Lochinvar 81-286 User Manual

KBII-SER Rev F

Service Manual

Models: 81 - 286

WARNING This manual must only be used by a qualified heating installer / service technician. Read all instructions, including this manual and the Knight Boiler Installation and Operation Manual, before installing. Perform steps in the order given. Failure to comply could result in severe personal injury, death, or substantial property damage.

Save this manual for future reference.

Contents

CONTENTS........................................................................ |

2 |

2. MAINTENANCE |

|

|

Hazard Definitions.............................................................. |

2 |

Maintenance and Annual Startup................................ |

28-32 |

|

PLEASE READ BEFORE PROCEEDING ........................ |

3 |

3. TROUBLESHOOTING |

|

|

Handling Ceramic Fiber Materials...................................... |

3 |

Before Troubleshooting.................................................... |

|

33 |

When servicing boiler ................................................... |

4 |

Check Control Module Fuses .......................................... |

|

33 |

Boiler operation............................................................ |

4 |

Table 3-1 - Troubleshooting Chart - No Display .............. |

|

34 |

Boiler water................................................................... |

4 |

Checking Temperature Sensors ...................................... |

|

35 |

Freeze protection fluids ................................................ |

4 |

Table 3-3 - Troubleshooting Chart - Noisy System ......... |

36 |

|

WHAT IS IN THIS MANUAL .............................................. |

5 |

Table 3-4 - Troubleshooting Chart - Fault Messages . 37-46 |

||

1. SERVICE |

|

Combustion Analysis Procedure ...................................... |

|

46 |

Near Boiler Piping .............................................................. |

6 |

Table 3-5 - Flue Products ................................................ |

|

46 |

The Knight Boiler Display................................................... |

7 |

Table 3-6 - Troubleshooting Chart - Combustion Levels |

47 |

|

Control Inputs ............................................................... |

8 |

Gas Valve Adjustment Procedure.................................... |

|

47 |

Control Outputs............................................................. |

9 |

Revision Notes .................................................. |

Back Cover |

|

General Operation ...................................................... |

10 |

|

|

|

Sequence of Operation ............................................... |

11-12 |

|

|

|

Display Panel Menu Access ............................................ |

13 |

|

|

|

Display Panel Parameter Access..................................... |

14 |

|

|

|

Parameter Table.......................................................... |

15-18 |

|

|

|

Viewable and Changeable Control Parameters.......... |

19-27 |

|

|

|

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not related to personal injury or property damage.

2

Service Manual

Please read before proceeding

WARNING |

Installer – Read |

all |

instructions, |

NOTICE |

|

including this manual and the Knight |

|

||

|

Boiler Installation |

and |

Operation |

|

|

Manual, before installing. Perform steps |

|

||

|

in the order given. |

|

|

|

User – This manual is for use only by a qualified heating installer/service technician. Refer to the Knight Boiler User’s Information Manual for your reference.

Have this boiler serviced/inspected by a qualified service technician at least annually.

Failure to comply with the above could result in severe personal injury, death or substantial property damage.

Handling ceramic fiber materials

REMOVAL OF COMBUSTION CHAMBER LINING

When calling or writing about the boiler

– Please have the boiler model and serial number from the boiler rating plate.

Consider piping and installation when determining boiler location (see the Knight Boiler Installation and Operation Manual).

Any claims for damage or shortage in shipment must be filed immediately against the transportation company by the consignee.

WARNING The combustion chamber insulation in this appliance contains ceramic fiber material. Ceramic fibers can be converted to cristobalite in very high temperature applications. The International Agency for Research on Cancer (IARC) has concluded, “Crystalline silica in the form of quartz or cristobalite from occupational sources is carcinogenic to humans (Group 1).” Normal operating temperatures in this appliance are below the level to convert ceramic fibers to cristobalite. Abnormal operating conditions would have to be created to convert the ceramic fibers in this appliance to cristobalite.

The ceramic fiber material used in this appliance is an irritant; when handling or replacing the ceramic materials it is advisable that the installer follow these safety guidelines.

Avoid breathing dust and contact with skin and eyes.

•Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA requirements for cristobalite at the time this document was written. Other types of respirators may be needed depending on the job site conditions. Current NIOSH recommendations can be found on the NIOSH website at http://www.cdc.gov/niosh/homepage.html. NIOSH approved respirators, manufacturers, and phone numbers are also listed on this website.

•Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

Apply enough water to the combustion chamber lining to prevent airborne dust.

Remove the combustion chamber lining from the appliance and place it in a plastic bag for disposal.

Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid.

Eye: Irrigate immediately.

Breathing: Fresh air.

3

Service Manual

Please read before proceeding

When servicing boiler –

•To avoid electric shock, disconnect electrical supply before performing maintenance.

•To avoid severe burns, allow boiler to cool before performing maintenance.

Boiler operation –

•Do not block flow of combustion or ventilation air to the boiler.

•Should overheating occur or gas supply fail to shut off, do not turn off or disconnect electrical supply to circulator. Instead, shut off the gas supply at a location external to the appliance.

•Do not use this boiler if any part has been under water. The possible damage to a flooded appliance can be extensive and present numerous safety hazards. Any appliance that has been under water must be replaced.

Boiler water –

•Thoroughly flush the system (without boiler connected) to remove sediment. The high-efficiency heat exchanger can be damaged by build-up or corrosion due to sediment.

•Do not use petroleum-based cleaning or sealing compounds in the boiler system. Gaskets and seals in the system may be damaged. This can result in substantial property damage.

•Do not use “homemade cures” or “boiler patent medicines”. Serious damage to the boiler, personnel, and/or property may result.

•Continual fresh make-up water will reduce boiler life. Mineral buildup in the heat exchanger reduces heat transfer, overheats the stainless steel heat exchanger, and causes failure. Addition of oxygen carried in by makeup water can cause internal corrosion. Leaks in boiler piping must be repaired at once to prevent the introduction of makeup water.

Freeze protection fluids –

•NEVER use automotive antifreeze. Use only inhibited propylene glycol solutions which are specifically formulated for hydronic systems. Ethylene glycol is toxic and can attack gaskets and seals used in hydronic systems.

4

What is in this manual?

Service

Near boiler piping

• Typical system components

The Knight boiler display

• Display panel readout, buttons and their functions

Control module inputs

• Control module inputs and options

Control module outputs

• Control module outputs and options

General

•How the boiler operates

•How the control module operates

•Access modes -- user and installer

•Sequence of operation -- Domestic Hot Water (DHW)/space heating

Control panel menu access

•Accessing programming mode and locating menus (See separate guide covering the PC interface.)

Control panel parameter access

• Accessing and changing parameters from the display panel

Quick start information -- parameter table

•An index of available adjustments and readouts, where to access them and where to find detailed information.

Knight boiler operation

•General

•Temperature Setting

•Data Logging

•Functions

•DHW Settings

•Outdoor Reset

•Anti-cycling

•Control Modes

•Circulation Pumps

•Building Management System (BMS)

