Thank you for purchasing a Retracta Auto Rewind Hose

Reel.

The Retracta range of hose reels are a breakthrough in

industrial quality hose reel design, performance,

durability, versatility and cost. The efficiency, safety and

convenience benefits of auto rewind hose reels are

now available for most situations where a hose is

required

Manufactured from the highest quality weather resistant

materials, the tough high impact polypropylene is U.V.

stabilised , designed for all purpose corr osion free

durability. The rewind mechanism is lubricated and

sealed for trouble free operation.

This retractable hose reel promotes a neat and tidy

good-looking work area, reducing the possibility of

accidents, and improves the work environment. Safety is

enhanced by low recoil tension even with the hose fully

extended.

With your appropriate care, combined with the Macnaught

guarantee of dependable after sales service, you will be

assured of cont inu ous safe, eff ici ent and reliable

product operation.

GENERAL INFORMATION

This manual assists you in operating and maintaining

your new retractable hose reel. The information contained

wi ll help y ou e nsu r e ma ny y ear s of depe nda b le

performance and trouble free operation.

Please take a few moments to read through this manual

before installing and operating your new retractable hose

reel. If you experience problems with the product, refer to

the procedures contained within this instruction manual.

If you require further assistance please contact your local

Macnaught distributor, or local Macnaught service centre.

IMPORTANT INFORMATION

This hose reel contains a pre-tensioned spring inside

the drum assembly. For safety reasons the drum

assembly is a non-repairable item. DO NOT under any

circumstances try to open the drum assembly. A new

drum assembl y will be required if the spring is

damaged.

1

RETRACTA (Series 2)

OA100 OXY-ACETYLENE HOSE REEL

0003

RP123

0107

INSTRUCTION MANUAL

Your safety is important to us. Please read, understand

and follow all safety instructions listed below. Some of

these instructions alert you to the potential for personal

injury. “Cautions” listed throughout the manual advise

of potential practices or procedures which may cause

damage to your equipment.

PLEASE READ THIS IMPORTANT SAFETY

INFORMATION CAREFULLY BEFORE USE.

The following additional safety information applies to

the Retracta Oxy-Acetylene Reel. For your safety please

read and follow the safety instructions detailed below.

Oxygen Acetylene Gas is hazardous material that can

cause serio us accide nts and injur ies if proper

precautions and safe practices are not followed.

Op erat ion and ma inte nanc e of Ox y Acet y len e

Gasequipment should conform to the provisions of the

American National Standard Z49-1 “Safety in Welding

and Cutting”.

Make sure all operators have access to adequate

instructions about safe operating and maintenance

procedures.

1

This reel contains a positive latching mechanism,

which enables the reel to be mounted in any position.

Please read and retain this instruction manual to

assist you in the operation and maintenance of this

quality product.

INTRODUCTION

The maximum weight of hose end tools is 2kg (4lb).

The maximum installation height is 4.5 meters (15ft)

above the ground.

DO NOT exceed the maximum working pressure stated

on the product label.

2

DO examine the hose, reel swivel and other equipment

for damage (includ in g leaks) should a “Flashback”

occur. Replacement of swivel seals is recommended.

The use of “Flashback” check valves to reduce the risk of

backflow and “Flashback” is also recommended.

DO use only Retracta replacement swivel components

and seals as supplied by Macnaught. Obtain replacemant

parts from your local Authorised Macnaught Service

Centre or from Macnaught.

DO NOT allow grease and oil to come into contact with

any Oxy-Acetylene equipment, components or hose.

These materials ignite easily and burn violently in the

presence of Oxygen.

DO NOT use pipe fitting compounds or thread lubricants

in making connections.

DO NOT direct the gas flame at the hose or hose reel.

DO NOT exceed the recommended maximum Acetylene

draw off rate from the cylinder and only operate when the

cylinder is upright. Liquid acetone solvent contained in

the cylinder can escape and damage the hose, hose reel

seals and other equipment.

DO NOT work with damaged or faulty equipment or hoses.

INSTALLATION

1) Attach the carry handle to the reel casing above the reel

hose mouth, using the screws provided.

