Mazda 1979-1984 RX7 Workshop Manual

This file is available for free download at http://www.iluvmyrx7.com

This file is fully text-searchable – select Edit and Find and type in what you’re looking

for. This file is intended more for online viewing than printing out so some graphics may

not print 100% legibly, you can zoom in on them if you need to.

www.iluvmyrx7.com

1.3L ENG NO START/BLOWN FUSE - SHORT IN WIRE HARNESS CAT. 15, NO. 012/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

TECHNICAL SERVICE BULLETIN

APPLICATION

1979-84 RX7

SUBJECT

"ENGINE" Fuse Blows/No Start

REFERENCE

Mazda Motors Corp., Service Bulletin, No. 15 012/85, September, 1985

CONDITION & CAUSE

Monday, August 27, 2001 06:29AM

Some 1979-84 RX7 vehicles may exhibit an "ENGINE" fuse that blows,

preventing the engine from starting. This problem may be caused by an

electrical short circuit in the wiring harness.

REPAIR

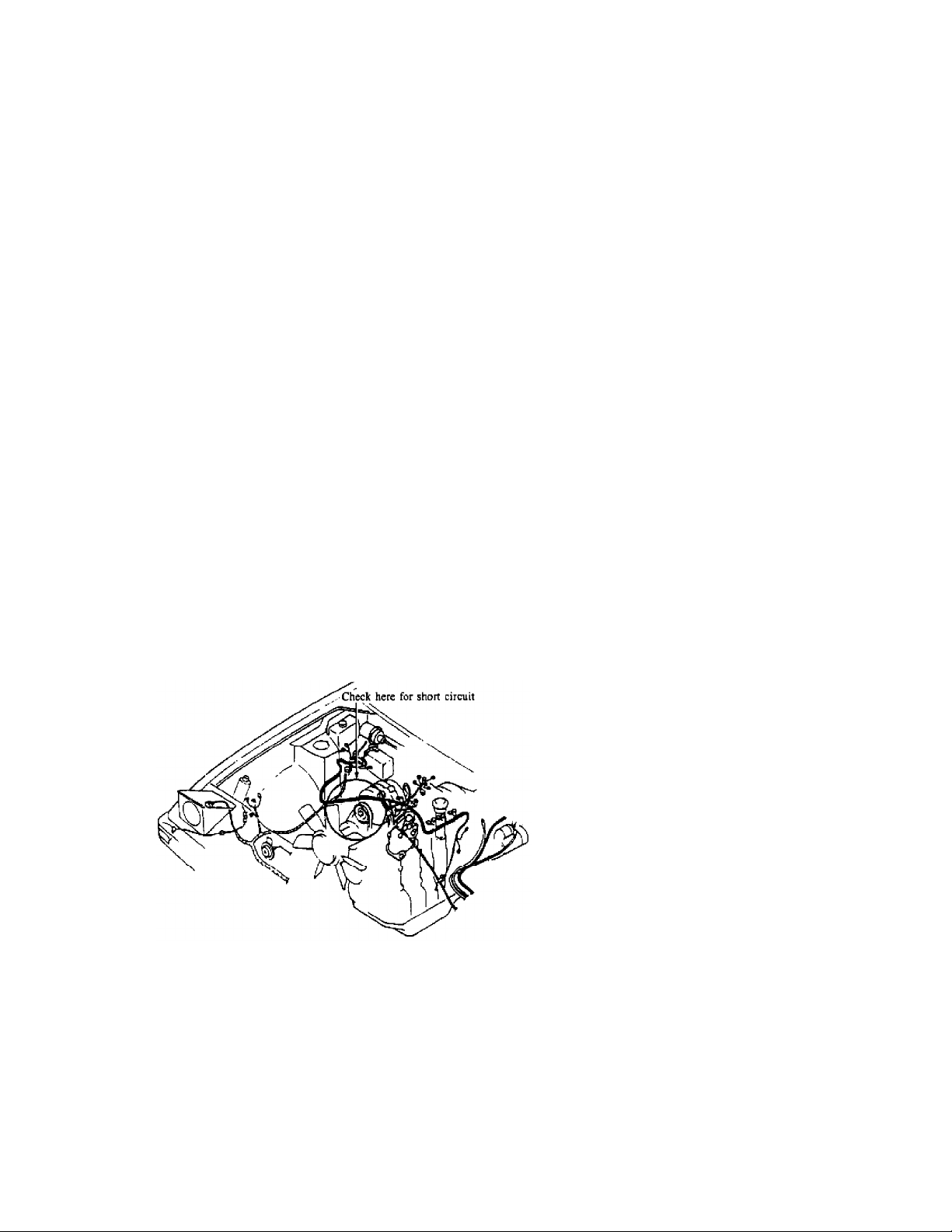

Check for a short circuit in the wire harness in the area of the

thermostat and air hose to the air cleaner. See Fig. 1.

Fig. 1: View of Wiring Harness

END OF ARTICLE

ACCEPTABLE BATTERY DRAIN CAT. 5, NO. 017/88

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:29AM

TECHNICAL SERVICE BULLETIN

CURRENT DRAW FROM THE BATTERY

Model: All Models

Bulletin No.: 017/88

Date: 7/27/88

Category: 5

DESCRIPTION

In order to maintain the memory of the electrical equipment such as

radio, clock, and several other control units, a small amount of

current is drawn from the battery even though the vehicle is not in

use. Although the actual current may vary according to the electrical

equipment in each vehicle, the following specification can be used to

determine if the current draw of the vehicle in question is normal or

not.

CURRENT DRAW AMPERAGE

All Vehicles: 15 to 25 mA (Ignition key is removed or in the lock

position).

NOTE:

If the ignition key is in the ACC position, up to 250 mA is drawn from

the battery. This current draw is large enough to discharge the

battery in a few days.

TEST PROCEDURES

1. Turn the ignition switch off and remove the key from the cylinder.

2. Turn off all electrical loads. Make sure all doors and the trunk

lid are completely closed.

3. Open the hood and disconnect the negative battery terminal.

NOTE:

If the vehicle is equipped with theft-deterrent system, disconnect the

coupler from the hood switch so that the warning light of the theftdeterrent system is not operable.

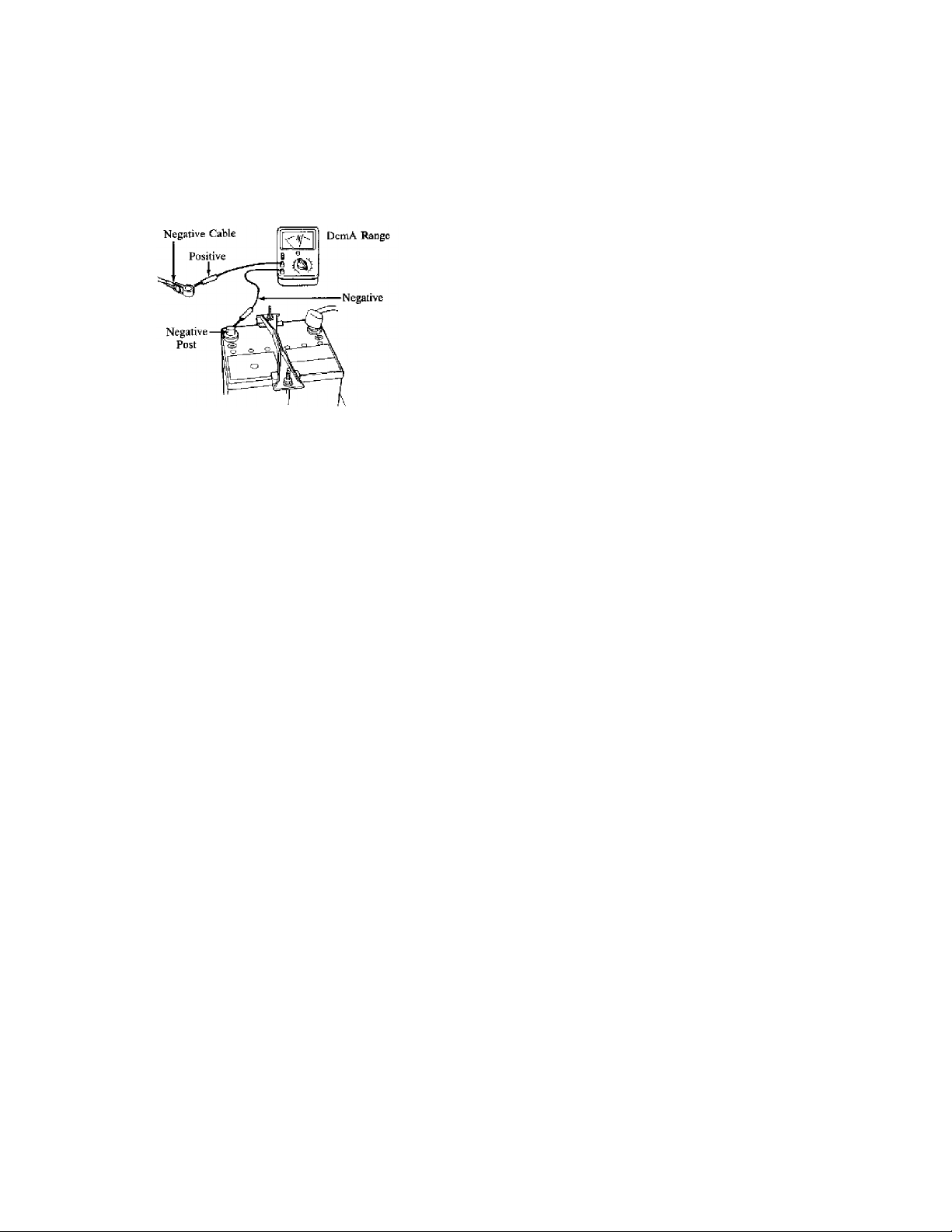

4. Set the circuit tester to the "DC mA" range, to at least 100 mA

range and check the current as follows:

Positive lead from tester to Negative Battery Cable

Negative lead from tester to Negative Battery Post.

CAUTION:

Do not open the door while checking the current, as the tester will be

ACCEPTABLE BATTERY DRAIN CAT. 5, NO. 017/88

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:29AM

damaged by the excessive current.

