Legrand DT-355 User Manual

|

|

|

|

|

Wattstopper® |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

360° Dual Technology • Line Voltage Occupancy Sensor (version 3) |

|

|

|

|

|

|

|

|

|

|

|

with Light Level feature |

No: 24038 – 10/17 rev. 3 |

Double technologie à 360° • Détecteur de mouvement de tension de ligne (v3) |

||||

avec les fonctionnalités de niveau de luminosité |

|||||

|

|

|

|

|

Doble tecnología de 360° • Sensor de ocupación de voltaje de línea (v3) |

|

|

|

|

|

con nivel de luz |

|

|

|

|

|

Installation Instructions • Instructions d’Installation • Instrucciones de Instalación |

Catalog Number • Numéro de Catalogue • Número de Catálogo: DT-355

Country of Origin: Made in China • Pays d’origine: Fabriqué en Chine • País de origen: Hecho en China

DT-355-U is BAA and TAA compliant (Product produced in the U.S.)

SPECIFICATIONS

Voltages.................................................................... |

120//230/277/347VAC, 50/60Hz |

Load Requirements |

|

@120VAC........................................................... |

0-800W Ballast/Tungsten/LED |

@230VAC (Single Phase)................................................ |

0-1200W Ballast/LED |

@277VAC......................................................................... |

0-1200W Ballast/LED |

@347VAC......................................................................... |

0-1500W Ballast/LED |

Operating Temperature....................................................... |

32° to 131°F (0° to 55°C) |

Terminal Torque Rating............................................ |

4.428 inch pound-force (0.5Nm) |

Ballast Operating Temperature........................................... |

32° to 131°F (0° to 55°C) |

Light Level One-Step Adjustment.......................................................... |

10FC–300FC |

Time Delay Adjustment...................................................... |

30 seconds to 30 minutes |

Walk-Through Mode............................................ |

3 minutes if no activity after 30 sec |

Test Mode...................................................................... |

5 sec. upon DIP switch reset |

PIR Coverage (Typical).................................................................................. |

1300 ft2 |

Sensitivity Adjustment.............................................. |

High or Low (DIP switch setting) |

Ultrasonic Coverage (Typical)........................................................................ |

1300 ft2 |

Sensitivity Adjustment............................................................... |

Min. to Max. (trimpot) |

Frequency......................................................................................................... |

40kHz |

UNIT DESCRIPTION

The Wattstopper DT-355 360° Dual Technology occupancy sensors combine advanced passive infrared (PIR) and ultrasonic technologies into one unit. The combination of these technologies helps to eliminate false triggering problems even in difficult applications.

The DT-355 turns lighting systems on and off based on occupancy and ambient light levels. The light level feature can be used to keep lights from turning on if the ambient light level is sufficient.

The DT-355 offers numerous operating modes that can be combined to create the ideal custom control. The sensors can be configured to turn lighting on, and hold it on as long as either or both technologies detect occupancy. After no movement is detected for the userspecified time the lights are switched off. A “walk-through” mode can turn lights off after only 3 minutes, if no activity is detected after 30 seconds of an occupancy detection. The DT-355 operates on 120VAC, 230VAC (1Ø), 277VAC, or 347VAC line voltage.

PLACEMENT GUIDELINES

Depending upon obstacles such as furniture or room layout, the area of coverage may be less or more than the sensing distances shown in the coverage pattern. This must be considered when planning the number of sensors and their placement. It is also recommended to place the sensor at least 4 to 6 feet away from air supply vents.

Mount the sensor to the ceiling. The DT-355 is designed for a ceiling heights of about 8 12 feet. Mounting above or below this range will significantly affect the coverage patterns. As a general rule, each occupant should be able to clearly view the sensor.

36'

36'

20%

Ultrasonic

Overlap

PIR Coverage 36 ft (10.97m)

Masking the PIR Lens: Opaque adhesive tape is supplied so that sections of the PIR lens can be masked. This restricts the sensor’s view and allows you to eliminate PIR coverage in unwanted areas such as hallways outside of the desired coverage area. Since masking removes bands of coverage, remember to take this into account when troubleshooting coverage problems. The Ultrasonic coverage cannot be masked, but you can adjust its sensitivity to reduce the coverage area.

Ultrasonic Coverage 36 ft (10.97m)

Sensor |

20% |

|

Ultrasonic |

||

|

||

|

Overlap |

If the space is larger than 30’ x 30’ it will be necessary to use more than one sensor to ensure complete coverage.

