KTM 250EXC 2003, 450EXC 2003, 525EXC 2003 Owner's manual

250 EXC RACING, 450/525 SX, EXC, MXC RACING

BEDIENUNGSANLEITUNG

OWNERS’S MANUAL MANUALE D’USO MANUEL D’UTILISATION

MANUAL DE INSTRUCCIONES

2003

Art.Nr. 3.210.50 04/2002

IMPORTANT

WE STRONGLY SUGGEST THAT YOU READ THIS MANUAL CAREFULLY AND COMPLETELY BEFORE GOING ON YOUR FIRST RIDE. IT CONTAINS A GREAT DEAL OF INFORMATION AND ADVICE WHICH WILL HELP YOU USE AND HANDLE YOUR BIKE PROPERLY. IN YOUR OWN INTEREST, PLEASE PAY PARTICULAR ATTENTION TO NOTICES THAT ARE MARKED AS FOLLOWS:

WARNING

IGNORING THESE INSTRUCTIONS, CAN ENDANGER YOUR BODY AND YOUR LIFE.

! |

CAUTION |

! |

IGNORING THESE INSTRUCTIONS COULD CAUSE DAMAGE TO PARTS OF YOUR MOTORCYCLE OR THAT THE MOTOR-CYCLE IS NOT ROAD-SAFE ANYMORE.

Please insert the serial numbers of your motorcycle in the boxes below

Frame number

Engine number

Key number

Stamp of dealer

COMSUMER INFORMATION FOR AUSTRALIA ONLY

Tampering with noise control system prohibited

Owners are warned that the law may prohibit:

(a)The removal or rendering inoperative by any person other than for purposes of maintenance, repair or replacement, of any device or element of design incorporated into any new vehicle for the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use; and

(b)the use of the vehicle after such device or element of design has been removed or rendered inoperative by any person.

KTM SPORTMOTORCYCLE AG RESERVES THE RIGHT TO MODIFY ANY EQUIPMENT, TECHNICAL SPECIFICATIONS, COLORS,

MATERIALS, SERVICES OFFERED AND RENDERED, AND THE LIKE SO AS TO ADAPT THEM TO LOCAL CONDITIONS WITHOUT PREVIOUS ANNOUNCEMENT AND WITHOUT GIVING REASONS, OR TO CANCEL ANY OF THE ABOVE ITEMS WITHOUT SUBSTI-

TUTING THEM WITH OTHERS. IT SHALL BE ACCEPTABLE TO STOP MANUFACTURING A CERTAIN MODEL WITHOUT PREVIOUS ANNOUNCEMENT. IN THE EVENT OF SUCH MODIFICATIONS, PLEASE ASK YOUR LOCAL KTM DEALER FOR INFORMATION.

ENGLISH 1

ENGLISH 2

Introduction

We would like to congratulate you on your purchase of a KTM motorcycle.

You are now the owner of a state-of-the-art sport motorcycle that guarantees to bring you lots of fun and enjoyment, provided that you clean and maintain it appropriately.

Before you go for your first ride, be sure to read this manual carefully and thoroughly in order to familiarize yourself with how to operate your new motorcycle and with its characteristics, even if this means that you will have to dedicate some of your valuable time to this task. Only by doing so will you learn how to tune your motorcycle to your specific needs and how to protect yourself against injury. Besides, this manual contains important information on motorcycle maintenance. At the time this manual was typeset, it was up-to-date with the latest state of this production series. It cannot be completely ruled out, however, that minor discrepancies may exist resulting from further design upgrades of these motorcycles.This manual is an important part of your motorcycle and should be passed on to any subsequent owner in case you decide to sell it.

We expressly point out that work marked with an asterisk in the chapter "Maintenance work on the chassis and engine" must be performed. If maintenance work should become necessary during a competition it should be performed by a trained mechanic. KTM strongly recommends that all service work to your KTM should be performed by a qualified KTM dealer.

For your own safety, use KTM-approved parts and accessories only. KTM is not liable for damage that arises in connection with the use of other products.

Take special care to follow the recommended run in, inspection, and maintenance intervals. Heeding these guidelines will significantly increase the life of your motorcycle. To ensure that all work to your KTM is performed properly and to avoid warranty conflicts, KTM recommends that you always have your KTM serviced by a recognized and qualified KTM dealer.

Off-road motorcycle driving is a wonderful sport and we hope that you will be able to enjoy it to the full. It may, however, involve potential problems for the environment or lead to conflicts with others. These problems or conflicts can be avoided if the motorcycle is used responsibly. To safeguard the future of motorcycle sports, make sure that you use the motorcycle in accordance with the law, show that you are environmentally conscious and respect the rights of others.

We wish you a lot of fun when driving !

KTM SPORTMOTORCYCLE AG 5230 MATTIGHOFEN, AUSTRIA

Attachments: Spare parts manual chassis & engine

ALL RIGHTS RESERVED TO MAKE ALTERATIONS TO DESIGN AND MODEL.

© by KTM SPORTMOTORCYCLE AG, AUSTRIA All rights reserved

IMPORTANT LIMITED WARRANTY AND LIMITED GUARANTEE INFORMATION

KTM sports motorcycles are designed and constructed to resist the usual wear and tear of normal use in competitions.

The motorcycles comply with the regulations and categories currently in effect with the leading international motorcycle associations.

Observance of the service, maintenance and tuning instructions for the engine and chassis specified in the Owner's Manual is a prerequisite for faultless operation and the avoidance of premature wear. An improperly tuned chassis can lead to damage and breakage of the chassis components (see chapter on checking the basic chassis setting).

The service work specified in the "Lubrication and Maintenance Schedule" must be performed and service records must be kept for warranty documentation. Lack of proper service and maintenance records or documentation could void warranty.

The fuels and lubricants specified in the Owner's Manual or fluids with equivalent specifications must be used in accordance with the maintenance schedule.

No claims can be filed under the warranty for damage or consequential damage caused by manipulations or conversions to the motorcycle.

The use of the motorcycle under extreme conditions, e.g. on extremely muddy and wet terrain, can lead to higher than average wear on components such as the drive train or the brakes. In this case it may become necessary to service or replace wear parts before the service limit specified in the maintenance schedule has been reached.

THE SX/SXS, MXC AND OTHER “COMPETITION ONLY“ LABELED MODELS ARE PROHIBITED ON PUBLIC ROADS.

“On the road“ approved models are only allowed on public roads in the original homologated (throttled) version. Without this performance restriction (i.e. de-throttled), these models are only allowed to be driven off-road and not on public roads.

The EXC models are designed for off-road sports endurance competitions(enduro) and not suitable for predominant motocross use.

Note: The above is a general statement. Specific limited warranty and limited guarantee information may vary depending upon distribution. Please check with your local KTM dealer for limited warranty and limited guarantee information specific to your KTM model and region.

ENGLISH 3

In accordance with the international quality management ISO 9001 standard, KTM uses quality assurance processes that lead to the highest possible product quality.

ENGLISH 4

TABLE OF CONTENTS

Page SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . . . .5 Chassis number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Engine number, engine type . . . . . . . . . . . . . . . . . . . . . .5

OPERATION INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . .5 Clutch lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Hand decompression lever . . . . . . . . . . . . . . . . . . . . . . .5 Hand brake lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Digital speedometer, indicator lamps . . . . . . . . . . . . . . . .6 Electronic speedometer . . . . . . . . . . . . . . . . . . . . . . . . . .6 Tripmaster switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Short circuit button (SX/MXC) . . . . . . . . . . . . . . . . . . .11 Combination switch (EXC) . . . . . . . . . . . . . . . . . . . . . . .11 Headlamp switch (EXC USA) . . . . . . . . . . . . . . . . . . . . .11 Flasher switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 Emergency OFF button (EXC) . . . . . . . . . . . . . . . . . . . .11 Emergency OFF switch (EXC Australia) . . . . . . . . . . . . .12 Filler cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Fuel tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Choke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Hot start device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Shift lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Kickstarter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Foot brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Side stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Compression damping of fork . . . . . . . . . . . . . . . . . . . .14 Rebound damping of fork . . . . . . . . . . . . . . . . . . . . . . .14 Damping action during compression of shock absorber (SX) . .14 Compression damping of shock absorber (MXC, EXC) . .15 Rebound damping of shock absorber (SX, MXC, EXC) . .15 Steering lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

