Maxtor DiamondMax, 4320, 91728D8, 91512D7, 91303D6 User Manual

...

HARD DRIVE

P RODUCT

MANUAL

DiamondMax

™

4320

91728D8, 91512D7, 91303D6

91080D5 90845D4, 90648D3

90432D2

DiamondMax™ 4320

91728D8, 91512D7, 91303D6, 91080D5

90845D4, 90648D3, 90432D2

All material contained herein Copyright © 1998 Maxtor Corporation.

DiamondMax™, DiamondMax™ 1280, DiamondMax™ 1750,

DiamondMax™ 2160, DiamondMax™ 2880, DiamondMax™ 3400,

DiamondMax™ 4320, DiamondMax™ Plus 2500 and MaxFax™ are

trademarks of Maxtor Corporation. No Quibble

®

Service is a registered

trademark of Maxtor Corporation. Other brands or products are

trademarks or registered trademarks of their respective holders.

Contents and specifications subject to change without notice. All

rights reserved.

Corporate Headquarters

510 Cottonwood Drive

Milpitas, California 95035

Tel: 408-432-1700

Fax: 408-432-4510

Research and Development

Engineering Center

2190 Miller Drive

Longmont, Colorado 80501

Tel: 303-651-6000

Fax: 303-678-2165

Part #1407

Revisions Manual No. 1407

Before You Begin

Thank you for your interest in the Maxtor DiamondMax™ 4320 AT hard disk drives. This manual provides

technical information for OEM engineers and systems integrators regarding the installation and use of DiamondMax

hard drives.

Drive repair should be performed only at an authorized repair center. For repair information, contact

the Maxtor Customer Service Center at 800-2MAXTOR or 408-432-1700.

Before unpacking the hard drive, please review Sections 1 through 4.

CAUTION

Maxtor DiamondMax 4320 hard drives are precision products. Failure to

follow these precautions and guidelines outlined here may lead to

product failure, damage and invalidation of all warranties.

1

BEFORE unpacking or handling a drive, take all proper electro-static discharge (ESD)

precautions, including personnel and equipment grounding. Stand-alone drives are sensitive to

ESD damage.

2

BEFORE removing drives from their packing material, allow them to reach room

temperature.

3

During handling, NEVER drop, jar, or bump a drive.

4

Once a drive is removed from the Maxtor shipping container, IMMEDIATELY secure the drive

through its mounting holes within a chassis. Otherwise, store the drive on a padded, grounded,

antistatic surface.

5

NEVER switch DC power onto the drive by plugging an electrically live DC source cable into

the drive's connector. NEVER connect a live bus to the drive's interface connector.

Please do not remove or cover up Maxtor factory-installed drive labels.

They contain information required should the drive ever need repair.

