Lg B-mmc12fa-1, B-mmc09fa-1 Owner's Manual

HEAT CONTROLLER, INC.

Wall Mounted

Multi-Split System

Air Conditioning/Heat Pump

Indoor Unit: B-MMC09FA-1

B-MMH09FA-1

B-MMC12FA-1

B-MMH12FA-1

Outdoor Unit : A-MMH18FA-1

A-MMC24FA-1

A-MMH24FA-1

A-MMC36FA-1

A-MMH36FA-1

Before servicing the unit, read the

“safety precautions” in this manual.

Only for authorized service personnel.

Multi type Air Conditioner Service Manual

TABLE OF CONTENTS

Combination table.......................................................................................................................................3

Safety Precautions......................................................................................................................................4

Installation guide at the seaside..............................................................................................................10

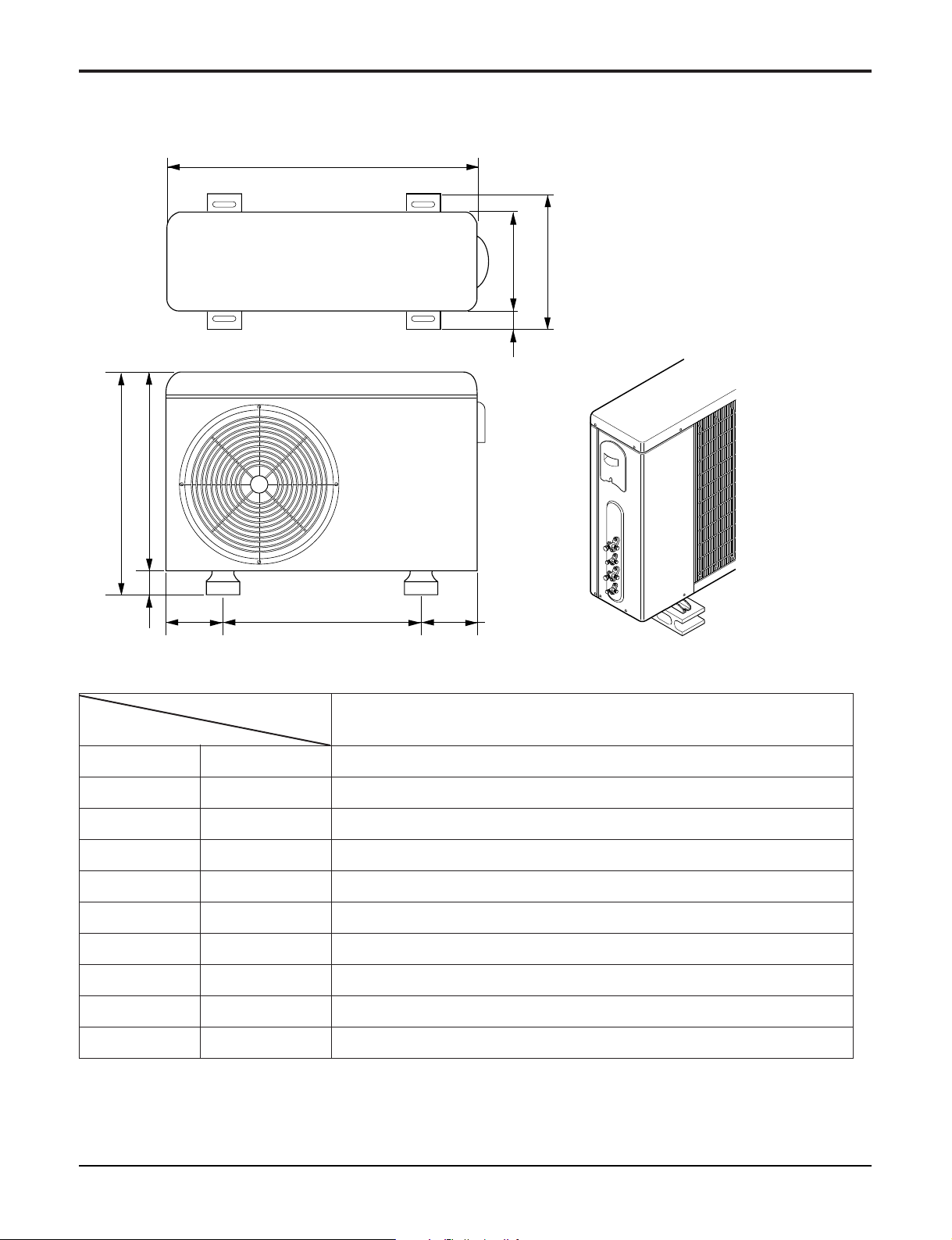

Dimensions................................................................................................................................................11

Indoor Unit..............................................................................................................................................11

Outdoor Unit ...........................................................................................................................................12

Product Specifications .............................................................................................................................15

Indoor Unit..............................................................................................................................................15

Outdoor Unit ...........................................................................................................................................16

Installation .................................................................................................................................................19

Installation Parts.....................................................................................................................................19

Installation Tools.....................................................................................................................................19

Select the best location .........................................................................................................................20

Piping length and elevation ....................................................................................................................21

Fixing Installation Plate(Standard Type).................................................................................................22

Drill a hole in the wall ...........................................................................................................................22

Flaring Work and Connection of Piping..................................................................................................23

Flaring work............................................................................................................................................24

Connecting the Piping ............................................................................................................................24

Connecting the Cable between Indoor Unit and Outdoor Unit .............................................................31

Connect the cable to the Indoor unit. .....................................................................................................31

Connect the cable to the Outdoor unit....................................................................................................32

Connection method of the connecting cable(Example)..........................................................................33

Connect the cable to the indoor unit.......................................................................................................34

Checking the Drainage, Forming the Pipings and Long Pipe Setting .................................................35

Checking the drainage............................................................................................................................35

Forming the piping..................................................................................................................................36

Air Purging and Evacuation.....................................................................................................................37

Checking method ...................................................................................................................................37

Evacuation..............................................................................................................................................38

Charging ....................................................................................................................................................39

Test Running .............................................................................................................................................40

Operation ...................................................................................................................................................41

Function of control..................................................................................................................................41

Function of Indoor Unit...........................................................................................................................46

Function of Outdoor Unit ........................................................................................................................47

Remote Control Operation .....................................................................................................................48

Disassembly ..............................................................................................................................................49

Indoor Unit..............................................................................................................................................49

Schematic Diagram...................................................................................................................................52

Electronic Control Device .......................................................................................................................52

Wiring Diagram.......................................................................................................................................55

Components Locations...........................................................................................................................57

Troubleshooting Guide .............................................................................................................................61

Refrigeration Cycle Diagram ..................................................................................................................61

Self-diagnosis Function ..........................................................................................................................64

Cycle Troubleshooting Guide..................................................................................................................65

Electronic Parts Troubleshooting Guide .................................................................................................66

Error Code..............................................................................................................................................71

2-way, 3-way Valve ....................................................................................................................................75

Exploded View & Replacement Parts List ..............................................................................................79

Indoor Unit .............................................................................................................................................79

Outdoor Unit ...........................................................................................................................................81

2 Multi type Air Conditioner

NOTICE

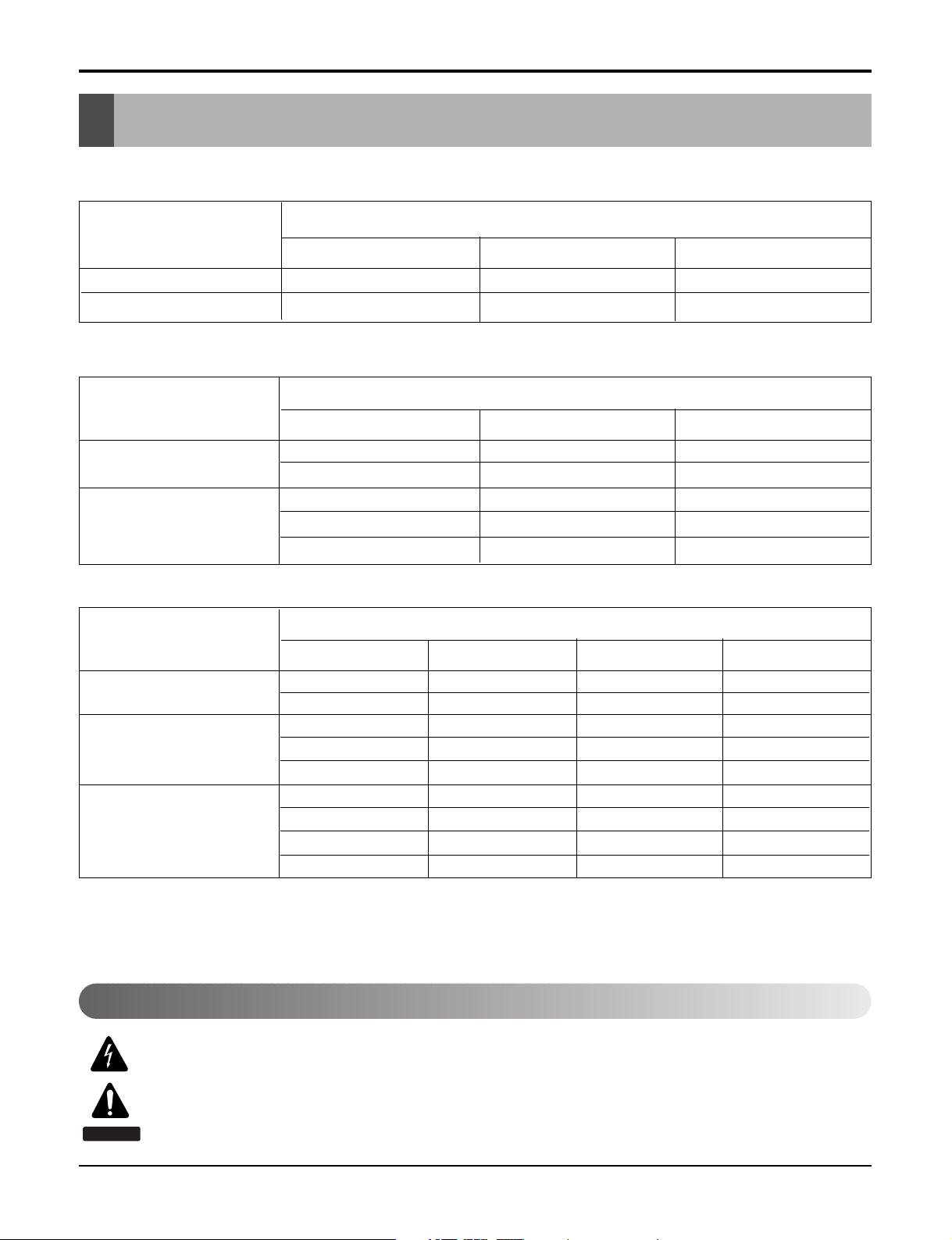

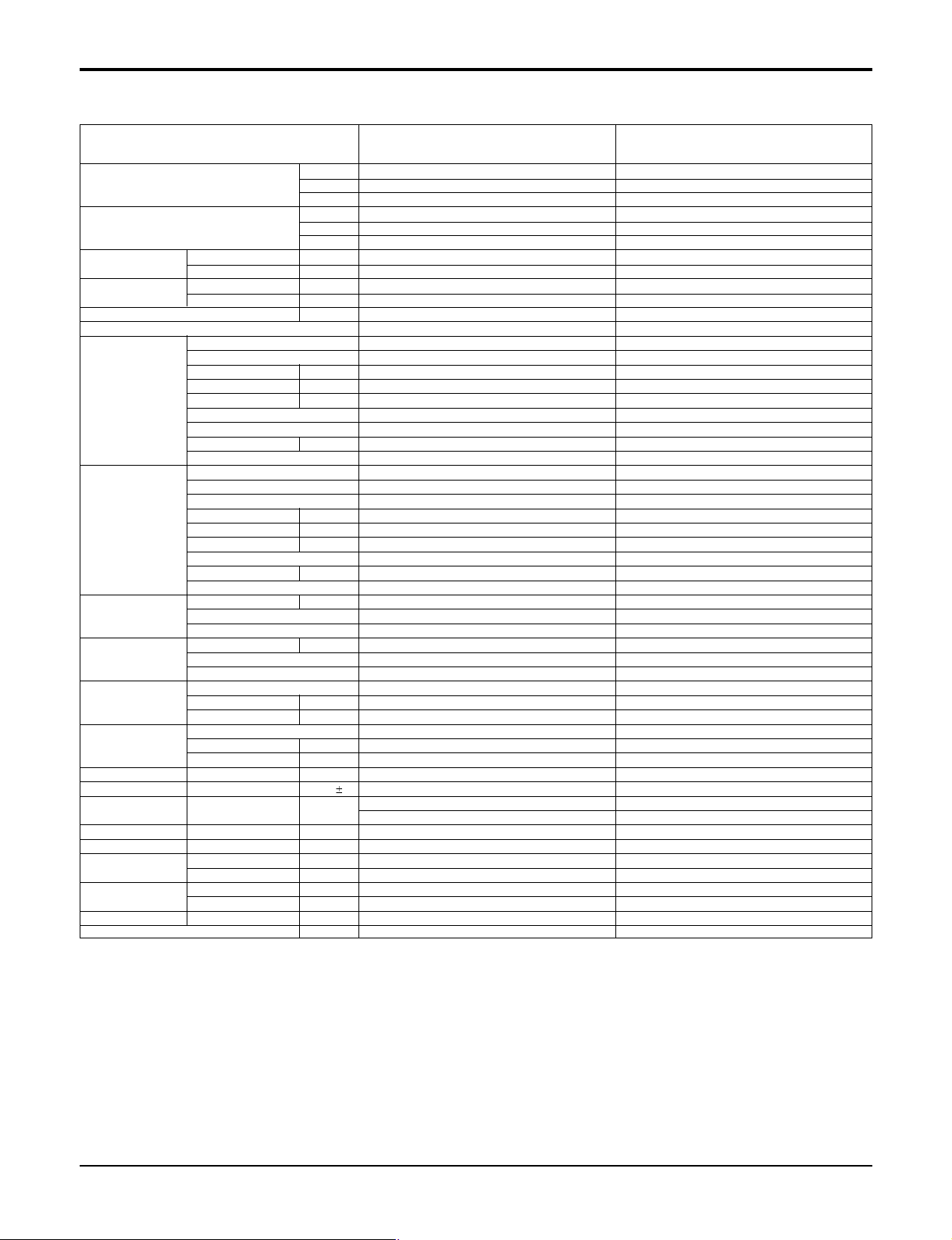

Combination table

18 kBtu( 2 rooms)

