Lifebreath RNC120F, 120ERV User Manual

Models RNC120F/120ERV

Shipping and Packing List

Package 1 of 1 contains: 1 - Assembled ventilator

1 - Bag assembly containing:

4 - Hanging straps

1 - Installation manual

1 - Remote electrical control box

1 - Bag containing sealant putty

Required Tools

Installation Tools

• |

tin snips |

• |

large zip ties |

• |

assorted screw drivers |

• |

fabric flexible duct |

• |

electric drill |

|

- class I rated |

• |

hammer |

• |

mastic tape |

• |

wire strippers |

• |

alum. foil duct tape |

• |

knife |

• |

zip ties |

• |

caulking gun |

• |

1/2” I.D. drain hose |

•smoke pencil

Balancing Tools

•Pitot Tube Balancing Kit

[Case, 8 ft. vinyl tubing, Pitot tube, magnehelic gauge (0 - 0.25”), and mounting plate]

or

•Pitot Tube with instructions

and Digital Manometer (with resolution of 0 - 0.25” - must read to 1/100ths of an inch)

Optional Accessories

•20 Minute Fan Timer

•Wall Mounted Dehumidistat

•Weather hood Kit

•Round Diffuser

4” (100mm) 5” (125mm) 6” (150mm) 8” (200mm)

•Kitchen Grille

-may be required by code for kitchen applications

-contains removable grease filter

Application

Heat Recovery Ventilators (HRV) are designed to provide fresh air while exhausting an equal amount of stale air.

The HRV is equipped with an aluminum core. The device uses the stale air that is being exhausted to condition the fresh air as it is being brought in.

General

These instructions are intended as a general guide and do not supersede local codes in any way. Consult authorities who have jurisdiction before installation.

Table of Contents

Shipping and Packaging List ...................................... |

1 |

Required Tools............................................................ |

1 |

Application .................................................................. |

1 |

General ....................................................................... |

1 |

Engineering Data ..................................................... |

2-5 |

Installation Instructions ............................................... |

6 |

Clearances & Requirements ....................................... |

7 |

Installation.............................................................. |

7-10 |

Application Illustrations ........................................ |

11-16 |

Remote Control Devices ........................................... |

17 |

Wiring the Controls ................................................... |

18 |

Electrical .................................................................. |

19 |

Operation .................................................................. |

20 |

Wiring Diagrams ....................................................... |

21 |

Interlocking HRV to Furnace..................................... |

22 |

Air Flow Balancing ............................................... |

24-25 |

Troubleshooting ........................................................ |

26 |

Maintenance ............................................................ |

27 |

* LEAVE FOR HOMEOWNER |

|

|

TI-CCU-001 |

NOTE: Due to ongoing research and product development, specifications, |

|

|

0108 |

ratings and dimensions are subject to change without notice. |

|

Engineering Data |

Model RNC120F |

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

Each Air stream has an independent motorized impeller. 3 speed operation 120VAC

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced polyester straps that are supplied with the unit.

DEFROST

Fan defrost system. Fresh air motor turns off and Exhaust motor switches to high speed to defrost core.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation. Drain connection 1 - 1/2" (12 mm) OD.

CONTROLS

Unit is supplied with a remote HRV control box which can be conveniently located within 3’-0” of the HRV.

HRV System Control

HRV defaults to LOW SPEED when plugged in. HIGH SPEED option is accessible by connecting remote controls to designated terminals inside electrical box of HRV.

Standard LOW SPEED SETTING can be increased to medium low.

Off (Standby)/Low or OFF/HIGH speed operation is also available.

DUCT CONNECTIONS

5” duct connections with “field” selectable standard airflow or reverse airflow for limited room installations.

WEIGHT 42 lbs. (19 kg)

SHIPPING WEIGHT 45 lbs. (20.5 kg)

OPTIONAL ACCESSORIES

99-132 20 Minute Fan Timer - initiates high speed ventilation for 20 minutes. (3 wire) 20 gauge wire (min.) 100’ length

99-101 Crank Timer

99-116 Dehumidistat Ventilation Control - Dehumidistat with ON/OFF 99-130 Dehumidistat Control - Dehumidistat

99-185 Weatherhoods, Two - 5” (125mm) c/w 1/4” (6mm) mesh screen

99-2040 20/40 ON/OFF Dehumidistat

WARRANTY

Units carry a lifetime warranty on the heat recovery core and a five year replacement parts warranty.

