Mazda 13B-MSP Workshop Manual

up to October, 2008. Any changes that occur

2008 Mazda Motor Corporation

PRINTED IN U.S.A., OCTOBER 2008

Part No. 9999-95-E13B-MSP09

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

GENERAL INFORMATION

To c o f S C T

GENERAL INFORMATION . . . . 00-00

To c o f S C T

00–00 GENERAL INFORMATION

HOW TO USE THIS MANUAL . . . . . . . . . 00–00–1

Range of Topics . . . . . . . . . . . . . . . . . . 00–00–1

Service Procedure . . . . . . . . . . . . . . . . 00–00–2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . 00–00–4

Advisory Messages . . . . . . . . . . . . . . . . 00–00–4

UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00–00–5

Conversion to SI Units

(Système International d'Unités) . . . . . 00–00–5

Rounding Off. . . . . . . . . . . . . . . . . . . . . 00–00–5

Upper and Lower Limits . . . . . . . . . . . . 00–00–5

FUNDAMENTAL PROCEDURES. . . . . . . 00–00–6

Preparation of Tools and Measuring

Equipment. . . . . . . . . . . . . . . . . . . . . . 00–00–6

Special Service Tools . . . . . . . . . . . . . . 00–00–6

Disassembly . . . . . . . . . . . . . . . . . . . . . 00–00–6

Inspection During Removal,

Disassembly. . . . . . . . . . . . . . . . . . . . 00–00–6

Arrangement of Parts . . . . . . . . . . . . . . 00–00–7

Cleaning of Parts . . . . . . . . . . . . . . . . . 00–00–7

Reassembly . . . . . . . . . . . . . . . . . . . . . 00–00–7

Adjustment . . . . . . . . . . . . . . . . . . . . . . 00–00–8

Rubber Parts and Tubing . . . . . . . . . . . 00–00–8

Hose Clamps . . . . . . . . . . . . . . . . . . . . 00–00–8

Torque Formulas . . . . . . . . . . . . . . . . . 00–00–8

Vise . . . . . . . . . . . . . . . . . . . . . . . . . . . 00–00–9

ELECTRICAL SYSTEM. . . . . . . . . . . . . . 00–00–9

Connectors. . . . . . . . . . . . . . . . . . . . . . 00–00–9

SAE STANDARDS. . . . . . . . . . . . . . . . . . 00–00–11

ABBREVIATIONS . . . . . . . . . . . . . . . . . . 00–00–11

IDENTIFYING SPECIFICATION . . . . . . . 00–00–12

00

SECTION

00–00

End of Toc

HOW TO USE THIS MANUAL

Range of Topics

• This manual contains procedures for performing all required service operations. The procedures are divided

into the following five basic operations:

— Removal/Installation

— Disassembly/Assembly

— Replacement

— Inspection

— Adjustment

• Simple operations which can be performed easily just by looking at the vehicle (i.e., removal/installation of

parts, jacking, vehicle lifting, cleaning of parts, and visual inspection) have been omitted.

CHU000000001E01

Revised 6/2008 (Ref. No. R108/08)

00–00–1

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

GENERAL INFORMATION

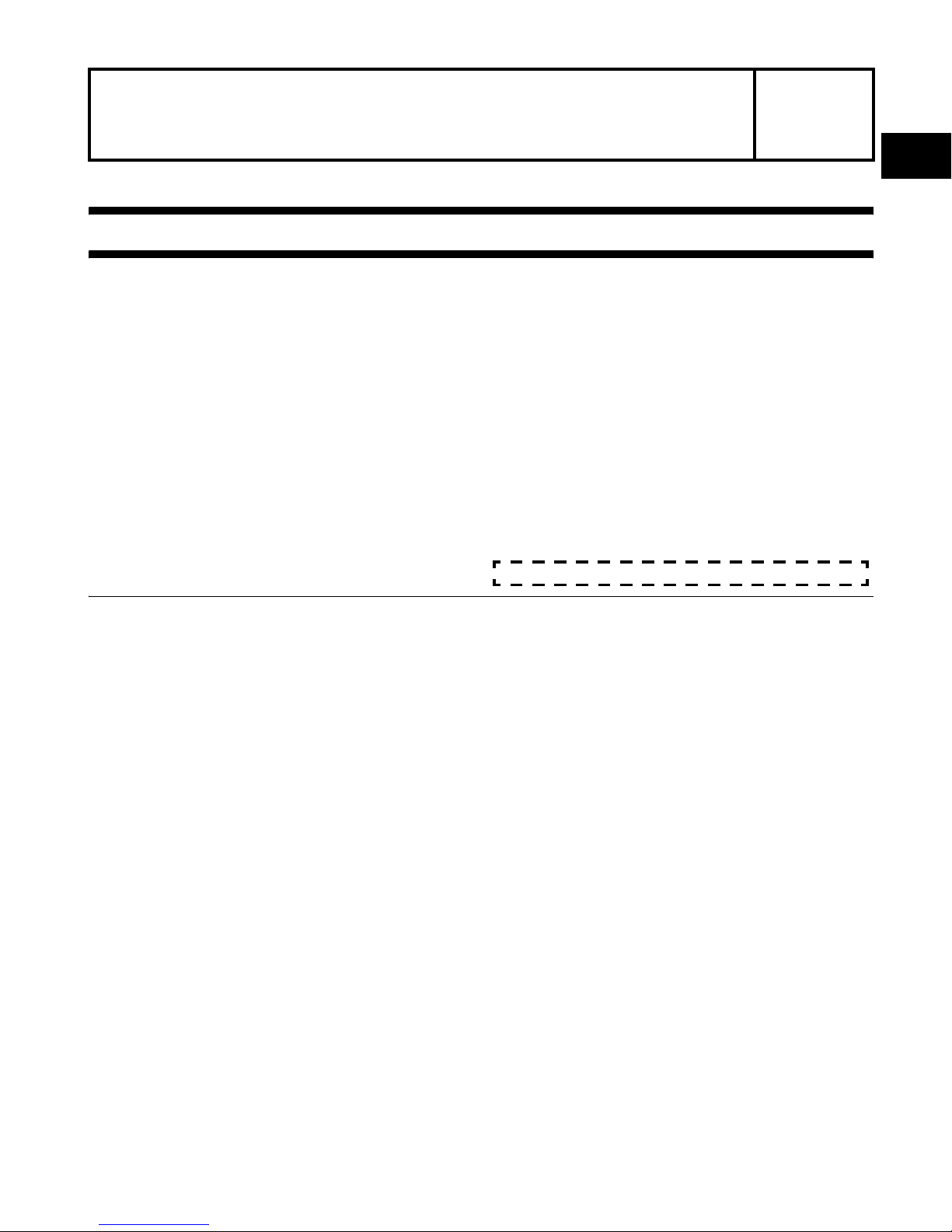

Service Procedure

Inspection, adjustment

• Inspection and adjustment procedures are

divided into steps. Important points regarding the

location and contents of the procedures are

explained in detail and shown in the illustrations.

Fluid Pressure Inspection

1. Assemble the SSTs as shown in the figure.

49 1232 670A

SHOWS PROCEDURE ORDER

FOR SERVICE

Tightening torque

39—49 N·m {4.0—5.0 kgf·m, 29—36 ft·lbf}

49 H002 671

SHOWS TIGHTENING

TORQUE

49 H032 322

Caution

Connect the gauge set from under

the vehicle to prevent contact with

the drive belt and the cooling fan.

SPECIFICATIONS

WGIWXX0009E

00–00–2

GENERAL INFORMATION

Repair procedure

1. Most repair operations begin with an overvie w illustration. It identifies the compo nent s , shows how the parts fit

together, and describes visual part inspection. However, only removal/installation procedures that need to be

performed methodically have written instructions.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration. In addition, symbols indicating parts requiring the use of special s ervi c e too ls or equivalent are also

shown.

3. Procedure steps are numb er ed and the part th at is the main poin t of that procedure is shown in the illustration

with the corresponding number. Occasionally, there are important points or additional information concerning a

procedure. Refer to this information when servicing the related par t.

00–00

YLU000WA0

00–00–3

GENERAL INFORMATION

OIL

TF

GREASE

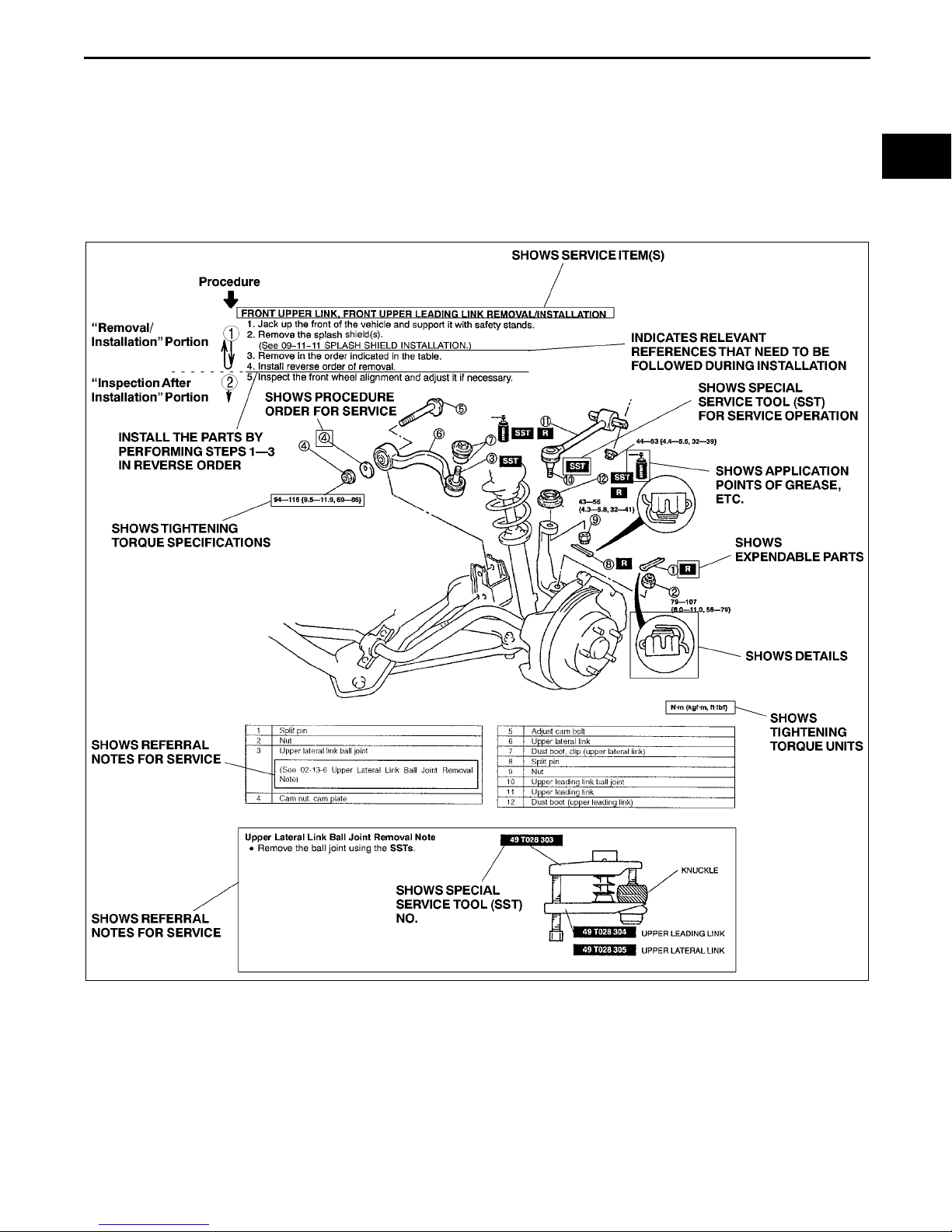

Symbols

• There are eight symbols indicating oil, grease, fluids, sealant, and the use of SST or equivalent. These symbols

show application points or use of thes e materia ls duri ng se rvic e.