DIAMONDMAX 4320 PRODUCT MANUAL

i

Contents

Section 1 — Introduction

Maxtor Corporation 1 - 1

Products 1 - 1

Support 1 - 1

Manual Organization 1 - 1

Abbreviations 1 - 1

Conventions 1 - 2

Key Words 1 - 2

Numbering 1 - 2

Signal Conventions 1 - 2

Section 2 — Product Description

The DiamondMax™ 4320

Product Features 2 - 2

Functional/Interface 2 - 2

Zone Density Recording 2 - 2

Read/Write Multiple Mode 2 - 2

UltraDMA - Mode 2 2 - 2

Multi-word DMA (EISA Type B) - Mode 2 2 - 2

Sector Address Translation 2 - 2

Logical Block Addressing 2 - 3

Defect Management Zone 2 - 3

On-the-Fly Hardware Error Correction Code (ECC) 2 - 3

Software ECC Correction 2 - 3

Automatic Head Park and Lock Operation 2 - 3

Cache Management 2 - 4

Buffer Segmentation 2 - 4

Read-Ahead Mode 2 - 4

Automatic Write Reallocation (AWR) 2 - 4

Write Cache Stacking 2 - 4

Major HDA Components 2 - 5

Drive Mechanism 2 - 5

Rotary Actuator 2 - 5

Read/Write Electronics 2 - 5

Read/Write Heads and Media 2 - 5

Air Filtration System 2 - 5

Microprocessor 2 - 5

Subsystem Configuration 2 - 6

Dual Drive Support 2 - 6

Cable Select Option 2 - 6

Jumper Location/Configuration 2 - 6

4092 Cylinder Limitation 2 - 6

DIAMONDMAX 4320 PRODUCT MANUAL

ii

Section 3 — Product Specifications

Models and Capacities 3 - 1

Drive Configuration 3 - 1

Performance Specifications 3 - 1

Physical Dimensions 3 - 2

Power Requirements 3 - 3

Power Mode Definitions 3 - 3

Spin-up 3 - 3

Seek 3 - 3

Read/Write 3 - 3

Idle 3 - 3

Standby 3 - 3

Sleep 3 - 3

EPA Energy Star Compliance 3 - 3

Environmental Limits 3 - 3

Shock and Vibration 3 - 4

Reliability Specifications 3 - 4

AFR 3 - 4

MTBF 3 - 4

Quality Acceptance Rate 3 - 4

Start/Stop Cycles 3 - 4

Data Reliability 3 - 4

Component Design Life 3 - 4

EMC/EMI 3 - 5

EMC Compliance 3 - 5

Canadian Emissions Statement 3 - 5

Safety Regulatory Compliance 3 - 5

Section 4 — Handling and Installation

Pre-formatted Drive 4 - 1

Important Notice 4 - 1

Hard Drive Handling Precautions 4 - 1

Electro-Static Discharge (ESD) 4 - 1

Unpacking and Inspection 4 - 2

Repacking 4 - 3

Physical Installation 4 - 3

Before You Begin 4 - 4

Please Read 4 - 4

Handling Precautions 4 - 4

Tools for Installation 4 - 4

Drive Identification Information 4 - 4

Capacity Barriers 4 - 4

Protecting Your Existing Data 4 - 4

General Requirements 4 - 5

System Hardware Requirements 4 - 5

DIAMONDMAX 4320 PRODUCT MANUAL

iii

BIOS Requirements 4 - 5

Ultra Direct Memory Access (UDMA) 4 - 5

OS Requirements for Large Capacity Hard Drives 4 - 5

Hard Drive Identification 4 - 6

Identifying IDE Devices on the Interface 4 - 6

Jumper Settings 4 - 6

Systems Using Cable Select 4 - 6

Relationship to Other IDE Devices 4 - 6

Mounting Drive in System 4 - 7

Attaching Interface and Power Cables 4 - 7

Attaching System Cables 4 - 7