•Service Notification

Service Manual

Maintenance

•Service and maintenance schedules

•Address reported problems

•Inspect boiler area and boiler interior

•Clean condensate trap

•Check all piping for leaks

•Check air openings

•Flue vent system and air piping

•Check water system

•Check expansion tank

•Check boiler relief valve

•Inspect ignition electrode

•Check ignition ground wiring

•Check all boiler wiring

•Check control settings

•Perform start-up and checks

•Check burner flame

•Check flame signal

•Check flue gas temperature

•General maintenance

•Review with owner

•Cleaning boiler heat exchanger

•Oiled bearing circulators

Troubleshooting

•Troubleshooting table - No display

•Checking temperature sensors

•Sensor tables

•Troubleshooting table - Fault messages displayed on boiler interface

•Combustion analysis procedure

•Gas valve adjustment procedure

5

Service Manual

1 Service

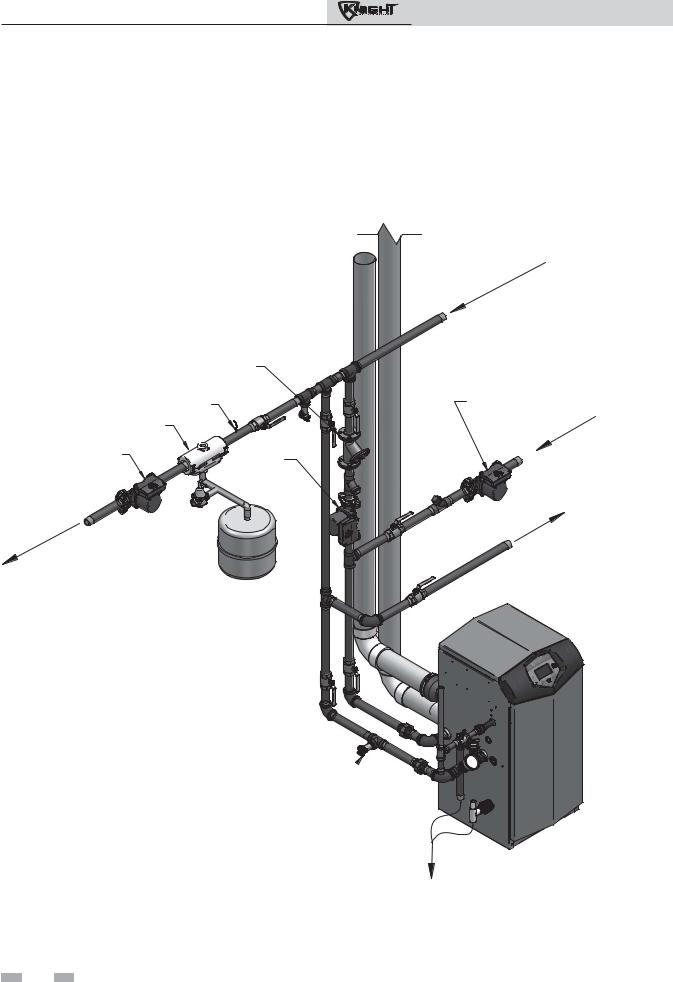

Near boiler piping

This piping reference is included to specify the Near Boiler Piping specific to the Knight boiler. This piping scheme is important for proper operation of the SMART SYSTEM control. See the Knight Boiler Installation and Operation Manual for more detailed piping diagrams.

Y-STRAINER (RECOMMENDED)

SYSTEM SENSOR

AIR SEPARATOR

SYSTEM |

BOILER |

PUMP |

|

|

PUMP |

M

E

T

S

Y

S

O

T

M

E

T

S

Y

S

M

O

R

F

DOMESTIC HOT

WATER PUMP

M

O

R

F

INDIRECT

DOMESTIC

HOT WATER

TANK

O

T

DRAIN  (TYPICAL)

(TYPICAL)

TO FLOOR

DRAIN

6

Service Manual

1 Service (continued)

The Knight boiler display

NAVIGATION DIAL

The information on the bottom of the display shows the functions of the two SELECT keys (on either corner), and the NAVIGATION dial (in the center):