GENERAL TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

DRIVING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . .17

PERIODIC LUBRICATION AND MAINTENANCE-SCHEDULE . . .20

MAINTENANCE WORK ON CHASSIS AND ENGINE . . . . .24 Checking and adjusting the steering head bearing . . . . .24 Breather plug front fork . . . . . . . . . . . . . . . . . . . . . . . . .25 Cleaning the dust sleeves of the telescopic fork . . . . . . .25 Adjusting the spring preload on the fork (SX) . . . . . . . .25 Basic suspension setup for the weight of the driver . . . .26 How to change the handlebar position . . . . . . . . . . . . .28 Changing the spring preload of the shock absorber . . . .28 Pivot bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 Check chain tension . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Correct chain tension . . . . . . . . . . . . . . . . . . . . . . . . . .29 Chain maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Chain wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 General information about KTM disc brakes . . . . . . . . .31 Adjusting the free travel at the hand brake lever . . . . . .32

|

|

Page |

Checking the brake fluid level - front brake . . . . . |

. . . |

. .32 |

Refilling the front brake fluid reservoir . . . . . . . . . |

. . . |

. .32 |

Checking the front brake pads . . . . . . . . . . . . . . |

. . . |

. .32 |

Replacing the front brake pads . . . . . . . . . . . . . . . |

. . . |

.33 |

Changing the basic position of the brake pedal . . |

. . . |

.33 |

Checking the rear brake fluid level . . . . . . . . . . . . |

. . . |

.33 |

Refilling the rear brake fluid reservoir . . . . . . . . . . |

. . . |

.33 |

Checking the rear brake pads . . . . . . . . . . . . . . . . |

. . . |

.34 |

Replacing the rear brake pads . . . . . . . . . . . . . . . |

. . . |

.34 |

Dismounting and mounting the front wheel . . . . . |

. . . |

.34 |

Dismounting and mounting the rear wheel . . . . . |

. . . |

.35 |

Tires, air pressure . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.36 |

Checking the spoke tension . . . . . . . . . . . . . . . . . |

. . . |

.36 |

Replacing the battery of the digital speedometer |

. . . . .36 |

|

Setting the clock . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.37 |

Kilometers or miles . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.37 |

Checking/setting distance of the magnetic sensor |

. . . .38 |

|

Battery (MXC/EXC) . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.39 |

Charging the battery . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.39 |

Fuse (MXC/EXC) . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.40 |

Replacing the headlight/parking light lamp . . . . . |

. . . |

.40 |

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.41 |

Checking the coolant level . . . . . . . . . . . . . . . . . . |

. . . |

.41 |

Bleeding the cooling system . . . . . . . . . . . . . . . . . |

. . . |

.41 |

Replacing the glassfiber yarn packing of the silencer |

. .42 |

|

Cleaning the spark arrestor (MXC/EXC USA) . . . . |

. . . |

.42 |

Cleaning the air filter . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.43 |

Checking adjustment of the hand decompression release cable . |

.43 |

|

Adjusting the throttle cables . . . . . . . . . . . . . . . . . |

. . . |

.43 |

Changing the original position of the clutch lever |

. . . .44 |

|

Checking the oil level of the hydraulic clutch . . . . |

. . . |

.44 |

Bleeding of the hydraulic clutch . . . . . . . . . . . . . . |

. . . |

.44 |

Carburetor adjustment . . . . . . . . . . . . . . . . . . . . . |

. . . |

.45 |

Adjusting the mixture control screw . . . . . . . . . . . |

. . . |

.45 |

Checking the float level . . . . . . . . . . . . . . . . . . . . |

. . . |

.45 |

Draining the float chamber of the carburetor . . . . |

. . . |

.46 |

Oil circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.46 |

Checking the engine oil level . . . . . . . . . . . . . . . . |

. . . |

.46 |

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.47 |

Changing the engine oil . . . . . . . . . . . . . . . . . . . . |

. . . |

.47 |

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.49 |

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.51 |

CONSERVATION FOR WINTER OPERATION . . . . . |

. . . |

.51 |

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.51 |

Using after storage . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.51 |

TECHNICAL SPECIFICATIONS - ENGINE . . . . . . . . . |

. . . |

.52 |

TECHNICAL SPECIFICATIONS - CHASSIS . . . . . . . . . |

. . . |

.55 |

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

.56 |

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . .Appendix

1

A

2

3

B

B

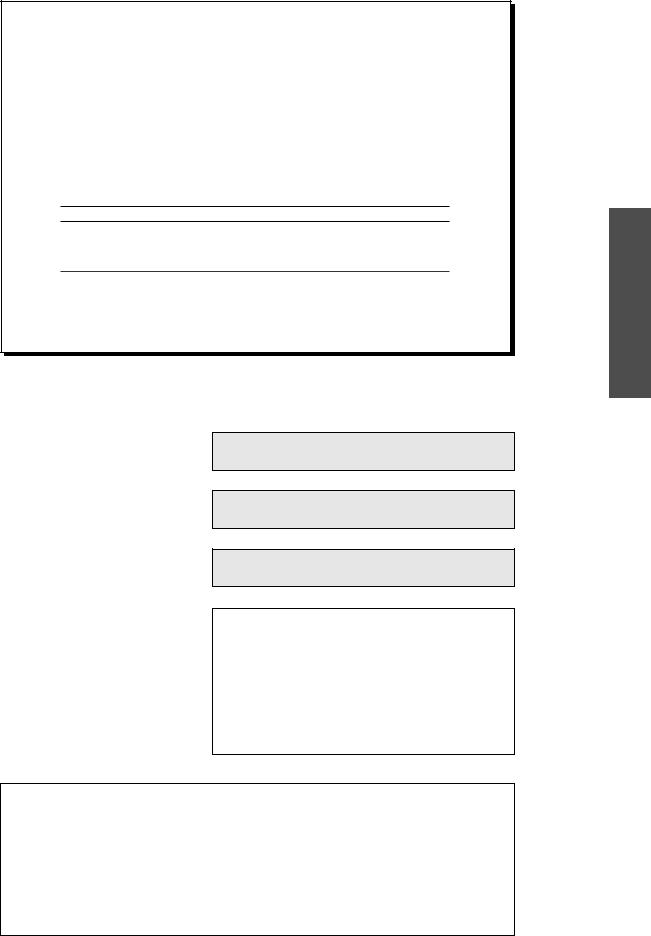

SERIAL NUMBER LOCATIONS

Chassis number

The chassis number is stamped on the right side of the steering head tube. Enter this number in the field on page no 1.