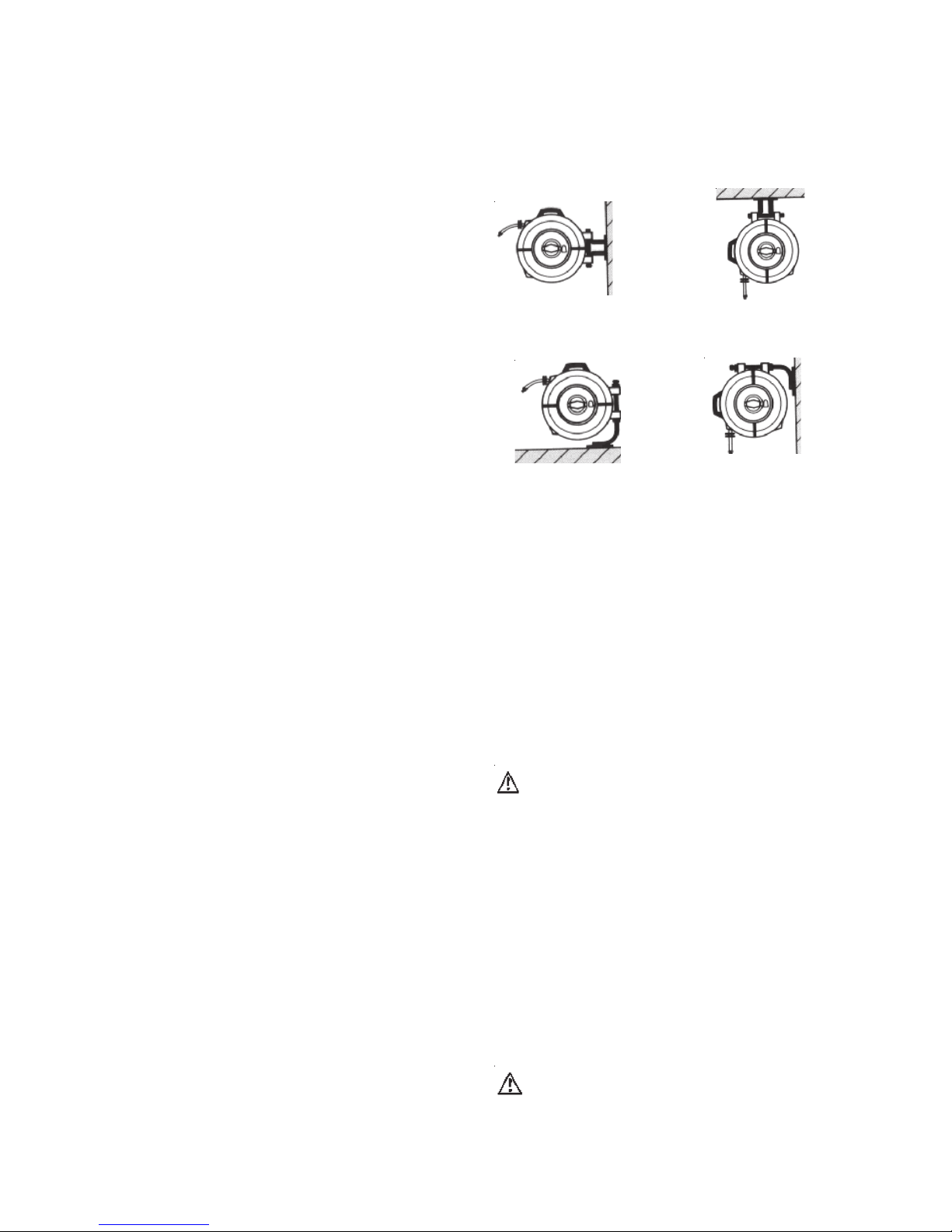

2) The reel can only be mounted in one of the following

positions shown. (Refer Fig 1, 2, 3, 4 )

Fig.1 Wall / BU100 Fig.2 Overhead / BU100

If you choose the most popular positions (1) and (2) you

should use the standard (BU100) bracket. If using

position (3) and (4) you will need the optional

bracket (BB100).

Make all connections dry. DO NOT use pipe fitting

compounds, thread lubricants, oil or grease. Tighten hose

connections with a spanner. Oxygen hoses use only right

hand threaded connections. Note Acetylene hoses use

left hand threaded connections.

CAUTION

Test the system and all connections for leaks prior to

use. Re-test the system frequently (once per month

approx) and on each change of gas cylinder or after

maintenance.

Leak test all connections and hose reel swivels prior

to initial use (refer “Gas Leak Test Procedure”) and

repeat at frequent intervals. It is recommended that

leak tests on all equipment be carried out at least

monthly and on the replacement of cylinders and after

maintenance or replacement of any equipment,

component part or hose.

For O-Ring seal lubrication use only ‘Tranz’ 1434 or an

equivalent inert lubricant when required. DO NOT allow

oil or grease to come in contact with the swivel or

Oxy-Fuel gas equipment.

SAFETY PRECAUTIONS

ONLY use this Retracta reel for the Oxy Acetylene gas

combination.

DO locate equipment in well ventilated areas.

