KROHNE MAGCHECK User Manual

General advice on safety

Use of MagCheck on converters, which are not listed as may cause damage to these converters, to MagCheck and, in case of connection to hazardous area versions of these converters damage to protective elements. As a result safety risks in later operation of these converters cannot be excluded.

Product liability and warranty

Responsibility for suitability and intended use of this instrument rests solely with the user. Improper installation and operation may lead to loss of warranty. In addition, the general conditions of sale are applicable and are the basis for the purchase contract.

If the instrument needs to be returned to KROHNE, please note the information given in the service part of these instructions.

Items included with supply

A rugged suitcase containing:

•MagCheck

•Operating and installation instructions (hard copy)

•CD with MagCheck PC program, operating and installation instructions, Excel spreadsheets for data processing

•IFC 010 connecting cable

•IFC 020 connecting cable

•IFC 090 connecting cable

•IFC 110 connecting cable

•PC RS 232 connecting cable

•Power supply adapter 100..230V to 15 V DC

•Power plug adapter for different plug standards

2 |

MagCheck |

Table of contents

General advice on safety |

3 |

|

Product liability and warranty |

3 |

|

Items included with supply |

3 |

|

1 |

MagCheck introduction |

4 |

1.1 |

Introduction |

4 |

1.2 |

MagCheck as automatic verificator for KROHNE IMoCom converters |

4 |

1.3 |

MagCheck as manual signal calibrator |

5 |

2 |

Connecting and operating MagCheck |

6 |

2.1 |

Preparation |

6 |

2.2 |

Connecting cables |

6 |

2.3 |

Connection diagrams |

7 |

2.4 |

User interfaces |

9 |

2.5 |

Starting phase |

9 |

2.6 |

How to operate the menu |

10 |

3 |

Description of MagCheck menu functions |

12 |

3.1 |

Menu structure |

12 |

3.2 |

Automatic verification with KROHNE IMoCom converters |

13 |

3.3 |

MagCheck as manual flow signal calibrator |

14 |

3.4 |

MagCheck Menu functions for manual calibration test |

17 |

4 |

Using MagCheck with a PC |

21 |

4.1 |

System specifications |

21 |

4.2 |

Installation PC software |

21 |

4.3 |

Settings of MagCheck PC software |

21 |

4.4 |

Connecting MagCheck to PC |

22 |

4.5 |

Downloading and storing MagCheck verification data onto PC |

22 |

4.6 |

Exporting and importing verification files from / to floppy or hard disk |

23 |

4.7 |

Trend analysis |

24 |

5 |

Interpretation of verification results |

26 |

5.1 |

Accuracy data ADC, field current, mA or frequency output |

26 |

5.2 |

Coil resistance |

26 |

5.3 |

Electrode resistance with full pipe |

26 |

5.4 |

Electrode resistance with empty pipe |

27 |

5.5 |

Coil insulation |

28 |

5.6 |

Limitations of accuracy statement |

28 |

6 |

Service and recalibration |

29 |

6.1 |

Recalibration |

29 |

6.2 |

Software |

29 |

6.3 |

Spare parts |

29 |

Appendix 1 |

29 |

|

MagCheck |

3 |

1MagCheck introduction

1.1Introduction

MagCheck is an all-round portable testing and verification device for KROHNE electromagnetic flowmeters, enabling a complete functionality and accuracy verification of the EMF without taking the meter out of the pipeline nor interrupting the process. MagCheck measures autonomously and can be used on KROHNE EMF-converters (not on Ex-converters!). MagCheck can be employed either as an automatic verification instrument or as a manual flow signal calibrator, depending on the converter type.

MagCheck is used for precise analysis and verification of magnetic flowmeters. Precision of these meters is not only a function of accuracy of electric data, but also depends on the mechanical installation of flowhead and converter. Faulty installation, both mechanical or electrical, may not be detected by MagCheck.