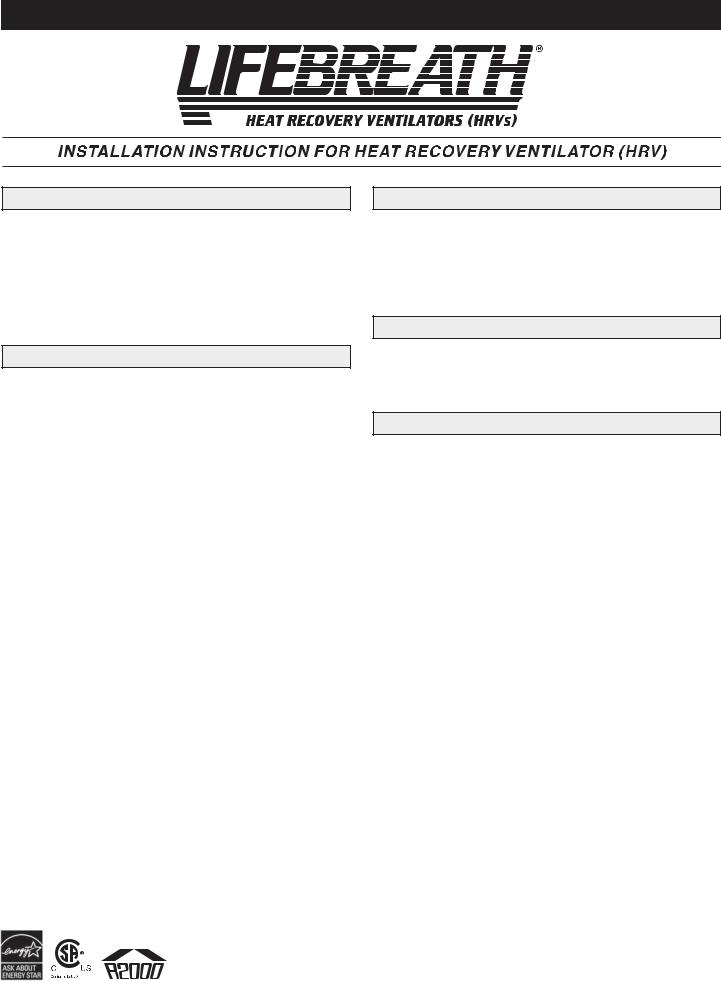

TOP VIEW |

|

EXHAUST |

FRESH AIR |

TO BUILDING |

|

AIR FROM |

|

BUILDING |

|

18” |

All Duct Collars are |

FRESH AIR |

5" diameter (127 mm) |

|

|

FROM |

EXHAUST AIR |

OUTSIDE |

|

|

TO OUTSIDE |

9” |

|

19” |

SERVICE CLEARANCE FROM |

BOTTOM OF UNIT IS MINIMUM 3'0" |

Performance

Net supply air flow in cfm (L/s) against external static pressure

E.S.P |

|

|

|

(external static pressure) |

|

[cfm (L/s)] |

|

@ 0.1" (25 Pa) |

|

125 |

(59) |

@ 0.2" (50 Pa) |

|

120 |

(56) |

@ 0.3" (75 Pa) |

|

114 |

(54) |

@ 0.4" (100 Pa) |

|

109 |

(51) |

@ 0.5" (125 Pa) |

|

106 |

(50) |

@ 0.6" (150 Pa) |

|

99 |

(47) |

@ 0.7" (175 Pa) |

|

94 |

(44) |

@ 0.8" (200 Pa) |

|

89 |

(42) |

|

|

|

|

Sensible Effectiveness |

|

|

|

@ 65 cfm (30 L/s) |

32°F (0°C) |

72% |

|

*Sensible Efficiency |

|

|

|

@ 65 cfm (30 L/s) |

32°F (0°C) |

55% |

|

*Sensible Efficiency |

|

|

|

@ 65 cfm (30 L/s) |

-13°F (-25°C) |

45% |

|

VAC @ 60HZ |

|

|

120 |

WATTS / Low speed. |

|

|

63 |

|

|

|

|

WATTS / High speed |

|

|

150 |

|

|

|

|

Amp rating |

|

|

1.5 |

*Sensible Efficiency - thermal **Latent Efficiency - moisture

Note: Effectiveness - based on temp. differential between the 2 airstreams Efficiency - takes into account all power inputs

