Manitowoc Ice Q 800 User Manual

Marine

Q 800

Ice Machine

Installation and

Owner/Operator

Use and Care Manual

Thank you for selecting a Manitowoc Ice Machine, the dependability leader in ice making equipment and related products. With proper installation, care and maintenance, your new Manitowoc Ice Machine will provide you with many years of reliable and economical performance.

Part Number 80-1207-3

Rev. C 7/00

Safety Notices

When using or servicing a Q Model Ice Machine, be sure to pay close attention to the safety notices in this manual. Disregarding the notices may lead to serious injury and/or damage to the ice machine.

Throughout this manual, you will see the following types of safety notices:

WARNING

WARNING

Text in a Warning box alerts you to a potential personal injury situation. Be sure to read the Warning statement, and then proceed carefully.

CAUTION

CAUTION

Text in a Caution box alerts you to a situation in which you could damage the ice machine. Be sure to read the Caution statement, and then proceed carefully.

Procedural Notices

When using or servicing a Q Model Ice Machine, be sure to read the procedural notices in this manual. These notices supply helpful and important information.

Throughout this manual, you will see the following types of procedural notices:

Important

Important boxes serve two functions.

They call the operator’s attention to important information.

They also provide the service technician with information that may help perform a procedure more efficiently. Disregarding this information may slow down the work.

NOTE: Text set off as a Note provides you with simple, but useful, extra information.

CAUTION

CAUTION

Proper installation, care and maintenance are essential for maximum ice production and troublefree operation of your Manitowoc Ice Machine.

Read and understand this manual. It contains valuable care and maintenance information. If you encounter problems not covered by this manual, feel free to contact Manitowoc Ice, Inc. We will be happy to provide assistance.

Important

Routine adjustments and maintenance procedures outlined in this manual are not covered by the warranty.

|

Table of Contents |

|

Table of Contents |

|

|

Model/Serial Number Location ...................................................................................................................... |

1-2 |

|

Owner Warranty Registration Card.............................................................................................................. |

1-3 |

|

Warranty Coverage ......................................................................................................................................... |

1-3 |

|

General.............................................................................................................................................................. |

2-1 |

|

Ice Machine Dimensions.................................................................................................................................. |

2-1 |

|

Ice Storage Bin Dimensions ............................................................................................................................ |

2-3 |

|

Location of Ice Machine .................................................................................................................................. |

2-5 |

|

Leveling the Ice Storage Bin ........................................................................................................................... |

2-6 |

|

Electrical Service.............................................................................................................................................. |

2-6 |

|

Water Service/Drains....................................................................................................................................... |

2-10 |

|

Installation Checklist....................................................................................................................................... |

2-19 |

|

Before Starting the Ice Machine..................................................................................................................... |

2-20 |

|

Component Identification ............................................................................................................................... |

3-1 |

|

Ice Making Sequence of Operation ................................................................................................................ |

3-2 |

|

Operational Checks ......................................................................................................................................... |

3-4 |

|

General.............................................................................................................................................................. |

4-1 |

|

Ice Machine Inspection.................................................................................................................................... |

4-1 |

|

Exterior Cleaning............................................................................................................................................. |

4-1 |

|

Cleaning the Condenser .................................................................................................................................. |

4-1 |

|

Interior Cleaning and Sanitizing .................................................................................................................... |

4-3 |

|

Removal of Parts for Cleaning/Sanitizing ..................................................................................................... |

4-6 |

|

Water Treatment/Filtration............................................................................................................................ |

4-11 |

|

Checklist............................................................................................................................................................ |

5-1 |

|

Safety Limit Feature........................................................................................................................................ |

5-2 |

|

i

Table of Contents

Page Intentionally Left Blank

ii

Section 1 |

General Information |

Section 1

General Information

Owner Warranty Registration Card

GENERAL

Warranty coverage begins the day your new ice machine is installed.

Important

Complete and mail the OWNER WARRANTY REGISTRATION CARD as soon as possible to validate the installation date.

If you do not return your OWNER WARRANTY REGISTRATION CARD, Manitowoc will use the date of sale to the Manitowoc Distributor as the first day of warranty coverage for your new ice machine.

Warranty Coverage

GENERAL

The following Warranty outline is provided for your convenience. For a detailed explanation, read the warranty bond shipped with each product.