Symbol Meaning Kind

OIL

BRAKE

FLUID

AATF

GREASE

SEALANT

P

R

Apply oil

Apply brake fluid

Apply automatic

transaxle/

transmission fluid

Apply grease

Apply sealant

Apply petroleum

jelly

Replace part

New appropriate

engine oil or gear

oil

New appropriate

brake fluid

New appropriate

automatic

transaxle/

transmission fluid

Appropriate

grease

Appropriate

sealant

Appropriate

petroleum jelly

O-ring, gasket,

etc.

SST

Use SST or

equivalent

Appropriate tools

Advisory Messages

• You will find several Warnings, Cautions, Notes, Specifications and Upper and Lower Limits in this

manual.

Warning

• A Warning indicates a situation in which serious injury or death could result if the warning is ignored.

Caution

• A Caution indicates a situation in which damage to the vehicle or parts could result if the caution is ignored.

Note

• A Note provides added information that will help you to complete a particular procedure.

Specification

• The values indicate the allowable range when performing inspections or adjustments.

Upper and lower limits

• The values indicate the upper and lower limits that must not be exceeded when performing inspections or

adjustments.

End Of Sie

00–00–4

GENERAL INFORMATION

UNITS

Electric current A (ampere)

Electric power W (watt)

Electric resistance ohm

Electric voltage V (volt)

Length

Negative pressure

Positive pressure

Number of

revolutions

Torque

Volume

Weight

mm (millimeter)

in (inch)

kPa (kilo pascal)

mmHg (millimeters of mercury)

inHg (inches of mercury)

kPa (kilo pascal)

2

kgf/cm

centimeter)

psi (pounds per square inch)

rpm (revolutions per minute)

N·m (Newton meter)

kgf·m (kilogram force meter)

kgf·cm (kilogram force centimeter)

ft·lbf (foot pound force)

in·lbf (inch pound for ce)

L (liter)

US qt (U.S. quart)

Imp qt (Imperial quart)

ml (milliliter)

cc (cubic centimeter)

cu in (cubic inch)

fl oz (fluid ounce )

g (gram)

oz (ounce)

(kilogram force per square

CHU000000002E01

00–00

Conversion to SI Units (Système International d'Unités)

• All numerical values in this manual are based on SI units. Numbers shown in conventional units are converted

from these values.

Rounding Off

• Converted values are rounded off to the same number of places as the SI unit value. For example, if the SI uni t

value is 17.2 and the value after conversion is 37.84, the converted value will be rounded off to 37.8.

Upper and Lower Limits

• When the data indicates upper and lower limits, the converted values are rounded down if the SI unit value is

an upper limit and rounded up if the SI unit value is a lower limit. Therefore, converted values for the same SI

unit value ma y differ afte r conversion. For example, co ns ide r 2.7 kg f/c m

210—260 kPa {2.1—2.7 kgf/cm

270—310 kPa {2.7—3.2 kgf/cm

• The actual converted values for 2.7 kgf/cm

2

, 30—38 psi}

2

, 39—45 psi}

2

are 264 kPa and 38.4 psi. In the first specification, 2.7 is used as

2

in the following specifications:

an upper limit, so the conver ted values are rounded down to 260 and 38. In the second specification, 2.7 is

used as a lower limit, so the converted values are rounded up to 270 and 39.

End Of Sie

00–00–5

GENERAL INFORMATION

FUNDAMENTAL PROCEDURES

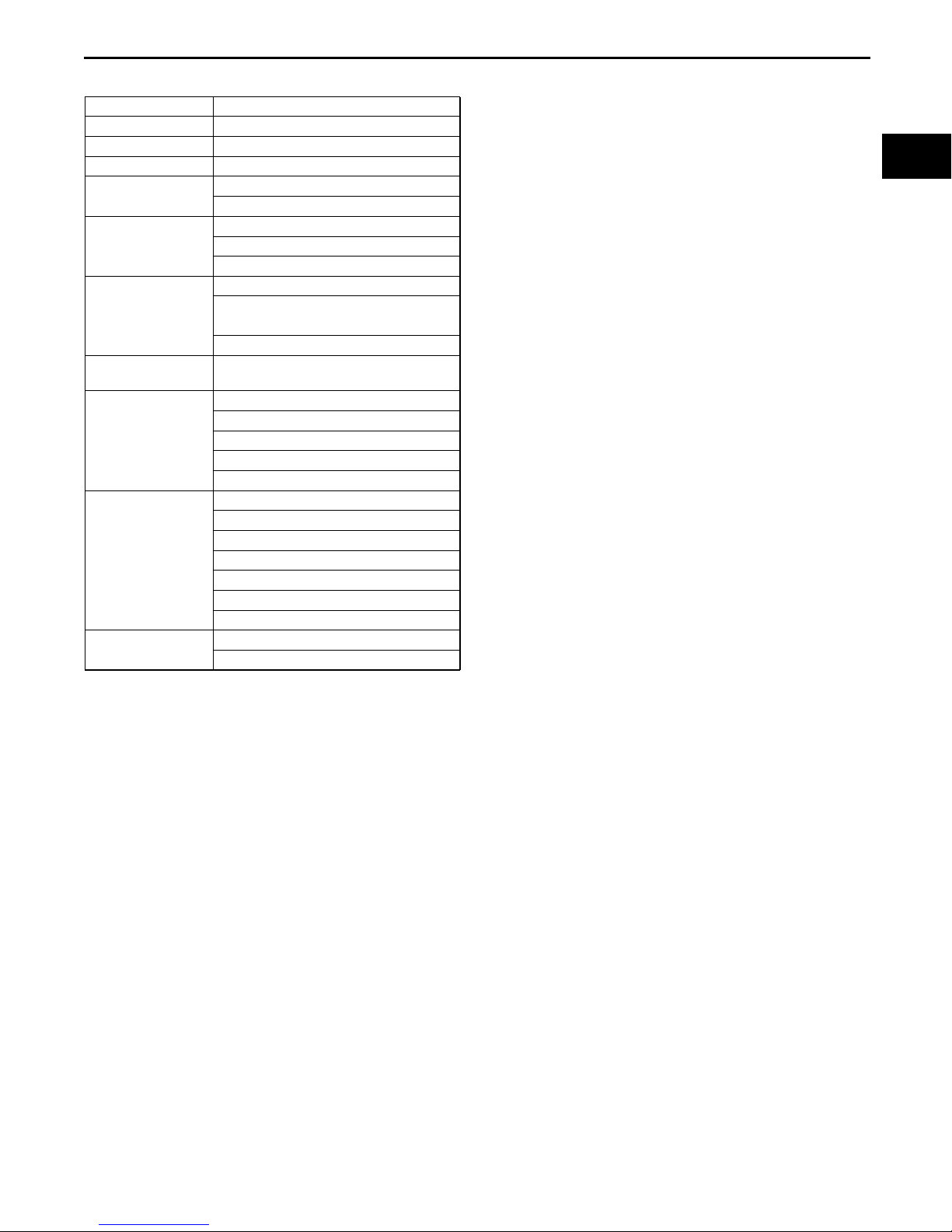

Preparation of Tools and Measurin g Equipment

• Be sure that all neces sa ry tools and measuring

equipment are available before starting any work.

Special Service Tools

• Use special service tools or equivalent when they

are required.

CHU000000004E01

CHU0014W003

49 SE01 310

Disassembly

• If the disassembly procedure is complex,

requiring many parts to be disassembled, all parts

should be marked in a place that will not affect

their performance or exter nal appearance and

identified so that reassembly can be performed

easily and efficiently .

Inspection During Removal, Disassembly

• When removed, each part should be carefully

inspected for malfunction, deformation, damage

and other problems.

WGIWXX0024E

WGIWXX0027E

00–00–6

WGIWXX0028E

GENERAL INFORMATION

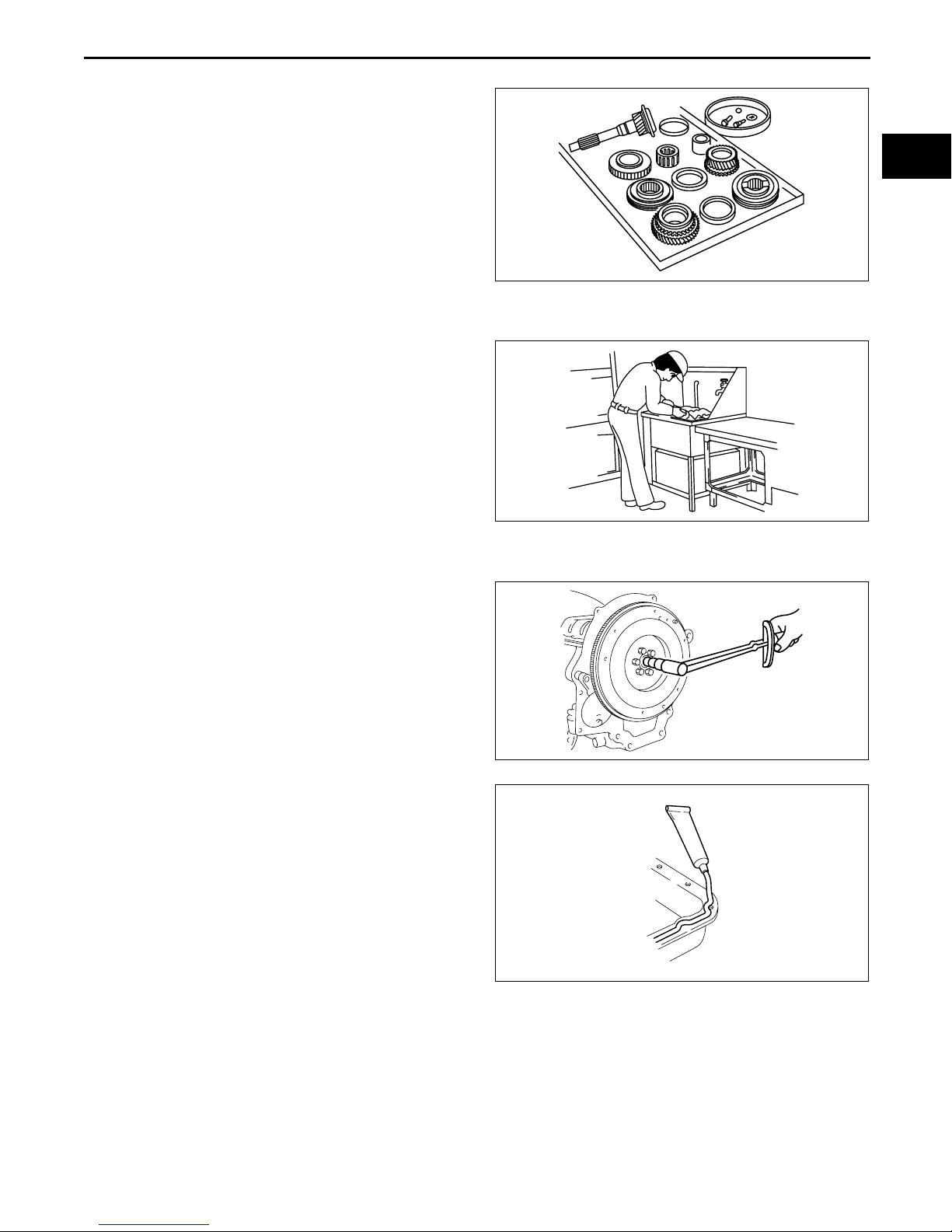

Arrangement of Parts

• All disassembled parts should be carefully

arranged for reassembl y.