Common application – Classroom: Position the sensor so that the maximum coverage is achievable. Be sure that the sensor is not pointing out the door. To get complete coverage in an open office area, install multiple sensors so that there is approximately 20% overlap with each adjacent sensor’s ultrasonic coverage area.

Sensor

Sensor

36'

36'

COVERAGE PATTERN

The DT-355 provides a 360° coverage pattern. The coverage shown represents walking motion at a mounting height of 8-12 feet. For building spaces with lower levels of activity or with obstacles and barriers, coverage size may decrease. The coverage for PIR ONLY trigger mode varies with mount height. Refer to pattern below for details. Ultrasonic coverage is roughly the same for 8-12 foot mount heights. Refer to PIR and Ultrasonic trigger mode coverage for details.

|

|

|

|

Side View |

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

8ft |

|

|

|

|

|

|

|

|

|

(2.4m) |

|

|

|

|

|

|

|

|

|

10ft |

|

|

|

|

|

|

|

|

|

(3.0m) |

|

|

|

|

|

|

|

|

|

12ft |

|

|

|

|

|

|

|

|

|

(3.7m) |

40ft |

30ft |

20ft |

10ft |

0 |

10ft |

20ft |

30ft |

40ft |

|

|||||||||

|

(12.2m) |

(9.1m) |

(6.1m) |

(3.0m) |

|

(3.0m) |

(6.1m) |

(9.1m) |

(12.2m) |

PIR Only Coverage

Top View

PIR

Coverage

Ultrasonic

Coverage

36 ft x 36 ft

(10.97m x 10.97m)

36 ft

(10.97m)

* Drawings not to scale, representative of PIR and Ultrasonic Trigger Mode major motion coverage

8-12 foot Mounting Height

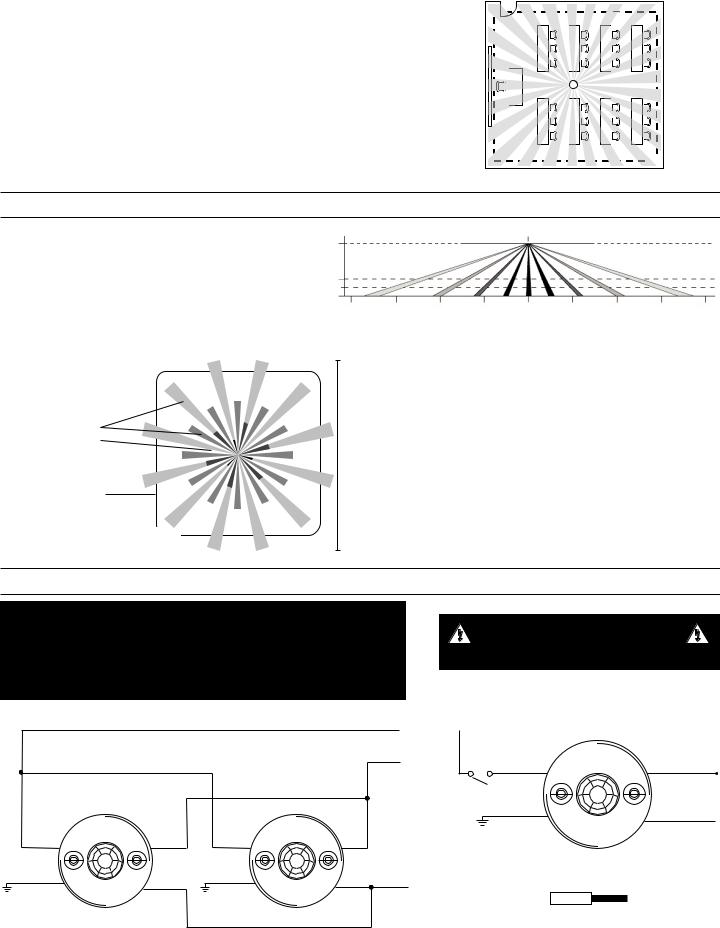

WIRING DIRECTIONS

WARNING: DO NOT INSTALL THE SENSOR IN A SPACE

WARNING: DO NOT INSTALL THE SENSOR IN A SPACE  CONTROLLING A TOTAL LOAD THAT IS HIGHER THAN THE RATING OF THE DEVICE. EACH SENSOR WILL NEED TO SWITCH THE ENTIRE

CONTROLLING A TOTAL LOAD THAT IS HIGHER THAN THE RATING OF THE DEVICE. EACH SENSOR WILL NEED TO SWITCH THE ENTIRE

LOAD EVEN IF ADDITIONAL SENSORS ARE INSTALLED. RISK OF OVERLOAD, PRODUCT DAMAGE, SMOKE AND/OR FIRE MAY RESULT.

