Lincoln Impinger II - Advantage User Manual

SERVICE MANUAL

(DOMESTIC)

IMPINGER CONVEYOR OVENS

IMPINGER II - ADVANTAGE SERIES

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

United States of America

Phone: (800) 374-3004

U.S. Fax: (888) 790-8193 • Int’l Fax: (260) 436-0735

Technical Service Hot Line

(800) 678-9511

www.lincolnfp.com

1100AdvSvc |

REV 3/20/08 |

TABLE OF CONTENTS |

|

TABLE OF CONTENTS |

2 |

SEQUENCE OF OPERATIONS |

4 |

SEQUENCE OF OPERATIONS |

5 |

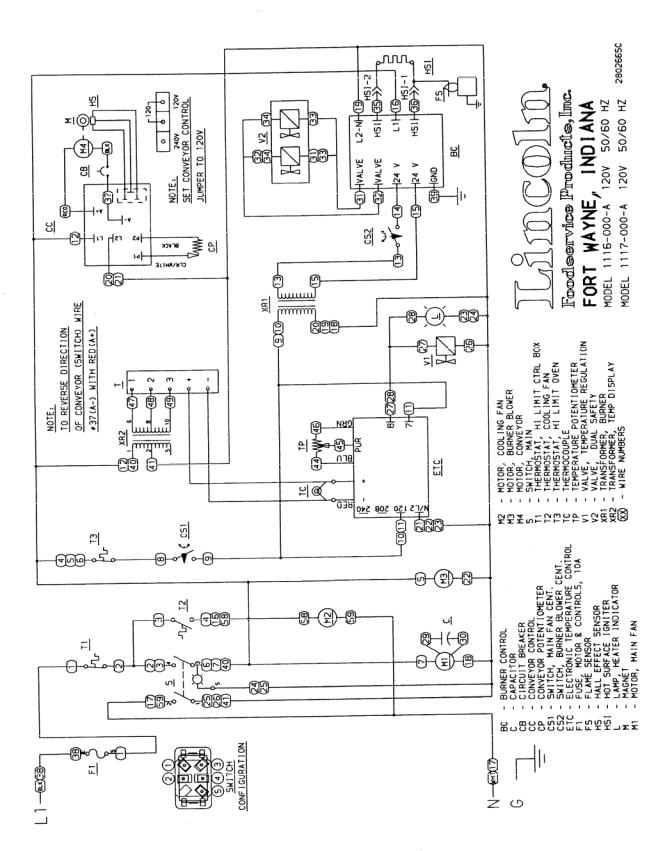

SCHEMATIC 1116-000-A, 1117-000-A |

6 |

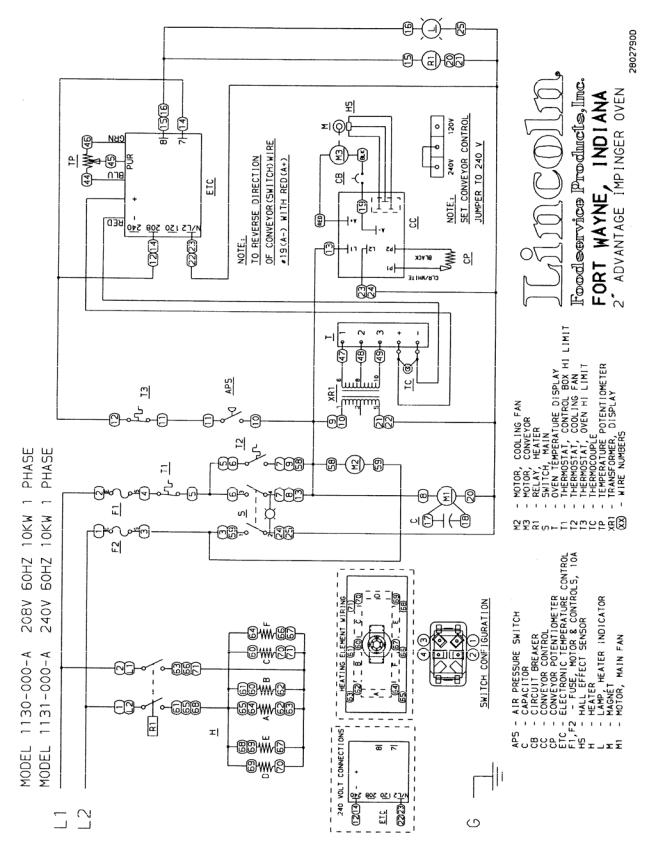

SCHEMATIC 1130-000-A / 1131-000-A |

7 |

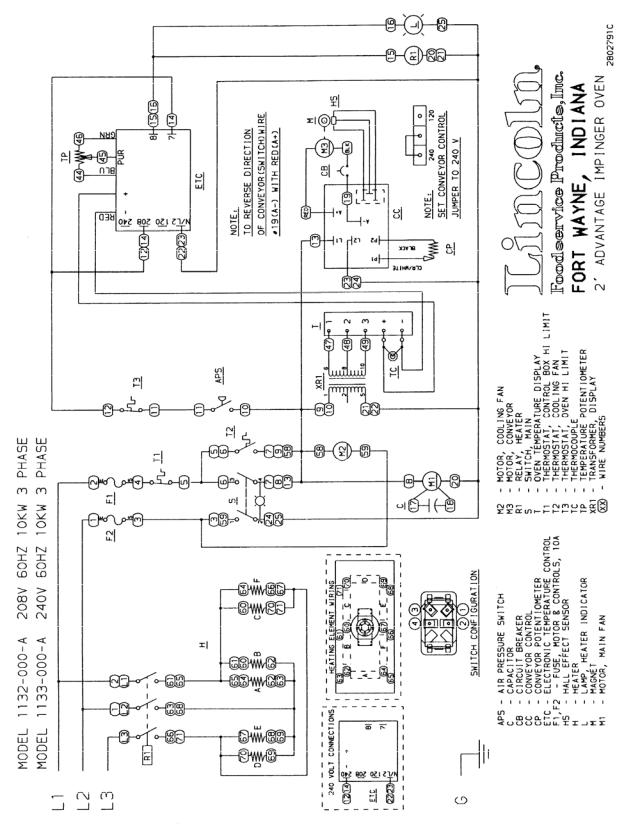

SCHEMATIC 1132-000-A / 1133-000-A |

8 |

TROUBLESHOOTING GUIDE / GAS OVENS |

9 |

TROUBLESHOOTING GUIDE / ELECTRIC OVENS |

14 |

REMOVAL, INSTALLATION, AND ADJUSTMENT |

18 |

PARTS / GENERAL |

26 |

BLOW UP / GENERAL |

27 |

PARTS / CONTROL BOX 1116-000-A, 1117-000-A |

28 |

BLOW UP / CONTROL BOX – 1116-000-A, 1117-000-A |

29 |

PARTS / CONTROL BOX – 1130-000-A THRU 1133-000-A |

30 |

BLOW UP / CONTROL BOX – 1130-000-A THRU 1133-000-A |

