Lumos GSX Solar Module System

Installation Manual

February 2016

Version 4

Page 1

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Warnings and Safety Guidelines

Page 2

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Installation, operation and maintenance of photovoltaic systems can be dangerous, and should be performed only by qualified persons. This manual should be

read and understood fully before attempting to install any Lumos GSX Module System components.

Installations must conform to all applicable building and/or electrical codes and regulations, both national and local. It is the installer’s responsibility to determine

and fulfill all necessary requirements, including obtaining permits and inspections, if necessary.

Installers should maintain a safe installation environment. All OSHA or equivalent guidelines should be followed. Protective headgear, eye protection, insulating

gloves, protective footwear and insulated tools are recommended. Do not attempt to install modules in windy or wet conditions. Do not install any photovoltaic

components where flammable gasses may be present.

Modules should be handled with care. Keep the modules in the original packaging as long as possible. Stack module boxes neatly and evenly. Do not drop the

module. Do not drop any objects on the module. Avoid bending the module. Do not use sharp tools or chemicals to clean the module, other than as specifically

directed by this manual, as this may damage the module. Do not attempt to drill any holes in any part of the module. Do not use the junction box as a handle.

Lumos GSX Modules should only be installed with Lumos approved racking. Lumos does not accept any responsibility for loss or damage as a result of

attempting to install GSX Modules with other mounting systems.

Approved suction cups may be used to handle the modules. However, Lumos does not accept any responsibility for damages related to the use of suction cups,

approved or otherwise. If utilizing suction cups to handle the modules, check that they are clean and free of dirt or debris. Ensure that the suction cup is fully

adhered to the module before attempting to move the module.

Modules are to be installed only on approved structures. It is the installer’s responsibility to certify that the structure upon which the modules are to be mounted

can handle the loads induced by the modules.

Photovoltaic modules generate DC power when they are exposed to sunlight. Contact with electrically active parts of the module can be hazardous. Avoid

unnecessary handling of the module during installation. Do not disassemble any of the module components, or remove any affixed nameplates,

labels or stickers. Do not disconnect any of the modules when they are under load.

Modules with broken glass prevent a serious shock hazard. Before handling broken modules, cover them with material that will block out all light, and wear

insulating gloves. Dispose of broken modules safely and promptly (if making a warranty claim, store the module in a safe and secure location until the claim is

resolved).

This manual provides safe and proper methods to install the Lumos GSX Module System. This is for the safety of the installers as well as the protection of the

equipment. It is the responsibility of the installer to read and understand the information presented in this document. Failure to adhere to the guidelines set

forth in this document may invalidate any applicable warranties.

Due to the fact that installation methods and conditions are beyond Lumos’s control, Lumos does not accept responsibility and expressly disclaims liability for

any loss, damage, or expenses that result during the installation, operation, or maintenance of the Lumos GSX Module System.

Lumos assumes no responsibility for any infringement of patents or other rights of third parties which may result from the use of Lumos GSX Module System

products. No license is granted by implication or otherwise under any patent or patent rights.

Lumos reserves the right to modify this document, the GSX products and components, and any other product specifications and/or data sheets at any time.

This document does not in any way constitute a warranty, express or implied. For warranty information on Lumos products, please contact Lumos directly.

Disclaimer of Liability

Important Statements:

Page 3

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

1.The fire rating of this module is valid only when mounted in the manner specified in the mechanical mounting instructions.

2.The module is considered to be in compliance with UL 1703 only when the module is mounted in the manner specified by

the mounting instructions below.

3.A module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is electrically

grounded in accordance with the instructions presented below and the requirements of the National Electrical Code.

4.Any module without a frame (laminate) shall not be considered to comply with the requirements of UL 1703 unless the

module is mounted with hardware that has been tested and evaluated with the module under this standard or by a field

inspection certifying that the installed module complies with the requirements of UL 1703.

5.Artificially concentrated sunlight shall not be directed on the module or panel.

6.Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or

voltage than reported at standard test conditions. Accordingly, the values of ISC and VOC marked on this module should be

multiplied by a factor of 1.25 when determining component voltage ratings, conductor ampacities, fuse sizes, and size of

controls connected to the PV output.

7.Refer to Section 690-8 of the National Electrical Code for an additional multiplying factor of 125 percent (80 percent

derating) which may be applicable.

8.The electrical characteristics are within ±10 percent of the indicated values of ISC and VOC under standard test conditions

(irradiance of 100 mW/cm2, AM 1.5 spectrum, and a cell temperature of 25°C (77°F)).

9.For field connections, utilize a minimum of 12 AWG Cu wire, insulated to a minimum of 90°C.

List of Editions of these instructions:

1.First Edition: January 13, 2016

2.Second Edition: February 4, 2016

3.Third Edition: February 10, 2016

4.Fourth Edition: February 10, 2016

Page 4

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

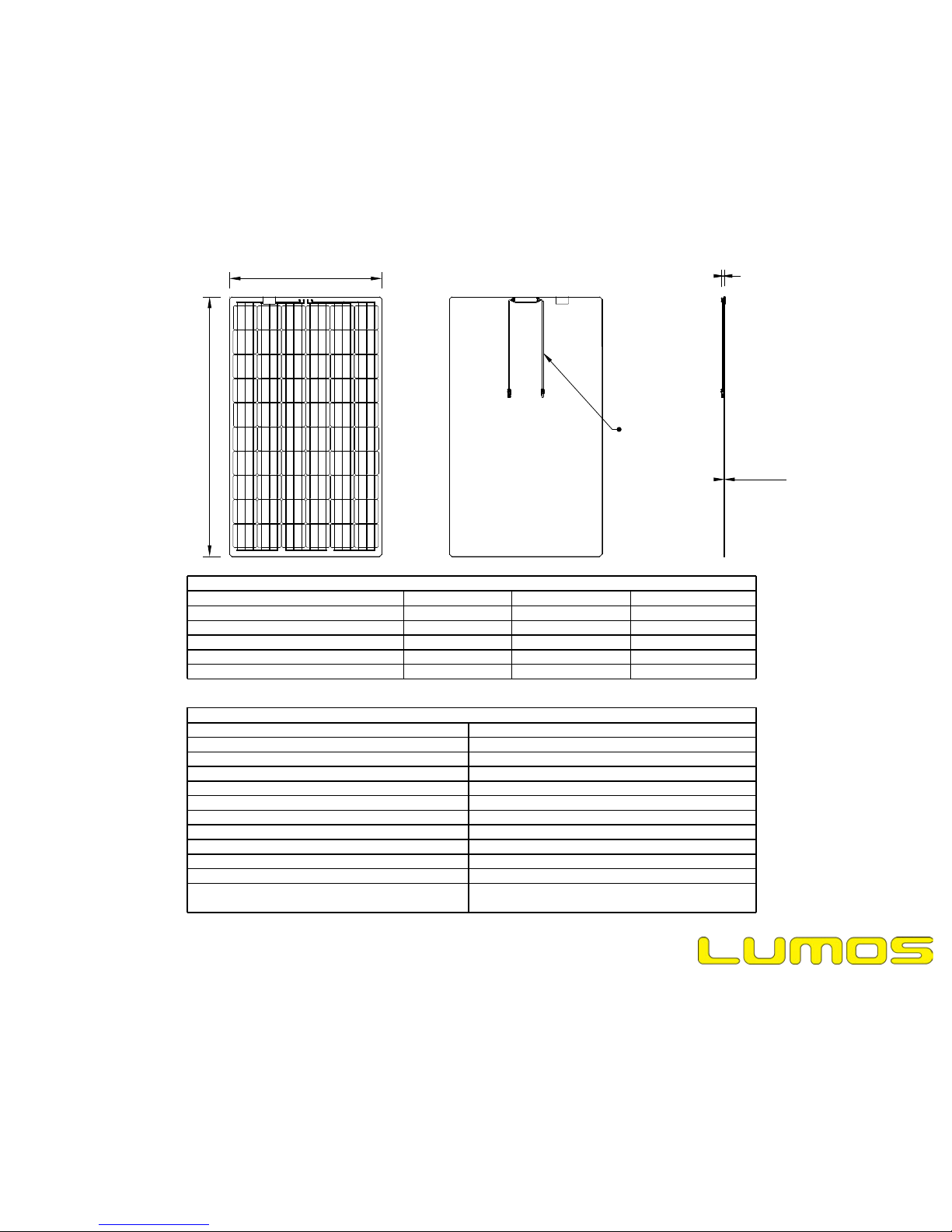

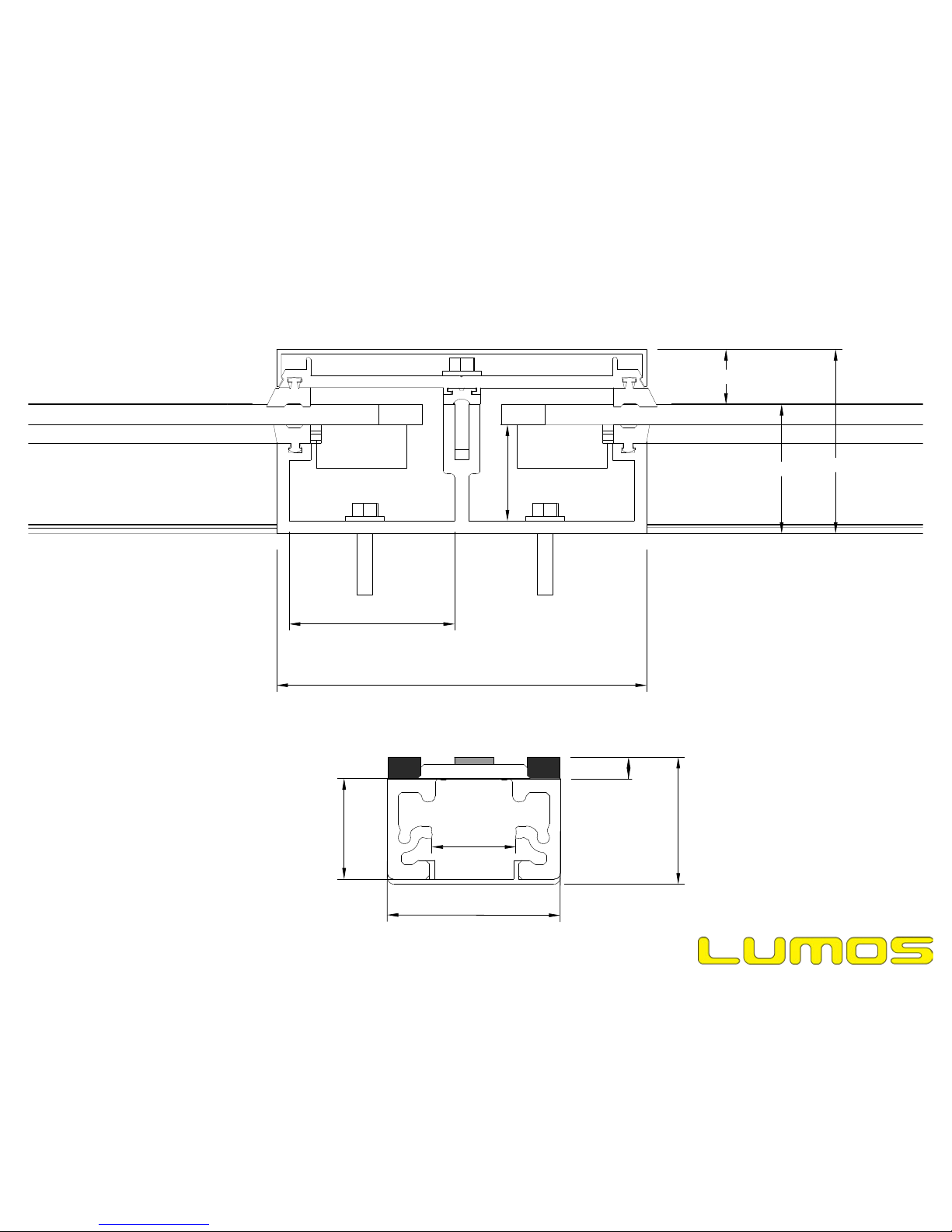

39.37"

66.93"

22.64"

Cable Length

0.95"

0.29"

Laminate Thickness

GSX Electrical Specifications

Model:

GSX260GSX265GSX270

Rated Power @STC (W)260265270

Peak Power Voltage, Vmp (V)31.3831.6331.88

Maximum Power Current, Imp (A)8.298.388.47

Open Circuit Voltage, Voc (V)39.0339.3539.66

Short Circuit Current, Isc (A)8.788.878.97

GSX Mechanical Specifications

Solar CellMonocrystalline 6” x 6”

Number of Cells60 (6 x 10)

Module Dimensions1700mm x 1000mm (66.93” x 39.37”)

Module Area1.7m² (18.30ft²)

Module Weight66.8lb (30.30kg)

Module Weight/Area3.65 psf (17.82 kg/m²)

Racking Weight/Area2.27 psf (11.08 kg/m²)

System Weight/Area5.92 psf (28.9 kg/m²)

Front Glass3.2mm Low-Iron PV Glass

Back Glass3.2mm Low-Iron PV Glass

Light Transmittance3.8%

Daylight Opening (D.L.O.)37.62” x 62.8”

(36.5” x 62.8” for modules at ends of columns)