System Setup 4 - 8

Setting the BIOS (CMOS) 4 - 8

BIOS (CMOS) Parameters 4 - 8

Hard Drive Preparation 4 - 10

System Hangs During Boot 4 - 12

Section 5 — AT Interface Description

Interface Connector 5 - 1

Pin Description Summary 5 - 1

Pin Description Table 5 - 2

PIO Timing 5 - 3

DMA Timing 5 - 4

Ultra DMA Timing Parameters 5 - 5

Section 6 — Host Software Interface

Task File Registers 6 - 1

Data Register 6 - 1

Error Register 6 - 1

Features Register 6 - 1

Sector Count Register 6 - 2

Sector Number Register 6 - 2

Cylinder Number Registers 6 - 2

Device/Head Register 6 - 2

Status Register 6 - 2

Command Register 6 - 3

Read Commands 6 - 3

Write Commands 6 - 3

Mode Set/Check Commands 6 - 3

Power Mode Commands 6 - 3

Initialization Commands 6 - 3

Seek, Format, and Diagnostic Commands 6 - 3

S.M.A.R.T. Commands 6 - 3

Summary 6 - 4

Control Diagnostic Registers 6 - 5

DIAMONDMAX 4320 PRODUCT MANUAL

iv

Alternate Status Register 6 - 5

Device Control Register 6 - 5

Digital Input Register 6 - 5

Reset and Interrupt Handling 6 - 6

Section 7 — Interface Commands

Command Summary 7 - 1

Read Commands 7 - 2

Read Sector(s) 7 - 2

Read Verify Sector(s) 7 - 2

Read Sector Buffer 7 - 2

Read DMA 7 - 3

Read Multiple 7 - 3

Set Multiple 7 - 3

Write Commands 7 - 4

Write Sector(s) 7 - 4

Write Verify Sector(s) 7 - 4

Write Sector Buffer 7 - 4

Write DMA 7 - 5

Write Multiple 7 - 5

Ultra DMA 7 - 5

Set Feature Commands 7 - 5

Set Features Mode 7 - 5

Power Mode Commands 7 - 7

Standby Immediate 7 - 7

Idle Immediate 7 - 7

Standby 7 - 7

Idle 7 - 7

Check Power Mode 7 - 7

Set Sleep Mode 7 - 7

Default Power-on Condition 7 - 7

Initialization Commands 7 - 9

Identify Drive 7 - 9

Initialize Drive Parameters 7 - 12

Seek, Format, and Diagnostic Commands 7 - 13

S.M.A.R.T. Command Set 7 - 14

Section 8 — Service and Support

Service Policy 8 - 1

No Quibble Service 8 - 1

Support 8 - 1

Glossary

Glossary GL - 1

DIAMONDMAX 4320 PRODUCT MANUAL

v

Figures

Figure Title Page

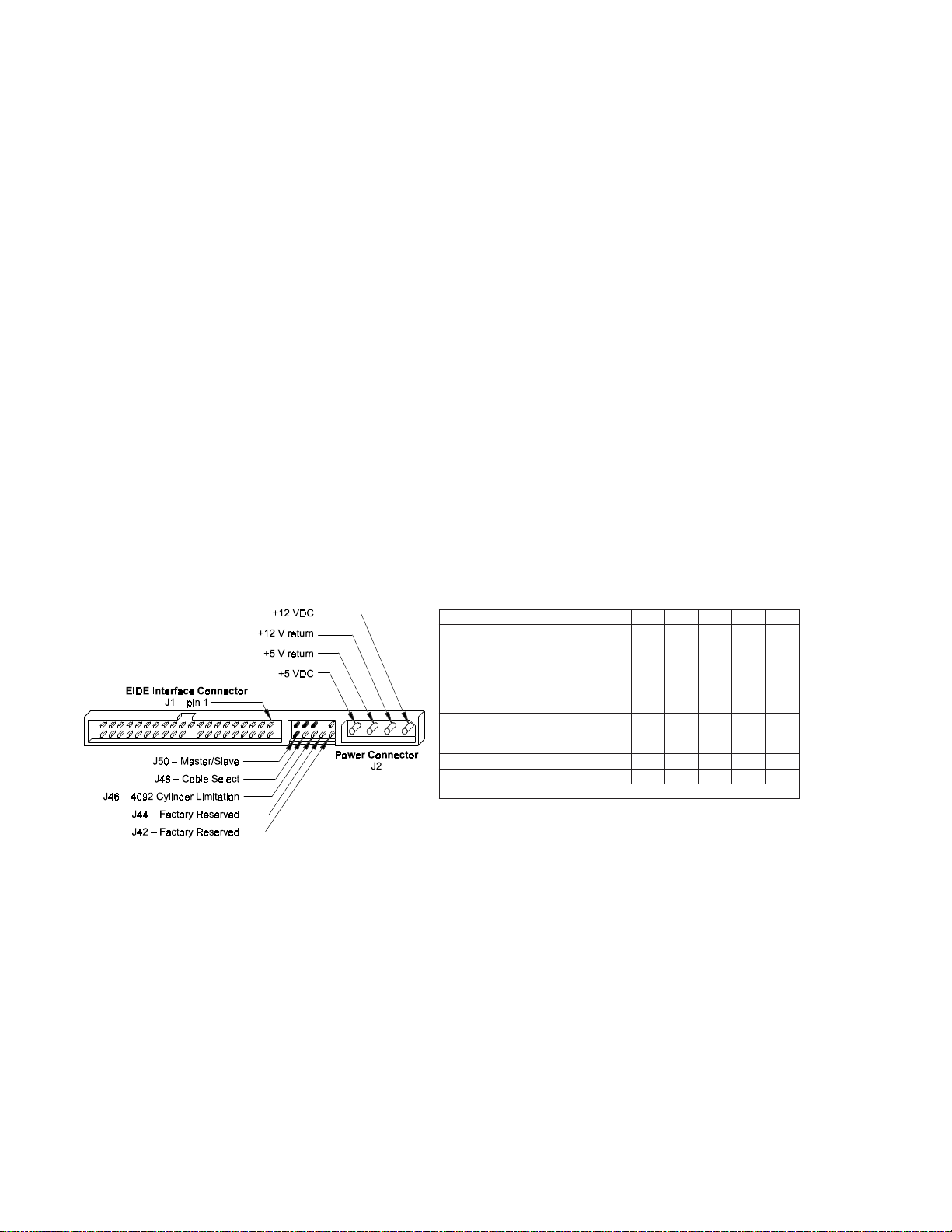

2 - 1 PCBA Jumper Location and Configuration 2 - 6

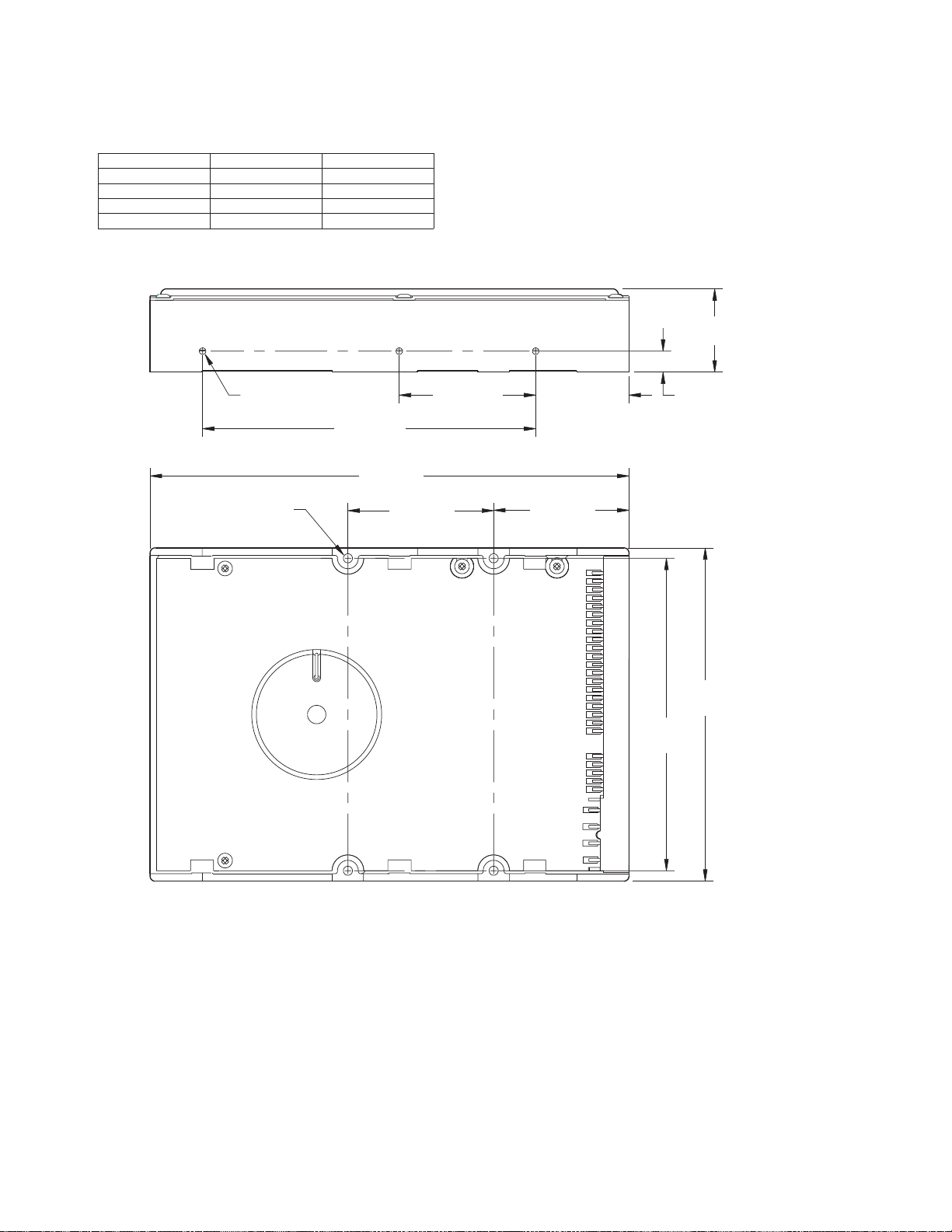

3 - 1 Outline and Mounting Dimensions 3 - 2

4 - 1 Multi-pack Shipping Container 4 - 2

4 - 2 Single-pack Shipping Container (Option A) 4 - 3

4 - 3 Single-pack Shipping Container (Option B) 4 - 3

4 - 4 Master, Slave and Cable Select Settings 4 - 5

4 - 5 5.25-inch Mounting Brackets and Rails 4 - 6

4 - 6 IDE Interface and Power Cabling Detail 4 - 7

4 - 7 Master, Slave and Cable Select Settings 4 - 10

5 - 1 Data Connector 5 - 1

5 - 2 PIO Data Transfer to/from Device 5 - 3

5 - 3 Multi-word DMA Data Transfer 5 - 4

5 - 4 Initiating an Ultra DMA Data In Burst 5 - 5

5 - 5 Sustained Ultra DMA Data In Burst 5 - 6

5 - 6 Host Pausing an Ultra DMA Data In Burst 5 - 6

5 - 7 Device Terminating an Ultra DMA Data In Burst 5 - 7