31 |

PARTS / CONVEYOR & DOOR |

32 |

BLOW UP / CONVEYOR & DOOR |

33 |

PARTS / OVEN BACK ASSEMBLY |

34 |

BLOW UP / OVEN BACK ASSEMBLY |

35 |

2 |

Impinger II – Advantage Service Manual - Domestic |

SEQUENCE OF OPERATIONS

IMPINGER II ADVANTAGE

MODEL 1116-000-A / NATURAL GAS / 120 VAC / 60 HZ / 1 PHASE

MODEL 1117-000-A / L.P. GAS / 120 VAC / 60 HZ / 1 PHASE

POWER SUPPLY |

Electrical power is supplied to the oven by a three conductor cordset. Voltage |

|

from the black conductor to the white conductor is 120 VAC. The white |

|

conductor is neutral. The green conductor is ground. |

CONTROL BOX AUTO |

When the temperature in the control box reaches 120°F ± 3° (48.9°C ± 1.7°C), |

|

the |

COOL DOWN |

interrupt power to the fans when the control box temperature falls to 100°F ± 3° |

|

(37.8°C ± 1.7°C). |

MAIN FAN CIRCUIT |

Power is permanently supplied, through a 10A fuse, and through a normally |

|

closed control box hi-limit thermostat, to the normally open main fan switch. |

|

Power is also supplied to the normally open cooling fan thermostat. Closing the |