MENU = Left SELECT Key

SETPOINTS = NAVIGATION Dial - Pressing Down

SHDN = Right SELECT Key

7

Service Manual

1 Service

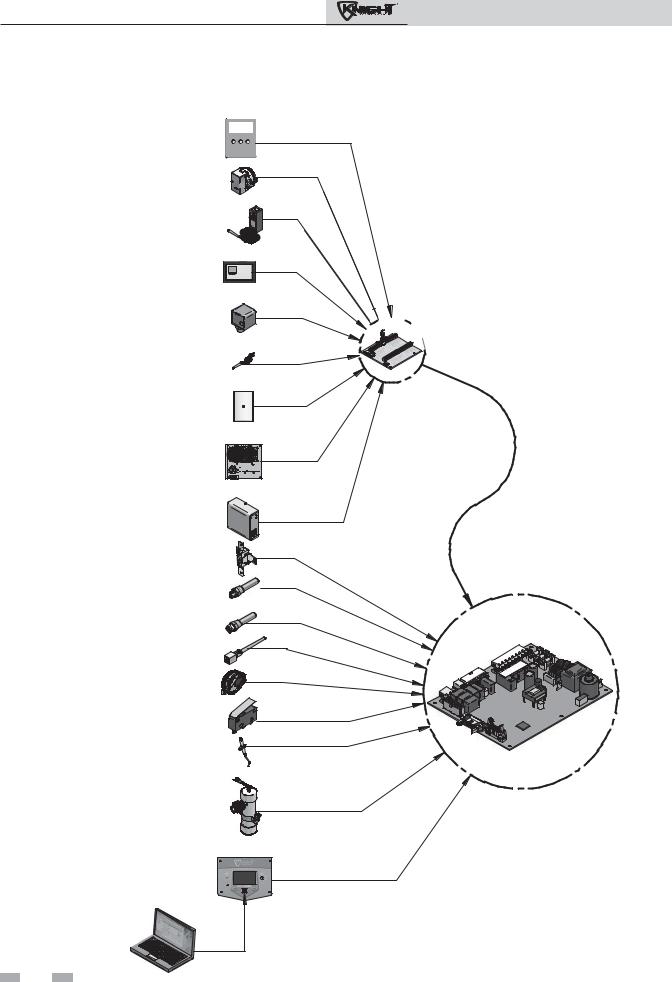

Control inputs

SYSTEM PUMP SPEED CONTROL

GAS PRESSURE SWITCH

DHW THERMOSTAT

ROOM THERMOSTAT /

ZONE CONTROL

FLOW SWITCH

SYSTEM SENSOR

OUTDOOR SENSOR

SEQUENCER / BUILDING MANAGMENT SYSTEM

LOW WATER CUTOFF

O-TEMP HEAT EXCHANGER SWITCH

INLET TEMPERATURE

SENSOR

OUTLET TEMPERATURE /

HI-LIMIT SENSOR

FLUE GAS SENSOR

LOW VOLTAGE

CONNECTION

CONNECTION

BOARD

BOARD

AIR PRESSURE SWITCH

LOUVER PROVING SWITCH |

FLAME SENSOR

BLOCKED DRAIN SWITCH

SMART CONTROL

MODULE

DISPLAY PANEL

PC INTERFACE

IMG00006

8

1 Service (continued)

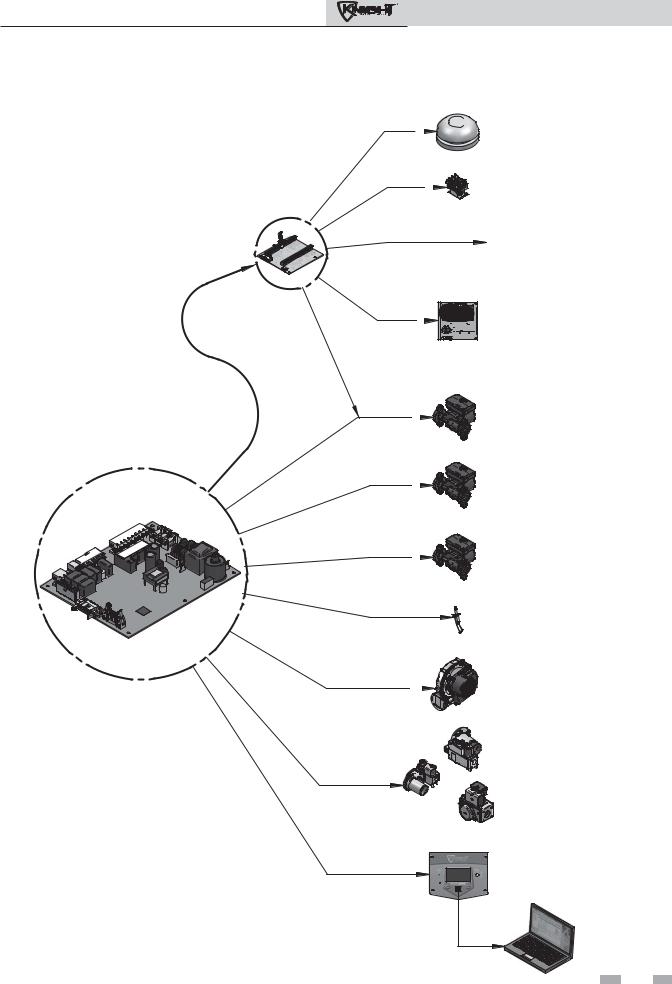

Control outputs

LOW VOLTAGE |

CONNECTION |

BOARD |

SMART CONTROL

MODULE

Service Manual

ALARM BELL

LOUVER RELAY

RUN TIME CONTACTS

BUILDING MANAGEMENT

SYSTEM

BOILER PUMP

SYSTEM PUMP

DHW PUMP

IGNITOR

BLOWER

GAS VALVE |

DISPLAY PANEL |

PC INTERFACE |

9 |

1 Service

General Operation

How the boiler operates

The Knight boiler uses an advanced stainless steel heat exchanger and an electronic control module that allows fully condensing operation. The blower pulls in gas and air and pushes flue products out of the boiler through the heat exchanger and flue piping. The control module regulates blower speed to control boiler firing rate. The gas valve senses the amount of air flowing into the boiler and allows only the right amount of gas to flow.

How the control module operates