5 - 8 Host Terminating an Ultra DMA Data In Burst 5 - 7

5 - 9 Initiating an Ultra DMA Data Out Burst 5 - 8

5 - 10 Sustained Ultra DMA Data Out Burst 5 - 8

5 - 11 Device Pausing an Ultra DMA Data Out Burst 5 - 9

5 - 12 Host Terminating an Ultra DMA Data Out Burst 5 - 9

5 - 13 Device Terminating an Ultra DMA Data Out Burst 5 - 10

DIAMONDMAX 4320 – INTRODUCTION

1 – 1

SECTION 1

Introduction

Maxtor Corporation

Maxtor Corporation has been providing high-quality computer storage products since 1982. Along the way,

we’ve seen many changes in data storage needs. Not long ago, only a handful of specific users needed more than

a couple hundred megabytes of storage. Today, downloading from the Internet and CD-ROMs, multimedia,

networking and advanced office applications are driving storage needs even higher. Even home PC applications

need capacities measured in gigabytes, not megabytes.

Products

Maxtor’s products meet those demanding storage capacity requirements with room to spare. They feature

proven compatibility and reliability. While DiamondMax™ 4320 is the latest addition to our family of high

performance desktop hard drives, the DiamondMax™ 3400 series hard drives deliver industry-leading

capacity, performance and value for many PC applications.

Support

No matter which capacity, all Maxtor hard drives are supported by our commitment to total customer

satisfaction and our No Quibble

®

Service guarantee. One call – or a visit to our home page on the Internet

(http://www.maxtor.com) – puts you in touch with either technical support or customer service. We’ll

provide you the information you need quickly, accurately and in the form you prefer – a fax, a downloaded

file or a conversation with a representative.

Manual Organization

This hard disk drive reference manual is organized in the following method:

❏ Section 1 – Introduction

❏ Section 2 – Description

❏ Section 3 – Specifications

❏ Section 4 – Installation

❏ Section 5 – AT Interface

❏ Section 6 – Host Software Interface

❏ Section 7 – Interface Commands

❏ Section 8 – Service and Support

❏ Appendix – Glossary

Abbreviations

VRBBANOITPIRCSEDVRBBANOITPIRCSED

ATAtnemhcattaTABMetybagem

ipbhcnirepstibces/stibMdnocesrepstibagem

SHCrotces-daeh-rednilycces/BMdnocesrepsetybagem

bdslebicedzHMztrehagem

ABddethgiewA,slebicedsmdnocesillim

AMDsseccayromemtceridBSMtibtnacifingistsom

CCEedocnoitcerrocrorreVmstlovillim

icfhcnirepsegnahcxulfsnsdnocesonan

GnoitareleccaOIPtuptuo/tupnidemmargorp

BGetybagigMPRetunimrepsnoitulover

zHztrehipthcnirepskcart

BKetybolikAMDUsseccayromemtceridartlu

ABL)gni(sserddakcolblacigolcesµdnocesorcim

BSLtibtnacifingistsaelVstlov

AmserepmaillimWsttaw

DIAMONDMAX 4320 – INTRODUCTION

1 – 2

Conventions

If there is a conflict between text and tables, the table shall be accepted as being correct.