DO run leak tests on your total system including the Hose

Re el Sw ivel freq uent ly. ( R efe r to t h e Re t rac ta

Operating and Service Instructions).

DO repair or replace equipment and hoses immediately

any gas leak is detected. Leaking Oxygen or Acetylene

can cause serious fire and personal injury.

Up to 6ft above ground Up to 15ft above ground

Fig.3 Floor/Bench/BB100 Fig.4 High Wall/BB100

Between 1.8m (6ft) and

4.5m (15ft) above ground

3) Fix mounting bracket in required location and position

reel onto bracket. (Brackets can be padlocked for

additional security). Oxy Acetylene reels should only

be used in well ventilated areas.

4) Connect supply hose to reel inlet allowing sufficient

space for reel to swivel 180° on bracket. Swivel

rotation can be avoided (in the overhead position only)

by adding the locking bracket (RB9) supplied.

POSITIVE LATCH OPERATION

Pull out the hose to the required length.

Note: A clicking noise can be heard every half revolution

of the drum.

To latch the reel, allow the reel to slowly retract after

hearing the 1st, 2nd or 3rd click.

To unlatch the reel, slowly pull out the hose until the

clicking noise stops, then let the hose slowly retract until

the hose stopper rests against the reel mouth.

CAUTION

To prevent injury or damage occurring, do not let go of

the hose during rewinding.

3

3) Rem ove the inl e t side plat e (R efe r Re m ova l/

Replacement Inlet Connection Side Plate).

4) Re mov e circl ip (5) fro m e nd o f s wive l s haft

assembly (1) and slide the inlet shaft from the swivel

body (4).

5) Carefully remove the existing O-Rings by lifting O-Rings

out from grooves using a small screwdriver. With

o-rings extended, cut through the O-Ring onto the

screwdriver face. Be careful you do not score o-ring

grooves.

Do not damage or score inlet shaft surface when

removing or cutting o-ring.

CAUTION

5) Before fitting the new o-rings ensure that both the inlet

shaft and swivel are thoroughly wiped clean. Apply

‘Tranz’ 1434 lubricant (supplied in kit) or equivalent to

the o’ring grooves of the inlet shaft.

6) Slide the o-ring applicator sleeve (supplied in kit) over

the inlet shaft to expose only the furthermost o-ring

groove. Put the first o-ring onto the sleeve and slide up

to the exposed groove. Withdraw the sleeve, stopping

at each groove, and fit the o’rings one at a time

following the same procedure.

SWIVEL RE-ASSEMBLY

7) Slide the inlet shaft back into the swivel body and

replace the circlip. Note that if the circlip groove is not

exposed after fitting, the swivel body is back to front.

GAS LEAK TEST PROCEDURE

Test Oxygen /Acetylene hose lines seperately. Ensure

that all connections from the cylinder through to the torch

are tight.

1) Close both torch valves.

2) Open the Oxygen cylinder valve and adjust the delivery

pressure to 25psi or more.

3) Close the Oxygen valve and observe the delivery

pres sure gaug e. If a drop in pres sur e occ urs,

re-pressure the hose and test all the connections

includi ng the ho se, swiv el and sw ive l bod y by

brushing with warm soapy water solution looking for

the presence of any bubbles.

4) Open the Oxygen valve at the torch and re-close to vent

the Oxygen line. Repeat steps 1, 2 and 3 with the

Acetylene, with the delivery pressure set at 10 psi. Vent

the Acetylene line.

5) Replace or repair any faulty items immediately and

repeat ‘Leak test’ procedure.

MAINTENANCE

This section details the step-by-step procedures that you

may require for the general use and maintenance of your

ree l. Please keep this instruction manual for future

reference.

REMOVAL / REPLACEMENT OF INLET

CONNECTION SIDE PLATE

2) Place reel on a clean bench with the inlet side plate (3)

face up. Remove screw located at the edge of the inlet

plate. Rotate plate clockwise.

4) To replace inlet side plate, suspend reel between your

body and edge of bench. Reposition the plate and turn

counter-clockwise. Relocate side screw.

3) Swivel assembly and hose will come away attached to

the inlet side plate.

SWIVEL SEAL REPLACEMENT

CAUTION

Use only genuine Retracta O-Ring replacement kits. The

use of any other seals can be dangerous. Ensure that

the replacement procedure is carried out in an oil and

grease free, clean environment.

2) Place reel on a clean bench with the inlet side plate (3)

face up. Remove screw located at the edge of the inlet

plate. Rotate plate clockwise.

1) Pull the hose out until it is fully extended and allow the

hose to latch after hearing the 1st, 2nd or 3rd click.