Engine number, engine type |

ENGLISH |

||

The engine number and the engine type are stamped into the left side of |

|||

|

|||

the engine below the engine sprocket. Enter this number on page 1. |

|

||

|

|

5 |

|

|

|

||

OPERATION INSTRUMENTS |

|

|

|

|

|

|

|

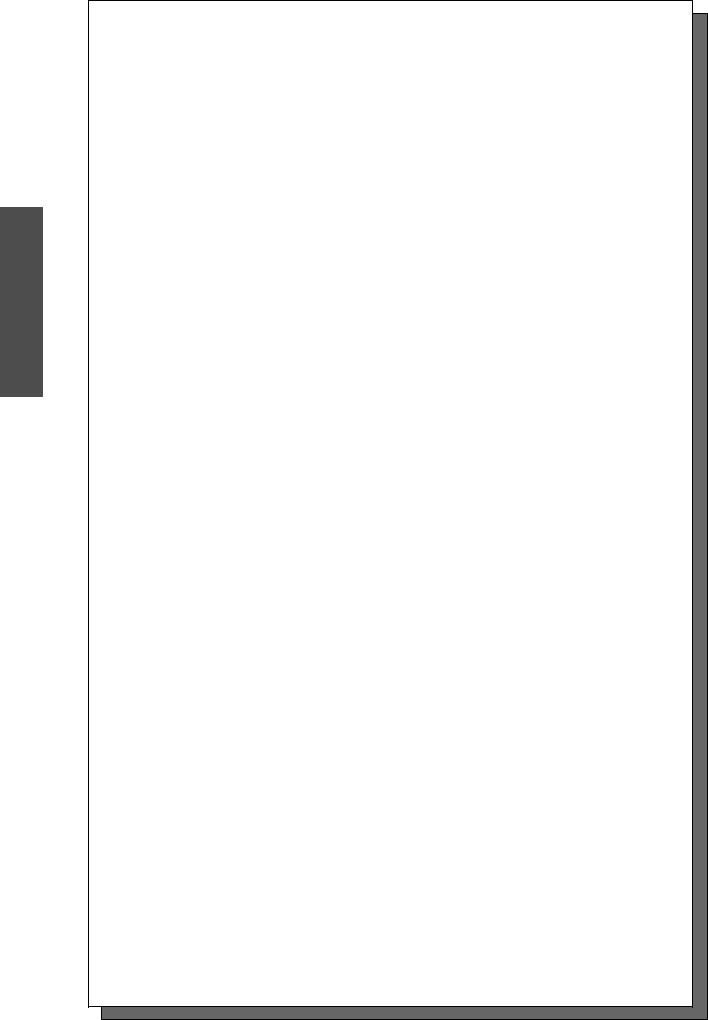

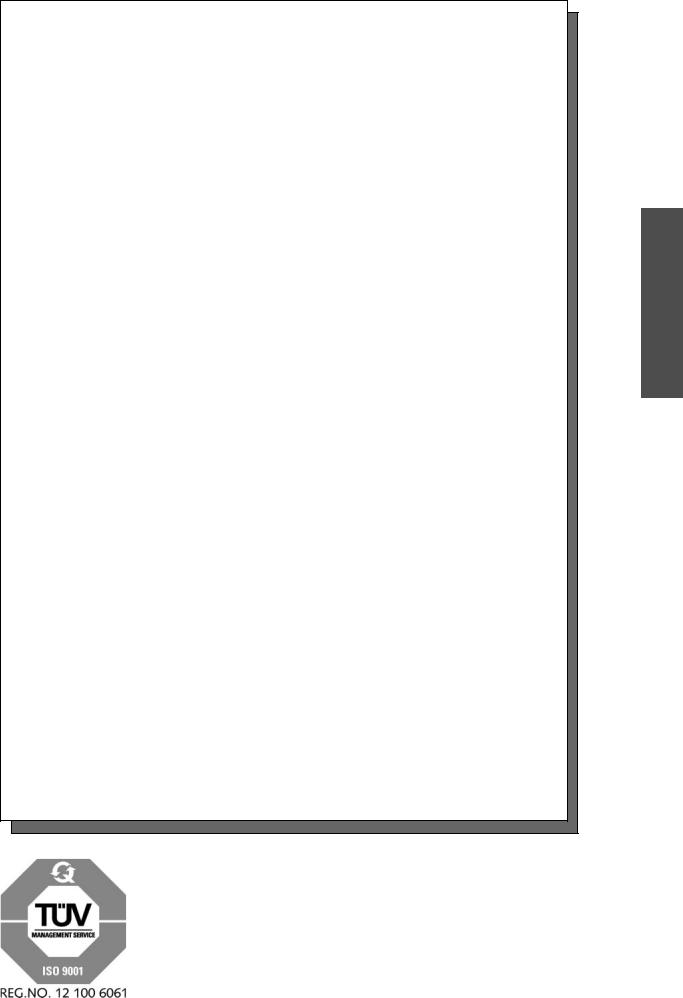

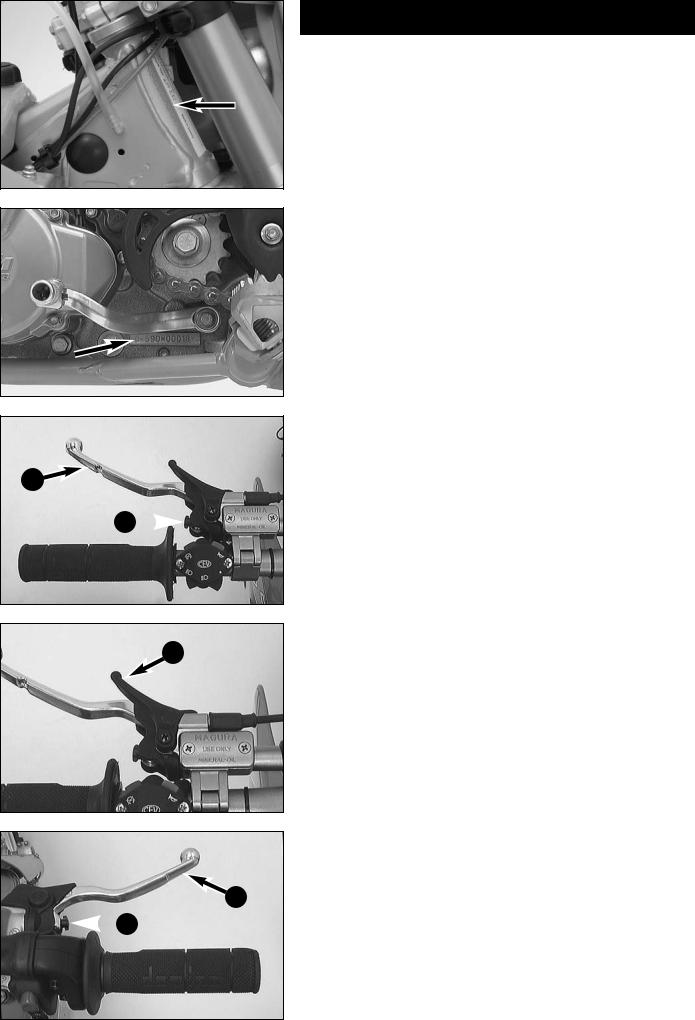

Clutch lever |

|

||

The clutch lever 1 is located on the left side of the handlebar. The adjust- |

|

||

ing screw A is used to change the original position of the clutch lever (see |

|

||

maintenance work on chassis and engine). |

|

||

Hand decompression lever |

|

||

The hand decompression lever 2 is needed only if the carburetor overflows |

|

||

after a fall. To "pump the engine free", pull the hand decompression lever |

|

||

during the starting procedure. |

|

||

The outer end of the lever must provide for a backlash of approx. 10mm |

|

||

(0.4 in) at all times. Only thereafter may it cause valve motion (to be |

|

||

recognized by the stronger resistance which the hand decompression lever |

|

||

encounters). |

|

||

Hand brake lever |

|

||

The hand brake lever 3 is mounted on the handlebars on the right and |

|

||

actuates the front wheel brake. The adjusting screw B can be used to |

|

||

change the basic position of the hand brake lever (see "Maintenance"). |

|

||

1

2

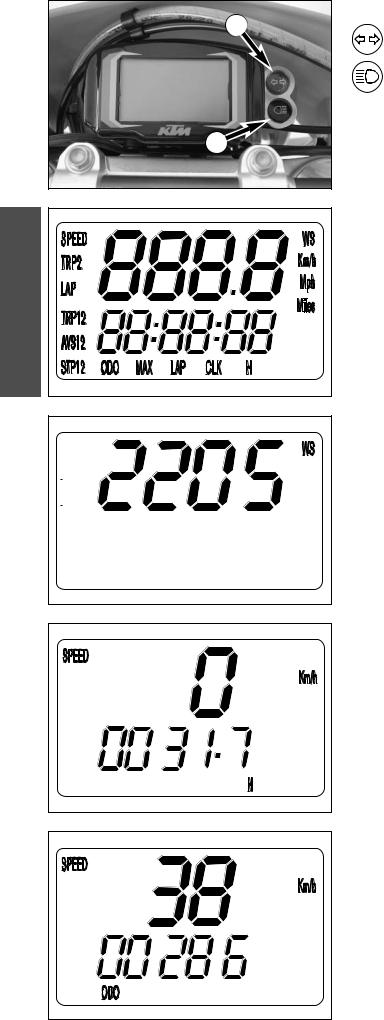

Digital speedometer, indicator lamps

The green control lamp 1 flashes in the same rhythm as the flashing indicator when the indicator is working.

The blue control lamp 2 lights up when the high beam is on.

ENGLISH |

6 |

Electronic speedometer

The electronic speedometer display is activated as soon as the engine is switched on and the motorcycle starts to move.

The engine must be started in order for the speedometer to be supplied with electricity from the generator. An impulse must be received from the wheel sensor to activate the display; the front wheel must turn at least one time.

TEST

All of the display elements will light up for 1 second for the function test.

WS (wheel size)

The display will change and briefly show the diameter of the front wheel in millimeters.

If the front wheel does not turn, the display will automatically change to the SPEED/H mode.

If the front wheel turns, the display will automatically change to the SPEED /ODO mode.

