Liebherr A900C User Manual

Operating Weight: 17,400 - 19,600 kg

Engine Output: 95 kW / 129 HP

Bucket Capacity: 0.32 - 0.95 m³

A 900 C

Wheeled Excavator

2

A 900 C Litronic

Operating Weight: 17,400 - 19,600 kg

Engine Output: 95 kW / 129 HP

Bucket Capacity: 0.32 - 0.95 m³

A 900 C

3

A 900 C Litronic

Reliability

Liebherr hydraulic excavators have been designed and

built to withstand the toughest of conditions at the buil-

ding site. Their rugged design, high-tensile materials and

individual components ensure maximum availability and

long life-expectancy.

Performance

Liebherr wheel excavators have been designed for maxi-

mum productivity. Maximum digging performances, high

lift capacities and quick working cycles are prerequisite

for effi cient building site operation, and a wide variety of

attachments optimize every excavator application.

Comfort

Largely dimensioned and ergonomically designed, the

Liebherr excavator cab features an operator’s seat which

can be individually adjusted, as well as clearly arranged

control instruments and ideal all-round view. Automatic

air-conditioning guarantees an optimum temperature in

the Liebherr Feel-Good cab at all times.

Economy

The Liebherr-Litronic-System increases machine perfor-

mance, reduces fuel consumption and minimises service

and maintenance costs. Due to Liebherr’s well- balanced

range, the ideal machine can always be selected to suit

every application.