The Knight boiler control module receives input from boiler sensors. The control module activates and controls the blower and gas valve to regulate heat input and switches boiler, DHW and system pumps on and off as needed. The user/installer programs the module to meet system needs by adjusting control parameters. These parameters set operating temperatures and boiler operating modes. Boiler operation can be based on boiler outlet water temperature, boiler return water temperature or system supply temperature, depending on the parameter setting.

Sequence of operation

Table 1-1 shows control module normal sequences of operation for space heating and DHW operation. The combined operation sequence is for a typical application, programmed to provide DHW priority.

Service Manual

Access modes

User

The user can adjust space heating and tank target temperatures by pressing the NAVIGATION dial when “SETPOINTS” is flashing at the bottom of the display. The date and time, and the temperature units can also be changed.

Installer

Most parameters are available only to the installer, accessible only by entering the installer password (5309).

Saving parameters (reference the Parameter Table - Table 1-4 on pages 15 - 18 of this manual)

NOTICE |

Please note that the brackets ([]) denote |

|

screen status. |

|

To save parameters and exit programming:

Press the RIGHT SELECT [SAVE] key and then press the RIGHT SELECT [HOME] key.

To enter a parameter and continue programming:

Press the RIGHT SELECT [SAVE] key 1 time to return to the parameter listings; press again to return to the menu listings. Remember to press the RIGHT SELECT [HOME] key when finished programming in order to save the changes made.

10

10

Service Manual

1 Service (continued)

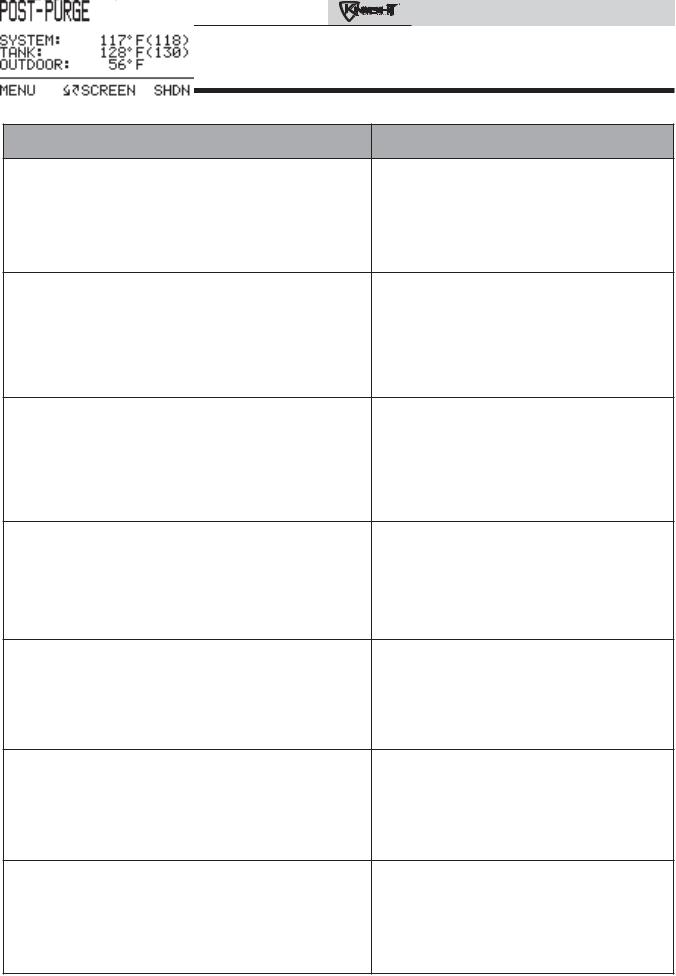

Table 1-1 Sequence of Operation

OPERATION |

DISPLAY |

1.Upon a call for heat, the gas pressure switch(es) must be closed.