SPEED/H (hours) display mode

When you stop driving and no impulses are sent from the wheel sensor, the display mode will automatically change from SPEED/ODO to SPEED/H. H shows the operating hours. The operating hour counter starts to count as soon as you start the engine. The displayed figure cannot be cleared.

Service intervals are indicated in operating hours for some KTM offroad motorcycles, making the operating hour counter a very practical function.

SPEED/ODO display mode

The SPEED/ODO mode shows the speed and the total kilometers traveled. When the front wheel stops turning, the display will automatically change to the SPEED/H mode.

The information will disappear in the display when the front wheel stops turning for 1 minute.

NOTE:

A Tripmaster switch (part no 583.14.069.244) is available as an accessory and enhances the electronic speedometer by providing the following functions:

2x Tripmaster

2x chronometer for the lap time Average speed

Maximum speed Clock

Display in miles

+ |

|

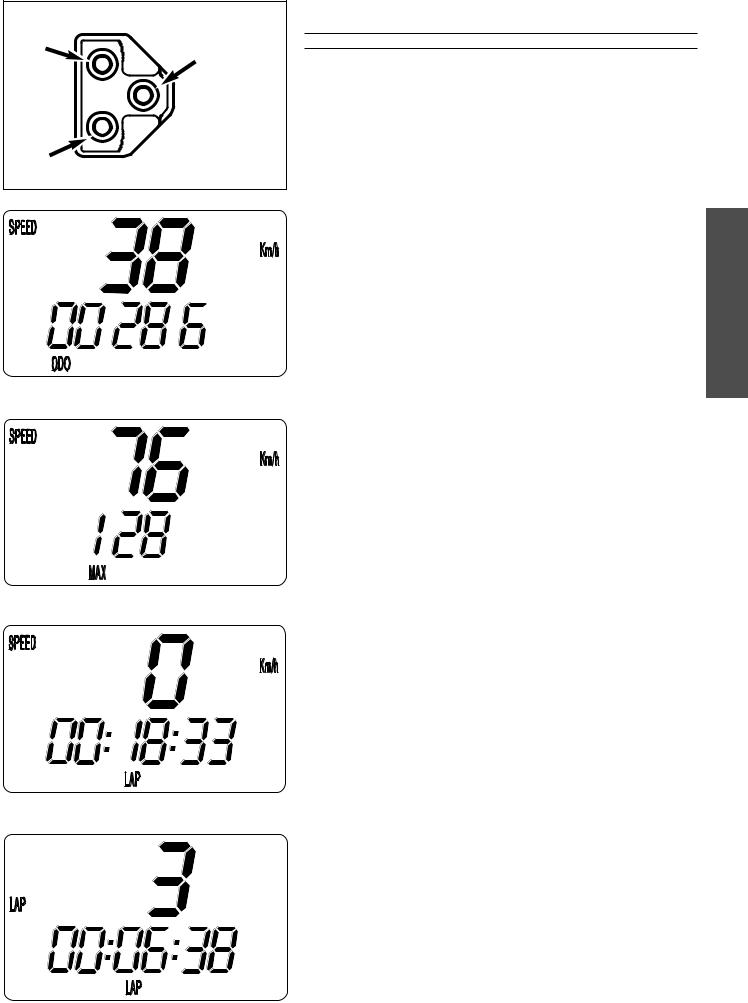

Tripmaster switch |

|

|

|

|

The switch has three buttons: MODE, + (plus) and – (minus). |

||||

MODE |

|

|

WARNING |

|

|

DO NOT TRY TO CHANGE THE MODE OR READ THE SETTINGS WHILE DRIVING. YOUR |

|||||

|

|

ATTENTION WILL BE DISTRACTED FROM THE TRAFFIC WHICH CAN EASILY LEAD TO AN |

|||

|

|

ACCIDENT. |

|

|

|

– |

|

Electronic speedometer functions provided by the Tripmaster |

|||

|

switch |

|

|

|

|

|

The display modes on the electronic speedometer will change in the |

||||

|

following |

order. If not, please read the chapter "ACTIVATING AND |

|||

|

|

DEACTIVATING THE DISPLAY MODE." |

|

||

|

|

SPEED/ODO display mode |

|

|

|

|

|

SPEED displays the speed in KPH or MPH. The displayed figure cannot be |

|||

|

|

cleared. |

|

|

|

|

|

ODO displays the kilometers or miles traveled. The displayed figure cannot |

|||

|

|

be cleared. |

|

|

|

|

|

+ BUTTON |

no function |

|

|

|

|

– BUTTON |

no function |

|

|

|

|

press the MODE BUTTON to change to the next mode |

|

||

|

|

press and hold the MODE BUTTON 3 SECONDS to change to the next mode |

|||

SPEED/MAX display mode

MAX displays the maximum speed. It is always active.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to reset the MAX figure to 0

SPEED/LAP display mode

LAP displays the stopped lap time in hours, minutes and seconds.

Starts and stops the stop watch. The lap time is not reset to 0. Stops the running stop watch, stores the lap time and restarts the stop watch. The time is reset to 0. A total of 10 lap times can be stored and read in the SPEED/LAP display mode. To clear all of the stored lap times, hold the MODE button for 3 seconds in the SPEED/LAP mode.

press the MODE BUTTON to change to the next mode

If no lap time is stored or the motorcycle is driving, the LAP/LAP mode will be skipped.

press and hold the MODE BUTTON 3 SECONDS to reset the LAP figure and all stored lap times to 0

LAP/LAP display mode

The lap number is shown at the top and the lap time in hours, minutes and seconds at the bottom of the display.

If no lap time is stored or the motorcycle is driving, the LAP/LAP mode will be skipped.

Hold the MODE button for 3 seconds in the SPEED/LAP mode to clear the stored lap times.

+ BUTTON |

changes to the next lap time. |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to change to the next mode

ENGLISH 7

ENGLISH 8

SPEED/CLK (clock) display mode

CLK will display time in hours, minutes and seconds.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode.

press and hold the MODE BUTTON 3 SECONDS to set the time in the menu (see SETTING THE CLOCK)

SPEED/H (hours) display mode

When you stop driving and no impulses are sent from the wheel sensor, the display mode will automatically change from SPEED/ODO to SPEED/H. H shows the operating hours. The operating hour counter starts to count as soon as you start the engine. The displayed figure cannot be cleared.

Service intervals are indicated in operating hours for some KTM offroad motorcycles, making the operating hour counter a very practical function.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to change to the SETUP mode (see REVEALING/CONCEALING functions).

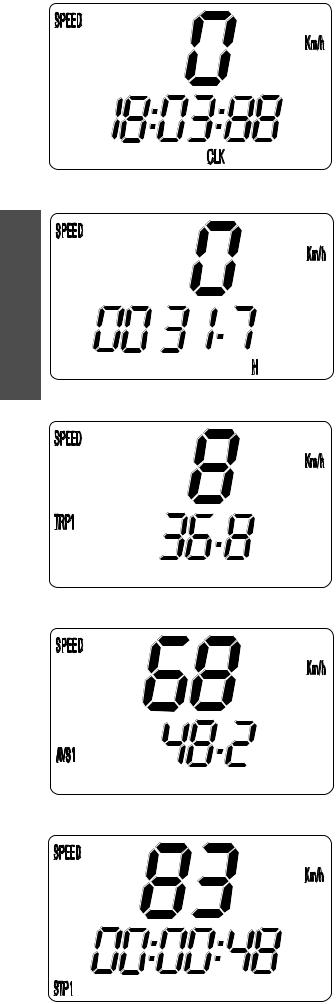

SPEED/TRP1 (trip 1) display mode

The TRP1 trip meter is always active and counts to 999.9. It is used to measure the length of a trip or the distance between 2 refueling stops. TRP1 is linked to AVS1 and STP1. The calculation of these figures is activated by the first impulse received from the wheel sensor (when the front wheel starts to turn) and stops 3 seconds after the last impulse is received (when the front wheel has stopped).

The TRP1, AVS1 and STP1 figures are automatically reset to 0 after passing 999.9.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode.

press and hold the MODE BUTTON 3 SECONDS to automatically reset the TRP1, AVS1 and STP1 figures to 0.

SPEED/AVS1 (average speed 1) display mode

AVS1 is always active and shows the average speed based on the TRP1 and STP1 figures. The calculation of this figure is activated by the first impulse received from the wheel sensor and stops 3 seconds after the last impulse is received.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to reset the TRP1, AVS1 and STP1 figures to 0.