Use of MagCheck on converters, which are not listed as compatible may cause damage to these converters, to MagCheck and in case of connection to hazardous area versions of these converters damage to protective elements!

MagCheck can and must NOT be used on:

• TIV 50, TIV 60 |

• CAPAFLUX, IFC 090 K / CAP |

||

• |

K300, F200 |

• |

NB 900 Power Booster |

• |

SC150 |

• |

Any Ex Zone 1/div 1 versions (hazardous area versions) of |

• ALTOFLUX 2W, IFC 040 |

ALTOFLUX 2W, IFC 040; SC80A / AS, SC100A / AS; |

|

• |

IFC 090i |

IFC 080, IFC 200, IFC 200 E; IFC 090, IFC 090i; IFC 110; |

• |

TIDALFLUX* |

IFC 210 Ex versions! |

*) Verification of the conventional electromagnetic flowmeter part of TIDALFLUX IFM 4110 PF is possible after disabling the level input to IFC 110 PF. This will allow for a statement of flow velocity measurement part, not of total the performance of TIDALFLUX.

1.2MagCheck as automatic verificator for KROHNE IMoCom converters

MagCheck is able to perform a fully automatic verification on magnetic flowmeters in combination with these converters. In this mode accuracy of the converter and all electric data of the primary head are verified which are vital for their function and accuracy. During the fully automatic test run the display will indicate all measured data. MagCheck reads and stores all settings of the IMoCom converter and all measured data of up to 70 meters.

MagCheck can verify KROHNE electromagnetic flowmeters with following IMoCom signal converters:

• |

IFC 010 |

• |

IFC 110 |

Non-Ex and non TIDALFLUX-versions only |

• |

IFC 020 |

• |

IFC 210 |

Non-Ex versions |

•IFC 090 Non-Ex versions

Data may be downloaded onto a PC (Microsoft Windows 95, 98, 2000, NT) using the KROHNE MagCheck PC-program. After downloading data into the PC the related memory areas in the MagCheck are cleared and can be used for further measurements. The KROHNE MagCheck PCprogram evaluates the downloaded data. If all data are within their limits, the program will create a final certificate confirming the meter operates with an accuracy deviation of less then 1% related to reference conditions. If the evaluation shows data exceeding their limits, the certificate will state, that the meter is not working properly.

4 |

MagCheck |

1.3MagCheck as manual signal calibrator

MagCheck replaces KROHNE Simulators GS8 / GS8A. With its integrated microprocessor, calibrated mA-meter and frequency meter MagCheck allows for verifying the accuracy of converters without the need for any further instruments like calculators, mAand frequency meters.

MagCheck generates precise adjustable flow signals. The flow signal can be set in steps of 0.1% of full scale. These very precise flow signals will be fed into the signal inputs of the converter. The output signals (mA, frequency) are indicated on the MagCheck display. In this manual flow signal calibrator mode no data will be stored in MagCheck. The measured/indicated data must be noted and evaluated manually (see Appendix 1).

With non-IMoCom converters: In the flow signal calibrator mode with these previous converters data as meter size (DN), GK, full scale setting must be entered into MagCheck manually.

MagCheck may be used as flow signal calibrator for following KROHNE electromagnetic flowmeter signal converters:

•T900

•SC100A, SC 100AS Non-Ex versions only!

•SC80A, SC 80AS Non-Ex versions only!

•AQUAFLUX 070

•IFC 080 Non-Ex versions only!

•IFC 200E, IFC 200. Non-Ex versions only!

•and all IMoCom converters as listed under 1.2

With IMoCom converters MagCheck loads data as meter size (DN), GK, full scale setting, current and pulse output settings automatically down from IMoCom converter through the IMoCom interface.

