Makita UC3503A, UC4503A, UC4003A, UC3003A User Manual

T

ECHNICAL INFORMATION

Models No.

UC3003A, UC3503A, UC4003A, UC4503A

PRODUCT

P 1 / 8

Description

Chain saws 300mm, 350mm, 400mm, 450mm

CONCEPT AND MAIN APPLICATIONS

For European market, the above models have been developed

as upgraded chain saws of the current UC3001A series models.

The new UC3003A seies models feature contnuous rating input

of 2000W while the UC3001A series 1800W.

Additionally, the new series includes Model UC4503A,

450mm (18") chain saw which is not in the lineup of UC3001A

series.

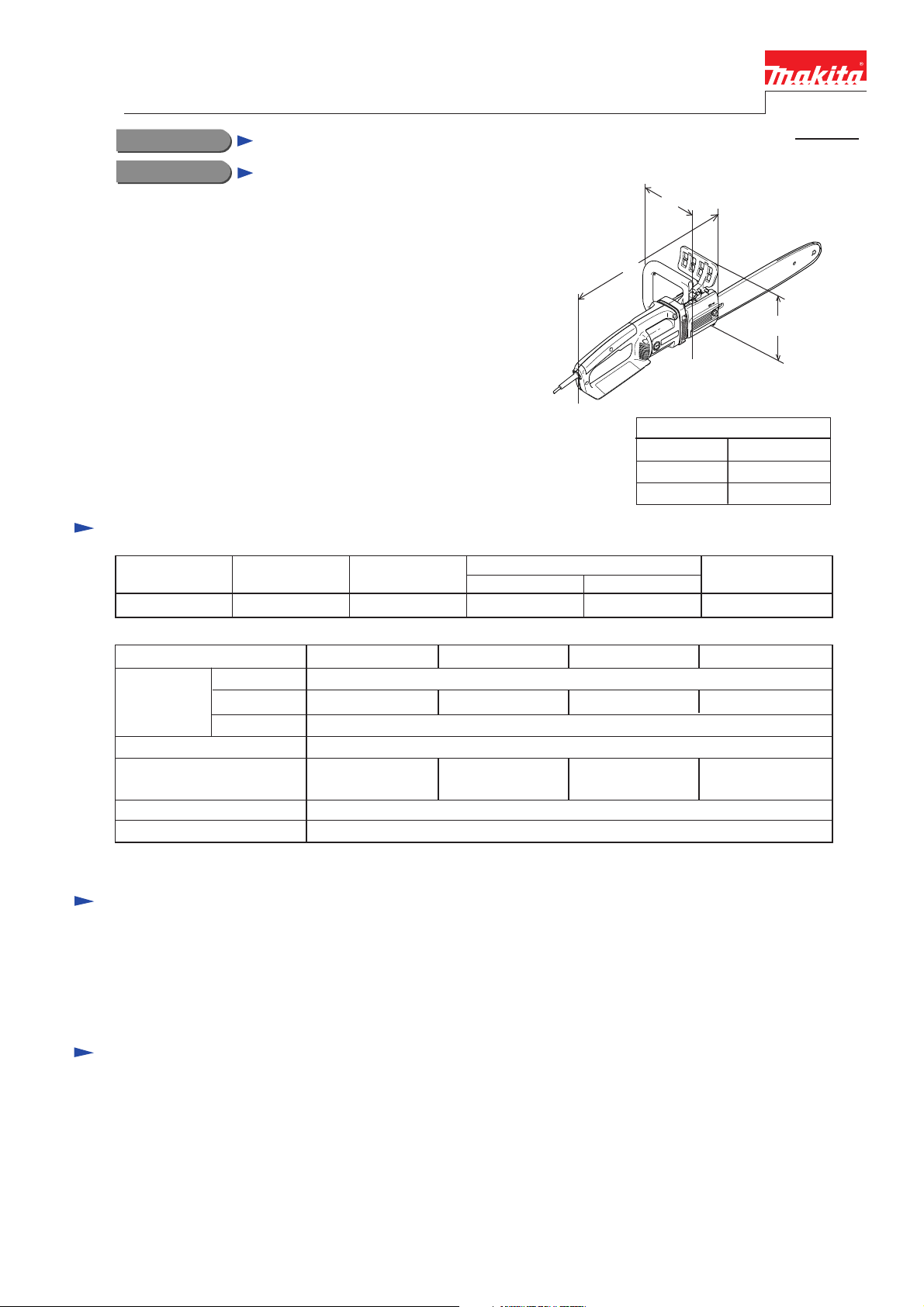

Specification

Voltage (V)

230 - 240

Current (A)

8.8 2,000 2,2001,100

Cycle (Hz)

50 / 60

L

Length ( L )

Width ( W )

Height ( H )

Continuous Rating (W)

Input Output

W

H

Dimensions: mm ( " )

470 (18-1/2)

179 (7)

215 (8-1/2)

Max. Output (W)

Model No.

Chain type

Chain blade

No load chain speed: m/s

Guide bar length: mm (")

Electric brake

Clutch

Pitch

Gauge

UC3003A UC3503A UC4503AUC4003A

91VG

3/8" 46 drive links

300

(12)

3/8" 52 drive links 3/8" 56 drive links 3/8" 62 drive links

0.050"

13.3

350

(14)

Yes

Yes

400

(16)

Standard equipment

* Guide bar scabbard .................... 1 pc.

* Wrench ....................................... 1 pc.

< Note > The standard equipment for the tool shown may differ from country to country.

Optional accessories

* Chain blade

* Guide bar

450

(18)

Repair

CAUTION:

First of all, remove the chain blade for your safe repair and maintenance.