|

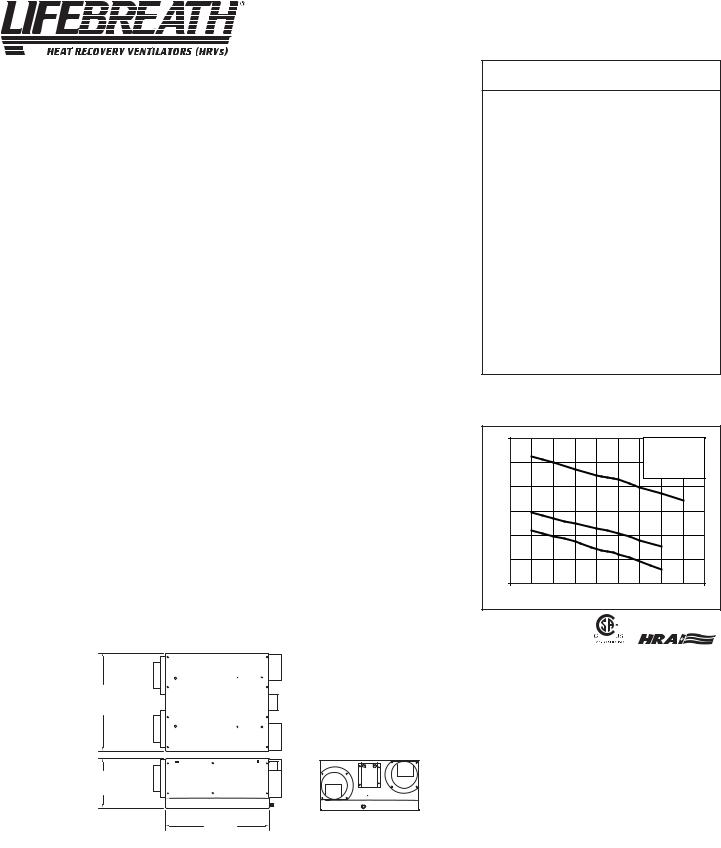

140 |

|

|

|

|

|

|

3 - High Speed |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

2 - Medium Low Speed |

|

|

|

120 |

3 |

|

|

|

|

|

1 - Low speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

(cfm) |

|

|

|

|

|

|

|

|

|

|

Flow |

80 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Air |

|

1 |

|

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

0 |

0.1 |

0.2 |

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

Static Pressure (in w.g.)

All units conform to CSA and UL standards.

