Lenze MC3000 User Manual

MC3000 Series Drives

Metasys N2 Communications Guide

About These Instructions

This documentation applies to the use of an MC3000 Series Variable Frequency Drive with Metasys N2 protocol and should be used in conjunction with the MC3000 Series Installation and Operation Manual (Document M301) that shipped with the drive. These documents should be read in their entirety as they contain important technical data and describe the installation and operation of the drive.

Metasys® is a registered trademark of Johnson Controls, Inc., http://www.johnsoncontrols.com

© 2003 Lenze AC Tech Corporation

No part of this documentation may be copied or made available to third parties without the explicit written approval of Lenze AC Tech Corporation. All information given in this documentation has been carefully selected and tested for compliance with the hardware and software described. Nevertheless, discrepancies cannot be ruled out. Lenze AC Tech does not accept any responsibility nor liability for damages that may occur. Any necessary corrections will be implemented in subsequent editions.

|

|

|

|

Contents |

1 |

Safety Information.............................................................................................................. |

1 |

||

|

1.1 |

Warnings, Cautions and Notes............................................................................... |

1 |

|

|

|

1.1.1 |

General..................................................................................................... |

1 |

|

|

1.1.2 |

Application................................................................................................ |

1 |

|

|

1.1.3 |

Installation................................................................................................ |

1 |

|

|

1.1.4 |

Electrical Connection................................................................................ |

2 |

|

|

1.1.5 |

Operation.................................................................................................. |

2 |

2 |

Introduction....................................................................................................................... |

|

3 |

|

|

2.1 |

Metasys N2 Communications................................................................................ |

3 |

|

|

2.2 |

Serial Communications Wiring............................................................................... |

3 |

|

3 Drive Setup and Programming........................................................................................... |

4 |

|||

|

3.1 |

Serial Communication Setup................................................................................. |

4 |

|

|

3.2 |

Communication Overrides..................................................................................... |

5 |

|

4 |

MC3000 N2 Points............................................................................................................. |

6 |

||

|

4.1 |

Metasys N2 Point Map........................................................................................... |

7 |

|

|

4.2 |

Analog Input (AI) Point Descriptions....................................................................... |

8 |

|

|

4.3 |

Binary Input (BI) Point Descriptions........................................................................ |

11 |

|

|

4.4 |

Analog Output (AO) Point Descriptions................................................................... |

11 |

|

|

4.5 |

Binary Output (BO) Point Descriptions.................................................................... |

13 |

|

|

4.6 |

Reference and Links.............................................................................................. |

13 |

|

i |

RG-MCMET |

Safety Information

1 Safety Information

1.1Warnings, Cautions and Notes

1.1.1General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live, moving and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be carried out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or DIN VDE0110 and national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with the installation, assembly, commissioning, and operation of the product and who have the qualifications necessary for their occupation.

1.1.2Application

Drive controllers are components designed for installation in electrical systems or machinery. They are not to be used as appliances. They are intended exclusively for professional and commercial purposes according to EN 61000-3-2. The documentation includes information on compliance with EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as directed) is prohibited until it is proven that the machine complies with the regulations of the EC Directive 98/37/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting drive as directed) is only allowed when there is compliance to the EMC Directive (89/336/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 73/23/EEC. The harmonised standards of the series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause radio interference in residential areas. In the case of radio interference, special measures may be necessary for drive controllers.

1.1.3Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not change any insulation distances during transport or handling. Do not touch any electronic components and contacts. Controllers contain electrostatically sensitive components, which can easily be damaged by inappropriate handling. Do not damage or destroy any electrical components since this might endanger your health! When installing the drive ensure optimal airflow by observing all clearance distances in the drive's user manual. Do not expose the drive to excessive: vibration, temperature, humidity, sunlight, dust, pollutants, corrosive chemicals or other hazardous environments.

1 |

RG-MCMET |

Safety Information

1.1.4Electrical Connection

When working on live drive controllers, applicable national regulations for the prevention of accidents (e.g. VBG 4) must be observed.

The electrical installation must be carried out in accordance with the appropriate regulations (e.g. cable cross-sections, fuses, PE connection). Additional information can be obtained from the regulatory documentation.

The regulatory documentation contains information about installation in compliance with EMC (shielding, grounding, filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values demanded by EMC legislation.

1.1.5Operation

Systems including controllers must be equipped with additional monitoring and protection devices according to the corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.). You are allowed to adapt the controller to your application as described in the documentation.

DANGER!

•After the controller has been disconnected from the supply voltage, do not touch the live components and power connection until the capacitors have discharged. Please observe the corresponding notes on the controller.

•Do not continuously cycle input power to the controller more than once every three minutes.

•Close all protective covers and doors during operation.