1) Pull the hose out until it is fully extended and allow the

hose to latch after hearing the 1st, 2nd or 3rd click.

8) Slide the inlet shaft back into the drum assembly (6),

pushing the complete unit home.

9) Replace the inlet side plate. (Refer to ‘Removal /

Replacement of Inlet Connection Side Plate’).

HOSE REPLACEMENT

1) Pull the hose out until it is fully extended and allow the

hose to latch after hearing the 1st, 2nd or 3rd click.

2) Remove the inlet side plate (3) (Refer “Removal/

Replacement of Inlet Connection Side Plate”). The

swivel shaft assembly (1) will come away attached

to the inlet side plate.

3) R emo ve ho s e fro m swi vel b ody ( 4). R emov e

remaining old hose from the mouth of the reel.

4) U s e onl y r eco m men ded le ngth a nd typ e o f

replacement hose.

5) Feed the new hose through top of reel mouth and into

opening on reel drum which gives access to the swivel

compartment. Replace and secure the internal hose

stopper 5” (13cm) from the end of hose assembly.

Reconnect hose.

6) Re pla ce inl e t sid e plate (3) (Re fer “R emov al/

Replacement Inlet Connection Side Plate”).

7) Place the reel in a vertical position and while holding

the reel pull the hose out past the last clicking niose

and carefully guide the hose onto the drum

8) If the replacement hose is the same lenght as the old

hose no tension adjustment is necessary. If spring

tension adjustment is required rerer to the “ Spring

tensioning and latch side plate removal” proceedure.

SPRING TENSION AND LATCH SIDE

PLATE REMOVAL

1) Place reel on a clean bench with latching plate (9) face

up.

2) Release spring tension by opening tension plate (8)

and place handle of a pair of pliers in the exposed

slots. Grip the pliers firmly and remove the two screws

holding the tension plate (8) and carefully allow the

tension plate to slowly unwind counter clockwise.

3) Remove screw holding tension plate and remove

tension plate. Remove screw located at the edge of

the latching plate. Turn latching plate clockwise and

remove, this will expose the latching cup assembly.

4) To replace latching plate, suspend reel between your

body and edge of the bench. Reposition the plate and

turn counter clockwise. Relocate side screws, replace

tension plate and fixing screw.

5) Reload spring tension by using the same tool (as in

step 2) and wind tension plate clockwise until hose

sto pper is fir mly aga ins t th e re el mout h, some

resistance will be felt. Then add approximately six (6)

complet 360 deg. tetension turns. Hold the tension

plate in this position align dimples on tension plate la

latching side plate and replace the two screws. Close

CAUTION

Test the reel for leaks prior to any further use

4

CAUTION

Test the reel for leaks prior to any further use.

tension plate and cover.

PARTS LIST

PARTS DIAGRAM

1

2

3

5

6

7

8

9

10

11

12

13

7

5

O A 1 0 0 R E E L P A R T S

I T E M P A R T N o . N o . o f f P A R T o r S E T K I T . R E F D E S C R I P T I O N

1 R S 79 1 R S 79 s ( A U S T ) S W I V E L S H A F T A S S EM B L Y

2 R S 59 1 O A - 1K R S 53 s ( U S A ) S W I V E L S E A L K IT

3 R P 2 1 o r d er R P 3 4 s IN L E T S ID E P L A T E

4 R S 8 0 1 R S 79 s ( A U S T ) S W I V E L B O D Y A S S E M B L Y

5 Z 9 1 Z 9 s C IR C L IP

6 R P 3 5 1 R P 3 5 - B la c k D R U M A S S EM B L Y ( in cl S p ri ng )

7 R P 3 6 1 R P 3 6 C s * i nc l R P 6 s O U T E R C A S IN G ( LO W E R )

7 R P 3 6 s 1 O U T E R C A S IN G i nc l M O U T H G U A R D

8 R P 9 0 1 T E N S IO N I N G P L A T E A S SE M B L Y

9 R P 114 1 R P 3 4 s ( in cl It e m 3 ) L A T C H S ID E P LA T E A S S E M B L Y

10 R P 115 1 R A T C H E T P LA T E

11 R P 6 1 R P 6 s C A R R Y HA N D L E

12 Z 2 2 s 1 R H 3 0 s H O S E ST O P P ER

13 R H 3 0 1 H O SE R E P LA C E M E N T K IT

R B 9 1 R B 9 s L O C K IN G B R A C K E T

B U 10 0 1 B U 10 0 S T A N D A R D W A L L B R A C K ET

* N O M I N A T E C O L O U R W H E N O R D E R I N G R E P L A C E M E N T M O U L D I N G S

4

LATCHING PLATE ASSEMBLY

LATCHING PLATE

LATCH PAWL

SPRING

PLASTIC SLEEVE

USE ONLY genuine Retracta ‘O’ Ring Replacement Kit and lubricant specified. The use of any

other materials can be dangerous.