Fig. 1: Testing Currant Draw

END OF ARTICLE

Article Text (p. 2)

1983 Mazda RX7

ALTERNATOR/REGULATOR TEST PROCESS/REPLACEMENT INFO CAT. 5, NO. 058/83

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:30AM

TECHNICAL SERVICE BULLETIN

IC REGULATOR CHECKING PROCEDURE

Models All Models

Bulletin No. 058/83

Category 5

Date 11/9/83

DESCRIPTION

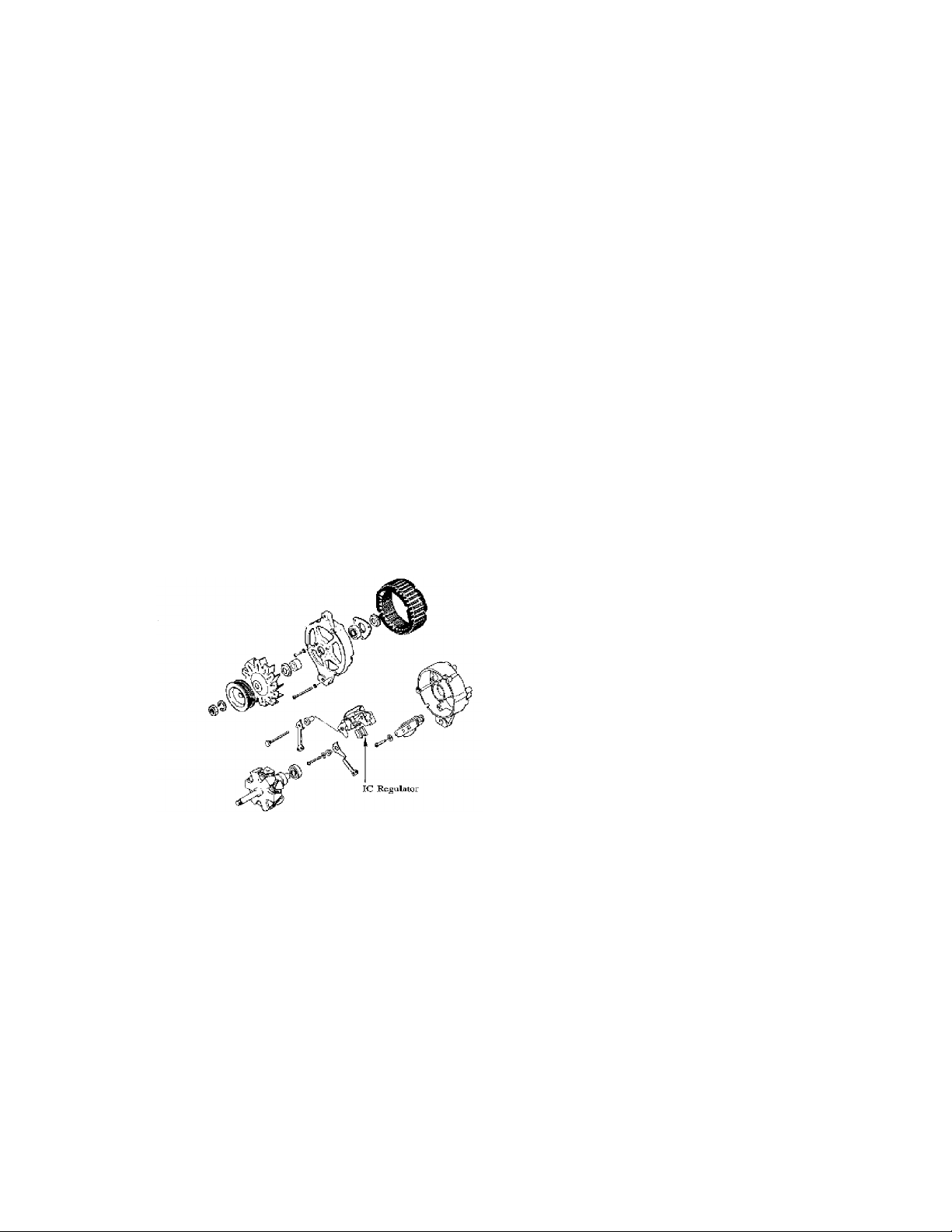

Checking procedure for the built-in IC regulator has been

established to pin point the alternator problem. Basically, the

alternator should be replaced as a unit through the exchange program.

However, in case of a shortage of refurbished alternators, you may

replace the IC regulator to minimize inconvenience of customers (see

Fig. 1).

Fig. 1: Exploded View of Alternator

PARTS INFORMATION

Regulator N221 24 520

CHECKING PROCEDURE

1. Make sure the battery is fully charged.

2. Turn ignition key on to "Ig" position. If the alternator warning

light is "off", the problem is likely to be caused by regulator.

Leave the key in "Ig" position and take the following step to

assure the cause.

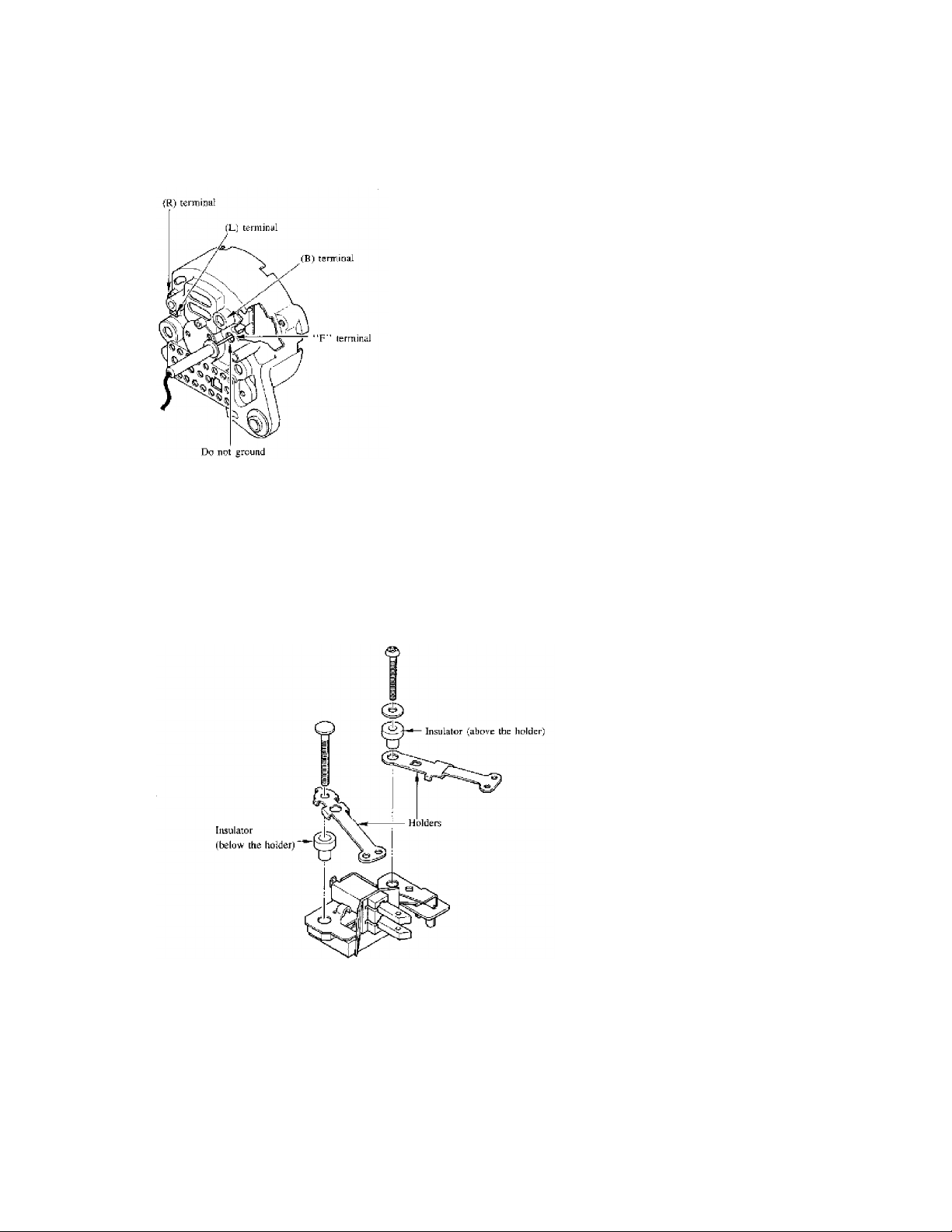

3. Insert volt meter between "F" terminal and nearest ground point

(Fig. 2).

4. Do not ground to the body of the alternator while positive probe

of voltmeter is inserted through the hole for "F" terminal.

ALTERNATOR/REGULATOR TEST PROCESS/REPLACEMENT INFO CAT. 5, NO. 058/83

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:30AM

Fig. 2: Location of "F" Terminal

REPAIR PROCEDURE

Article Text (p. 2)

1983 Mazda RX7

Please refer to the Service Information for IC regulator replacing

procedure.

NOTE: Be sure the insulators are in the proper position as shown in

Fig. 3.

Fig. 3: Proper Location of Insulators

END OF ARTICLE

AUDIO SYSTEM TROUBLESHOOTING PROCEDURES CAT. 15, NO. 078/89

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:30AM

TECHNICAL SERVICE BULLETIN

AUDIO SYSTEM TROUBLESHOOTING

Model All Mazda Models

Category 15, Body Electrical System

Bulletin No. 078/89

Date May 5, 1989

DESCRIPTION

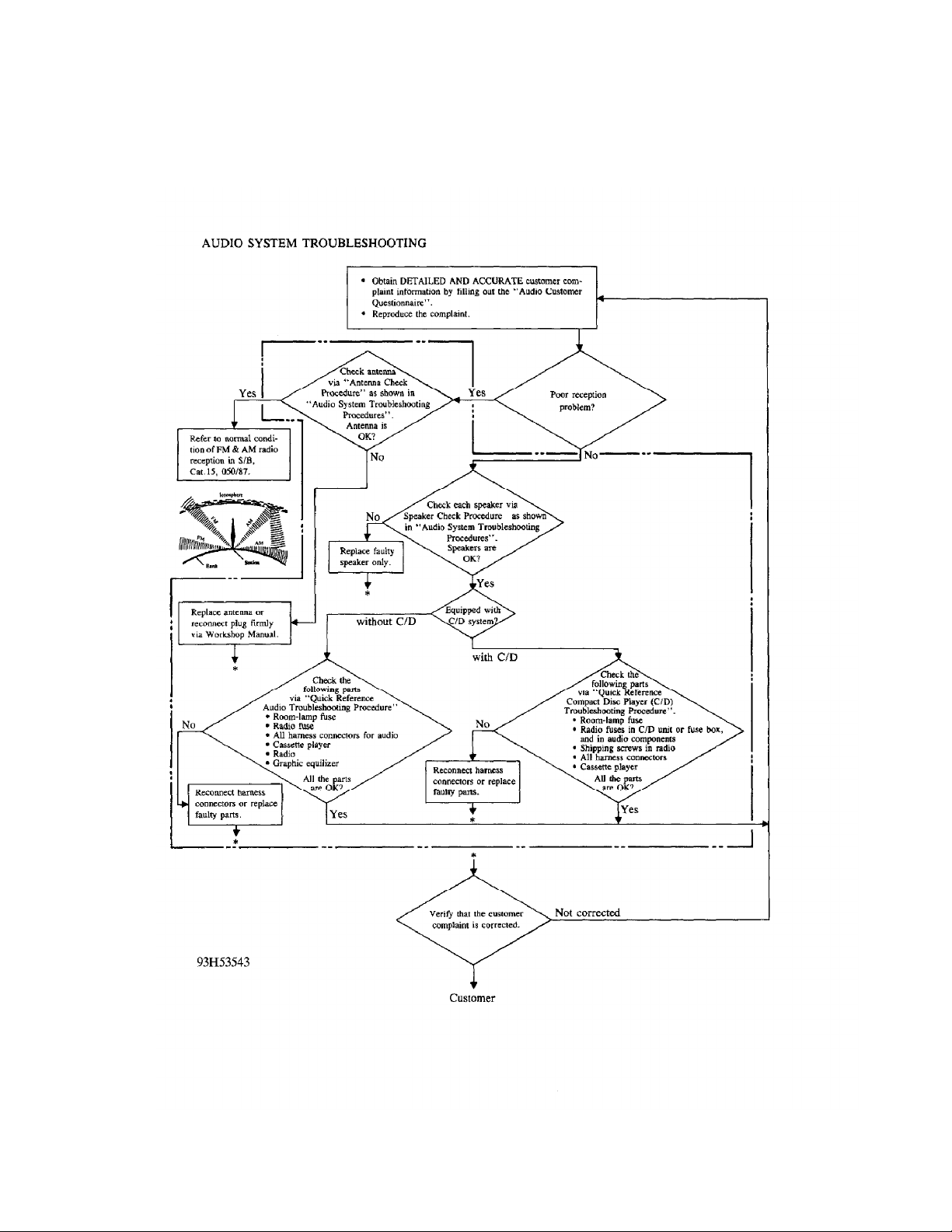

To simplify audio system troubleshooting, a flow chart (see Fig. 1)

has been prepared. It contains essentials of audio system troubleshooting procedures, focusing on the following:

* Obtain accurate information of customer's complaint.

* Carry out appropriate diagnosis or troubleshooting to find the

faulty part.

* Avoid replacing unnecessary parts.

* Verify whether the customer's complaint results from specific

characteristics of FM radio waves. If so, the complaint cannot be

corrected by audio component replacement.