• Be sure to separate or otherwise identify the parts

to be replaced from those tha t will be re used.

Cleaning of Parts

• All parts to be reused should be carefully and

thoroughly cleaned in the appropriate method.

Warning

•

• Using compressed air can cause dirt and

••

other particles to fly out causing injury to

the eyes. Wear protective eye wear

whenever using compressed air.

00–00

WGIWXX0029E

Reassembly

• Standard values, such as torque s and certain

adjustments, must be strictly observed in the

reassembly of all parts.

• If removed, the following parts should be replaced

with new ones:

— Oil seals

— Gaskets

— O-rings

— Lock washers

— Cotter pins

— Nylon nuts

• Depending on location:

— Sealant and gaskets , or both, sh oul d be

applied to specified locations. When sealant

is applied, parts should be installed before

sealant hardens to prevent leakage.

— Oil should be applied to the movin g

components of parts.

— Specified oil or grease shou ld be appl ie d a t

the prescribed locations (such as oil seals)

before reassembly.

WGIWXX0030E

WGIWXX0031E

CHU0014W006

00–00–7

GENERAL INFORMATION

Adjustment

• Use suitable gauges and testers when making

adjustments.

Rubber Parts and Tubing

• Prevent gasoline or oil from getting on rubber

parts or tubing.

CHU0014W005

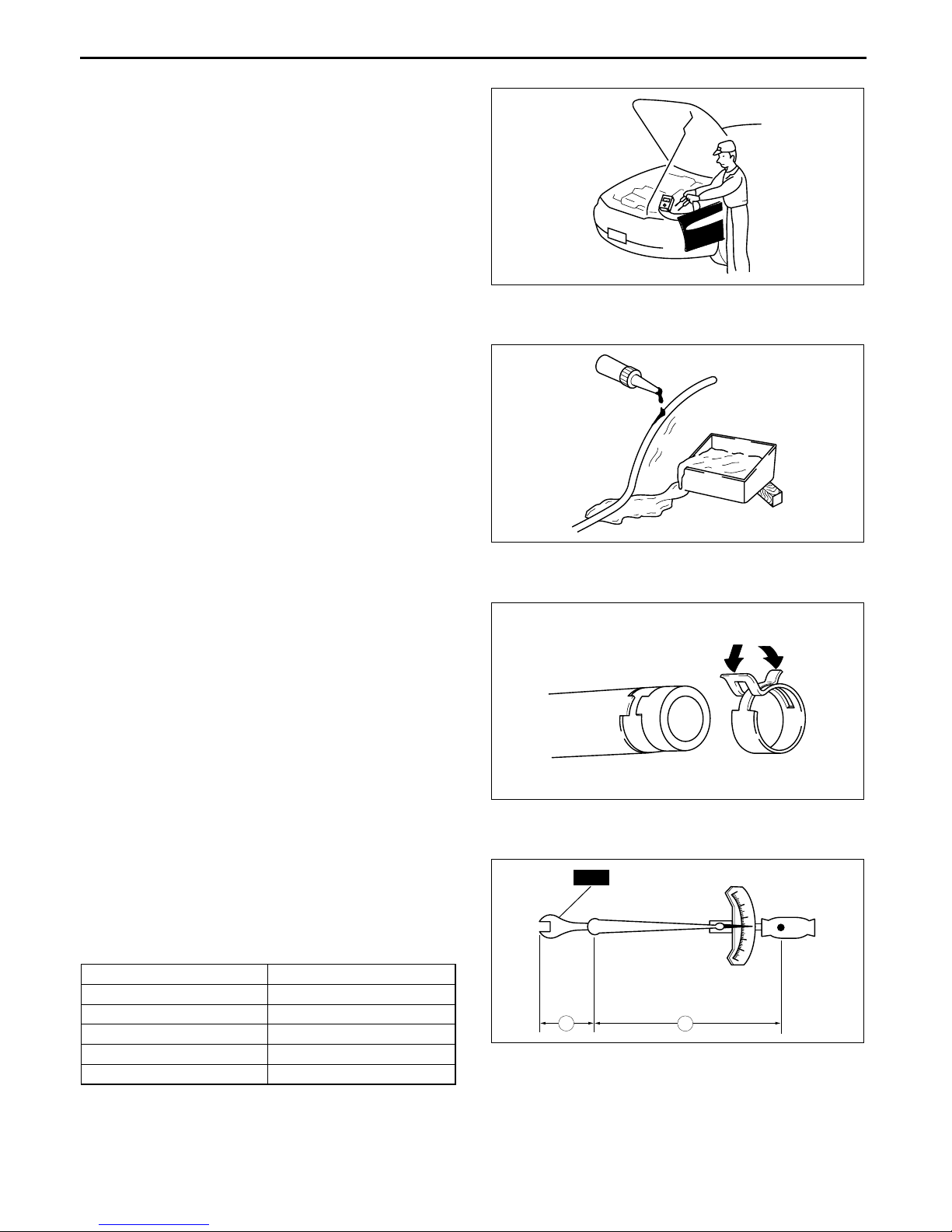

Hose Clamps

• When reinstalling, pos i tion the hos e cl amp in the

original location on the hose and squeeze the

clamp lightly with large pliers to ensure a good fit.

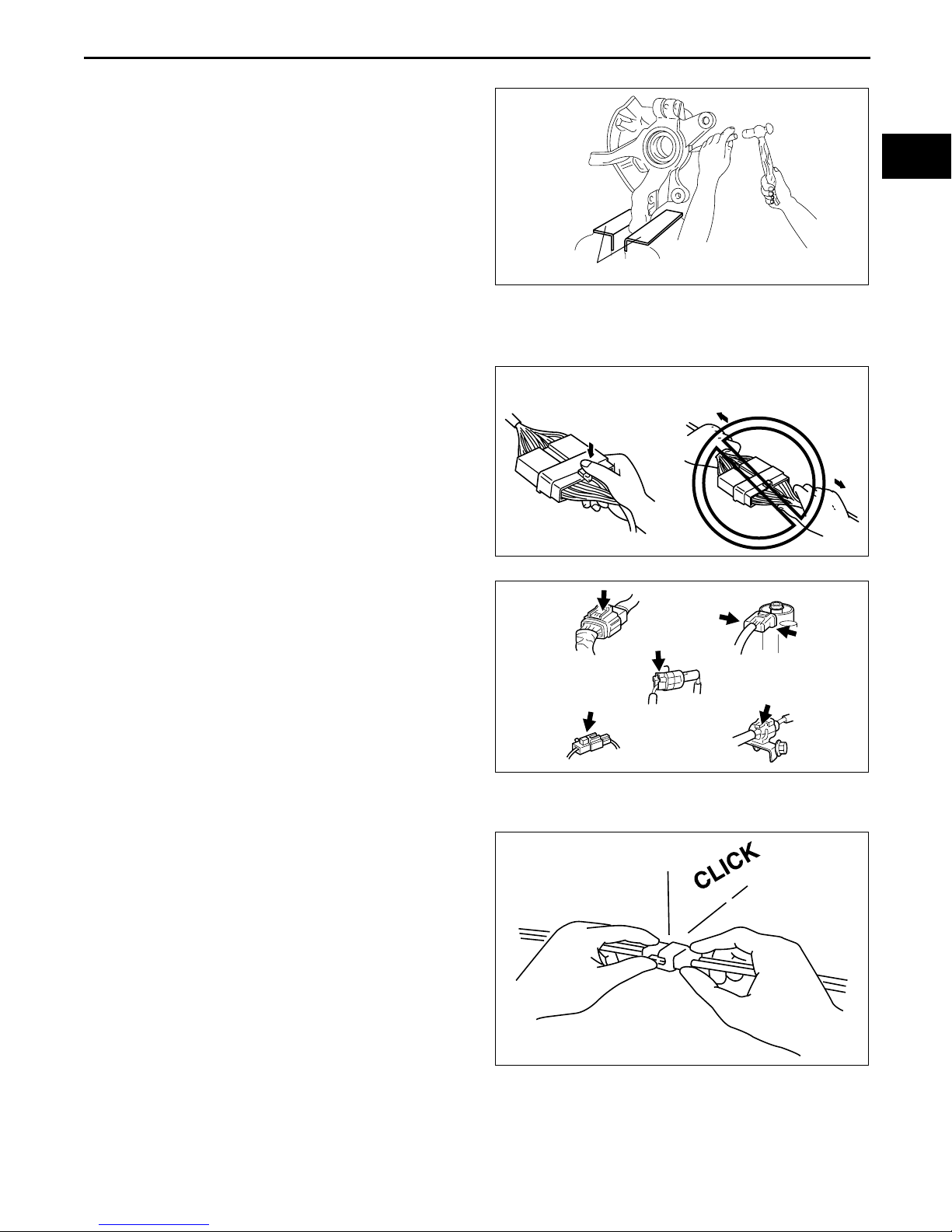

Torque Formulas

• When using a torque wrench-SST or equivalent

combination, the writt en torque must be

recalculated due to the ext ra le ngth that the SST

or equivalent adds to the torque wrench.

Recalculate the torque by using the following

formulas. Choose the formula that applies to you.

Torque Unit Formula

N·mN·m × [L/(L+A)]

kgf·mkgf·m × [L/(L+A)]

kgf·cm kgf·cm × [L/(L+A)]

ft·lbf ft·lbf × [L/(L+A)]

in·lbf in·lbf × [L/(L+A)]

WGIWXX0034E

WGIWXX0035E

SST

A

L

3

2

1

0

1

2

3

WGIWXX0036E

A : The length of the SST past the torque wrench drive.

L : The length of the torque wrench.

00–00–8

GENERAL INFORMATION

Vise

• When using a vise, put protective plates in the

jaws of the vise to prevent damage to parts.