2.Once the gas pressure switch(es) are closed, the control turns on the appropriate pumps (system and boiler pumps for space heating, DHW pump for DHW). The flow switch and/or LWCO must close.

3.The control turns on power to the louver relay. The louver proving switch, air pressure switch, and blocked drain switch must close.

4.The control starts the prepurge cycle by initiating the blower.

5.The control starts the trial for ignition by firing the spark electrode and opening the gas valve.

6.If flame is not detected after the sparking ends, the control will perform a postpurge, then start another prepurge cycle and try to light the burner again. The control will perform a total of 4 attempts before locking out.

7.If flame is detected, it holds the firing rate steady for a few seconds to let the flame stabilize, then it begins to modulate the firing rate based on a set point or some other command (such as a 0-10V BMS signal).

11

11

Service Manual

1 Service

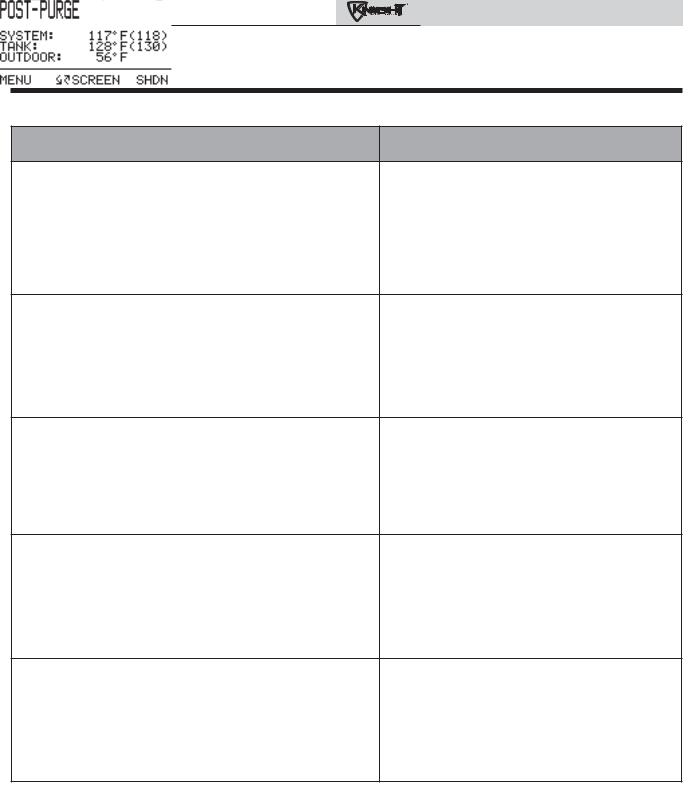

Table 1-1 (continued from previous page) Sequence of Operation

OPERATION |

DISPLAY |

8.If the space heating call for heat is active, and the tank thermostat or sensor starts a DHW call for heat, the boiler will switch to the DHW mode. If programmed for normal DHW operation (not as a zone), the DHW pump will turn on first, then the boiler pump will turn off 2 seconds later. This will divert the boiler’s outlet water from the heating system and send it to the tank coil instead. The control will then modulate to maintain the outlet temperature to the DHW boiler set point.

9.If the boiler is not part of a Cascade, and both the space heating and DHW calls for heat remain active long enough, the boiler will switch back and forth between the two heating modes until one of them is satisfied.

10.Once both calls for heat are satisfied, the control will turn off the burner. The blower will continue to run during the postpurge period.

11.Any pumps that are running will continue to run for their respective pump delay times before turning off, unless programmed to remain on continuously. A 60 second anti-cycle period will start, which will delay any new call for heat until it times out.

12.In Standby, ready to start a new cycle.