Use the following materials with the attached flow chart when

carrying out inspection and repair of the audio system.

* Audio System Troubleshooting Procedures (plastic sheet)

* Service Bulletin, Category 15, 050/87 (FM Reception)

* Audio Customer Questionnaire

* Workshop Manual

NOTE: If it becomes necessary to disconnect power to the audio

system, be sure to copy down the customer's preset stations.

Re-set these stations after repairs are complete.

AUDIO SYSTEM TROUBLESHOOTING PROCEDURES CAT. 15, NO. 078/89

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:30AM

Fig. 1: Audio System Troubleshooting

END OF ARTICLE

BATTERY REMOVAL/INSTALL WIRE CLIP WARNING CAT. 14, NO. 009/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:31AM

TECHNICAL SERVICE BULLETIN

BATTERY CLAMP BOLT & NUT

Models RX-7

Bulletin No. 009/85

Category 14

Date 1/22/85

DESCRIPTION

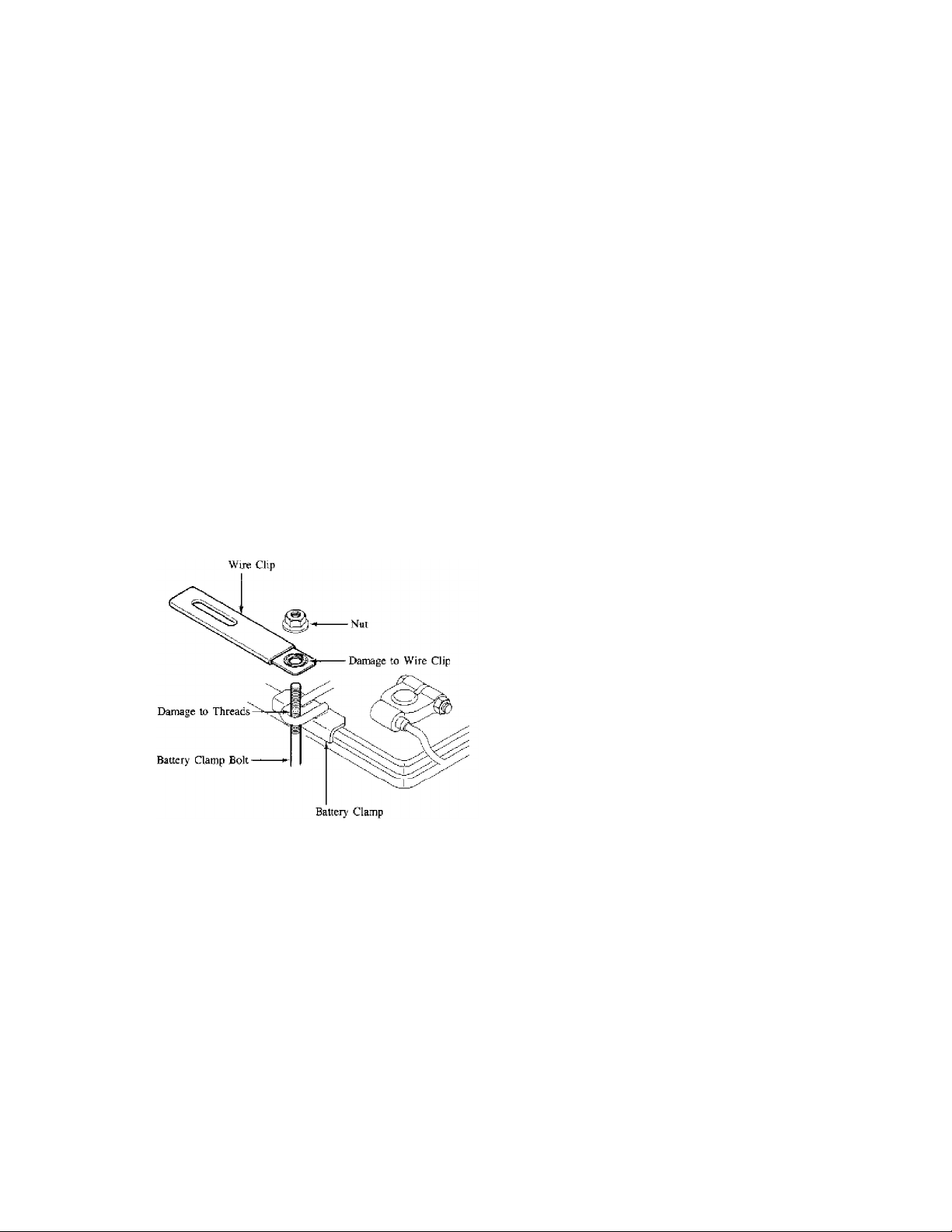

During installation of the battery clamp rod and nut, it is possible

for wire clip to become pinched in the threads on the clamp bolt,

resulting in the nut binding on the clamp rod. See Fig. 1.

If you encounter this problem, please follow the repair procedure

below.

Fig. 1: Battery Clamp Bolt & Nut

PARTS INFORMATION

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

PART NUMBER DESCRIPTION

0613 65 857A Clamp Bolt

9994 00 602 Nut

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

REPAIR PROCEDURE

1. Carefully remove the nut from the battery clamp bolt.

2. Use a die to repair the threads on the clamp bolt.

3. Install a small washer on top of the wire clip to prevent damage

to the threads on the clamp bolt during reinstallation.

END OF ARTICLE

FUSIBLE LINK REFERENCE CHART NO. T-2-3

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:31AM

TECHNICAL SERVICE BULLETIN

FUSIBLE LINK REFERENCE CHART

Model: All Mazda

Date: November 1, 1990 (Revised - April 27, 1992)

No: T-2-3

Group: Parts Bulletin

SERVICE INFORMATION

For easy reference, the following list of Fusible Links have been

compiled.

FUSIBLE LINK REFERENCE CHART

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Year Model Location P/N

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

1979-82 626 Engine Compartment 8174-66-760B

1983-85 626 Gas Engine Compartment 3775-67-099

1983-85 626 Diesel Engine Compartment H047-67-099

1983-85 626 Alternator HA67-67-099

1979 RX-7 Under Dash 1175-66-710A

1980 RX-7 Under Dash 8130-66-710

1980 RX-7 Engine Compartment 8341-18-055

1981 RX-7 Under Dash FA02-67-099

1981-85 RX-7 Engine Compartment 3777-67-099

1981-85 RX-7 Transmission 8341-18-055

1981-85 RX-7 Engine Compartment 8871-67-099

1984-85 RX-7 Engine Compartment 3775-67-099

1981-85 GLC Engine Compartment B003-67-099

1981-85 GLC Engine Compartment B005-67-099

1981-85 GLC Engine Compartment B006-67-099

1977-82 B2000 Engine Compartment B094-67-099

1983-84 B2000/B2200 Engine Compartment UA47-66-099

1988-93 MX-6 Engine Compartment FB01-67-099

M/T,

Non-Turbo A/T

1988-93 626 Sedan Engine Compartment FB01-67-099

1988-93 626 Hatchback Engine Compartment FB01-67-099

M/T,

Non-Turbo A/T

1990-92 929, 929S Engine Compartment FB01-67-099

1986-92 323 Engine Compartment FB01-67-099

1987-89 323 Wagon Engine Compartment FB01-67-099

1986-91, 93 RX-7 Engine Compartment FB01-67-099

FUSIBLE LINK REFERENCE CHART NO. T-2-3

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:31AM

1992 MX-3 Engine Compartment FB01-67-099

1984-86 GLC Wagon Engine Compartment 8573-66-760

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

END OF ARTICLE

HIGH PITCH BUZZING NOISE AT DASH: REMOVE OSCILLATOR

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Saturday, September 08, 2001 10:01AM

TECHNICAL INFORMATION TIP

BUZZING ROTARY

YEAR(S): 1979-85

MANUFACTURER: Mazda

MODEL(S): RX-7

ISSUE: HIGH PITCH BUZZING NOISE AT DASH - REMOVE OSCILLATOR

If you hear a high pitched buzzing noise coming from the center

of the dash with the key off on a 1979-85 Mazda RX-7, the cause may be

a defective oscillator. The oscillator is located under the hood, in

the area near the left headlight.

To stop the noise, unplug the oscillator. The oscillator is used

as a dash instrument circuit backup. Removing the oscillator has no

other effect except to stop the constant buzzing noise.

Courtesy of Import Service Magazine

with thanks to

James Halderman

Sinclair College

Dayton, Ohio

REFERENCE NUMBER: MAZ0170AP

NOTE: This information has been obtained from sources generally

believed to be reliable. Use your own judgment before relying

on this data. Neither the suppliers of these Technical

Information Tips, nor Mitchell International, guarantees or

assumes responsibility for data accuracy or completeness, nor

is liability assumed by the suppliers of these Technical

Information Tips or Mitchell International for any claims or

damages resulting from the use of this information.

END OF ARTICLE

KEYLESS SWITCH SPEED NUT INFORMATION CAT. 15, NO. 010/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:32AM

TECHNICAL SERVICE BULLETIN

SPEED NUT FOR IGNITION KEY SWITCH

Models GLC, 626, RX-7 & B2000

Bulletin No. 010/85

Category 15

Date 6/25/85

DESCRIPTION

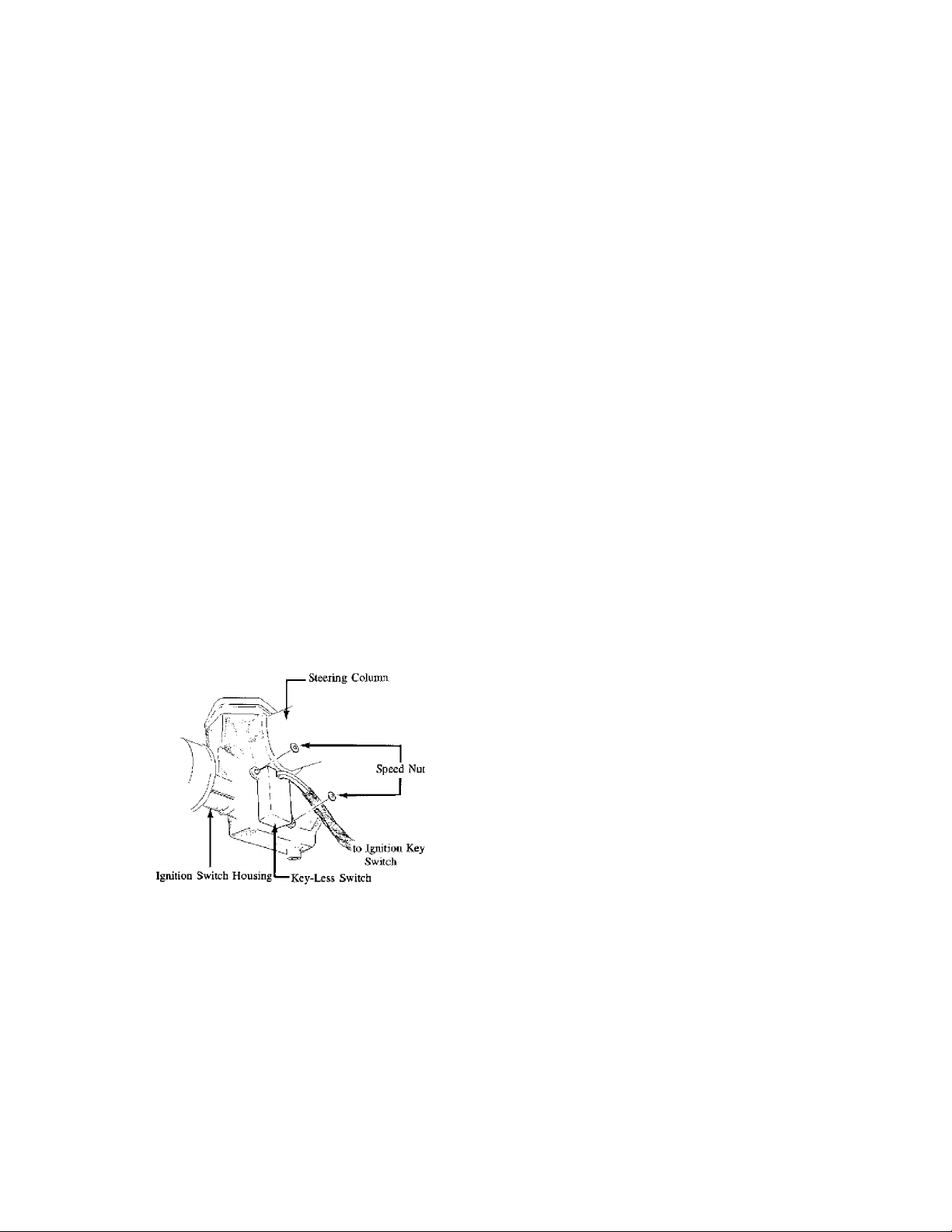

The speed nut for fixing the key-less switch to the ignition key

cylinder housing has been established as a service part. If the

replacement of the ignition key switch is necessary, please use the

new speed nut to secure the key-less switch. See Fig. 1.