SPEED/STP1 (stop 1) display mode

STP1 shows the traveling time based on TRP1 and continues to count whenever it receives impulses from the wheel sensor. The calculation of this figure is activated by the first impulse received from the wheel sensor and stops 3 seconds after the last impulse is received.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to reset the TRP1, AVS1 and STP1 figures to 0.

SPEED/TRP2 (trip 2) display mode

The TRP2 trip meter is always active and counts to 999.9. Contrary to TRP1, the displayed figure can be changed using the + and – buttons. This is a very useful function for trips taken according to a roadbook.

TRP2 is activated by the first impulse received from the wheel sensor and stops automatically 3 seconds after the last impulse is received.

+ BUTTON increases the TRP2 figure

– BUTTON decreases the TRP2 figure

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to reset TRP2 to 0

SPEED/AVS2 (average speed 2) display mode

AVS2 shows the average speed based on the TRP2 and STP2 figures. The calculation of this figure is activated by the first impulse received from the wheel sensor and stops 3 seconds after the last impulse is received.

The displayed figure will deviate from the actual average speed if TRP2 was changed manually or if STP2 was not stopped after the trip.

+ BUTTON |

no function |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to change to the next mode

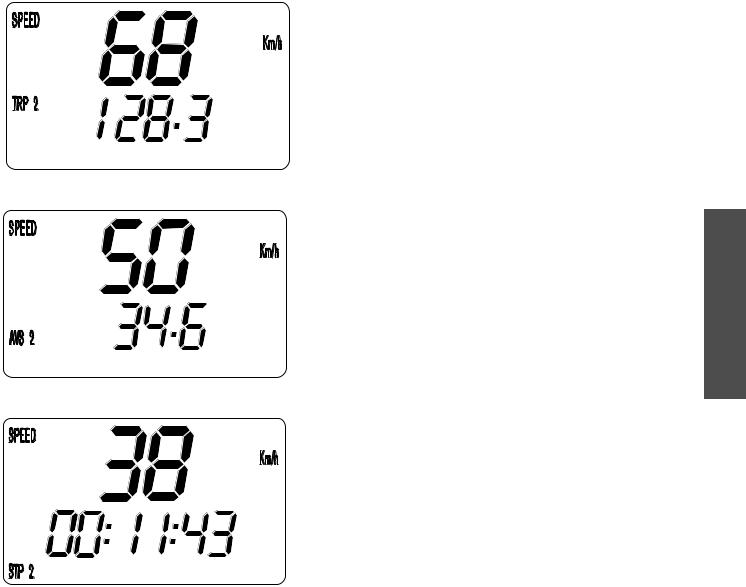

SPEED/STP2 (stop 2) display mode

STP2 is a manual stop watch. Start the stop watch by pressing the + button, press again to hold. Press again to continue timing.

Press the MODE button to change to the next mode. The STP2 display will blink in the other modes if STP2 continues to run in the background. To stop STP2, return to the SPEED/STP2 mode and press the + button.

+ BUTTON |

starts and stops the stop watch |

– BUTTON |

no function |

press the MODE BUTTON to change to the next mode

press and hold the MODE BUTTON 3 SECONDS to reset STP2 figures to 0

ENGLISH 9

ENGLISH

10

Standing motorcycle |

Driving motorcycle |

|

OVERVIEW OF TRIPMASTER FUNCTIONS |

|||

|

|

|

|

|

||

Display |

Press + |

Press – |

Press MODE |

Hold MODE for 3 sec |

||

|

X |

SPEED / ODO |

no function |

no function |

next display mode |

no function |

|

|

|

|

|

|

|

X |

X |

SPEED / MAX |

no function |

no function |

next display mode |

resets MAX to 0 |

|

|

|

|

|

|

|

X |

X |

SPEED / LAP |

starts / stops LAP |

stops LAP, stores LAP |

next display mode |

clears all LAP figures |

|

|

|

figure LAP remains |

figure, resets LAP to 0 |

|

|

|

|

|

|

|

|

|

X |

|

LAP / LAP |

next figure |

no function |

next display mode |

next display mode |

|

|

|

|

|

|

|

X |

X |

SPEED / CLK |

no function |

no function |

next display mode |

set clock menu |

|

|

|

|

|

|

|

X |

|

SPEED / H |

no function |

no function |

next display mode |

display setup menu |

|

|

|

|

|

|

|

X |

X |

SPEED / TRP1 |

no function |

no function |

next display mode |

resets TRP1, STP1 and |

|

|

|

|

|

|

AVS1 to 0 |

|

|

|

|

|

|

|

X |

X |

SPEED / AVS1 |

no function |

no function |

next display mode |

resets TRP1, STP1 and |

|

|

|

|

|

|

AVS1 to 0 |

|

|

|

|

|

|

|

X |

X |

SPEED / STP1 |

no function |

no function |

next display mode |

resets TRP1, STP1 and |

|

|

|

|

|

|

AVS1 to 0 |

|

|

|

|

|

|

|

X |

X |

SPEED / TRP2 |

increases TRP2 figure |

decreases TRP2 figure |

next display mode |

resets TRP2 to 0 |

|

|

|

|

|

|

|

X |

X |

SPEED / AVS2 |

no function |

no function |

next display mode |

next display mode |

|

|

|

|

|

|

|

X |

X |

SPEED / STP2 |

starts / stops STP2 |

no function |

next display mode |

sets STP2 to 0 |

|

|

|

|

|

|

|

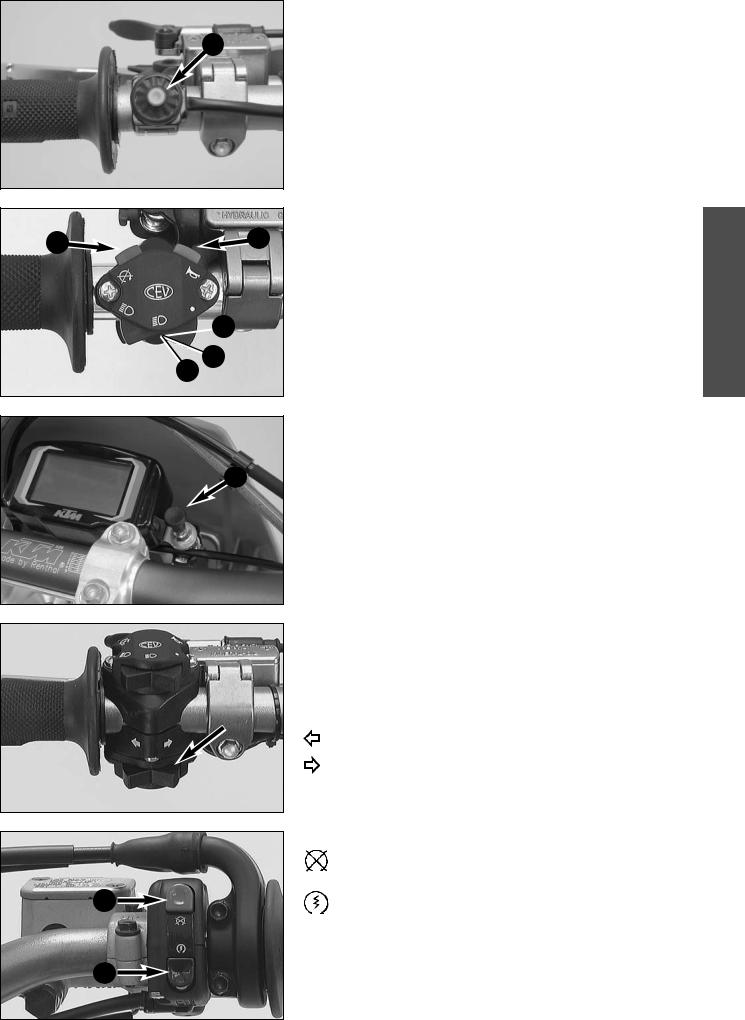

Short circuit button (SX/MXC)

The short circuit button 1 turns off the engine. When pressing this button,

the ignition circuit is short-circuited.

1

3 |

2 |

A

A

B

C

4

Combination switch (EXC)

The light switch has 2, respectively 3 switch positions. A = Light off (this function is not available in all models) B = Low beam on

C = High beam on

You may use button 2 to actuate the horn.

The red short circuit button 3 serves to switch off the engine. Leave the switch pressed until the engine stops.