Multiple Sensors Connected in Parallel

Load |

Neutral |

|

|

|

Hot |

|

Load |

Line |

Load |

Line |

|

Ground |

Neutral |

Ground |

Neutral |

|

(Optional) |

(Optional) |

|||

|

|

NOTE: This application does not allow for Load to increase

WARNING: TURN THE POWER

OFF AT THE CIRCUIT BREAKER

BEFORE INSTALLING SENSORS.

Single Sensor, Single Load

|

|

Neutral |

|

Load |

|

|

|

|

|

|

|

Load |

Hot |

Ground |

Neutral |

|

|

(Optional) |

|

#12 to #16 AWG

Strip Gauge

Cu Wire Only

2

MOUNTING THE SENSOR

Using a 4-Inch Square Junction Box

1.Pull the line voltage wires into the J Box through the conduit knockout.

2.Run the wires through the CA-1 adapter then connect the line voltage wires to the appropriate terminals on the sensor.

3.Align the CA-1 and the sensor with the J-Box so that the mounting screw tabs on the box match the mounting holes on the sensor’s rear housing and the CA-1.

4.Use two machine screws (included with the sensor) to attach the sensor to the mounting tabs on the J Box.

5.Snap the front cover onto the sensor.

Mounting to a 4” Square Wiremold V5752 box or 4”

Square Junction Box with Double-Gang Mudring

Ceiling

4" Square

4" Square

Wiremold #V5752 box

CA-1 Adapter |

Rear Housing |

Sensor Flange |

Screws |

Front Cover |

Using an Octagonal J-Box

1.Pull the line voltage wires into the J Box through the conduit knockout.

2.Connect the line voltage wires to the appropriate terminals on the sensor.

3.Loosen the appliance mounting screws attached to the J Box

4.Align the sensor in the J-Box so that the mounting screws on the box match the key holes on the sensor’s rear housing.

5.Push the sensor up into the JBox and twist it so that the mounting screws are seated in the keyhole slots.

6.Tighten the two screws to secure the sensor to the J Box.

7.Snap the front cover onto the sensor.

Mounting to an Octagonal Junction Box

4" Octagonal, 2.25" Deep*  Junction Box

Junction Box

Ceiling

Sensor

Sensor

Screws

Screws

Front

Front

Cover

* The Junction Box must be at least 2.25” deep.

If it is not, an extension ring is required.

SENSOR ADJUSTMENT

NOTE: This unit is pre-set for basic operation as described in this guide. Adjustment is optional.

The sensors are factory preset to allow for quick installation in most applications. Verification of proper wiring or coverage, or customizing the sensor’s settings can be done using the following procedures. To make adjustments, open the Front Cover with a small screwdriver.

There is a 30 second warm-up period when power is first applied.

Before making adjustments, make sure the office furniture is installed, lighting circuits are turned on, and the HVAC systems are in the overridden/ on position. VAV systems should be set to their highest airflow. Set the Logic Configuration and Time Delay to the desired settings. See the DIP switch Configuration Chart.

To Test Occupancy Sensors

Ultrasonic |

Light level pushbutton |

Keyhole slots |

|

sensitivity |

(for mounting to |

||

|

|||

trimpot |

|

4" octagonal box) |

|

DIP switches |

|

Double gang |

|

|

|

mudring |

|

Ultrasonic |

|

mounting holes |

|

transducer |

|

PIR Activity |

|

cones |

|

||

|

|

LED (Red) |

|

Ultrasonic |

|

|

|

activity |

|

PIR lens |

|

LED (Green) |

|

||

|

|

1.Ensure the Time Delay is set for Test Mode* using the “Test Mode/20 minutes” setting. (DIP switches 1, 2, & 3 are OFF).

2.Ensure that the Light Level is at default (maximum). Press and hold the pushbutton for 5 seconds or until the Green LED flashes rapidly. Wait 10 seconds for the flashing to stop.

3.Ensure that the Ultrasonic Sensitivity trimpot is set to about 70%, clockwise.

4.Remain still. The red and green LEDs should not flash. The lights should turn off after 5 seconds. (If not, see “Troubleshooting”).