Date: ______________________________________________ |

Contractor: __________________________________________ |

Tag: ________________________ Qty: __________________ |

Supplier: ____________________________________________ |

Project: _____________________________________________ |

Quote#: ____________________________________________ |

Engineer: ___________________________________________ |

Submitted by: ________________________________________ |

|

|

2

Engineering Data |

Model RNC120F |

|

|

|

|

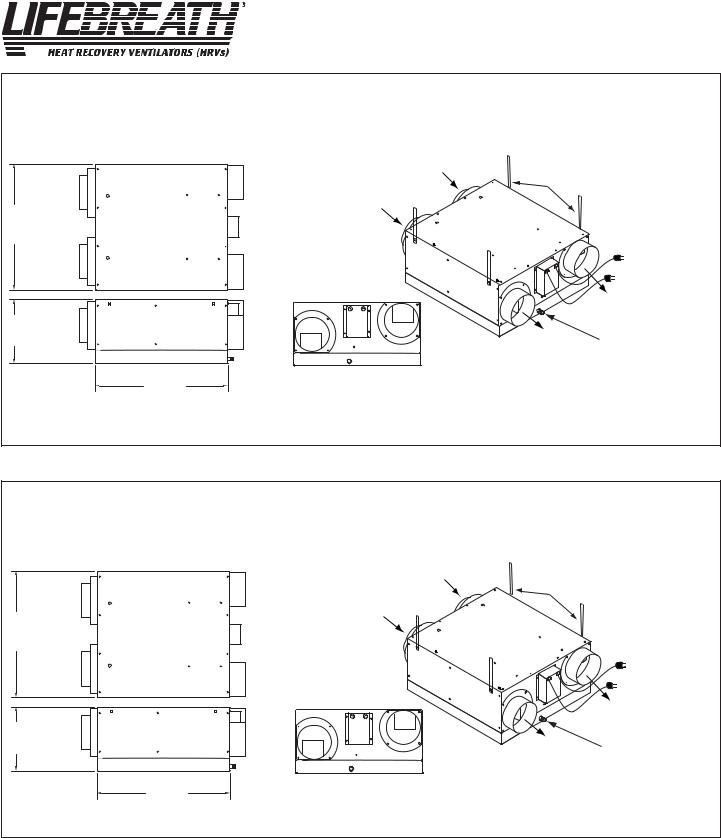

Option 1 - Standard Duct Configuration Dimensions inches |

|

|

||

TOP VIEW |

|

EXHAUST AIR |

|

|

|

FROM BUILDING |

|

|

|

|

|

HANGING |

|

|

|

FRESH AIR |

|

|

|

EXHAUST |

|

STRAPS |

|

|

TO BUILDING |

FRESH AIR |

|

||

|

|

|||

AIR FROM |

|

FROM OUTSIDE |

|

PLUG-IN CONNECTOR |

BUILDING |

|

|

||

|

|

|

||

18” |

|

|

|

FOR CONNECTING TO |

|

|

|

REMOTE ELECTRICAL |

|

|

|

|

|

|

FRESH AIR |

|

|

|

BOX |

FROM |

EXHAUST AIR |

|

|

|

OUTSIDE |

|

|

|

|

|

TO OUTSIDE |

|

|

|

|

|

|

|

FRESH AIR |

|

|

|

|

TO BUILDING |

9” |

|

|

EXHAUST AIR |

|

|

|

|

DRAIN |

|

|

|

|

TO OUTSIDE |

|

|

|

|

CONNECTION |

|

|

|

|

|

|

19” |

SERVICE CLEARANCE FROM |

|

|

|

BOTTOM OF UNIT IS MINIMUM 3'0" |

|

|

||

ALL DUCT CONNECTION COLLARS ARE 5" DIAMETER |

|

|

|

|

Option 2 - Reverse Duct Configuration Dimensions inches |

|

|

||

TOP VIEW |

|

FRESH AIR |

|

|

|

FROM OUTSIDE |

|

|

|

|

|

HANGING |

|

|

|

EXHAUST AIR |

|

|

|

FRESH AIR |

EXHAUST AIR |

STRAPS |

|

|

FROM |

TO OUTSIDE |

|

|

|

FROM BUILDING |

|

|

||

OUTSIDE |

|

|

PLUG-IN CONNECTOR |

|

|

|

|

||

18” |

|

|

|

FOR CONNECTING TO |

|

|

|

REMOTE ELECTRICAL |

|

|

|

|

|

|

EXHAUST |

|

|

|

BOX |

|

|

|

|

|

AIR FROM |

FRESH AIR |

|

|

|

BUILDING |

|

|

|

|

TO BUILDING |

|

|

|

|

|

|

|

|

|

|

|

|

|

EXHAUST AIR |

9” |

|

|

|

TO OUTSIDE |

|

|

FRESH AIR |

|

|

|

|

|

DRAIN |

|

|

|

|

TO BUILDING |

|

|

|

|

CONNECTION |

|

|

|

|

|

|

19” |

SERVICE CLEARANCE FROM |

|

|

|

BOTTOM OF UNIT IS MINIMUM 3'0" |

|

|

||

ALL DUCT CONNECTION COLLARS ARE 5" DIAMETER |

|

|

|

|

|

|

3 |

|

|

Engineering Data |

Model 120ERV |

|

|

Latent Recovery/Moisture Transfer Core

The cross flow energy recovery core transfers heat and water vapor between the two air streams. It is easily removed for cleaning and service.

MOTORS AND BLOWERS

Each Air stream has an independent motorized impeller. 3 speed operation 120VAC.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE ERV

Four threaded inserts at corners of case designed to accept four reinforced polyester straps that are supplied with the unit.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resistance. Insulated to prevent exterior condensation.

CONTROLS

Unit is supplied with a remote ERV box which can be conveniently located within 3’ of the ERV.

ERV System Control

ERV defaults to LOW SPEED when plugged in. HIGH SPEED option is accessible by connecting remote controls to designated terminals inside electrical box of ERV.

Standard LOW SPEED SETTING can be increased to medium low. Off (Standby)/Low or OFF/HIGH speed operation is also available.

DUCT CONNECTIONS

5” duct connections with ‘field’ selectable standard airflow or reverse airflow for limited room installations.

WEIGHT 42 lbs. (19 kg) SHIPPING WEIGHT 45 lbs. (20.5 kg)

OPTIONAL ACCESSORIES

99-132 20 Minute Fan Timer - initiates high speed ventilation for 20 minutes. (3 wire) 20 gauge wire (min.) 100’ length

99-101 Crank Timer

99-116 Dehumidistat Ventilation Control - Dehumidistat with ON/OFF 99-130 Dehumidistat Control - Dehumidistat

99-185 Weatherhoods, Two - 5” (125mm) c/w 1/4” (6mm) mesh screen

99-2040 20/40 ON/OFF Dehumidistat

WARRANTY

Units carry a lifetime warranty on the heat recovery core and a five year replacement parts warranty.

Performance

Net supply air flow in cfm (L/s) against external static pressure

E.S.P |

|

|

(external static pressure) |

[cfm (L/s)] |

|

@ 0.1" (25 Pa) |

113 |

(53) |

@ 0.2" (50 Pa) |

110 |

(52) |

@ 0.3" (75 Pa) |

103 |

(49) |

@ 0.4" (100 Pa) |

99 |

(47) |

@ 0.5" (125 Pa) |

96 |

(45) |

@ 0.6" (150 Pa) |

89 |

(42) |

@ 0.7" (175 Pa) |

86 |

(41) |

@ 0.8" (200 Pa) |

81 |

(38) |

|

|

|

Cooling Mode @ 50 cfm (24 L/s) 95°F (35°C) |

|

|

*Sensible Effectiveness |

62% |

|

**Latent Transfer |

35% |

|

Total Efficiency |

44% |

|

Heating Mode @ 50 cfm (24 L/s) 32°F (0°C)

*Sensible Effectiveness |

65% |

**Latent Transfer |

38% |

Total Efficiency |

56% |

|

|

VAC @ 60HZ |

120 |

WATTS / Low speed. |

63 |

WATTS / High speed |

150 |

|

|

Amp rating |

1.5 |

|

|

*Sensible Efficiency - thermal |

**Latent Efficiency - moisture |

Note: Effectiveness - based on temp. differential between the 2 airstreams Efficiency - takes into account all power inputs

|

140 |

|

|

|

|

|

|

3 - High Speed |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

2 - Medium Low Speed |

|

|

|

120 |

|

|

|

|

|

|

1 - Low speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

(cfm) |

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flow |

|

2 |

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

Air |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

40 |

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

0 |

0.1 |

0.2 |

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

Static Pressure (in w.g.)