PARTS INFORMATION

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

NEW PART NO. OLD PART NO. DESCRIPTION

BC46 66 158 ÄÄ Speed Nut

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Fig. 1: Securing Key-Less Switch with Speed Nut

END OF ARTICLE

MISCELLANEOUS BLOWN FUSES/ELECTRICAL PROBLEMS CAT. 15, NO. 016/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:32AM

TECHNICAL SERVICE BULLETIN

APPLICATION

1979-85 RX7

SUBJECT

Miscellaneous Blown Fuses/Electrical Problems

REFERENCE

Mazda Motors Corp., Service Bulletin, No. 15 016/85, October, 1985

CONDITION & CAUSE

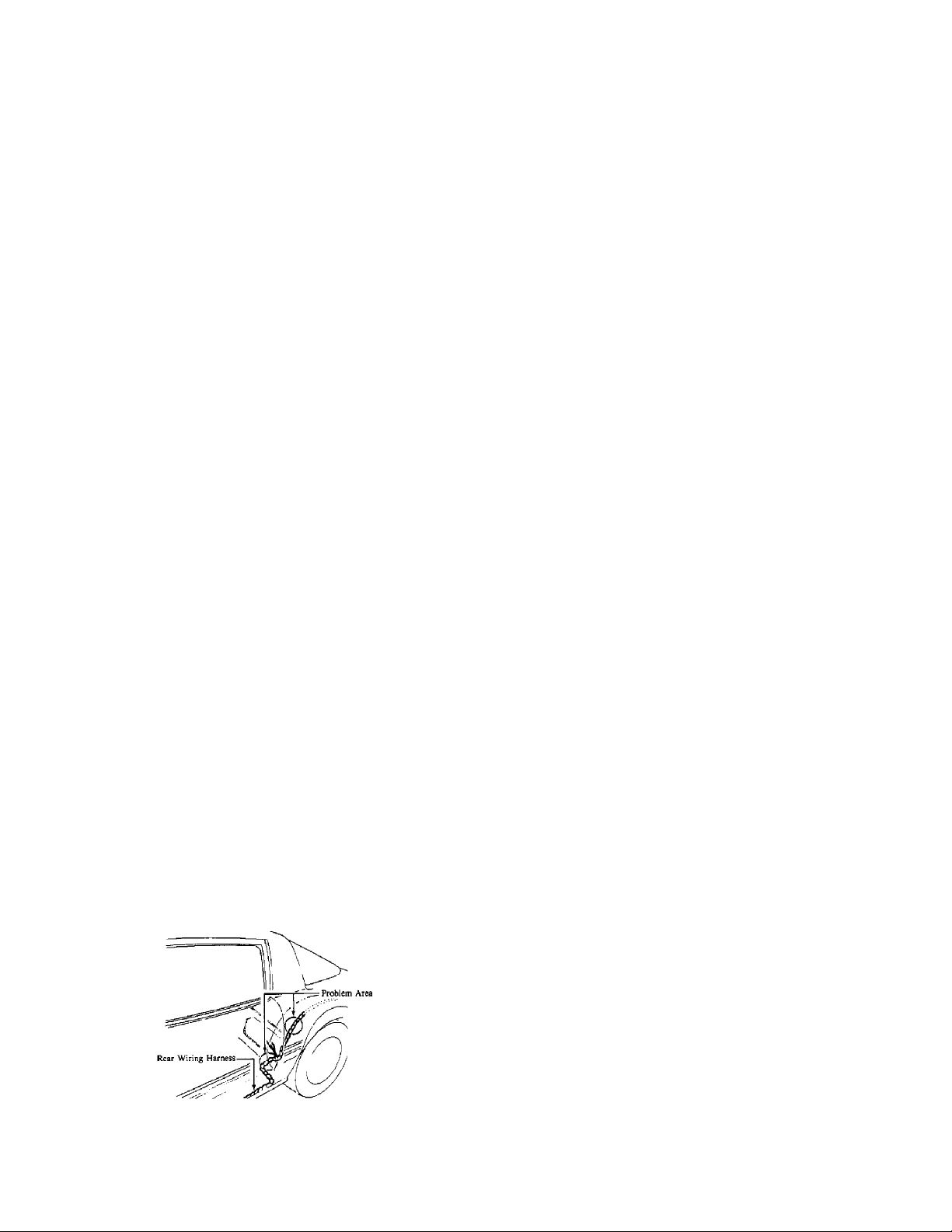

Some 1979-85 RX7 vehicles may exhibit one or more of the following

electrical problems:

* RADIO, ANTENNA fuse blown

* TAIL, ILLUM fuse blown

* METER, BACK fuse blown

* OPENER fuse blown

* Inoperative rear defroster/rear wiper

* Rear wiper operates with wiper switch in OFF position

One or more of the above problems may be caused by a short circuit in

the rear harness. The rear harness may be cut by a sharp metal edge

where the harness is routed over the inner wheel well. See Fig. 1.

This was fixed in production beginning with VIN JM1FB33 F0852204.

REPAIR

If this problem is present, repair the rear harness as necessary.

Fig. 1: View of Rear Wiring Harness

END OF ARTICLE

REAR WINDOW DEFROSTER GRID LINE REPAIR PROCEDURE CAT. T, NO. 015/95

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:33AM

TECHNICAL SERVICE BULLETIN

REAR WINDOW DEFROSTER GRID LINE REPAIR

Model(s): All Mazda Models

Category: T - Body Electrical System

Bulletin No.: 015/95

Date Issued: November 14, 1995

Date Revised: December 21, 1995

DESCRIPTION

The following procedure should be used to repair broken grid lines

on rear window defrosters. Place a copy of these procedures in the

appropriate section of the workshop manual.

REPAIR PROCEDURE

1. Turn the defroster switch on with the ignition in the on position.

2. Determine the broken grid line visually or with a test light or

voltage meter.

3. Turn the defroster and ignition Off.

4. Clean the area with a glass cleaner.

5. Remove the protective backing from the stencil.

6. Align both ends of the broken grid line with the opening in the

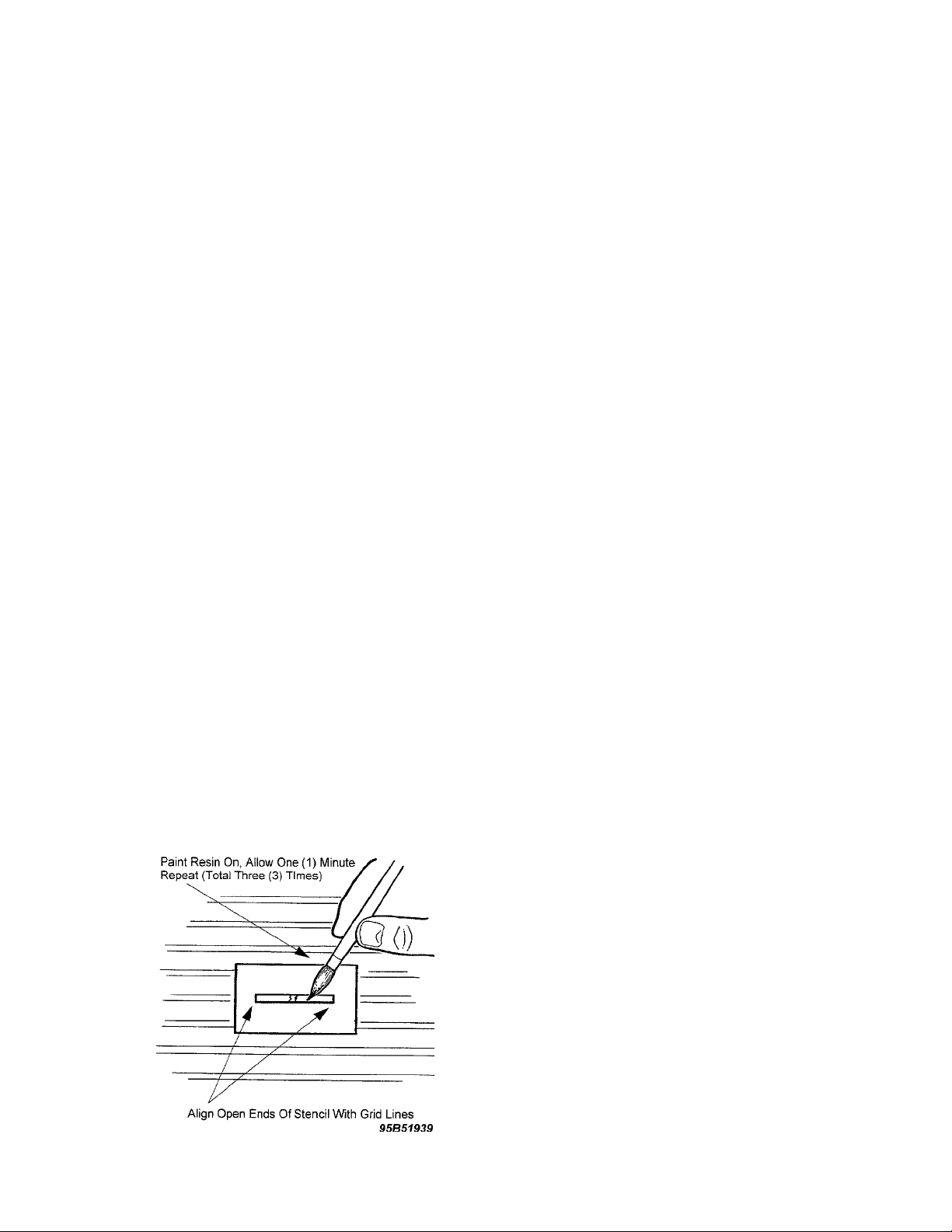

stencil and press firmly to attach. See Fig. 1

Fig. 1: Resin Application Location

REAR WINDOW DEFROSTER GRID LINE REPAIR PROCEDURE CAT. T, NO. 015/95

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:33AM

NOTE: Make sure both ends are aligned prior to attaching.

7. Shake the bottle of resin well.

CAUTION: Continuity failure will occur if the ingredients are not

mixed completely.

8. Brush on the resin overlapping both ends of the broken grid line.

NOTE: Use paint remover to clean brush for future applications.

9. Repeat application (total of 3 times) when the surface is tack-free

(approximately one (1) minute).

10. Allow to dry twenty (20) minutes.

11. Carefully peel stencil from glass.

12. Allow twenty-four (24) hours before activating rear defroster.

PARTS INFORMATION

PARTS INFORMATION TABLE

ЪДДДДДДДДДДДДДДВДДДДДДДДДДДДД¿

³

Part Number ³ Description

ГДДДДДДДДДДДДДДЕДДДДДДДДДДДДД´

³

0000 88 5067 ³ Resin

АДДДДДДДДДДДДДДБДДДДДДДДДДДДДЩ

WARRANTY INFORMATION

³

³

(Applies To Verified Customer Complaints On Vehicles Covered Under

Normal Warranty. Refer To The SRT Microfiche For Warranty Term

Information.)

