KROHNE OPTIFLEX1300C User Manual

Guided Radar (TDR) Level Meter

Supplementary Instructions for ATEX applications

Supplementary Instructions for ATEX applicationsSupplementary Instructions for ATEX applications

Supplementary Instructions for ATEX applications

OPTIFLEX 1300 C

OPTIFLEX 1300 COPTIFLEX 1300 C

OPTIFLEX 1300 C

Supplementary instructions

Supplementary instructions Supplementary instructions

Supplementary instructions

© KROHNE 06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

CONTENTS

2

www.krohne.com 06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

OPTIFLEX 1300 C

1 General safety information 4

1.1 Scope of the document..................................................................................................... 4

1.2 Device description ............................................................................................................ 4

1.3 Standards and approvals.................................................................................................. 4

1.4 Device categories ............................................................................................................. 5

1.4.1 Ex ia / Ex iaD-approved devices.............................................................................................. 5

1.4.2 Ex d[ia] / Ex tD[iaD]-approved devices ................................................................................... 5

1.4.3 Ex nA devices .......................................................................................................................... 5

1.4.4 Definitions of device categories.............................................................................................. 5

1.5 ATEX nameplates.............................................................................................................. 6

2 Installation 8

2.1 Precautions....................................................................................................................... 8

2.1.1 General notes.......................................................................................................................... 8

2.1.2 Electrostatic discharge........................................................................................................... 8

2.1.3 Special conditions ................................................................................................................... 9

2.2 Operating conditions ........................................................................................................ 9

2.2.1 Ambient and flange temperature ...........................................................................................9

2.2.2 Maximum surface temperature of the housing ................................................................... 13

2.2.3 Process pressure.................................................................................................................. 13

3 Electrical connections 14

3.1 General notes ................................................................................................................. 14

3.2 Terminal compartment .................................................................................................. 14

3.2.1 How to open the terminal compartment .............................................................................. 14

3.2.2 How to close the terminal compartment ............................................................................. 15

3.3 Terminal tightening capacity.......................................................................................... 15

3.4 Equipotential bonding system........................................................................................ 15

3.5 Ex ia / Ex iaD equipment................................................................................................. 15

3.5.1 How to connect the electrical cables ................................................................................... 15

3.5.2 Maximum intrinsically-safe values for the electrical circuit............................................... 16

3.5.3 Supply voltage....................................................................................................................... 16

3.5.4 Electrical schema ................................................................................................................. 17

3.6 Ex d[ia] / Ex tD[iaD] equipment ...................................................................................... 18

3.6.1 General notes........................................................................................................................ 18

3.6.2 How to connect the electrical cables ................................................................................... 18

3.6.3 Supply voltage....................................................................................................................... 19

3.6.4 Electrical schema ................................................................................................................. 19

3.7 Ex nA equipment............................................................................................................. 20

3.7.1 How to connect the electrical cables ................................................................................... 20

3.7.2 Supply voltage....................................................................................................................... 20

3.7.3 Electrical schema ................................................................................................................. 20

4 Start-up 21

CONTENTS

3

www.krohne.com06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

OPTIFLEX 1300 C

5 Service 22

5.1 Periodic maintenance..................................................................................................... 22

5.2 Keep the device clean..................................................................................................... 22

5.3 Returning the device to the manufacturer..................................................................... 22

5.3.1 General information.............................................................................................................. 22

5.3.2 Form (for copying) to accompany a returned device............................................................ 23

1 GENERAL SAFETY INFORMATION

4

OPTIFLEX 1300 C

www.krohne.com 06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

1.1 Scope of the document

These instructions are applicable only to the explosion-protection version of the TDR level

transmitter. For all other data, use the Quick Start and Handbook. If you do not have these

documents, please contact the nearest office or download them from the manufacturer's

internet site.