Key Words

The names of abbreviations, commands, fields and acronyms used as signal names are in all uppercase type

(e.g., IDENTIFY DRIVE). Fields containing only one bit are usually referred to as the “name” bit instead of

the “name” field.

Names of drive registers begin with a capital letter (e.g., Cylinder High register).

Numbering

Numbers that are not followed by a lowercase “b” or “h” are decimal values. Numbers that are followed by

a lowercase “b” (e.g., 01b) are binary values. Numbers that are followed by a lowercase “h” (e.g., 3Ah) are

hexadecimal values.

Signal Conventions

Signal names are shown in all uppercase type.

All signals are either high active or low active signals. A dash character (-) at the end of a signal name

indicates that the signal is low active. A low active signal is true when it is below ViL and is false when it is

above ViH. A signal without a dash at the end indicates that the signal is high active. A high active signal is

true when it is above ViH and is false when it is below ViL.

When a signal is asserted, it means the signal is driven by an active circuit to its true state.

When a signal is negated, it means the signal is driven by an active circuit to its false state.

When a signal is released, it means the signal is not actively driven to any state. Some signals have bias

circuitry that pull the signal to either a true or false state when no signal driver is actively asserting or negating

the signal. These instances are noted under the description of the signal.

PRODUCT DESCRIPTION

2 – 1

SECTION 2

Product Description

Maxtor DiamondMax™ 4320 AT disk drives are 1-inch high, 3.5-inch diameter random access storage devices

which incorporate an on-board ATA-4/Ultra DMA controller. High capacity is achieved by a balanced

combination of high areal recording density and the latest data encoding and servo techniques.

Maxtor's latest advancements in electronic packaging and integration methods have lowered the drive's power

consumption and increased its reliability. Advanced magneto-resistive read/write heads, an state-of-the-art head/

disk assembly using an integrated motor/spindle design allow up to four disks in a 3.5-inch package.

Exceptionally high data transfer rates and 9.0 ms access times make these performance series disk drives especially

well-suited to high speed desktop and server applications.

DiamondMax 4320 Key Features

ANSI ATA-4 compliant PIO Mode 4 interface (Enhanced IDE)

Supports Ultra DMA Mode 2 for up to 33 MB/sec data transfers

256/512 KB buffer with multi-adaptive cache manager

9.0 ms seek time

Zone density and I.D.-less recording

High reliability with

>

500,000 hour MTBF

Outstanding shock resistance at 200 Gs

High durability with 50K constant start/stop cycles

Advanced multi-burst on-the-fly Error Correction Code (ECC)

Extended data integrity with ECC protected data and fault tolerant servo synchronization fields

Supports EPA Energy Star Standards (Green PC Friendly) with ATA powering savings commands

Auto park and lock actuator mechanism

Low power consumption

S.M.A.R.T. Capability

Note: Maxtor defines one megabyte as 10

6

or one million bytes and one gigabyte as 10

9

or one billion bytes.

PRODUCT DESCRIPTION

2 – 2

Product Features

Functional / Interface

Maxtor DiamondMax™ 4320 hard drives contain all necessary mechanical and electronic parts to interpret control

signals and commands from an AT-compatible host computer. See Section 3 Product Specifications, for complete

drive specifications.

Zone Density Recording

The disk capacity is increased with bit density management – common with Zone Density Recording. Each

disk surface is divided into 16 circumferential zones. All tracks within a given zone contain a constant

number of data sectors. The number of data sectors per track varies in different zones; the outermost zone

contains the largest number of data sectors and the innermost contains the fewest.

Read/Write Multiple Mode

This mode is implemented per ANSI ATA/ATAPI-4 specification. Read/Write Multiple allows the host to

transfer a set number of sectors without an interrupt request between them, reducing transfer process

overhead and improving host performance.

UltraDMA - Mode 2

Maxtor DiamondMax 4320 hard drives fully comply with the new ANSI Ultra DMA protocol, which greatly

improves overall AT interface performance by significantly improving burst and sustained data throughput.

Multi-word DMA (EISA Type B) - Mode 2

Supports multi-word Direct Memory Access (DMA) EISA Type B mode transfers.

Sector Address Translation

All DiamondMax 4320 drives feature a universal translate mode. In an AT/EISA-class system, the drive may

be configured to any specified combination of cylinders, heads and sectors (within the range of the drive's

formatted capacity). DiamondMax 4320 drives power-up in a translate mode:

LEDOMLYCDHTPSenoZLmocPWABLXAMYTICAPAC

8D82719384,336136)*()*(468,057,33BM082,71

7D21519892,926136)*()*(483,235,92BM021,51

6D30319942,526136)*()*(299,054,52BM030,31

5D08019829,026136)*()*(424,590,12BM008,01

4D54809383,616136)*()*(460,415,61BM554,8

3D84609655,216136)*()*(844,656,21BM084,6

2D23409473,86136)*()*(299,044,8BM023,4

(*) The fields LZone (Landing Zone) and WPcom (Write Pre-comp) are not used by the Maxtor hard drive

and the values may be either 0 or the values set by the BIOS. All capacities listed in the above table are based

on 10

6

or one million bytes.