Warranty Type: A

Symptom Code: D5

Damage Code: AA

Part Number Main Cause: 0000 88 5067

Quantity: 0

Operation Number: XX0777RX

Labor Hours: 0.3 Hrs.

END OF ARTICLE

REVISED WIPER LINK BUSHING CAT. 14, NO. 022/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:33AM

TECHNICAL SERVICE BULLETIN

WIPER LINK

Models 1981-1985 RX-7

Bulletin No. 022/85

Category 14

Date 10/18/85

DESCRIPTION

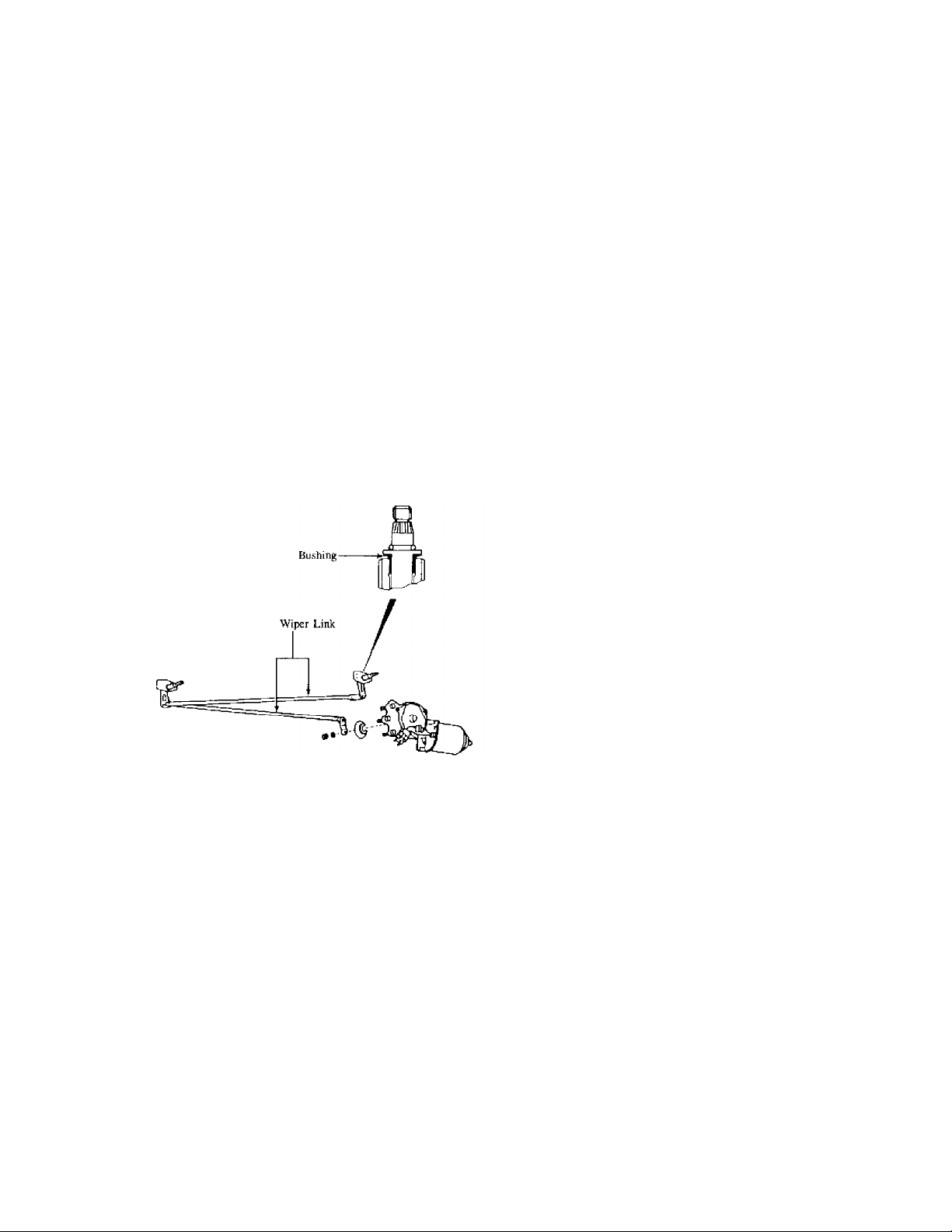

A new wiper link has been established as a service part. This new

wiper link features a bushing as shown in Fig. 1.

Fig. 1: 1981-85 RX7 Wiper Link

PARTS INFORMATION

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

NEW PART NO. OLD PART NO. DESCRIPTION INTERCHANGEABILITY APPLIED

MODEL

FA54 76 601A FA54 76 601 Wiper Link NEW -> OLD 1984-85 RX-7

8871 76 601B 8871 76 601A Wiper Link NEW -> OLD 1981-83 RX-7

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

NOTE: A new part can be used in place of the former part, but the

former part may not be used in place of the new part.

END OF ARTICLE

TURN SIGNAL DOESN'T CANCEL - REPLACE CANCEL CAM CAT. 14, NO. 010/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:34AM

TECHNICAL SERVICE BULLETIN

TURN SIGNAL SWITCH CANCEL CAM

Models All Models

Bulletin No. 010/85

Category 14

Date 1/22/85

Symptom Turn Signal Doesn't Cancel

DESCRIPTION

If the turn signal switch does not cancel, the most probable cause

is a broken cancel cam. The cancel cam is available separately and can

be replaced as shown below.

REPAIR PROCEDURE

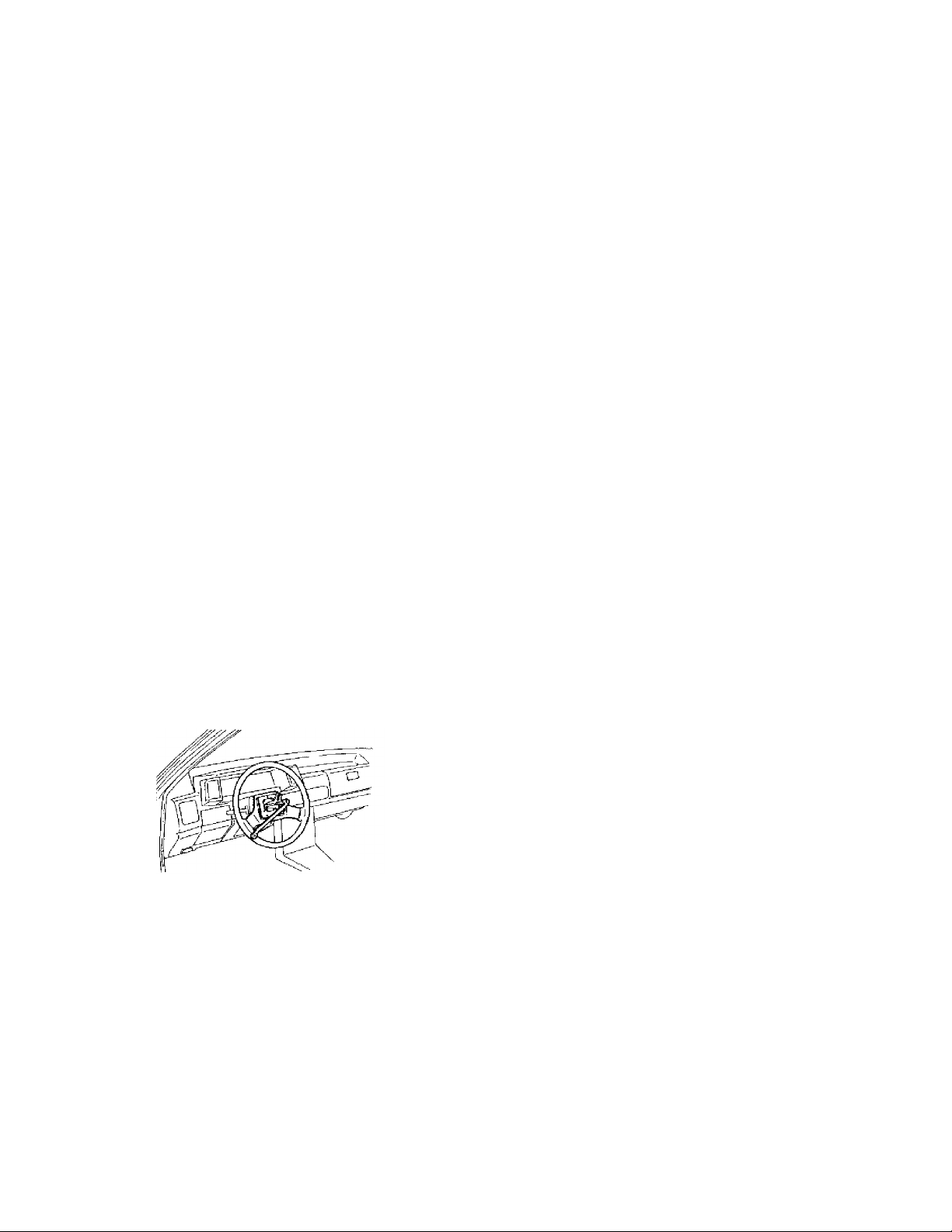

1. Put a mark on the steering wheel and steering shaft so that the

steering wheel can be reinstalled in the same position.

2. Remove the retaining nut for the steering wheel and remove the

steering wheel with a steering wheel puller. See Fig. 1.

CAUTION: Do not strike the steering shaft with a hammer as this will

damage the steering shaft.