1 UNIT 9 - 9

2 UNIT 9 9 18

24 kBtu( 2 rooms)

1 UNIT

2 UNIT 9 12 21

Combination table

Combination

Unit-A Unit-B Total

Combination

Unit-A Unit-B Total

9-9

12 - 12

9918

12 12 24

36 kBtu (3 rooms)

Combination

Unit-A Unit-B Unit-C Total

1 UNIT

2 UNIT 9 12 - 21

3 UNIT

Notes :

1.Cooling Capacity is based on : indoor temp. 26.7°C(80.1°F)DB, 19.4°C(66.9°F)WB; outdoor temp. 35°C(95°F)DB, 23.9°C(75°F)WB

2.Heating Capacity is based on : indoor temp. 21.1°C(70°F)DB, 15.6°C(60.1°F)WB; outdoor temp. 8.3°C(46.9°F)DB, 6.1°C(43°F)WB

9-- 9

12 - - 12

99-18

12 12 - 24

99927

9 9 12 30

9121233

12 12 12 36

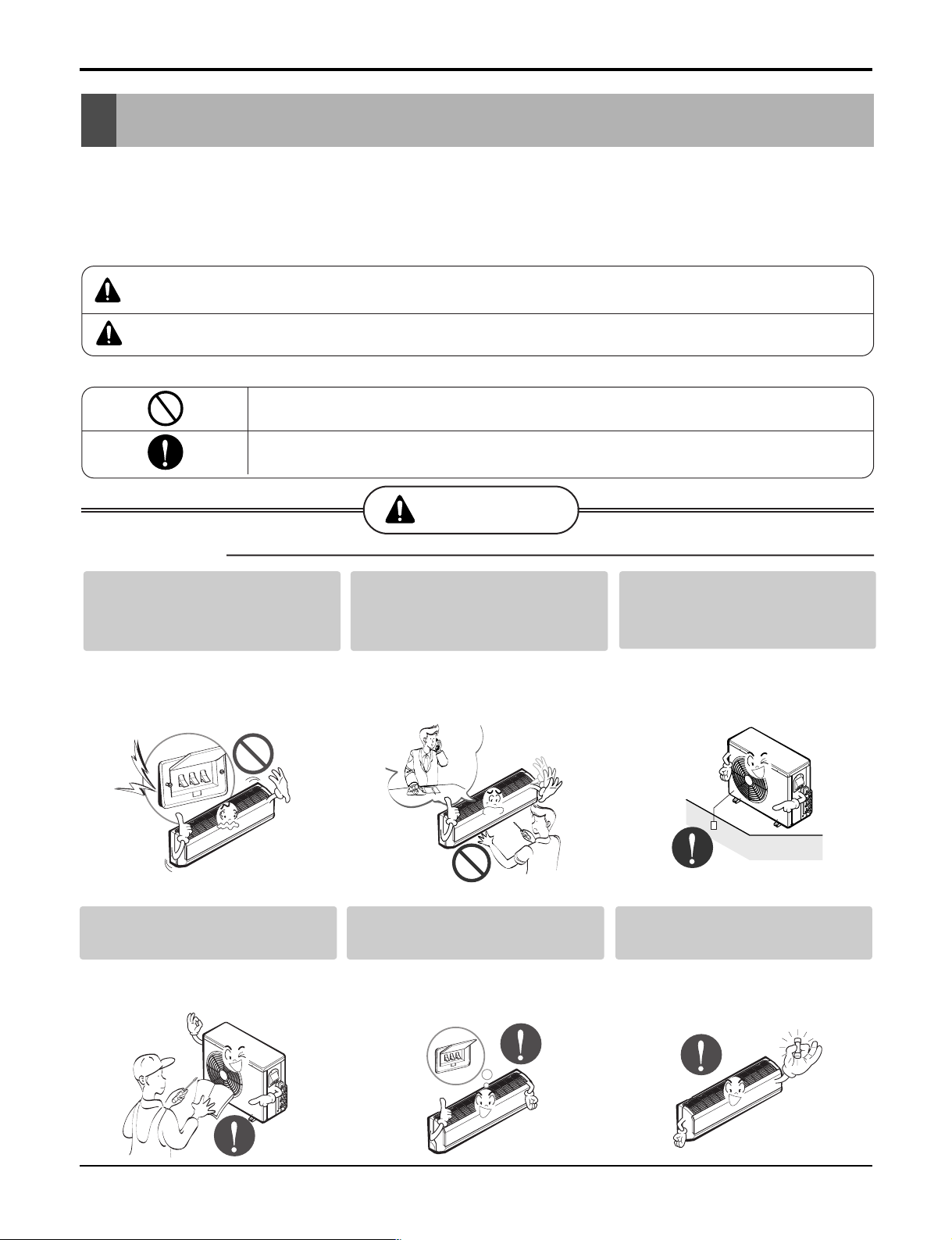

Symbols Used in this Manual

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

Service Manual 3

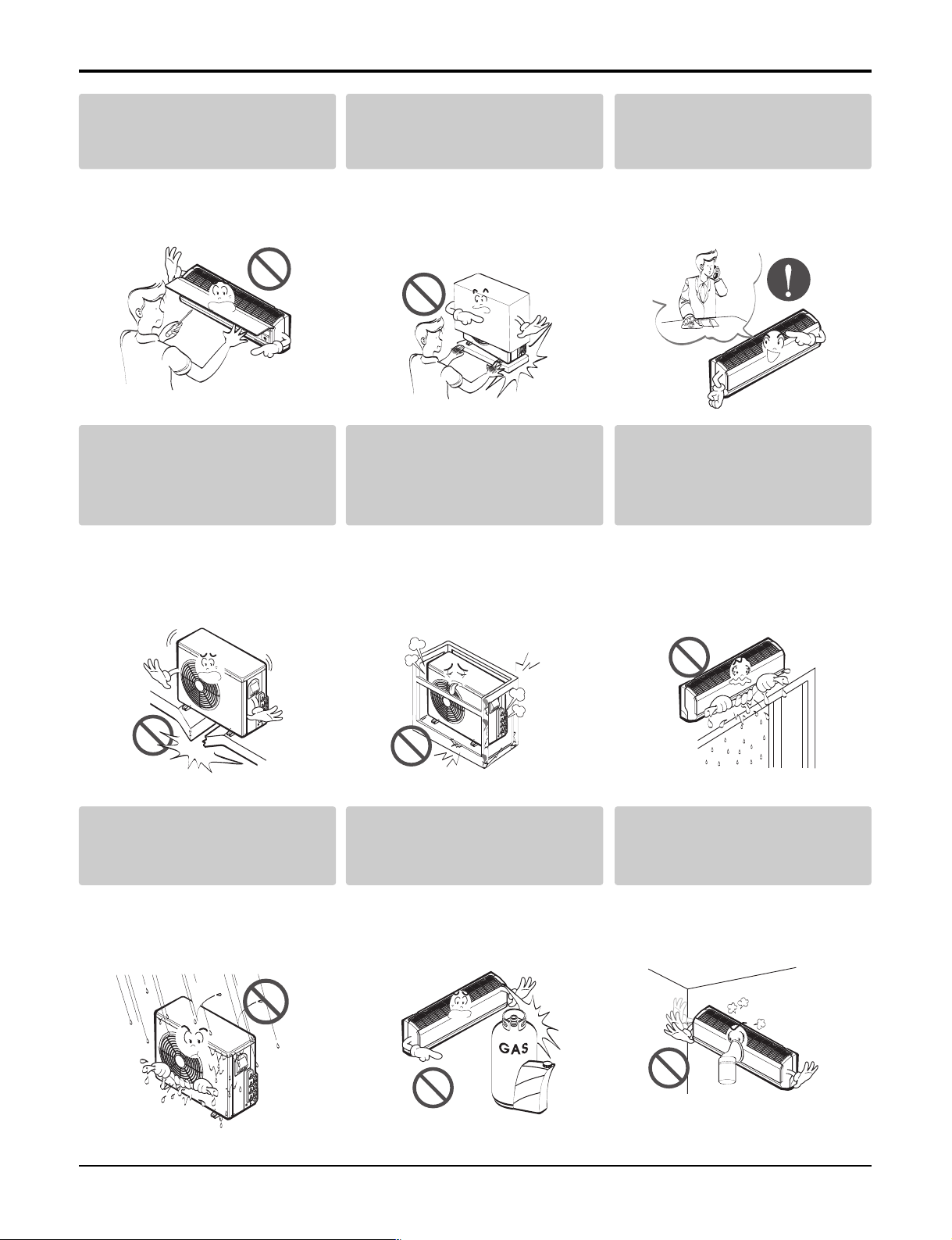

Safety Precautions

WARNING

CAUTION

WARNING

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

Do not use a defective or underrated circuit breaker. Use this

appliance on a dedicated circuit.

• There is risk of fire or electric

shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric

shock.

For electrical work, contact the

dealer, seller, a qualified electrician,

or an Authorized Service Center

• Do not disassemble or repair the

product. There is risk of fire or

electric shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may

cause fire or electric shock

.

Always ground the product.

• There is risk of fire or electric

shock.

Use the correctly rated breaker or fuse.

• There is risk of fire or electric

shock.

4 Multi type Air Conditioner

Safety Precautions

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury.

Be especially careful of the case

edges and the fins on the condenser and evaporator.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing

property damage, product failure,

and personal injury.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and wet or

damage furniture.

Do not allow water to run into

electric parts.

• It may cause There is risk of fire,

failure of the product, or electric

shock.

Do not store or use flammable

gas or combustibles near the

product.

• There is risk of fire or failure of

product.

Gasolin

Do not use the product in a

tightly closed space for a long

time.

• Oxygen deficiency could occur.

Service Manual 5

Safety Precautions

When flammable gas leaks,

turn off the gas and open a

window for ventilation before

If strange sounds, or smoke

comes from product. Turn the

breaker off.

turn the product on.

• Do not use the telephone or turn

switches on or off. There is risk of

explosion or fire

Do not open the inlet grill of the product

during operation. (Do not touch the electrostatic filter, if the unit is so equipped.)

• There is risk of physical injury,

electric shock, or product failure.

• There is risk of electric shock or

fire.

When the product is soaked

(flooded or submerged), contact

an Authorized Service Center.

• There is risk of fire or electric

shock.

Stop operation and close the

window in storm or hurricane.

If possible, remove the product from the window before

the hurricane arrives.

• There is risk of property damage,

failure of product, or electric shock.

Be cautious that water could

not enter the product.

• There is risk of fire, electric shock,

or product damage.

Ventilate the product from time to time when

operating it together with a stove, etc.

• There is risk of fire or electric shock.

6 Multi type Air Conditioner

Turn the main power off when cleaning or

maintaining the product.

• There is risk of electric shock.

Safety Precautions

CAUTION

When the product is not to be used for a long time,

disconnect the power by turning off the breaker.

• There is risk of product damage or failure, or unintended operation.

■ Installation

Always check for gas (refrigerant) leakage after installation or repair of product.

Install the drain hose to ensure that

water is drained away properly.

Take care to ensure that nobody could step on

or fall onto the outdoor unit.

• This could result in personal injury and product damage.

Keep level even when

installing the product.

• Low refrigerant levels may cause

failure of product.

Do not install the product

where the noise or hot air

from the outdoor unit could

oftend neighbors.

• It may cause a problem for your

neighbors.

• A bad connection may cause water

leakage.

Use two or more people to lift

and transport the product.

• Avoid personal injury.

• To avoid vibration or water leakage.

90°

Do not install the product

where it will be exposed to

sea wind (salt spray) directly.

• It may cause corrosion on the

product. Corrosion, particularly on

the condenser and evaporator fins,

could cause product malfunction or

inefficient operation.

Service Manual 7

Safety Precautions

■ Operational

Do not expose the skin directly to cool air for long periods

of time.

(Don't sit in the draft.)

• This could harm to your health.

Use a soft cloth to clean. Do

not use harsh detergents, solvents, etc.

• There is risk of fire, electric shock,

or damage to the plastic parts of

the product.

Do not use the product for

special purposes, such as

preserving foods, works of

art, etc. It is a consumer air

conditioner, not a precision

refrigeration system.

• There is risk of damage or loss of

property.

Do not touch the metal parts of

the product when removing the

air filter. They are very sharp!

• There is risk of personal injury.

Do not block the inlet or outlet

of air flow.

• It may cause product failure.

Do not step on or put anyting

on the product. (outdoor

units)

• There is risk of personal injury and

failure of product.

Thinner

Wax

Always insert the filter securely. Clean the filter every two

weeks or more often if necessary.

•

A dirty filter reduces the efficiency of

the air conditioner and could cause

product malfunction or damage.

8 Multi type Air Conditioner

Do not insert hands or other

objects through the air inlet or

outlet while the product is

operated.

• There are sharp and moving parts

that could cause personal injury.

Do not drink the water drained

from the product.

• It is not sanitary and could cause

serious health issues.

Safety Precautions

Use a firm stool or ladder when cleaning or

maintaining the product.

• Be careful and avoid personal injury.

Do not recharge or disassemble the batteries.

Do not dispose of batteries in a fire.

• They may burn or explode.

Replace the all batteries in the remote control

with new ones of the same type. Do not mix

old and new batteries or different types of batteries.

• There is risk of fire or explosion

If the liquid from the batteries gets onto your

skin or clothes, wash it well with clean water.

Do not use the remote if the batteries have

leaked.

• The chemicals in batteries could cause burns or other

health hazards.

If you eat the liquid from the batteries, brush

your teeth and see doctor. Do not use the

remote if the batteries have leaked.

• The chemicals in batteries could cause burns or other

health hazards.