PRODUCT DESCRIPTION

2 – 3

Logical Block Addressing

The Logical Block Address (LBA) mode can only be utilized in systems that support this form of translation.

The cylinder, head and sector geometry of the drive, as presented to the host, differs from the actual physical

geometry. The host AT computer may access a drive of set parameters: number of cylinders, heads and

sectors per track, plus cylinder, head and sector addresses. However, the drive can’t use these host parameters

directly because of zoned recording techniques. The drive translates the host parameters to a set of logical

internal addresses for data access.

The host drive geometry parameters are mapped into an LBA based on this formula:

LBA = (HSCA - 1) + HHDA x HSPT + HNHD x HSPT x HCYA (1)

= (HSCA - 1) + HSPT x (HHDA + HNHD x HCYA) (2)

where HSCA = Host Sector Address, HHDA = Host Head Address

HCYA = Host Cylinder Address, HNHD = Host Number of Heads

HSPT = Host Sectors per Track

The LBA is checked for violating the drive capacity. If it does not, the LBA is converted to physical drive

cylinder, head and sector values. The physical address is then used to access or store the data on the disk and

for other drive related operations.

Defect Management Zone (DMZ)

Each drive model has a fixed number of spare sectors per drive, all of which are located at the end of the

drive. Upon detection of a bad sector that has been reassigned, the next sequential sector is used.

For example, if sector 3 is flagged, data that would have been stored there is “pushed down” and recorded

in sector 4. Sector 4 then effectively becomes sector 3, as sequential sectors are “pushed down” across the

entire drive. The first spare sector makes up for the loss of sector 3, and so maintains the sequential order of

data. This push down method assures maximum performance.

On-the-Fly Hardware Error Correction Code (ECC)

33 bits, single burst, guaranteed

Software ECC Correction

81 bits, single burst, guaranteed

33 bits, double bursts, guaranteed

Automatic Park and Lock Operation

Immediately following power down, dynamic braking of the spinning disks delays momentarily allowing the

read/write heads to move to an inner mechanical stop. A small fixed magnet holds the rotary actuator in

place as the disk spins down. The rotary actuator is released only when power is again applied.

PRODUCT DESCRIPTION

2 – 4

Cache Management

Buffer Segmentation

The data buffer is organized into two segments: the data buffer and the micro controller scratch pad.

The data buffer is dynamically allocated for read and write data depending on the commands received.

A variable number of read and write buffers may exist at the same time.

Read-Ahead Mode

Normally, this mode is active. Following a read request, disk read-ahead begins on the first sector and

continues sequentially until the allocated buffer is full. If a read request is received during the read-ahead

operation, the buffer is examined to determine if the request is in the cache. If a cache hit occurs, read-

ahead mode continues without interruption and the host transfer begins immediately.

Automatic Write Reallocation (AWR)

This feature is part of the write cache and reduces the risk of data loss during deferred write operations. If a

disk error occurs during the disk write process, the disk task stops and the suspect sector is reallocated to a

pool of alternate sectors located at the end of the drive. Following reallocation, the disk write task continues

until it is complete.

Write Cache Stacking

Normally, this mode is active. Write cache mode accepts the host write data into the buffer until the buffer

is full or the host transfer is complete. A command complete interrupt is generated at the end of the transfer.

A disk write task begins to store the host data to disk. Host write commands continue to be accepted and

data transferred to the buffer until either the write command stack is full or the data buffer is full. The drive

may reorder write commands to optimize drive throughput.

PRODUCT DESCRIPTION

2 – 5

Major HDA Components

Drive Mechanism

A brush-less DC direct drive motor rotates the spindle at 5,400 RPM (±0.1%). The dynamically balanced

motor/spindle assembly ensures minimal mechanical run-out to the disks. A dynamic brake provides a fast

stop to the spindle motor upon power removal. The speed tolerance includes motor performance and motor

circuit tolerances.

Rotary Actuator

All DiamondMax™ 4320 drives employ a rotary voice coil actuator which consists of a moving coil, an

actuator arm assembly and stationary magnets. The actuator moves on a low-mass, low-friction center shaft.

The low friction contributes to fast access times and low power consumption.

Read/Write Electronics

An integrated circuit mounted within the sealed head disk assembly (near the read/write heads) provides up

to eight head selection (depending on the model), read pre-amplification and write drive circuitry.

Read/Write Heads and Media

Low mass, low force magneto-resistive read/write heads record data on 3.5-inch diameter disks. Maxtor uses

a sputtered thin film medium on all disks for DiamondMax 4320 drives.

Air Filtration System

All DiamondMax 4320 drives are assembled in a Class 100 controlled environment. Over the life of the drive,

a 0.1 micron filter and breather filter located within the sealed head disk assembly (HDA) maintain a clean

environment to the heads and disks. DiamondMax 4320 drives are designed to operate in a typical office

environment with minimum environmental control.