Headlamp switch (EXC USA)

In this model the headlamp is switched on with the pull switch 4.

ENGLISH

11

5

6

Flasher switch

The flasher switch is a separate unit and is mounted on the left portion of the handlebar.

The wire harness is designed in a way that whenever you want to use your bike off-road, you can dismount the entire turn indicator system without affecting the function of the remaining electrical system.

Flasher left

Flasher right

Emergency OFF button (EXC)

The red emergency-OFF button 5 is arranged adjacent to the throttle grip. To turn off the engine, push the button until the engine comes to a standstill.

Pushing the black starter button 6 will actuate the E-starter.

ENGLISH

12

1

2

3

OFF ON RES

SX

MXC

EXC

4

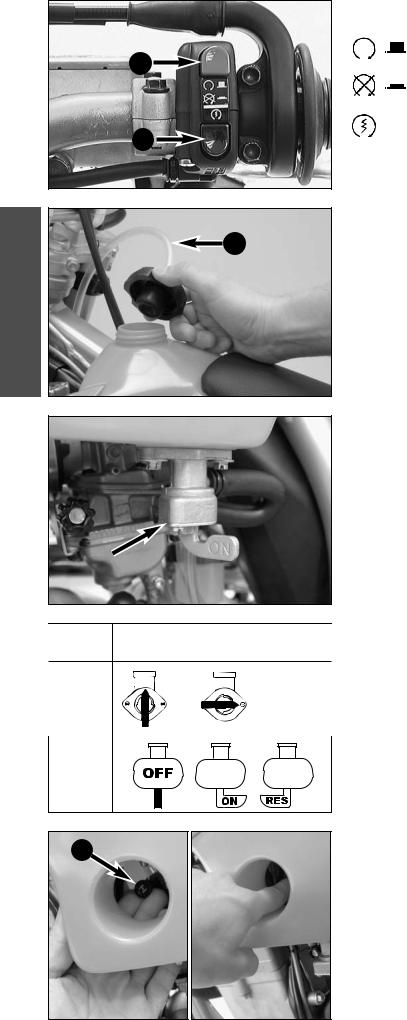

Emergency OFF switch (EXC Australia)

The red emergency-OFF switch 1 is arranged adjacent to the throttle grip.

In this position, the E-starter is operational and the engine can be started.

In this position, the E-starter and ignition circuits are interrupted. The E-starter cannot be actuated, and the engine will not start, not even if you attempt to start it with the kickstarter.

Pushing the black starter button 2 will actuate the E-starter.

Filler cap

To open the filler cap: Turn the filler cap counter-clockwise.

To close the filler cap: Put the filler cap on and tighten it by turning it clockwise.

Install the tank breather hose 3 without kinks.

Fuel tap

OFF In this position the fuel tap is closed. No fuel can flow to the carburetor. ON During operation the twist grip must be turned to ON. This means that the fuel can flow to the carburetor. With the twist grip in this

position the tank will be emptied until only the reserve is left.

RES The reserve tank cannot be tapped until the rotating handle is turned to the RES position. Fill the tank as soon as possible and remember to turn the rotating handle back to the ON position so that you will have backup fuel next time, too.

Reserve MXC . . . . . . . . . . . . . 3.0 l (0,8 US gallons)

Reserve EXC . . . . . . . . . . . . . . 1.0 l (0,3 US gallons)

Choke

If you pull the choke button 4 out as far as possible, a bore in the carburetor will be opened through which the engine may take in additional fuel. The result is a „fat“ fuel-air mixture of the type needed for cold starts. To deactivate the choke, push the choke button back into its basic position.

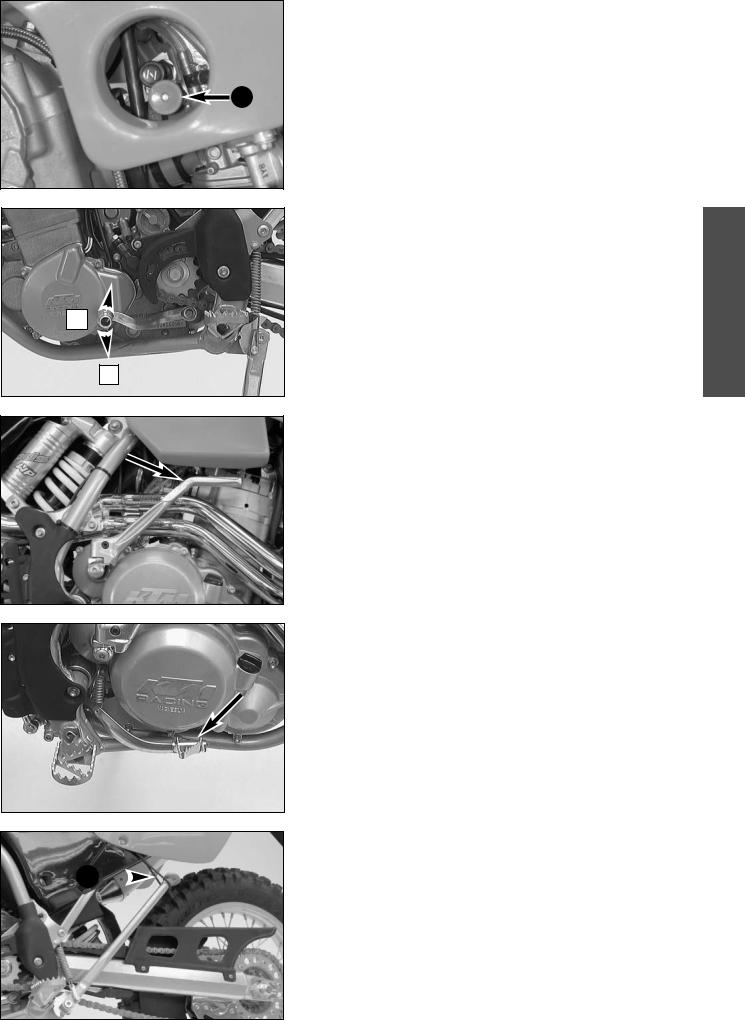

Hot start device (450/525 SX)

If you pull the hot start device 1 out as far as possible, a bore in the carburetor will be opened through which the engine may take in additional air. The result is a „lean“ fuel-air mixture of the type needed for hot starts.

To deactivate the hot start device, push the hot start button back into its basic position.

1

|

Shift lever |

|

|

The shift lever is mounted on the left side of the engine. The position of the |

|

|

gears is shown in the illustration. Neutral, or the idle speed, is located |

|

|

between first and second gear. |

|

2,3,4 (5,6) |

||

|

N

1

Kickstarter

The kickstarter is mounted on the right side of the engine. Its upper part can be swivelled.

Foot brake pedal

The foot brake pedal is located in front of the right footrest. Its basic position can be adjusted to your seat position (see maintenance work).

Side stand

Push the side stand to the ground with your foot and load it with the motorcycle. Make sure that you put your bike on solid ground and in a 2  secure position. For off-road riding, you can use the rubber band 2 to

secure position. For off-road riding, you can use the rubber band 2 to

additionally secure the center stand in its folded-up position.