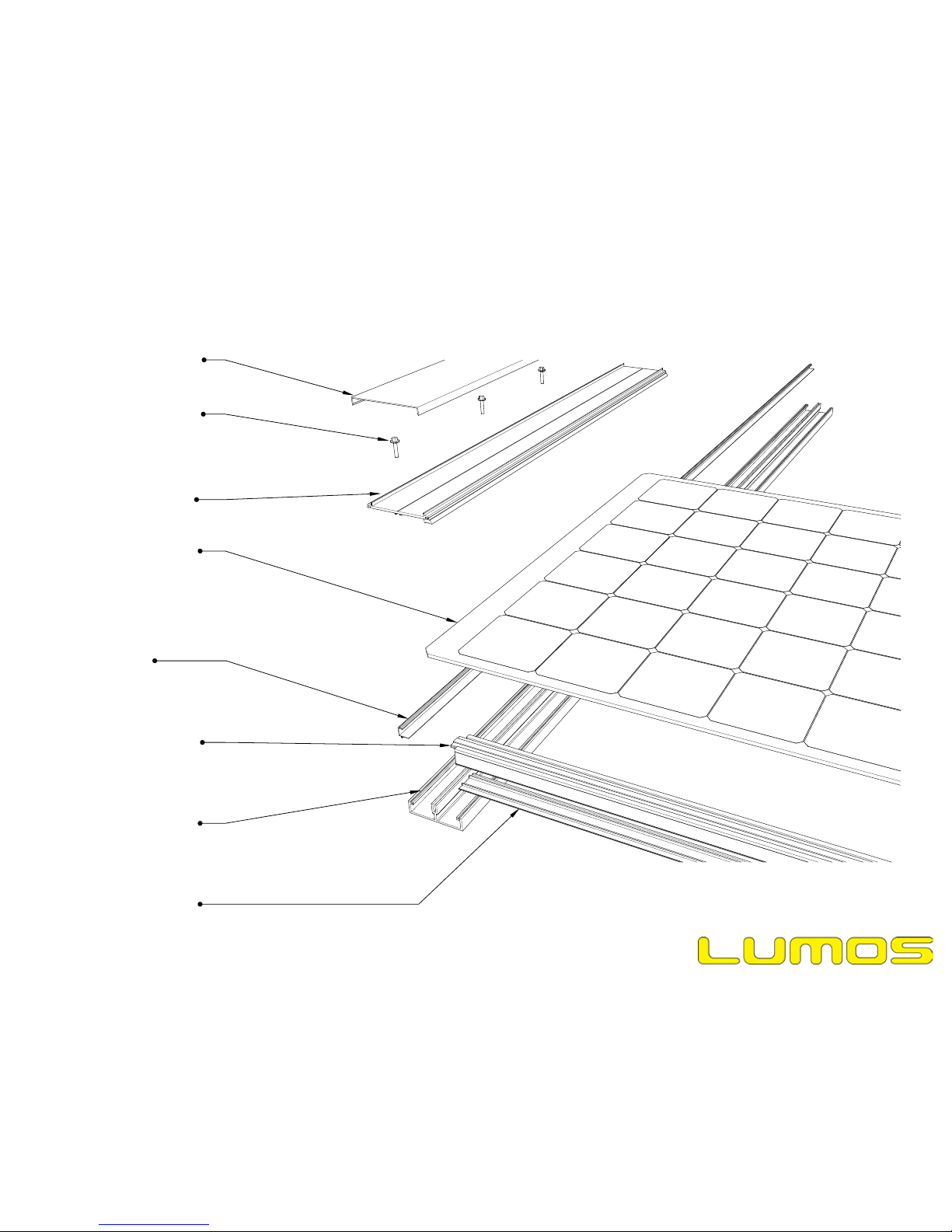

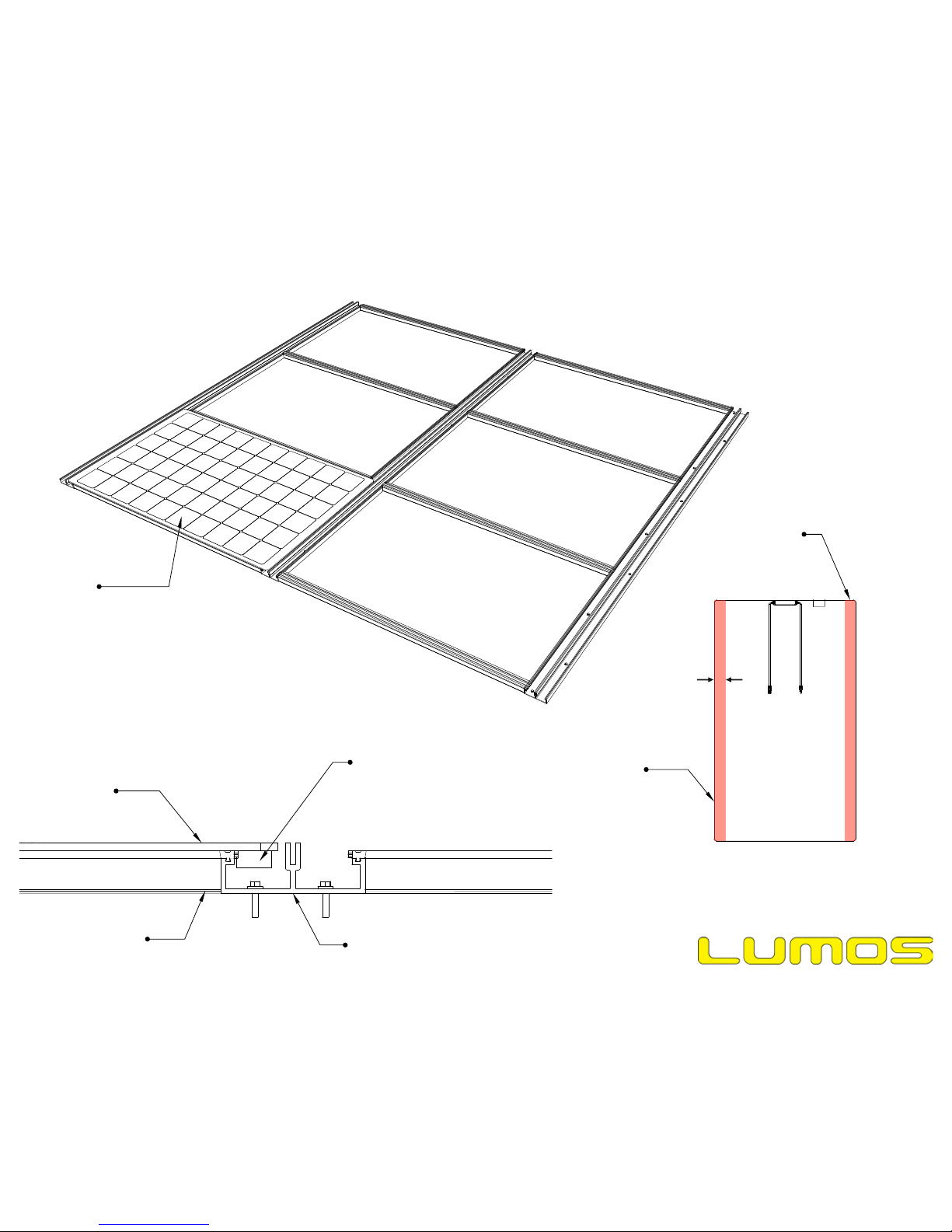

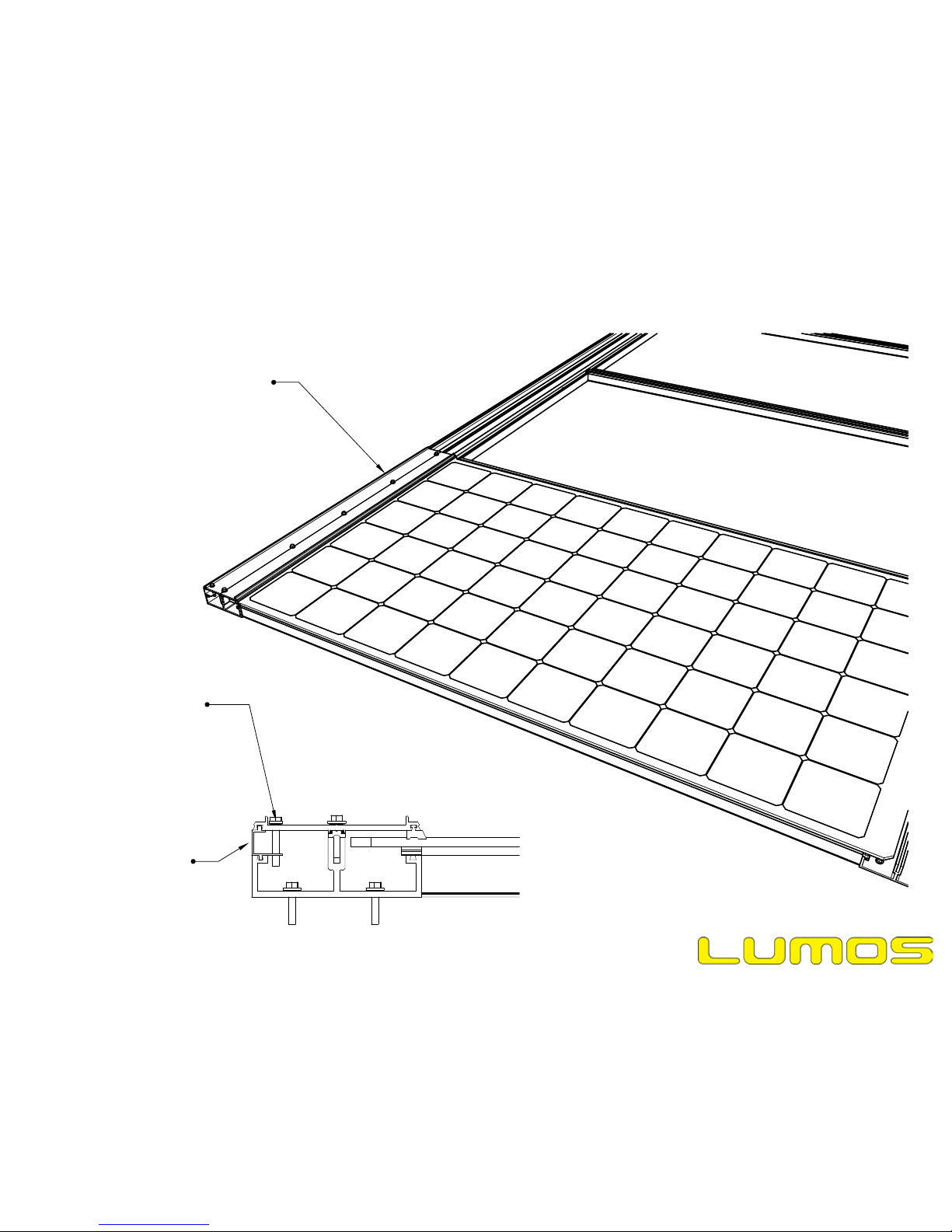

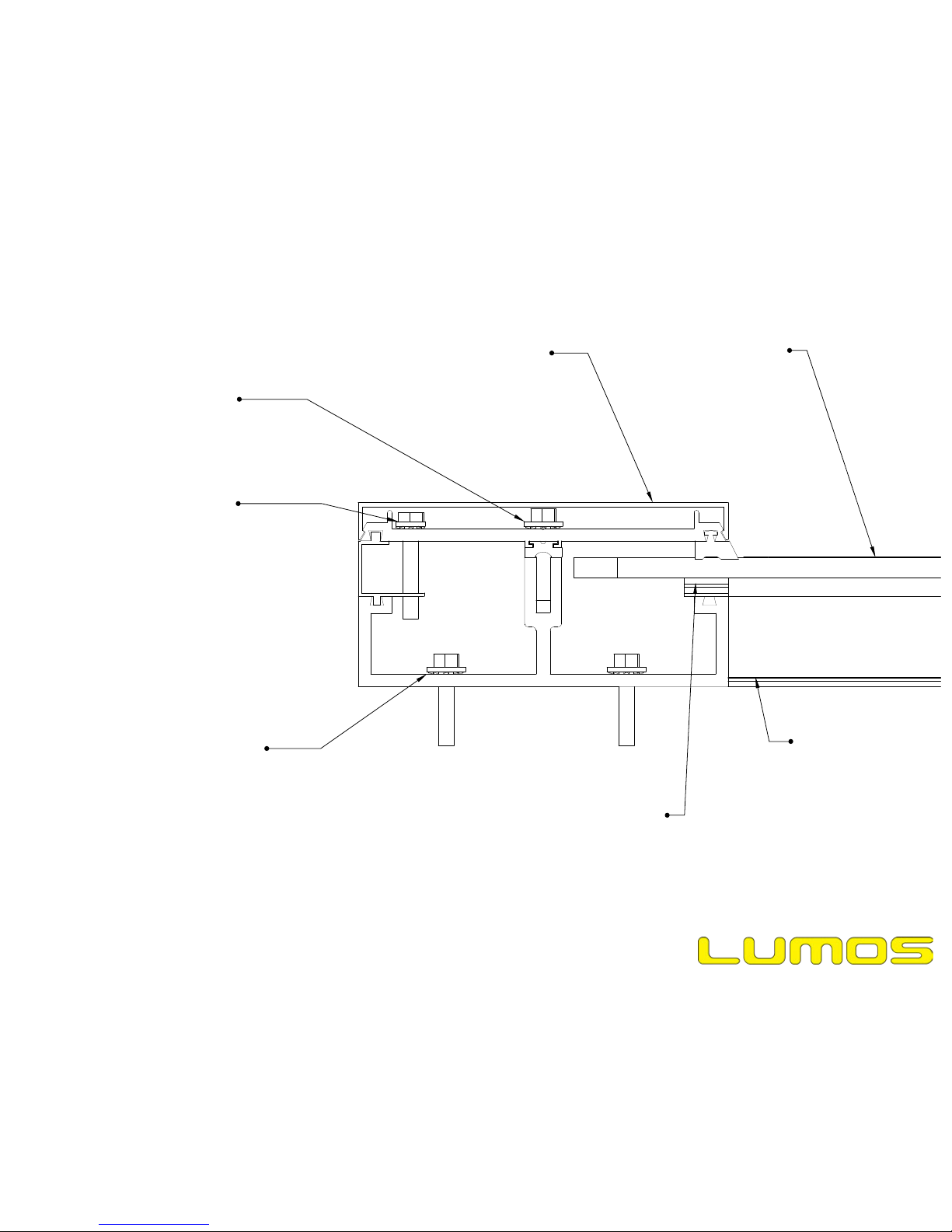

Mullion Top Cap

Pressure Plate Screws

Pressure Plate

GSX Module

Mullion Edge Filler

(Present only at

array edges)

Mullion

Transom

Page 5

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Transom Bottom Cap

Mechanical Installation

Mullion Screw

TBD per project

requirements

Mullion screws pierce

base of mullion. Pre-drilling

may or may not be required,

depending on fastener spec.

