KROHNE M10 User Manual

© KROHNE 11/2002 |

7.02247.22.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

GR

GR

Supplementary Installation and

Operating Instructions

Variable-area flowmeters H250/H54

Stand: 08/2000

ANL. A.1 EG-Baumusterprüfbescheinigung PTB 00 ATEX 2063

Signal converter M10 of hazardous-duty design EEx d

PTB 01 ATEX 1154

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Contents |

|

|

|

1 |

General safety information .................................................................................................. |

3 |

|

2 |

Safety-relevant type code .................................................................................................... |

4 |

|

3 |

Main safety-relevant characteristics ................................................................................... |

4 |

|

3.1 |

Process products .................................................................................................................... |

4 |

|

3.2 |

Category / Zone allocation ...................................................................................................... |

4 |

|

3.3 |

Type of protection ................................................................................................................... |

4 |

|

3.4 |

Special lock............................................................................................................................. |

|

4 |

3.5 |

Cable entries / sealing plugs................................................................................................... |

5 |

|

3.6 |

Power supply |

.......................................................................................................................... |

5 |

3.7 |

I/O functions............................................................................................................................ |

|

5 |

3.8 |

Ambient temperatures / temperature classes ......................................................................... |

5 |

|

4 |

Marking.................................................................................................................................. |

|

6 |

5 |

Mounting and installation .................................................................................................... |

6 |

|

5.1 |

Electrical connection............................................................................................................... |

7 |

|

5.1.1 General................................................................................................................................... |

|

7 |

|

5.1.2 Terminal compartment............................................................................................................ |

7 |

||

5.1.3 Connecting cables .................................................................................................................. |

7 |

||

5.1.4 Connection of power and I/O function..................................................................................... |

7 |

||

6 |

Initial startup ......................................................................................................................... |

9 |

|

7 |

Operation............................................................................................................................... |

|

9 |

8 |

Preventive maintenance....................................................................................................... |

9 |

|

8.1 |

Maintenance ........................................................................................................................... |

|

9 |

8.2 |

Dismantling ........................................................................................................................... |

|

10 |

8.2.1 General................................................................................................................................. |

|

10 |

|

8.2.2 Replacement of signal converter / display ............................................................................ |

10 |

||

8.2.3 Replacement of complete device.......................................................................................... |

10 |

||

Attachment A.1 |

EC Type Test Certificate PTB 01 ATEX 1154................................................. |

11 |

|

Attachment A.2 |

Declaration of Conformity ............................................................................... |

19 |

|

If you need to return a device for testing or repair to KROHNE.............................................. |

20 |

||

2 |

Signal converter M10-EEx d – Supplementary instructions |

11/2002 |

1 General safety information

These additional “Ex“ Instructions apply to the hazardous-duty versions of H..../..../M10-EEx variable-area flowmeters. They are supplementary to the Installation and Operating Instructions for the non-hazardous-duty versions.

The information given in these Instructions contains only the data relevant to explosion protection. The technical details given in the Installation and Operating Instructions for the non-hazardous- duty version apply unchanged unless excluded or superseded by these Instructions.

In compliance with European Directive 94/9 EG (ATEX 100a), variable-area flowmeters of the H..../..../M10-EEx series are certified in conformity with European Standards EN 50xxx for use in hazardous areas under

PTB 01 ATEX 1154

by the Physikalisch-Technische Bundesanstalt (PTB).

This certification together with its boundary conditions is required to be observed without fail (see Attachment A.1 ”EC type test certificate“).

IMPORTANT!

Mounting, installation, (initial) startup and maintenance work may only be carried out by personnel who have received "training in explosion protection"!

Maintenance work of a safety-relevant nature within the meaning of explosion protection may only be carried out by the manufacturer, his authorized representative or under the supervision of authorized inspectors.

Note!

