Liebherr EP 944 C User Manual

Stationary Electric Material Handlers

EP 934 C Working Radius: 13 - 20 m

EP 944 C Working Radius: 15 - 22 m

EP 954 C Working Radius: 16 - 24 m

EP 934 C

Working radius: |

13 - 20 m |

Motor rating: |

160 kW/ 217 hp |

Weight: |

39,100 kg |

EP 954 C

Working radius: |

16 - 24 m |

Motor rating: |

250 kW/ 340 hp |

Weight: |

64,500 kg |

EP 944 C

Working radius: |

15 - 22 m |

Motor rating: |

200 kW/ 272 hp |

Weight: |

51,900 kg |

2 EP 934 C EP 944 C EP 954 C Material Handlers

Performance

These new electric Material Handlers have been designed to meet the specific needs of industrial handling. A wide range of equipment and uppercarriages optimized for long working radius provide the ideal answer to all the demands which arise in the industry.

The performance of the kinematic chain formed from components from our in-house production, combined with the power of the electric motor, maximize the performance of the machine when it comes to lifting power, precision, and speed of operation.

Reliability

Backed by more than 30 years experience in the construction of electric excavators, Liebherr designed the new EP 934 C, EP 944 C and EP 954 C with the aim of providing top performance whatever the challenge might be. The structure of the machine, using components from our own manufacture for the electric drive, has been completely rethought, and so moves away from simply being an adaptation of a diesel-engine machine.

Being intended for key functions in the organization of industrial sites, Liebherr electric Material Handlers provide a very high level of reliability. The service life of the hydraulic components has also been increased, thanks to the smoother movement of the electric drive.

The concept of the single actuator (one single electric motor for all the hydraulic functions) allows for the risk area associated with the low voltage at the electric cabinet to be reduced even further.

Comfort

Helping the operator to concentrate on his work and get the best out of his machine is achieved by providing a comfortable driving position, good visibility, and a highly ergonomic layout of the controls. The new electric Material Handlers offer the same level of comfort as on the mobile excavators (arrangement of the controls, driver’s seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks to the low noise emissions and absence of vibration.

For Liebherr, comfort also means ease of daily maintenance of the machine in terms of access to the service and inspection points, so as to minimize downtime.

Economy

Investing in the acquisition of an electric Material Handler is a great long-term advantage. Constant increases in the costs of conventional energy sources are pushing up operating charges, and reducing profit margins considerably. Environmental criteria, in particular CO2 emissions, are also playing a constantly greater part in the choice of power systems and working methods. With the electric drive, Liebherr offers an economical alternative to conventional diesel-engine machines, and a solution with real respect for the environment.

EP 934 C EP 944 C EP 954 C Material Handlers |

3 |

Ideal balance between power, speed, and precision

•When it comes to handling metals, timber, or any other application, a wide choice of equipment in a broad range of configurations means that the most varied demands can always be met by specific solutions

•Optimization of the Material Handlers goes well beyond just the choice of equipment. It even includes the adjustment of the hydraulics to meet the needs of the site and of the operator

4 EP 934 C EP 944 C EP 954 C Material Handlers

Distributor

•Fine response of hydraulic control for maximum working precision

•Immediate response to operator‘s commands

•Three-pump hydraulic system, one of which is a closed circuit dedicated to the slewing of the Material Handlers

Performance

These new electric Material Handlers have been designed to meet the specific needs of industrial handling. A wide range of equipment and uppercarriages optimized for a long operating radius provide the ideal answer to all the demands which arise in the industry.

The performance of the kinematic chain, formed from components from our own in-house production, combined with the power of the electric motor, maximize the performance of the Material handlers when it comes to lifting power, precision, and speed of operation.