|

main fan switch supplies 120 VAC to the main fan motor, the cooling fan motor, |

|

the primary of the temperature display transformer, the heat and conveyor |

|

circuits. |

BURNER CIRCUIT |

Closing the main fan switch supplies 120 VAC to the burner blower motor. 120 |

|

VAC is also supplied, through the normally closed oven cavity hi-limit thermostat, |

|

the main fan centrifugal switch (this switch closes when main fan reaches |

|

approximately 1600 RPM) to the electronic temperature control and to the |

|

primary of the burner transformer. |

IGNITION CONTROL |

The ignition control operates on both 24 VAC and 120 VAC. When the control is |

|

energized by 24 VAC from the transformer, 120 VAC is switched by the ignition |

|

control to the hot surface ignitor for 45 seconds for the hot surface ignitor warm |

|

up. The ignitor glows red, 24 VAC is switched to the gas valve which opens and |

|

ignition should now occur. |

TEMPERATURE CONTROL |

When the centrifugal switch of the main fan motor closes, power is applied to the |

|

temperature control. The 1K ohm temperature pot is adjusted to desired |

|

temperature. The thermocouple will provide varying millivolts to the temperature |

|

controller. The temperature controller supplies 120 VAC to the solenoid valve at |

|

intermittent intervals to maintain desired temperature. The heat lamp is |

|

energized with the solenoid valve. |

CONVEYOR DRIVE |

Closing the on/off switch supplies 120 VAC to the motor control board. AC volts |

|

are converted to DC volts and are supplied to the conveyor motor at terminals A+ |

|

and A-. |

|

Adjustment of the speed control potentiometer will change resistance at terminals |

|

P1 and P2 varying the DC voltage to the motor. The speed of the conveyor |

|

motor will increase or decrease as the DC voltage from the board increases or |

|

decreases respectively. |

NOTE: |

The conveyor control uses a sensor and magnet, mounted on the conveyor |

|

motor that senses the motor speed. Any change in motor load (±RPM) is |

|

detected by the sensor and the voltage to the motor is adjusted accordingly. |

Temperature Display |

Closing the switch supplies 120 VAC to the primary of the temperature display |

|

transformer. The secondary of this transformer supplies 12 VAC to the temperature |

|

display. The thermocouple supplies D.C. millivolts to the temperature display. The |

|

display converts this millivolt reading to a temperature reading. |

Impinger II –Advantage Service Manual - Domestic |

3 |

SEQUENCE OF OPERATIONS

|

1130-000-A / 208V / SINGLE PHASE |

|

1131-000-A / 240V / SINGLE PHASE |

|

1132-000-A / 208V / THREE PHASE |

|

1133-000-A / 240V / THREE PHASE |

POWER SUPPLY |

Electrical power to be supplied to the oven by a three-conductor service on single |

|

phase and a four-conductor service on three phase. |

|

Black conductor is Hot |

|

Red conductor is Hot |

|

Orange conductor is Hot (Used on 3 phase only) |

|

Green conductor is ground. |

CONTROL BOX AUTO COOL DOWN |

When the temperature in the control box reaches 120°F ± 3°F (48.9°F ± 1.7°C), |

|

the cooling fan thermostat will switch power to the cooling fans. The thermostat |

|

will interrupt power to the fans when the temperature falls to 100°F ± 3°F (37°C ± |

|

1.7°C). |

MAIN FAN CIRCUIT |

Power is permanently supplied through the 10A fuses, through the normally |

|

closed control box high limit thermostat, to the normally open main fan switch. |

|

Power is also supplied to the normally open cooling fan thermostat. Closing the |

|

main fan switch supplies 208/240 VAC to the main fan motor, the cooling fan |

|

motor, to the primary of the temperature display transformer and to the heat and |

|

conveyor circuits. |

HEATER CIRCUIT |

Closing the fan switch supplies 208/240 VAC, through the normally open air |

|

pressure switch (closed by air pressure from the main fan) through the normally |

|

closed oven cavity hi-limit thermostat, to the electronic temperature control. The |