18”

|

TOP VIEW |

|

EXHAUST |

FRESH AIR |

All units conform to CSA |

TO BUILDING |

and UL standards. |

|

AIR FROM |

|

|

BUILDING |

|

All Duct Collars are |

|

|

5" diameter (127 mm) |

FRESH AIR |

|

|

FROM |

EXHAUST AIR |

|

OUTSIDE |

|

|

|

TO OUTSIDE |

|

8” |

|

19” |

SERVICE CLEARANCE FROM |

BOTTOM OF UNIT IS MINIMUM 3'0" |

Date: ______________________________________________ |

Contractor: __________________________________________ |

Tag: ________________________ Qty: __________________ |

Supplier: ____________________________________________ |

Project: _____________________________________________ |

Quote#: ____________________________________________ |

Engineer: ___________________________________________ |

Submitted by: ________________________________________ |

4

Engineering Data |

Model 120ERV |

|

|

|

|

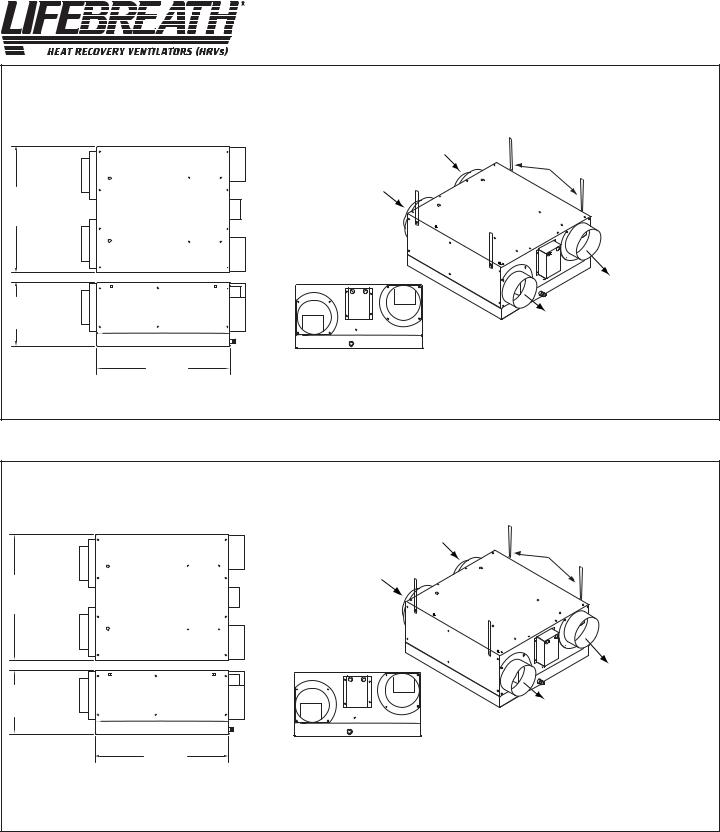

Option 1 - Duct Configuration Dimensions |

inches |

|

||

TOP VIEW |

|

EXHAUST AIR |

|

|

|

FROM BUILDING |

|

||

|

|

HANGING |

||

|

FRESH AIR |

|

||

EXHAUST |

|

STRAPS |

||

TO BUILDING |

FRESH AIR |

|||

|

||||

AIR FROM |

|

FROM OUTSIDE |

PLUG-IN CONNECTOR |

|

BUILDING |

|

|||

|

|

|||

18” |

|

|

FOR CONNECTING TO |

|

|

|

REMOTE ELECTRICAL |

||

|

|

|

||

FRESH AIR |

|

|

BOX |

|

FROM |

EXHAUST AIR |

|

|

|

OUTSIDE |

|

|

||

|

TO OUTSIDE |

|

|

|

|

|

|

FRESH AIR |

|

|

|

|

TO BUILDING |

|

8” |

|

|

EXHAUST AIR |

|

|

|

|

||

|

|

|

TO OUTSIDE |

|

19” |

SERVICE CLEARANCE FROM |

|

||

BOTTOM OF UNIT IS MINIMUM 3'0" |

|

|||

ALL DUCT CONNECTION COLLARS ARE 5" DIAMETER |

|

|

||

Option 2 - Duct Configuration Dimensions inches |

|

||

TOP VIEW |

|

FRESH AIR |

|

|

FROM OUTSIDE |

|

|

|

|

HANGING |

|

|

EXHAUST AIR |

|

|

FRESH AIR |

EXHAUST AIR |

STRAPS |

|

FROM |

TO OUTSIDE |

|

|

FROM BUILDING |

|

||

|

|

||

OUTSIDE |

|

PLUG-IN CONNECTOR |

|

|

|

||

18” |

|

|

FOR CONNECTING TO |

|

|

REMOTE ELECTRICAL |

|

|

|

|

|

EXHAUST |

|

|

BOX |

|

|

|

|

AIR FROM |

FRESH AIR |

|

|

BUILDING |

|

|

|

TO BUILDING |

|

|

|

|

|

|

|

|

|

|

EXHAUST AIR |

8” |

|

|

TO OUTSIDE |

|

|

FRESH AIR |

|

|

|

|

|

|

|

|

TO BUILDING |

19” |

SERVICE CLEARANCE FROM |