End Of Sie

ELECTRICAL SYSTEM

Connectors

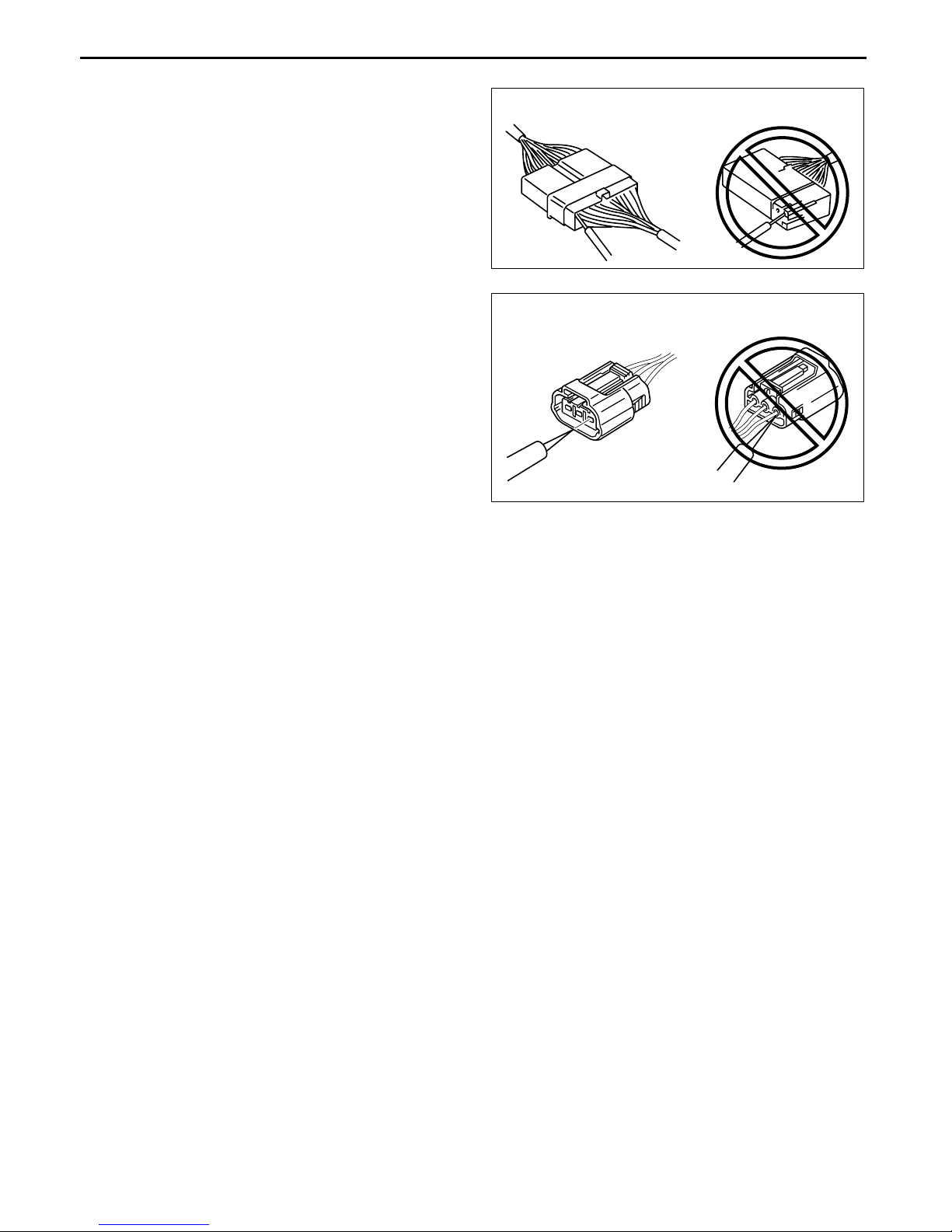

Disconnecting connectors

• When disconnecting connector, grasp the

connectors, not the wires.

PROTECTIVE PLATES

GOOD

00–00

CHU0014W010

CHU000000006E01

NO GOOD

• Connectors can be disconnected by pressing or

pulling the lock lever as shown.

Locking connector

• When locking connectors, listen for a click

indicating they are securely locked.

CHU0000W014

WGIWXX0042E

WGIWXX0043E

00–00–9

GENERAL INFORMATION

Inspection

• When a tester is used to inspect for continuity or

measuring voltage, insert the tester probe from

the wiring harness side.

• Inspect the terminals of waterproof connectors

from the connector side since they cannot be

accessed from the wiring harness side.

Caution

•

• To prevent damage to the terminal, wrap

••

a thin wire around the tester probe before

inserting into terminal.

End Of Sie

GOOD

NO GOOD

GOOD NO GOOD

CHU0000W011

CHU0000W012

00–00–10

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

GENERAL INFORMATION

SAE STANDARDS

CHU000000003E02

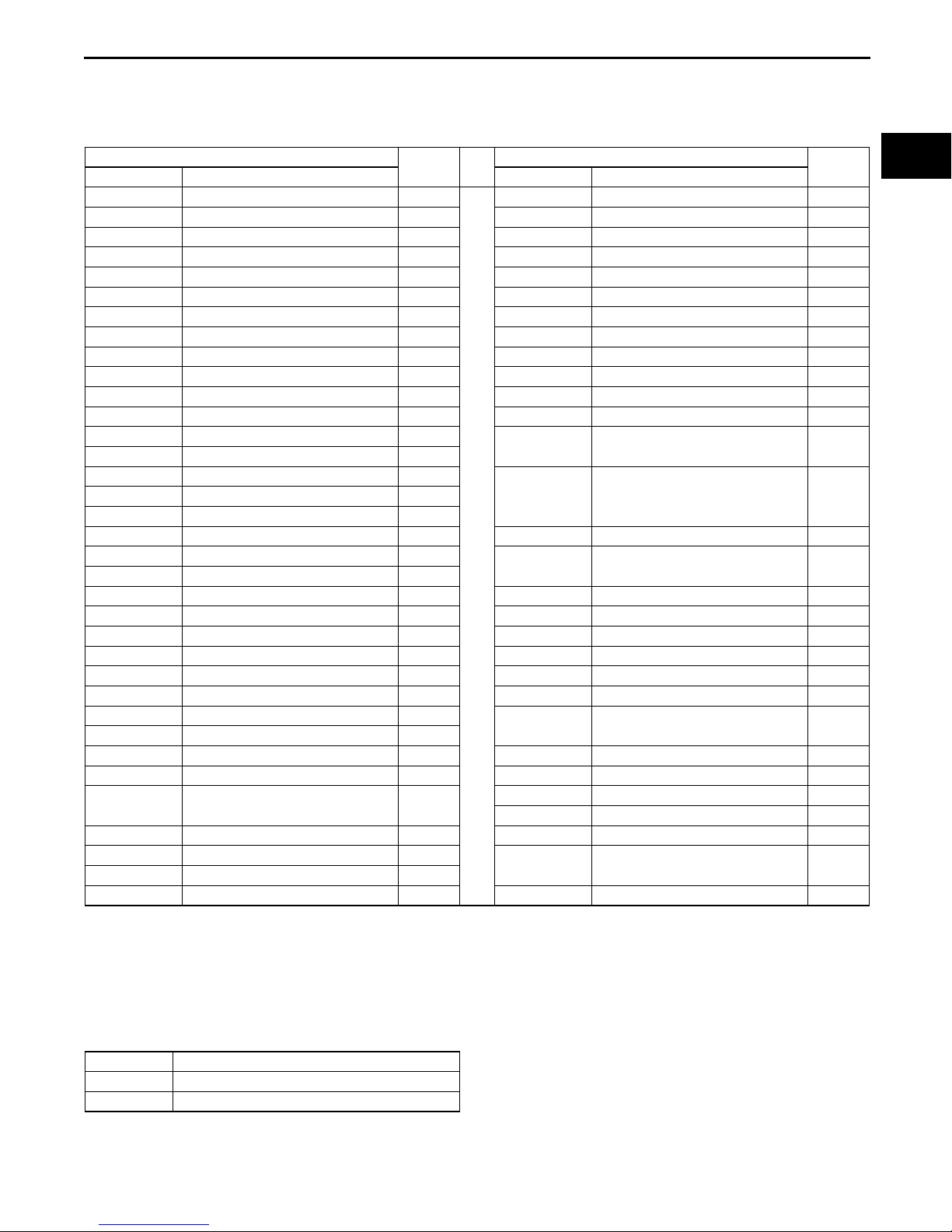

• In accordance with new regulations, SAE (Society of Automotive Engineers) standard names and abbreviations

are now used in this manual. The table below lists the names and abbreviations that have been used in Mazda

manuals up to now and their SAE equivalents.

SAE Standard

Abbreviation Name Abbreviation Name

AP Accelerator Pedal MAP Manifold Absolute Pressure

APP Accelerator Pedal Position MAF Mass Air Flow

ACL Air Cleaner MAF sensor Mass Air Flow Sensor

A/C Air Conditioning MFL Multiport Fuel Injection

A/F Air Fuel Ratio OBD On-board Diagnostic System

BARO Barometric Pressure OL Open Loop

B+ Battery Positive Voltage OC Oxidation Catalytic Converter

CMP sensor Camshaft Position Sensor O2S Oxygen Sensor

LOAD Calculated Load Value PNP Park/Neutral Position

CAC Charge Air Cooler PID Parameter Identification

CLS Closed Loop System PSP Power Steering Pressure

CTP Closed Throttle Position PCM Powertrain Control Module #3

CPP Clutch Pedal Position

CIS Continuous Fuel Injection System

CKP sensor Crankshaft Position Sensor

DLC Data Link Connector

DTM Diagnostic Test Mode #1

DTC Diagnostic Test Code(s) SAPV Secondary Air Pulse Valve

DI Distributor Ignition

DLI Distributorless Ignition

EI Electronic Ignition #2 3GR Third Gear

ECT Engine Coolant Temperature TWC Three Way Catalytic Converter

EM Engine Modification TB Throttle Body

EVAP Evaporative Emission TP Throttle Position

EGR Exhaust Gas Recirculation TP sensor Throttle Position Sensor

FC Fan Control TCC Torque Converter Clutch

FF Flexible Fuel

4GR Fourth Gear

GEN Generator TR Transmission (Transaxle) Range

GND Ground TC Turbocharger

HO2S Heated Oxygen Sensor

IAC Idle Air Control VAF sensor Volume Air Flow Sensor

IAT Intake Air Temperature

KS Knock Sensor

MIL Malfunction Indicator Lamp WOP Wide Open Throttle

Remark

With

heater

PAIR Pulsed Secondary Air Injection

AIR Secondary Air Injection

SFI

TCM

VSS Vehicle Speed Sensor

VR Voltage Regulator

WU-TWC

SAE Standard

Sequential Multiport Fuel

Injection

Transmission (Transaxle) Control

Module

Warm Up Three Way Catalytic

Converter

Remark

Pulsed

injection

Injection

with air

pump

#4

00–00

#1 : Diagnostic trouble codes depend on the diagnostic test mode.