Microprocessor

The microprocessor controls the following functions for the drive electronics:

Command execution

Cache management

Data correction and error recovery

Diagnostic execution

Data sequencing

Head positioning (including error recovery)

Host interface

Index detection

Spin speed control

Seeks

Servo

S.M.A.R.T.

PRODUCT DESCRIPTION

2 – 6

NOITARUGIFNOCREPMUJ05J84J64J44J24J

evalS/retsaM

*metsysevirdelgnisnievirdylnO

*metsysevirdlaudnievirdretsaM

metsysevirdlaudnievirdevalS

C

C

O

tceleSelbaC

*delbasiD

delbanE

O

C

noitatimiLrednilyC2904

*delbasiD

delbanE

O

C

devreseRyrotcaFO

devreseRyrotcaF O

desolC=CtluafeD=*yeK

)dellatsnirepmuj(

nepO=O

)dellatsnirepmujon(

Figure 2-1

PCBA Jumper Location and Configuration

4092 Cylinder Limitation

On some older BIOS', primarily those that auto-configure the disk drive, a hang may occur when the drive

cylinder value exceeds 4096. The 4092 Cylinder Limitation jumper reduces the capacity in the Identify Drive to

4092 allowing large capacity drives to work with older BIOS'. A software driver is required to access the full

capacity of the drive.

Subsystem Configuration

Dual Drive Support

Two drives may be accessed via a common interface cable, using the same range of I/O addresses. The drives

are jumpered as device 0 or 1 (Master/Slave), and are selected by the drive select bit in the

Device/Head register of the task file.

All Task File registers are written in parallel to both drives. The interface processor on each drive decides

whether a command written to it should be executed; this depends on the type of command and which

drive is selected. Only the drive selected executes the command and activates the data bus in response to

host I/O reads; the drive not selected remains inactive.

A master/slave relationship exists between the two drives: device 0 is the master and device 1 the slave.

When J50 is closed (factory default, figure 2-1), the drive assumes the role of master; when open, the drive

acts as a slave. In single drive configurations, J50 must be closed.

Cable Select Option

CSEL (cable select) is an optional feature per ANSI ATA specification. Drives configured in a multiple drive

system are identified by CSEL’s value:

– If CSEL is grounded, then the drive address is 0.

– If CSEL is open, then the drive address is 1.

Jumper Location/Configuration

Darkened jumper pins indicate factory-installed (default) shunts.

PRODUCT SPECIFICATIONS

3 – 1

SECTION 3

Product Specifications

Models and Capacities

Performance Specifications

LEDOM8D827197D215196D303195D080194D548093D846092D23409

ecafretnI/rellortnoCdetargetnI AMDartlU/4-ATA

dohteMgnidocnE 71/61LLR4RPE

evaelretnI 1:1

metsySovreS deddebmE

epyT/eziSreffuBSBK652:sledoMksiD-2dna-1MARDMARDSBK215:sledoMksiD-4dna-3/

ecafruSrepsenoZataD 61

sdaeH/secafruSataD8765432

sksiDforebmuN4433221

ytisneDlaerA001,3ni/bM

2

ecafruSrepskcarT )srednilyC( 13, 592

ytisneDkcarT 000,31ipt

ytisneDgnidroceR 732-681ipbk

kcolB/rotceSrepsetyB 215

kcarTrepsrotceS320 3-48

evirDrepsrotceS

468,057,33483,235,92299,054,52424,590,12460,415,61844,656,21299,044,8

LEDOM8D827197D2151919

303

6D5D080194D548093D846092D23409

semiTkeeS )lacipyt(

kcarT-ot-kcarT

sm9.0

egarevA

sm0.9

mumixaM sm02<

ycnetaLegarevA sm55.5

deepSlanoitatoR )%1.0±( MPR004,5

daehrevOrellortnoC sm5.0<

etaRrefsnarTataD

ecafretnImorf/oT

)2edoM-AMDartlU(

ces/BM0.33otpu

ecafretnImorf/oT

)2edoM-AMDdrow-itluM/4OIP(

ces/BM7.61otpu

aideMmorf/oT

ces/BM0.22otpu

emiTtratS )ydaeRevirDot0( lacipytces8.8<

Drive Configuration

LEDOM

8D827197D215196D303195D080194D548093D846092D23409

yticapaCdettamroF

)edoMABLBM(

082,71021,51030,31008,01554,8084,6023,4

01saetybagemenosenifedrotxaM

6

01saetybagigenodnasetybnoillimenoro

9

.setybnoillibenoro

PRODUCT SPECIFICATIONS

3 – 2

Physical Dimensions

1.028 max

[25.9 mm]

.25 ± .01

1.122 ± .02

[28.4 mm]

1.638 ± .005

[41.61 mm]

1.625 ± .02

4.000 ± .01

[101.6 mm]

1.75 ± .02

5.787 max

[146.6 mm]

6 x 6-32

UNC Tap

4 x 6-32

UNC Tap

4.00 ± .01

[102.1 mm]

3.75 ± .01

[95.25 mm]

Figure 3 - 1

Outline and Mounting Dimensions

RETEMARAPDRADNATSCIRTEM

thgieHhcni20.1sretemillim9.52

htgneLsehcni77.5sretemillim6.641

htdiWsehcni20.4sretemillim1.201

thgieWsdnuop3.1smargolik95.0

PRODUCT SPECIFICATIONS

3 – 3

Power Requirements (Average)

Power Mode Definitions

Spin-up

The drive is spinning up following initial application of power and has not yet reached full speed.