|

|

BOTTOM OF UNIT IS MINIMUM 3'0" |

|

||

ALL DUCT CONNECTION COLLARS ARE 5" DIAMETER |

|

|

|

|

|

5 |

|

Installation Instructions

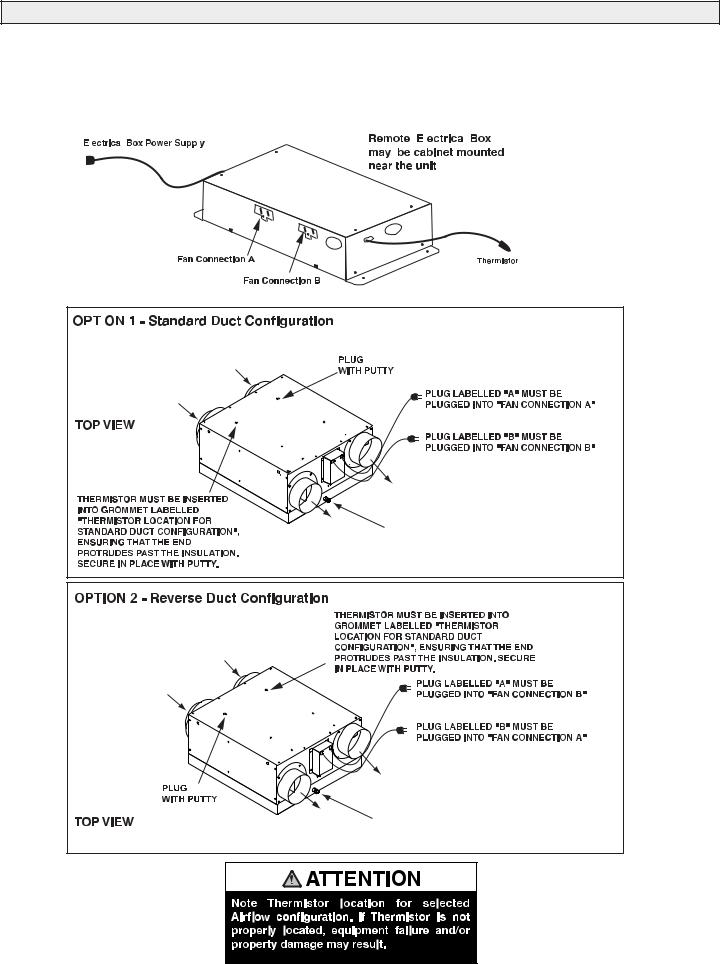

The RNC120F model can be setup in two different airflow |

electrical control box contains two receptacles labelled |

|||||||||||

configurations as illustrated in the engineering data sec- |

“Fan Connection A” and “Fan Connection B”. It is critical |

|||||||||||

tion of the manual. Because of this, it is extremely |

that the proper fan be plugged into the proper recepta- |

|||||||||||

important that the unit be connected properly. The remote |

cle. |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FRESH AIR

FROM OUTSIDE

EXHAUST AIR

FROM BUILDING

|

EXHAUST AIR |

|

|

TO OUTSIDE |

|

FRESH AIR |

DRAIN |

|

TO BUILDING |

||

CONNECTION |

||

|

EXHAUST AIR

FROM BUILDING

FRESH AIR

FROM OUTSIDE

|

FRESH AIR |

|

|

TO BUILDING |

|

EXHAUST AIR |

DRAIN |

|

TO OUTSIDE |

||

CONNECTION |

||

|

6

Clearances and Requirements

WARNING

WARNING

Before installation, careful consideration must be given to how this system will operate if connected to any other piece of mechanical equipment, i.e. a forced air furnace or air handler, operating at a higher static. After installation, the compatibility of the two pieces of equipment must be confirmed, by measuring the air flows of the ventilator, by using the balancing procedure found in this manual.

It is always important to assess how the operation of any HRV may interact with vented combustion equipment (i.e. Gas Furnaces, Oil Furnaces, Wood Stoves, etc.)

NEVER install a ventilator in a situation where its normal operation, lack of operation or partial failure may result in the backdrafting or improper functioning of vented combustion equipment!

Connecting Appliances to the HRV

The following appliances should not be connected to the HRV:

•clothes dryer

•range top

•stovetop fan

•central vacuum system

CAUTION

CAUTION

Lint, dust or grease will collect in the HRV damaging the unit.

NOTE: Connecting any of these to the HRV will

invalidate your warranty.

Installation

WARNING

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life. Installation and service must be performed by a qualified installer or service agency.

