Lincoln Electric Pipeliner 200D User Manual

Pipeliner® 200D |

ENGINE DRIVEN WELDERS |

|

200 Amp DC Diesel Engine Driven W

The Pipeliner® 200D, our 200-amp diesel engine driven welder, continues the long established reputation of Lincoln’s 200 amp pure DC generator welder for the cross-country pipeline welding industry. This is the diesel version of the Pipeliner® 200G gasoline engine driven product. It is similar to the older SA-200 and Classic® I gasoline engine driven products manufactured for years, many of which are still

in use today. The Pipeliner® 200D continues to use a DC exciter, as requested by the most discriminating operators. The Pipeliner® 200D runs at a speed slower than the more common 1800 RPM units, making this industrial product unique and especially suited to the needs of cross-country pipeline operators.

Processes

Stick, Flux-Cored(1), Gouging

Advantage Lincoln

Output

CV (1)

1.75

kW

Input

D

•Pure DC Generator Welding Output

−Produces the welding arc preferred by pipeline operators and contractors for precise code consistency!

•DC Exciter

−Supplies pure DC current to the welding generator as desired by the most discriminating operators.

•All Copper Windings

−Enhances arc stability for a really smooth, high performance arc.

•Custom Arc® Dial

−Dial in the right arc, right now! 150 RPM high idle OCV adjustment for enhanced fine tuning on pipe. (See inside)

•Five Current Ranges with Overlap

−For stick welding and other processes where slope control is desired. Fine-tuning within each range.

•200 Amps Output @ 60% Duty Cycle

−Welds up to 7/32" (5.6 mm) low hydrogen electrode.

•Reliable Industrial Diesel Engine

−4-Cylinder water-cooled Kubota® engine with electronic governor for precise speed control.

−Standard engine gauges allow you to monitor performance at a glance.

TECHNICAL SPECIFICATIONS

|

|

|

|

No. |

|

Dimensions |

|

Product |

Rated Output |

Output |

Engine |

of |

HP & Speed |

H x W x D |

Net Weight |

Name |

Current/Voltage/Duty Cycle |

Range |

Model |

Cyl. |

(rpm) |

inches (mm) |

lbs (kg) |

Pipeliner® 200D |

200A DC/40V/60% |

40-300 DC |

Kubota® |

4 |

27.8 @ 1600 |

45.5 x 24.0 x 68.0 |

1311 |

|

|

1750 watts |

V2403M |

|

|

(1156 x 610 x 1727) |

(595) |

|

|

DC Auxiliary Power |

EPA Tier 4i |

|

|

|

|

|

|

120V DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

(1) With Wire Feed Module. Rated at 200 amps, 35 volts at 60% duty cycle, 250 amps, 30 volts at 35% duty cycle.

Publication E6.132 4/05

Web Update 5/08 www.lincolnelectric.com

A CLOSER LOOK

PERFORMANCE

Arc Performance

•Pure DC generator welding arc is preferredby pipelinersand contractorsfor precise code consistency.

•DC exciterfor supplyingpure DC currentto the weldinggeneratoras desired by the most discriminatingoperators.

•All copper windings enhance arc stability.

•Custom Arc® 150 RPM high idle (OCV) adjustmentrange — enhanced fine tuning for performanceon pipe.

•200 amps DC @ 60% duty cycle, 104˚F (40˚C). Weld up to 7/32” (5.6mm) low hydrogenelectrode.

•Gouge with up to 5/32" (4.0 mm) carbons.

DC AuxiliaryPerformance

•1,750 total watts of DC auxiliary power from a single 120V outlet for grinders and lights. DC power is less likely to bog down a grinder comparedto AC power.(Not for use with AC voltage equipment.)

Use the High Idle (OCV) engine speed adjustmentdial to change the heat input to the arc:

•Set the arc in the machine’s“sweet spot”.

•Dial in a softer or more digging arc.

•Reduce root pass internal undercut,especiallyon X60 and X70 pipe.

•Stack iron faster with low heat and a clear puddle on fill passes.

•Avoid arc breaks. Avoid slag that crowds the arc.

•Control fusion on the cap pass with good puddle size and clarity.

FEATURES

•Quiet, smooth-running,4-cylinder,water-cooledKubota® industrial diesel engine with electronicgovernor for precise speed control.

•Noise at 200A/40V rated output: 97.9 dB sound power (Lwa), 73.6 dBA at 23 ft. (7 m)

•Five overlappingcurrent ranges for stick pipe welding and other processeswhere slope control is desired. Fine-tuningwithin each range providesprecise control.

