KROHNE BM102 User Manual

© KROHNE 03/2004 |

7.02267.22.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

GR

GR

Handbook

BM 102

MICROFLEX

T D R Level gauge

2-WIRE

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Subject to change without notice.

Table of contents

Device description and range of applications ……………………………………………………….. 4 Principal gauge components ……………………..………………………………………………….…. 4 Items included with supply …………………………………………………..…………………….……. 6 Documentation supplied …………………………………………………..……………………….……. 6 Product liability and warranty ………………………….………………………………………….……. 6

1 |

Mechanical installation......................................................................................................... |

7 |

1.1 |

Handling and storage .............................................................................................................. |

7 |

1.2 |

Installation restrictions............................................................................................................. |

8 |

1.3 |

Mounting on the tank............................................................................................................... |

8 |

1.3.1 |

Installation instructions: general notes .................................................................................... |

8 |

1.3.2 |

Installation instructions: nozzle................................................................................................ |

9 |

1.3.3 |

Installation instructions: Gauge - all applications................................................................... |

11 |

1.3.4 |

Specific installation instructions: gauge - liquid applications ................................................. |

14 |

1.3.5 |

Specific installation instructions: gauge - solid applications .................................................. |

16 |

2 |

Electrical connections ........................................................................................................ |

18 |

2.1 |

Electrical installation instructions........................................................................................... |

18 |

2.1.1 |

Wiring general notes ............................................................................................................. |

18 |

2.1.2 |

Wiring connections: DIN connector ....................................................................................... |

18 |

2.1.3 |

Wiring connections: M16 terminal box .................................................................................. |

19 |

2.1.4 |

’Ex’ equalizing conductor ...................................................................................................... |

19 |

2.2 |

Power Supply........................................................................................................................ |

20 |

2.2.1 |

Non-hazardous-duty version ................................................................................................. |

20 |

2.2.2 |

Hazardous-duty version ........................................................................................................ |

21 |

2.3 |

Electrical output..................................................................................................................... |

22 |

2.3.1 |

Network options .................................................................................................................... |

22 |

2.3.2 |

HART® communication protocol........................................................................................... |

22 |

3 |

User interface ...................................................................................................................... |

23 |

3.1 |

Power-on and start-up........................................................................................................... |

23 |

3.2 |

Available user interfaces ....................................................................................................... |

23 |

3.3 |

Operator control .................................................................................................................... |

23 |

3.3.1 |

PCSTAR 2 for Windows : basic installation & operating instructions .................................... |

23 |

3.3.2 |

Summary of User Functions in PCSTAR 2 (F2 – Configuration)........................................... |

27 |

3.3.3 |

Quick Configuration: configuration examples........................................................................ |

33 |

3.3.4 |

HART® Communicator: installation & operating instructions ................................................ |

38 |

3.3.5 Characters available for alpha-numerical data functions in PC STAR 2 and on the HART® |

|

|

|

console.................................................................................................................................. |

46 |

3.3.6 |

Local user display (instruments equipped with DIN connectors only) ................................... |

47 |

3.4 |

BM 102 MICROFLEX T.D.R. meter characteristics............................................................... |

48 |

3.4.1 |

Gauge operating logic when the reflection is lost.................................................................. |

49 |

3.4.2 |

Gain and voltage amplitude .................................................................................................. |

50 |

3.4.3 |

Level measurement when more than one phase or layer in the tank.................................... |

56 |

4 |

Service / Maintenance......................................................................................................... |

57 |

4.1 |

Replacement of the signal converter..................................................................................... |

57 |

4.2 |

Fault clearing......................................................................................................................... |

59 |

2 |

BM 102 |

|

5 |

Technical data..................................................................................................................... |

63 |

5.1 |

Technical data ...................................................................................................................... |

63 |

5.1.1 |

Accuracy ............................................................................................................................... |

65 |

5.1.2 |

Start-up characteristics ......................................................................................................... |

66 |

5.2 |

BM 102 equipment architecture ............................................................................................ |

67 |

5.2.1 |

BM 102 mechanical options (by probe type)......................................................................... |

67 |

5.2.2 |

Definition of terms................................................................................................................. |

69 |

5.2.3 |

Probe measurement limits .................................................................................................... |

70 |

5.3 |

Gauge dimensions................................................................................................................ |

71 |

6 |

Measuring principle............................................................................................................ |

72 |

6.1 |

General principle................................................................................................................... |

72 |

6.1.1 |

Level measurement of one product....................................................................................... |

73 |

7 |

Certificates and Approvals ................................................................................................ |

74 |

8 |

PCSTAR 2 software user’s guide ...................................................................................... |

75 |

8.1 |

Software installation.............................................................................................................. |

75 |

8.2 |

PCSTAR 2 software history .................................................................................................. |

75 |

8.3 |

Supported networks .............................................................................................................. |

75 |

8.4 |

PCSTAR 2 functions ............................................................................................................. |

75 |

8.4.1 |

F1 Help ................................................................................................................................. |