5.Move around within the coverage area. The lights should come on. Adjust the Ultrasonic Sensitivity as necessary to provide the desired coverage (Green LED indicates activation from the ultrasonic sensor).

When testing and adjustment is complete, reset DIP Switches and Light Level to the desired settings, and replace the cover on the sensor.

•Test Mode is a temporary state that starts when you first set the sensor’s DIP switches for the “Test Mode/20 minutes” (switches 1, 2, 3 OFF). If you need to invoke the Test Mode and the DIP switches are already set for Test Mode/20 minutes, toggle DIP switch 1 ON then back to the OFF position. This provides a 10 minute test period. During the test period, the Time Delay is only 5 seconds.

3

DIP SWITCH SETTING

Time Delay: Switches 1, 2, 3

The sensor will hold the lights ON as long as occupancy is detected. The time delay countdown starts when no motion is detected. After no motion is detected for the length of the time delay, the sensor will turn the lights OFF.

Walk-through: Switch 4

Walk-through mode turns the lights OFF three minutes after the area is initially occupied, if no motion is detected after the first 30 seconds. If motion continues beyond the first 30 seconds, the selected time delay applies.

PIR Sensitivity: Switch 5

•Minimum forces a reduced detection range for the PIR.

•Maximum causes the DT-355 to monitor the controlled environment and automatically select the maximum sensitivity that will provide reliable operation without false detection. This setting is constantly updated.

Occupancy Logic: Switches: 6, 7, 8

The DT-355 has 8 logic configurations for occupancy triggers, set with DIP switches 6, 7 & 8. Determine the appropriate Occupancy Logic Option using the Trigger matrix, then set the DIP switches accordingly.

Initial Occupancy: The method that activates a change from “Standby” (area unoccupied and loads are OFF) to “Occupied” (area occupied and loads are ON).

•Both requires detection by PIR and Ultrasonic.

•Either requires detection by only one technology.

•PIR requires detection by the PIR.

•Man. requires activation of the Manual Switch. (See Manual ON functions” for further information).

Maintain Occupancy: The method indicating that the area is still occupied and the lights should remain ON.

Re-trigger: After the time delay elapses and the lights turn OFF, detection by the selected technology within the number of seconds indicated turns the lights back ON.

LIGHT LEVEL FEATURE

|

Feature |

|

Switch# |

|

|

Time Delay |

1 2 3 |

||

|

Test Mode/20 min |

|

||

|

30 seconds |

|

||

|

5 minutes |

|

||

|

10 minutes |

|

||

|

15 minutes |

|

||

|

20 minutes |

|

||

|

25 minutes |

|

||

|

30 minutes |

|

||

|

Walk-Through |

4 |

||

|

|

Enabled |

|

|

|

|

Disabled |

||

|

PIR Sensitivity |

5 |

||

|

|

Minimum |

|

|

|

Maximum |

|

||

|

|

Settings |

6 7 8 |

|

|

|

Standard |

|

|

|

Occupancy Logic |

Option 1 |

|

|

|

Option 2 |

|

||

|

|

|

||

|

|

Option 3 |

|

|

|

|

Option 4 |

|

|

|

|

Option 5 |

|

|

|

|

Standard |

|

|

Logic |

|

Standard |

Either(5)Re |

|

Standard BothOccupancy |

EitherOccupancy |

|||

|

|

Initial |

Maintain |

trigger - |

|

Trigger |

(seconds duration) |

||

Occupancy |

Option 1 |

Either Either |

Either(5) |

|

Option 2 PIR |

Either Either(5) |

|||

|

Option 3 Both |

PIR |

Both(5) |

|

|

Option 4 PIR |

PIR |

PIR(5) |

|

|

Option 5 Either PIR |

Either(5) |

||

= Factory Setting

= ON

= ON  = OFF

= OFF

The Light Level feature holds lights off upon initial occupancy if adequate ambient light exists. It will not turn the lights off if they are on. The default setting is for maximum, meaning that even the brightest ambient light will not hold the lights off.

Notes on Functionality

•Avoid mounting the sensor close to lighting fixtures.

•Adjust during daylight hours when ambient light in the area is at desired level.

•Light Level cannot be enabled while Test Mode is active. Either wait for Test Mode to expire or select any of the other Time Delay settings before enabling the Light Level feature.

•Ultrasonic occupancy indicator from LED is disabled when the Light Level feature is enabled. PIR occupancy indicator LED may still respond when lights are being held off. LEDs will also flash periodically to indicate the sensor has Light Level enabled.