Service Manual 9

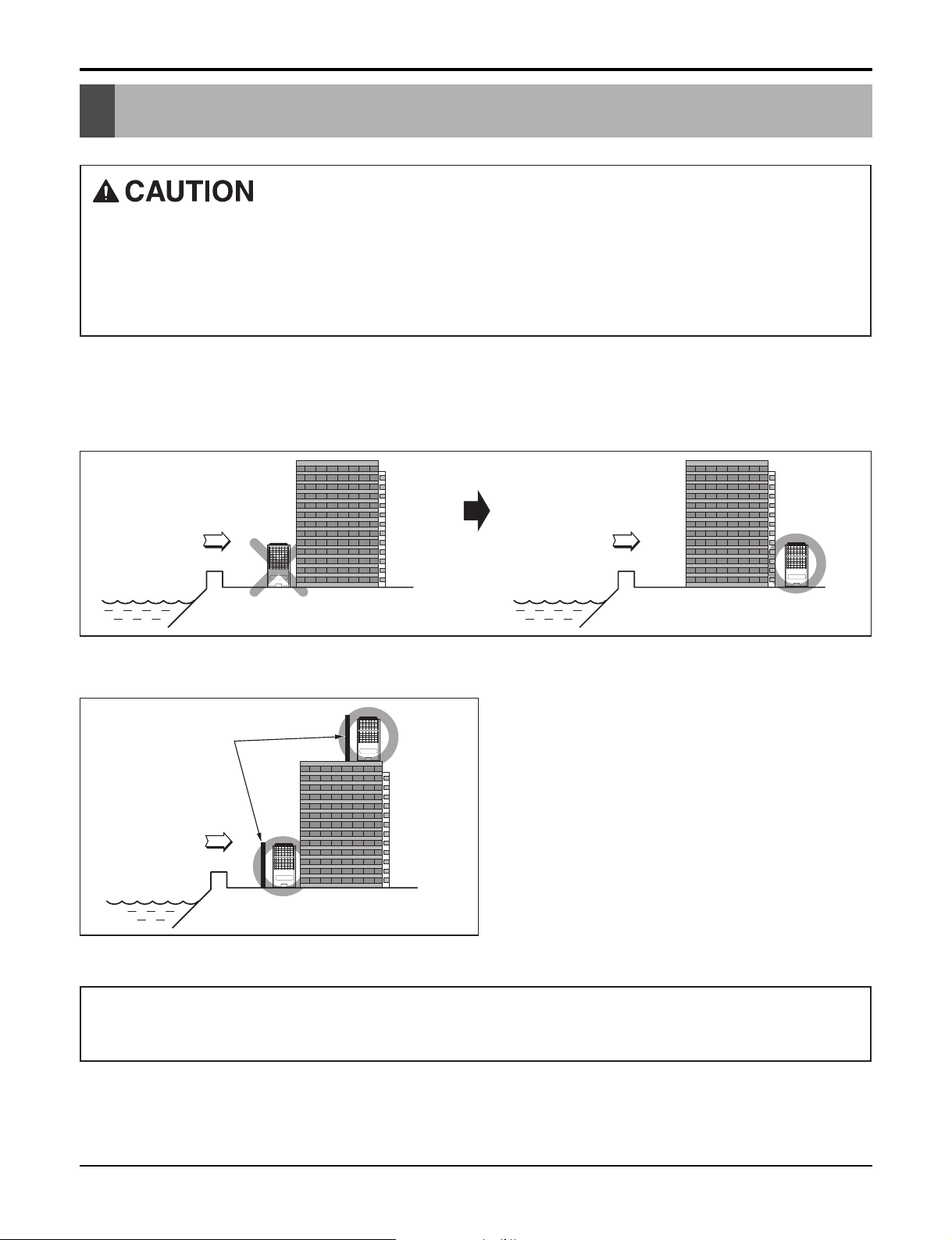

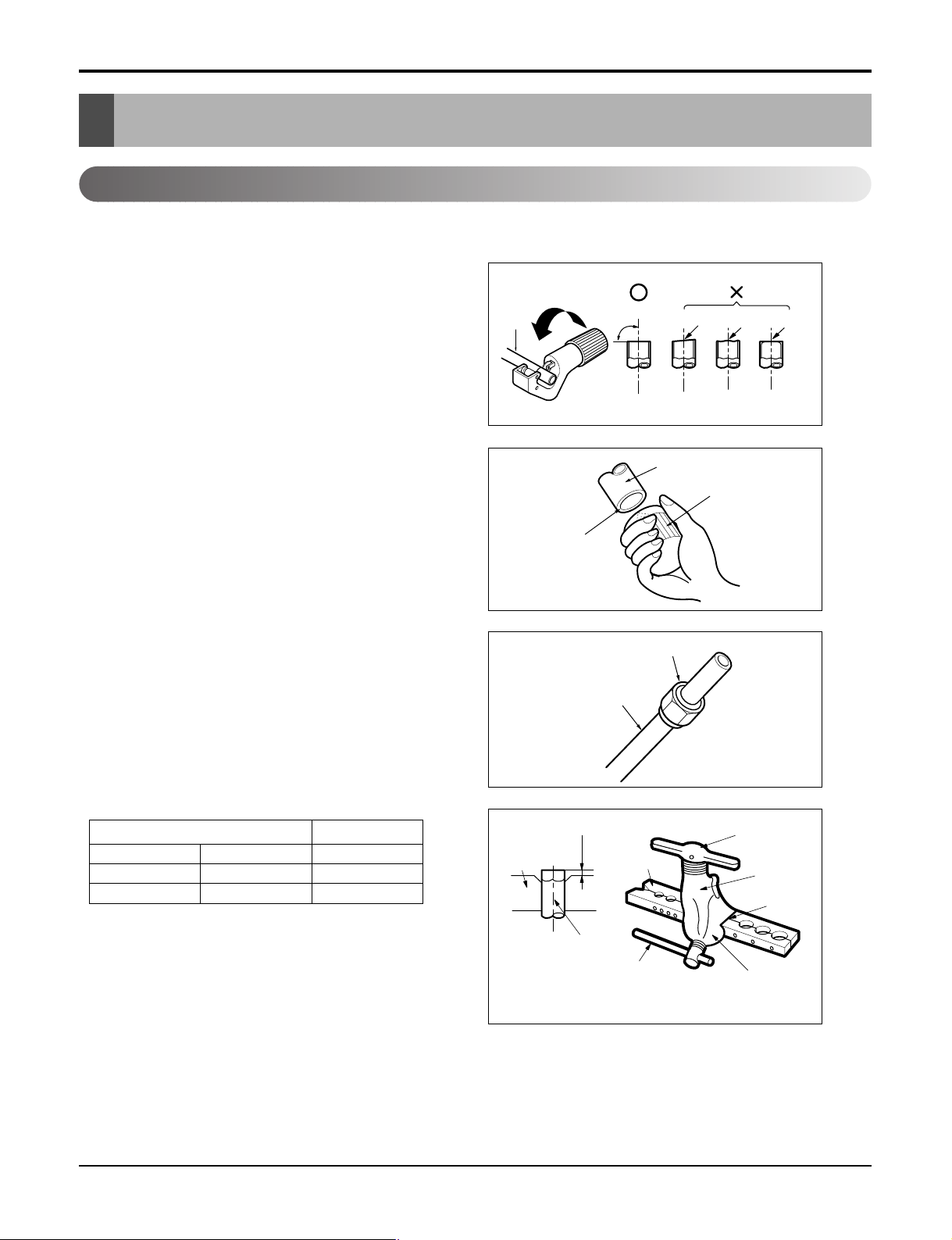

Installation guide at the seaside

Sea wind Sea wind

Installation guide at the seaside

1.

Air conditioners should not be installed in areas where corrosive gases, such as acid or alkaline gas, are produced.

2. Do not install the product where it could be exposed to sea wind (salty wind) directly. It can result corrosion

on the product. Corrosion, particularly on the condenser and evaporator fins, could cause product malfunction or inefficient performance.

3. If outdoor unit is installed close to the seaside, it should avoid direct exposure to the sea wind. Otherwise it

needs additional anticorrosion treatment on the heat exchanger.

Selecting the location(Outdoor Unit)

1) If the outdoor unit is to be installed close to the seaside, direct exposure to the sea wind should be avoided.

Install the outdoor unit on the opposite side of the sea wind direction.

2) In case, to install the outdoor unit on the seaside, set up a windbreak not to be exposed to the sea wind.

Windbreak

Sea wind

3) Select a well-drained place.

1.

If you can’t meet above guide line in the seaside installation, please contact LG Electronics for the additional anticorrosion treatment.

2. Periodic ( more than once/year ) cleaning of the dust or salt particles stuck on the heat exchanger by using water

• It should be strong enough like concrete to prevent

the sea wind from the sea.

• The height and width should be more than 150% of

the outdoor unit.

• It should be keep more than 70 cm of space

between outdoor unit and the windbreak for easy

air flow.