76 |

8.4.2 |

F2-Connection: on-line functions .......................................................................................... |

76 |

8.4.3 |

F3 Exit:.................................................................................................................................. |

84 |

8.4.4 |

F4 Serial (parameters): ......................................................................................................... |

84 |

8.4.5 |

F5 Record (Reading): ........................................................................................................... |

84 |

8.4.6 |

F9 Colors .............................................................................................................................. |

87 |

8.4.7 |

Other important PCSTAR 2 functions ................................................................................... |

87 |

8.5 |

Fault Clearing PCSTAR 2 ..................................................................................................... |

88 |

Appendix A: BM 102 Level Gauge Configuration Record ………………………………………... 89 Appendix B: BM 102 – CE Declaration of Conformity…………………………………………..…. 90 Appendix C: Returning a device for testing or repair to KROHNE …………………………..…. 91

BM 102 |

3 |

Device description and range of applications

The BM 102 MICROFLEX level gauge uses the Time Domain Reflectometry (TDR) measuring principle and two-wire technology for level measurement. It is designed solely for measuring the distance, level, volume and ullage of liquids, pastes, slurries and powder products. It can continue to measure the level or distance and total volume in applications with two products.

The level measurement data can be displayed and the gauge configured using either a HART Handheld Communicator console (HHC) or a PC work station equipped with PCSTAR2 software supplied as standard with the gauge.

Principal gauge components

BM 102 housing and probes (non-Ex and Ex versions) |

with high- |

with inactive |

|

temperature |

length |

|

option |

option |

1Nameplate (see next page for details)

2Cable entry (output and power supply) to wiring compartment

3Equi-potential bonding system connection (Ex – see section 2.1.4)

4Flange (process connection onto tank or other suitable mounting)

5Single cable probe

6Counterweight (with threaded hole in base for anchoring)

7Twin cable probe

8Spacer

9Chuck / ring (for single cable probes)

10Turnbuckle (for twin or single cable probes)

11Threaded process connection (e.g. 1” G, 1” NPT, …)

12Coaxial probe

13Extension tube for high temperature applications

14Single rod probe

15Inactive length: coaxial tube under the process connection (i.e. an inactive length of the probe) for installations with long nozzles or concrete roofs – for single rod and single cable probe versions only

4 |

BM 102 |

Standard nameplate

*eg. VF030415B0112110110100000. The “type code” gives the options chosen for this unit and is defined in the BM 102 Data Sheet. This document is available from your local KROHNE Sales office or on the “Download Centre” on KROHNE’s website http://www.krohne.com/.

BM 102 |

5 |

Items included with supply:

The scope of supply encompasses:

•Signal converter with probe in the version ordered. The version is stated on the nameplate.

•PCSTAR 2 computer software for data display and gauge configuration.

Documentation supplied:

Installation & Operating instructions:

Installation, connection, start-up and safety advice in condensed form, but sufficient for most applications. This is supplied as a printed document with the device delivered.

Handbook (this manual):

Detailed user manual and reference book, including how to configure meter parameters available in the user menu and how to perform basic maintenance. This is not shipped with the level meter ordered.

Supplementary Installation and Operating Instructions BM 102 KEMA 00 ATEX 1101X:

Supplementary instructions covering devices to be installed and used in hazardous areas. This document is only supplied with specially approved instruments. This document is available from your local KROHNE Sales office or on the “Download Centre” on KROHNE’s website http://www.krohne.com/.

Product liability and warranty:

The BM 102 TDR level gauge is designed for measuring the distance, level, and volume of liquids, pastes, slurries and powders. It may equally measure level, distance, total volume and ullage in applications where two or more products are present.

Special codes and regulations apply to its use in hazardous areas. Please refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions for further information. This document is available from your local KROHNE Sales office or on the “Download Centre” on KROHNE’s website http://www.krohne.com/.

Responsibility as to suitability and intended use of these level gauges rests solely with the user. Improper installation and operation of our level gauges may lead to loss of warranty.

In addition, the "General conditions of sale", forming the basis of the purchasing contract, are applicable.

If you need to return measuring instruments to KROHNE, please note the information given in Appendix C. KROHNE regrets that they cannot repair or check your device unless it is accompanied by the completed form.

The level gauge does not form part of an overfill protection system (as defined for example in WHG: German water resources act) nor is it concerned by the Pressure Equipment Directive (PED) 97/23/EC.

6 |

BM 102 |

1 Mechanical installation

1.1Handling and storage

To carry: the device will weigh between 3 kg or 7 lb and 12 kg or 25 lb. Carry using both hands to lift the device carefully by the converter housing. If necessary, use lifting gear.

No attempt should be made to lift the instrument by its probe.

Caution:

The probe is a critical gauge component. Do not damage– Handle with care!!!

Avoiding blows

When handling the BM 102, avoid hard blows, jolts, impacts, etc.

Caution:

Fragile electronics

Avoid bending (single rod and coaxial probes)

Support the probe to avoid bending.