MagCheck |

5 |

2 Connecting and operating MagCheck

2.1Preparation

2.1.1 Initial preparations

Make sure that there is sufficient memory space left for new verifications. Connect MagCheck to a power outlet via its power adapter. MagCheck will start searching for the IMoCom interface. Stop this by pressing F1. Enter Menu 1.1. test MID. Press arrow →. MagCheck will indicate (example): 1.1 test MID

no connection inputs: 69/70

In this case only one set of data (one verification) can be stored additionally. Download existing data into the PC to clear more memory space (refer to chapter 5) if necessary. Take print-outs of the Excel spreadsheets (Refer to Appendix 1) and results of earlier verifications/ tests on related meters with you.

2.1.2 Document flowmeter data

Read and note all totalisers and counter values before and after verification and document the following (you may note these in the dedicated Excel spreadsheets, refer to chapter 7):

2.1.3 Disconnecting cables

Prior to connecting MagCheck to the magnetic flowmeter, signal-, field-, output cables of the flowmeter must be disconnected by pulling the connectors. All flowmeter outputs are interrupted, related process instrumentation will see open inputs. As a result the meter will not indicate the actual flow during the verification the meter.

Before changing any connections act according all process related safety and information rules existing in your organisation! Disable all alarms and take all controls to manual, which are dependent on the flowmeter outputs!

2.2Connecting cables

MagCheck is supplied with connection cables for IFC 010, IFC 020, IFC 090, IFC 110 F and a RS 232 cable (25 pole to 9 pole connector) for connecting MagCheck to PC (download of verification data) and a 100..230 Volt AC power supply, that is only used during download of verification data from MagCheck into PC. There is no need to unscrew any terminal screw with these cables. For manual calibration tests on older Non-IMoCom converters special cables can be supplied on request.

The 25-pin connector must be plugged into the MagCheck. Its securing screws must be fid to avoid contact failures during verification runs, e.g. due to accidental mechanical stress on the cable (see connection diagrams)

The following connections to the signal converter must be established:

•IMoCom (for tests on IMoCom converters only as listed under 1.2.)

•Electrode signal

•Field current

•Outputs (mA and pulse)

Connection to flow head (flow tube) only is necessary for automatic verification with IMoCom converters, not for use of MagCheck as precision flow signal calibrator for converter verifications. The following connections to the flow head must be established±

•Electrode signal

•Field coil connection

6 |

MagCheck |

During verification and test of converters as listed above, MagCheck does not need any external power supply or batteries. MagCheck takes all its power from the field current of these signal converters. The external power supply supplied with MagCheck is only needed during download of verification data into a PC.