•Light Level settings are only saved in the event of a power loss. Disabling Light Level and then reenabling it will not return it to previous settings.

•If Test Mode is enabled after Light Level has been set, Light Level functionality will cease to function throughout the duration of Test Mode. When Test Mode period expires, the Light Level functionality will resume, even if the Dip Switches remain set to Test Mode.

Setting Light Level

1.Make sure Test Mode is not active.

2.Toggle the state of the sensor, by briefly pressing the Light Level button, to include or exclude the lighting load from the light level calibration. Open the Front Cover and locate the Light Level pusbbutton. See Sensor Adjustment.

3.Press and hold the Light Level button for 2 or more seconds, or until the detection LEDs turn On. Do not exceed 5 seconds.* The sensor enters setup mode, as indicated by the rapidly flashing LEDs. The LEDs will flash throughout the setup process. Occupancy indications from the LEDs are disabled during setup.

4.Move away from the sensor to avoid interference with light level detection. The sensor measures the light level for a 10 second period, then averages the readings and automatically sets the level that will be used as the new setting. The sensor will hold lights off when the ambient light exceeds this setting.

5.When the two LEDs stop flashing, replace the Front Cover.

4

Disabling Light Level

Pressing the pushbutton for 5 seconds or more resets the light to default (maximum).

Press and hold the Light Level button for 5 seconds or until the detection LED(s) turn ON and then OFF. The LEDs flash rapidly for 10 seconds after the setting has changed.

TROUBLESHOOTING

For any unexpected operation

1. Check DIP switch settings. Make sure the switches are set according to the defined settings in the DIP Switch Setting chart.

Lights do not turn on when entering the room.

Neither LED Flashes

1.Check that the circuit breaker has been turned back on.

2.Check all sensor connections.

Red LED does not flash

1.When power is initially applied to the sensor, there is a warm-up period of 30 to 60 seconds before the LED becomes active.

2.Make sure PIR sensitivity is set to 100% (DIP switch #5 is in the “off” position).

Green LED is on steady

Check ultrasonic sensitivity trimpot. Fully counterclockwise position is the override for the sensor. Turn trimpot clockwise until LED flashes only when movement occurs in the desired coverage area.

Red and Green LEDs flash

1.Check all sensor connections.

2.Check if Light Level is enabled.

•If occupancy indicator LEDs blink together every few seconds, sensor is using Light Level feature.

•If Light Level functionality is not desired, press and hold for 5 seconds to return sensor to the default setting (maximum).

Lights do not turn off automatically.

Green LED flashes

Reduce ultrasonic sensitivity by turning adjustment pot counter-clockwise until it only flashes when movement occurs.

Red LED randomly flashes

Set PIR sensitivity to minimum by turning DIP switch 5 to the “on” position.

Lights do not turn off

Check all sensor andconnections.

SERVICE

To override all sensor functions, set the Ultrasonic Sensitivity trimpot to the fully counterclockwise (Service) position. This bypasses the occupancy control functions of the sensor.

|

ORDERING INFORMATION |

|

|

|

|

Catalog # |

Description |

DT-355 |

360° Dual Technology Occupancy Sensor, Line Voltage, w/light level sensor |

CA-1 |

Cosmetic adapter for ceiling installation with 4” square j-box or Wiremold #V5752 box. All sensors are white. |

All sensors are White

5

INSTRUCTIONS EN FRANÇAIS

DESCRIPTION DE L’APPAREIL

Les détecteurs de présence à double technologie 360° DT-355 de Wattstopper associent les technologies avancées de l’infrarouge passif (IRP) et des ultrasons dans une seule unité. L’association de ces technologies permet de contribuer à éliminer les problèmes de faux déclenchements même dans les applications difficiles.

Le DT-355 allume et éteint les systèmes d’éclairage en fonction des niveaux de présence et d’éclairage ambiants. La fonction de niveau d’éclairage peut être utilisée

pour empêcher les lumières de s’allumer si le niveau d’éclairage ambiant est suffisant.

Le DT-355 propose différents modes de fonctionnement qui peuvent être associés pour obtenir une régulation personnalisée idéale. Les détecteurs peuvent être configurés pour allumer l’éclairage et le maintenir ainsi tant que l’une des deux ou les deux technologies détectent une présence. Sans détection de mouvements durant la temporisation sélectionnée par l’utilisateur, les lumières s’éteignent. Le mode « passage » permet d’éteindre

les lumières au bout de 3 minutes seulement si aucun mouvement n’est détecté 30 secondes après la détection d’une présence.