Support probe here

BM 102 |

7 |

Avoid cable kinks and fraying

Do not coil the cable less than 400 mm or 16 “ in diameter. Cable kinks or fraying will cause measurement errors.

Storage temperature

Store within the given storage temperature limits.

1.2Installation restrictions

Hazardous-duty systems (Ex, FM,…)

•Refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions for further information on installing gauges approved for use in hazardous locations. This document is available from your local KROHNE Sales office or on the “Download Centre” on KROHNE’s website http://www.krohne.com/.

•Check that the flange, gasket and probe materials are compatible with the product. Read the information given on the converter nameplate, the flange markings and specifications in the approval certificates.

1.3Mounting on the tank

1.3.1 Installation instructions: general notes

The fitter should give some thought to tank fittings and tank shape.

•Nozzle position in relation to the tank walls and other objects inside the tanks

(Warning : this free area will depend on the probe type selected: refer to later on in this section)

•Type of tank roof, i.e. floating, concrete, integral, etc; and base, i.e. conical, etc.

Whenever working on an installation, remember to:

•Disconnect the power supply before starting work. However,

•The gauge may be installed when the tank contains product.

8 |

BM 102 |

1.3.2 Installation instructions: nozzle |

|

Threaded process connections |

Nozzle height |

The simplest and most economic way is to |

Recommendation |

mount the BM 102 directly on the tank with a |

Do not fit a nozzle longer than its |

GAS or NPT threaded connection. |

diameter , especially for single |

|

probes and powder applications |

h ≤ Ød |

, where h = nozzle height and |

|

d = nozzle diameter |

Contact KROHNE if this relationship cannot be respected.

Nozzles extending into tank

Caution:

Do not use nozzles that extend into the tank. This will disturb the electromagnetic emitted pulse and the measurement.

BM 102 |

9 |

Installation of two devices

If two devices are to be used on the same tank, these should be mounted at a distance of at least 2 m or 6 ¾ ft away from each other. If not, interferences from the electromagnetic (EM) fields generated by both instruments may cause measurement errors.

Not applicable to coaxial probes - the outer shell of the probe contains the EM field: no minimum distance required.

Process connection

For the gauge to make accurate measurements:

•The tank process connection must be level.

•Ensure a good fit with the gauge process connection

•The tank roof should not deform under the weight of the gauge

Process connection and entry pipe

Caution:

Do not put the nozzle close to the entry pipe. Pouring the product directly onto the probe will give false readings. Install deflector plate if impossible to distance gauge from entry pipe.

10 |

BM 102 |

Stilling wells

Tanks with floating roofs for petro-chemical applications: use a stilling well.

1 Stilling well

2 Tank

3 Floating roof

4 Product (petroleum applications)

5 Well fixed to tank base (no roof deformation)

6 Sediment

1.3.3 Installation instructions: Gauge - all applications

BM102 gauges are designed to be mounted on a suitable process connection on a tank or sump. Install the gauge using two people to avoid damaging the probe. Support the housing and the probe.

Installation of single and twin cable probe level meters

1Caution :

Do not over-bend probe!

2Inserting the probe: hold more than one metre above the opening to avoid cable bending.

BM 102 |

11 |

Probes: entanglement, straightness and tank bottom clearance

Rigid section length of single and twin cable probes

Cable diameter |

Rigid section length |

Single cable |

|

Ø4mm or 0.15” |

40mm or 1½” |

Ø8mm or 0.15” |

200mm or 8” |

Twin cable |

|

Ø4mm or 0.15” |

40mm or 1½” |

•Cable probes must be straight once inserted into the tank. They must also be far from other objects (e.g. mixers) to avoid entanglement.

•In order to maintain the gauge’s operating characteristics, it is recommended to avoid touching the tank bottom with the counterweights (for cable probes) or probe end (other types).

Objects (discontinuities) inside the tank that influence the probe’s EM (electromagnetic) field

Install the gauge far from protruding objects such as:

•Heating tubes,

•Sudden changes in tank cross-section,

•Tank wall reinforcements and beams,

•Weld lines and dip-stick pipes, etc...

TDR gauges generate electromagnetic (EM) fields when a measurement pulse is emitted. This field is affected by any nearby discontinuities and these will weaken and potentially block the emitted pulse. A minimum distance is recommended depending on the probe type to be installed. See the table on the next page for recommended free space dimensions.

Alternatively, the fitter may use a reference chamber or stilling well. However, the chamber walls must be smooth (i.e. no visible weld lines), straight and vertical to maintain the pulse strength and gauge accuracy.

For clean applications only :

Coaxial (type 3) probes may be used close to or touching objects or walls as the EM field generated by the probe is contained within the probe’s outer sheath (refer also to the EM field sizes/free area given in the figures on the next page).