Page 6

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

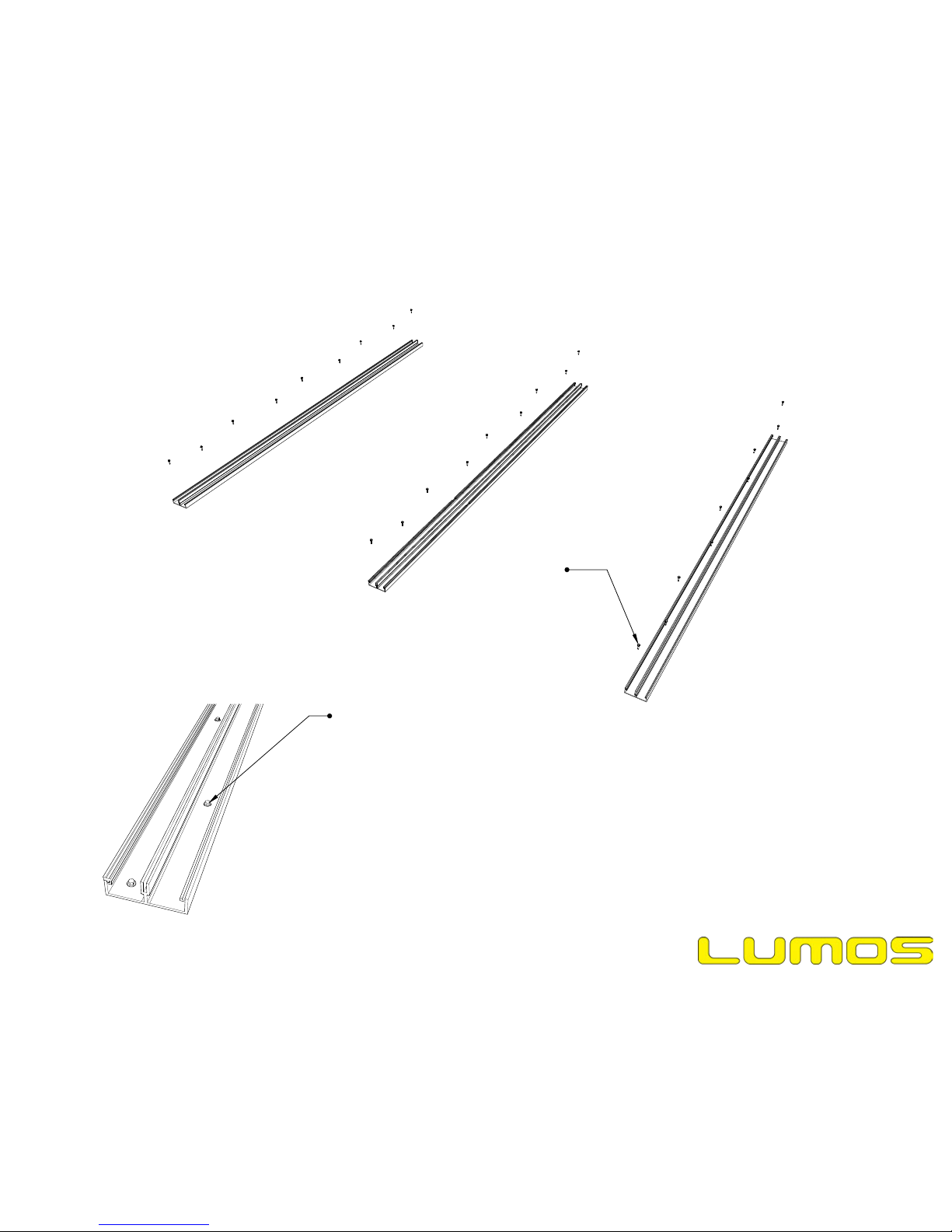

NOTES:

1.Use only 300 series stainless steel fasteners. If using self drilling

screws, use bi-metal fasteners.

2.Lumos recommends installing galvanic isolation material between

dissimilar metals to prevent corrosion issues. This is typically an

issue where the mullions/transoms rest on a steel substructure.

Applying electrical tape or thin rubber to these areas is sufficient.

Mechanical Installation

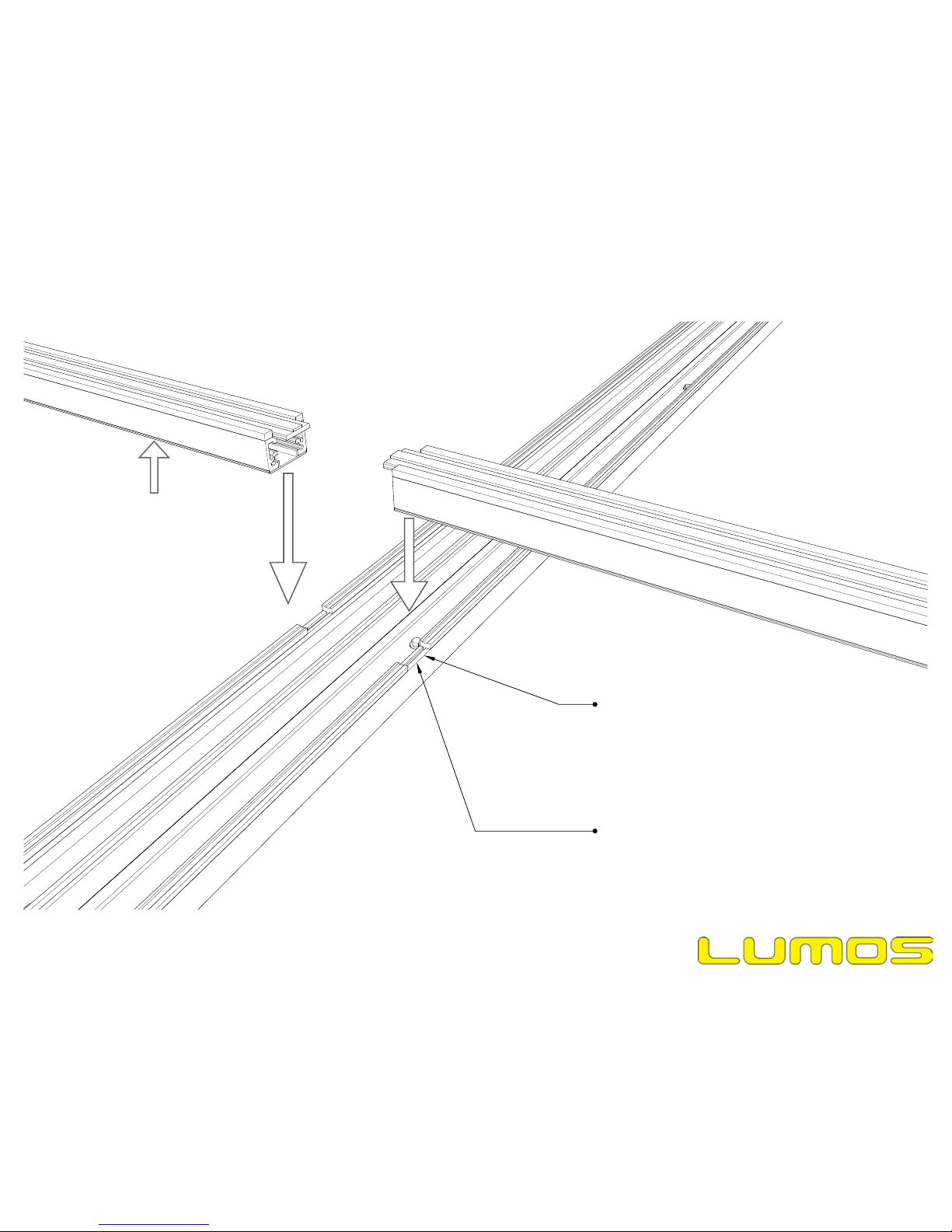

Notch rubber on mullions for

transoms. Transoms lay into

the notch. Fasteners attaching

transoms to mullions may or may

not be required, depending on

site specific conditions.