1.2 Device description

This device is a 2-wire level transmitter that uses TDR (Time Domain Reflectometry) / Guided

Radar technology. If the device has the FOUNDATION™ Fieldbus or the PROFIBUS PA output

options, it is connected to the fieldbus network as a 4-wire device. The device measures the

level, distance, volume and mass of liquids, liquid gases, pastes, powders, slurries and granular

products. It is also suitable for the continuous and simultaneous measurement of level and

interface of 2 liquids. Measurements are displayed via a DTM (device type manager) for remote

communication or an optional integrated display screen with wizard-driven setup and online

help functions.

The level transmitter is approved for use in potentially explosive atmospheres when equipped

with the appropriate options.

1.3 Standards and approvals

The certificate is given on the CD-ROM supplied with the device. You can also download the

certificate from our internet site.

INFORMATION!

The information in these supplementary instructions only contains the data applicable to

explosion protection. The technical data for the non-Ex version in the Handbook shall be valid in

its current version, provided that it is not rendered invalid or replaced by these supplementary

instructions.

WARNING!

Installation, commissioning and maintenance may only be carried out by "Personnel trained in

explosion protection".

DANGER!

In compliance with European Directive 94/9/EC (ATEX 100a), the ATEX version of the device

described in these Supplementary Instructions conforms to European Standards EN 60079-

0:2006, EN 60079-1:2007, EN 60079-11:2007, EN 60079-15:2005, EN 60079-26:2007, EN 60079-

27:2008, EN 61241-0:2006, EN 61241-1:2004 and EN 61241-11:2006. The Ex ia / Ex iaD and

Ex d[ia] / Ex tD[iaD] versions are certified for use in hazardous areas by the KEMA Quality B.V.

under KEMA 04ATEX1219 X. The Ex nA version is certified for use in zone 2 under our sole

responsibility. For more data, refer to the manufacturer's declaration given on the CD-ROM

supplied with the device. You can also download the manufacturer's declaration from our

internet site.

WARNING!

Carefully read the ATEX approval certificate. Obey the boundary conditions.

GENERAL SAFETY INFORMATION 1

5

OPTIFLEX 1300 C

www.krohne.com06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

1.4 Device categories

1.4.1 Ex ia / Ex iaD-approved devices

These devices are suitable for use in potentially explosive atmospheres of all flammable

substances in Gas Groups IIA, IIB and IIC. The Ex ia-approved device is certified for applications

requiring Category 1 G (gases, vapours or mists), 1/2 G or 2 G equipment when fitted with the

appropriate options. The Ex iaD-approved device is certified for applications requiring Category

1 D (dust), 1/2 D or 2 D equipment when fitted with the appropriate options.

1.4.2 Ex d[ia] / Ex tD[iaD]-approved devices

These devices are suitable for use in potentially explosive atmospheres of all flammable

substances in Gas Groups IIA, IIB and IIC. The Ex d[ia]-approved device is certified for

applications requiring Category 1/2 G (gases, vapours or mists) or 2 G equipment when fitted

with the appropriate options. The Ex tD[iaD]-approved device is certified for applications

requiring Category 1/2 D (dust) or 2 D equipment when fitted with the appropriate options.

1.4.3 Ex nA devices

The Ex nA version of this device is suitable for use in potentially explosive atmospheres of all

flammable substances in Gas Group II. It is designed for applications requiring Category 3 G

equipment when fitted with the appropriate options.

1.4.4 Definitions of device categories

Category 1

Category 1Category 1

Category 1

The device is installed in hazardous areas requiring Category 1 G or 1 D equipment.

Category 1/2

Category 1/2Category 1/2

Category 1/2

The signal converter is installed in hazardous areas requiring Category 2 G or 2 D equipment.

The probe is installed in hazardous areas requiring Category 1 G or 1 D equipment.

Category 2

Category 2Category 2

Category 2

The device is installed in hazardous areas requiring Category 2 G or 2 D equipment.

Category 2/3

Category 2/3Category 2/3

Category 2/3

The signal converter is installed in hazardous areas requiring Category 3 G or 3 D equipment.

The probe is installed in hazardous areas requiring Category 2 G or 2 D equipment.