12 |

BM 102 |

1 |

Agitator |

2 |

Support beam perpendicular to the |

|

pulse direction |

3 |

Abrupt changes in tank cross section |

4 |

Heating tubes |

5 |

Alternative solution: reference chamber |

|

-electromagnetic field is contained |

|

within chamber |

6 |

Gauge electromagnetic field: |

|

Any intruding metallic object will be |

|

detected in this zone if perpendicular to |

|

the emitted pulse direction. |

= Do not fit the gauge near to these objects.

Recommended minimum distance of probe from objects inside the tank

Probe Type |

Minimum free space |

|

|

Single (types 1,2 and 6) |

300 mm or 12” |

Twin (type 4) |

100 mm or 4” |

Coaxial (type 3) |

0 mm or 0” |

Electromagnetic field shape around probe, by type (not to scale)

Single (types 1,2 and 6) |

Twin (type 4) |

Coaxial (type 3) |

No beam angle for any probe type.

BM 102 |

13 |

Avoid direct solar radiation

Fit a sunshade on the gauge for open-air installations: this is either supplied on demand by KROHNE or provided by the customer. The ambient temperature limits of the gauge are given below.

1.3.4 Specific installation instructions: gauge - liquid applications

Probe bending in agitated products: recommended solutions

1 Agitator

2 Turnbuckle for anchoring probe to tank bottom

3 Bypass chamber

4 Probe and counterweight (centred on request)

Mounting on a reference vessel or still well is ideal. To ensure that the probe does not come into contact with the tank wall, the probe should be fixed to the bottom of the chamber or centred.

14 |

BM 102 |

Fastening the probe to the tank bottom

Flexible probes can be fastened with a chuck (ring), turnbuckle or similar fastening device to the tank bottom:

Chuck (ring) |

Turnbuckle for Ø8 mm cable |

|

probes |

Shortening cable probes |

|

Turnbuckle for Ø4 mm cable probes

If required, the cable probe can be shortened, but this applies only when used in liquids.

Procedure

Step Action

1Detach socket set screw M6x10 (ISO 4026) with a 3mm Allen (hexagon) key (ISO 2936).

2Pull cable (2) out of counterweight (3) and shorten to required length using cable cutters to prevent the cable wires and strands from splaying out.

3Insert cable back into counterweight and tighten down screws

4Change configuration parameters to new probe length; the reference point is the top edge of the weight (user menu function 1.1.6)

Dimensions in mm (inches).

BM 102 |

15 |

1.3.5 Specific installation instructions: gauge - solid applications

False readings:

1 Do not let probe touch the side of the nozzle

Conical silo nozzles, false readings and traction on the cable probes

Caution

2High traction forces :

We recommend that the probe should not be anchored to avoid excessive traction loads on the cable.

3Bending and traction:

Position the connection on the roof at ½ radius of the tank and with minimum nozzle height. This will avoid damage due to bending and traction during emptying.

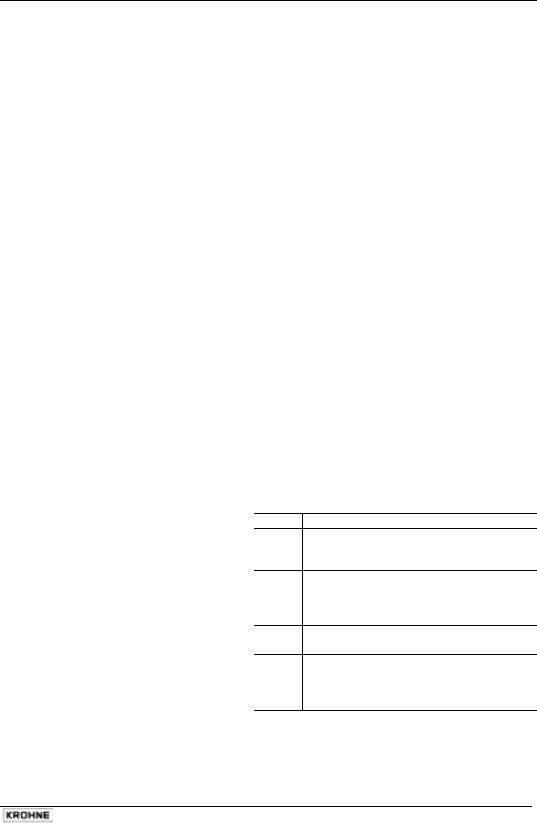

Traction forces during emptying cycles for powder applications

Traction load is dependent upon the height and shape of the tank, product particle size & density, and the rate at which the tank is emptied. The table below gives the load up to which cable probes will hold.

Cable maximum design load, traction

|

Probe |

|

|

Maximum Load |

|

|

|

|||

|

Single cable Ø8 mm or Ø0.3” |

|

3.5 T or 7700 lb |

|

|

|

||||

|

Traction on cable according to product (approximate value in metric tons) |

|

|

|

||||||

|

|

|

|

|

Probe Length / m (ft) |

|

|

|

||

|

Probe used |

Material |

10 (33) |

|

20 (65.5) |

|

24 |

(79) |

|

|

|

Single cable Ø8mm or |

Cement |

1.0 T or 2200 lb |

|

2.0 T or 4410 lb |

|

2.4 T or |

5290 lb |

|

|

|

Ø0.3” |

Flyash |

0.5 T or 1100 lb |

|

1.0 T or 2200 lb |

|

1.2 T or |

2650 lb |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

BM 102 |

|

|

|

|

|

|

|

Electro static discharge (E.S.D.)