Le DT-355 fonctionne sur alimentation secteur 120 VCA, 230 VCA (1Ø), 277 VCA, ou 347 VCA.

CARACTÉRISTIQUES

Tensions.............................................................. |

|

|

120//230/277/347 VCA, 50/60 Hz |

Exigences en matière de charge |

|

|

|

120 VCA................................................................ |

|

|

0 - 800 W Ballast/Tungstène/DEL |

à 230 |

VCA (monophasé)............................................. |

|

0 - 1 200 W Ballast/DEL |

à 277 |

VCA.................................................................... |

|

0 - 1 200 W Ballast/DEL |

à 347 |

VCA.................................................................... |

|

0 - 1 500 W Ballast/DEL |

Température de fonctionnement......................................... |

|

0 à 55 °C (32 à 131 °F) |

|

Couple nominal des bornes................................................... |

|

4,428 po-lb (0,5 N.m) |

|

Réglage du niveau de luminosité en une étape |

................................10 FC–300 FC |

||

Réglage de la temporisation.......................................... |

|

30 secondes à 30 minutes |

|

Mode passage...................................... |

3 minutes si aucune activité après 30 sec. |

||

Mode test............................................ |

|

5 sec. après activation de l’interrupteur DIP |

|

Portée IRP (normale).............................................................................. |

|

(1 300 pi2) |

|

Réglage de la sensibilité............................................. |

|

Élevée ou faible (réglage de |

|

l’interrupteur DIP) |

|

|

|

Portée ultrasonique (normale)................................................................ |

|

(1 300 pi2) |

|

Réglage de la sensibilité.................................. |

Min. à Max. (potentiomètre d’ajustement) |

||

Fréquence..................................................................................................... |

|

|

40 kHz |

UL & CUL listés pour une utilisation avec les blocs d’alimentation Wattstopper

INSTRUCTIONS DE PLACEMENT

En fonction des obstacles, tels que des meubles ou la disposition de la pièce, la portée de l’unité peut être réduite ou augmentée par rapport aux distances de perception illustrées dans le schéma de la portée. Cela doit être pris en compte dans le choix du nombre de détecteurs et de leur placement. Il est également conseillé de placer le détecteur à une distance de 1,2 à 1,8 mètres (4 à 6 pieds) minimum des conduits d’aération.

Montez le détecteur sur le plafond. Le DT-355 est conçu pour une hauteur de plafond d’environ 2,44 à 3,66 m (de 8 à 12 pi). Le placer à une hauteur supérieure ou inférieure à celle recommandée affectera de manière significative la portée de l’appareil. En règle générale, chaque occupant doit être capable de voir clairement le détecteur.

Obstruction de la lentille IRP: du ruban adhésif opaque est fourni de manière à pouvoir masquer des parties de la lentille IRP. Cela limite le champ de vision du détecteur et permet d’empêcher la portée de l’IRP dans les zones non désirées, telles que des couloirs hors de la zone de portée souhaitée. Étant donné que cette obstruction diminue la portée, n’oubliez pas d’en tenir compte en cas de dépannage des problèmes de portée. La portée des ultrasons ne peut pas être bloquée, mais vous pouvez réglez la sensibilité pour réduire la zone de portée.

Application habituelle – Salle de classe Placez le détecteur de telle sorte que la portée maximum puisse être obtenue. Assurezvous que le détecteur n’est pas dirigé vers la porte. Pour obtenir une portée de détection complète dans un bureau à aires ouvertes,

installez plusieurs détecteurs de manière à obtenir un chevauchement d’environ 20 % entre les zones de portée de deux détecteurs à ultrasons adjacents.

36' |

36' |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

36' |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

36' |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Portée |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IRP 36 pi |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(10,97 m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 % |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chevauchement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

des ultrasons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Portée des |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ultrasons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36 pi |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(10,97 m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

double technologie |

20 % |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chevauchement |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

des ultrasons |

|||||||||

Détecteur |

Si l’espace mesure plus de 9,15 m par 9,15 m (30 pi x |

|||||||||||||||||||||||||||||

30 pi), il sera nécessaire d’utiliser plus d’un détecteur |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

pour assurer une portée sur l’ensemble de l’espace. |

|||||||||||||||||

6

Loading...

Loading...