4

A 900 C Litronic

Features

• High-tensile steel plates in high-

stress areas for the toughest of

applications

• Well-thought-out and secure bearings

for attachments and cylinders

• Maximum resistance, even when

lifting heavy loads

5

A 900 C Litronic

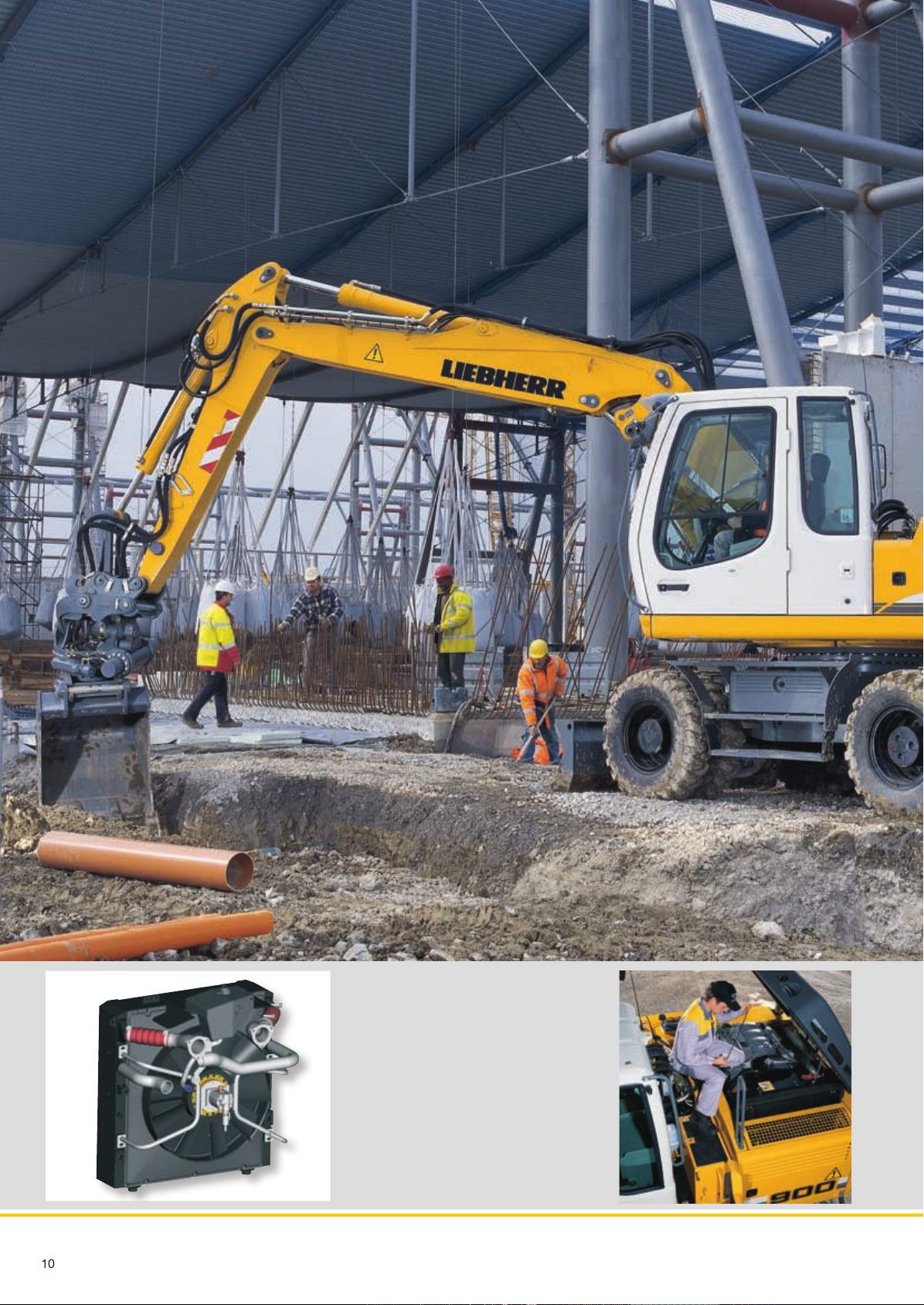

Reliability

Liebherr construction machinery is proven all over the world every day on the

most diverse of building sites. Many years of experience as the world’s largest

manufacturer of rubber-tyre excavators, continuous development and the in-

troduction of the latest technology are evident in every machine, guarantee-

ing absolute safety during applications. With its rugged design, and featuring

Liebherr components, the Liebherr hydraulic excavators have been designed

for extremely long life-expectancy.

Quality in detail

Liebherr components

Components such as engine, hydraulic cylinders,

swing gear and electric parts have been specially

designed, tested and manufactured by Liebherr

for construction machinery. Parts including en-

gines and pumps for example, are already being

synchronized with each other as early as the

construction phase, yielding a constant standard

of quality.

Functional safety

Safety-orientated components, fi tted as standard,

allow high availability.

The operator can thus concentrate fully on the

task at hand, due to the integrated on-board elec-

tronics performing a constant balancing of pre-

defi ned set data.

Filtering of metallic fi lings by the magnetic rod, fi t-

ted in the hydraulic system as standard, increases

life-expectancy of the hydraulic components and

the oil.

Rugged attachments

Working attachment

The durable attachments have been designed for

the toughest of applications. All components are

optimised to the FEM methods and the hoist cy-

linders feature bearings on both sides.

Piping

The hydraulic lines are arranged optimally to sa-

feguard against damage. The electric cabling is

made with high-grade materials, thus guarantee-

ing a reliable supply to the consumer.

Liebherr hydraulic cylinders

• Specifi c size for each machine

• High-grade surface coating of

the piston rods

• All Liebherr cylinders feature

special long-life sealing systems

• Shock absorption at both sides

in the working cylinders

Functional safety

• Essential operating data is stored and can

be recalled at any time.

• Control and monitoring functions increase

functional safety of the machine.

• Four fi xed working modes for output discharge

facilitate an effective and effi cient operation:

– Eco-Mode: for high output at big fuel savings

– Power-Mode: for heavy-duty digging-and loading

performance under severe conditions

– Lift-Mode: for precise handling of heavy loads

– Fine-Mode: for fi ne control at precision work

6

A 900 C Litronic

Liebherr diesel engine

• Long life-expectancy, expansive cylinder

capacity and increased weight

• According to level IIIA / Tier 3

• Specially designed for construction

machinery operation

• Oil supply even with extreme tilt angle

7

A 900 C Litronic

Performance

Liebherr wheel excavators have been designed for maximum productivity. Per-

fectly harmonized, the Liebherr-developed and Liebherr-manufactured com-

ponents including diesel engine, hydraulic pump and motor, as well as swing

gear and cylinders, guarantee maximum performance. Tremendous digging

and breakout forces, extensive lifting capacities and quick working and travel

movements are thus resulted.