For processes involving combustible and highly flammable products, easily removable threaded connections to DIN 11851; SMS; TriClamp (e.g. DIN 32676; ISO 2852 Clamp); are not allowed.

11/2002 |

Signal converter M10-EEx d – Supplementary instructions |

3 |

2 Safety-relevant type code

The safety-relevant type code is made up of the following elements: (1)

|

|

H |

.... / |

.... |

|

/ M10 - E Ex |

||

|

|

|

1 |

|

2 |

3 |

4 |

5 |

1 |

: |

Model series |

: measuring section |

|||||

|

|

H54 |

|

: |

|

measuring section, Series H54 |

||

|

|

H250 |

|

: |

|

measuring section, Series H250 |

||

|

|

H250C |

|

: |

|

measuring section, Series H250C |

||

2 |

: |

Material of wetted parts |

|

|

||||

|

|

RR |

|

: |

|

stainless steel |

||

|

|

HC |

|

: |

|

Hastelloy |

|

|

|

|

Ti |

|

: |

|

titanium |

|

|

|

|

PTFE |

|

: |

|

PTFE, ceramics |

||

3 |

: |

Model series |

: |

indicator section |

|

|||

|

|

M10 |

|

: |

|

signal converter M10 |

||

4 : Territorial application of the approval

E:Europe (EC, CENELEC area of validity)

5 : Safety function

Ex: explosion-protected electrical equipment

(1) places for items not needed may be omitted from the type code

3 Main safety-relevant characteristics

The H..../..../M10-EEx variable-area flowmeter consists of a combination of signal converter and measuring tube. The main characteristics of the explosion-protected version are described below.

3.1Process products

Flammable products are allowed provided they are not present in potentially explosive form.

3.2Category / Zone allocation

The H..../..../M10-EEx variable-area flowmeter is basically designed in Category 2 for use in Zone 1.

3.3Type of protection

The H..../. .../M10-EEx variable-area flowmeters bear the following marking: EEx d IIC T6

3.4Special lock

The sealing covers of the electronics compartment are secured by a special lock. The locking screw requires use of an Allen key (3 mm size).

4 |

Signal converter M10-EEx d – Supplementary instructions |

11/2002 |

3.5Cable entries / sealing plugs

Cable entries and sealing plugs must, in ready-to-operate condition, satisfy the IP Class of Protection IP67 and each be separately certified in conformity with EN 50 018. Any requirements specified in the test certificates of the components shall be observed.

3.6Power supply

Type H..../..../M10-EEx variable-area flowmeters do not require any separate power source. The necessary supply is obtained via the current output.

3.7I/O functions

When connecting the I/O interfaces of the H..../..../M10-EEx variable-area flowmeters, the following values need to be taken into account.

I/O function (1) |

Nominal values of the non- |

Added restriction |

|

|

|

certified receiver instrument |

|

See Standard Installation |

See Standard Installation |

Supply power for receiver |

|

and Operating Instructions |

and Operating Instructions |

instruments max. 253V |

|

(1) |

Only for connection to circuits with “functional extra-low voltage with protective separation |

||

|

|||

|

(PELV)” |

|

|

|

Peak values UAC ≤ 25V ; UDC ≤ 60V |

|

|

3.8Ambient temperatures / temperature classes

The permissible ambient temperature for the variable-area flowmeters is limited to a value of Tamb ≤ 60 °C.

With regard to maximum surface temperatures, variable-area flowmeters are exposed to three heat sources:

•Ambient temperature Tamb

•Electric power loss Pv

•Process temperature Tm

Accordingly, at a given maximum ambient temperature (Tamb ≤ 60°C) and a given maximum power loss (Pv ≤ 3 W), we obtain maximum surface temperatures as a factor of the process temperature. For that reason, the devices are not allocated to any specific temperature class; rather, the temperature class of the devices is a function of the actual process temperature and ambient temperature, see table below.