Page 7

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

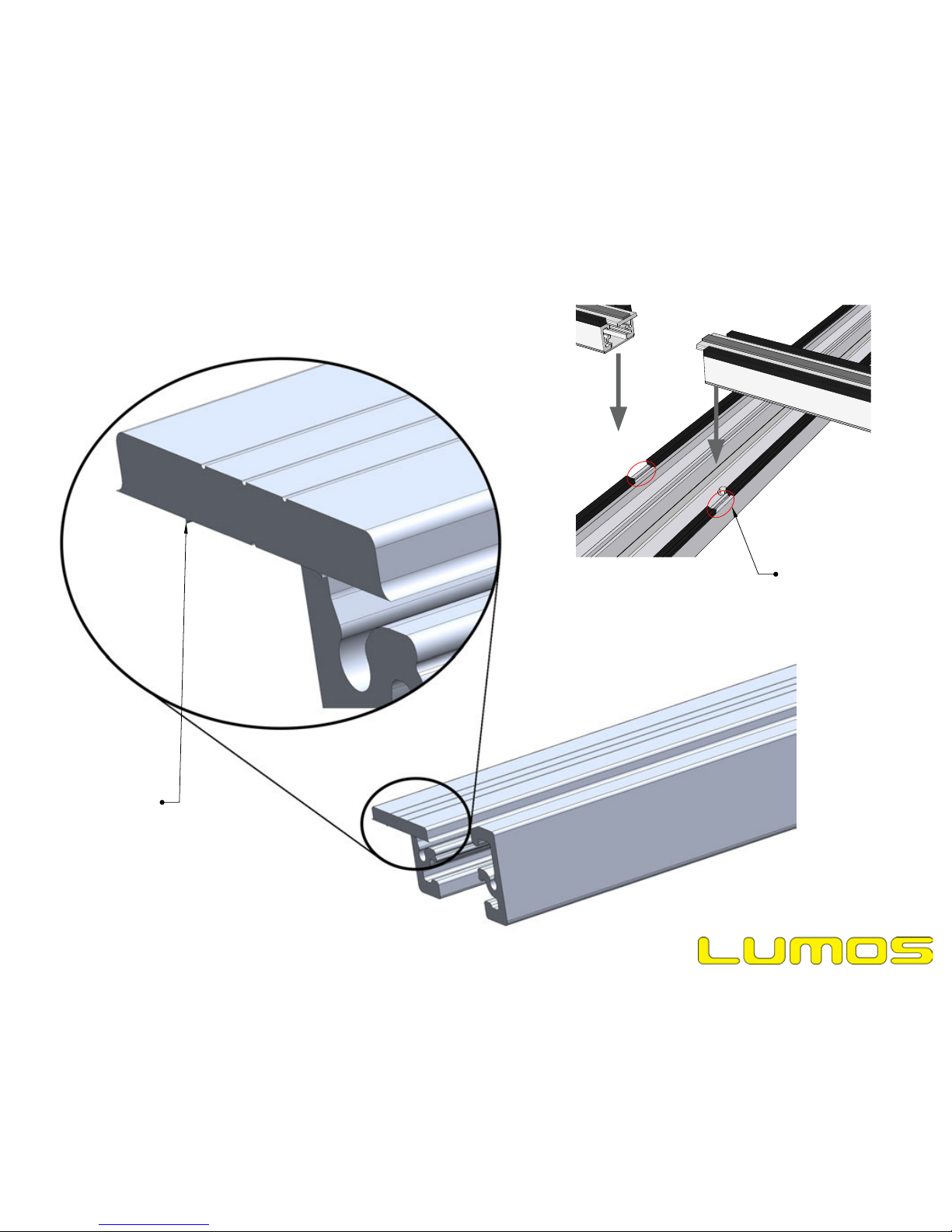

Mechanical Installation

Snap in the Transom Bottom

Cap before placing the transom

in the Mullion Base.

Remove paint from this

area to ensure electrical

bond with transom.

Page 8

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

NOTES:

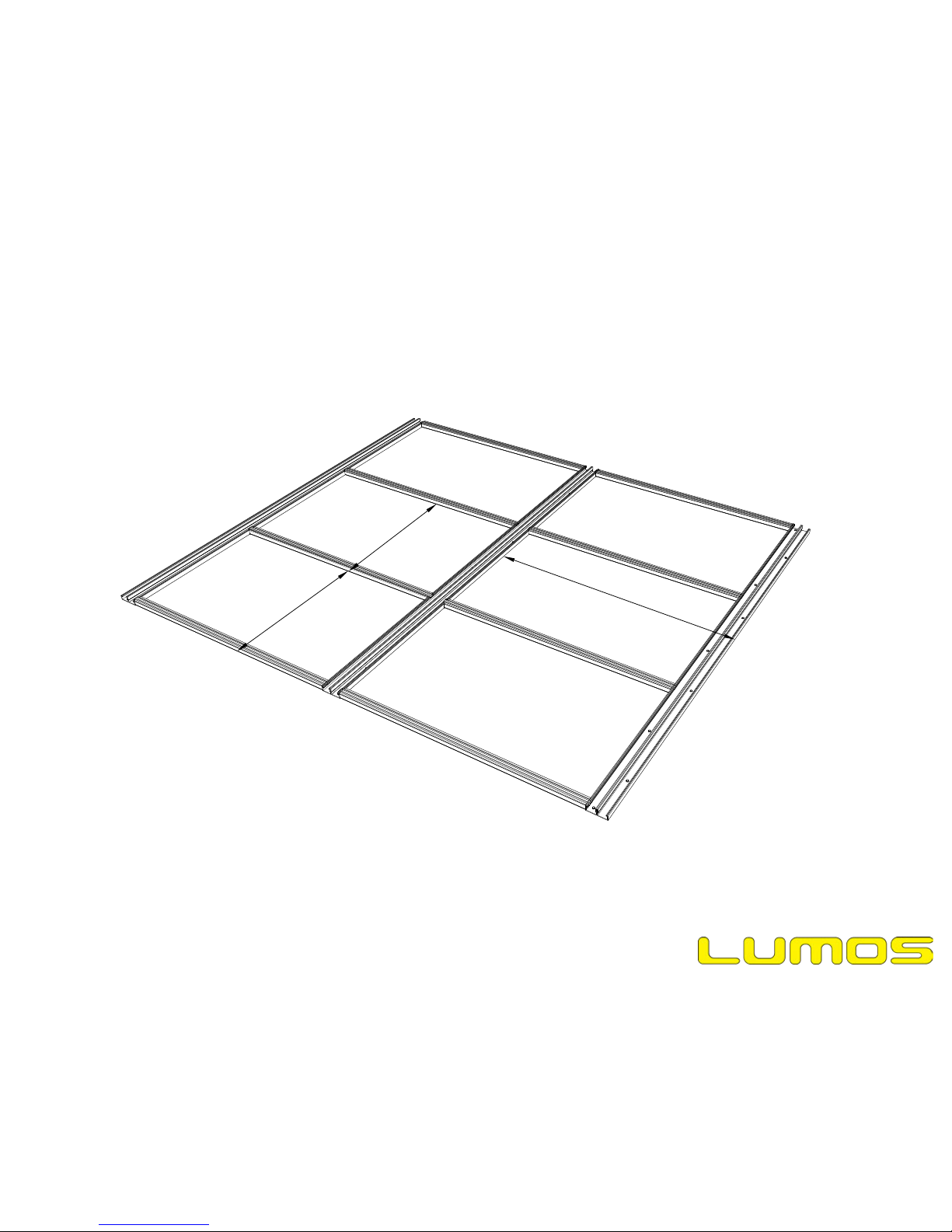

1.Tolerance on Mullion placement is +/- 1/8".

2.VISUALLY INSPECT each interior transom to ensure it is centered, +/- 1/16", under the gap

between modules (the modules must be dry fit in order to verify this).

3.VISUALLY INSPECT each edge transom to ensure it is flush with the edge of the module.

Mechanical Installation

38-1/2"

O.C. @ Edge

39-5/8"

O.C. @ Interior

67-7/8"

O.C. Everywhere

Apply caulk for first module

Apply Caulk for first module

Caulk is shown in red for

visibility. Actual color will not be

red.

Page 9

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Notes:

1)Intall home run wires and/or jumpers

before installing modules. Make all

intermodule connections as modules are

placed. Once modules are installed, wire

ways will be inaccessible.

2)Clean all surfaces to be caulked as

instructed below.

Mechanical Installation

Clean this surface

prior to applying

caulk.

Clean this surface

prior to applying

caulk.

Use a cloth with isopropyl alcohol (IPA) to

clean, then wipe with a second, dry cloth.

IPA should be 70% minimum.

Cleaning:

Place first module

on racking

Junction box goes

inside mullion. Wiring

runs inside mullion.

Mullion

Transom

GSX Module

Page 10

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Clean this area

before bonding

module to transom

Clean this area

before bonding

module to transom

2" wide cleaning

area

Use a cloth with isopropyl alcohol (IPA) to

clean, then wipe with a second, dry cloth.