Contact your local Manitowoc representative or Manitowoc Ice, Inc. if you need further warranty information.

Important

This product is intended exclusively for commercial application. No warranty is extended for personal, family, or household purposes.

PARTS

1.Manitowoc warrants the ice machine against defects in materials and workmanship, under normal use and service for three (3) years from the date of original installation.

2.The evaporator and compressor are covered by an additional two (2) year (five years total) warranty beginning on the date of the original installation.

LABOR

1.Labor required to repair or replace defective components is covered for three (3) years from the date of original installation.

2.The evaporator is covered by an additional two

(2) year (five years total) labor warranty beginning on the date of the original installation..

EXCLUSIONS

The following items are not included in the ice machine’s warranty coverage:

1.Normal maintenance, adjustments and cleaning as outlined in this manual.

2.Repairs due to unauthorized modifications to the ice machine or use of non-standard parts without prior written approval from Manitowoc Ice, Inc.

3.Damage caused by improper installation of the ice machine, electrical supply, water supply or drainage, or damage caused by floods, storms, or other acts of God.

4.Premium labor rates due to holidays, overtime, etc.; travel time; flat rate service call charges; mileage and miscellaneous tools and material charges not listed on the payment schedule. Additional labor charges resulting from the inaccessibility of equipment are also excluded.

5.Parts or assemblies subjected to misuse, abuse, neglect or accidents.

6.Damage or problems caused by installation, cleaning and/or maintenance procedures inconsistent with the technical instructions provided in this manual.

7.This product is intended exclusively for commercial application. No warranty is extended for personal, family, or household purposes.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a refrigeration service company, qualified and authorized by your Manitowoc distributor, or a Contracted Service Representative must perform the warranty repair.

Normal maintenance, adjustments and cleaning as outlined in this manual are not covered by the warranty.

1-1

General Information |

Section 1 |

Page Intentionally Left Blank

1-2

Section 2 |

Installation Instruction |

Section 2

Installation Instructions

General

These instructions are provided to assist the qualified installer. Check your local Yellow Pages for the name of the nearest Manitowoc distributor, or call Manitowoc Ice, Inc. for information regarding start-up services.

Important

Failure to follow these installation guidelines may affect warranty coverage.

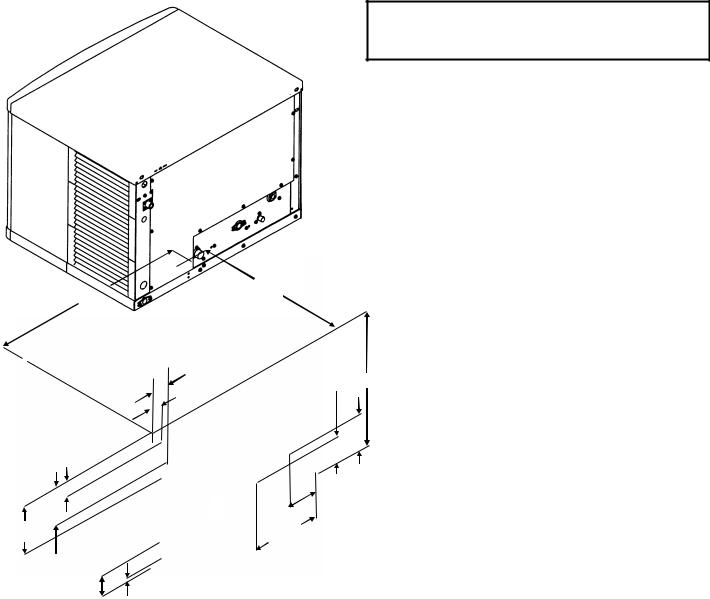

Ice Machine Dimensions

Q800 ICE MACHINE

WATER COOLED

24.50” 30.00” (62.23 cm)

(76.20 cm)

2.50” |

|

|

(6.35 cm) |

3.38” |

H |

|

||

1.88” |

(8.59 cm) |

|

(4.78 cm) |

|

|

2.38”

(6.05 cm)

5.00” (12.70 cm)

4.38” (11.12 cm)

7.88”

(20.02 cm) 10.38”

(26.37 cm)

5.75” |

|

(14.61 cm) |

SV1612 |

3.13” |

|

(7.95 cm) |

0.75” |

|

(1.91 cm) |

2-1

Installation Instructions |

Section 2 |

Location of Ice Machine

The location selected for the ice machine must meet the following criteria. If any of these criteria are not met, select another location.