#2 : Controlled by the PCM

#3 : Device that controls engine and powertrain

#4 : Directly connected to exhaust manifold

End Of Sie

ABBREVIATIONS

AT Automatic Transmission

MT Manual Transmission

SST Special Service Tool

End Of Sie

CHU000000011E01

00–00–11

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

GENERAL INFORMATION

IDENTIFYING SPECIFICATION

CHU000000000E01

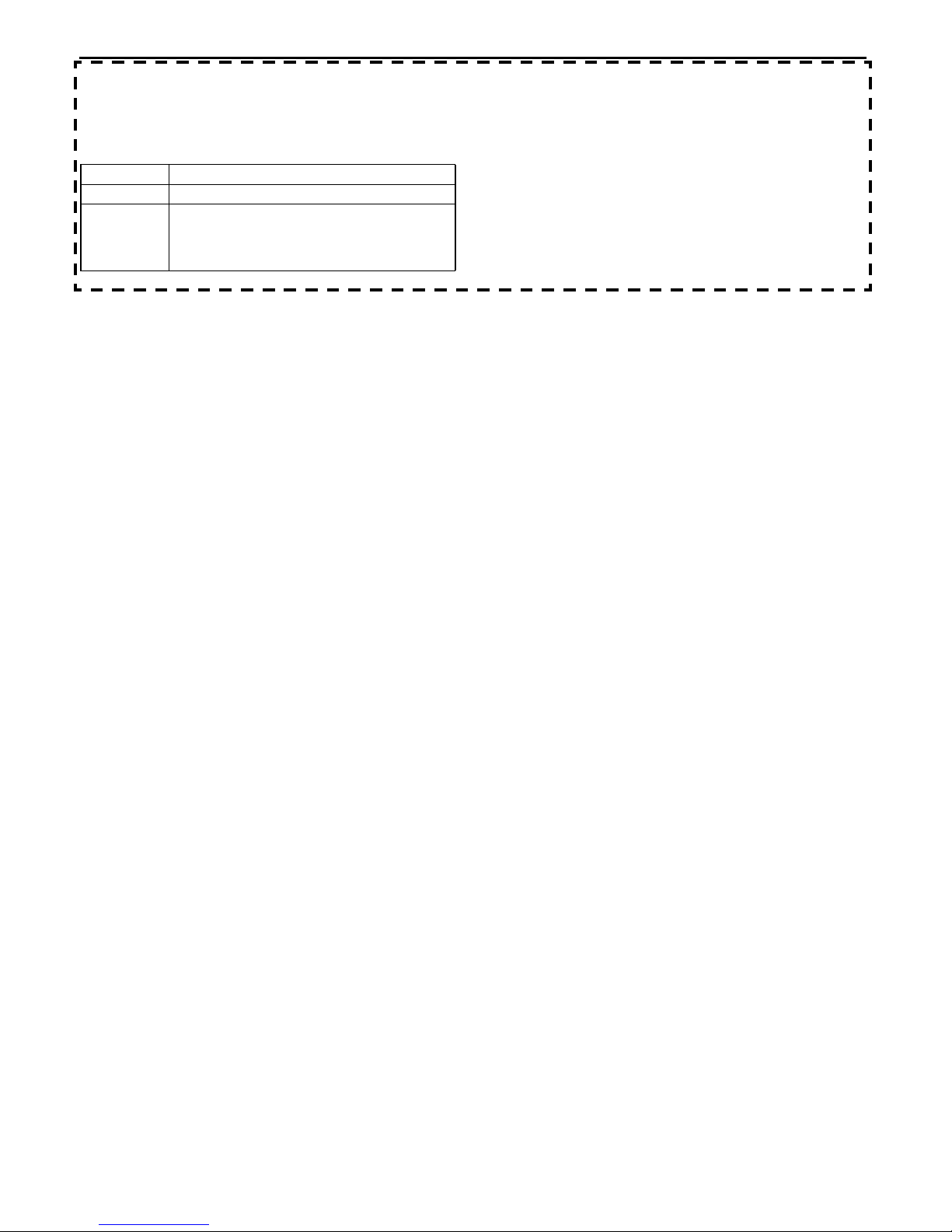

• Because the engine construction varies depending on the vehicle’s period of manufacture, determine the

service specification by referring to the following identification.

Identifying Specification

Applicable VIN

Type A Except below

JM1 FE172*9# 400001—

Type B

End Of Sie

JM1 FE174*9# 400001—

JM1 FE17M*9# 400001—

JM1 FE17P*9# 400001—

00–00–12

Added 6/2008 (Ref. No. R108/08)

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

To c o f S C T

MECHANICAL . . . . . . . . . . . . . 01-10

TECHNICAL DATA. . . . . . . . . . 01-50

To c o f S C T

01–10 MECHANICAL

ENGINE OVERHAUL SERVICE

WARNING . . . . . . . . . . . . . . . . . . . . . . . 01–10–2

ENGINE MOUNTING/DISMOUNTING . . 01–10–2

Mounting . . . . . . . . . . . . . . . . . . . . . . . 01–10–2

Dismounting . . . . . . . . . . . . . . . . . . . . . 01–10–3

HOUSING DISASSEMBLY I . . . . . . . . . . 01–10–4

Oil Pan Disassembly Note . . . . . . . . . . 01–10–5

Oil Pan Upper Block

Disassembly Note . . . . . . . . . . . . . . . 01–10–5

HOUSING DISASSEMBLY II. . . . . . . . . . 01–10–6

Pulley Lockbolt Disassembly Note . . . . 01–10–7

Front Cover Disassembly Note . . . . . . 01–10–7

Oil Pump Sprocket

Disassembly Note . . . . . . . . . . . . . . . 01–10–7

HOUSING DISASSEMBLY III . . . . . . . . . 01–10–8

Flywheel (MT), Counterweight (AT)

Disassembly Note . . . . . . . . . . . . . . . 01–10–9

Tension Bolt Disassembly Note . . . . . . 01–10–10

Rear Housing Disassembly Note . . . . . 01–10–10

Stationary Gear Disassembly Note . . . 01–10–10

Tubular Dowel Disassembly Note. . . . . 01–10–10

Rotor Housing Disassembly Note . . . . 01–10–11

Rotor Disassembly Note . . . . . . . . . . . 01–10–11

Intermediate Housing

Disassembly Note . . . . . . . . . . . . . . . 01–10–12

ROTOR DISASSEMBLY . . . . . . . . . . . . . 01–10–12

Oil Seal Disassembly Note. . . . . . . . . . 01–10–13

Oil Seal Spring Disassembly Note . . . . 01–10–13

SIDE HOUSING (FRONT, INTERMEDIATE,

REAR) INSPECTION. . . . . . . . . . . . . . . 01–10–13

ROTOR HOUSING INSPECTION . . . . . . 01–10–14

ROTOR INSPECTION . . . . . . . . . . . . . . . 01–10–15

APEX SEAL INSPECTION . . . . . . . . . . . 01–10–16

SIDE SEAL INSPECTION . . . . . . . . . . . . 01–10–17

CUT-OFF SEAL INSPECTION . . . . . . . . 01–10–18

OIL SEAL INSPECTION . . . . . . . . . . . . . 01–10–18

SPRING INSPECTION . . . . . . . . . . . . . . 01–10–18

Oil Seal Spring . . . . . . . . . . . . . . . . . . . 01–10–18

Cut-off Seal Spring. . . . . . . . . . . . . . . . 01–10–19

Side Seal Spring . . . . . . . . . . . . . . . . . 01–10–19

Corner Seal Spring . . . . . . . . . . . . . . . 01–10–19

Apex Seal Spring . . . . . . . . . . . . . . . . . 01–10–19

ROTOR BEARING OIL CLEARANCE

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01–10–20

ROTOR BEARING REPLACEMENT. . . . 01–10–21

Removal. . . . . . . . . . . . . . . . . . . . . . . . 01–10–21

Installation . . . . . . . . . . . . . . . . . . . . . . 01–10–21

ECCENTRIC SHAFT INSPECTION . . . . 01–10–22

ECCENTRIC SHAFT END PLAY

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01–10–22

SERVICE TOOLS . . . . . . . . . . . 01-60

01–10

PILOT BEARING

INSPECTION/REPLACEMENT [MT] . . .01–10–24

Inspection . . . . . . . . . . . . . . . . . . . . . . . 01–10–24

Replacement . . . . . . . . . . . . . . . . . . . . . 01–10–24

ECCENTRIC SHAFT BYPASS

VALVE. . . . . . . . . . . . . . . . . . . . . . . . . . . 01–10–25

ECCENTRIC SHAFT POSITION PLATE

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01–10–25

MAIN BEARING OIL CLEARANCE

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01–10–25

MAIN BEARING REPLACEMENT . . . . . .01–10–26

Removal . . . . . . . . . . . . . . . . . . . . . . . . 01–10–26

Installation . . . . . . . . . . . . . . . . . . . . . . . 01–10–27

OIL PUMP INSPECTION . . . . . . . . . . . . . 01–10–29

Typ e A . . . . . . . . . . . . . . . . . . . . . . . . . . 01–10–29

Typ e B . . . . . . . . . . . . . . . . . . . . . . . . . . 01–10–29

ROTOR ASSEMBLY . . . . . . . . . . . . . . . . . 01–10–30

Oil Seal Spring Assembly Note . . . . . . . 01–10–30

O-Ring Assembly Note . . . . . . . . . . . . . 01–10–31

Oil Seal Assembly Note . . . . . . . . . . . . 01–10–32

Cut-Off Seal Spring Assembly Note . . .01–10–32

Cut-Off Seal Assembly Note . . . . . . . . . 01–10–33

HOUSING ASSEMBLY I . . . . . . . . . . . . . . 01–10–34

Thrust Plate Assembly Note . . . . . . . . . 01–10–35

Rotor Assembly Note . . . . . . . . . . . . . . 01–10–35

Oil Jet Plug Assembly Note. . . . . . . . . . 01–10–36

Rotor Housing Assembly Note . . . . . . . 01–10–37

Intermediate Housing

Assembly Note . . . . . . . . . . . . . . . . . . 01–10–38

Rear Oil Seal Assembly Note . . . . . . . . 01–10–39

Rear Housing Assembly Note . . . . . . . . 01–10–40

Tension Bolt Assembly Note . . . . . . . . . 01–10–40

Flywheel (MT), Counterweight (AT)

Assembly Note . . . . . . . . . . . . . . . . . . 01–10–41

HOUSING ASSEMBLY II . . . . . . . . . . . . . 01–10–42

Spacer Assembly Note . . . . . . . . . . . . . 01–10–43

Oil Pump Drive Gear

Assembly Note . . . . . . . . . . . . . . . . . . 01–10–43

Oil Pump Sprocket Wheel

Assembly Note . . . . . . . . . . . . . . . . . . 01–10–43

Front Oil Seal Assembly Note . . . . . . . . 01–10–43

Front Cover Assembly Note . . . . . . . . . 01–10–44

Pulley Lockbolt Assembly Note . . . . . . . 01–10–44

HOUSING ASSEMBLY III . . . . . . . . . . . . . 01–10–45

Oil Pan Upper Block

Assembly Note . . . . . . . . . . . . . . . . . . 01–10–47

Oil Pan Assembly Note . . . . . . . . . . . . . 01–10–47

End of Toc

Revised 6/2008 (Ref. No. R108/08)

01–10–1

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

ENGINE OVERHAUL SERVICE WARNING

Warning

• Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after this work.