IPA should be 70% minimum.

Page 11

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mullion top cap

GSX Module

Mullion

Transom

Transom Bottom Cap

(snapped in during

installation)

If necessary, PV wires

can be run inside transoms

as well as mullions. This will

necessitate drilling a hole in

the mullion wall upon installation.

The circle in this view represents

an MC4 connector.

Mechanical Installation

Mullion Edge Filler

(present only at

edges of array)

Pressure Plate Screw

Pressure Plate

Page 12

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Edge filler

First pressure plate installed.

Module is also glued to transoms.

Page 13

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

TORQUE SPEC:

Torque pressure plate screws to 25 in-lb.

Install one grounding

screw per section of

mullion edge filler. Drill

1/4" through hole in

pressure plate and use

drill tip on screw to

penetrate mullion edge

filler. (see electrical

installation section of this

manual.)

Apply caulk for 2nd module

Apply caulk for 2nd module

1st module (already installed)

Caulk is shown in red for

visibility. Actual color will not be

red.

Page 14

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Place 2nd module on racking

Jbox of 2nd module can be in

either mullion. Grouping jboxes

into the same mullion can

simplifiy wire management.

Wires run inside mullion.

Page 15

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Use a cloth with isopropyl alcohol (IPA) to

clean, then wipe with a second, dry cloth.

IPA should be 70% minimum.

2nd pressure plate installed

3rd pressure plate installed

Page 16

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Apply caulk for 3rd module

Apply caulk for 3rd module

Caulk is shown in red for

visibility. Actual color will not be

red.

Page 17

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Use a cloth with isopropyl alcohol (IPA) to

clean, then wipe with a second, dry cloth.

IPA should be 70% minimum.

Place 3rd module on racking

Page 18

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Install 4th pressure plate

Page 19

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

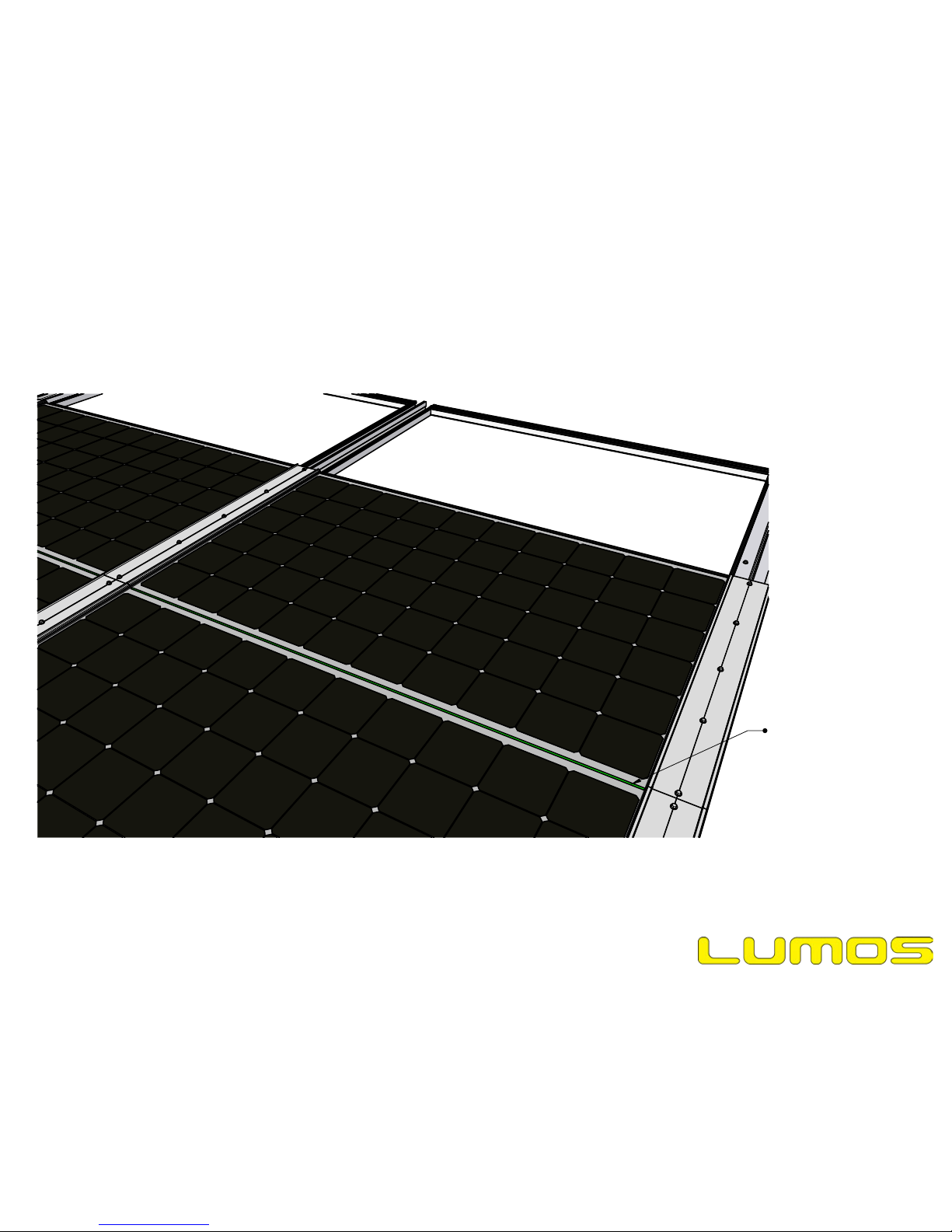

Mechanical Installation

Caulk is shown in green for

visibility. Actual color will not be

green.

Install weatherseal (i.e., caulk

the joint. Tape off and tool back

to ensure a clean finish.)

Page 20

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

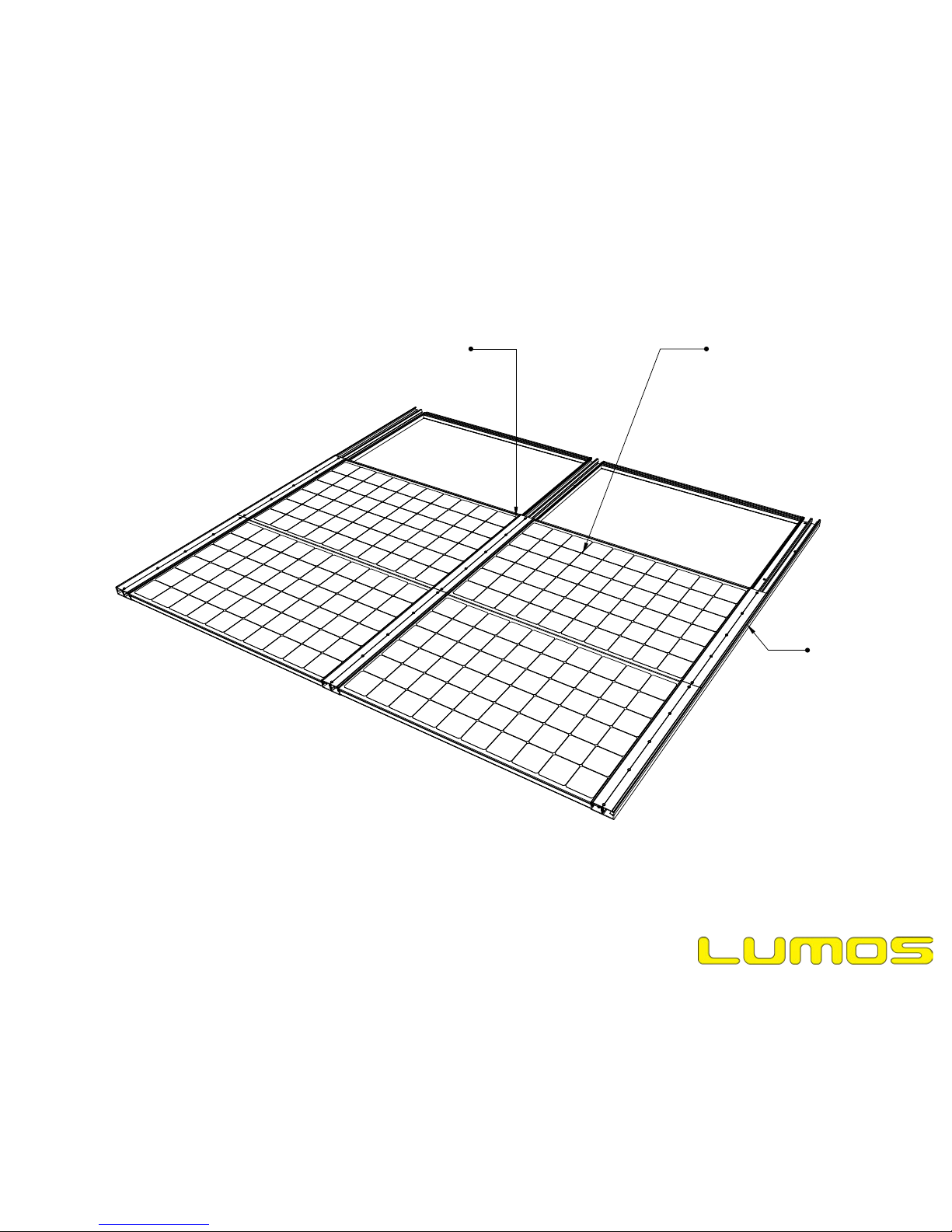

Mechanical Installation

Install the next module.