12

12

|

|

|

Service Manual |

1 Service (continued) |

|

||

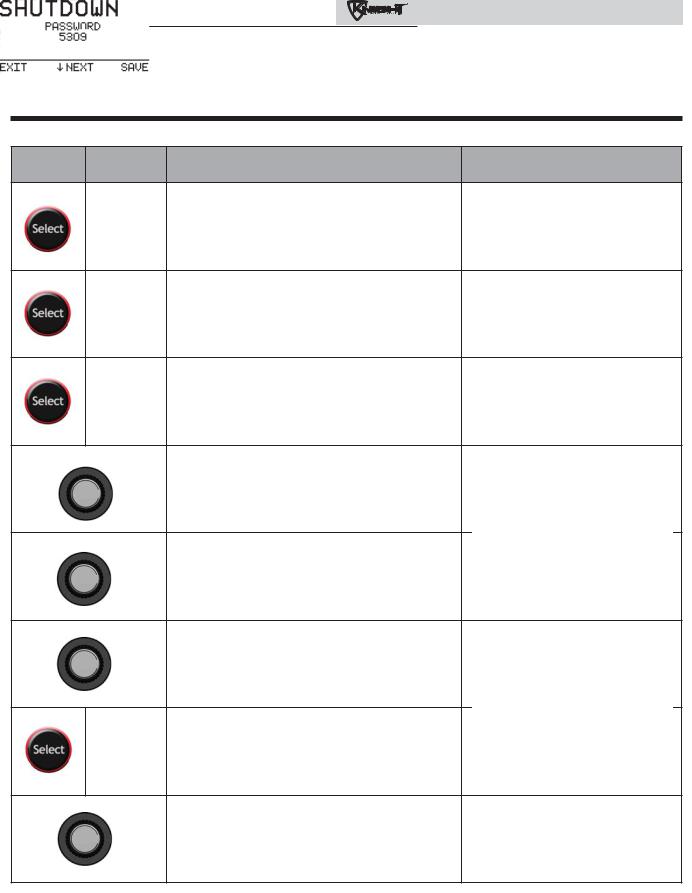

Display panel menu access |

|

||

Table 1-2 Use this procedure to access menus from the display panel |

|

||

BUTTON |

SCREEN |

OPERATION |

DISPLAY |

STATUS |

|||

|

[SHDN] |

Press the RIGHT SELECT soft key [SHDN]. |

|

|

[YES] |

Press the LEFT SELECT soft key [YES]. |

|

|

|

[MENU] |

Press and hold the LEFT SELECT soft key [MENU] |

|

for five (5) seconds. |

||

|

Rotate the NAVIGATION dial clockwise until 5 is displayed (first digit on the left).

Press the NAVIGATION dial to select the next digit. Rotate the NAVIGATION dial clockwise until 3 is shown in the display.

Press the NAVIGATION dial 2 times to move to the last digit. Rotate the NAVIGATION dial counterclockwise until 9 is displayed.

|

[SAVE] |

Press the RIGHT SELECT soft key [SAVE]. |

|

|

|

|

|

|

|

|

|

Rotate the NAVIGATION dial counterclockwise to select a category.