BM 102 non-Ex and Ex gauge electronics are shielded up to 4kV against E.S.D..

Note:

E.S.D. cannot be solved by BM102 E.S.D. protection. It is the customer’s responsibility to avoid E.S.D. by grounding the tank, product and probe installation.

1 |

Danger of injury |

The probe may receive an electrostatic discharge during operation; earth the probe by pushing it against tank wall with a suitably isolated tool just before touching it to avoid receiving a shock.

2 Earth the entry pipe and product.

Product deposits on the nozzle and probe

Product build-up can occur under the nozzle: this may weaken the pulse. Avoid cavities that permit the build-up of deposits.

Tank roof deformation

Tank roofs should support loads of at least 3.5 tonnes or 7700lb for gauge installations using Ø8mm or 0.3” (type 6) single cable probes.

BM 102 |

17 |

2 Electrical connections

2.1Electrical installation instructions

2.1.1 Wiring general notes

Connection to power is effected at the plug connector in the signal converter. Two wiring compartments are available: DIN connector or M16 terminal box. Observe applicable rules and regulations for cable connection: VDE 165 or equivalent national regulations.

Always disconnect from power supply before opening wiring compartment. This is not mandatory for Exi applications.

Hazardous-duty systems

Only certified intrinsically safe equipment may be connected to the BM 102 in hazardous areas. Please refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions for further information. This document is available from your local KROHNE Sales office or on the “Download Centre” on KROHNE’s website http:// www.krohne.com/.

2.1.2 Wiring connections: DIN connector

Terminals: |

3 poles and 1 x ground. Wire cross-section: max. 1.5 mm² |

||

|

(AWG 16) |

|

|

Cable entry: |

1 x PG11, cable diameter: 8 … 10 mm (0.31 … 0.39”), IP 65 |

||

Shielding: |

do not connect to the DIN connector. |

||

Signal cable: |

no shielding required |

||

|

1 |

Detach screw P and remove plug from signal |

|

|

|

converter. |

|

|

2 |

Separate part N from part R by inserting the flat |

|

|

|

tip of a screwdriver into gap F. |

|

|

3 |

Connect current loop to terminals 1 and 2 (any |

|

|

|

polarity). Use ferrules to protect cable ends. |

|

|

|

Terminals 3 and E are not connected. |

|

|

4 |

Fit parts N and R together again. |

|

|

5 |

Fit gasket, re-insert connector plug R on the |

|

|

|

signal converter, and replace screw P. |

|

|

|

Caution |

|

|

|

Grounding terminal E is not connected to |

|

|

|

the housing of the signal converter or to |

|

|

|

the device flange. To avoid ground current |

|

|

|

loops, the cable shielding may not be |

|

|

|

connected at both ends. |

|

|

|

Hazardous-duty systems |

|

|

|

When used in hazardous areas, only one |

|

|

|

intrinsically safe power supply may be |

|

|

|

connected to terminals 1 and 2. Ground |

|

|

|

terminal E and terminal 3 are not |

|

|

|

connected. |

|

18 |

|

BM 102 |

|

2.1.3 Wiring connections: M16 terminal box

Power terminals: |

Wire cross-section: max. 1.5 mm² (AWG 16) |

Cable entry: |

1 x M16 x 1.5, cable diameter: 3.5 … 8 mm (0.14 … 0.31”), IP 65 |

|

for USA: ½” NPT conduit connection |

Shielding: |

Do not connect shielding to the terminal compartment. |

Hazardous-duty systems

When used in hazardous areas, only one intrinsically safe power supply may be connected to terminals 1 and 2. Ground terminal E is not connected.

Caution

Ground terminal, E, is not connected to the signal converter housing or to the device flange. To avoid ground current loops, the cable shielding may not be connected at both ends.

1Detach the 4 screws, T, and remove cover from terminal compartment.

2Connect the cable ends, fitted with ferrules, to the power terminal, U (not polarity sensitive).

3Shut the terminal compartment.

2.1.4’Ex’ equalizing conductor

Refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions for further information.

Terminal for equipotential bonding U-clamp terminal,

max. conductor cross-section:

4 mm²/6.2 • 10-3 sq.in. on ’neck’ of signal converter

BM 102 |

19 |

2.2Power Supply

2.2.1 Non-hazardous-duty version

Power supply |

|

Rated voltage |

24 V DC |

Max. voltage |

35 V DC |

(Uinput): |

’Ex’ = 28 V DC |

Min. voltage |

dependent on |

(Uinput): |

load impedance, |

|

see graph below |

A supply voltage above 35 V DC can cause irreparable damage to the signal converter. Also, power supply voltages above the specified max. values and below the specified min. values can lead to faulty measurements or to a device reset.