This includes caulking the

transoms, and installing

the pressure plate(s).

Pressure plate

Pressure plate

Page 21

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Install weatherseal

Caulk is shown in green for

visibility. Actual color will not be

green.

Page 22

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

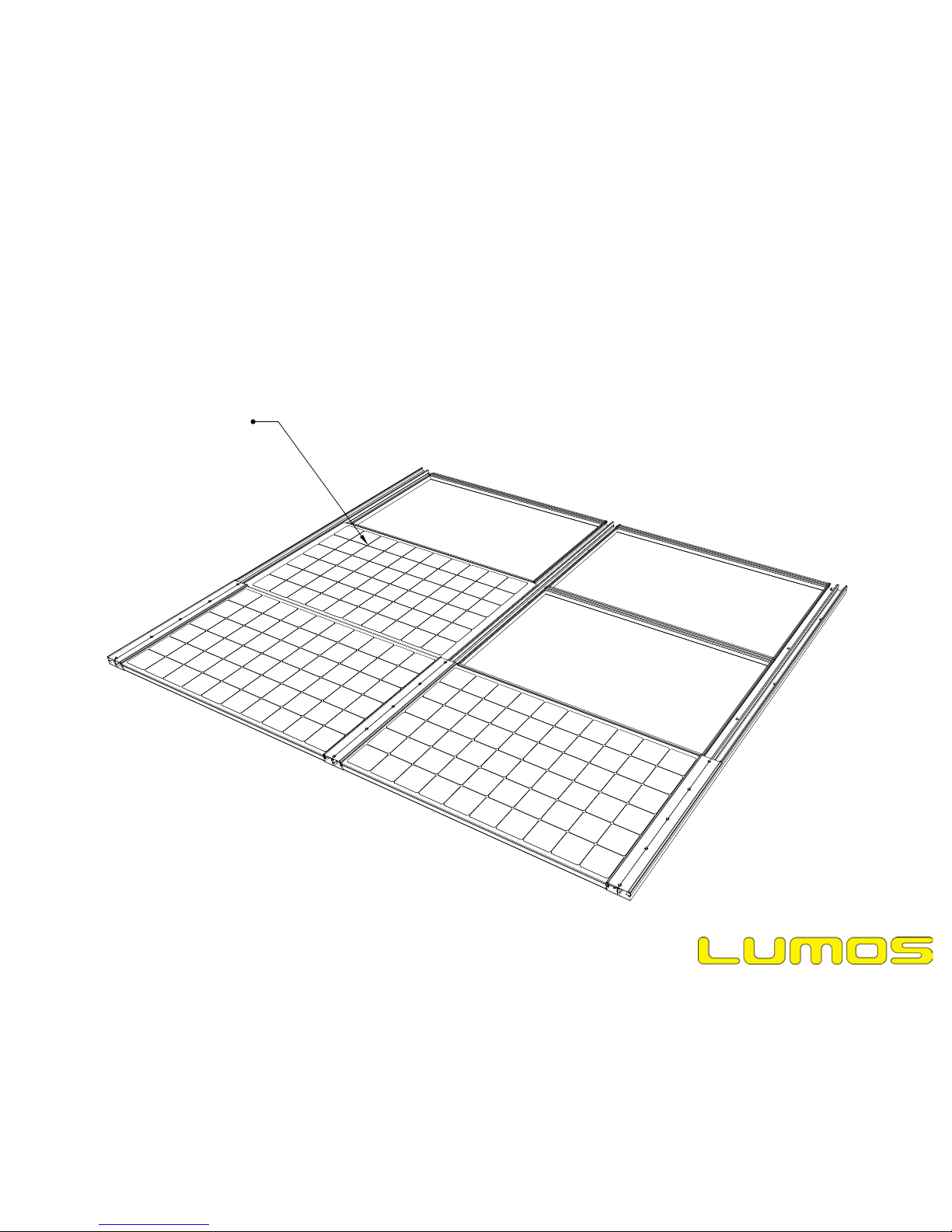

Follow the same pattern to install the rest of the modules. Be sure to apply caulk to the transoms

and weatherseals. All wiring must be completed as the modules are installed, as the wire ways will be

inaccessible once all modules are in place.

Page 23

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Install mullion top caps

by snapping them onto

pressure plates. A rubber

mallet works well.

Install mullion end caps

with included screws.

Page 24

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Mechanical Installation

Page 25

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Electrical Installation

Grounding/Electrical Bonding Information

(continued on next page)

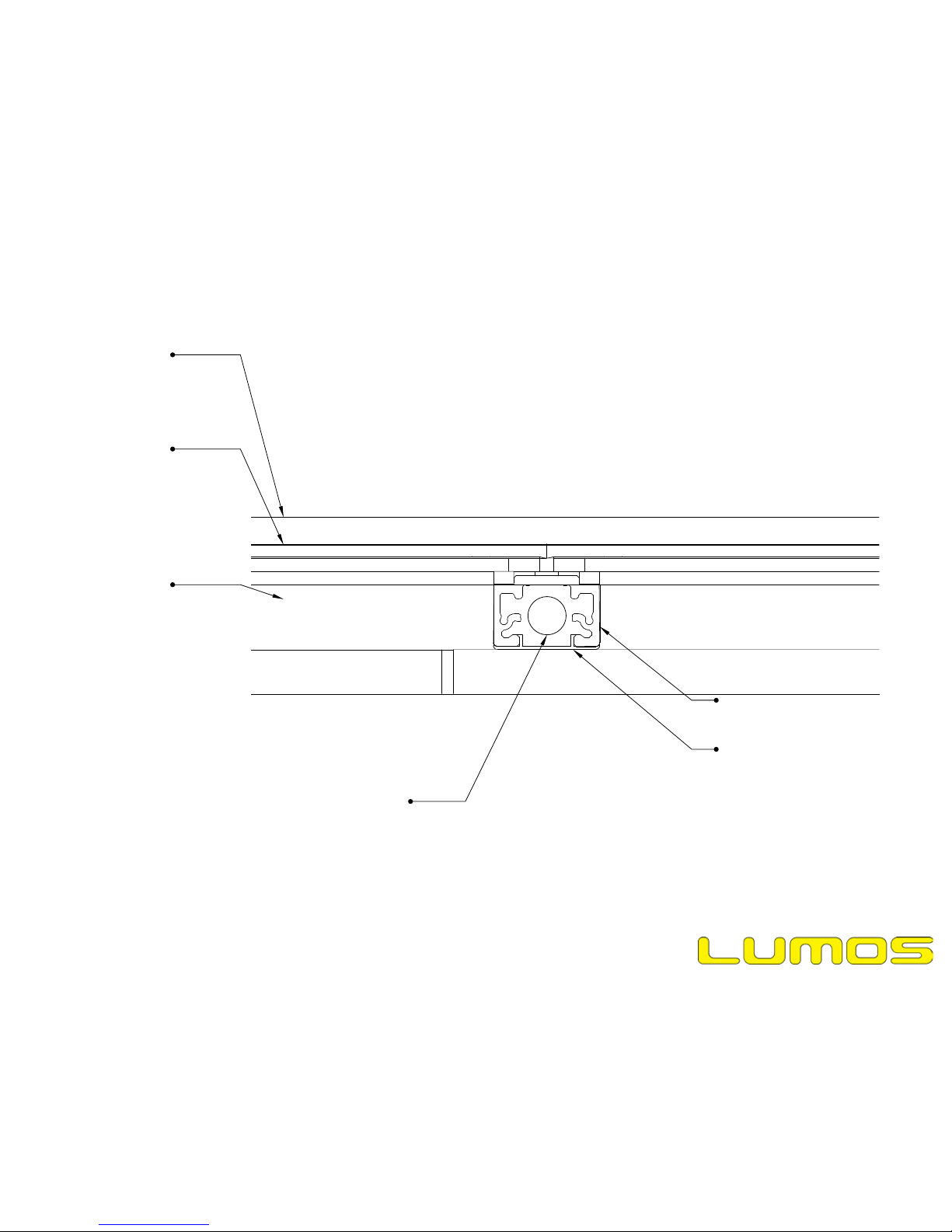

Top Cap is bonded to pressure

plate via direct metal to metal

contact inside the snap fit

Mullions can be gounded to

conductive substructure by fastener

with star washer.

Transom has grounding teeth

which ensure electrical bond

with mullion (remove any paint

from mullion with coarse

sandpaper, 40 grit

recommended)

Module is frameless, so

no grounding is required

1/4-14 SS self tapping screw

with SS star washer bonds

pressure plate to mullion

12-24 SS self drilling screw

with SS star washer bonds

mullion edge filler to pressure

plate. One screw per mullion

edge filler length. REQUIRES

FIELD DRILLING A 1/4"

THROUGH HOLE IN PRESSURE

PLATE.

