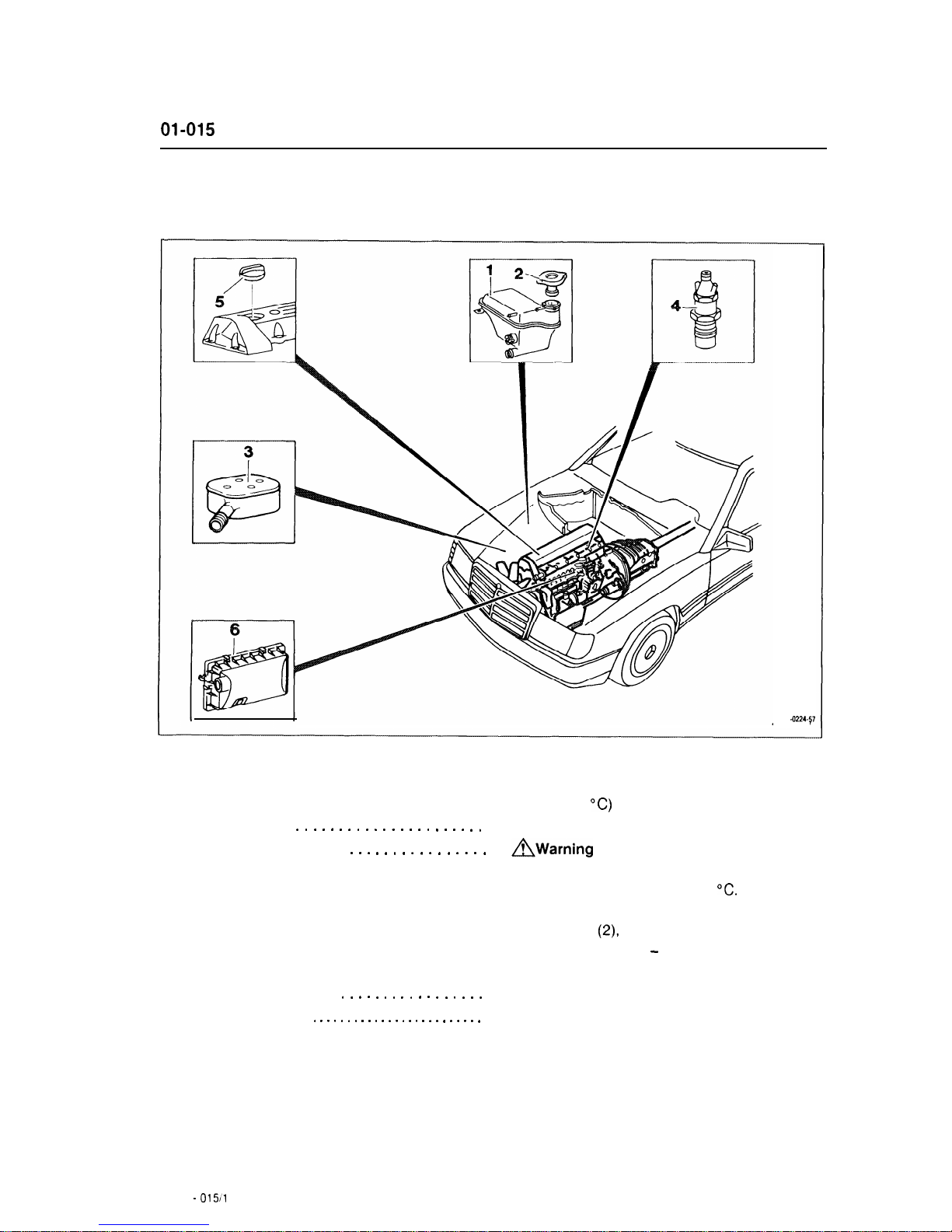

01-015

Checking cylinders for leaks

PO1 4224-57

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

warm up to operating temperature

(approx. 80 “C) (item 1).

Nozzle holders (4)

. . . . . . . . . . . . . . . . . . . . . .

remove, install

(07-230).

Coolant expansion tank (1)

. . . . . . . . . . . . . . . .

AWarning

Open cap (2) on coolant expansion tank only at

coolant temperatures below 90 “C.

Remove cap

(2)

install. Add coolant,

if necessary (items 3 - 4).

Air cleaner on naturally aspirated engines (6)

and on Turbo-engines (3)

. . . . . . . . . . . . . . . . .

remove air cleaner cover, install (item 5).

Oil filler cap (5) . . . . . . . . . . . . . . . . . . . . . . . .

.

remove, install (item 6).

01.10 -

015/l

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

move piston of cylinder to be checked to TDC,

ignition stroke, connect and calibrate cylinder

leakage tester (items 7 - 9).

Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

determine pressure loss (items 10 - 12).

Note

Check other cylinders in firing order.

Permissible pressure loss

Total, engine

max. 25

%

Valves and cylinder head gasket

max. 10 %

Piston rings

max.

20

%

Tightening torques

Union nuts on injection lines (reference value)

Nm

10-20

Nozzle holders in prechambers

70+10

Nozzle holders for angular injection

30

Special tool

1 000589650900

Commercially available tools

Cylinder leakage tester

e.g.

Bosch, EFAW 210 A

Sun, CLT 228

Adapters and connectors

e.g. Bosch

Order no. 1 687 010 016

01.10 -

01512

Testing

1

Warm engine up to operating temperature

(approx. 80 “C).

2

Remove all nozzle holders (07-230).

A

Warning

Open cap on coolant expansion tank only at

coolant temperatures below 90 “C.

3

Remove cap on coolant expansion tank.

4

Check coolant level in coolant expansion

tank and add, if necessary.

5

Open retaining strap on air cleaner cover on

naturally aspirated engines or unscrew hex. head

bolts on air cleaner cap on Turbo-engines,

remove air cleaner cap and take out filter

cartridge.

6

Remove

011

filler cap.

7

Move piston in cylinder to be checked to

TDC, ignition stroke.

8

Bolt appropriate adapter (01) with straight or

angular connector (02) into precombustion

chamber of cylinder to be checked.

9

Calibrate cylinder leakage tester and bolt

connection hose (03) of tester onto connector

(02).

01.10 -

01X.3

Loading...

Loading...