Seek

A random access operation by the disk drive.

Read/Write

Data is being read from or written to the drive.

Idle

The drive is spinning, the actuator is parked and powered off and all other circuitry is powered on.

The drive is capable of responding to read commands within 40 ms.

Standby

The spin motor is not spinning. The drive will leave this mode upon receipt of a command that requires

disk access. The time-out value for this mode is programmable. The buffer is active to accept write data.

Sleep

This is the lowest power state – with the interface set to inactive. A software or hardware reset is required

to return the drive to the Standby state.

EPA Energy Star Compliance

Maxtor Corporation supports the goals of the U.S. Environmental Protection Agency’s Energy Star program

to reduce the electrical power consumption of computer equipment.

Environmental Limits

RETEMARAPGNITAREPOEGAROTS/GNITAREPO-NON

erutarepmeTC°55otC°5)C°04-(erutarepmetwol

,3.105dohtem,E018-DTS-LIMrep)C°17(erutarepmethgih

.snoitidnocdecudni-toh;yrogetaccitamilc

tneidarGlamrehT (ruohrepC°52)mumixam

ytidimuHevitaleR %59ot%5gnisnednoc-non()

bluBteW 72°C )mumixam(

edutitlAteef000,01ot002-teef000,04ot002-

esioNcitsuocA)edomeldI(rewopdnuosegarevaABd53

)enohporcim01,9777OSIrep(

EDOM%5±V21%5±V5REWOP

pu-nipS)kaep(Am0761Am033W7.12

keeSAm076Am053W8.9

etirW/daeRAm032Am024W9.4

eldIAm042Am052W1.4

ybdnatSAm61Am051W9.0

peelSAm41Am05W4.0

PRODUCT SPECIFICATIONS

3 – 4

Reliability Specifications

AFR

< 1.7% The annualized average failure rate (AFR) applies to the period prior

to the expiration of component design life, and is based on failures

chargeable to Maxtor.

MTBF

> 500,000 hours Maxtor does not differentiate between various usage profiles (e.g.,

power-on hours, power saving modes, non-operating periods or

operating temperatures within the published specification.)

Quality Acceptance Rate

TBD (< 1,500 DPPM) The quality acceptance rate indicates the percentage of Maxtor

products successfully installed by our customers, and/or the number

of defective parts per million (DPPM) encountered during the entire

installation process.

Start/Stop Cycles

50,000 (minimum) This indicates the minimum cycles for reliable start/stop function at a

≥ 60% confidence level.

Data Reliability

< 1 per 10

14

bits read Data errors (non-recoverable). Average data error rate allowed with all

error recovery features activated.

Component Design Life

5 years (minimum) Component design life is defined as a.) the time period before

identified wear-out mechanisms impact the failure rate, or b.) the time

period up to the wear-out point when useful component life expires.

Shock and Vibration

RETEMARAPGNITAREPOGNITAREPO-NON

kcohSlacinahceMsrorreon,sm0.2,sG02 egamadon,sm0.2,sG002

kcohSlanoitatoR egamadon,ces/ces/daR000,51

noitarbiVmodnaRG400.0tazH54-01

2

zH/

G800.0tazH26-84

2

zH/

G400.0tazH003-56

2

zH/

G6000.0tazH005-103

2

zH/

srorreon

egamadon,smrG51.2tazH000,2-01

noitarbiVeniStpewS

zH02-5

zH003-12

edutilpmaelbuodsehcni940.0

)kaep-0(edutilpmakaepG0.1

PRODUCT SPECIFICATIONS

3 – 5

EMC/EMI

Radiated Electromagnetic Field Emissions - EMC Compliance

The hard disk drive mechanism is designed as a subassembly for installation into a suitable enclosure and is

therefore not subject to Subpart J of Part 15 of FCC Rules (47CFR15) or the Canadian Department of

Communications Radio Interference Regulations. Although not required, the disk mechanism has been

tested within a suitable end-use product and found to comply with Class B limits of the FCC Rules and

Regulations of the Canadian Department of Communications.

The CE Marking indicates conformity with the European Union Low Voltage Directive (73/23/EEC) when

the disk mechanism is installed in a typical personal computer. Maxtor recommends that testing and analysis

for EMC compliance be performed with the disk mechanism installed within the user's end-use application.

Canadian Emissions Statement

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital apparatus as set

out in the radio interference regulations of the Canadian department of communications.

Le present appareil numerique n'emet pas de bruit radioelectriques depassant les limites applicables aux

appareils numeriques de Class B prescrites dans le reglement sur le brouillage radioelectrique edicte par le

ministere des communications du Canada.

Safety Regulatory Compliance

All Maxtor hard drives comply with relevant product safety standards such as CE, CUL, TUV and UL rules and

regulations. As delivered, Maxtor hard drives are designed for system integration before they are used.

Loading...

Loading...