ENGLISH

13

ENGLISH

14

1

2

3

6

4

5

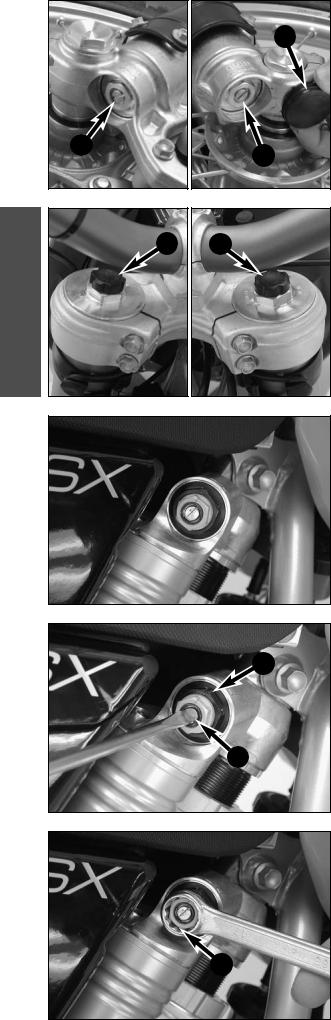

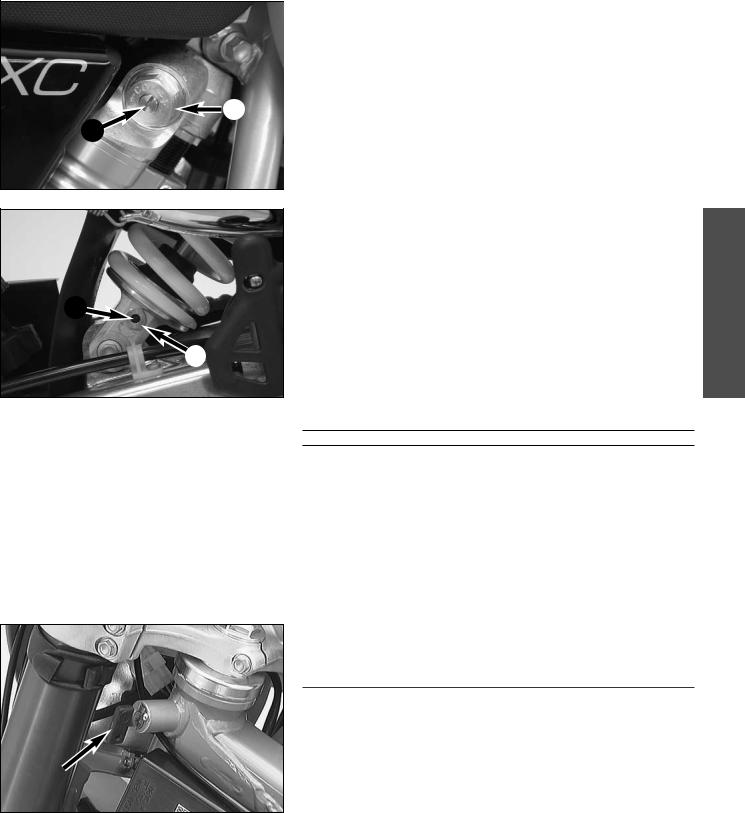

Compression damping of fork

Hydraulic compression damping determines the reaction when the fork is compressed. The degree of compression can be adjusted with adjusting screws at the bottom of the fork legs.Remove the protecting cap 1.

Turn the adjusting screws 2 clockwise to increase damping, turn it counterclockwise to reduce damping during compression.

STANDARD ADJUSTMENT

–turn adjusting screw clockwise as far as it will go

–turn it back by as many clicks as are specified for the relevant type of fork

Typ White Power |

1418X727 ...................... |

18 clicks (SX) |

Typ White Power |

1418X737 ...................... |

21 clicks (EXC/MXC) |

Rebound damping of fork

Hydraulic rebound damping determines the reaction when the fork is rebound. By turning the adjusting screw 1 (REB), the degree of damping of the rebound can be adjusted. Turn the knob clockwise to increase damping, turn it counterclockwise to reduce damping during rebounding.

STANDARD ADJUSTMENT

–turn adjusting screw clockwise as far as it will go

–turn it back by as many clicks as are specified for the relevant type of fork

Typ White Power |

1418X727 ...................... |

19 clicks (SX) |

Typ White Power |

1418X737 ...................... |

20 clicks (EXC/MXC) |

Damping action during compression of shock absorber (SX)

The shock absorber on the SX models can synchronize the compression damping in the low and high-speed range separately (Dual Compression Control).

Low and high speed refers to the movement of the shock absorber during compression and not to the speed of the motorcycle.

The low and high-speed technology overlaps.

The low-speed setting is primarily for slow to normal shock absorber compression rates.

The high-speed setting is effective at fast compression rates.

Turning in a clockwise direction will increase the damping, turning counterclockwise will decrease the damping.

Standard low-speed setting:

–turn the adjusting screw 4 to the limit in a clockwise direction using a screwdriver .

–unscrew the respective number of clicks for the specific type of shock absorber in a counterclockwise direction.

Typ White Power 1218X760 ...................... |

15 clicks |

Standard high-speed setting:

–turn the adjusting screw 5 to the limit in a counterclockwise direction using a box wrench.

–unscrew the respective number of turns for the specific type of shock absorber in a clockwise direction.

Typ White Power 1218X760 ...................... |

2 turns |

|

|

|

WARNING |

|

|

THE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGH-COMPRESSION NITROGEN. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO ANY MAINTE- NANCE WORK YOURSELF. SEVERE INJURIES COULD BE THE RESULT.

NEVER UNSCREW THE BLACK SCREW CONNECTION 6 (24MM).

1

3

|

|

|

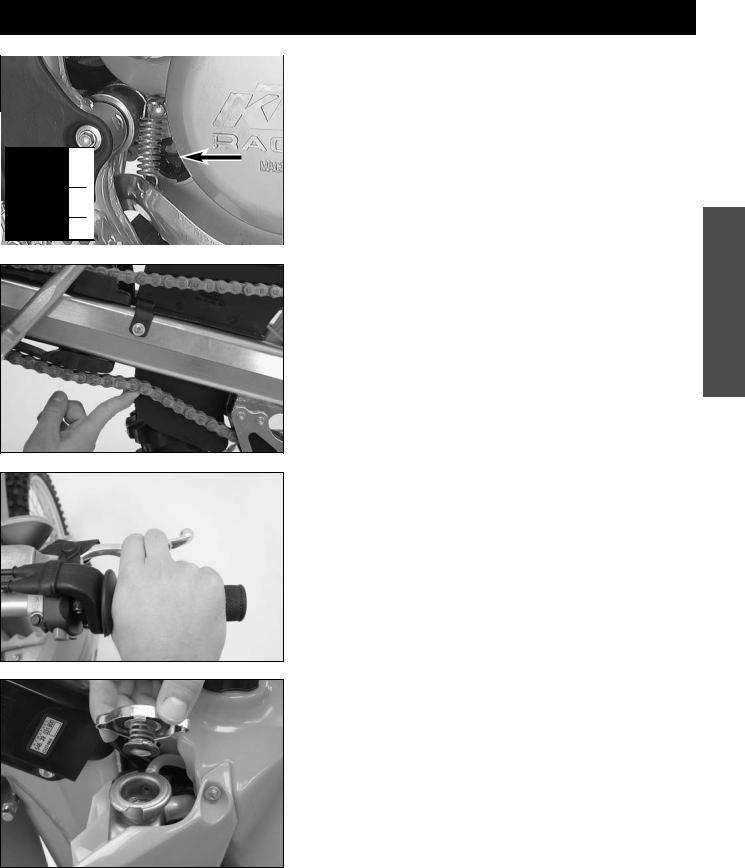

Compression damping of shock absorber (MXC, EXC) |

|||

|

|

|

The compression damping (during compression) can be adjusted for the |

|||

|

|

|

MXC and EXC shock absorbers (Mono Compression Control). |

|||

|

|

|

The degree of damping can be adjusted by turning adjusting screw 1 with |

|||

|

|

|

a screwdriver. Turning in a clockwise direction will increase the damping, |

|||

|

|

|

turning in a counterclockwise direction will decrease the damping. |

|||

|

|

|

|

|

|

|

2 |

|

|

STANDARD ADJUSTMENT: |

|

|

|

|

|

|

– turn the adjusting screw clockwise to the stop. |

|

||

|

|

|

|

|||

|

|

|

– then turn the adjusting screw counterclockwise, counting the number of |

|||

|

|

|

clicks that corresponds to the respective type of shock absorber. |

|||

|

|

|

Type White Power 1218X761 .............. |

17 clicks |

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|

||||

THE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGH-COMPRESSION NITROGEN. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO ANY MAINTE- NANCE WORK YOURSELF. SEVERE INJURIES COULD BE THE RESULT.

NEVER UNSCREW THE BLACK SCREW CONNECTION 2 (24MM).

Rebound damping of shock absorber (SX, MXC, EXC)

By using the adjusting screw 3, the degree of damping of the rebound can be adjusted. Turn the knob to the right side to increase damping, turn it to the left side to reduce damping during rebounding.

|

STANDARD ADJUSTMENT: |

|

4 |

|

|

– turn the adjusting screw clockwise to the stop. |

||

|

– then turn the adjusting screw counterclockwise, counting the number of |

|

|

clicks that corresponds to the respective type of shock absorber. |

|

|

Type White Power 1218X760 .............. |

26 clicks |

|

Type White Power 1218X761 .............. |

26 clicks |

WARNING

THE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGH-COMPRESSION NITROGEN. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO ANY MAINTE- NANCE WORK YOURSELF. SEVERE INJURIES COULD BE THE RESULT.