Category 3

Category 3Category 3

Category 3

The device is installed in hazardous areas requiring Category 3 G or 3 D equipment.

INFORMATION!

These devices can also be used for applications requiring Category 2/3 or 3 equipment.

INFORMATION!

These devices can also be used for applications requiring Category 2/3 or 3 equipment.

1 GENERAL SAFETY INFORMATION

6

OPTIFLEX 1300 C

www.krohne.com 06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

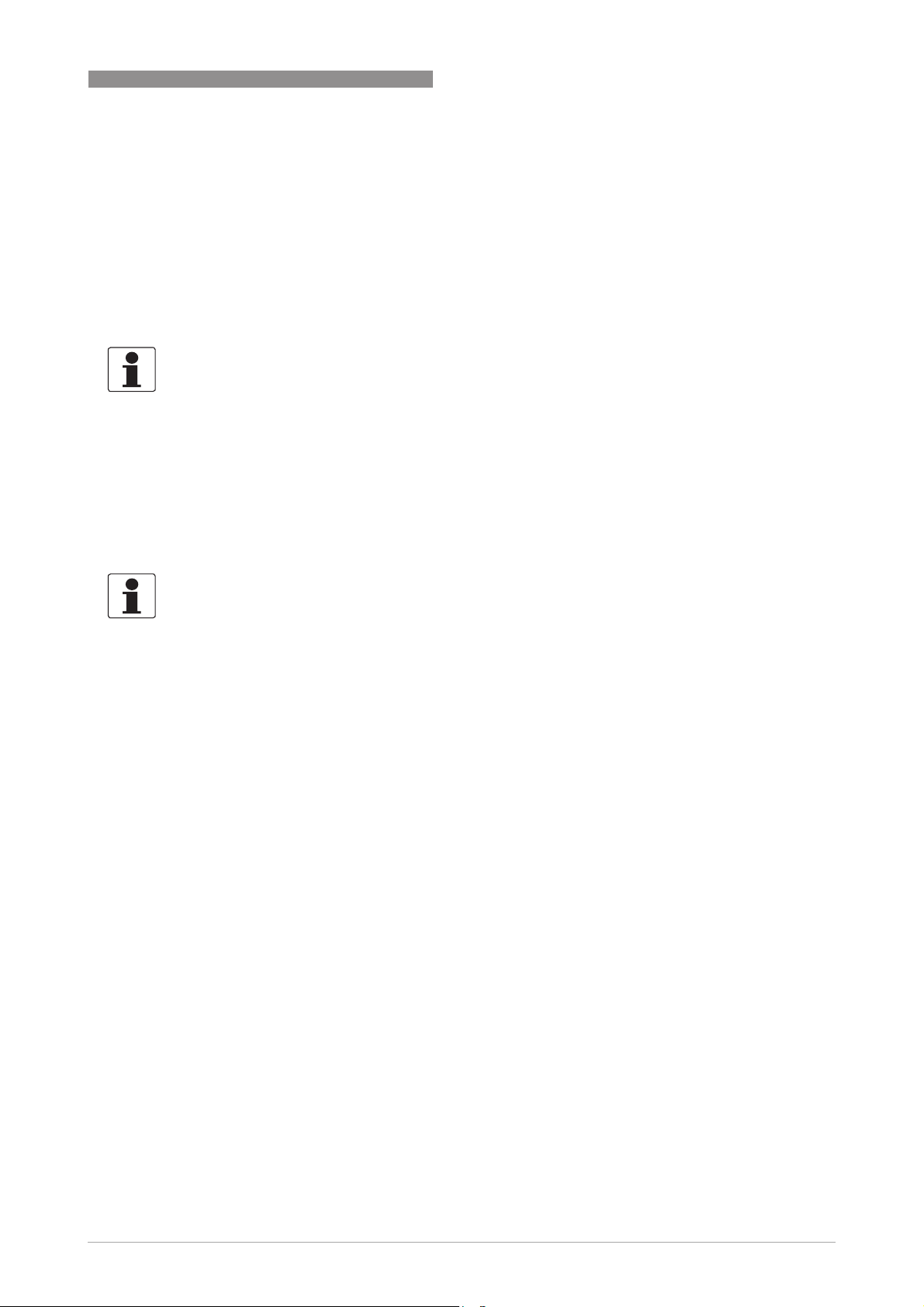

1.5 ATEX nameplates

Figure 1-1: Ex ia / Ex iaD nameplate (4...20 mA output)