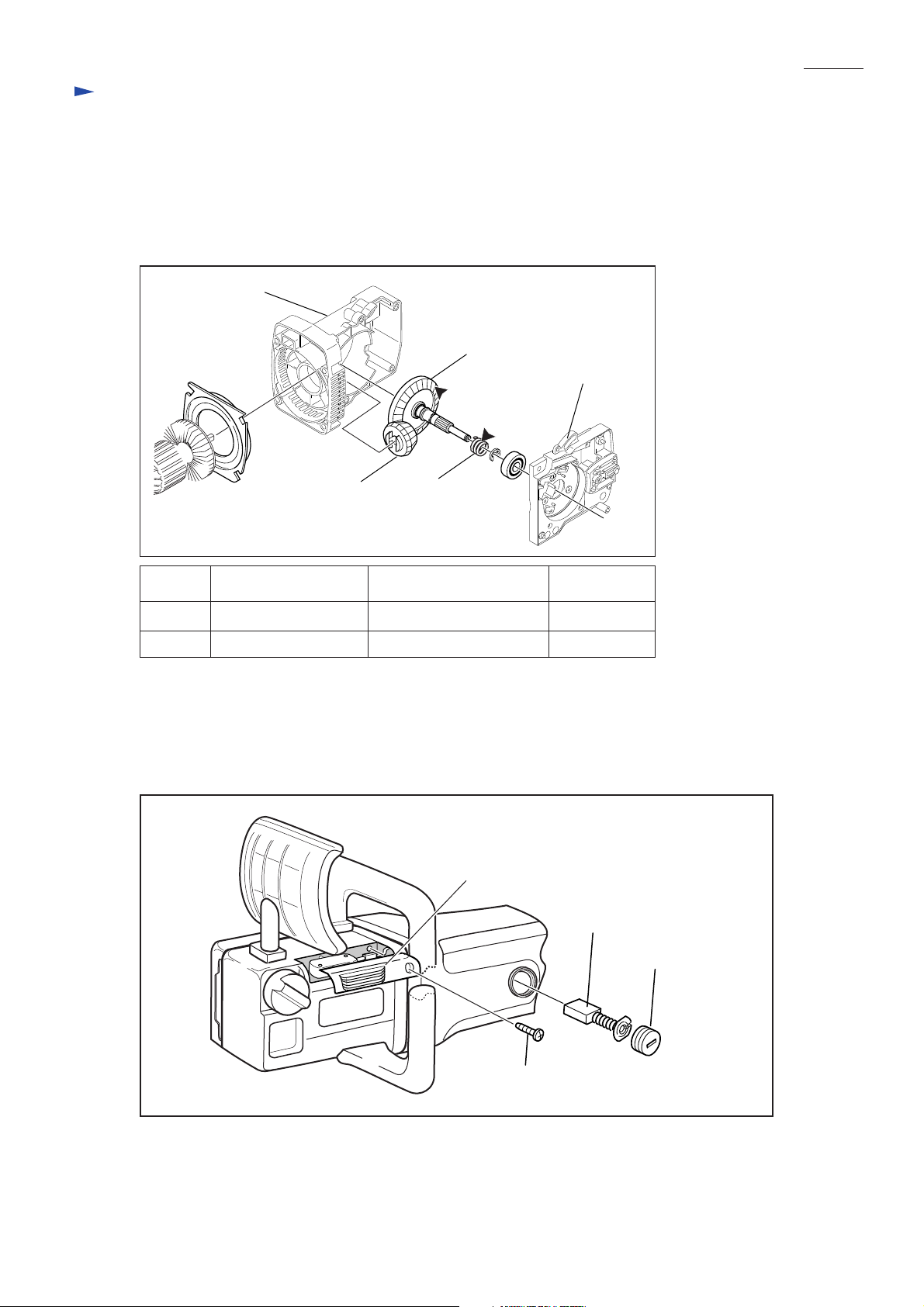

< 1 > Lubrication

Apply Makita grease N. No.1 to the following portions designated by black triangle

to protect parts and product from unusual abrasion. (Fig. 1)

Fig. 1

Gear housing L

(35)

Gear housing R

P 2 / 8

Straight

bevel gear 14

Item No.

(31)

(35) Straight bevel gear 43 Whole part approx. 3.0

Part Name

Worm gear Whole part approx. 1.0

(31)

Portion to be lubricated

Amount: g

< 2 > Removing Gear Housing from Motor Housing for Replacement of Armature Assembly

1. After removing brush holder caps, remove carbon brushes.

Remove a 4x18 tapping screw. Now cover (for switch) can be removed from gear housing L. (Fig. 2)

Fig. 2

Cover (for switch)

Carbon brush

Tapping screw 4x18

Brush holder cap

(to be continued to next page)