Great lifting power |

Thanks to the optimised rear offset and the broach |

|

kinematics of the equipment, the design concept |

|

of the new uppercarriages means they can oper- |

|

ate at exceptional outreach whilst guaranteeing a |

|

good balance of forces and better absorption of |

|

mechanical stresses. |

Excellent Working |

Tough and designed for the most demanding of |

Radius |

applications, Liebherr equipment systems are |

|

the perfect answer to every requirement when |

|

it comes to lifting power and range of outreach. |

|

Components are optimised by the finite element |

|

calculation method. |

Fast work cycles |

The EP 934 C, EP 944 C and EP 954 C electric ex- |

|

cavators are fitted with the Liebherr Torque Control |

|

system. The hydraulic guidance system on the ex- |

|

cavator operates as a closed circuit, and does not |

|

affect the speed of movement of the equipment |

|

during the working cycle. The high torque and high |

|

oil delivery from the guide pump maximize the ex- |

|

cavator rotation speed. |

|

A two-pump hydraulic system allows for operating |

|

speeds to be reached which are unequalled any- |

|

where. Regeneration on the circuits for the equip- |

|

ment allows for optimization of the hydraulic power |

|

available and minimizing response time to the op- |

|

erator’s commands. This all results in a fluidity of |

|

movements which operators really appreciate. |

Precision of work |

The fine response of the hydraulic control allows |

|

for exceptional precision of work to be achieved |

|

at long outreach, which contributes to the comfort |

|

and convenience of the operator as well as achiev- |

|

ing high performance results. Power is nothing |

|

without control. |

Tough structure

• High strength steel sheet at points subject to severe stress, stands up to the most extreme demands

• Stable mounting of equipment elements

• Exceptional strength, even under intense loading

EP 934 C EP 944 C EP 954 C Material Handlers |

5 |

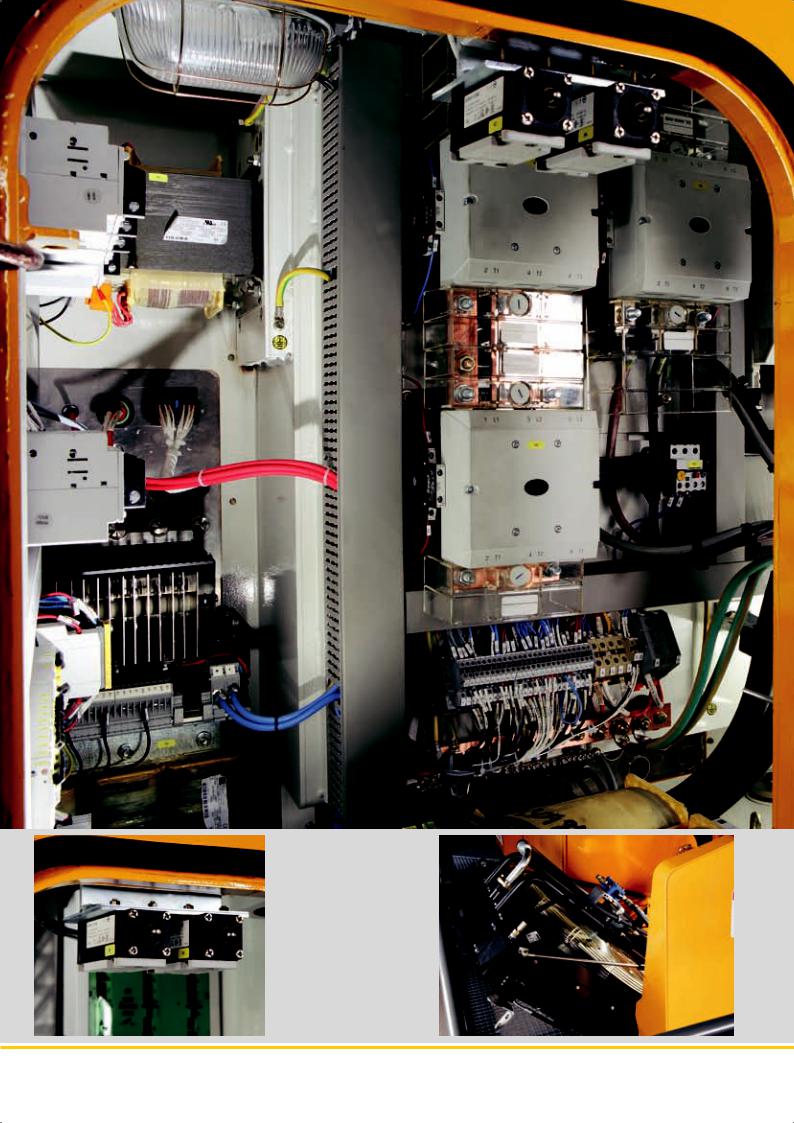

Reliability - Safety

•Automatic Power cut off if the cabinet doors are opened

•Automatic power cut off in the event of any anomalies (electric motor or its bearings overheating)

•Active safety on the transformers in the electric cabinet

6 EP 934 C EP 944 C EP 954 C Material Handlers

Reliability

Backed by more than 30 years experience in the construction of electrically powered excavators, Liebherr designed the new EP 934 C, EP 944 C and EP 954 C with the aim of providing top performance whatever the challenge might be. The structure of the excavator, using components from our own manufacture for the electric drive, has been completely rethought, and so moves away from simply being an adaptation of the diesel-engine excavator.