|

1K ohm temperature pot is adjusted to desired temperature. The thermocouple |

|

will provide varying millivolts to the temperature controller. The temperature |

|

control then supplies 208/240 VAC to the coil of the contactor at intermittent |

|

intervals to maintain the desired temperature. The heat lamp is energized with |

|

the contactor. |

CONVEYOR DRIVE |

Closing the on/off switch supplies 120 VAC to the motor control board. AC volts |

|

are converted to DC volts and are supplied to the conveyor motor at terminals A+ |

|

and A-. |

|

Adjustment of the speed control potentiometer will change resistance at terminals |

|

P1 and P2 varying the DC voltage to the motor. The speed of the conveyor |

|

motor will increase or decrease as the DC voltage from the board increases or |

|

decreases respectively. |

NOTE: |

The conveyor control uses a sensor and magnet, mounted on the conveyor |

|

motor that senses the motor speed. Any change in motor load (±RPM) is |

|

detected by the sensor and the voltage to the motor is adjusted accordingly. |

Temperature Display |

Closing the switch supplies 120 VAC to the primary of the temperature display |

|

transformer. The secondary of this transformer supplies 12 VAC to the |

|

temperature display. The thermocouple supplies D.C. millivolts to the |

|

temperature display. The display converts this millivolt reading to a temperature |