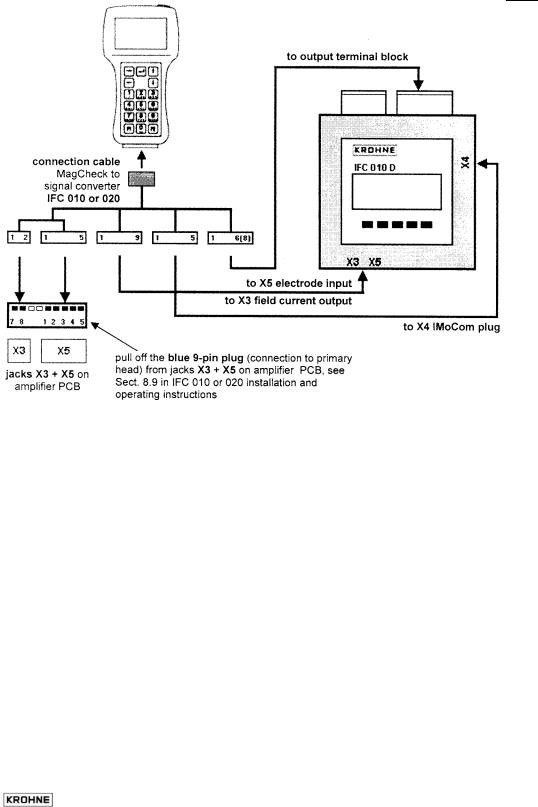

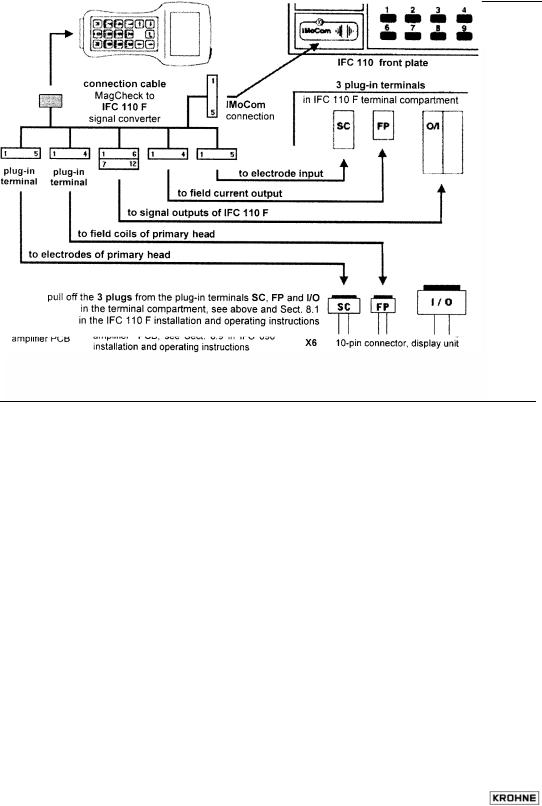

2.3Connection diagrams

For use of MagCheck as precision flow signal calibrator for detailed manual verification of converters Connections to flow head (field coils and electrodes) are not needed.

Please note!

In the drawing of IFC 010 manual in Sect. 7.5 the jacks X1 and X4 were named wrong: X1 must be X3 and X4 must be X5!

Connection MagCheck IFC 010 or IFC 020

|

|

|

|

MagCheck |

7 |

Connection MagCheck IFC 090

Connection MagCheck IFC 110 F

|

|

|

|

|

|

8 |

MagCheck |

|

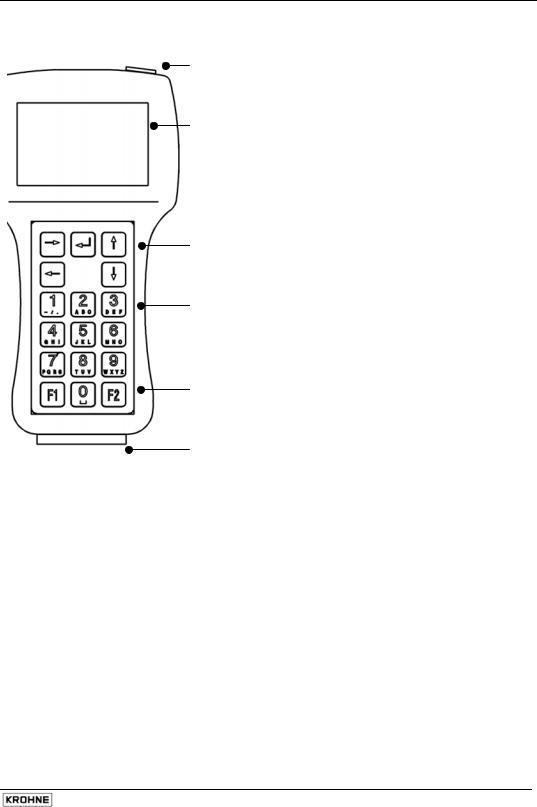

2.4User interfaces

Connector for external power supply

(necessary only for download of verification data into PC)

Display

4 rows, 16 digits each

Backlit with external power supply

Arrow keys

•Entering into a menu (→)

•Stepping from digit to digit (→ ←)

•Increasing or reducing values (↑ ↓)

•Confirmation of entered data ( )

•Stepping to the next (sub-)menu ( )

•Returning to the main menu ( )

Alpha-numerical keys

•Entering values,

•menu number

•Texts

F1 key

•start of MagCheck without IMoCom connection

F2 key

•For encoded access to MagCheck Service Menu only, no

function for verification

25-pole connector for

•converter verification cables

•PC-data transfer cable

2.5Starting phase

After connection to converter and after power supply of the converter has been switched on MagCheck will start a self test, checking all its EEPROM data for their validity. After it will signal "OK" (in case of an error it will indicate "ERROR"), for approximately 5 seconds.