NEVER UNSCREW THE BLACK SCREW CONNECTION 4 (15MM).

Steering lock

The handlebar can be locked by means of the lock located on the steering head. To lock it, turn handlebar all the way to the right, insert key, turn it to left, press it in, turn it to right, and remove it.

! |

CAUTION |

! |

NEVER LEAVE THE KEY INSERTED IN THE STEERING LOCK. IF YOU TURN THE HANDLEBAR TO THE LEFT THE KEY COULD GET DAMAGED.

ENGLISH

15

ENGLISH

16

GENERAL TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE

Instructions for initial operation

–Verify that your KTM dealer performed the PREPARATION OF VEHICLE jobs (see Customer Service Manual).

–Read these operating instructions carefully before your first ride.

–Familiarize yourself with the operating elements.

–Set the clutch lever, the handbrake lever, and the footbrake pedal to the positions that are most convenient for you.

–Get used to handling the motorcycle on an empty parking lot or open space, before starting on a longer drive. Also try to drive as slowly as possible and in a standing position, to improve your feeling for the vehicle.

–Do not drive along off-road tracks which go beyond your abitily and experience.

–Hold the handlebars with both hands and leave your feet on the foot rests while driving.

–Remove your foot from the foot brake lever when you are not braking. If the foot brake lever is not released the brake pads rub continuously and the braking system is overheated.

–Do not make any alterations to the motorcycle and always use ORIGINAL KTM SPARE PARTS. Spare parts from other manufacturers can impair the safety of the motorcycle.

–Motorcycles are sensitive to alterations in the distribution of weight. If you are taking luggage with you, this should be secured as close as possible to the middle of the vehicle; distribute the weight evenly between the front and rear wheel. Never exceed the maximum permissible laden weight and the axle weights. The maximum permissible laden weight is comprised of the following components:

–Motorcycle ready for operation and tank full

–Luggage

–Driver with protective clothing and helmet.

–Pay attention to the running-in procedure.

Running in the Racing models

Even very precisely machined sections of engine components have rougher surfaces than components which have been sliding across one another for quite some time. Therefore, every engine needs to be broken in.

For this reason, do not load the engine more than 50% of its capacity during the first 3 operating hours. Besides, the engine speed must not exceed 7000 rpm. Avoid going full-throttle!

In the following 12 operating hours, you may load the engine up to 75% of its capacity. Use the motorcycle on various types of terrain (road, easy off-road trails).

! |

CAUTION |

! |

THE 250/450/525 SX/MXC/EXC RACING MODELS WERE UNCOM-

PROMISINGLY DESIGNED FOR OFF-ROAD COMPETITION PURPOSES ONLY. EVEN THOUGH THE EXC MODELS ARE APPROVED FOR USE ON PUBLIC ROADS, THEIR USE ON ROADS IS RECOMMENDED ONLY TO A VERY LIMITED EXTENT. AVOID EXTENDED ON-ROAD RIDES AT FULL THROTTLE.

|

WARNING |

|

–WEAR SUITABLE CLOTHING WHEN DRIVING A MOTORCYCLE. CLEVER KTM DRIVERS ALWAYS WEAR A HELMET, BOOTS, GLOVES AND A

JACKET, REGARDLESS OF WHETHER DRIVING ALL DAY OR JUST FOR A SHORT TRIP. THE PROTECTIVE CLOTHING SHOULD BE BRIGHTLY COL- ORED SO THAT OTHER VEHICLES CAN SEE YOU AS EARLY AS POSSIBLE.

– ALWAYS TURN ON THE LIGHT TO MAKE SURE THAT OTHER DRIVERS BECOME AWARE OF YOU AS EARLY AS POSSIBLE.

–DO NOT DRIVE AFTER HAVING CONSUMED ALCOHOL.

–ONLY USE ACCESSORIES RECOMMENDED BY KTM. FOR EXAMPLE,

FRONT PANELLING CAN IMPAIR THE DRIVING PROPERTIES OF THE MOTORCYCLE. CASES, EXTRA TANKS, ETC. CAN ALTER THE WEIGHT DISTRIBUTION AND THUS ALSO IMPAIR THE VEHICLES DRIVING PROPERTIES.

– THE FRONT AND REAR WHEEL MAY ONLY BE FITTED WITH TIRES THAT HAVE THE SAME PROFILE TYPE.

– BE SURE TO CHECK THE SPOKE TENSION AFTER 30 MINUTES' RUNNING TIME. THE SPOKE TENSION WILL DECREASE QUICKLY ON NEW WHEELS. IF YOU CONTINUE TO DRIVE WITH LOOSE SPOKES, THE SPOKES MAY CRACK AND LEAD TO UNSTABLE HANDLING (SEE "CHECKING THE SPOKE TENSION").

– THE RACING MODELS ARE DESIGNED AND DIMENSIONED FOR 1 PER- SON ONLY. NEVER TAKE ANOTHER RIDER ALONG.

– OBSERVE THE TRAFFIC REGULATIONS, DRIVE DEFENSIVELY AND TRY TO LOOK AHEAD AS FAR AS POSSIBLE SO THAT ANY HAZARDS CAN BE RECOGNIZED AS EARLY AS POSSIBLE.

– ADJUST YOUR DRIVING SPEED ACCORDING TO THE CONDITIONS AND YOUR DRIVING SKILLS.

–DRIVE CAREFULLY ON UNKNOWN ROADS OR ON UNFAMILIAR TRIALS.

–WHEN DRIVING OFF-ROAD, ALWAYS HAVE A FRIEND ON A SECOND

MOTORCYCLE TO KEEP YOU COMPANY, SO THAT YOU CAN HELP EACH OTHER SHOULD DIFFICULTIES ARISE.

– REPLACE THE HELMET VISOR OR GOGGLE LENS WHEN SCRATCHED OR DAMAGED. IF BRIGHT LIGHT SHINES THROUGH A SCRATCHED VISOR OR LENS, THE OPERATOR WILL BE BLINDED.

– NEVER LEAVE YOUR MOTORCYCLE WITHOUT SUPERVISION IF THE ENGINE IS RUNNING.

|

WARNING |

|

– THE SX MODELS ARE NOT APPROVED FOR USE ON PUBLIC ROADS AND FREEWAYS.

– WHEN RIDING YOUR MOTORCYCLE, PLEASE BEAR IN MIND THAT OTHER PEOPLE MAY FEEL MOLESTED BY EXCESSIVE NOISE.

DRIVING INSTRUCTIONS

B |

A |

Check the following before each start

When you start off, the motorcycle must be in perfect technical condition. For safety reasons, you should make a habit of performing an overall check of your motorcycle before each start.

The following checks should be performed:

1CHECK THE OIL LEVEL

Insufficient oil results in premature wear and consequently to engine damage.

2FUEL

Check that there is sufficient fuel in the tank; when closing the filler cap, check that the tank venting hose is free of kinks.

3CHAIN

A loose chain can fall from the chain wheels; an extremely worn chain can tear, and insufficient lubrication can result in unnecessary wear to the chain and chain wheels. Excessive tensioning of the chain will put additional load on the components of the secondary drivetrain (chain, bearings of transmission and rear wheel). Aside from resulting in premature wear, if worst comes to worst the chain may rupture or the countershaft of the transmission may break.

4TIRES

Check for damaged tires. Tires showing cuts or dents must be replaced. The tread depth must comply with the legal regulations. Also check the air pressure. Insufficient tread and incorrect air pressure deteriorate the driving performance.

5BRAKES

Check correct functioning of the braking system. Check for sufficient brake fluid in the reservoir. The reservoirs have been designed in such a way that brake fluid does not need to be refilled even when the brake pads are worn. If the level of brake fluid falls below the minimum value, this indicates a leak in the braking system or completely worn out brake pads. Arrange for the braking system to be checked by a KTM specialist, as complete failure of the braking system can be avoided.

Also check the state of the brake hose and the thickness of the brake linings.

Check free travel at the hand brake lever and foot brake lever.

6CABLES

Check correct setting and easy running of all control cables.

7COOLING FLUID

Check the level of the cooling fluid when the engine is cold.

8ELECTRICAL SYSTEM

Check correct functioning of headlamps, tail-lights, brake lights, indicators, control lamps and horn while the engine is running.

9LUGGAGE

If you are taking luggage with you, check that this is securely fastened.

ENGLISH

17

Loading...

Loading...