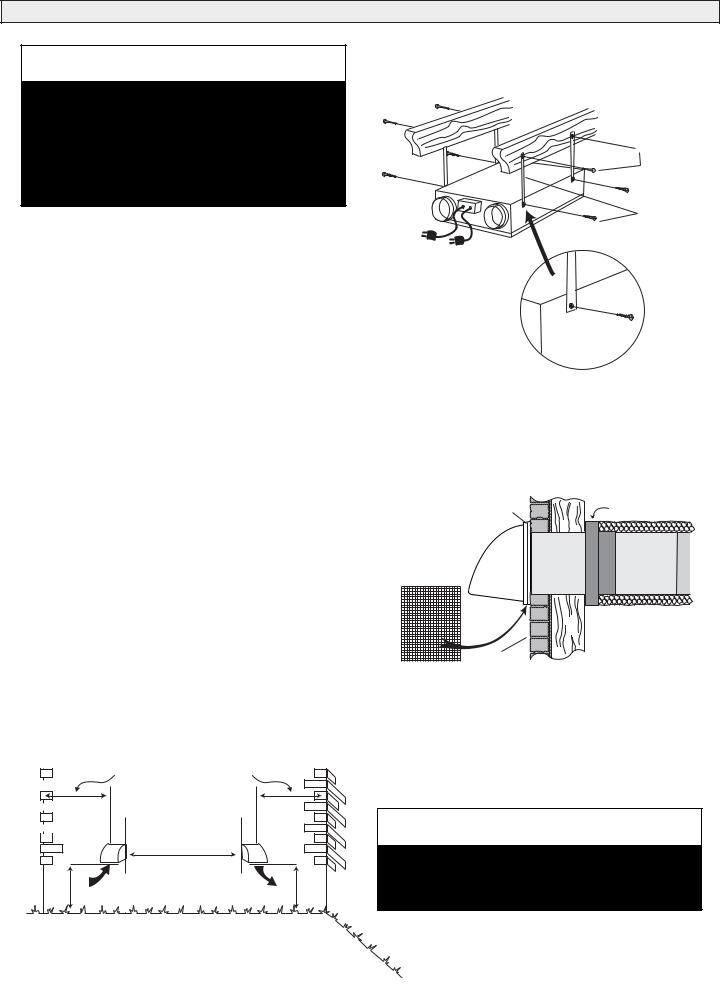

The HRV unit must be installed in a horizontal position as shown in the illustration below. The unit should be suspended using the provided hanging straps. The unit must be level for proper condensate drainage. Sufficient clearance below the access door is required for servicing the air filters and core. A minimum of 25" (635mm) clearance is recommended so the door can be removed. Four PVC reinforced polyester hanging straps are provided for hanging the HRV.

WARNING

WARNING

Electric shock hazard. Can cause injury or death. Before attempting to perform any service or maintenance, turn the electrical power to unit OFF at disconnect switch(es). Unit may have multiple power supplies.

Location Selection

The HRV must be located in a heated space where it will be possible to conveniently service the unit. Typically the HRV would be located in the mechanical room or an area close to the outside wall where the weather hoods will be mounted. If a basement area is not convenient or does not exist, a utility or laundry room may be used.

Attic installations are not normally recommended due to:

A)the complexity of work to install

B)freezing conditions in the attic

C)difficulty of access for service and cleaning

Suspending the Unit

The hanging straps should be attached to the unit at the top end corners (mounting screws are already located on the HRV case). Securely fasten the other end of the straps to the ceiling making sure the UNIT IS LEVEL. The straps are designed to reduce the possibility of noise, resonance or harmonics; therefore using the full length of the strap between the HRV and the floor joists is recommended.

Weatherhood Location and Installation

Weatherhood kit includes two fixed-cover hoods with a 1/4” (6mm) mesh screen.

Exhaust Weatherhood Requirements

•At least 6' (2 m) from the ventilation air intake*

•At least 18" (460mm) above ground or above the depth of expected snow accumulation*

•At least 3' (1 m) away from the corner of the building*

•At least 3’ away from gas meter, electric meter or a walkway where fog or ice could create a hazard*

•Not into a garage, workshop or other unheated space

7

Installation

CAUTION

CAUTION

Unit must be installed level to ensure proper condensate drainage. Due to the broad range of installation and operational conditions, consideration must be given for the possibility of condensation forming on the unit or connecting ducting. Objects below the installation may be exposed to condensate.

When installing the weather hood, its outside perimeter must be sealed with exterior caulking.

* Local code may require greater distances.

Intake Weatherhood Requirements

•Should be located upstream (if there are prevailing winds) from the exhaust outlet

•At least 6' (2 m) from the exhaust weather hood *

Suspending the Unit using the

Provided Hanging Straps

FASTENERS (not supplied)

FASTENERS (not supplied)

STRAPS

AND

DETAIL SCREWS (supplied)

Unit is designed for horizontal installation only as shown.

Using full length hanger straps is recommended for vibration control, but can be shorter if required.

•At least 6' (2 m) away from dryer vents and air handler exhaust (medium or high efficiency furnaces)*

•A minimum of at least 6' (2 m) from driveways, oil fill pipes, gas meters, or garbage containers, swimming pools*

Note: Illustration depicts unit suspended from wood floor joists. If a different ceiling system is used, securing straps to floor will be different.