NOTES:

6

NOTES:

7

TROUBLE SHOOTING GUIDE

1. Hose will not retract

1. Hose bunching.

2. Spring tension too light.

3. Replacement hose too heavy.

3. Reel Leaks.

1. Damaged Hose.

2. Loose fittings.

3. Worn swivel seals

PROBLEM

1. Pull hose out and rewind guiding the hose

to avoid bunching.

2. Refer to “Spring tension and latch side plate

removal”.

3. Replace hose with recommended hose,

refer to “Hose Replacement”.

1. Replace hose. Refer to “Hose Replace

ment”.

2. Tighten Fitting. refer to “Removal / Re

placement of inlet Connection Side Plate”.

3. Refer to “Swivel Seal Replacement”.

REMEDY

8

2. Reel will not latch

1. The hose has been pulled past the

latching teeth.

2. Broken latching pawl or pawl spring.

1. Allow the reel to slowly retract after

hearing the 1st, 2nd or 3rd click.1.

2. Replace broken components. Refer

to “Spring Tension and Latch Side

Plate Removal”.

Macnaught Pty Ltd

PO Box 90 Arncliffe NSW 2205 Australia

Telephone (02) 9567 0401

Facsimile (02) 9597 7773

Email: sales@macnaught.com.au

Web: www.macnaught.com.au

macnaught warranty

1. Macnaught Pty Ltd (“Macnaught”) warrants that all products manufactured by Macnaught and/ or sup plied by

Macnaught under the “Macnaught” brand, exluding M-Series positive displacemnt meters (“Meters”) and components

subject to wear, will be free from any defects caused by faulty materials or workmanship (“Warranty”) for a period of 5

years from the date of purchase of the product.

2. For products (exluding Meters) which carry the “Macnaughtdesign”endorsement, an additional Warranty period of 5 years

applies to all mechanical components (exluding electronic and electrical components), giving a total Warranty period of 10

years.

3. For Meters, the Warranty period is 12 months from the date of purchase of the product.

4. For components contained in all products which are usually subject to wear from normal operation of the products (such

as o-rings, seals, springs, hoses and battaries), the Warranty period is 12 months from the date of purchase of the relevant

product.

5. For products and componenets which are not manufactured by Macnaught and are supplied by Macnaught under a brand

name other than “Macnaught”, the Warranty period is the longer of 12 months from the date of purchase of the relevant

product and the period of the manufacturer’s warranty.

6. The warranties contained in clauses 1, 2, 3, 4 and 5 above are conditional on the purchaser, during the relevant Warranty

period:

a. delivering to Macnaught a detailed notice setting out full details of any defect in any product and

details of the date and place of purchase (together with copies of purchase receipts and/or

other supporting documents), and

b. at the purchaser’s own cost, returning the defective product to the nearest

authorised Macnaught service centre.

7. Subject to compliance by the purchaser with clause 6, Macnaught shall, at its option, repaire or replaice any product

or component found defective by its inspection by reason of faulty materials or workmanship of Macnaught.

8. This Warranty does not cover the failure of products, parts or components which, in the sole judgment of the Macnaught,

arises other than from faulty materials or workmaship of Macnaught, incuding misuse, abrasion,corrosion, negligence,

accident, substitution of non-Macnaught parts, unauthorised modification, improrer use, storage or handling, faulty installation or tampering by the purchaser or any third party.

9. If Macnaught’s inspection discloses no defect in material or workmanship, repair or replacement and return (at

Macnaught’s sole option) will be made at customary charges, which will be advised to the purchaser.

10. Macnaught’s liability and the purchaser’s rights under this Warranty shall be limited to the repair or replacement of

defective products or components and particular, shall not extend to any direct, special, indirect or consequential damage

or losses of any other warranties.

11. The foregoing Warranty supersedes, voids and is in lieu of any other warranties.

This Warranty does not form part of, nor does it constitute, a contract between Macnaught and the end-user or purchaser.

It is additional to any warranty given by the seller of the products. This Warranty does not exlude, limit, ristrict or modify

the non-excludable rights or remedies conferred upon the end-user or purchaser, or the non-excludable duties or liabilities

imposed on the seller or Macnaught, by Part V, Division 2, 2A, and Part VA of the Trade Act1974 (Commonwelth) or other

rights conferred on the end-user or purchaser or duties or liabilities imposed upon Macnaught.

Loading...

Loading...