Being intended for key functions in the organization of industrial sites, Liebherr electric Material Handlers provide a very high level of reliability. The service life of the hydraulic components has also been increased thanks to the smoother movement of the electric drive.

The concept of the single actuator (one single electric motor for all the hydraulic functions) allows for the risk area associated with the low voltage at the electric cabinet to be reduced even further.

Electrical |

Totally integrated into the structure of the uppercarriages |

|

system |

and accommodated in a metal container, the electric cabi- |

|

|

net provides a three-fold level of protection to the compo- |

|

|

nents of the electrical system: |

|

|

- Mechanical (insulation from vibrations and from the pos- |

|

|

sible impact of falling objects) |

|

|

- Heat (maintains a constant temperature thanks to the |

|

|

heating resistors which prevent corrosion from conden- |

|

|

sation) |

|

|

- Electrical earthing of the structure and disconnection |

|

|

from current is controlled from the cab by way of a mo- |

|

|

torised circuit-breaker. |

|

Protected electric |

The electric cabinet, like the rotating joint, provides IP55 |

|

cabinet |

class protection. A double filtration system (accessible |

|

|

from the outside) places the cabinet under pressure, |

|

|

which avoids any dust penetration and, with permanent |

|

|

ventilation, ensures the thermal balance of all the com- |

|

|

ponents. |

|

Electric motor |

Liebherr electric excavators are equipped with motors |

|

|

especially designed for really tough applications. The di- |

|

|

mensions of the motor allow for the full power to be drawn |

|

|

from the kinematic chain, and so maximises the perform- |

|

|

ance of the machine. The motor can resist a momentary |

|

|

overload of up to +25 % of its rated capacities. |

|

|

Protected against penetration by water and dust, its prop- |

|

|

erties correspond to protection class IP55. |

|

|

The temperature of the roller bearings and other bearing |

|

|

elements is constantly monitored, and, in the event of |

|

|

overheating, the operator is warned of malfunction on the |

|

|

console at the driving position. |

|

|

|

|

Cooling system |

Elastic base |

|

• Generous dimensions for high |

• Complete range of elastic bases especially |

|

cooling capacity |

designed for each model |

|

• Vertical arrangement for in- |

• Absorption of mechanical stresses (normally |

|

creased efficiency and minimal |

transferred to the chassis of an excavator) if |

|

incursion of foreign bodies |

mounted on a rigid structure (anchored metal |

|

• Powered by a thermostatically |

body, concrete body) |

|

|

||

regulated hydraulic motor |

• Protection for the machine (in particular the |

|

• Hinged to allow for complete |

elements of the rotation assembly), as well as |

|

for the load-bearing structure, against the axial |

||

cleaning |

||

and radial forces generated by the operating |

||

|

||

• Reversible actuation of the fan |

dynamics |

|

(without time limit) as option |

|

|

|

|

|

|

|

EP 934 C EP 944 C EP 954 C Material Handlers |

7 |

Cab with control panel

•The command arrangement for putting the electrical system under voltage is progressive (3 functions) and the emergency stop button allows for the general cutting of the electric cabinet supply

•Available as an option is a cut off system deriving from one source point, which can be activated from the driving position via an additional rotating joint