End Of Sie

ENGINE MOUNTING/DISMOUNTING

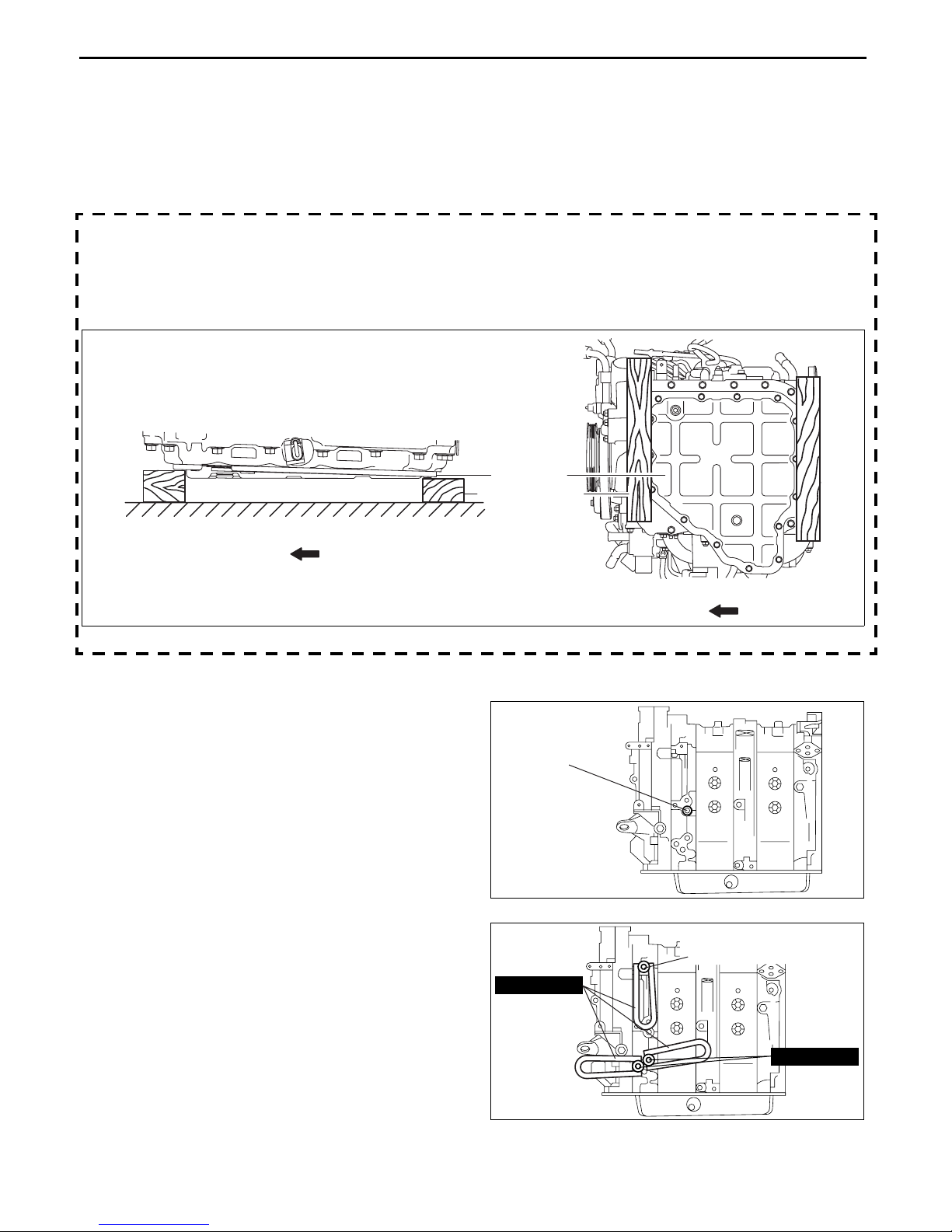

Caution

• The oil pan could be damaged or dented if the engine's own weight is subjected to an impact

against a level surface. Always set two pieces of wood in the positions shown in the figure to

prevent the oil pan from being dented. If the oil pan is dented, the amount of intake oil and the fluid

pressure will decrease. (Type B)

OIL PAN

PIECE OF WOOD

CHU011002000E01

CHU011002000E12

ENGINE FRONT SIDE

Mounting

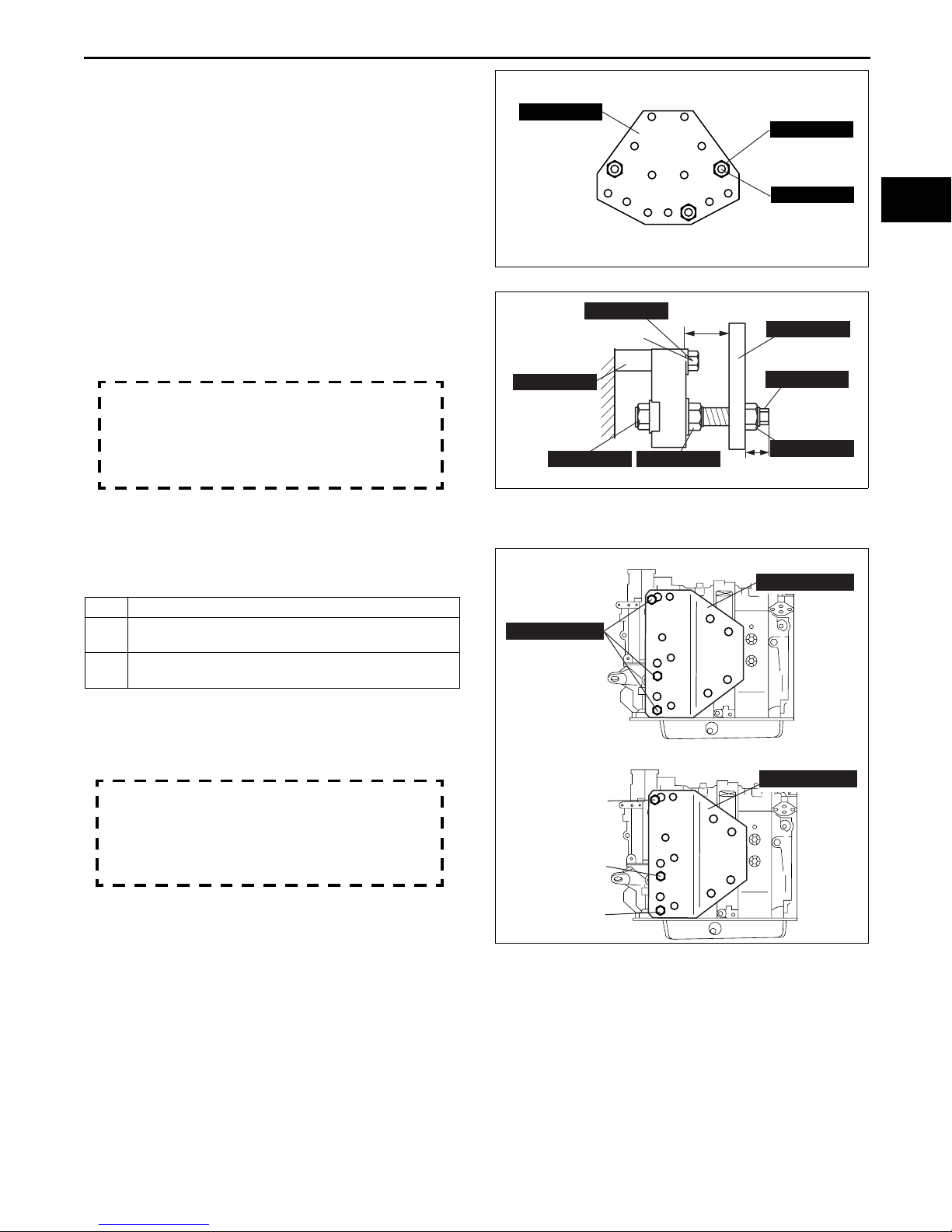

Using 49 L010 1A0

1. Remove the stud bolt.

2. Install the SSTs (arms) to the specified three

position as shown in the figure, and temporarily

tighten with the SSTs (bolts) and 99784 0890 or

M8×1.25 length 90 mm {3.55 in} bolt.

ENGINE FRONT SIDE

GHE0110E001

STUD BOLT

TT

LL

CHU0110E048

99784 0890 OR M8x1.25

LENGTH 90 mm {3.55 in} BOLT

49 L010 102

TT

LL

01–10–2

49 L010 107

CHU0110E049

Revised 6/2008 (Ref. No. R108/08)

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

3. Install the SSTs (bolt, nut) to the three specified

positions as shown in the figure.

4. Install the SSTs (bolts, nuts, hook, plate) in Step 3

to the SST (arms, bolts) set in Step 2.

5. Adjust the bolt threads by turning them so that

they project approx. 20 mm {0.79 in} from the

plate end.

6. Adjust the bolts and nuts so that the plate and

arms are parallel.

7. Mount the engine to the SST (engine stand).

8. Remove the oil pan drain plug and drain the

engine oil.

9. Replace with a new washer and install the oil pan

drain plug.

Tightening torque

Type A : 29.4—39.2 N·m {3.00—3.99 kgf·m,

21.7—28.9 ft·lbf}

Type B : 29.4—41.2 N·m {3.00—4.20 kgf·m,

21.7—30.3 ft·lbf}

49 L010 101

49 L010 107

99784 0890 OR M8x1.25

LENGTH 90 mm {0.55 in}

BOLT

49 L010 102

ENGINE

49 L010 10449 L010 103

PARALLEL

APPROX. 20 mm {0.79in}

49 L010 104

49 L010 105

BHJ0110E003

49 L010 101

49 L010 105

49 L010 104

CHU0110E050

01–10

Using 49 J010 3A0A

1. Install the SSTs to the position shown in the

figure.

AM8×1.25 length 25 mm {1.28 in} bolt

99940 1201 (left side engine mount installation nut)

B

or M12×1.5 nut

99756 1230 (left side engine mount installation nut)

C

+ washer

2. Mount the engine to the SST (engine stand).

3. Remove the oil pan drain plug and drain the

engine oil.