2.5.1 With IMoCom converters (IMoCom interface connected)

Next step is automatic start of communication with the IMoCom Bus of the IFC. After indicating : "Test of communication", MagCheck locks in onto the IMoCom Bus of the IFC. It will read the settings of the IFC and start to simulate a 100% signal.

2.5.2 With Non-IMoCom Converters or IMoCom-interface not connected

If there is no communication MagCheck will ask you to press "F1". and will stay in Menu 1.0 until settings are entered (see below). All meter parameters data in menu 1.2 must be entered manually.

If energy (field current level) received by MagCheck is too low, MagCheck display will flicker and MagCheck will not start. This can be caused by:

•poor connection or defective cable / connector connecting field current to MagCheck

•a defective field current supply of the converter

•You have connected to an IFC040 converter

MagCheck |

9 |

2.6How to operate the menu

2.6.1 Display in main menu

There are three main menus indicated with x.0.

|

|

|

|

|

|

|

|

1 |

. 0 |

o p e r a t |

i o N |

|

Menu line |

|

|

|

|

|

|

Indication line |

|

I |

o C o m- B u s |

|

) ( |

Status line for IMoCom connection |

|

|

f |

i e l |

d c u r r |

e n T |

+ - |

Status line for field current |

|

|

|

|

|

|

|

In the main menu display, the two last lines represent status lines.

The IMoCom-Bus status line displays the actual status of the IMoCom connection as follows:

() |

|

|

Two moving brackets |

IMoCom present, IMoCom data transfer operating |

|

|

|

||||||||||||||||||||||||||

() |

|

|

Two static brackets |

IMoCom present, no data transmission window present |

|

|

|

||||||||||||||||||||||||||

no |

|

|

|

|

|

|

No IMoCom connected |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

The field current status line displays the actual status of the field current as follows: |

|

|

|

||||||||||||||||||||||||||||||

+ - |

|

Plus, minus |

Correct (field current is switching from positive to negative current and vice |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

versa) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

|

Plus |

|

Positive DC or pulsating DC (defective converter, negative half wave |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

missing) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

|

|

Minus |

|

Negative DC or pulsating DC (defective converter, positive half wave |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

missing) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No indication |

No current (defective converter, no field current) |

|

|

|

|

|

|||||||||||||||||||||||

The indication lines are used to show error messages. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

2.6.2 Selecting menus and changing data |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

Moving the cursor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Cursor position is indicated by grey blinking background |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

. |

0 |

|

o p e r a t i o n |

|

Cursor to the right |

1 . |

|

1 |

|

t |

e s t |

M I D |

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

→ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

I M o C o m- B u s |

( ) |

|

|

|

|

|

|

|

← |

|

|

I M o C o m- B u s |

|

) ( |

|

|

||||||||||||||||

|

f i |

e l |

d |

c u r |

r e n t |

+ - |

|

Cursor to the left |

f i |

e l d |

c u r r |

e n t |

+ - |

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Changing the numbers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Alternatively the corresponding numerical key can be used |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 . |

|

3 |

|

z e r o |

s e t |

|

|

|

Increase number |

|

|

1 . |

|

4 |

|

s i |

m u l |

a t i |

o n |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

I M o C o m - B u s |

) ( |

|

|

|

|

|

|

|

|

↓ |

|

|

|

I M o C o m - B u s |

( ) |

|

||||||||||||||||

|

f i |

e l |

d |

c u r |

r e n t |

+ - |

|

|

Decrease number |

|

|

f i |

|

e l |

d |

c u r |

r e n t + - |

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

MagCheck |

Loading...

Loading...