|

reading. |

4 |

Impinger II – Advantage Service Manual - Domestic |

SCHEMATIC 1116-000-A, 1117-000-A

Impinger II –Advantage Service Manual - Domestic |

5 |

SCHEMATIC 1130-000-A / 1131-000-A

6 |

Impinger II – Advantage Service Manual - Domestic |

SCHEMATIC 1132-000-A / 1133-000-A

Impinger II –Advantage Service Manual - Domestic |

7 |

TROUBLESHOOTING GUIDE / GAS OVENS

|

MODEL 1116-000-A |

NATURAL GAS |

120 VAC |

60 HZ |

1 PHASE |

|||

|

MODEL 1117-000-A |

LP GAS |

|

120 VAC |

60 HZ |

1 PHASE |

||

|

|

|

|

|

|

|

||

|

SYMPTOM |

POSSIBLE CAUSE |

EVALUATION |

|

|

|

||

|

Oven fan will not run |

Incoming Power Supply |

Check breakers, reset it required. Check power plug |

|||||

|

|

|

|

to be sure it is firmly in receptacle. Measure |

||||

|

|

|

|

incoming power/call power company if needed. |

||||

|

|

Fuse, 10 Amp |

|

Check, replace if necessary. |

|

|

||

|

|

Fuse Holder |

|

Check, replace if necessary. |

|

|

||

|

|

Hi Limit Thermostat-Control |

Check for voltage on both sides of the switch. |

|||||

|

|

Box |

|

Terminals are normally closed. If open, reset and |

||||

|

|

|

|

test oven for proper operation. If thermostat will not |

||||

|

|

|

|

hold and control box temperature is not exceeding |

||||

|

|

|

|

140°F (60°), replace thermostat. |

||||

|

|

Main Fan Switch |

|

Check continuity between switch terminals. |

||||

|

|

Main Fan Motor |

|

Check for opens, shorts, or grounds. WITH POWER |

||||

|

|

|

|

OFF turn fan blade to check for locked rotor. |

||||

|

|

Capacitor |

|

Check for shorts or grounds. |

|

|

||

|

|

|

|

WARNING: Capacitor has a stored charge, |

||||

|

|

|

|

discharge before testing. |

|

|

||

|

No control box cooling |

Incoming Power |

|

Check main circuit breakers, reset if required, call |

||||

|

|

|

|

power company if needed. |

|

|

||

|

|

Main Fan Switch |

|

Check continuity between switch terminals |

||||

|

|

Cooling Fan |

|

120 VAC should now be at the fan motor. If voltage |

||||

|

|

|

|

is present, check motors for shorts or opens. WITH |

||||

|

|

|

|

POWER OFF: Check for locked rotor. |

||||

|

No automatic control |

Incoming Power Supply |

Check circuit breakers, |

|

|

|||

|

box cooling |

|

|

reset if required. Call the power company if needed. |

||||

|

|

Cooling Fan Thermostat |

Check the cooling fan thermostat. (Thermostat |

|||||

|

|

|

|

closes at 120°F and opens at 100°F). With the |

||||

|

|

|

|

cooling fan thermostat preheated, check for |

||||

|

|

|

|

continuity. If switch is open, replace. |

||||

|

|

Cooling Fan |

|

120 VAC should be at the motor. If voltage is |

||||

|

|

|

|

present, check motor for shorts, opens, or grounds. |

||||

|

|

|

|

WITH POWER OFF: check for locked rotor. |

||||

|

Oven will not heat |

Gas Supply |

|

Check for adequate gas supply and closed manual |

||||

|

|

|

|

gas shut offs. Also, check flexible gas line |

||||

|

|

|

|

connection. |

|

|

|

|

|

|

Main Fan |

|

If not operating, refer to "Oven fan will not run". |

||||

|

|

High Limit Oven Cavity |

Terminals are normally closed. If |

|||||

|

|

Thermostat |

|

open, push in reset button and retest. If thermostat |

||||

|

|

|

|

will not hold for maximum oven temperature, and |

||||

|

|

|

|

oven is not exceeding temperature dial setting, |

||||

|

|

|

|

check for proper location of capillary bulb in its |

||||

|

|

|

|

spring holder. If above checks okay, replace hi-limit |

||||

|

|

|

|

thermostat. |

|

|

|

|

|

|

Centrifugal Switch |

Check for 120 VAC at lead #9 |

|

|

|||

|

|

of Main Fan Motor |

(located at 6 pin connector in raceway near the main |

|||||

|

|

|

|

fan motor) to neutral. If no voltage is present, and |

||||

|

|

|

|

motor is running, replace motor. |

||||

8 |

|

|

|

Impinger II – Advantage Service Manual - Domestic |

||||

|

Burner Blower Motor |

Visually check to see if motor is running. If not, |

|

|

check for 120 VAC to motor at motor connector (wire |

|

|

#5 and #22). If voltage is not present, trace wiring |

|

|

back to fan switch. If voltage is present and motor is |

|

|

not running, check for opens, shorts, or grounds. |

|

|

Also, WITH POWER OFF: check for locked rotor. |

|

Transformer, Burner |

Primary is 120 VAC with 24 VAC secondary. If 120 |

|

|

VAC is not present, trace wiring back to Main Fan |

|

|

Centrifugal Switch. If 120 VAC is present, check for |

|

|

24 VAC at secondary of transformer. If no voltage is |

|

|

present, replace transformer. |

|

Centrifugal Switch of Burner |

Check of 120 VAC at motor connector, on wire #13 |

|

Blower Motor |

to neutral. If voltage is not present, trace wiring back |