4. Install the oil pan drain plug with a new washer.

Tightening torque

Type A : 29.4—39.2 N·m {3.00—3.99 kgf·m,

21.7—28.9 ft·lbf}

Type B : 29.4—41.2 N·m {3.00—4.20 kgf·m,

21.7—30.3 ft·lbf}

WHEN USING 49 J010 3A0A

49 J010 302A

ONLY WHEN USING 49 J010 301A

A

B

C

49 J010 301A

TT

LL

49 J010 301A

TT

LL

CHU0110E058

Dismounting

1. Dismount in the reverse order of mounting.

2. Tighten the stud bolt. (Only when using 49 L010 101.)

Tightening torque

14.7—34.3 N·m {1.50—3.49 kgf·m, 10.9—25.2 ft·lbf}

End Of Sie

Revised 6/2008 (Ref. No. R108/08)

01–10–3

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

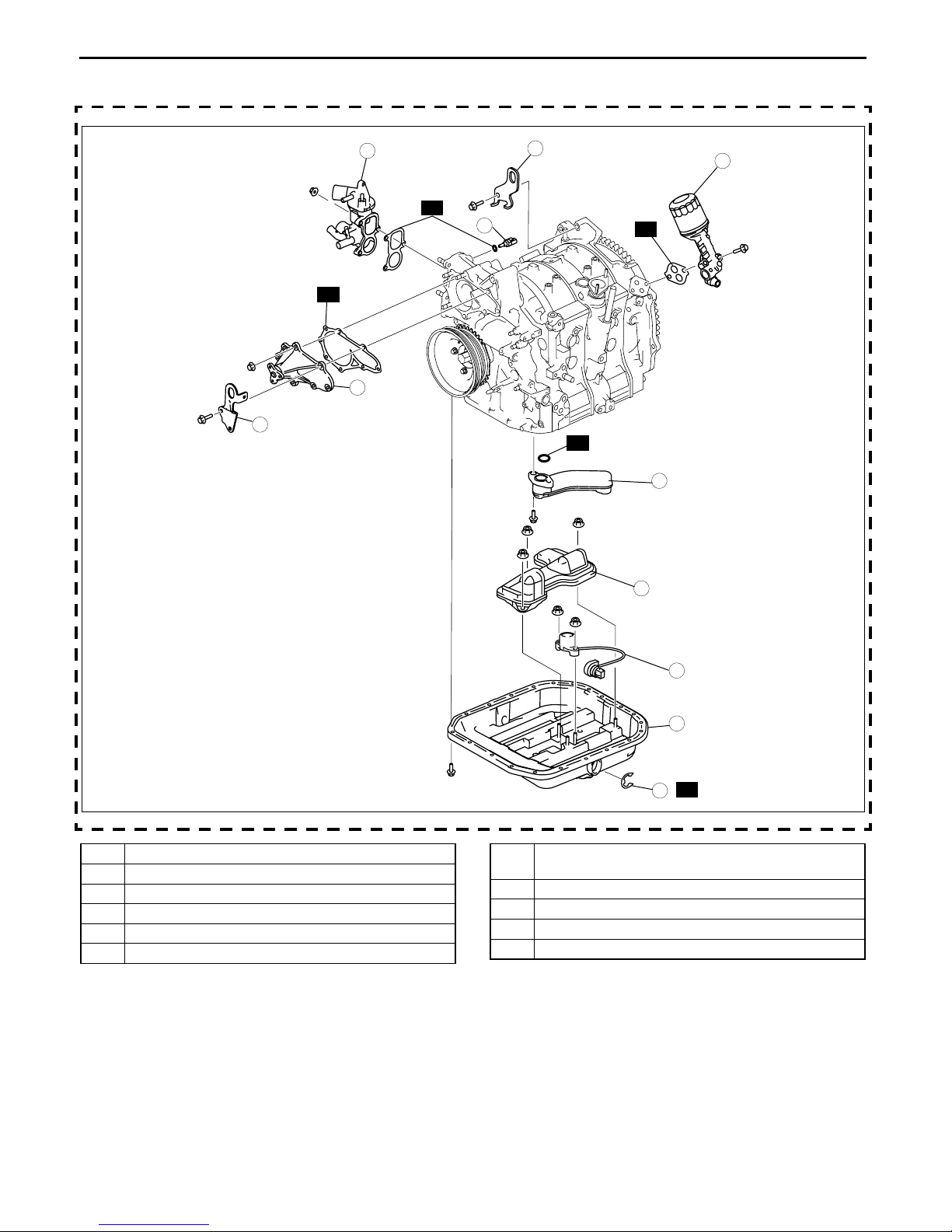

HOUSING DISASSEMBLY I

1. Disassemble in the order indicated in the table.

Type A

6

R

5

4

CHU011002000E04

2

1

R

3

R

R

11

.

1 Oil filter component

2 Engine hanger (engine rear side)

3 Engine coolant temperature sensor

4 Engine hanger (engine front side)

5 Water pump body

6 Thermostat component

9

10

7

R

8

7Oil pan

(See 01–10–5 Oil Pan Disassembly Note.)

8 Clip

9 Oil baffle plate

10 Oil-level sensor

11 Oil strainer

BHJ0110E006

01–10–4

Revised 6/2008 (Ref. No. R108/08)

01–10-4 MECHANICAL

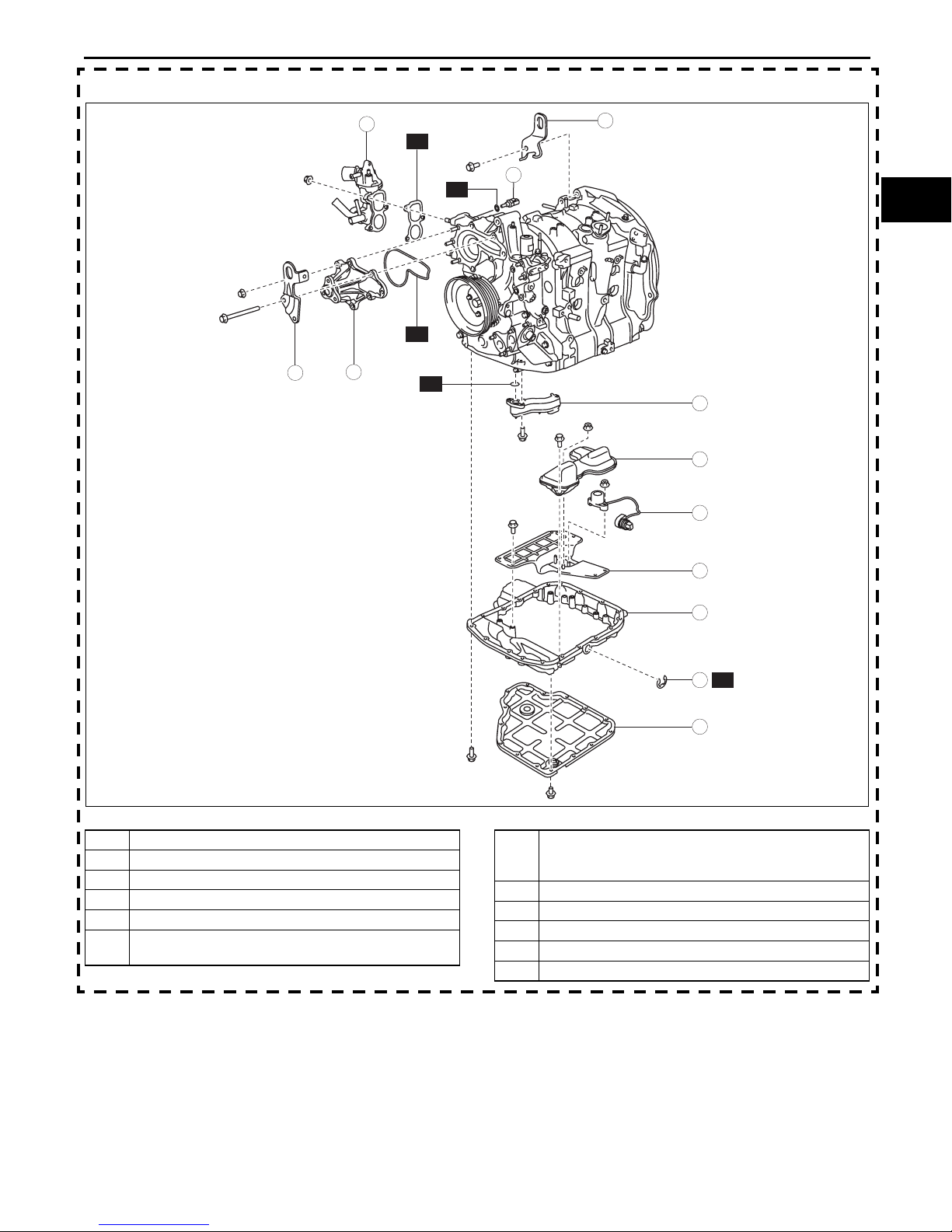

Typ e B

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

CHU011002000E04

5

R

1

2

R

R

3

4

R

01–10

12

8

10

11

.

1 Engine hanger (engine rear side)

2 Engine coolant temperature sensor

3 Engine hanger (engine front side)

4 Water pump body

5 Thermostat component

6 Oil pan

(See 01–10–5 Oil Pan Disassembly Note.)

End Of Sie

7

9

R

6

7 Oil pan upper block

(See 01–10–5 Oil Pan Upper Block Disassembly

Note.)

8 Baffle plate

9 Clip

10 Oil level switch

11 Baffle plate

12 Oil strainer

BHJ0110F002

Revised 6/2008 (Ref. No. R108/08)

01–10-4–1

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

THIS PAGE INTENTIONALLY

LEFT BLANK

01–10-4–2

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

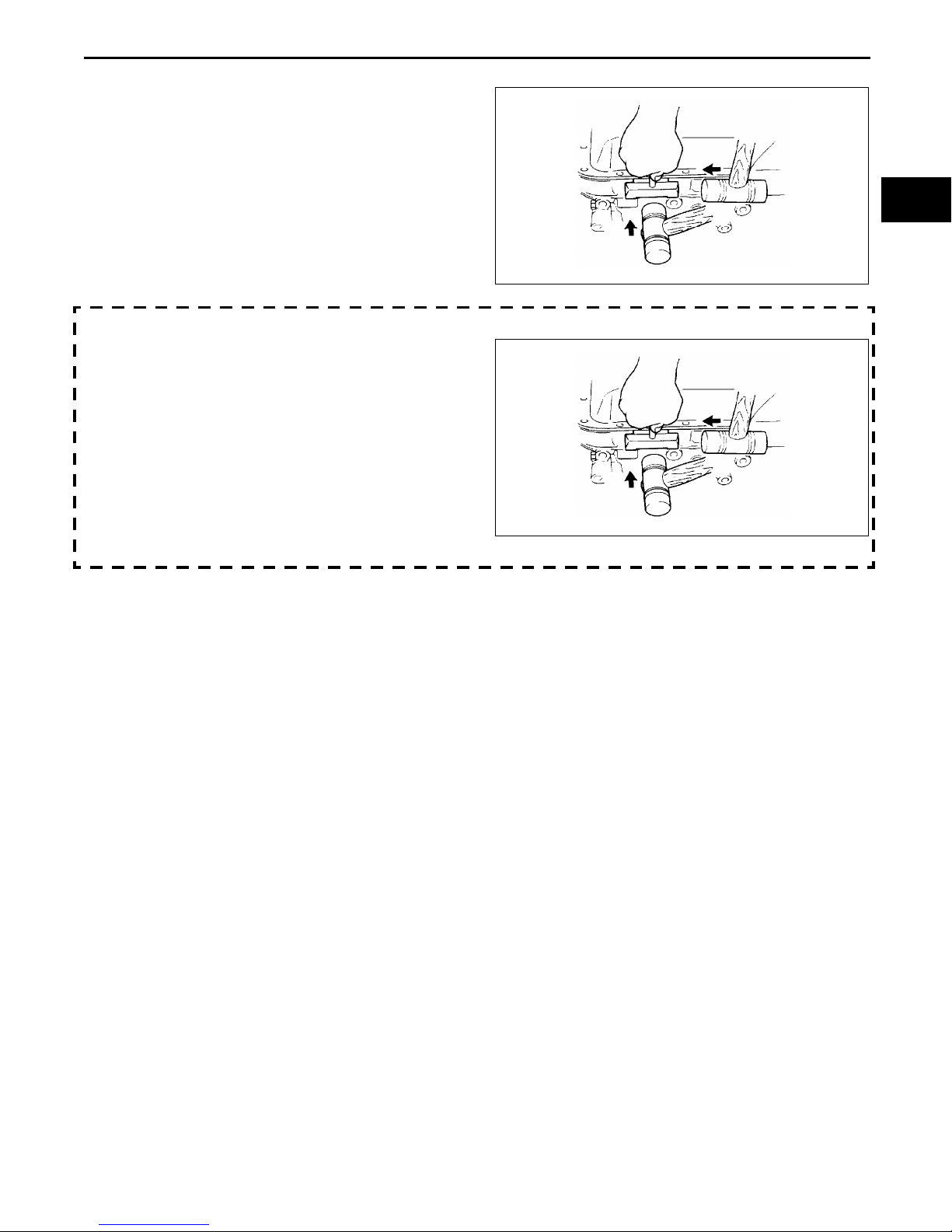

Oil Pan Disassembly Note

1. Remove the oil pan using the separator tool.

Oil Pan Upper Block Disassembly Note

1. Remove the oil pan upper block using the

separator tool.