10 Multi type Air Conditioner

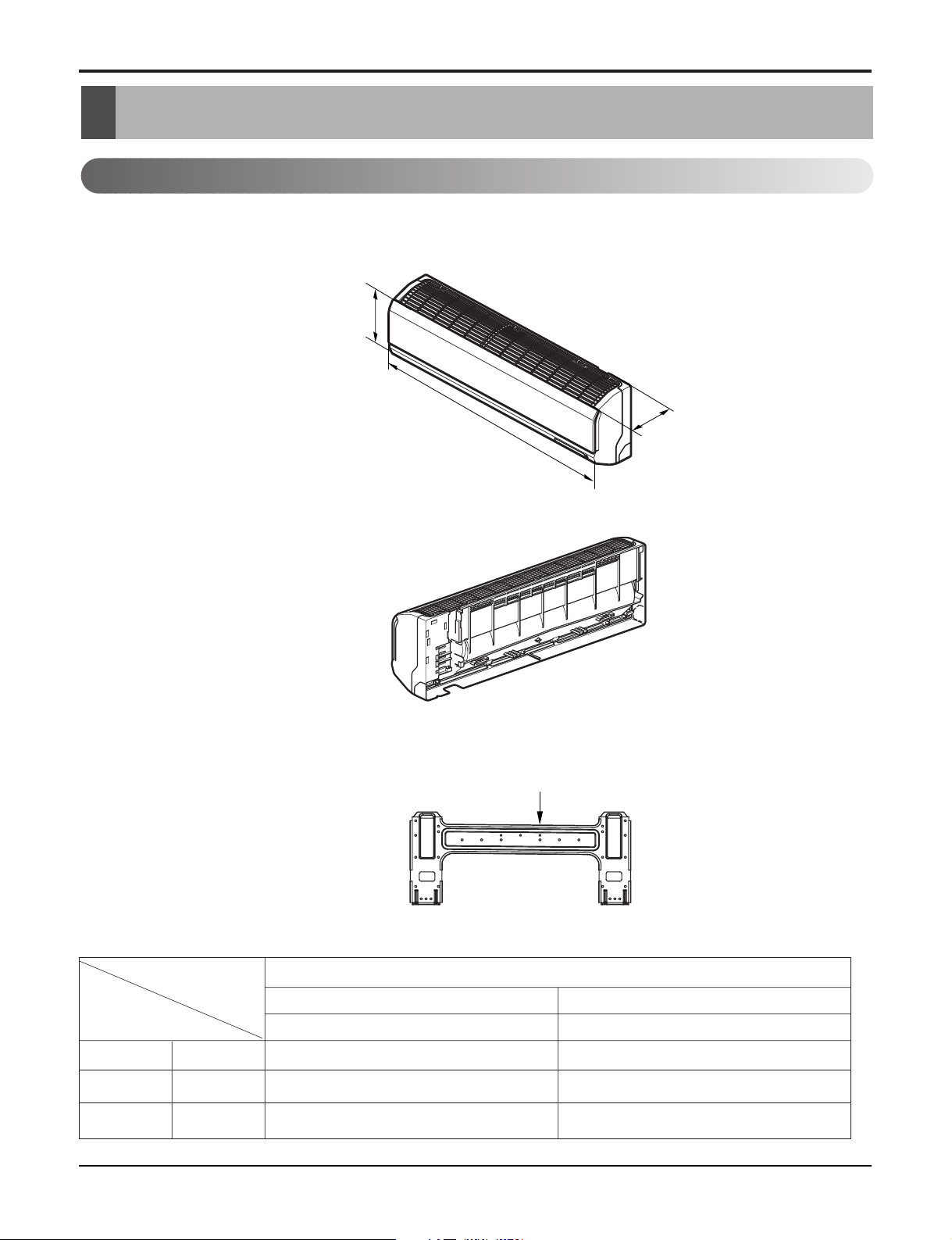

Dimensions

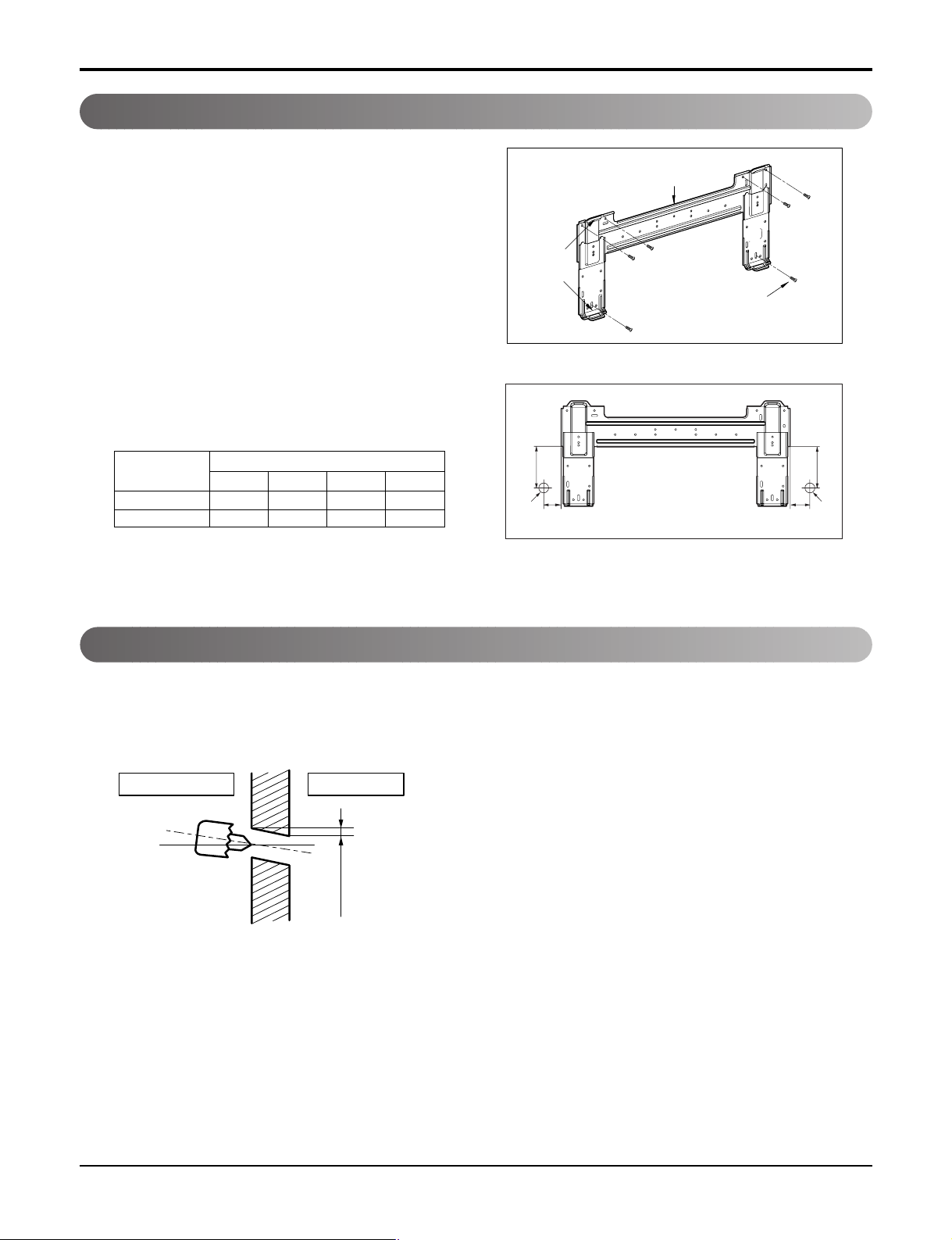

Installation plate

D

H

W

Indoor Unit

Split Type Indoor

Dimensions

Model

Dimension

W mm(in) 840(33) 895(35.2)

Split Type

S4

9 kBtu/h

SE

12 kBtu/h

H mm(in) 270(10.6) 282(11.1)

D mm(in) 153(6) 165(6.5)

Service Manual 11

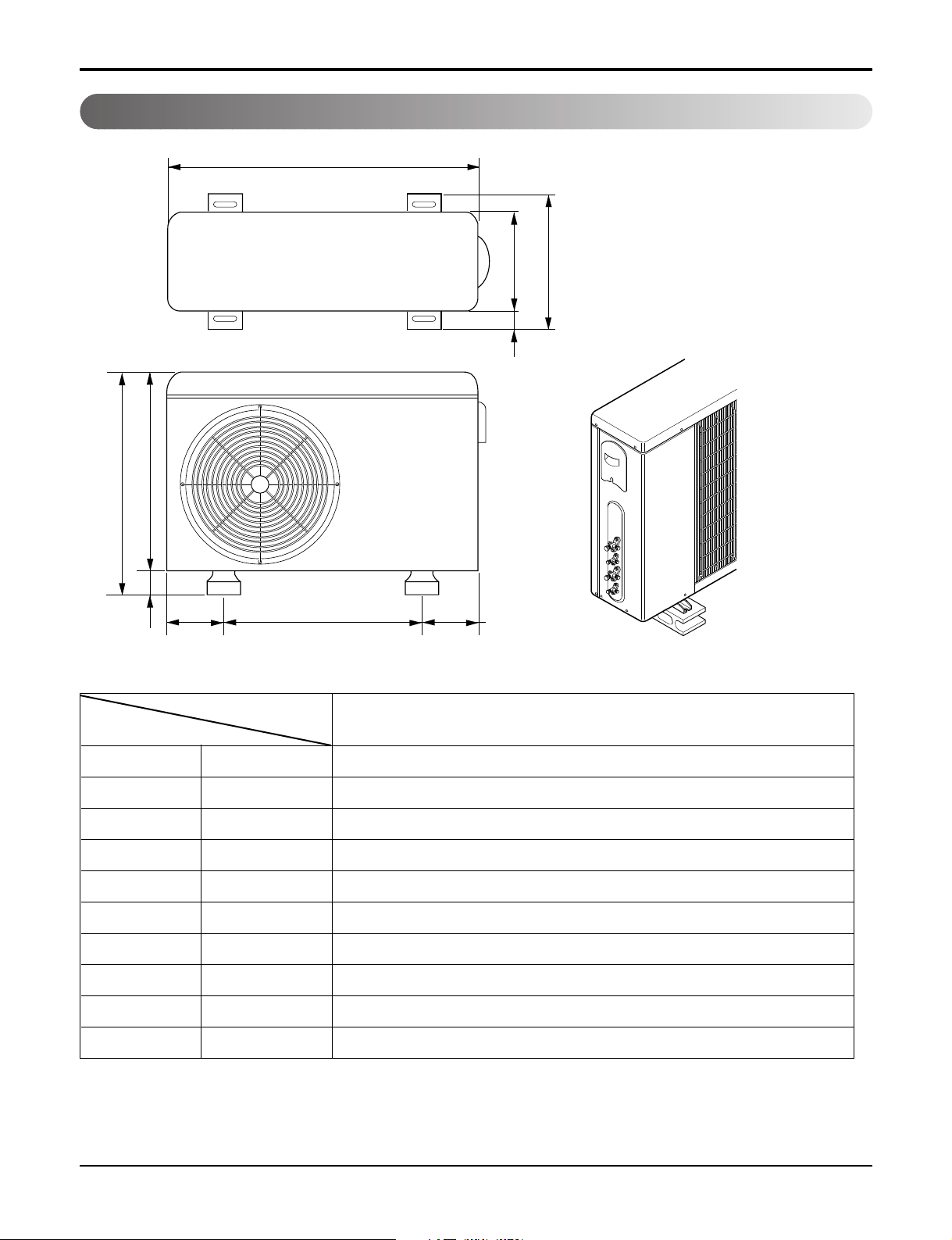

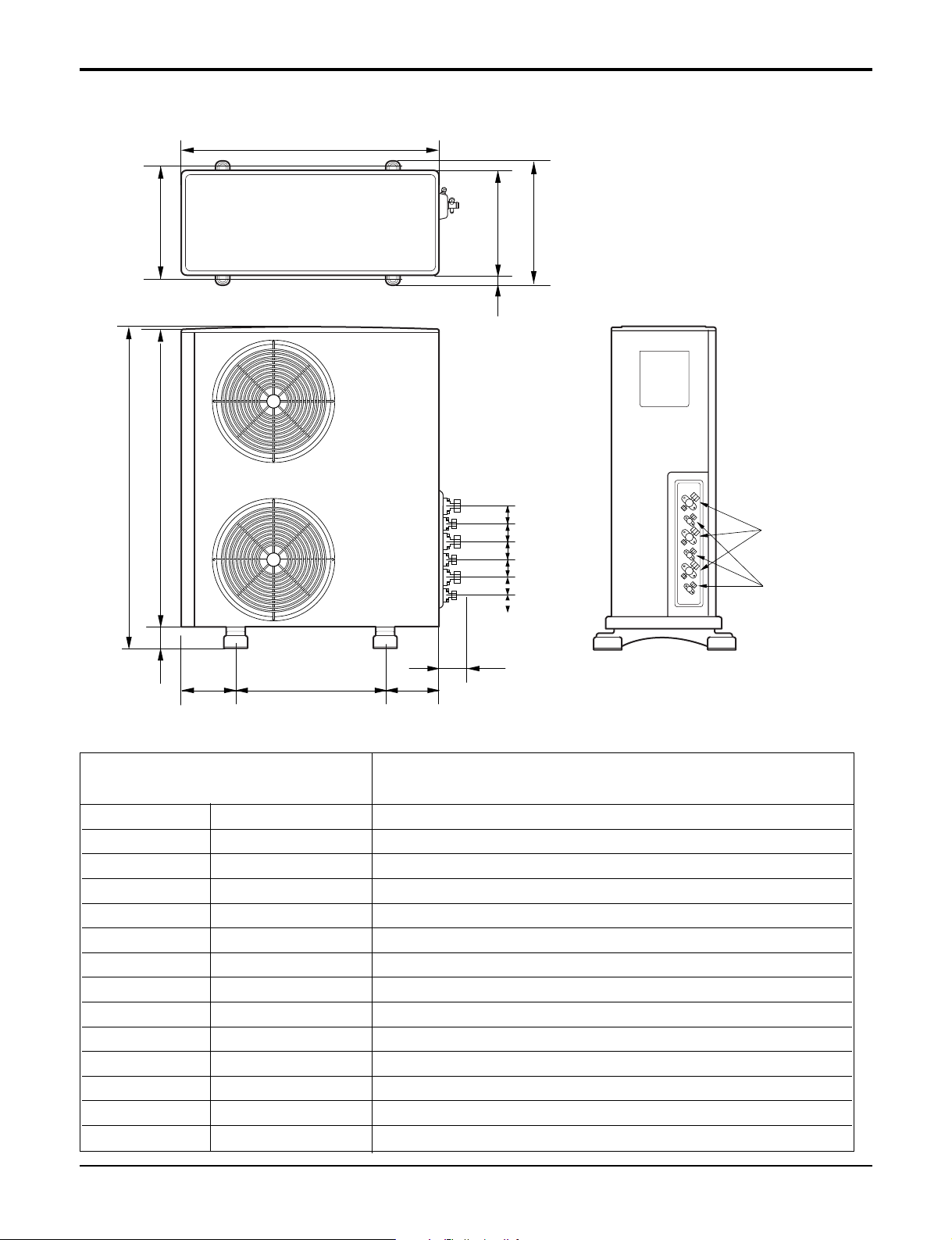

W

D

L1

L2

L4

L3

H

L7L5L6

Dimensions

Outdoor Unit

MODEL

DIM

W mm(in) 870(34.3)

H mm(in) 655(25.8)

D mm(in) 320(12.6)

L1 mm(in) 370(14.6)

L2 mm(in) 25(1.0)

L3 mm(in) 775(30.5)

L4 mm(in) 25(1.0)

L5 mm(in) 546(21.5)

L6 mm(in) 160(6.3)

L7 mm(in) 160(6.3)

UE

18kBtu/h

12 Multi type Air Conditioner

W

D

L1

L2

L4

L3

H

L7L5L6

MODEL

DIM

W mm(in) 870(34.3)

H mm(in) 808(31.8)

UE 1

24kBtu/h

D mm(in) 320(12.6)

L1 mm(in) 370(14.6)

L2 mm(in) 25(1.0)

L3 mm(in) 775(30.5)

L4 mm(in) 25(1.0)

L5 mm(in) 546(21.5)

L6 mm(in) 160(6.3)

L7 mm(in) 160(6.3)

Service Manual 13

Dimensions

L6L7 L8

L9

L4

H

L5

W

D

L1

L3

L2

L10 L11 L11 L11L11L11

Gas side

3-way valve

Liquid side

2-way valve

MODEL

DIM

W mm(in) 870(34.3)

H mm(in) 1038(40.7)

D mm(in) 320(12.6)

L1 mm(in) 360(14.2)

L2 mm(in) 340(13.4)

L3 mm(in) 25(1.0)

L4 mm(in) 1035(40.8)

L5 mm(in) 25(1.0)

L6 mm(in) 546(21.5)

L7 mm(in) 160(6.3)

L8 mm(in) 160(6.3)

L9 mm(in) 44(11.7)

L10 mm(in) 64.5(2.5)

L11 mm(in) 50(2.0)

UE2

36kBtu/h

14 Multi type Air Conditioner

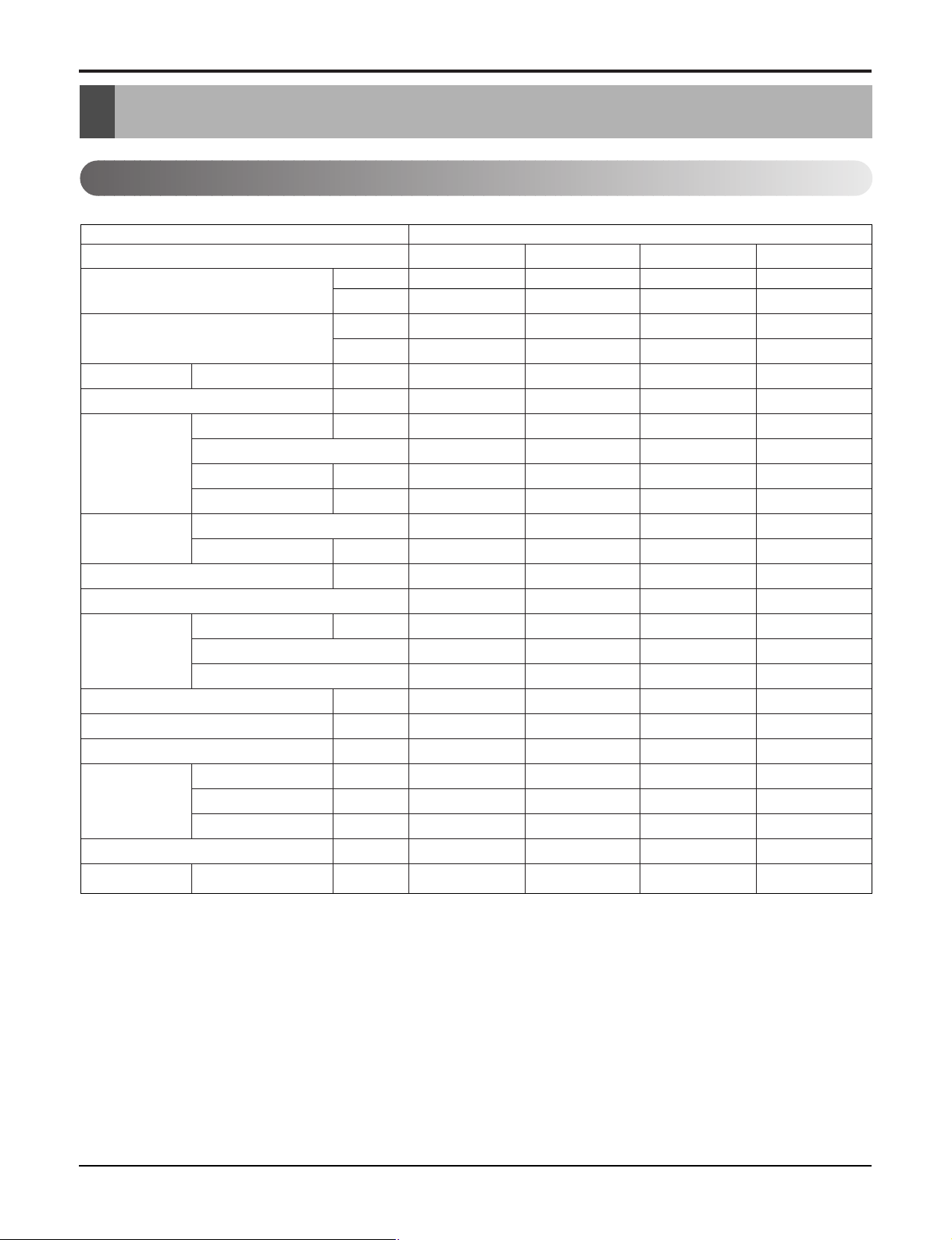

Product Specifications

Indoor Unit

Product Specifications

Indoor Unit Type

Model

Nominal Cooling Capacity kcal/h(W)