13

13

Service Manual

1 Service

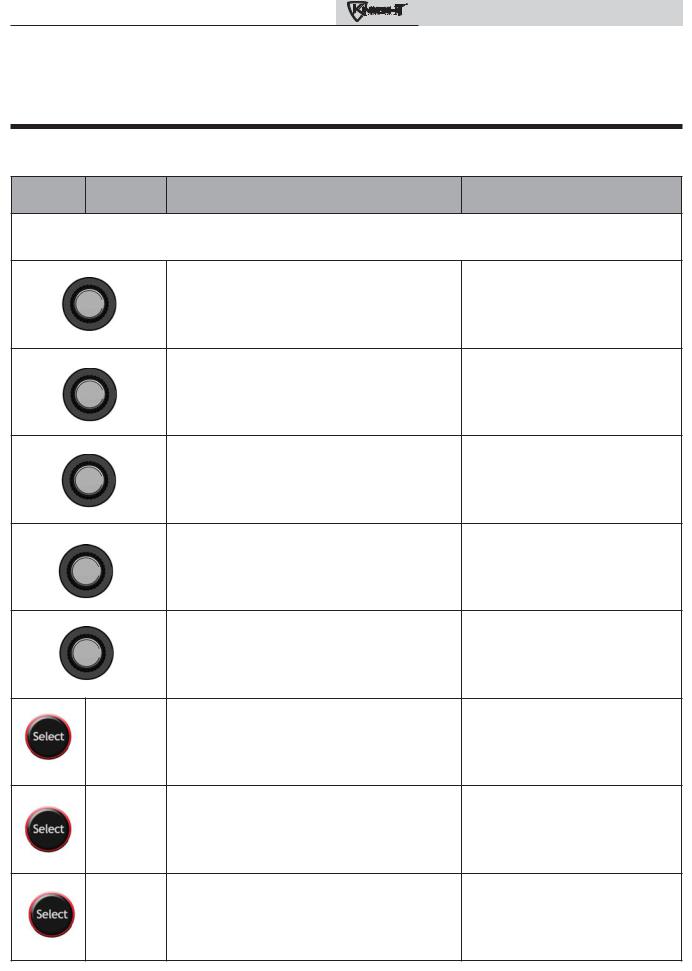

Display panel parameter access

Table 1-3 This is a typical example of accessing, adjusting, and saving a parameter, shown for parameter Temperature Settings, MIN SH Setpt

BUTTON |

SCREEN |

OPERATION |

DISPLAY |

STATUS |

This example shows how to access parameter Temperature Settings. The first display shown is at the beginning of the menu listings, after entering the installer access code.

Rotate the NAVIGATION dial counterclockwise until the arrow (>) is next to TEMPERATURE SETTINGS.

Press the NAVIGATION dial one time.

Rotate the NAVIGATION dial counterclockwise until the arrow (>) is next to MIN SETPT.

Press the NAVIGATION dial one time.

Rotate the NAVIGATION dial to the desired temperature.

|

[SAVE] |

Press the RIGHT SELECT soft key [SAVE] one time. |

|

|

|

||

|

|

|

|

|

|

|

|

[EXIT] |

Press the LEFT SELECT soft key [EXIT] if all desired |

|

changes have been made. |

||

|

|

[HOME] |

Press the LEFT SELECT soft key [HOME]. |

|

|

|

||

|

|

|

|

|

|

|

|

14

14

Service Manual

1 Service (continued)

Parameter table

Table 1-4 This table lists SMART SYSTEM control module parameters and where to access them

Menu

GENERAL

SETTINGSTEMPERATURE

DATA LOGGING

LOGGING

FUNCTIONS

Description |

See |

User Access |

Installer Access |

|||

|

|

|

|

|||

Page |

Display |

Modify |

Display |

Modify |

||

|

||||||

Time and Date |

19 |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

Software Version (read only) |

19 |

No |

No |

Yes |

No |

|

|

|

|

|

|

|

|

Temperature Units (ºC/ºF) |

19 |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH Night Setback Offset |

19 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH Night Setback On Times |

19 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH Night Setback Off Times |

19 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

DHW Night Setback Offset |

19 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

DHW Night Setback On Times |

19 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

DHW Night Setback Off Times |

19 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

Display Timeout |

20 |

No |

No |

Yes |

Yes |

|

SH1 Set Point |

20 |

Yes |

Yes |

No |

No |

|

|

|

|

|

|

|

|

Minimum SH Set Point |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

Maximum SH Set Point |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH1 Offset |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH1 Differential |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH2 Set Point |

20 |

Yes |

Yes |

No |

No |

|

|

|

|

|

|

|

|

SH2 Offset |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH2 Differential |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH3 Set Point |

20 |

Yes |

Yes |

No |

No |

|

|

|

|

|

|

|

|

SH3 Offset |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

SH3 Differential |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

3-Way Valve Time |

20 |

No |

No |

Yes |

Yes |

|

Reset Log Errors |

20 |

No |

No |

Yes |

Yes |

|

Service Mode Delay |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

Freeze Protection Pump On |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

Freeze Protection Burner On |

20 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

Freeze Protection Burner Differential |

21 |

No |

No |

Yes |

Yes |

|

|

|

|

|

|

|

|

15

15

Loading...

Loading...