Fig. 1: Steering Wheel Removal

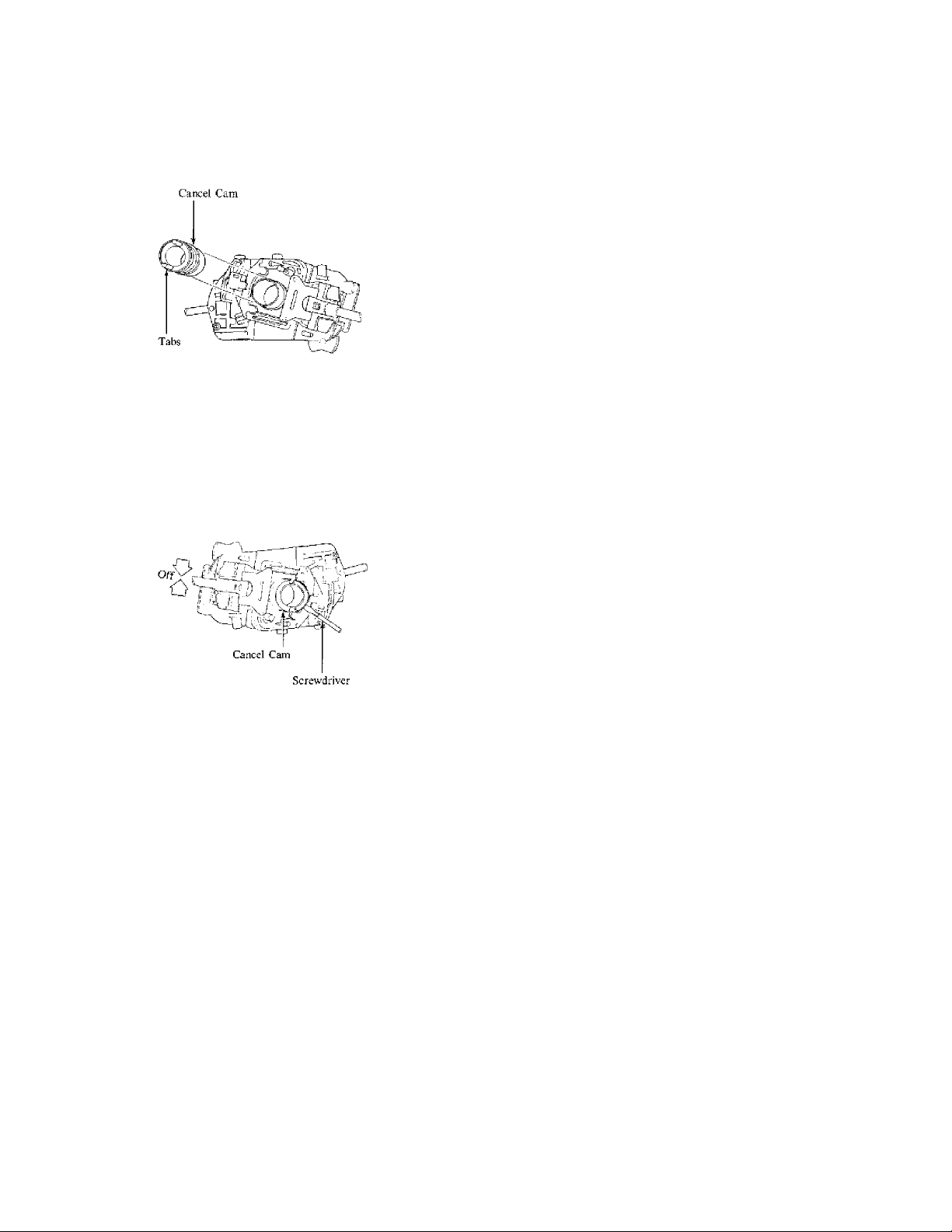

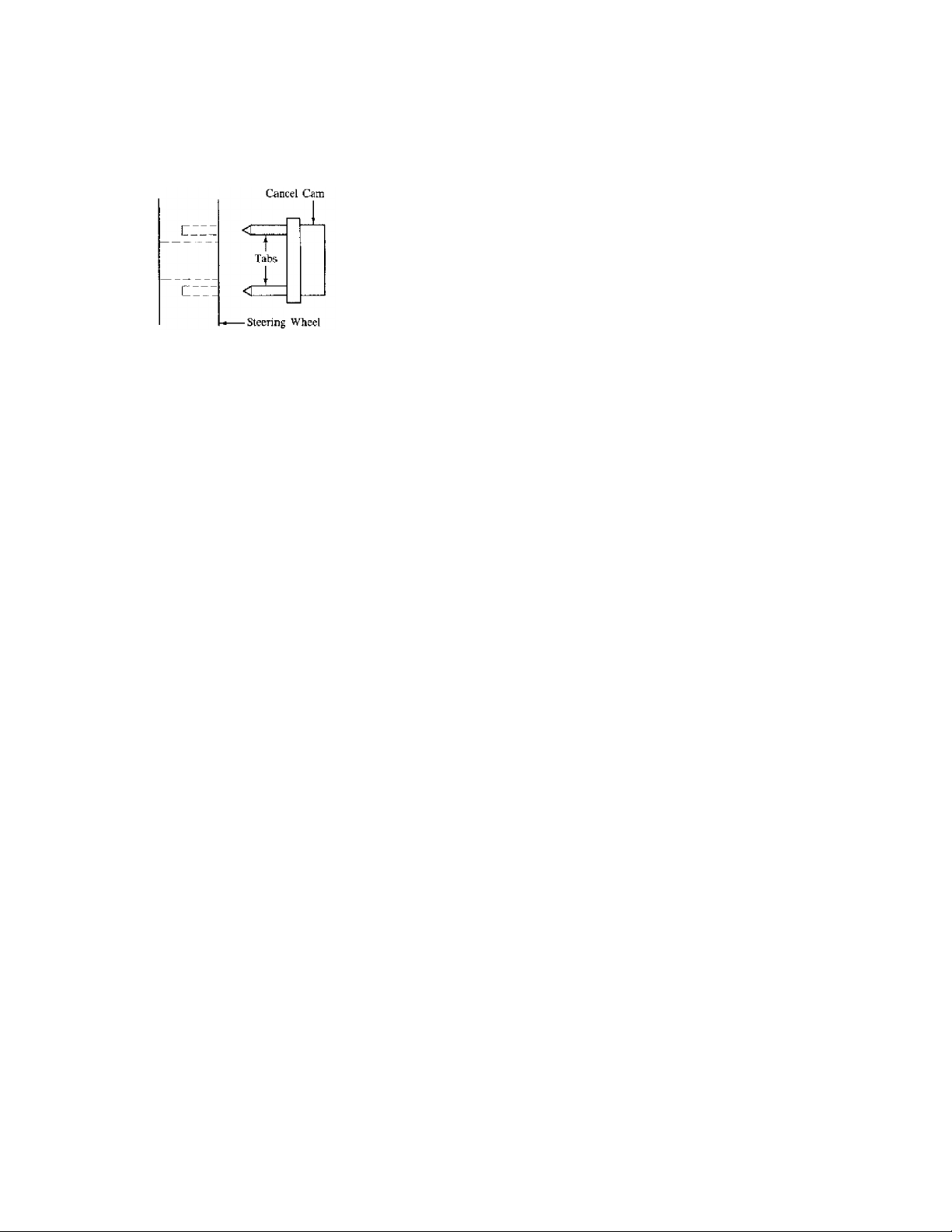

3. Inspect the cancel cam. If the tabs are broken off the cancel

cam, the combination switch can be repaired by replacing the

cancel cam. See Fig. 2.

NOTE: It is not necessary to remove the combination switch to replace

the cancel cam.

TURN SIGNAL DOESN'T CANCEL - REPLACE CANCEL CAM CAT. 14, NO. 010/85

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:34AM

Fig. 2: Turn Signal Cancel Cam

4. Place the turn signal in the "OFF" position .

5. Carefully pry the cancel cam from the combination switch using a

screwdriver. See Fig. 3.

6. Install the new cancel cam to the combination switch.

NOTE: It is not necessary to apply additional grease to the cancel

cam.

Fig. 3: Removing Cancel Cam from Switch

7. Align the tabs of the cancel cam with the holes in the steering

wheel and install the steering wheel.

NOTE: The cancel cam will be broken if the tabs are not aligned with

the holes in the steering wheel. See Fig. 4.

8. Install the steering wheel and torque the retaining nut to

specification.

TORQUE SPECIFICATION

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Model Specification

RX-7, 626, GLC 29-36 ft-lb

B2000, B2200 22-29 ft-lb

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

TURN SIGNAL DOESN'T CANCEL - REPLACE CANCEL CAM CAT. 14, NO. 010/85

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:34AM

Fig. 4: Aligning Cancel Cam Tabs

END OF ARTICLE

Article Text (p. 3)

1983 Mazda RX7

1.2L ENG MODIFIED A/C COMPRESSOR BRACKET INSTRUCTION CAT. 15, NO. 124/83

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:35AM

TECHNICAL SERVICE BULLETIN

A/C COMPRESSOR BRACKET INSTALLATION

Models 1983 RX-7

Bulletin No. 124/83

Category 15

Date 11/2/83

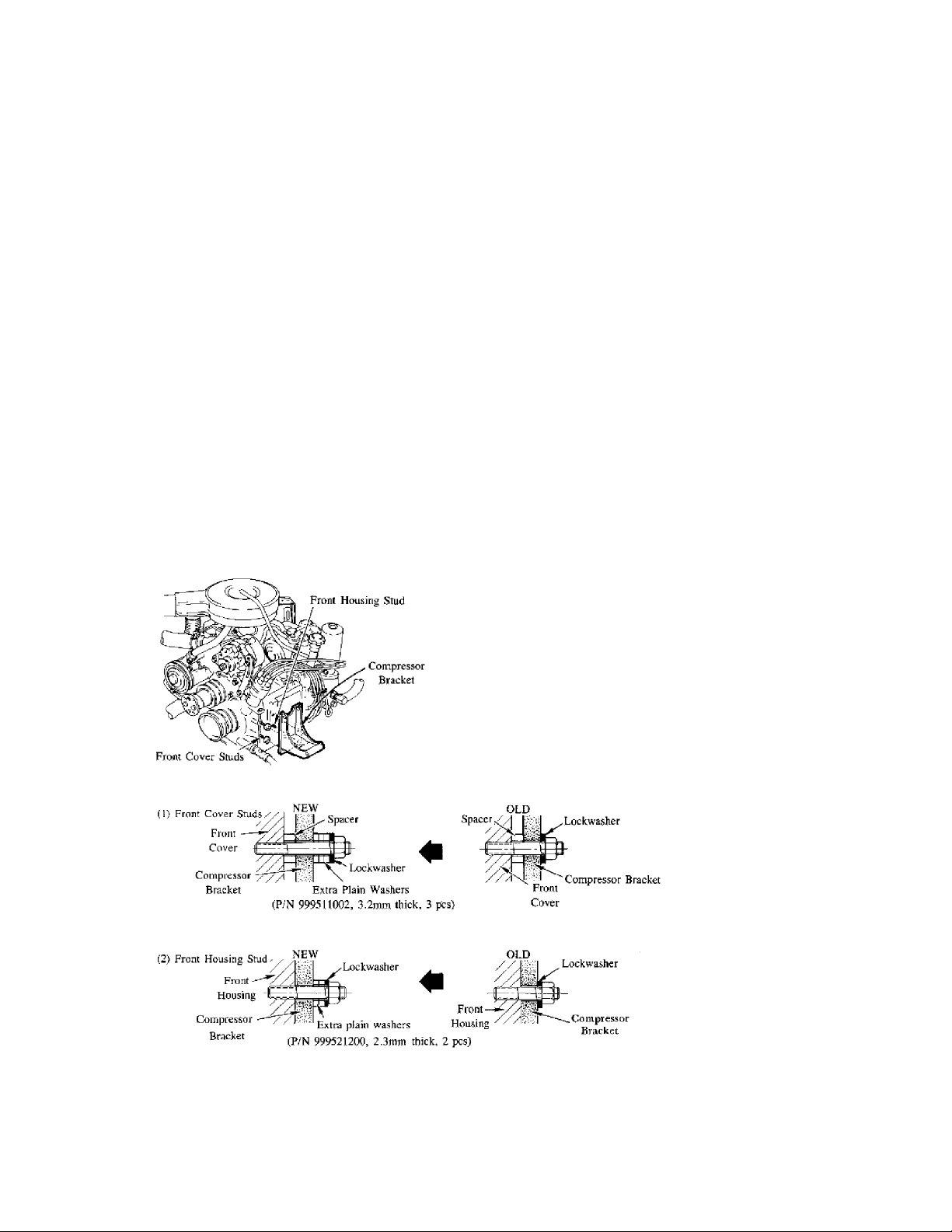

DESCRIPTION

The unthreaded portion of studs for air conditioner compressor

bracket has been extended for common use of the parts with other

models. Because of this change since the production date of September,

1983, it is necessary to insert plain washers between the bracket and

securing nuts in order to compensate for the extended length of the

studs.

Fig. 1: Installation of A/C Compressor Bracket

Fig. 2: Installation of A/C Compressor Bracket to Front Cover

Fig. 3: Installation of A/C Compressor Bracket to Front Housing

VIN OF PRODUCTION CHANGE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

RX-7: JMIFB331 D0762194 September, 1983

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

1.2L ENG MODIFIED A/C COMPRESSOR BRACKET INSTRUCTION CAT. 15, NO. 124/83

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:35AM

PARTS INFORMATION

Plain washers are not included in the 1983 RX7 kits but will be in

1984. However, these washers will be available under the following

part numbers:

9995 11 022 (3.2mm, 6 pcs.) for Front Cover Stud.

9995 21 200 (2.3mm, 2 pcs.) for Front Housing Stud.