Nominal Heating Capacity kcal/h(W)

Air Circulation H/M/L CMM(CFM)

Setting temperature range(cool/heat) °C

Fan motor Output W

Fan Type

Noise Level (Sound Press,1m)

Temperature controller

Coil Tube Size (OD) inch(mm)

Dehumidification Rate l/h

Dimensions (W*H*D) inch(mm)

Net Weight kg(lbs)

Piping Connection Liquid inch(mm)

Packing Dimension (W*H*D) inch(mm)

Stuffing Quantity With(Without) S/Parts 20/40ft(hi-c)

★

Btu/h

★

Btu/h

Model

Input V

Running Current A

No. Used / Diameter EA/inch(mm)

H/M/L dBA

Fins per inch

No. of Rows & Column

Gas inch(mm)

Drain hose (ID Ø) mm

Wall Mounted

B-MMC09FA-1 B-MMH09FA-1 B-MMC12FA-1 B-MMH12FA-1

2,267(2,637) 2,267(2,637) 3,023(3,516) 3,023(3,516)

9,000 9,000 12,000 12,000

- 2,267(2,637) - 3,023(3,516)

- 9,000 - 12,000

8.2(289) 8.2(289) 9.4(332) 9.4(332)

18~30 18~30 18~30 18~30

15 15 15 15

DL-88430LGIF DL-88430LGIF DL-88430LGIF DL-88430LGIF

DC36 DC36 DC36 DC36

0.15 0.15 0.15 0.15

Cross Flow Fan Cross Flow Fan Cross Flow Fan Cross Flow Fan

1/3.74(95) 1/3.74(95) 1/3.74(95) 1/3.74(95)

31 / 29 / 22 31 / 29 / 22 36 / 32 / 29 36 / 32 / 29

Thermistor Thermistor Thermistor Thermistor

0.197(5.0) 0.197(5.0) 0.197(5.0) 0.197(5.0)

20 20 18 18

2R,15C 2R,15C 2R,15C 2R,15C

- 1.1 - 1.2

33.0*10.6*6.0(840*270*153) 33.0*10.6*6.0(840*270*153) 35.2*11.1*6.5(895*282*165) 35.2*11.1*6.5(895*282*165)

7(15.4) 7(15.4) 9.5(20.9) 9.5(20.9)

1/4 (6.35) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35)

3/8 (9.52) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52)

20 20 20 20

35.7*13.1*8.8(906*332*223) 35.7*13.1*8.8(906*332*223) 38.3*9.1*14.6(973*231*372) 38.3*9.1*14.6(973*231*372)

440/910 (1091) 440/910 (1091) 353/719 (792) 353/719 (792)

Note : 1.★See the page "Combination Table"

2. Due to our policy of innovation some specifications may be changed without notification.

Service Manual 15

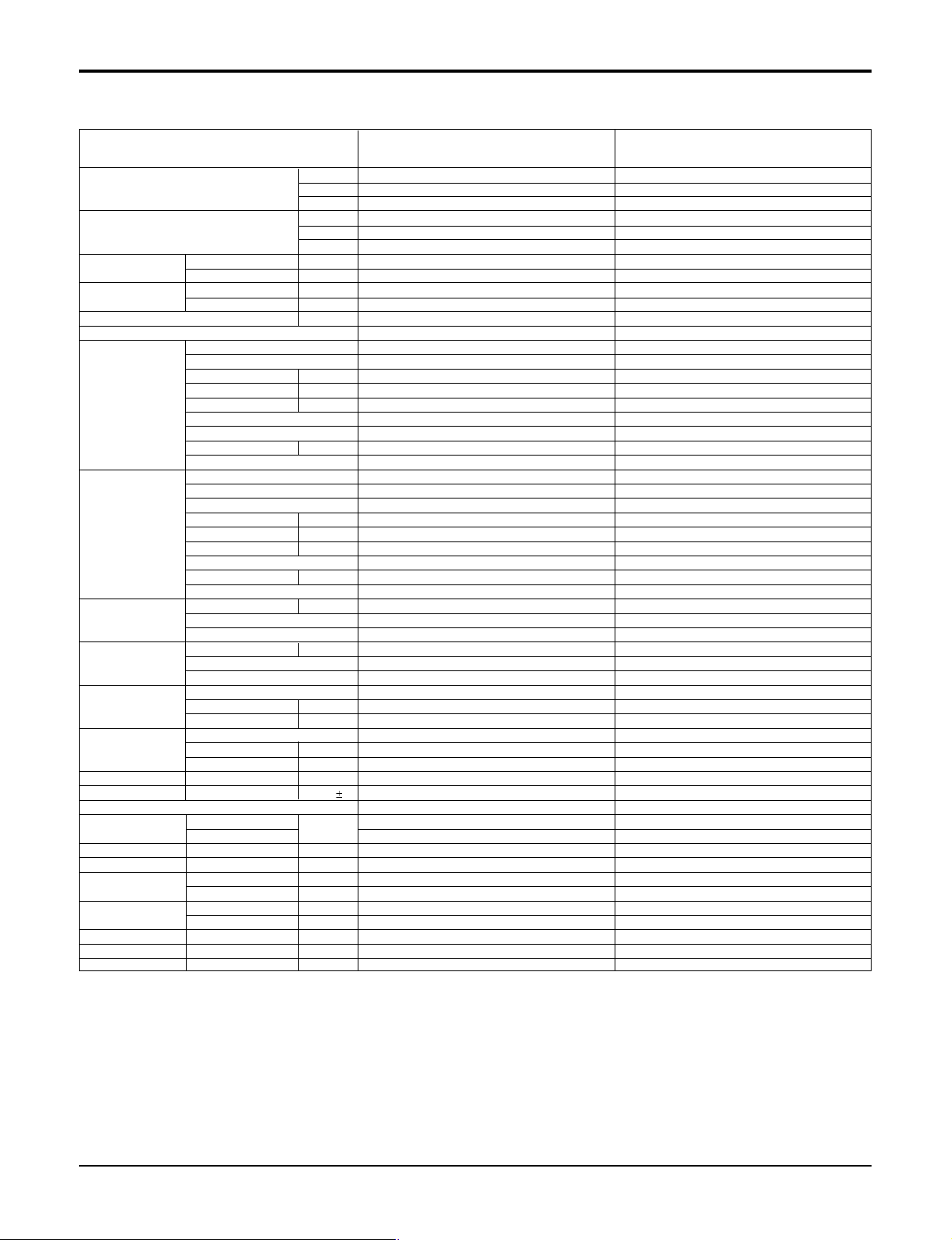

Product Specifications

Outdoor Unit - Multiple piping models

Model

Cooling Capacity★ Btu/hr

Heating Capacity★ Btu/hr

Input★ Cooling W

Running Current★(208/230V)

Power Supply Ø,V,Hz

Max. Number of Connectable Indoor Units

Compressor Type

(Constant) Model

Compressor Type

(Constant) Model

Refrigerant charge Charge g(oz)

Coil Tube Size (OD) inch(mm)

Fan motor Model

Fan Type

Air Circulation Outdoor CMM(CFM)

Noise Level(H/L) at 230V

Defrosting

SVC Valve Liquid inch(mm)

Dimensions W*H*D inch(mm)

Net Weight Outdoor kg(lbs)

Max. Interunit Piping Length

Max. Installation Indoor Unit~Outdoor Unit m

Height Difference Indoor Unit~Indoor Unit m

Packing Dimension W*H*D inch(mm)

Testing Combinations

Stuffing Quantity 20/40ft

Heating W

Cooling A

Heating A

Motor Type

Quantity Ea

Motor Input W

Oil Charge cc

Oil Type

Capacitor µF/Vac

O.L.P Type(model name)

Motor Type

Quantity Ea

Motor Input W

Oil Charge cc

Oil Type

Capacitor µF/Vac

O.L.P Type(model name)

Type

Control

Fins per inch

No. of Rows & Column/No.

Output W

Capacitor µF/Vac

No. Used / Diameter EA/inch(mm)

Discharge Side / Top

Sound Press,1m dB(A) 1

Gas

Total of Each Room m

For One Room m

W

kcal/hr

W

kcal/hr

A-MMH18FA-1

9,000~18,000

2637~5275

2267~4536

9,000~18,000

2637~5275

2267~4536

1070~1980

1040~1960

4.9~8.8

4.6~8.6

1,208/230,60

2

Rotary

GK094K

Hermetic

1

955

330±10

FVC68D

30 / 370

External Type(MRA98996-12026)

Rotary

GK113K

Hermetic

1

1,120

330±10

FVC68D

35 / 370

External Type(MRA12124-12026)

1400(49)

R410A

EEV

0.276(7.0)

18

2R,28C

IC-1640LG GE

90

6/370

Propeller

1 / 460

Side

50(1765.7)

51

Invertion Cycle

1/4 (6.35) * 2EA

3/8 (9.52) * 2EA

34.3*25.8*12.6 (870*655*320)

57(125.7)

30

15

7.5

7.5

40.2*28.2*17.2 (1020*716*437)

S4 9k + S4 9k

81/171

Note:

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 26.7˚C(80˚F) DB/19.4˚C(67˚F) WB

- Outdoor Temperature 35˚C(95˚F) DB/23.9˚C(75˚F) WB

Heating: - Indoor Temperature 21.1˚C(70˚F) DB/15.6˚C(60˚F) WB

- Outdoor Temperature 8.3˚C(47˚F) DB/6.1˚C(43˚F) WB

Piping Length - Interconnecting Piping Length 7.5m

- Level Difference of Zero

16 Multi type Air Conditioner

2. Wiring cable size must comply with the applicable local and national code.

3. Capacities are Net Capacities.

4. ★: See the page "Combination Table"

5. The specification may be subject to change without prior notice for purpose

of improvement.

Product Specifications

Model

Cooling Capacity★ Btu/hr

Heating Capacity★ Btu/hr

Input★ Cooling W

Running Current★(208/230V)

Power Supply Ø,V,Hz

Max. Number of Connectable Indoor Units

Compressor Type

(Constant) Model

Compressor Type

(Constant) Model

Refrigerant charge Charge g(oz)

Coil Tube Size (OD) inch(mm)

Fan motor Model

Fan Type

Air Circulation Outdoor CMM(CFM)

Noise Level(H/L) at 230V

Defrosting

SVC Valve Liquid inch(mm)

Dimensions W*H*D inch(mm)

Net Weight Outdoor kg(lbs)

Max. Interunit Piping Length

Max. Installation Indoor Unit~Outdoor Unit m

Height Difference Indoor Unit~Indoor Unit m

Packing Dimension W*H*D inch(mm)

Testing Combinations

Stuffing Quantity 20/40ft

Heating W

Cooling A

Heating A

Motor Type

Quantity Ea

Motor Input W

Oil Charge cc

Oil Type

Capacitor µF/Vac

O.L.P Type(model name)

Motor Type

Quantity Ea

Motor Input W

Oil Charge cc

Oil Type

Capacitor µF/Vac

O.L.P Type(model name)

Type

Control

Fins per inch

No. of Rows & Column/No.

Output W

Capacitor µF/Vac

No. Used / Diameter EA/inch(mm)

Discharge Side / Top

Sound Press,1m dB(A) 1

Gas

Total of Each Room m

For One Room m

W

kcal/hr

W

kcal/hr

A-MMC24FA-1 A-MMH24FA-1

9,000~24,000 9,000~24,000

2637~7033 2637~7033

2267~6037 2267~6037

- 9,000~24,000

- 2637~7033

- 2267~6037

1170~2390 1170~2390

- 1220~2440

7.7~10.1 7.7~10.1

- 7.4~9.8

1,208/230,60 1,208/230,60

22

Rotary Rotary

GK094K GK094K

Hermetic Hermetic

11

955 955

330±10 330±10

FVC68D FVC68D

30 / 370 30 / 370

External Type(MRA98996-12026) External Type(MRA98996-12026)

Rotary Rotary

GK141K GK141K

Hermetic Hermetic

11

1430 1,430

350±10 350±10

FVE FVE

35 / 370 35 / 370

External Type(MRA12105-12026) External Type(MRA12105-12026)

1600 1600

R410A R410A

EEV EEV

0.276(7.0) 0.276(7.0)

18 18

2R,36C 2R,36C

IC-1640LG GE IC-1640LG GE

90 90

6/370 6/370

Propeller Propeller

1 / 460 1 / 460

Side Side

53(1872) 53(1872)

54 54

- Invertion Cycle

1/4 (6.35) * 2EA 1/4 (6.35) * 2EA

3/8 (9.52) * 2EA 3/8 (9.52) * 2EA

34.3*31.8*12.6 (870*808*320) 34.3*31.8*12.6 (870*808*320)

64(141.1) 64(141.1)

30 30

15 15

7.5 7.5

7.5 7.5

40.2*34.3*17.2 (1022*870*437) 40.2*34.3*17.2 (1022*870*437)

SE 12K +SE 12K SE 12K +SE 12K

54/114 54/114

Note:

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 26.7˚C(80˚F) DB/19.4˚C(67˚F) WB

- Outdoor Temperature 35˚C(95˚F) DB/23.9˚C(75˚F) WB

Heating: - Indoor Temperature 21.1˚C(70˚F) DB/15.6˚C(60˚F) WB

- Outdoor Temperature 8.3˚C(47˚F) DB/6.1˚C(43˚F) WB

Piping Length - Interconnecting Piping Length 7.5m

- Level Difference of Zero

2. Wiring cable size must comply with the applicable local and national code.

3. Capacities are Net Capacities.

4. ★: See the page "Combination Table"

5. The specification may be subject to change without prior notice for purpose

of improvement.