Load impedance Rloop

Loop resistance, Rloop |

RHART + Rcable + Rammeter |

Min. Rloop |

0 ohms |

Max. Rloop |

750 ohms |

RHART resistance for HART® communication |

250 ohms (recommended) |

Line A = minimum voltage at the BM 102 terminals

Line B = voltage drop caused by a 250 ohm loop resistance

20 |

BM 102 |

Example for calculating the power supply:

The voltage drop is tested at 22 mA.

U power min. 22 = 22 mA x load impedance + Uinput min. 22

U power min. 22 = 22 mA x 250 ohms + 10 V = 5.5 V + 10 V = 15.5 V

In order to cover the whole current range, the voltage drop must also be tested at 4 mA. By analogy, the following applies:

U power min. 4 |

= 4 mA x load impedance + Uinput min. 4 |

U power min. 4 |

= 4 mA x 250 ohms + 18 V = 1 V + 18 V = 19 V |

At a load impedance of 250 ohms, a power supply voltage of 19 V is sufficient to energize the current device range of 4 to 20 mA.

2.2.2 Hazardous-duty version

The certified device may only be used with other ’Ex’ certified equipment. The minimum electrical safety data indicated on the nameplate must be observed. To ensure proper operation, the minimum parameters specified above in section 2.2.1 for the power supply must be observed to ensure that a given 4 to 20 mA converter is adequate for use with the BM 102. Refer to the BM 102 MICROFLEX KEMA 00 ATEX 1101X Supplementary Installation and Operating Instructions for further information. This document is available from the “Download Centre” on KROHNE’s website http:// www.krohne.com/.

In addition, the connected equipment must be HART®- compatible so that it can be operated with the communication software or the HART® communicator.

An ’Ex’ repeater power supply unit must be used. For calculation of the supply voltage the same applies as for the non-’Ex’ version.

BM 102 |

21 |

2.3Electrical output

2.3.1 Network options

The output is available in 2 versions:

1. |

Current output HART®, |

passive, HART® protocol |

2. |

Current output Ex-ia HART® |

intrinsically safe; passive, HART® protocol |

All versions with HART® protocol can be operated with the PC-STAR 2 program.

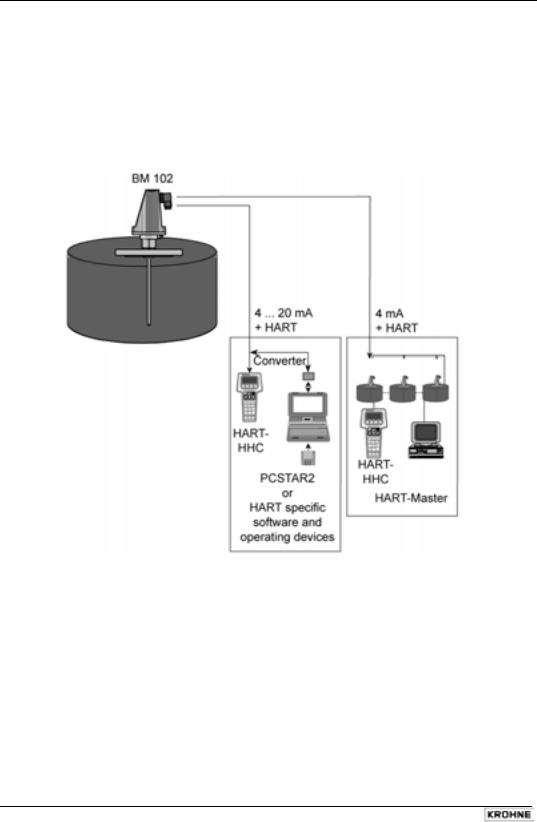

2.3.2 HART® communication protocol

In accordance with the Rosemount Standard, HART® communication can be used with a BM 102. It is used as a point-to-point connection between the BM 102 as slave and the HART® master.

Additional information

The following can be called up via the following interfaces:

•Current output: 22 mA for error signal.

•Digital HART® interfaces: scanning of error flags and error messages.

22 |

BM 102 |

3 User interface

3.1Power-on and start-up

The BM 102 is pre-configured in accordance to customer order specifications and measurements can be made immediately. A start-up time of less than 23 seconds should be allowed for once connected and the power is switched on.

If the probe length has been shortened since delivery, please refer to section 3.3.1: Summary of User Functions, user function 1.1.6: Probe length to modify configured probe length.

3.2 Available user interfaces

Measurements may be taken using either:

•PC STAR 2 software

•HART® Handheld Communicator (HHC)

•DA 06 local indicator

Included as standard with the instrument. The basic installation & operating instructions are presented in section 3.3.1 (requires PC workstation).