•The location must be free of airborne and other contaminants.

•The air temperature must be at least 35°F (1.6°C), but must not exceed 110°F (43.4°C).

•The location must not be near heat-generating equipment or in direct sunlight.

•The location must not obstruct air flow through or around the ice machine. Refer to the chart below for clearance requirements.

|

Water-Cooled |

Top/Sides |

5” (127 mm)* |

Back |

5” (127 mm)* |

*There is no minimum clearance required. This value is recommended for efficient operation and servicing only.

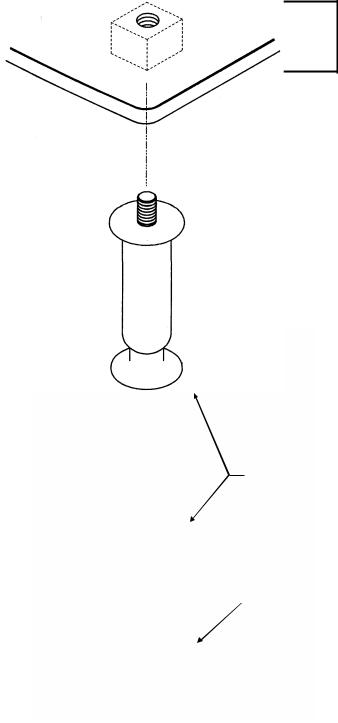

Leveling the Ice Storage Bin

1.Screw the leveling legs onto the bottom of the bin.

2.Screw the foot of each leg in as far as possible.

CAUTION

CAUTION

The legs must be screwed in tightly to prevent them from bending.

3.Move the bin into its final position.

4.Level the bin to assure that the bin door closes and seals properly. Use a level on top of the bin. Turn each foot as necessary to level the bin.

5.Inspect bin gasket prior to ice machine installation. (Manitowoc bins come with a closed cell foam gasket installed along the top surface of the bin.)

6.Install ice machine on bin.

NOTE: An optional caster assembly is available for use in place of the legs. Installation instructions are supplied with the casters.

THREAD

LEVELING LEG

INTO BASE OF

CABINET

THREAD “FOOT”

IN AS FAR AS

POSSIBLE

SV1606

Leveling Leg and Foot

2-2

Section 2 |

Installation Instructions |

Electrical Service

GENERAL

WARNING

WARNING

All wiring must conform to local, state and national codes.

VOLTAGE

The maximum allowable voltage variation is ± 10% of the rated voltage at ice machine start-up (when the electrical load is highest).

WARNING

WARNING

The ice machine must be grounded in accordance with national and local electrical codes.

FUSE/CIRCUIT BREAKER

A separate fuse/circuit breaker must be provided for each ice machine. Circuit breakers must be H.A.C.R. rated (does not apply in Canada).

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the wire size of the electrical supply. (Minimum circuit ampacity is not the ice machine’s running amp load.)

The wire size (or gauge) is also dependent upon location, materials used, length of run, etc., so it must be determined by a qualified electrician.

Q800 ICE MACHINE

|

Voltage |

Water Cooled |

|

Ice |

Phase |

Maximum |

Minimum |

Machine |

Cycle |

Fuse |

Circuit |

|

|

Circuit |

Amps |

|

|

Breaker |

|

Q800 |

208-230/1/60 |

20 |

11.4 |

208-230/3/60 |

15 |

8.2 |

|

|

230/1/50 |

20 |

10.6 |

Electrical Wiring Connections

WARNING

WARNING

These diagrams are not intended to show proper wire routing, wire sizing, disconnects, etc., only the correct wire connections.

All electrical work, including wire routing and grounding, must conform to local, state and national electrical codes.

Though wire nuts are shown in the drawings, the ice machine field wiring connections may use either wire nuts or screw terminals.

Water Cooled Ice Machine 208-230/1/60

L1 |

L1 |

N = 115V

OR

L2 = 208-230V

GROUND

GROUND

ICE MACHINE |

TO SEPARATE |

CONNECTIONS |

FUSE/ BREAKER |

SV1258

2-3

Loading...

Loading...