Service Manual 17

Product Specifications

Model

Cooling Capacity★ Btu/hr

Heating Capacity★ Btu/hr

Input★ Cooling W

Running Current★(208/230V)

Power Supply Ø,V,Hz

Max. Number of Connectable Indoor Units

Compressor Type

(Constant) Model

Compressor Type

(Constant) Model

Refrigerant charge Charge g(oz)

Coil Tube Size (OD) inch(mm)

Fan motor Model

Fan Type

Air Circulation Outdoor CMM(CFM)

Noise Level(H/L) at 230V

SVC Valve Liquid inch(mm)

Dimensions W*H*D inch(mm)

Net Weight Outdoor kg(lbs)

Max. Interunit Piping Length

Max. Installation Indoor Unit~Outdoor Unit m

Height Difference Indoor Unit~Indoor Unit m

Packing Dimension W*H*D inch(mm)

Stuffing Quantity 20/40ft

Heating W

Cooling A

Heating A

Motor Type

Quantity Ea

Motor Input W

Oil Charge cc

Oil Type

Capacitor µF/Vac

O.L.P Type(model name)

Motor Type

Quantity Ea

Motor Input W

Oil Charge cc

Oil Type

Capacitor µF/Vac

O.L.P Type(model name)

Type

Control

Fins per inch

No. of Rows & Column/No.

Output W

Capacitor µF/Vac

No. Used / Diameter EA/inch(mm)

Discharge Side / Top

Sound Press,1m dB(A) 1

Gas

Total of Each Room m

For One Room m

W

kcal/hr

W

kcal/hr

A-MMC36FA-1 A-MMH36FA-1

9,000~36,000 9,000~36,000

2637~10,550 2637~10,550

2267~9071 2267~9071

- 9,000~36,000

- 2637~10,550

- 2267~9071

1320~3680 1320~3680

- 1410~3340

5.9~16.6 5.9~16.6

- 6.3~15.0

1,208/230,60 1,208/230,60

33

Rotary Rotary

GK141K GK141K

2 Pole Induction(PSC) 2 Pole Induction(PSC)

11

1430 1430

350Å}10 350Å}10

FVC68D FVC68D

35 / 370 35 / 370

External Type External Type

Rotary Rotary

GJ230K GJ230K

2 Pole Induction(PSC) 2 Pole Induction(PSC)

11

2370 2370

700±10 7000±10

FVC68D FVC68D

50 / 400 50 / 400

Internal Type Internal Type

2400 2400

R410A R410A

EEV EEV

0.276(7.0) 0.276(7.0)

18 18

2R,48C 2R,48C

ARC286B01 * 2 ARC286B01 * 2

102 102

2/370 2/370

Propeller Propeller

2 / 15.7(400) 2 / 15.7(400)

Side Side

63(2225) 63(2225)

51 51

1/4 (6..35) * 3EA 1/4 (6..35) * 3EA

3/8 (9.52) * 3EA 3/8 (9.52) * 3EA

34.3*40.7*12.6 (870*1038*320) 34.3*40.7*12.6 (870*1038*320)

84(185.2) 84(185.2)

45 45

15 15

7.5 7.5

7.5 7.5

41.3*44.9*17.3 (1048*1140*439) 41.3*44.9*17.3 (1048*1140*439)

53/111 53/111

Note:

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 26.7˚C(80˚F) DB/19.4˚C(67˚F) WB

- Outdoor Temperature 35˚C(95˚F) DB/23.9˚C(75˚F) WB

Heating: - Indoor Temperature 21.1˚C(70˚F) DB/15.6˚C(60˚F) WB

- Outdoor Temperature 8.3˚C(47˚F) DB/6.1˚C(43˚F) WB

Piping Length - Interconnecting Piping Length 7.5m

- Level Difference of Zero

18 Multi type Air Conditioner

2. Wiring cable size must comply with the applicable local and national code.

3. Capacities are Net Capacities.

4. ★: See the page "Combination Table"

5. The specification may be subject to change without prior notice for purpose

of improvement.

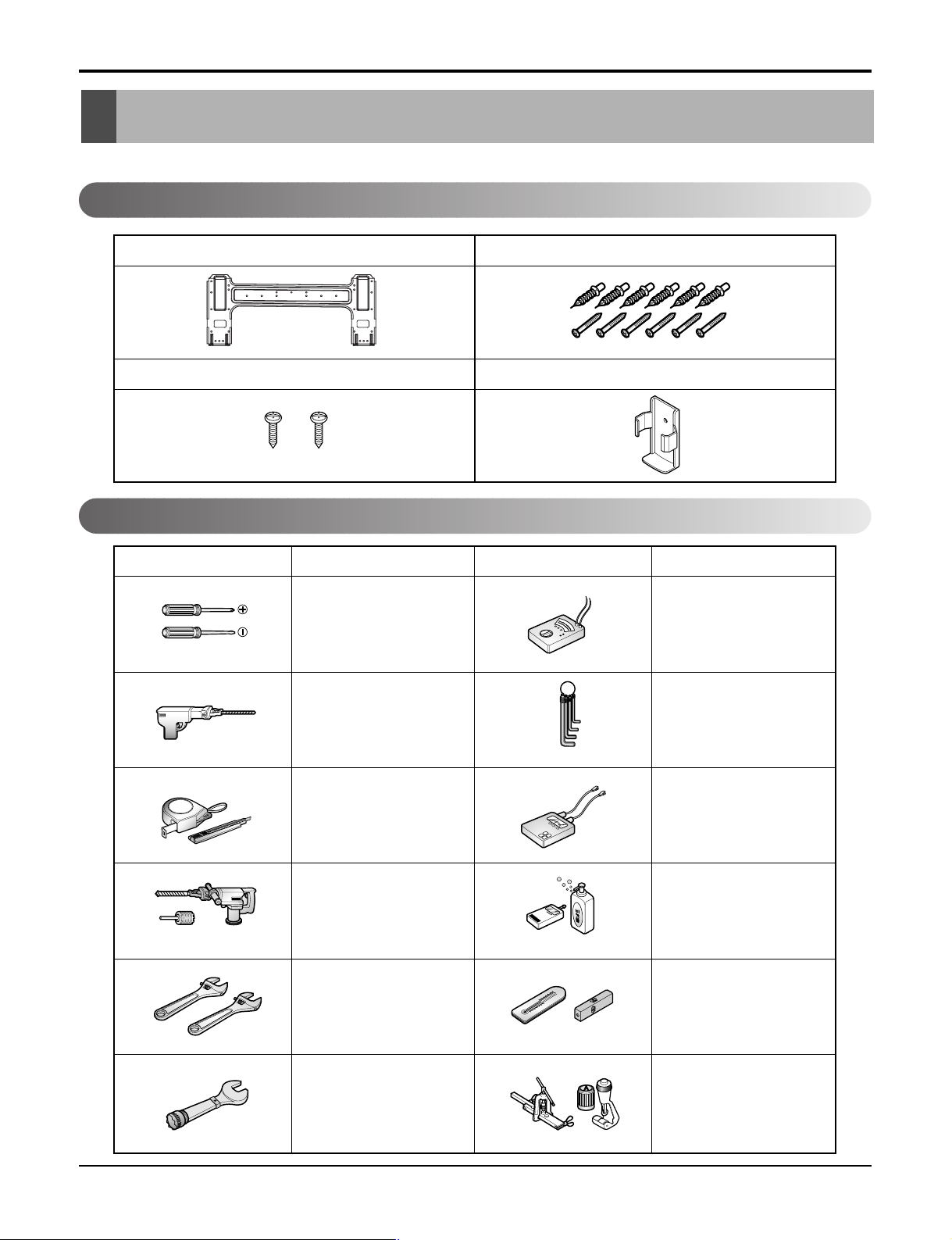

Installation

Type "A" screw and plastic anchor

Type "B" screw

Remote Control Holder

Installation plate

Figure FigureName

Screw driver

Electric Drill

Measuring Tape, Knife

Hole Core Drill

Spanner

Torque wrench

Ohmmeter

Hexagonal wrench

Ammeter

Gas Leak Detector

Thermometer,

Level

Flaring Tool Set

Name

Read carefully, and then follow step by step.

Installation Parts

Installation

Installation Tools

Service Manual 19

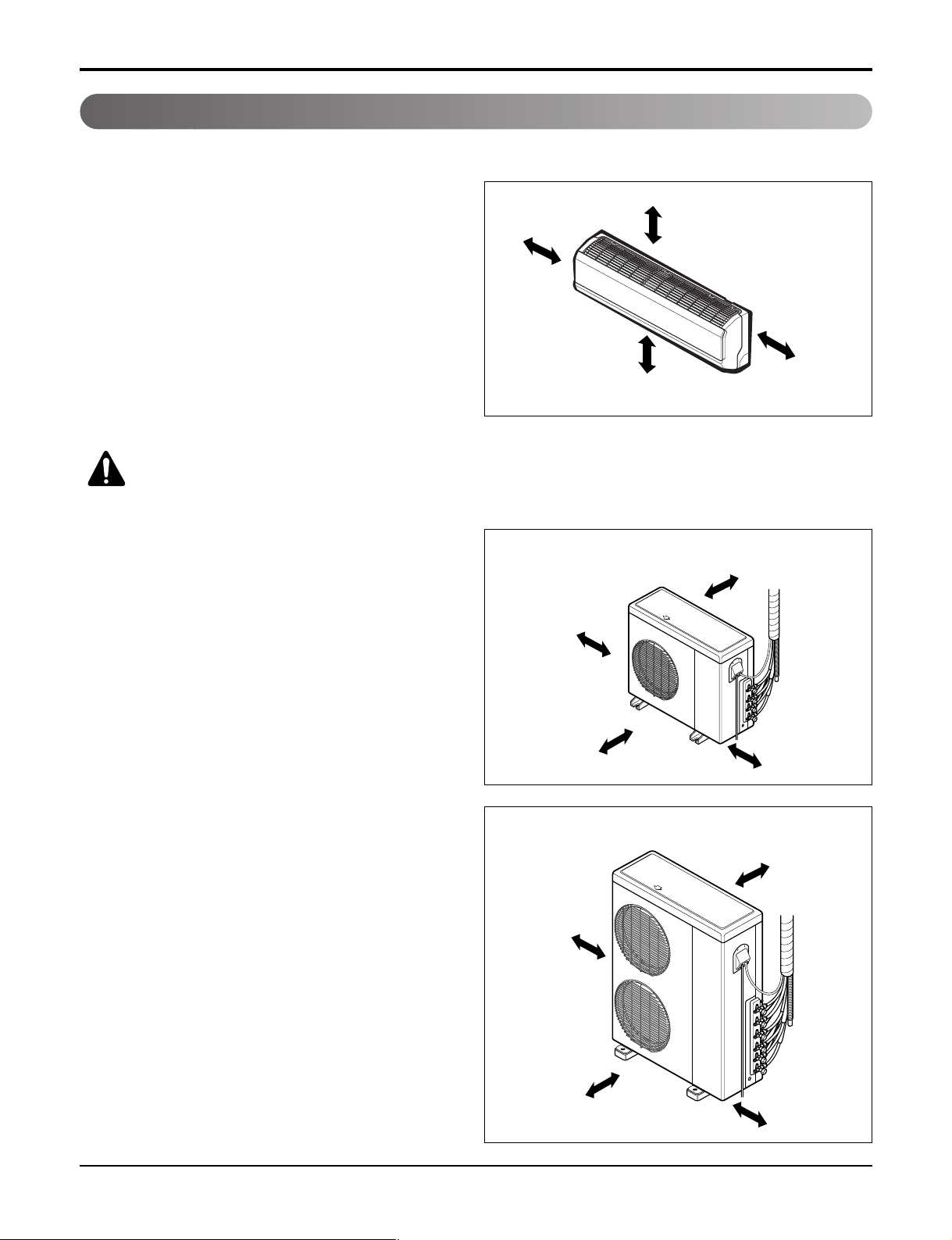

Installation

More than 20 cm

(7.9 inch)

More than 10 cm

(3.9 inch)

More than 10 cm

(3.9 inch)

More than 2.4m

(8 ft)

Select the best location

Indoor unit

1. Do not have any heat or steam near the unit.

2. Select a place where there are no obstacles in front

of the unit.

3. Make sure that condensation drainage can be conveniently routed away.

4. Do not install near a doorway.

5. Ensure the spaces indicated by arrows from the wall,

ceiling, fence or other obstacles.

6. Use a Metal Detector or Metal Scanner to locate

studs to prevent unnecessary damage to the wall.

CAUTION: Install the indoor unit

on the wall where the height from

the floors more than 2.4 m (8 ft).

Outdoor unit

1. If an awning is built over the unit to prevent direct

sunlight or rain exposure, make sure that heat radiation from the condenser is not restricted.

2. Ensure that the spaces indicated by arrows around

front, back and side of the unit.

3. Do not place animals and plants in the path of the

warm air.

4. Take the air conditioner weight into account and

select a place where noise and vibration are minimum.

Select a place so that the warm air and sound from

5.

the air conditioner do not disturb neighbors.