WARNING!

Network control permits automatic starting and stopping of the inverter drive. The system design must incorporate adequate protection to prevent personnel from accessing moving equipment while power is applied to the drive system.

Table 1: Pictographs used in these instructions

|

Pictograph |

Signal word |

Meaning |

Consequences if ignored |

|

|

|

|

|

|

|

|

|

|

DANGER! |

Warning of Hazardous Electrical |

Reference to an imminent danger that may |

|

|

|

|

Voltage. |

result in death or serious personal injury if the |

|

|

|

|

|

corresponding measures are not taken. |

|

|

|

|

|

|

|

|

|

WARNING! |

Impending or possible danger |

Death or injury |

|

|

|

|

for persons |

|

|

|

|

|

|

|

|

|

|

STOP! |

Possible damage to equipment |

Damage to drive system or its surroundings |

|

|

|

|

|

|

|

|

|

NOTE |

Useful tip: If observed, it will |

|

|

|

|

|

||

|

|

|

|

make using the drive easier |

|

|

|

|

|

|

|

|

|

|

|

|

|

RG-MCMET |

2 |

Introduction

2 Introduction

This document will explain how to operate a Lenze-AC Tech MC3000 Variable Frequency Drive using Metasys N2 protocol. It is intended as a serial communications supplement only and will not discuss normal drive operations. For more information regarding normal drive setup and functionality, refer to the MC3000 Installation and Operation Manual (M301).

2.1Metasys N2 Communications

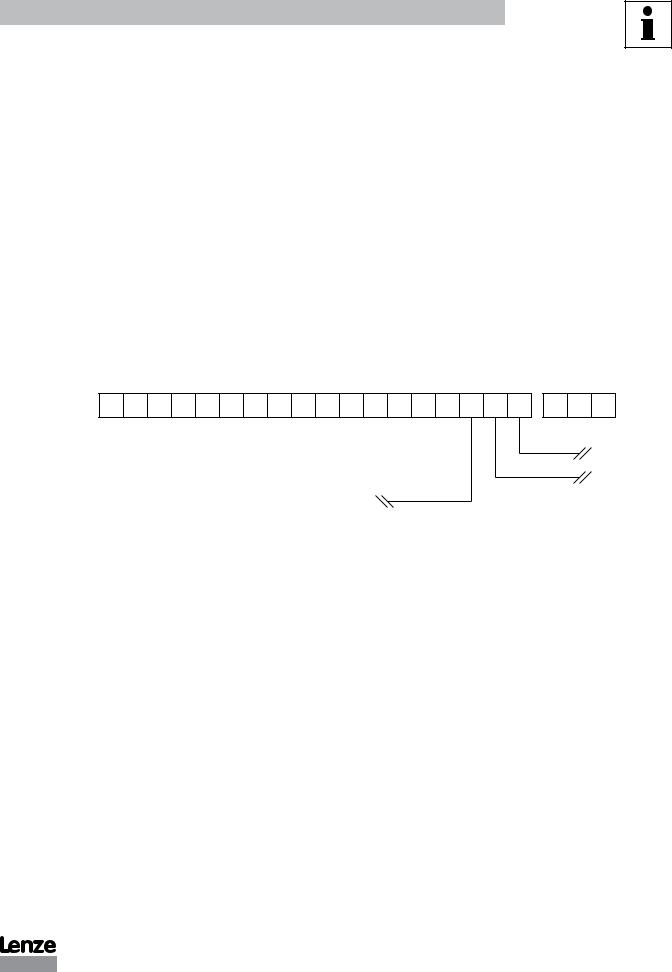

MC3000 drives running N2 protocol act as N2 devices on a Metasys® Network and function as slaves only. Thus the device communicating with an MC3000 drive must be an N2 master. The communication rate is 9600 bps with 8 data bits, no parity, 1 start bit and 1 stop bit. The bit sequence is as follows:

|

|

|

|

|

DATA |

|

|

|

|

|

START |

1 |

2 |

3 |

4 |

|

5 |

6 |

7 |

8 |

STOP |

|

|

|

|

|

|

|

|

|

|

|

2.2Serial Communications Wiring

Figure 1 illustrates the MC3000 Series Terminal Strip and connections for the N2 Metasys network.

1 |

2 5A 5B 6 10A 10B 2 12A 13A 13B 13C 13D 14 15 2 RXA TXB |

16 17 18 |

N2+

N2-

N2

Reference

Figure 1: MC3000 Terminal Strip

The N2+ terminal is connected to MC3000 drive terminal RXA.

The N2- terminal is connected to MC3000 drive terminal TXB.

The N2 Reference is connected to MC3000 drive terminal 2.

3 |

RG-MCMET |

Loading...

Loading...