End Of Sie

MECHANICAL

01–10

BHJ0111W014

BHJ0111E014

Revised 6/2008 (Ref. No. R108/08)

01–10–5

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

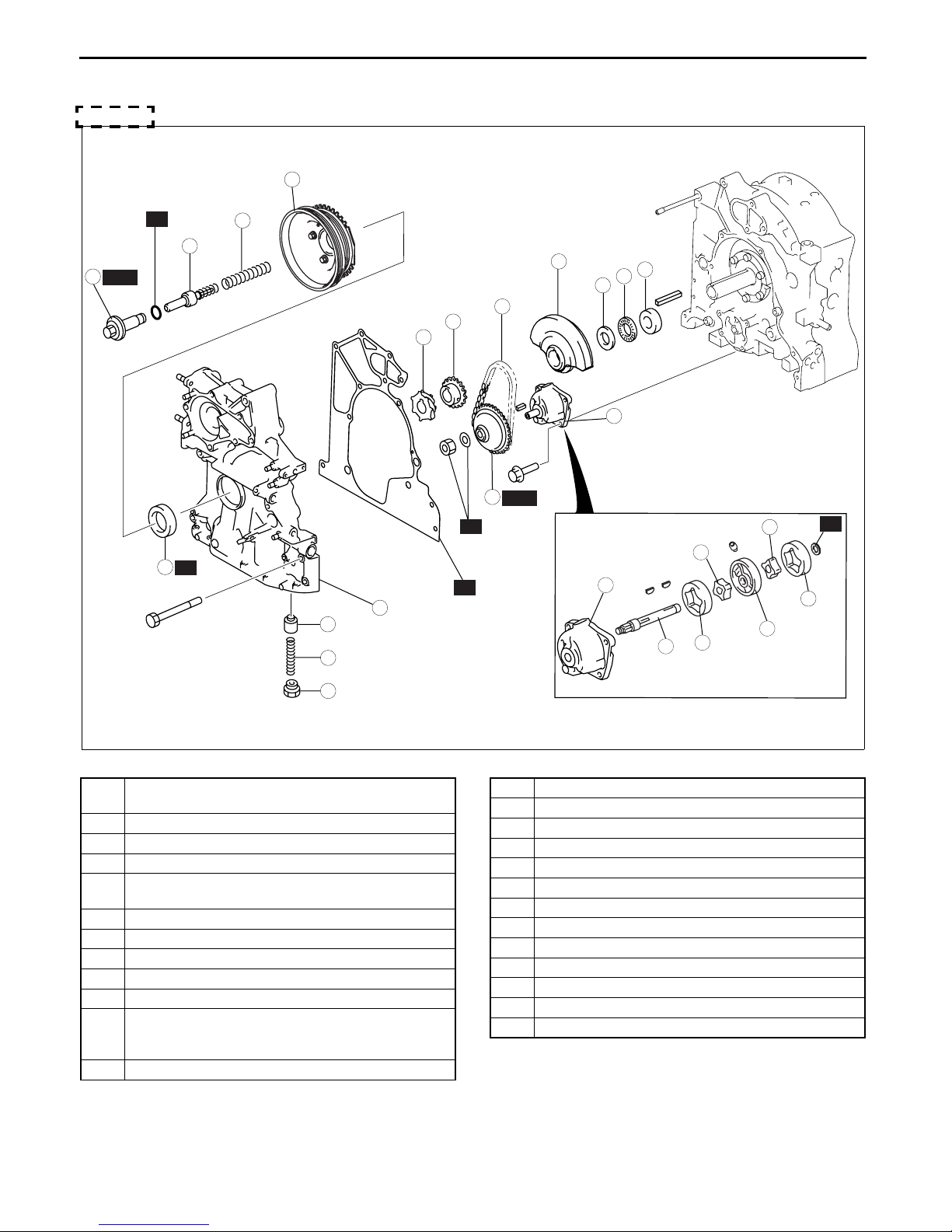

HOUSING DISASSEMBLY II

1. Disassemble in the order indicated in the table.

Type A

2

R

4

3

1

SST

6

R

5

9

8

10

13

CHU011002000E05

15

16

17

18

12

14

11

SST

R

20

R

23

R

25

19

21

22

24

.

1 Pulley lockbolt

(See 01–10–7 Pulley Lockbolt Disassembly Note.)

2 Pulley component

3 Eccentric shaft bypass valve

4Spring

5 Front cover

(See 01–10–7 Front Cover Disassembly Note.)

6 Front oil seal

7Plug

8 Control valve spring

9 Control valve

10 Metering oil pump drive gear

11 Oil pump sprocket wheel

(See 01–10–7 Oil Pump Sprocket Disassembly

Note.)

12 Oil pump chain

7

BHJ0110E008

13 Oil pump drive gear

14 Oil pump component

15 Balance weight

16 Thrust plate

17 Needle bearing

18 Spacer

19 Rear outer rotor

20 Rear inner rotor

21 Middle plate

22 Front outer rotor

23 Front inner rotor

24 Shaft

25 Oil pump body

01–10–6

Revised 6/2008 (Ref. No. R108/08)

01–10-6 MECHANICAL

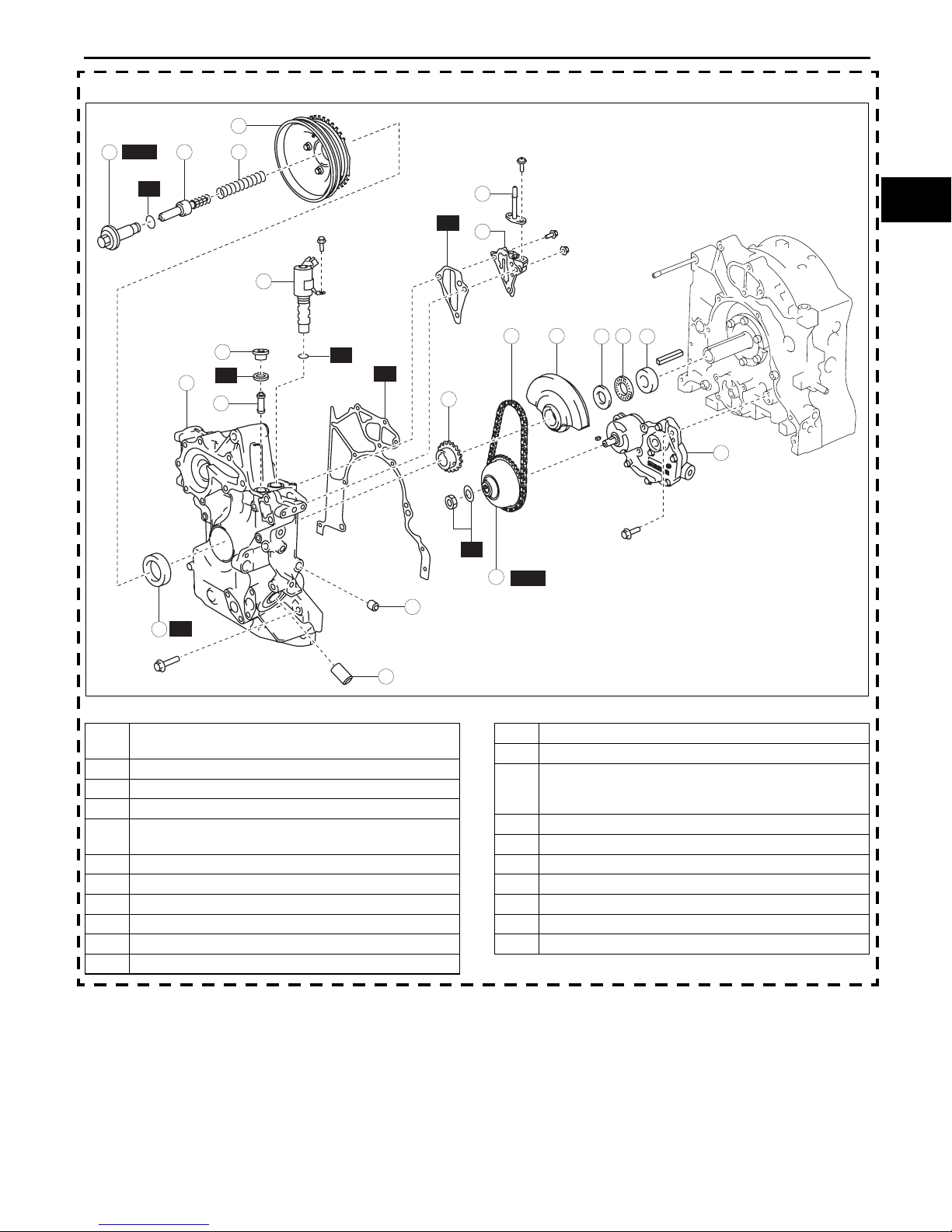

Typ e B

SST

1

Engine Workshop Manual 13B-MSP (Multi Side Port) (1773–1U–03C)

MECHANICAL

CHU011002000E04

2

43

R

8

R

9

01–10

7

15 18 192021

10

R

5

11

R

R

16

17

R

14

SST

13

6

R

.

1 Pulley lockbolt

(See 01–10–7 Pulley Lockbolt Disassembly Note.)

2 Pulley component

3 Eccentric shaft bypass valve

4Spring

5 Front cover

(See 01–10–7 Front Cover Disassembly Note.)

6 Front oil seal

7OCV

8 Oil pipe

9 OCV case

10 Plug

11 OCV oil filter

End Of Sie

12

BHJ0110F003

12 Oil filter joint

13 Plug

14 Oil pump sprocket wheel

(See 01–10–7 Oil Pump Sprocket Disassembly

Note.)

15 Oil pump chain

16 Oil pump drive gear

17 Oil pump component

18 Balance weight

19 Thrust plate

20 Needle bearing

21 Spacer

Revised 6/2008 (Ref. No. R108/08)

01–10-6–1

Loading...

Loading...