|

Temperature |

|

Ambient temperature |

|

|

Max. permissible process |

|

|

|

||

|

class |

|

in °C |

|

|

permanent temperature |

|

|

|

||

|

|

|

|

|

Wiring |

|

Wiring |

|

Wiring |

|

|

|

|

|

|

|

70°C |

|

80°C |

|

90°C |

|

|

|

T6 |

|

-40 … +60 |

|

85 |

|

85 |

|

85 |

|

|

|

T5 |

|

-40 … +50 |

|

100 |

|

100 |

|

100 |

|

|

|

|

|

-40 … +60 |

|

85 |

|

100 |

|

100 |

|

|

|

T4 |

|

-40 … +50 |

|

135 |

|

135 |

|

135 |

|

|

|

|

|

-40 … +60 |

|

85 |

|

135 |

|

135 |

|

|

|

T3 ... T1 |

|

-40 … +40 |

|

180 |

|

200 |

|

200 |

|

|

|

|

|

-40 … +50 |

|

135 |

|

190 |

|

200 |

|

|

|

|

|

-40 … +60 |

|

85 |

|

145 |

|

200 |

|

|

|

Table 1 |

Max. permissible process temperatures |

|

|

|

|

|

|

|||

|

|

The cable glands and line entries must have the same degree of thermal |

|

|

|||||||

|

|

stability as the connecting cable |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

|

11/2002 |

|

Signal converter M10-EEx d – Supplementary instructions |

5 |

|

||||||

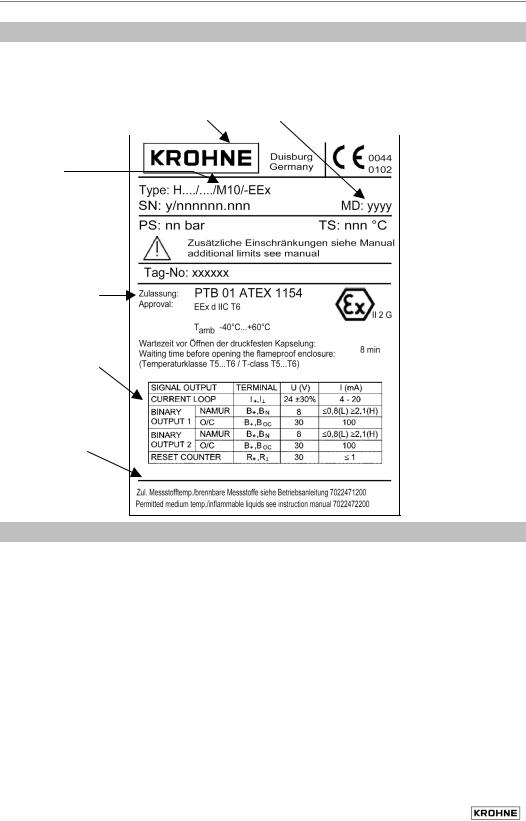

4 Marking

The variable-area flowmeters are identified by an adhesive label or metal plate attached to the signal converter. The type code is explained in Section 2.

H..../..../M10EEx, Category 2G

|

Manufacturer |

Year of manufacture |

|

|

|

Type |

|

|

Approval information

Technical data of circuits

Safety info

5 Mounting and installation

Mounting and installation to be carried out in conformity with the valid installation standards for hazardous areas (e.g. EN 60079-14 / VDE 0165) by specialist personnel trained in explosion protection.

The information given in the standard Installation and Operating Instructions, the Supplementary Installation and Operating Instructions (Ex) and also in the EC type test certificate (see Attachment A.1) must be observed without fail.

Verify that the variable-area flowmeter is suitable for the application in question by comparing the details on the nameplate with those in Section 3.2 (Categories / Zone allocation), Section 2 (Type code) and Section 4 (Marking).

When installing, please pay special attention to the following points.

6 |

Signal converter M10-EEx d – Supplementary instructions |

11/2002 |

Loading...

Loading...