Rooftop Installations:

If the outdoor unit is installed on a roof structure, be

sure to level the unit. Ensure the roof structure and

anchoring method are adequate for the unit location.

Consult local codes regarding rooftop mounting.

18 / 24 kBtu

more than 30 cm

(11.8 inch)

more than 70 cm

(27.6 inch)

36 kBtu

more than 30 cm

(11.8 inch)

more than 30 cm

(11.8 inch)

more than 60 cm

(23.6 inch)

more than 30 cm

(11.8 inch)

20 Multi type Air Conditioner

more than 70 cm

(27.6 inch)

more than 60 cm

(23.6 inch)

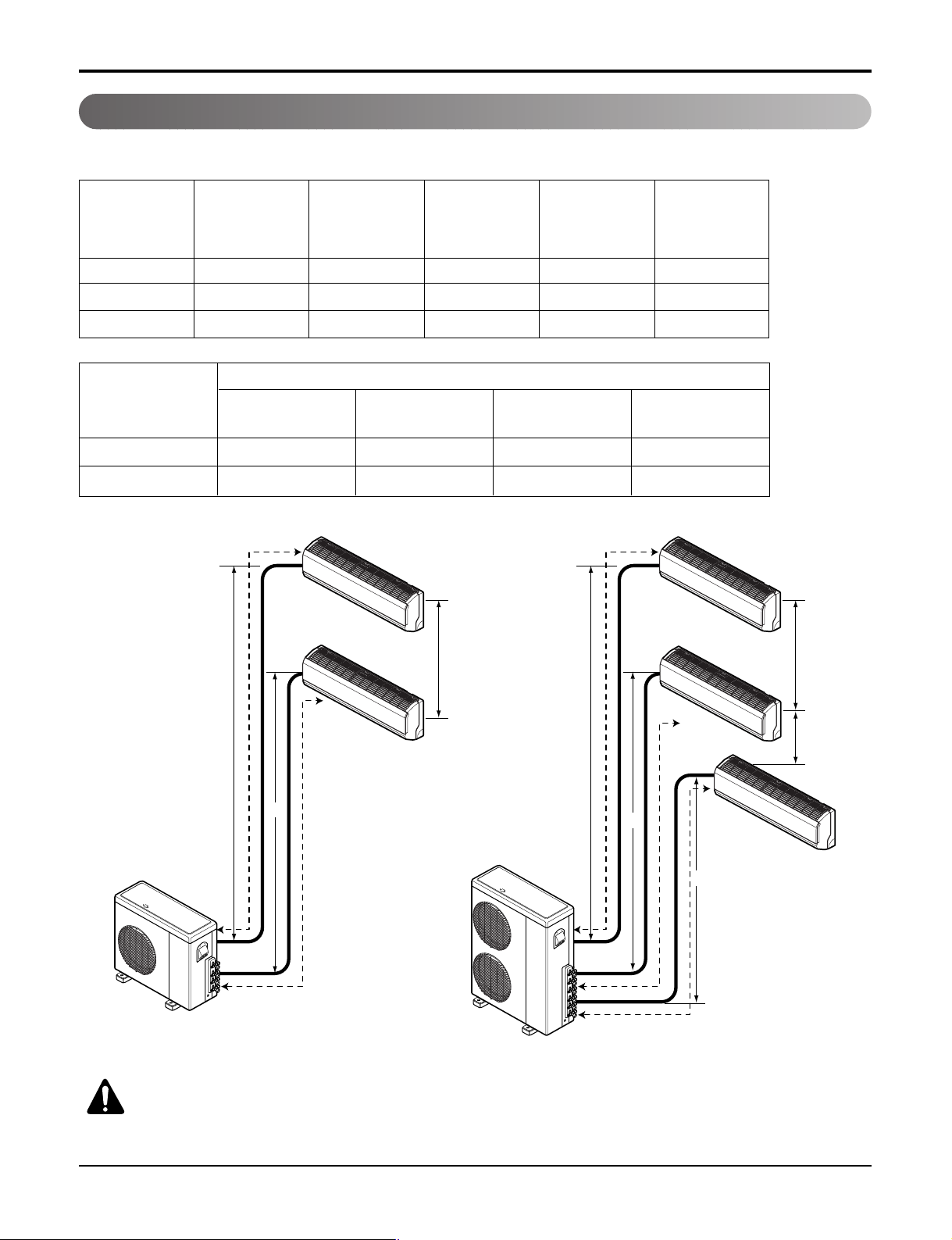

Piping length and elevation

h2

h2

h1

A

B

B

C

h2

h1

A

B

h1

h1

h1

Multi Piping Type

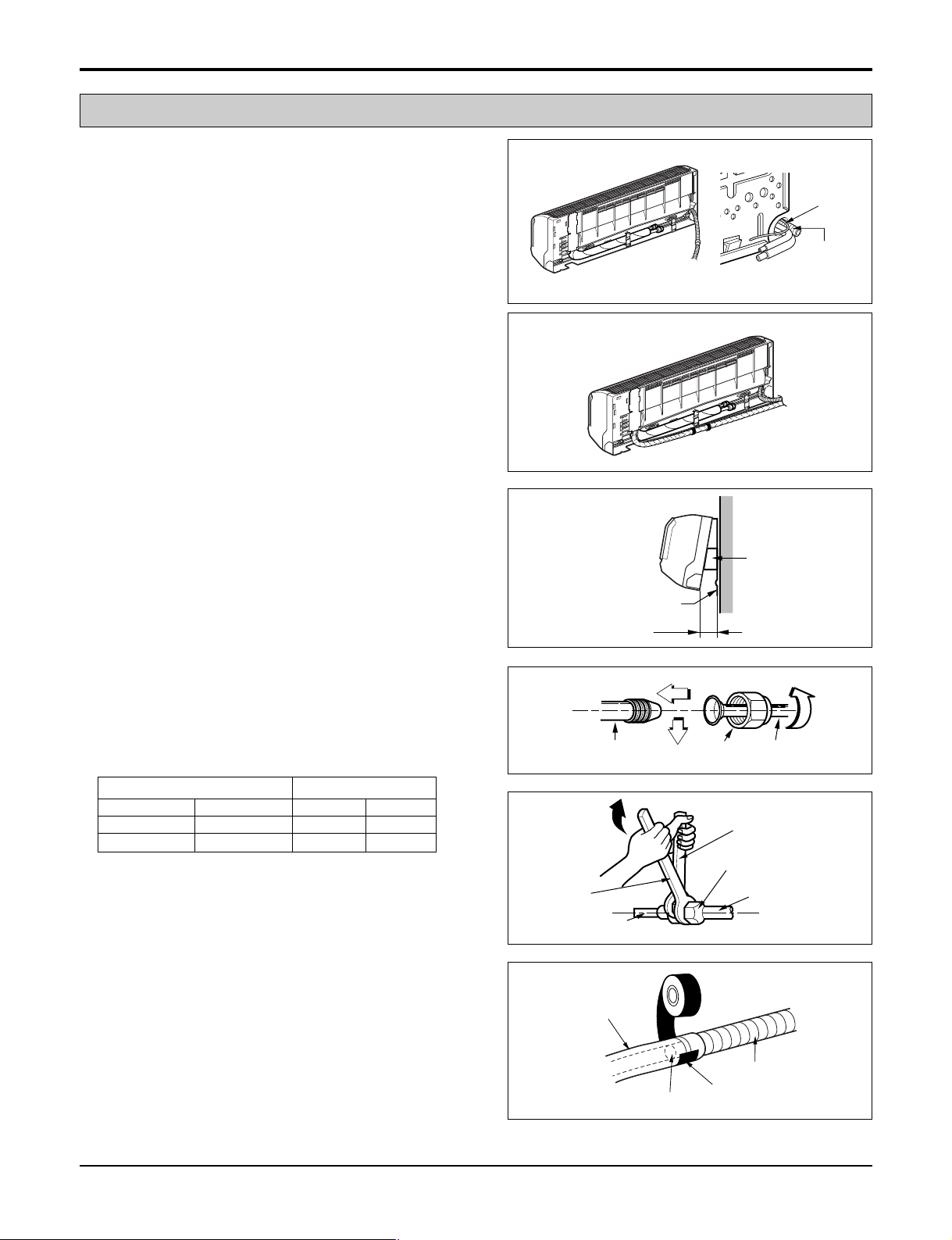

Installation

Capacity

Max total length

of all pipes

(A+B/A+B+C)

Max length of

each pipe

(A/B/C)

Min length of

each pipe

(A/B/C)

Max Elevation

between each

indoor unit and

outdoor unit (h1)

Max elevation

between indoor

units (h2)

18 kBtu 30 m (100 ft) 15 m (50 ft) 3 m (10 ft) 7.5 m (25 ft) 7.5 m (25 ft)

24 kBtu 30 m (100 ft) 15 m (50 ft) 3 m (10 ft) 7.5 m (25 ft) 7.5 m (25 ft)

36 kBtu 45 m (150 ft) 15 m (50 ft) 3 m (10 ft) 7.5 m (25 ft) 7.5 m (25 ft)

Pipe Size

Indoor Capacity

Gas Liquid Standard Length

Additional

Refrigerant

9 kBtu 9.52 mm (3/8") 6.35 mm (1/4") 7.5 m (25 ft) 20 g/m (0.22 oz/ft)

12 kBtu 9.52 mm (3/8") 6.35 mm (1/4") 7.5 m (25 ft) 20 g/m (0.22 oz/ft)

18 / 24 kBtu

36 kBtu

CAUTION: Capacity is based on standard length and maximum allowance length is on the

basis of reliability.

Service Manual 21

Installation

Installation Plate

Type "A" screw

Chassis

Hook

5-7 mm

(0.2"~0.3")

Indoor

WALL

Outdoor

Fixing Installation Plate(Standard Type)

The wall you select should be strong and solid enough to

prevent vibration

1. Mount the installation plate on the wall with

type "A" screws. If mounting the unit on a concrete wall,

use anchor bolts.

• Mount the installation plate horizontally by aligning the

centerline using a level.

2. Measure the wall and mark the centerline. It is also

important to use caution concerning the location of the

installation plate-routing of the wiring to power outlets is

through the walls typically. Drilling the hole through the

wall for piping connections must be done safely.

CHASSIS

(Grade)

S4 50 105 59 105

SE 65 110 85 110

ABCD

Distance (mm)

D

C

Ø70mm

Left rear piping Right rear piping

Installation plate

B

A

Ø70mm

Drill a hole in the wall

• Drill the piping hole with a Ø 70 mm (Ø 2.75 inch) hole core drill. Drill the piping hole at either the right or the left

with the hole slightly slanted to the outdoor side.

22 Multi type Air Conditioner

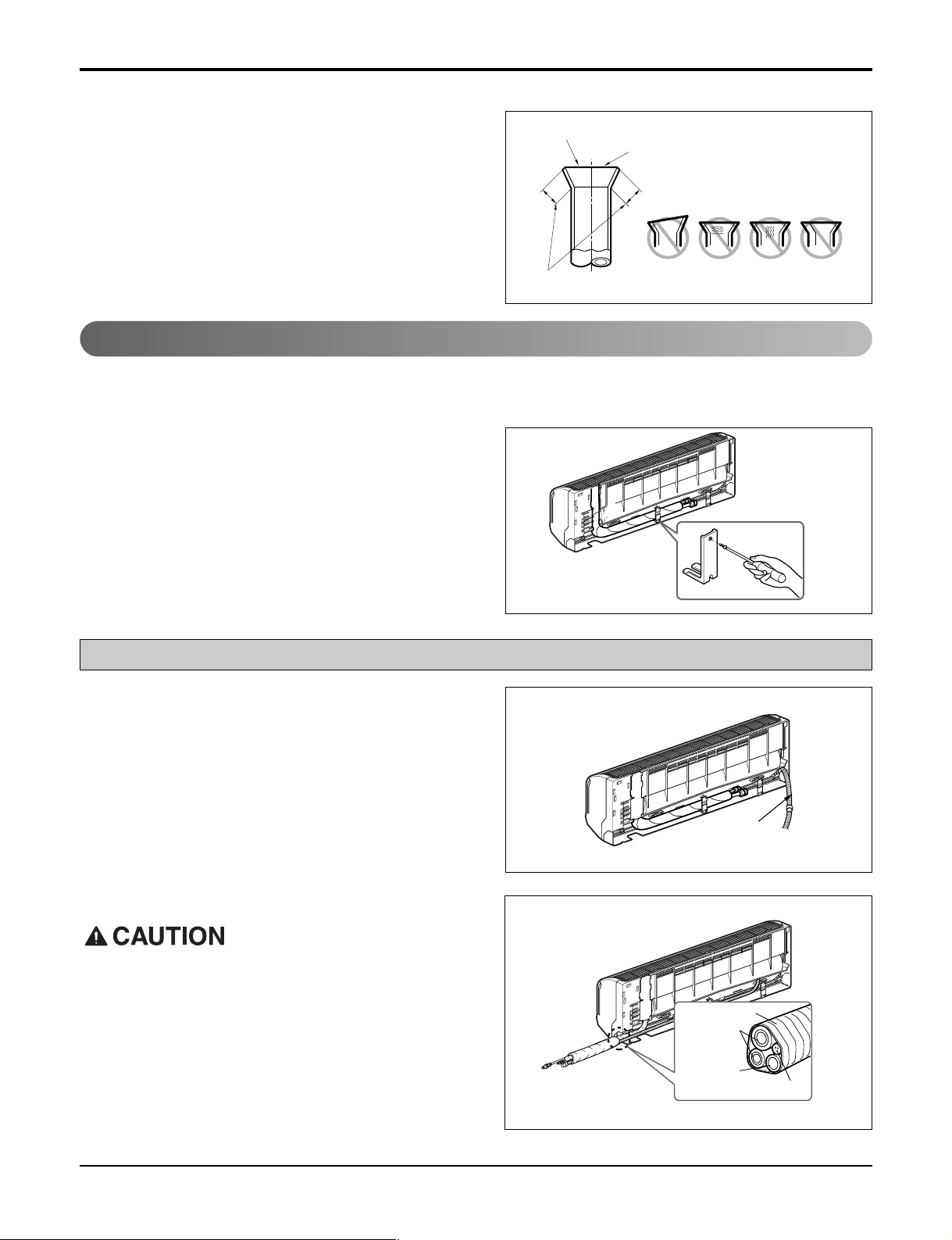

Flaring Work and Connection of Piping

Copper

pipe

90°

Slanted Uneven Rough

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Flaring Work and Connection of Piping

Flaring work

Main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the following procedure.