8 EP 934 C EP 944 C EP 954 C Material Handlers

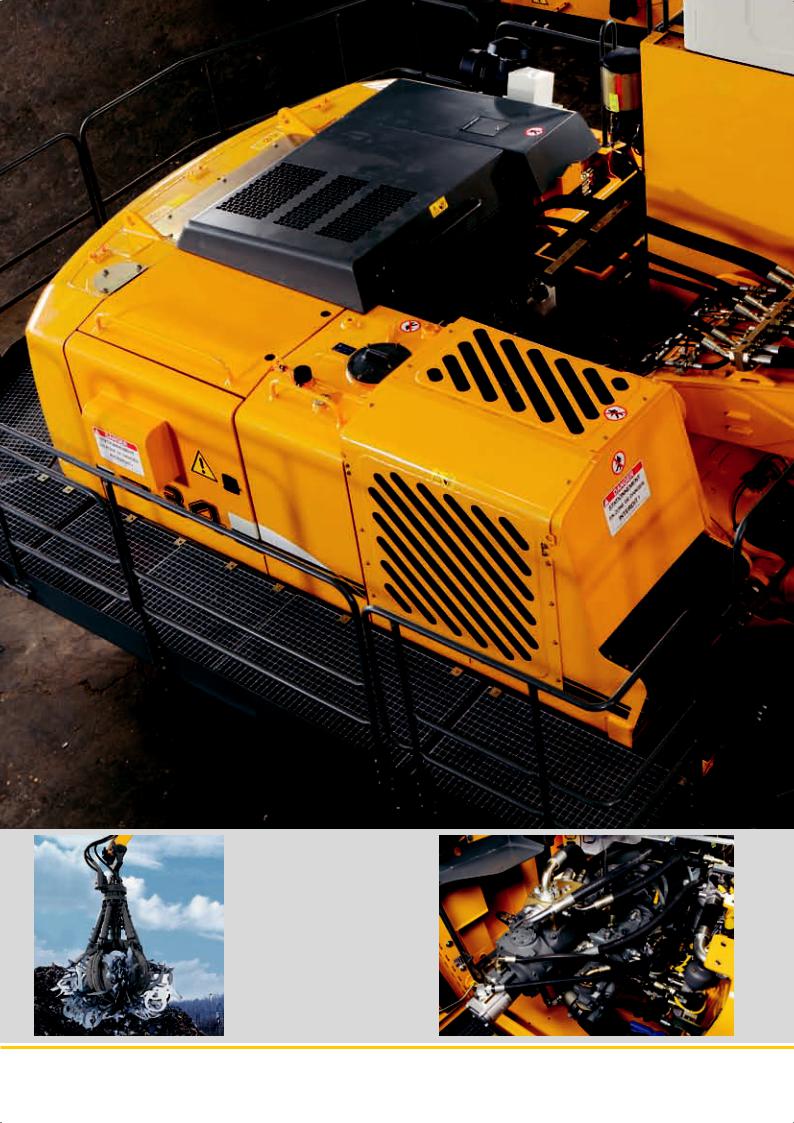

Comfort

Helping the operator to concentrate on his work and get the best out of his machine is achieved by a driving position which provides comfort, good visibility, and a highly ergonomic layout of the controls. The new electric Material handlers offer the same level of comfort as on the mobile excavators (arrangement of the controls, driver’s seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks to the low noise emissions and absence of vibration.

For Liebherr, comfort also means ease of daily maintenance of the machine in terms of access to the service and inspection points, so as to minimize downtime.

Driving position |

Mounted as standard on a fixed platform of 1 200 mm |

|

(2 000 mm or hydraulic platform on request), the |

|

new cab on the electric excavators meets all safety |

|

standards in force (24 V supply in the operator's |

|

compartment), comfort, panoramic visibility, and |

|

ergonomic arrangement of the controls for perfect |

|

control of the machine. |

Wide walkway with |

Arranged on the upperdeck, combines safety and |

safety rail |

convenience for accessing all the maintenance |

|

points on the machine. Access to the lower structure |

|

(metallic base, concrete pedestal, chassis) can be |

|

tailor-made depending on the type of installation. |

Low noise emissions |

Liebherr electric excavators are really quiet in opera- |

|

tion. Their measured acoustic level is from 4 to 5 dB |

|

lower than an equivalent diesel-engine version. |

|

The level of noise intensity from a Liebherr electric |

|

excavator represents less than a third of the noise |

|

generated by a diesel-engine unit. |

Carbon gas emission |

Zero grams of CO2 emitted per tonne of product |

|

handled! |

Climate control entirely automatic |

Easy maintenanc |

• Automatic climate control ensures a |

• Optimum placement of components |

level of comfort similar to a private car |

on the uppercarriage |

• Two sensors for precise temperature |

• Wide service walkway |

regulation |

• Easy access to service points thanks to |

|

|

• Ventilation flaps can be adjusted |

grouping together of inspection points |

at the touch of a button |

• Downtimes reduced to the minimum |

|

|

• Rapid demisting and defrosting |

|

of the windscreen thanks to the |

|

«reheat“ function |

|

|

|

|

|

EP 934 C EP 944 C EP 954 C Material Handlers |

9 |

Wide range of solutions

•Modular arrangement for rapid changeover

•Liebherr quick-coupling system, mechanical and hydraulic, for efficient equipment changeover

•Quick-coupling arrangement for hydraulic lines (Multi-Coupler)

•Complete range of grapples

•Range of different wood grapples and grab buckets from Liebherr

10 EP 934 C EP 944 C EP 954 C Material Handlers

Loading...

Loading...