Sold separately. Automatic recognition of the instrument when connected. A list of HHCaccessible parameters is given in section 3.3.4. Sold as an option for devices equipped with DIN connectors. For displaying readings only. Refer to section 3.3.6 for technical data.

3.3Operator control

You can configure the device by way of the HHC or the PC-STAR 2 software. This is explained further in sections 3.3.1 and 3.3.2. Operator control via the separate HHC is described in the operating instructions supplied with the communicator.

3.3.1 PCSTAR 2 for Windows : basic installation & operating instructions

Software description

PC STAR 2 is a Windows program that permits clear and concise display of data and configuration of the BM 102 from a remote location. The program is available in English, German or French.

PC-STAR 2 system requirements

•PC with at least 486 processor 75 MHz, recommended: Pentium 120 MHz or higher

•Microsoft Windows 9x, Me, 2000, NT and XP*

•min. 16 MB main memory (RAM)

•min. 3 MB available hard disk storage

•3 ½ “ Floppy disk drive

•Mouse or other pointing device

•Serial RS 232 port

* XP may not be automatically recognized by PCSTAR 2 in versions prior to V2.01. Refer to Section 8.5 for the corrective procedure.

BM 102 |

23 |

Installing and connecting PCSTAR 2 to the gauge

1.Connect the HART® adapter (not included in supply) through a load impedance of 350 ohms maximum (for hazardous-duty purposes, fix to the non-intrinsically safe side of the repeater power supply unit) and plug it into a serial interface on your PC. The repeater power supply unit must have HART® capability.

2.Installing the program: Access the files on the floppy disk supplied with the instrument and execute the file "setup.exe" and follow the instructions on the screen.

3.Running the program: once the program is installed, execute the program. The screen shown below will be displayed.

24 |

BM 102 |

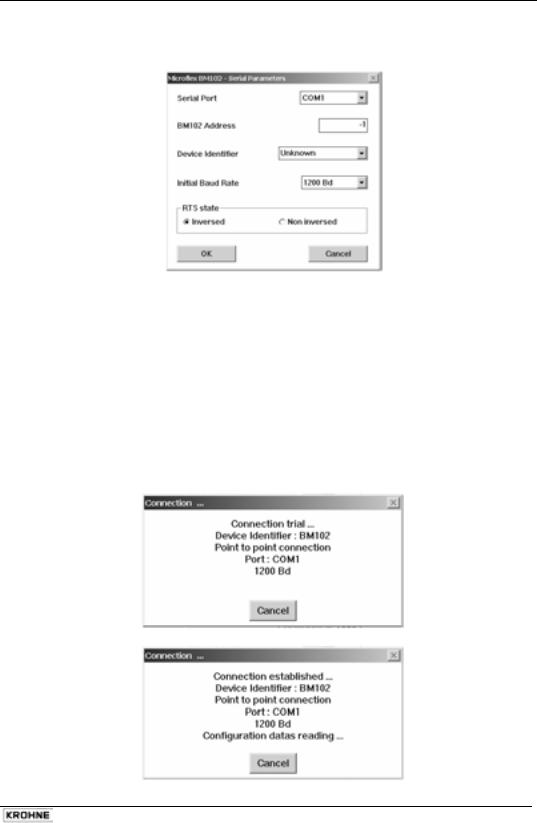

4.Define device interface: type F4 or left-click on “F4-Serial” at the bottom of the screen - to define the interface to which the device is to be connected.

Serial Port |

The serial port allows the user to select a free serial port (COM 1 to 4) on the |

|

computer. |

BM102 Address |

Type the “Address” that you have given a gauge (a value between 0 and 15) |

|

and press ENTER or OK. This will select the required device. If you are in a |

|

point to point network leave the box at its default value (-1). |

Device Identifier |

Device Identifier refers to the “Device number” given in User Function No. |

|

1.4.4. |

Initial baud rate |

Transmission rate of data. Has a default value of 1200 bd. |

RTS state |

The RTS state depends on the type of RS232 converter used. For |

|

RS232<>HARTTM(i.e. VIATOR from MACTEK) use inversed RTS state. |

5.On-line connection with the gauge: Press F2 or left-click on “F2-Connection” to set up the connection with the device - the configuration parameters are automatically loaded into the computer.