•At least 18" (460mm) above the ground, or above the depth of expected snow accumulation*

•At least 3' (1 m) from the inside/outside corner of the building*

•Do not locate in a garage, attic or crawl space

* Local code may require greater distances.

Weatherhood Clearances

OUTSIDE CORNER |

36" (1m) |

36" (1m) |

INSIDE CORNER |

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

recommended min. |

recommended min. |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6' (2m) |

|

recommended min. |

INTAKE |

EXHAUST |

18" (460mm) min. |

18" (460mm) min. |

Weatherhood Installation

COLLAR IS SUPPLIED TO

1/4" (6 mm) SCREEN

(front view)

SCREEN |

ENSURE VAPOUR BARRIER |

(side view) |

IS 100% SEALED TO |

|

WALL PLATE |

|

12" galvanized |

|

pipe supplied |

EXTERIOR

WALL

1. Thermal Collar slides over galvanized sleeve of Weatherhood.

2. Fasten Thermal Collar to Belt.

3. Slide the Insulated Flexible Ducting over the Weatherhood's galvanized sleeve and fasten it to the Thermal Collar.

4. Hood is hinged to allow for easy accessfor cleaning of bird screen.

CAUTION

CAUTION

Weather hood arrangement - requires a minimum of 6’ (2m) separation and a minimum of 18" (460mm) clearance above grade or anticipated snow level.

8

Installation

Air Duct Design and Installation

A well designed and installed ducting system will allow the HRV to operate at its maximum efficiency.

Always try to keep duct runs as short and straight as possible. See Installation Diagrams for various installation options.

The inner and outer liners of the flexible insulated duct must be clamped to the sleeve of the weather hoods (as close to the outside as possible) and the appropriate port on the HRV. It is very important that the fresh air intake line be given special attention to make sure it is well sealed. A good bead of high quality caulking (preferably

silicone sealant) will seal the inner flexible duct to both the HRV port and the weather hood prior to clamping with a large zip tie.

To minimize air flow restriction, the flexible insulated duct that connects the two outside weather hoods to the HRV should be stretched tightly and be as short as possible.

Twisting or folding the duct will severely restrict air flow. See below for the recommended connection of flexible insulated ducts to the the outside weather hoods and the HRV.

Installing the Ducting Between

the HRV & Living Areas in the Home

To maximize airflow in the duct system, all ducts should be kept short and have as few bends or elbows as possible. Forty-five degree elbows are preferred to 90° elbows. Use “Y” tees instead of 90° elbows whenever possible.

All duct joints must be fastened with screws, rivets or duct sealant and wrapped with mastic or a quality duct tape to prevent leakage. Mastic is preferred but if duct tape is used, we recommend aluminum foil duct tape.

Galvanized ducting from the HRV to the living areas in the house is recommended whenever possible, although flexible duct can be used in moderation if necessary.

To avoid possible noise transfer through the duct system, a short length (approximately 12 inches or 300mm) of nonmetallic flexible insulated duct should be connected between the HRV and the supply/exhaust duct system.

The main supply and return lines to/from the HRV must be the same size or larger than the duct connection collar. Branch lines to the individual rooms may be as small as 4 inches (100mm), but 5 inch (125mm) lines are preferred .

All ducts running through attics and unheated spaces must be sealed and insulated to code.

Fresh Air Ducting

In applications that do not include an air handler, fresh air should be supplied to all bedrooms and living areas, excluding bathrooms, kitchen and utility areas. Grilles should be located high on a wall or in ceiling locations.

WARNING

WARNING

Include a short length of fabric, flex duct or other non-metallic connector in the “Fresh Air to Building” hard ducted line in order to keep the HRV separately grounded (electrically) from the air handler. This will avoid a possible shock hazard to service people if a short to ground develops in one of the devices.

Grilles that diffuse the air comfortably such as the Round Diffuser are recommended.

If the floor is the only option available, then special care should be taken in locating grilles. Areas such as under baseboard heaters will help to temper the air. Also optional inline duct heaters are available for mounting in the supply duct work to add heat if required.

Direct Connection to Air Handler Duct System

Should you wish to hard duct the fresh air from the HRV directly into the cold air return of the air handler, remember to check the air flow balance of the HRV with the air handler fan both "ON" and "OFF" to determine that it does not imbalance the unit more than 10%.

Indirect Connection to Air Handler Duct System

If permitted by local codes, an indirect connection may be made between the HRV fresh air duct and the air handler return plenum. The fresh air from the unit may be directed at a grille installed in the cold air return duct of the air handler. The fresh air outlet from the HRV should be no closer than 4 inches (100mm) and no more than 12 inches (300mm) from the grille.

FRESH AIR

FROM HRV

4" MINIMUM |

RETURN AIR |

12" MAXIMUM |

DUCT FOR |

|

AIR HANDLER |

HRV

9

Loading...

Loading...