Cut the pipes

1. Use the piping kit accessory or the pipes purchased locally.

2. Measure the distance between the indoor and the outdoor unit.

3. Cut the pipes a little longer than measured distance.

4. Cut the cable 1.5m (5.0ft) longer than the pipe length.

Burrs removal

1. Completely remove all burrs from the cut cross section of

pipe/tube.

2. Put the end of the copper tube/pipe in a downward direction

as you remove burrs in order to avoid dropping burrs into the

tubing.

Pipe

Reamer

Putting nut on

• Remove flare nuts attached to indoor and outdoor unit, then

put them on pipe/tube having completed burr removal.

(not possible to put them on after flaring work)

Flaring work

• Carry out flaring work using flaring tool as shown below.

• Firmly hold copper pipe in a Bar in the dimension shown in the

table Below.

Outside diameter A

mm inch mm

Ø6.35 1/4 0~0.5

Ø9.52 3/8 0~0.5

Point down

Flare nut

Copper tube

Service Manual 23

Flaring Work and Connection of Piping

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Check

1. Compare the flared work with the figure by.

2. If a flared section is defective, cut it off and do flaring work

again.

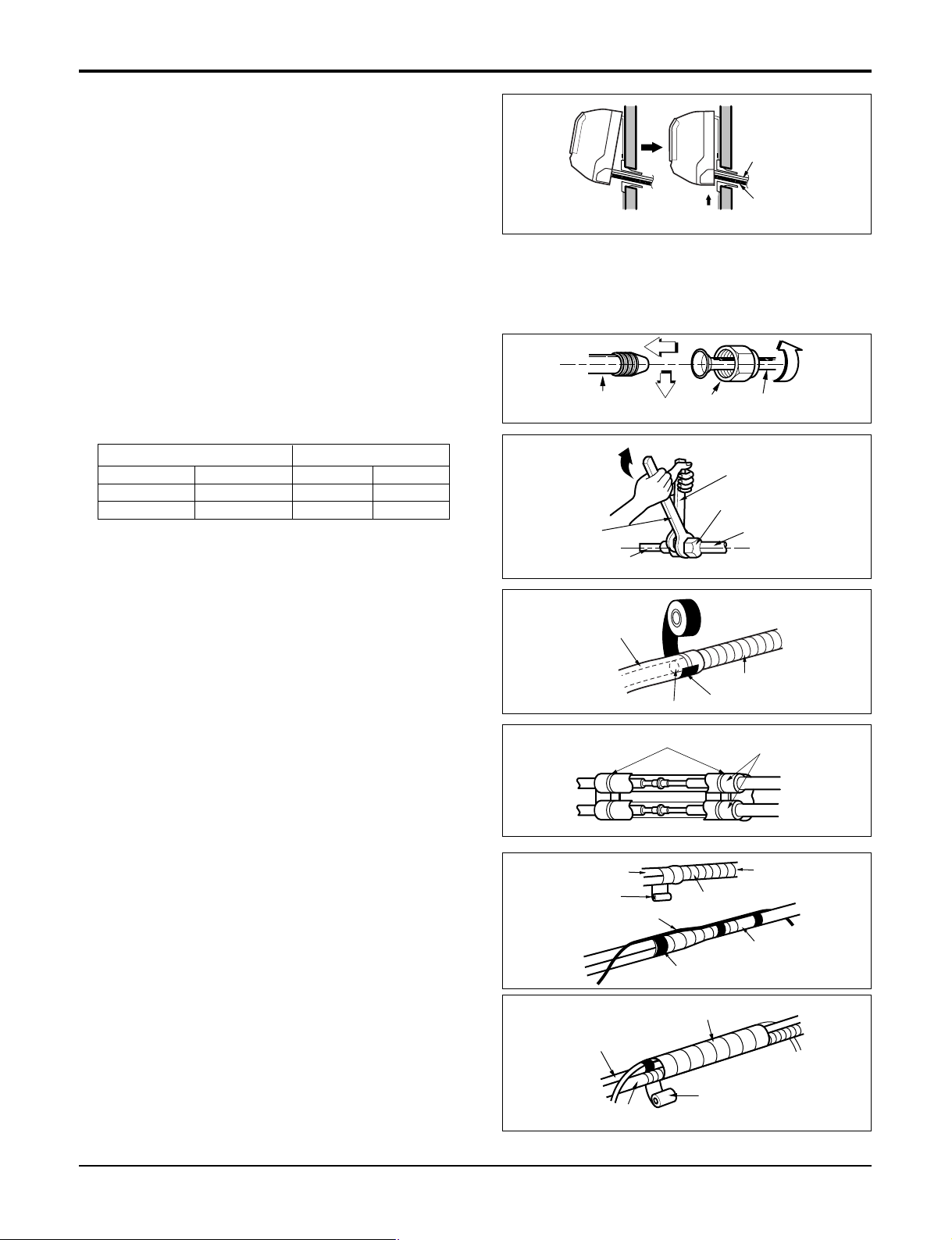

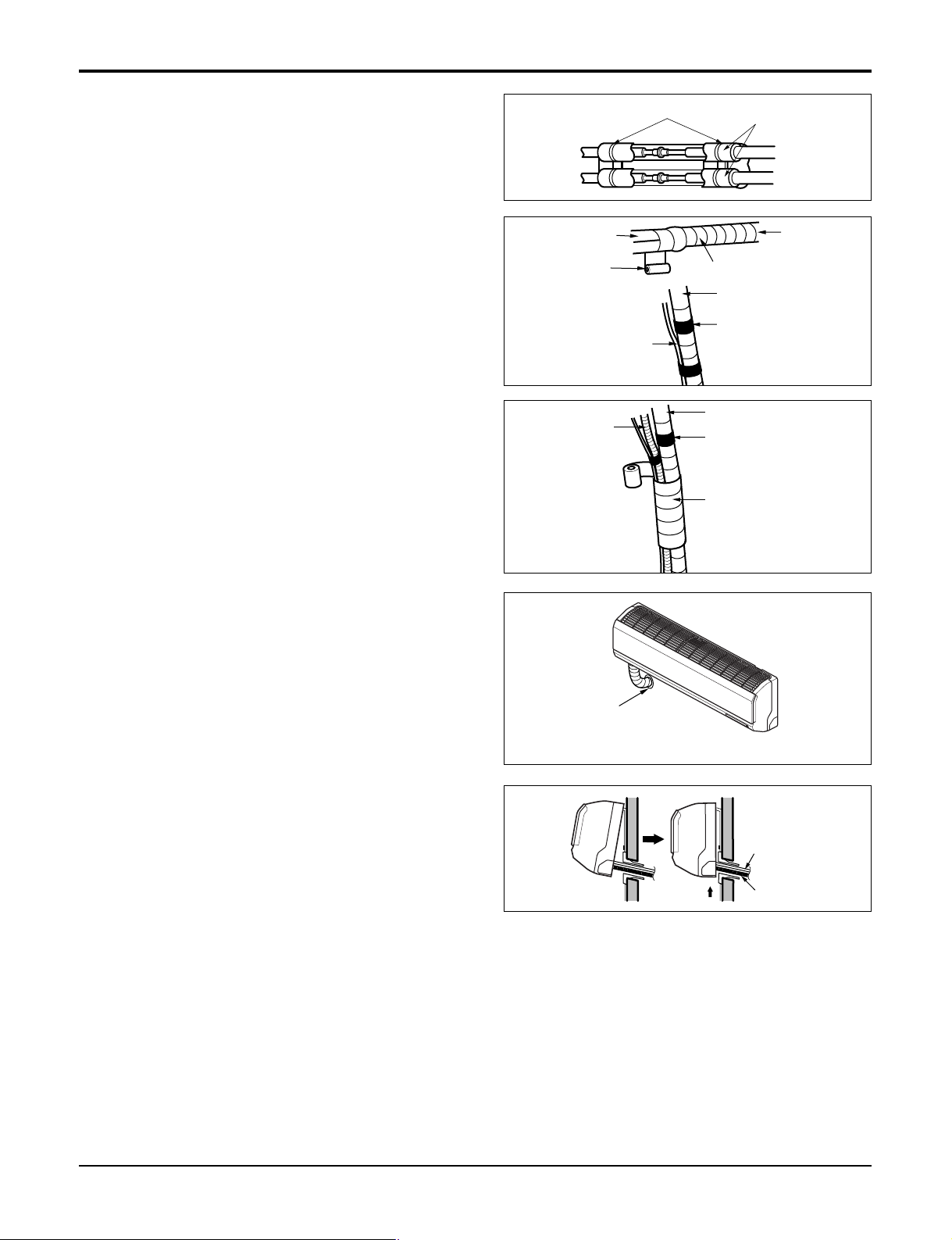

Connecting the Piping

Indoor

1. Prepare the indoor unit's piping and drain hose for installation through the wall.

2. Remove the plastic tubing retainer(see the illustration by)

and pull the tubing and drain hose away from chassis.

3. Replace only the plastic tubing holder 1, not the holder 2 in

the original position.

For right rear piping

1. Route the indoor tubing and the drain hose in the direction

of rear right.

2.

Insert the connecting cable into the indoor unit from the outdoor unit through the piping hole.

• Do not connect the cable to the indoor unit.

•

Make a small loop with the cable for easy connection later.

3. Tape the tubing, drain hose, and the connecting cable. Be

sure that the drain hose is located at the lowest side of the

bundle. Locating at the Upper side can cause drain pan to

overflow inside the unit.

If the drain hose is routed inside the room, insulate the hose

with an insulation material* so that dripping from "sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

Drain hose

Tape

Connecting

pipe

Drain hose

Connecting cable

24 Multi type Air Conditioner

4. Indoor unit installation

Drain hose

Connecting

cable

Hook the indoor unit onto the upper portion of the installation plate.(Engage the two hooks of the rear top of the

indoor unit with the upper edge of the installation plate.)

Ensure that the hooks are properly seated on the installation plate by moving it left and right.

Press the lower left and right sides of the unit against the

installation plate until the hooks engage into their

slots(clicking sound).

Connecting the piping to the indoor unit and drain hose

to drain pipe.

1. Align the center of the pipes and sufficiently tighten the

flare nut by hand.

2. Tighten the flare nut with a wrench.

Flaring Work and Connection of Piping

Indoor unit tubing Flare nut Pipes

Outside diameter Torque

mm inch kg.m lbf.in

Ø6.35 1/4 1.8 156.2

Ø9.52 3/8 4.2 364.5

3. When extending the drain hose at the indoor unit, install

the drain pipe.

Wrap the insulation material around the connecting portion.

1. Overlap the connection pipe insulation material and the

indoor unit pipe insulation material. Bind them together

with vinyl tape so that there may be no gap.

2. Wrap the area which accommodates the rear piping housing section with vinyl tape.

3. Bundle the piping and drain hose together by wrapping

them with vinyl tape for enough to cover where they fit into

the rear piping housing section.

Wrench

Indoor unit tubing

Drain pipe

Connection pipe

Vinyl tape (wide)

Connecting cable

Open-end wrench (fixed)

Flare nut

Indoor unit drain hose

Vinyl tape(narrow)

Adhesive

Plastic bands

Insulation material

Wrap with vinyl tape

Vinyl tape(narrow)

Connection pipe

Indoor unit pipe

Pipe

Wrap with vinyl tape

Pipe

Vinyl tape(wide)

Drain hose

Service Manual 25

Flaring Work and Connection of Piping

For left rear piping

1. Route the indoor tubing and the drain hose to the required

piping hole position.

2. Insert the piping, drain hose, and the connecting cable into

the piping hole.

3.

Insert the connecting cable into the indoor unit.

• Don't connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection

later.

4. Tape the drain hose and the connecting cables.

5. Indoor unit installation

• Hang the indoor unit from the hooks at the top of the

installation plate.

• Insert the spacer etc. between the indoor unit and the

installation plate and separate the bottom of the indoor

unit from the wall.

Connecting the piping to the indoor unit and the drain

hose to drain pipe.

1. Align the center of the pipes and sufficiently tighten the

flare nut by hand.

Connecting

cable

Drain pipe

Indoor unit

Spacer

Installation plate

8cm

2. Tighten the flare nut with a wrench.

Outside diameter Torque

mm inch kg.m lbf.in

Ø6.35 1/4 1.8 156.2

Ø9.52 3/8 4.2 364.5

3. When extending the drain hose at the indoor unit, install

the drain pipe.

26 Multi type Air Conditioner

Indoor unit tubing Flare nut Pipes

Open-end wrench (fixed)

Flare nut

Wrench

Indoor unit tubing

Drain hose

Indoor unit drain hose

Adhesive

Vinyl tape

Connection pipe

(narrow)

Wrap the insulation material around the connecting por-

Plastic bands

Insulation material

tion.

1. Overlap the connection pipe heat insulation and the indoor

unit pipe heat insulation material. Bind them together with

vinyl tape so that there may be no gap.

2. Wrap the area which accommodates the rear piping housing section with vinyl tape.

3. Bundle the piping and drain hose together by wrapping

them with cloth tape over the range within which they fit

into the rear piping housing section.

Reroute the pipings and the drain hose across the back

of the chassis.

Flaring Work and Connection of Piping

Connection

pipe

Vinyl tape

(wide)

Connecting cable

Drain hose

Wrap with vinyl tape

Pipe

Vinyl tape(narrow)

Pipe

Vinyl tape(narrow)

Wrap with

vinyl tape(wide)

Indoor

unit piping

Indoor unit installation

1. Remove the spacer.

2. Ensure that the hooks are properly seated on the installation plate by moving it left and right.

3. Press the lower left and right sides of the unit against the

installation plate until the hooks engage into their

slots(clicking sound).

Piping for

passage through

piping hole

Connecting

cable

Drain hose

Service Manual 27

Loading...

Loading...