Transom bottom

cap is bonded to

transom via direct

metal to metal

contact inside the

snap fit

Note:

All hardware must be 300 series stainless steel.

Page 26

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Grounding Teeth on

transom ensure

electrical bond with

mullion.

Electrical Installation

Grounding/Electrical Bonding Information

(continued on next page)

Remove any paint

from mullion with

coarse sandpaper,

40 grit

recommended)

Page 27

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

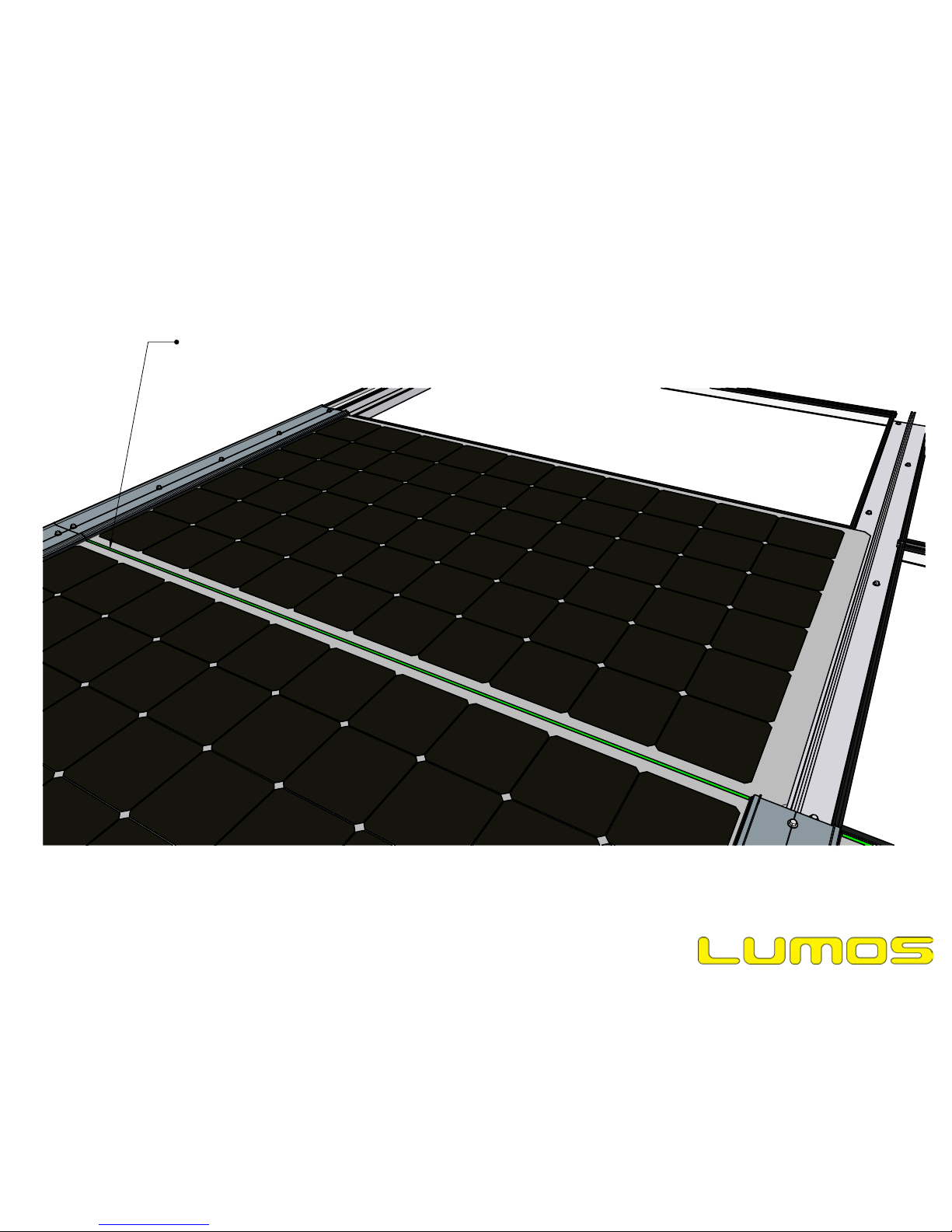

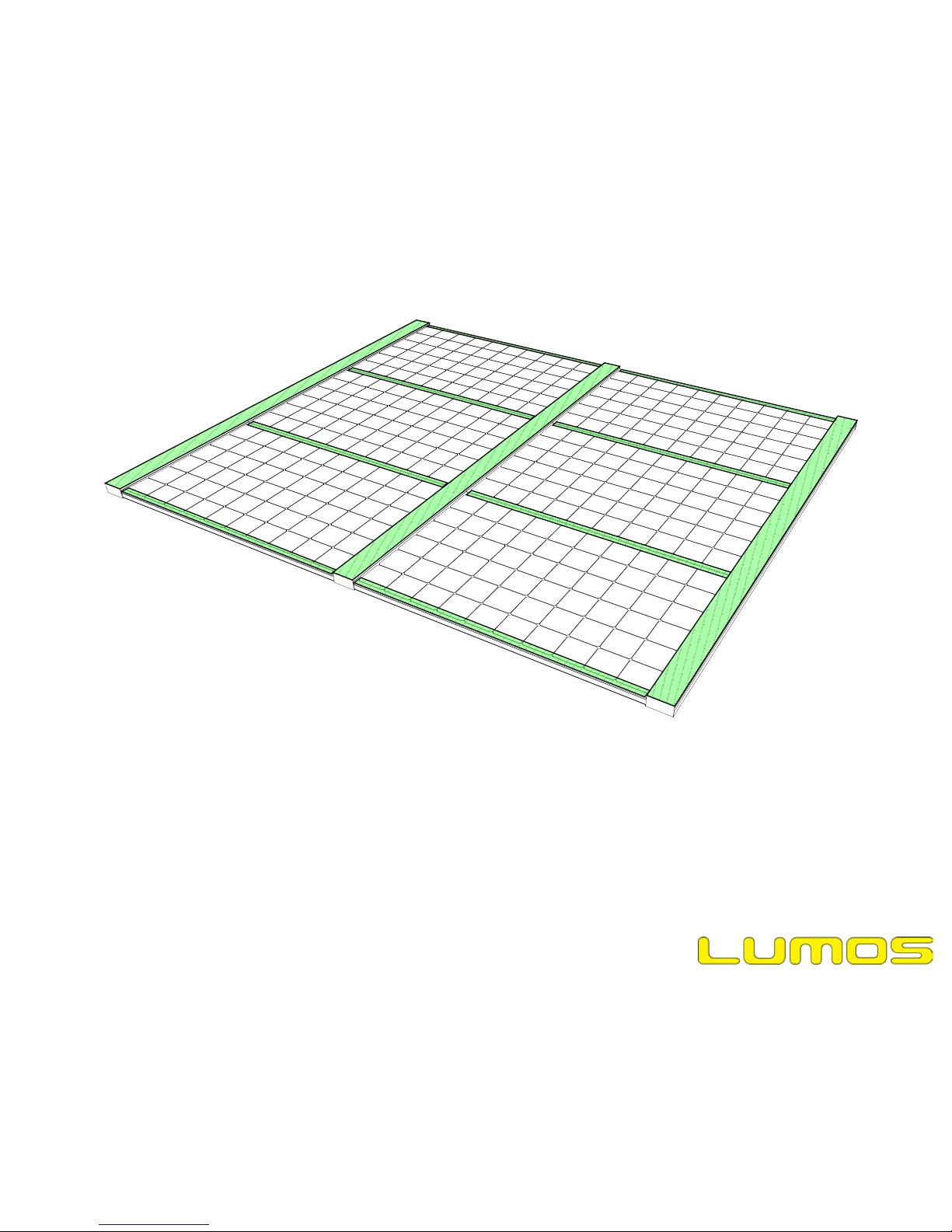

Walking on the Array

Lumos permits stepping and walking on our GSX modules, but ONLY OVER THE TRANSOMS AND MULLIONS. Stepping

anywhere other than these locations, which are highlighted in green with hatch marks in the above image, could cause damage

to the solar cells and lower the power output of the module.

Page 28

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

5"

1 5/16"

1 3/4"

Useful Dimensions:

2"

1/4"

1 3/16"1"1 1/2"

2 1/4"

2 1/2"

3/4"

Page 29

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Useful Dimensions:

Page 30

Date Modified: Feb 10, 2016

File Name: 20160210_Rev004_GSX Installation Manual

Returns

Returns are only accepted with an approved RMA (Return Material Authorization) form. Returns must be packed appropriately, as the product was received, in

the original packaging. Improperly packed returns will not be credited. If original packaging has been discarded or lost, contact Lumos for instructions.

For questions regarding RMA forms or to submit an RMA form, please contact Lumos directly.

Contact Lumos

For more information on the Lumos GSX Module System, GSX installation processes, maintenance, warranties, purchasing inquiries, finding an authorized

dealer, or for more information on any other Lumos products and services, please contact:

Lumos Solar

929 Pearl St., Ste. 250

Boulder, CO 80302

Tel: (877) 301 - 3582

Fax: (303) 442 - 1829

info@lumossolar.com

Loading...

Loading...