|

|

to transformer. If voltage is not present and motor is |

|

|

running, replace the burner blower motor. |

|

Ignition Control |

24 volts should be present at 24 volt terminals. If not |

|

|

present, trace wiring back to centrifugal switch. |

|

|

When 24 VAC is supplied, the control switches 120 |

|

|

VAC from L1 and L2 to the hot surface ignitor. if 120 |

|

|

VAC is not present at L1 and L2, trace wiring |

|

|

back to fan switch. If 24 VAC and 120 VAC are |

|

|

present and 120 VAC is not across the hot surface |

|

|

ignitor terminals, replace the ignition control. |

|

Hot Surface Ignitor |

If 120 VAC is present at hot surface ignitor terminals, |

|

|

visually check to see that the ignitor is heating. |

|

|

(Ignitor may be viewed through the port glass in end |

|

|

of burner tube.) The ignitor should glow bright red. |

|

|

If the ignitor does not heat, replace the ignitor. |

|

Ignition Control |

After 45 seconds of hot surface ignitor pre-heat, the |

|

|

ignition control will switch 24 VAC to the gas control |

|

|

valves. Check for 24 VAC output from ignition |

|

|

control, across terminals marked "valve" and "valve |

|

|

ground". If no voltage is present, replace ignition |

|

|

control. |

|

Gas Control Valves |

When 24 VAC is supplied to the gas control valve, |

|

|

the valve should open. Check for gas pressure at |

|

|

the manifold tap located just before the burner. If |

|

|

there is no pressure, check the incoming gas supply |

|

|

to be sure all manual valves are open and flexible |

|

|

gas hose is properly connected. If gas is present |

|

|

and coils of gas valve are energized, the gas valve is |

|

|

probably defective. |

Flame will not stay lit |

Hot Surface Ignitor |

Six seconds after the gas valve opens, ignition must |

|

|

occur. if flame is not detected, the ignition control |

|

|

will shut off and lock out. To reset the ignition |

|

|

control, turn off the burner switch for 45 seconds, |

|

|

then turn on the burner switch to retry ignition. The |

|

|

ignition control requires a minimum of 0.8 D.C. |

|

|

microamps. To check flame sensing operation, |

|

|

connect a digital multimeter (capable of measuring |

|

|

D.C. micro-amps) between the "ground" terminal on |

|

|

ignition control and the ground lead. |

|

|

NOTE: This is a current measurement and the |

|

|

meter must be connected in series. If these |

|

|

readings are not achieved, replace the hot surface |

|

|

ignitor. |

|

|

NOTE: The D.C. micro amp test must be conducted |

|

|

with the oven in low flame (bypass) operation. Turn |

|

|

the temperature control to the lowest setting. |

Impinger II –Advantage Service Manual - Domestic |

9 |

|

Power Supply |

If there is sufficient micro-amp current, but the flame |

|

|

will not stay lit, check for proper polarity of the 120 |

|

|

VAC power supply. |

|

Ignition Control |

If there is sufficient micro-amp current, and the 120 |

|

|

VAC polarity is correct, but the flame will not stay lit, |

|

|

replace ignition control. |

|

|

NOTE: Check for proper ground connection on |

|

NOTE: Flame should be lit at |

ignition control. |

|

|

|

|

this time. |

|

Low flame is on, |

Temperature Control |

Check for 120 VAC at terminal #7 |

but no main flame |

|

to neutral on temperature control. If no voltage, |

|

|

trace voltage back through centrifugal switch and hi- |

|

|

limit. Turn the temperature adjustment knob to |

|

|

maximum temperature position and check for 120 |

|

|

VAC at the load terminal #8 and neutral. If 120 VAC |

|

|

is present and unit is not heating, refer to |

|

|

"Temperature Solenoid Valve" for next check. If 120 |

|

|

VAC is not present, proceed. |

|

Thermocouple Probe |

WITH POWER ON AND THERMOCOUPLE LEADS |

|

|

ATTACHED TO THE TEMPERATURE CONTROL |

|

|

BOARD: Measure the D.C. millivolt output of these |

|

|

leads. Refer to thermocouple chart in Section D for |

|

|

proper readings. If these readings are not achieved, |

|

|

replace the thermocouple. |

|

Temperature Set |

Disconnect the potentiometer leads |

|

Potentiometer |

from the board. Place ohm meter test leads on the |

|

|

blue and green pot leads. Reading should be 1 K |

|

|

ohms. Place meter leads across the blue and purple |

|

|

pot leads and rotate knob from high to low. Repeat |

|

|

on green and purple leads. Check for even rise and |

|

|

fall of ohms reading to insure that there are no open |

|

|

or dead spots in the potentiometer. Check each |

|

|

lead to ground for shorts. Replace pot if it does not |

|

|

meet the above test. |

|

Temperature Solenoid |

If 120 VAC is present on the |

|

Valve |

temperature control board at load terminal #8 to |

|

|