END OF ARTICLE

A/C LITE DIM/NOT ON - WIRE HARNESS CONNECTOR CAT. 16, NO. 008/85

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:35AM

TECHNICAL SERVICE BULLETIN

AIR CONDITIONER INDICATOR LIGHT

Models RX-7

Bulletin No. 008/85

Category 16

Date 7/16/85

Symptom No A/C Light

DESCRIPTION

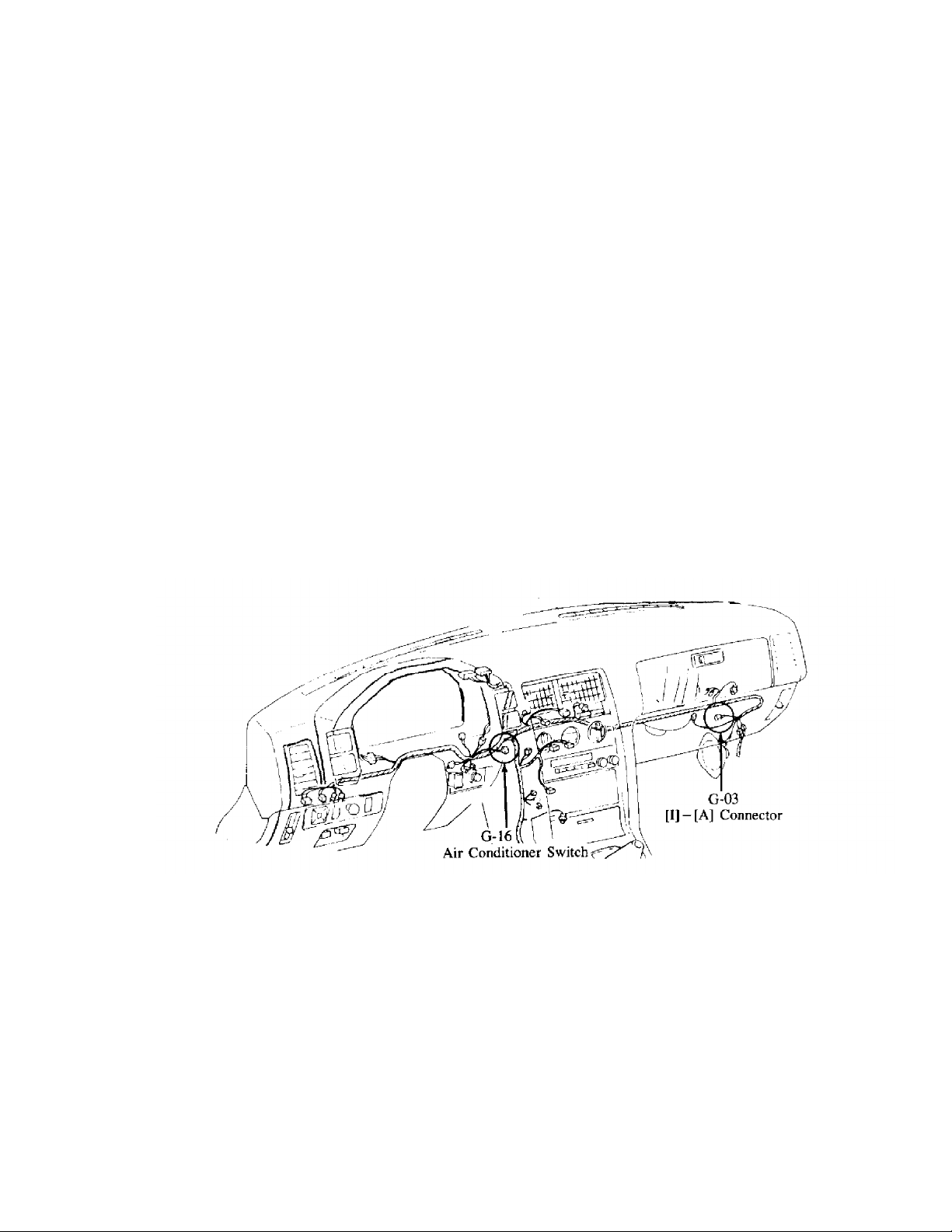

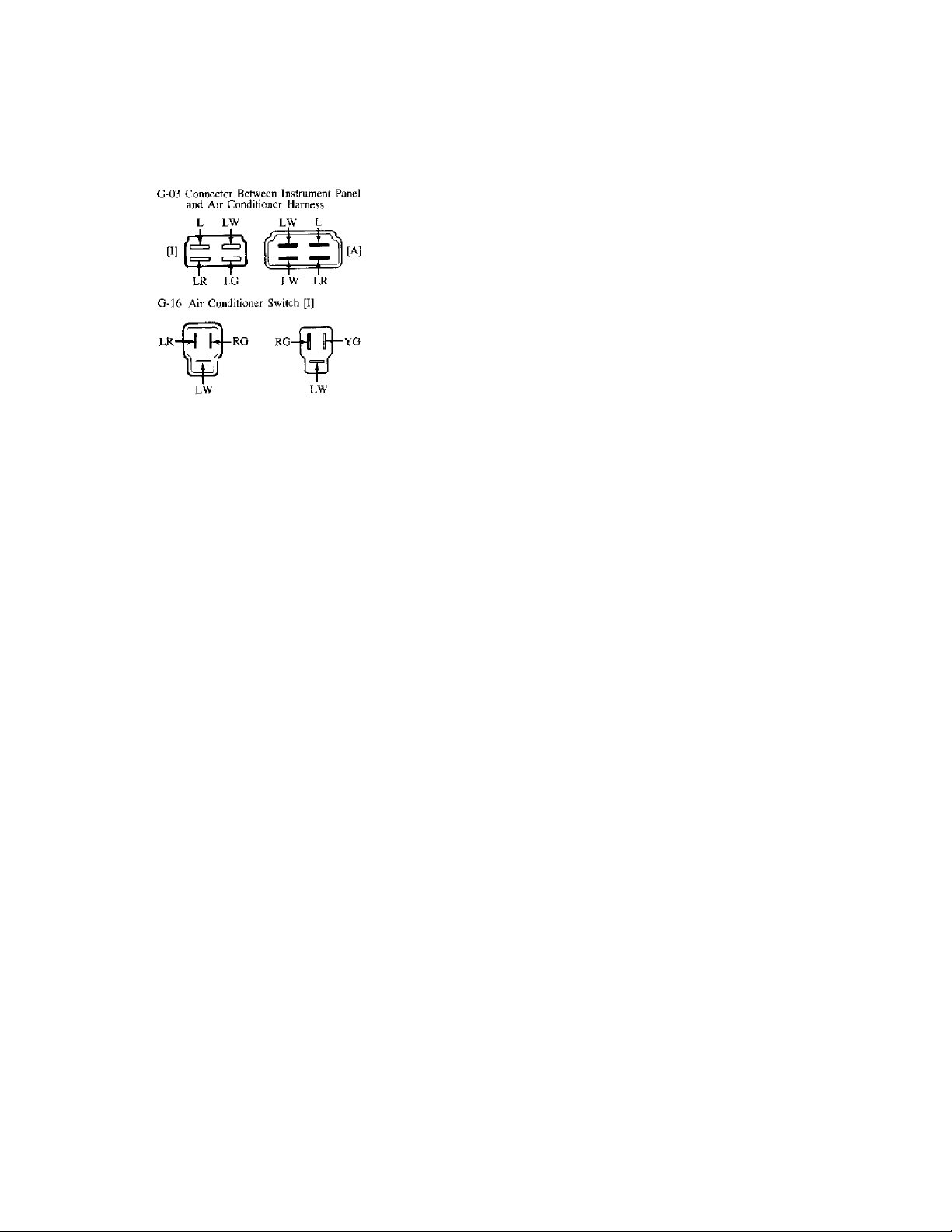

Some air conditioner kits manufactured by Lone Star Manufacturing

Company may contain incorrectly assembled harness connectors. If the

indicator light on the air conditioner switch does not illuminate. or

illuminates dimly after installation, the problem may be due to

incorrectly assembled G-03 or G-16 connectors. See Fig. 1.

Fig. 1: A/C Indicator Light Harness Routing

REPAIR PROCEDURE

1. Check that the G-03 accessory connector (A) is assembled

correctly as viewed from the harness side of the connector.

If not, remove the incorrect terminals and reassemble according

to the connector diagram.

2. Check that the G-16 accessory connector (A) is assembled

correctly as viewed from the harness side of the connector.

If not, remove the incorrect terminals and reassemble according

to the connector diagram. See Fig. 2.

A/C LITE DIM/NOT ON - WIRE HARNESS CONNECTOR CAT. 16, NO. 008/85

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:35AM

Fig. 2: RX7 A/C Accessory Connectors

END OF ARTICLE

CORRECT FREON CHARGE WARNING SPECS CAT. 16, NO. 034/88

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:36AM

TECHNICAL SERVICE BULLETIN

REFRIGERANT CHARGE SERVICE

Model: ALL MODELS WITH A/C

Bulletin No.: 034/88

Date: 6/30/88

Category: 16

DESCRIPTION

To insure proper and efficient operation of the Air Conditioning

System, it is of extreme importance to verify that the Air

Conditioning System is properly charged. Also, please note that overcharging the Air Conditioning system can cause higher than normal

system pressures which could result in Air Conditioning System

component damage.

The recommended refrigerant charge for 1988 Mazda vehicles is as

follows:

323, RX-7, B-Series Truck...............................28 ounces

626, MX-6...............................................35 ounces

929.....................................................39 ounces

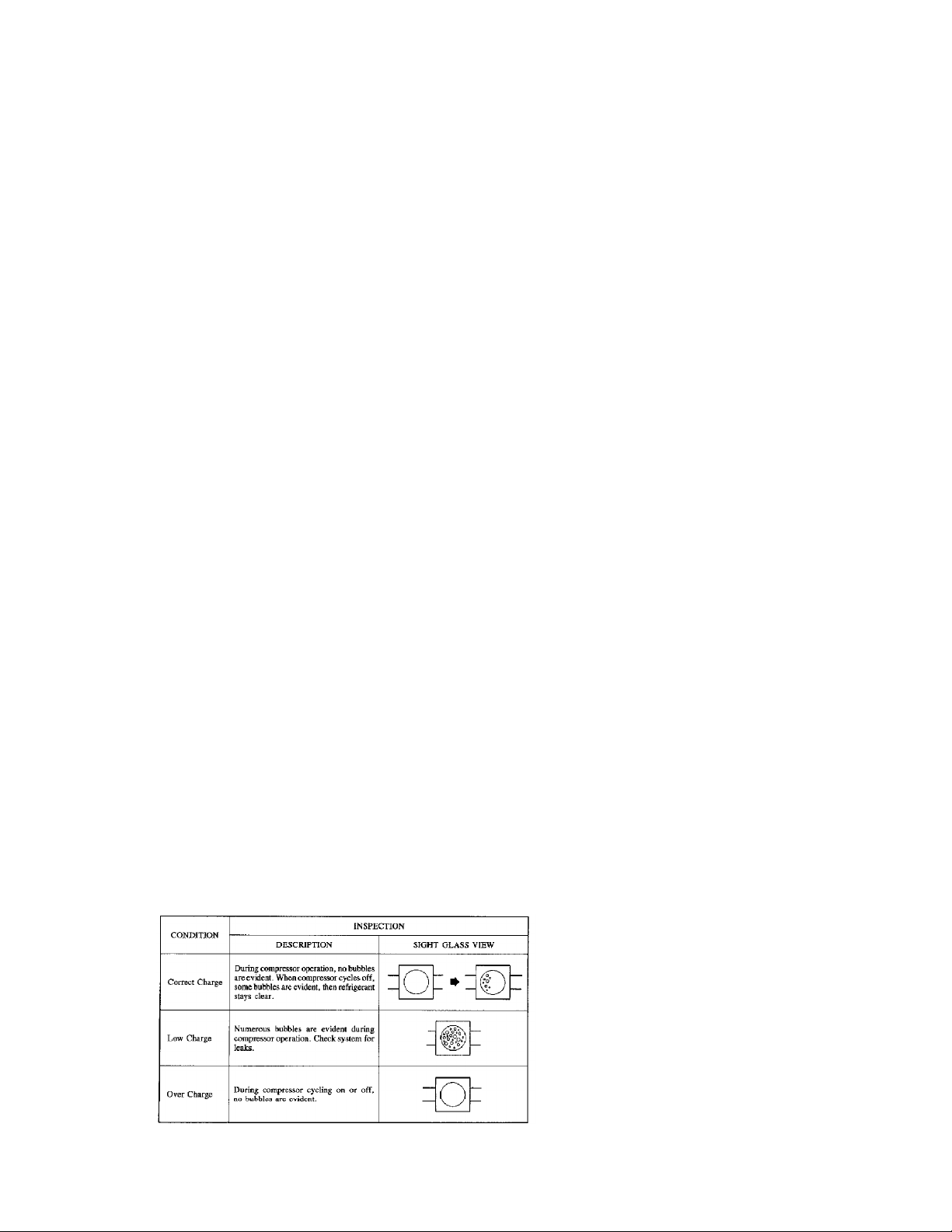

QUICK VISUAL CHECK

It is possible to make a quick visual check of the Air Conditioning

System to verify the correct refrigerant charge.