•Gauges indicate oil pressure,engine temperatureand battery charging amps.

•Single-sideengine access for easy routine maintenance.

•Oil drain system is standard.Includes ball valve and hose to direct oil beyond the base of the machine.

•Compact size for installationon truck beds.

•Local/Remoteswitch and remote receptacleare factory installed to allow easy connectionof the optional remote control.

Stick Welding

•Optional K924-5 Remote Control Kit for stick welding includes remote box and 100 ft. (30.5m) cable. Make fine current adjustments at the work, not back at the welder.

Wire Welding

•Optional Wire Feed Module for CV-wirewelding. Increasesproductivity and reduces welding costs. Use LN-25 or LN-15 Across-The- Arc wire feeders. Built-in contactor for “cold-tip”electrode.(When CV wire welding with optional Wire Feed Module, idler may need to be set to “high” position for low current processes.)

•Optional K2464-1 Remote Control Kit for stick and wire welding. For machines that have the K623-1 Wire Feed Module installed.Make output adjustmentsup to 100 ft. from the machine.

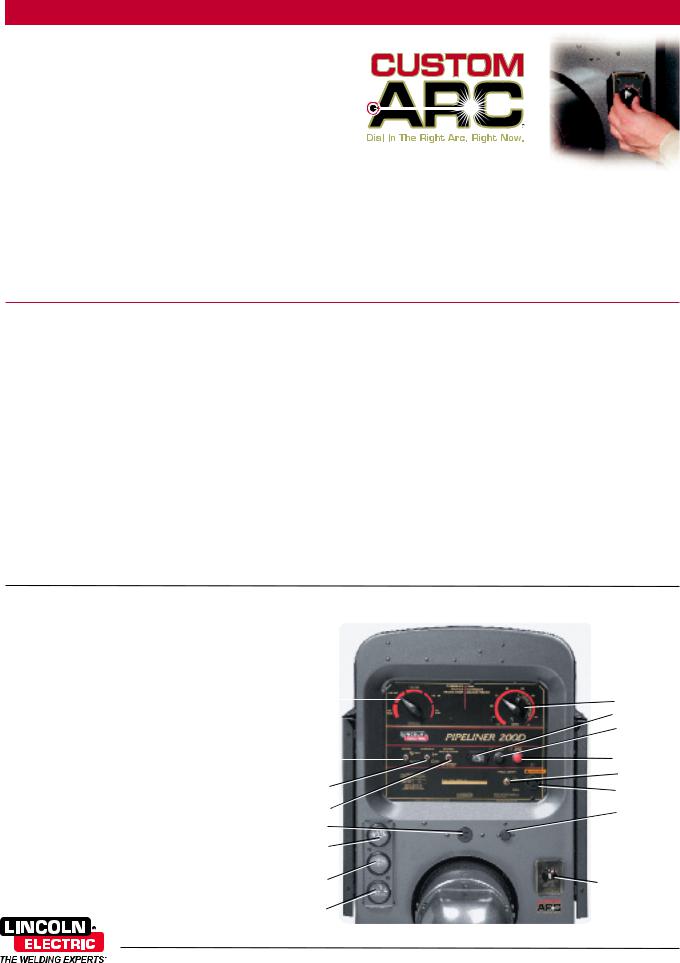

Key Controls

1.Current Range Selector

2.Idler Control Switch

3.On/Off Switch

4.Engine Protection Light

5.120V DC Receptacle

6.Engine Temperature Gauge

7.Battery Charging Ammeter

8.Engine Oil Pressure Gauge

9.Fine Current Adjustment

10.Engine Hour Meter

11.Start Button

12.Glow Plug Button

13.Local/Remote Control Switch

14.Local/Remote Control Receptacle

15.15 Amp Fuse for auxiliary receptacle and remote

16. Custom Arc® High Idle Speed (OCV) Adjustment Dial

1. |

|

|

9. |

|

|

||||

|

|

|

10. |

|

|

|

|

11. |

|

2. |

|

|

|

12. |

|

|

|

||

3. |

|

|

13. |

|

|

|

14. |

||

|

|

|

||

4. |

|

|

15. |

|

5. |

|

|

|

|

6. |

|

|

|

|

7. |

|

|

16. |

|

8. |

|

|

|

|

|

|

|

|

Pipeliner® 200D |

[2] |

|

www.lincolnelectric.com |

||

Loading...

Loading...