neutral, check for voltage at temperature regulation |

|

|

valve. If voltage is present, listen for valve to open |

|

|

and close. Also check for opens or shorts in the coil. |

|

|

Replace as necessary. |

Intermittent Heating |

Thermal/Overload of Main Fan |

The main fan motor and the burner blower motor are |

|

and Burner Blower Motors |

equipped with internal thermal protection and will |

|

|

cease to operate if over heating occurs. As the |

|

|

motors overheat and then cool, this will cause the |

|

|

units to cycle on and off intermittently. This may be |

|

|

caused by improper ventilation or preventive |

|

|

maintenance. Also, most of the problems listed |

|

|

under "Oven will not heat" can cause intermittent |

|

|

failure. |

Conveyor will not run |

Voltage Supply |

Check incoming voltage supply at line 1 to neutral. |

|

|

There should be a voltage reading of 120 VAC. If |

|

|

not present, check breakers. |

|

10 Amp Fuse |

Check and/or replace. |

|

Fuseholder |

Check and/or replace. |

|

Fan Switch |

See procedure for checking on Page 10. |

10 |

Impinger II – Advantage Service Manual - Domestic |

|

Speed Adjustment |

This is a 0 to 10 K ohm, 1 turn potentiometer. With |

|

Potentiometer |

power off, remove the black and white pot leads |

|

|

from the motor control board at terminals P1, P2. |

|

|

Place the meter leads on the black lead (P2) and on |

|

|

the white lead (P1). Rotating the pot., slowly, from |

|

|

low to high, the meter readings should show an even |

|

|

transition from 0 to 10 K ohms ± 5%. There should |

|

|

be no dead or open spots through out the 1 turn of |

|

|

the pot. Check both leads to ground. There should |

|

|

be no continuity to ground. If any of the above |

|

|

checks fail, replace the pot. |

|

DC Motor Control Board |

Check for 120 VAC input to the control board at |

|

|

terminals L1 and L2. If not present, check wiring |

|

|

back to the oven fan switch. If 120 VAC is present |

|

|

at L1 and L2, check both fuses on control board (8A |

|

|

line and 1A armature), check the VDC output at |

|

|

terminals A+ and A-. If 120 VAC is present at |

|

|

terminals L1 and L2 and DC voltage is present at |

|

|

A+ and A-, but the motor does not run, check gear |

|

|

motor as follows: |

|

Conveyor Gear Motor |

If DC voltage is present at A+ and A- and the motor |

|

|

does not run, first check the mini breaker and then |

|

|

the conveyor. Refer to the next possible cause. |

|

|

Check the leads to the motor for evidence of any |

|

|

shorts or opens, and each lead to ground. Check |

|

|

motor brushes. From the top of the motor, rotate |

|

|

motor shaft to determine if there is a locked rotor or |

|

|

a locked gear box (use care so magnet and H.S. |

|

|

board are not damaged). Replace motor as needed. |

|

Conveyor |

Check for any mechanical misalignment. Also, |

|

|

check for worn bearings. A conveyor belt that is |

|

|

over tightened will cause excessive bearing wear |

|

|

and sometimes, irregular speed. |

Conveyor speed varying or |

Power Supply |

Check power supply at the DC control board for the |

intermittent |

|

120 VAC at board terminals L1 and L2. |

|

Motor Control Board |

Place the test meter probes on terminals A+ and A-. |

|

|

(With speed potentiometer set to maximum speed |

|

|

(Approximately 2 min.) The meter reading should be |

|

|

approximately 100 VDC (±3%), if voltage is not |

|

|

steady within limits, then the board is probably bad. |

|

|

Always check the speed pot., be sure it is okay |

|

|

before changing a board. This test is not always |

|

|

100% accurate as this test is not performed at |

|

|

operating speeds. However, this test is the best |

|

|

method currently available. |

|

DC Gearmotor |

If the DC control board is steady then the problem |

|

|

may be the motor or gearbox. Check the brushes in |

|

|

the motor for excessive arching and/or unusual |

|

|

wear. Check the motor and gearbox from instruction |

|

|

located on Page 11 under "possible cause" listing |

|

|

"conveyor gear motor." |

|

Magnet |

Check to insure that the magnet (cemented to shaft |

|

|

of conveyor drive motor) has not been damaged, or |

|

|

come loose from motor shaft. Replace as needed. |

|

Hall Effect Sensor |

Check for any physical damage to hall effect sensor |

|

|

(mounted on conveyor drive motor.) Check all wiring |

|

|

and connections for damage. Check all connections |

|

|

for tightness or proper location and check all wiring |

|

|

for visible damage. Replace as needed. Connect |

|

|

new hall effect to system and check for steady |

|

|

operation. |

Impinger II –Advantage Service Manual - Domestic |

11 |

|

Loading...

Loading...