P 3 / 8

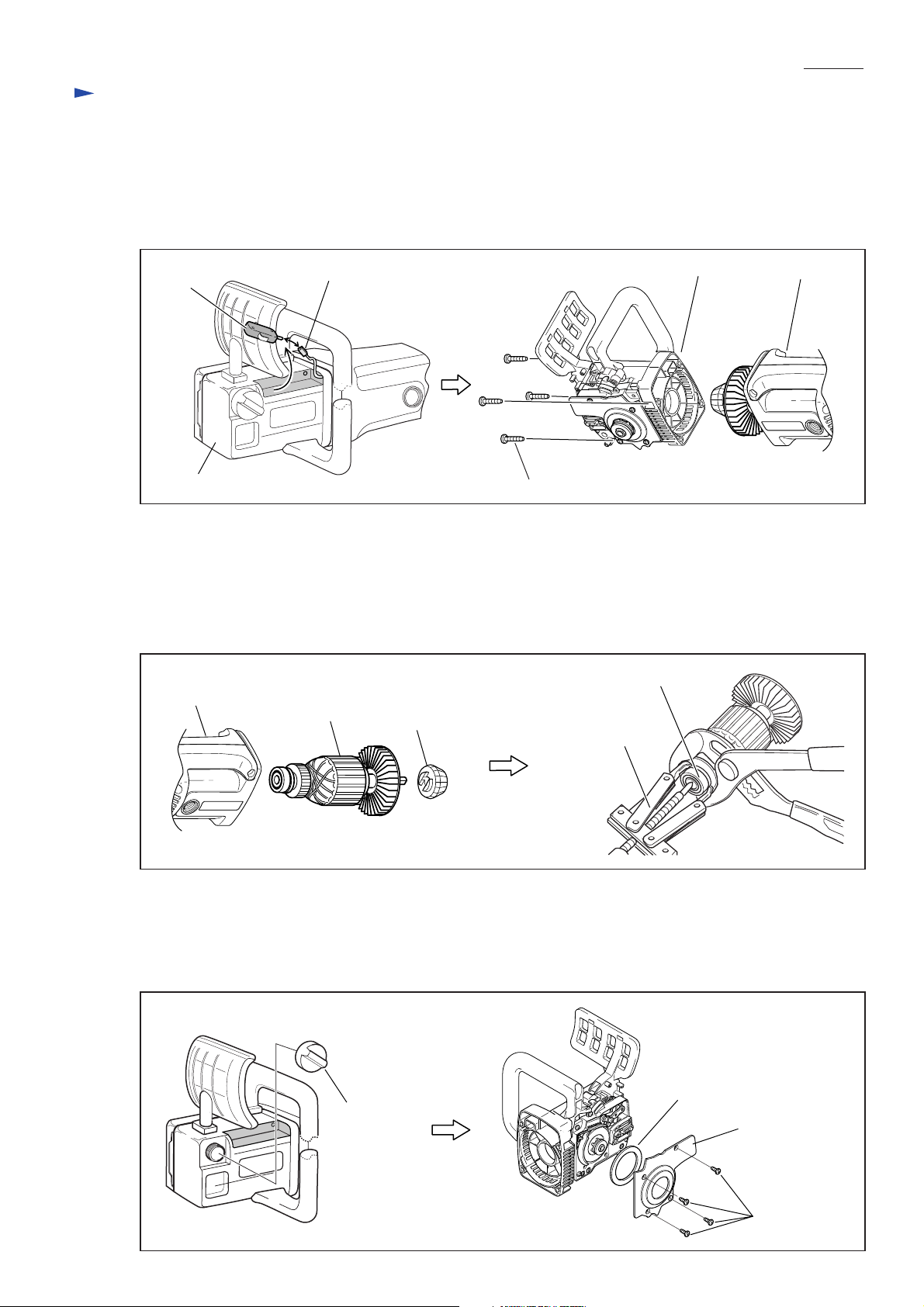

Repair

< 2 > Removing Gear Housing from Motor Housing for Replacement of Armature Assembly (cont.)

2. Take switch out of gear housing L, and then disconnect the connecting terminal from switch

as illustrated to left in Fig. 3.

3. Remove four 5x25 tapping screws as illustrated to right in Fig. 3.

Now motor housing can be separated from gear housing section.

Fig. 3

Switch

Gear housing L

4. Replace armature assembly as described below (Fig. 4):

1) After removing motor housing from gear housing, take armature assembly out of motor housing.

2) Remove straight bevel gear 14 from the armature. This gear can be removed by hand.

3) Remove ball bearing 629ZZ on the commutator end of armature assembly using Bearing extractor (No.1R269)

and pliers as illustrated to right in Fig. 4.

Ball bearing 6301LLB on the drive end of armature assembly can be removed in the same way.

Fig. 4

Motor housing

Connecting terminal

Armature

Straight

bevel gear 14

Tapping screw 5x25 (4 pcs)

Bearing extractor

(No.1R269)

Gear housing section

Ball bearing 629ZZ

Motor housing

< 3 > Disassembling Gear Housing

1. Remove oil tank cap, and remove chain oil from oil tank as illustrated to left in Fig. 5.

2. Separate cover plate from gear housing R by removing four BT3.5x9.5 tapping screws as illustrated to right

in Fig. 5.

Fig. 5

Gasket

Oil tank cap

(to be continued to next page)

Cover plate

Tapping screw

BT3.5x9.5

Loading...

Loading...