then …

BM 102 |

25 |

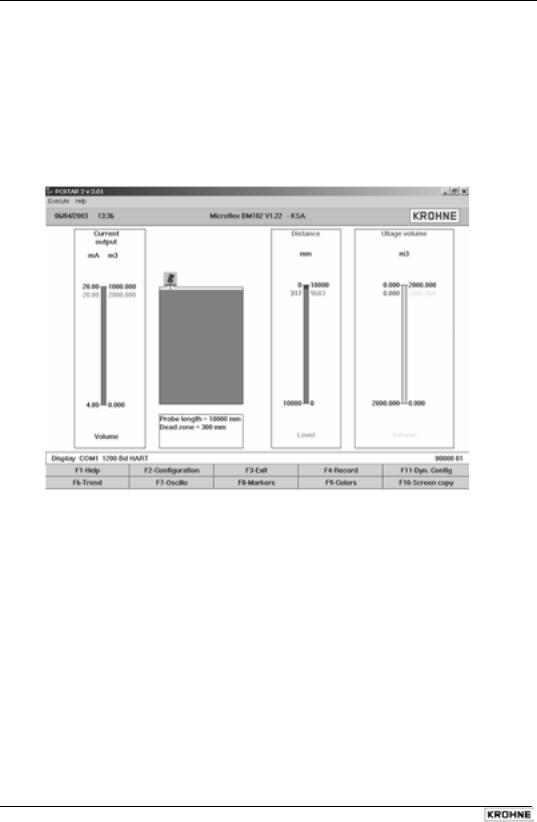

6.After the connection has been established, the following screen is shown. This will show the current status of the tank. No further configuration should be necessary. The following functions are available on the screen and will be discussed further in section 8.4:

•F2 – Device configuration: a summary of the parameters are given on the next page,

•F7 – Oscilloscope function: have all reflections occurring at the probe displayed,

•F11 – Dynamic/on-line device configuration,

•F4 – View and record all information during operation,

•F6 – Trend: observe the level trend since start of the program,

•F8 – Marker: read the status of the device

•and F10 – make printouts (screen shots).

26 |

BM 102 |

3.3.2 Summary of User Functions in PCSTAR 2 (F2 – Configuration)

The table below provides an overview of all parameters that can be set in the configuration menu using F2 in PCSTAR2. Reset default values are in bold type in the “Input Range” column.

|

Function |

Input Range |

Description |

||

|

1.0.0 Operation |

|

|

|

|

|

1.1.0 Basic parameters |

|

|

|

|

|

1.1.1 Tank height |

Enter 0 … 60 m or |

The tank height forms the basis for |

||

|

|

|

0 … 197 ft. |

calculating level measurements and |

|

|

|

|

As per order |

for the relevant current output. It is |

|

|

|

|

|

|

defined as the distance between the |

|

|

|

|

|

lower flange surface and the |

|

|

|

|

|

reference point at the bottom of the |

|

|

|

|

|

tank. |

|

|

|

|

|

The output unit is determined via Fct. |

|

|

|

|

|

1.2.4.: Length Unit |

|

|

|

|

|

The set tank height is the upper limit |

|

|

|

|

|

for Fct. 1.3.4: Scale I1 max (if Fct. |

|

|

|

|

|

1.3.1 is set to “Level” or “Distance”). |

|

|

|

|

|

Note: the device will not measure |

|

|

|

|

|

beyond the programmed probe length |

|

|

|

|

|

if the current output is configured to |

|

|

|

|

|

measure distance or level . |

|

1.1.2 Dead zone |

Enter a value |

The dead zone is the minimum |

||

|

|

|

Fct.1.5.1(Detection |

measuring distance from the process |

|

|

|

|

delay) … probe |

connection (reference point) to the |

|

|

|

|

length. |

surface of the product. So as not to |

|

|

Warning : Critical Parameter |

|

• |

Twin probe with |

impair measurement accuracy, the |

|

|

|

|

probe length<1m |

minimum values given in Section |

|

|

|

|

or 3.3 ft |

5.2.3 should be adhered to. |

|

|

|

|

0.2 m or 8 in |

The BM 102 will ignore signals in the |

|

|

|

• |

Single probe or |

dead zone and display the last |

|

|

|

reading taken. |

||

|

|

|

|

twin probe with |

|

|

|

|

|

The output unit is set via Fct. 1.2.4: |

|

|

|

|

|

probe |

|

|

|

|

|

Length Unit |

|

|

|

|

|

length >1m |

|

|

|

|

|

|

|

|

|

|

|

or 3.3 ft |

|

|

|

|

|

0.4 m or 16 in |

|

|

|

|

• |

Coaxial probe |

|

|

|

|

|

0 m or 0 in |

|

|

1.1.3 Time constant |

1 … 100 seconds |

This function filters possible signal |

||

|

|

|

5 seconds |

fluctuations when the liquid is |

|

|

|

|

|

|

turbulent. |

BM 102 |

27 |

Function |

Input Range |

Description |

1.1.6 Probe length |

Enter 0.1 m or 3.9” … |

This value must be equal to the exact |

|

probe length (max.: |

length of the probe. This value should |

|

24000 mm or 78¾ ft.) |

be modified when the probe has been |

|

As per order |

replaced or shortened (cable probes). |

|

|

The output unit is set via Fct. 1.2.4 |

|

|

Length Unit. |

|

|

An automatic search for the probe tip |

|

|

can be carried out when the tank is |

|

|

empty to update the parameter using |

|

|

the function F11 in the “Dynamic |

|

|

Configuration” menu. |

|

|

Probe length may be set greater than |

|

|

tank height but less than 24 m or |

|

|

78¾ ft. for special installations. |

28 |

BM 102 |

Loading...

Loading...