Innovative solutions

Intelligent

undercarriage

The entire travel drive unit is integrated in the sturdy

undercarriage. Intelligently built and robust in ser-

vice, the undercarriage offers the travel drive unit

the best possible protection from debris, stones

and soil. Its advantages are perfect all-terrain com-

patibility and extremely high ground clearance.

Multitude of

attachments

Liebherr provide an individual, application-related

range of diverse attachments. Hydraulic booms,

adjustable both in height and offset positions, as

well as standard and offset-adjustable goosenecks,

can be combined with different sticks.

Extensive lifting

capacities

Canalization and the lifting of pipes are everyday

tasks for rubber-tyre excavators. These require-

ments are endorsed via an intelligent concept of

uppercarriage sectioning together with the posi-

tioning of the Liebherr engine, mounted at a trans-

versal angle directly in front of the counterweight.

Separate hoist cylinder bearing points at the up-

per end of the basic boom also increase the lifting

capacities considerably.

High productivity

Quick working cycles

High swing torque – attained as a result of the

Liebherr swing ring featuring internal teeth and

swing drive, specially designed to increase the

torque.

Performance without

compromise

Maximum performance and maximum forces are

available to the operator at all times.

Rugged undercarriage

• Various undercarriage designs fea-

turing welded, durable outriggers

allow safe positioning, optimum sta-

bility, and long life-expectancy of the

machine for every application.

• Prop-up blade / dozing blade in

box-type design – only two bearing

points for high torsional resistance

• Optional protection system for blade

cylinders

Litronic

• Increases productivity of the

excavator

• Reduces fuel consumption

• Reduces service costs and eases

operation

• Allows maximum sensitivity and as

many overlapping movements as are

required

8

A 900 C Litronic

Large-sized cab

• Adjustable steering column

• Operator’s seat, adjustable in height and

can also be adapted to the individual weight

of the operator.

• Consoles with or without possibility

of horizontal adjustment.

• Large roof window

• Sun blinds

9

A 900 C Litronic

Comfort

Fully-automatic air-conditioning system

• The air-conditioning system, fi tted as

standard, offers the same comfort as that

of a regular car

• Two sensors for precise temperature

regulation

• Ventilation fl aps are controlled via keys

• Reheat function for quick dehumidifying /

defrosting of the windshield

Storage compartment –

Everything has its place

• Suffi cient storage space for a commer-

cially-approved cooler box behind the

operator’s seat

• Drinks holder and storage compart-

ment in operator’s cab

• Large storage box behind the

operator’s cab

• Two standard tool boxes in the

undercarriage

The excavator operator is provided with an ergonomically-arranged working

area within Liebherr hydraulic excavator cabs. All switches and functions are

logically laid out, and operator’s seat, steering column and consoles can be

adjusted individually. Conditioning and concentration can thus be maintained

throughout the entire working day, guaranteeing constant, maximum producti-

vity of the operator.

Mobile comfort

Easy access

Wide steps, ergonomically-positioned handles

and adjustable steering column allow an easy ac-

cess into the Liebherr operator’s cab.

Optimum visibility

A well-thought-out design of the uppercarriage,

featuring large glass panels and rounded edges,

increase overall visibility and guarantees a safe

overview of the entire working area.

Pleasant surroundings

Reduced engine speed together with elaborate

sound insulation, as well as optimised hydraulic

components, allow a comfortable noise level both

inside and out. The noise level is comparable with

that of a diesel car.

Maintenance features

Easy maintenance

Semi-Automatical Central lubrication for swing

gear and main parts of the attachment.

Ease of operation

A shut-off valve, fi tted to the hydraulic tank as

standard, disconnects the system and guarantees

ease of maintenance to the hydraulic system.

Easy access

Large maintenance fl aps allow comfortable and

safe access to all maintenance points.

10

A 900 C Litronic

Hydrostatic fan drive

• Accelerated warm-up period

• Guaranteed constant oil quality as a

result of constant oil temperature

• Increased life-expectancy of drive

components

• The fan only runs at the output re-

quired, thus conserving fuel and re-

ducing the noise level considerably

Loading...

Loading...