Figure 1-2: Ex ia / Ex iaD nameplate (PROFIBUS PA or FOUNDATION™ Fieldbus output)

1 ATEX certification agency code

2 Equipment category (explosive atmosphere - gas)

3 Types of device protection including approved Gas Groups (IIA, IIB or IIC) and temperature classes (T6...T3 or T2 - de-

pends on the probe type)

4 Equipment category (explosive atmosphere - dust)

5 Types of device protection (explosive atmosphere - dust)

6 Degree of ingress protection (if fitted with the appropriate cable glands) and maximum surface temperature

7 Intrinsically-safe circuit data

8 Cable entry type and size (Aluminium housing: M26×1.5, M20×1.5, ½NPT or G ½; Stainless steel housing: M25×1.5,

M20×1.5, ½ NPT or G ½)

GENERAL SAFETY INFORMATION 1

7

OPTIFLEX 1300 C

www.krohne.com06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

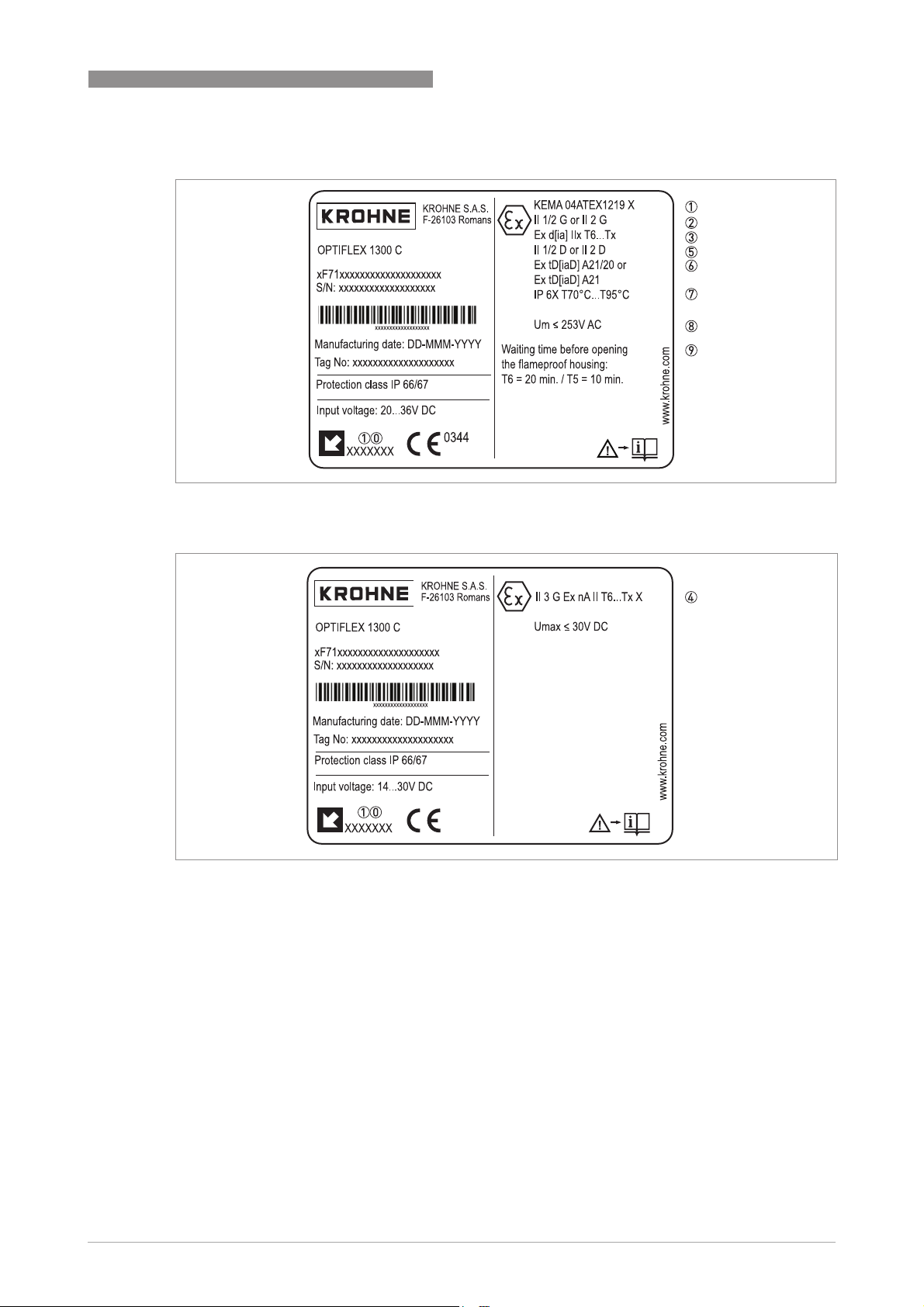

Figure 1-3: Ex d[ia] / Ex tD[iaD] nameplate (4...20 mA output)

Figure 1-4: Ex nA nameplate (4...20 mA output)

1 ATEX certification agency code

2 Equipment category (explosive atmosphere - gas)

3 Types of device protection including approved Gas Groups (IIA, IIB or IIC) and temperature classes (T6...T3 or T2 - de-

pends on the probe type)

4 Equipment category (explosive atmosphere - gas), types of device protection including approved Gas Groups (IIA, IIB

or IIC) and temperature classes (T6...T3 or T2 - depends on the probe type)

5 Equipment category (explosive atmosphere - dust)

6 Types of device protection (explosive atmosphere - dust)

7 Degree of ingress protection (if fitted with the appropriate cable glands) and maximum surface temperature

8 Maximum voltage in accordance with EN 60079-0