1) Run the engine as fast idle.

2) Operate the Air Conditioning System at maximum cooling for

approximately 5 minutes.

3) Observe the sight glass and compare to the possible results as

shown in Fig. 1.

Fig. 1: A/C Charging Sight Glass Symptoms

HEATING SYSTEM TROUBLESHOOTING CAT. U, NO. 93-04

Article Text

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Monday, August 27, 2001 06:36AM

TECHNICAL SERVICE BULLETIN

HEATING SYSTEM TROUBLESHOOTING MANUAL

Model All Mazda Models

Category U

Bulletin No. 93-04

Date September, 1993

DESCRIPTION

This Service Bulletin contains a new Heating System Troubleshooting

Manual that was developed by the Mazda Canada Quality Assurance

Section. The diagnostic procedures were developed and tested in

Canada during a Cold Weather Test that took place in February 1993.

The diagnostic procedures were tested on vehicles in which customers

had complained about a lack of heat for several winters. The

effectiveness of these procedures was confirmed.

SPECIAL NOTE

This same manual will also be used as a hand out for all forth coming

Training Courses on Climate Control Systems.

HEATER AND DEFROSTER TROUBLESHOOTING MANUAL

INTRODUCTION

An investigation was conducted using customer vehicles at dealer-ships

across North America over a two year period. The investigation was

conducted to determine if there were any concerns that were difficult

to repair using existing Mazda repair manuals.

The following list represents items most commonly left unrepaired or

undiagnosed by the dealer.

1. Air leakage between the blower unit and the cooler unit.

2. Missing or mis-installed sealing grommets in the firewall.

3. Incorrect operation of the thermostat.

4. Improper usage of the recirculation and fresh air mode of the

ventilation system.

In order to assist in the correct diagnosis and repair of Heating

System concerns the following troubleshooting manual was developed.

See Fig. 1. for a visual description of the Climate Control System.

HEATING SYSTEM TROUBLESHOOTING CAT. U, NO. 93-04

Article Text (p. 2)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:36AM

Fig. 1: Climate Control System

USING THIS MANUAL

Follow the flow charts and diagnostic procedures below to repair the

complaints which were determined on the Customer Comment Sheet.

³ 1. Complete customer

³ comment sheet.

ЪДДДДДДДДДДДДДДДДДБДДДДДДДДДДДДДДДД¿

³ 2. Determine Nature of complaint

³ a) problem or b) improper usage

ЪДДДДДДДДДДБДДДДДДДДДДДДДД¿

АДДДДДДДДДДДДДДДДДВДДДДДДДДДДДДДДДДЩ

ЪДДДДДДДДДДДДДДДДДДДБДДДДДДДДДДДДДДДДДДДД¿

ЪДДДДДДДДДДДДДДДДДДДДДД¿

³

³

АДДДДДДДДДДДВДДДДДДДДДДЩ

ЪДДДДДДДДДДДДДДБДДДДДДДДД¿

³

³

³ 3a. Use diagnostic flow ³ ³ 3b. Instruct on proper

³ chart to determine ³ ³ system usage.

³ repair procedure. ³

³ 4. Use check sheet to

³ perform repairs.

АДДДДДДДДДДВДДДДДДДДДДДДДДЩ

ЪДДДДДДДДДДБДДДДДДДДДДДД¿

³

³

АДДДДДДДДДДДДДДДДДДДДДДДЩ

АДДДДДДДДДДДДДДДДДДДДДДДДЩ

³

³

Diagnostic Procedures

HEATING SYSTEM TROUBLESHOOTING CAT. U, NO. 93-04

Article Text (p. 3)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:36AM

1. Collect detailed complaint information from the customer using

the Customer Comment Sheet.

2. Use the information collected on the Customer Comment Sheet to

determine the nature of the complaint.

3a. Refer to the diagnostic flow chart and determine the necessary

checks.

3b. After determining the complaint is of a usage nature instruct

the customer on the proper operation of the system.

4. Use the Check Sheet to perform the necessary repairs.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

CUSTOMER COMMENT SHEET

Please complete the following with the aid of the customer.

1. Heater Concern

ДДДДВДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДВДДДДДДДДДВДДДДДДДДДДДДДДДДДДД

No. ³ Customer Comment ³ Checked ³ Result

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

1 ³ Water temp indicator reads low at ³

³ high speed ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

2 ³ While driving the interior temp. ³

³ is cooler than when parked ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

3 ³ Heater outlet air temperature is ³

³ always cold ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

4 ³ Passenger side is cooler than ³

³ driver's side ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

5 ³ Passenger feels cold air at feet ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

6 ³ After vehicle interior has ³

³ reached normal temperature cool ³

³ air is felt at body ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

7 ³ Upper body is cooler than foot ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

8 ³ Temperature is unbalanced between ³

³ driver's and passenger's side ³

ДДДДБДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДБДДДДДДДДДБДДДДДДДДДДДДДДДДДДД

³

³

³

³

³

³

³

³

³

³

³

³

³

³

³

2. Defroster Concern

ДДДДВДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДВДДДДДДДДДВДДДДДДДДДДДДДДДДДДД

1 ³ At cold temperatures or high ³

³

HEATING SYSTEM TROUBLESHOOTING CAT. U, NO. 93-04

Article Text (p. 4)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:36AM

³ humidity the windows never clear ³

³ (all) ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

2 ³ Even after reaching normal ³

³ operating temp. the front wind- ³

³ shield is only cleared 30-50 % ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

3 ³ Rear window does not clear ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

4 ³ Rear window clears only in the ³

³ middle ³

ДДДДБДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДБДДДДДДДДДБДДДДДДДДДДДДДДДДДДД

³

³

³

³

³

³

³

³

3. Temperature Control Concern

ДДДДВДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДВДДДДДДДДДВДДДДДДДДДДДДДДДДДДД

1 ³ Difficult to set temperature ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

2 ³ Temperature unbalance between ³

³ head and foot ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

3 ³ Temperature unbalance between ³

³ driver and passenger seat ³

ДДДДБДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДБДДДДДДДДДБДДДДДДДДДДДДДДДДДДД

³

³

³

³

³

4. Other Concerns

ДДДДВДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДВДДДДДДДДДВДДДДДДДДДДДДДДДДДДД

1 ³ ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

2 ³ ³

ДДДДЕДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЕДДДДДДДДДЕДДДДДДДДДДДДДДДДДДД

3 ³ ³

ДДДДБДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДБДДДДДДДДДБДДДДДДДДДДДДДДДДДДД

³

³

³

Record in the appropriate column if the item was checked and the

result.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

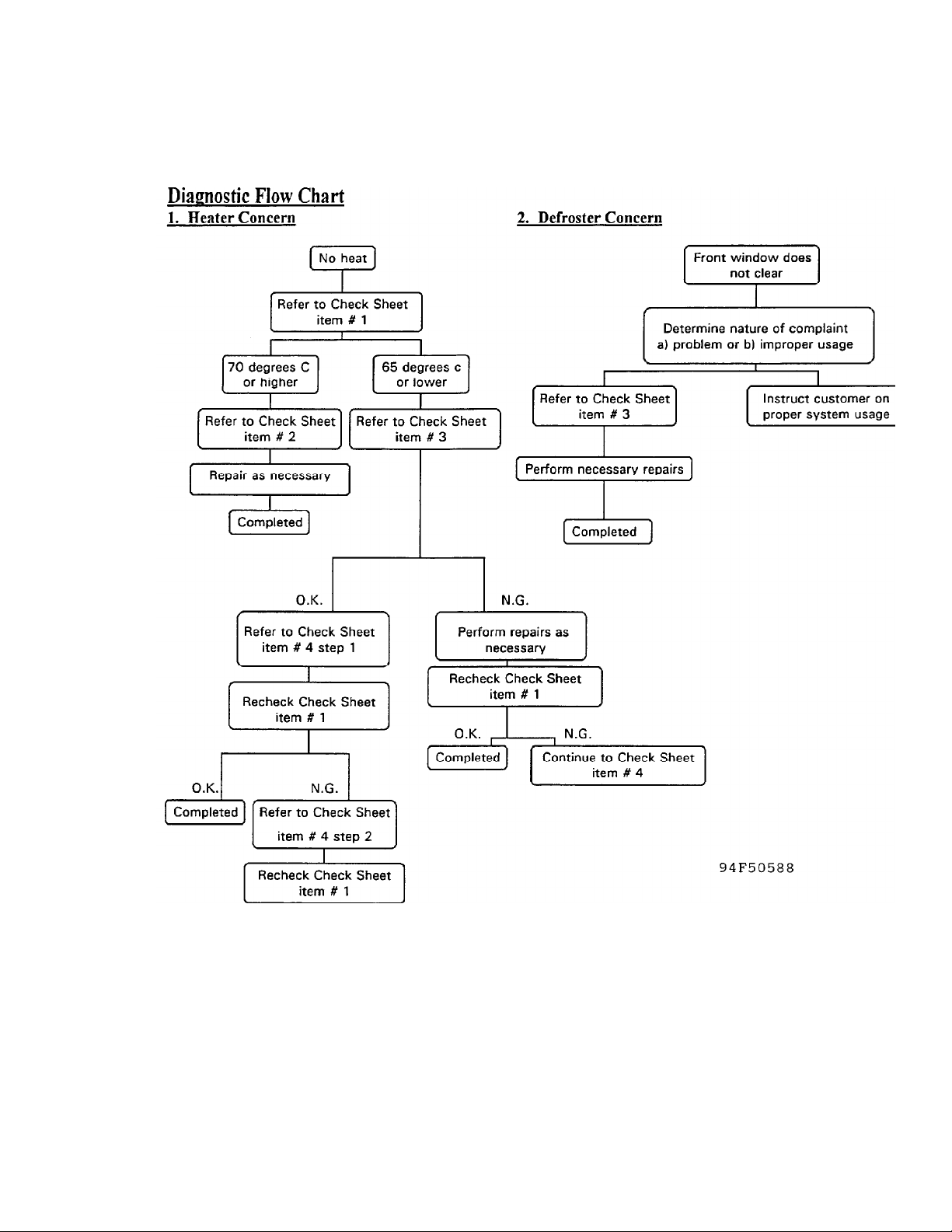

1. Heater Concern - Use the Diagnostic Flow Chart (see Fig. 2) to

determine the necessary diagnostic checks.

Refer to the Check Sheet.

HEATING SYSTEM TROUBLESHOOTING CAT. U, NO. 93-04

Article Text (p. 5)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, August 27, 2001 06:36AM

Fig. 2: Diagnostic Flow Chart

CHECK SHEET

Heater concern

Item 1: Measuring Vent Outlet Air Temperature

1. Place transmission in park or place manual transmission in

neutral and set the parking brake.

2. Start the engine and let idle until the engine reaches normal

operating temperatures.

Loading...

Loading...