9 Minimum waiting time after power-off before it is safe to open the terminal compartment

10 Cable entry type and size (Aluminium housing: M26×1.5, M20×1.5, ½ NPT or G ½; Stainless steel housing: M25×1.5,

M20×1.5, ½ NPT or G ½)

2 INSTALLATION

8

OPTIFLEX 1300 C

www.krohne.com 06/2010 - 4000091403 - AD ATEX OPTIFLEX 1300 R05 en

2.1 Precautions

2.1.1 General notes

2.1.2 Electrostatic discharge

Take the necessary antistatic precautions if you:

• handle,

• install or

• use

the device in potentially explosive atmospheres. Do not install in a location (near to ventilation

systems, for example) where the electrostatic charge can increase.

WARNING!

When you install the device, obey the conditions in the EC-Type Examination certificate. These

conditions include:

•

The special conditions for safe use.

•

The Essential Health and Safety Requirements.

The certificate is given on the CD-ROM supplied with the device. You can also download the

certificate from our internet site.

DANGER!

This installation must agree with EN 60079-14: Explosive atmospheres - Part 14: Electrical

installations design, selection and erection and EN 61241-14: Electrical apparatus for use in the

presence of combustible dust - Part 14: Selection and installation.

DANGER!

Risk of electrostatic discharge from the blue plastic sun cover, the conduit of the remote housing

option and the optional plastic protective sheath for the single rod probe. Make sure that all

personnel and equipment are correctly grounded.

Figure 2-1: ESD warning sticker (below the device nameplate)

1 Text: Plastic Parts

2 Text: Warning! Potential electrostatic hazard - see instructions

PLASTIC PARTS

WARNING:

POTENTIAL ELECTROSTATIC HAZARD

SEE INSTRUCTIONS

!

Loading...

Loading...