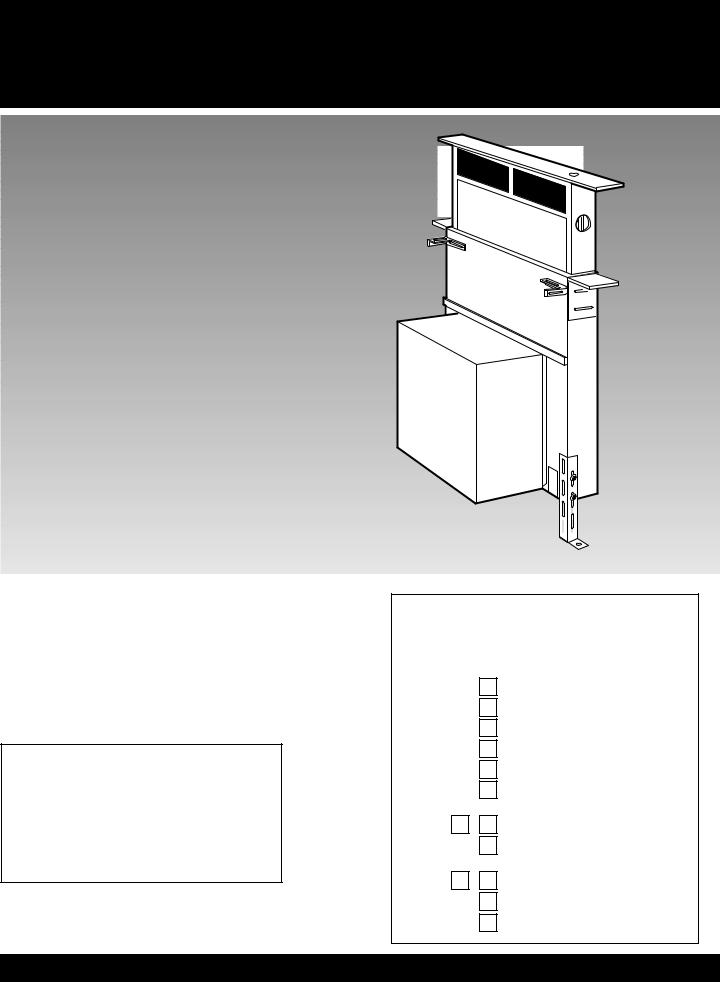

KitchenAid KIRD861HSS, KIRD802HSS, KIRD801HSS, GZ7930XHS, GZ7936XHS Installation Instructions

...

Installation Instructions and

Use and Care Guide

30" (76.2 cm)

36" (91.4 cm)

Retractable (Pop-up)

Downdraft Vent Systems

IMPORTANT:

Read and save these instructions.

IMPORTANT:

Installer: Leave Installation Instructions with the homeowner.

Homeowner: Keep Installation Instructions for future reference.

Save Installation Instructions for local electrical inspector's use.

Part No. 4329225/9763381

Quick Reference

Table of Contents:

Pages

2Before you start

3Electrical requirements

4Product dimensions

4Cabinet dimensions

5Countertop cutout dimensions

6Vent system requirements Interior-mounted vent motor

7 - 9 Installation steps

9Vent system requirements Exterior-mounted vent motor

10 - 11 Installation steps

12Use and Care Information

13Accessories

Before you start...

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING”.

These words mean:

DANGER

DANGER

You can be killed or seriously injured if you don’t immediately follow instructions.

WARNING

WARNING

You can be killed or seriously injured if you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

IMPORTANT: Observe all governing codes and ordinances.

Failure to meet codes and ordinances could lead to fire or electrical shock.

Proper installation is your responsibility. Make sure you have everything necessary for correct installation. It is the responsibility of the installer to comply with the installation clearances specified on the model/serial rating plate. The model/serial rating plate is located on the front of the downdraft vent above the wiring box cover.

Check location where downdraft vent will be installed. The location should be away from strong draft areas, such as windows, doors and strong heating vents or fans. Before making countertop cutout, check that downdraft vent and cooktop location will clear cabinet walls, backsplash, and rear wall studs inside cabinet.

Mobile home installation

The installation of this downdraft vent system must conform to the Manufactured Home Construction Safety Standards, Title 24 CFR, Part 328 (formerly the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD, Part 280) or when such standard is not applicable, the Standard for Manufactured Home Installation 1982 (Manufactured Home Sites, Communities and Setups) ANSI A225.1/NFPA 501A*, or latest edition, or with local codes.

All openings in the wall or floor where retractable downdraft vent is to be installed must be sealed.

Electrical ground is required. See “Electrical requirements,” page 3.

When installing downdraft vent, the cabinet drawer will need to be removed and the drawer front installed permanently to cabinet.

NOTE: Downdraft vent is installed directly behind the cooktop. Install downdraft vent first.

Cabinet construction: Downdraft vent is designed for use in a cabinet with a depth of 24"

(61 cm). Some installations require a countertop deeper than 25" (63.5 cm). See chart on page 5. The maximum depth of the overhead cabinet is 13" (33 cm). Overhead cabinets installed at either side of the downdraft vent must be 18" (45.7 cm) above the cooking surface.

See cooktop Installation Instructions before making any cutouts and for the minimum distance between the front edge of the countertop and front edge of cooktop. The minimum horizontal distance between the overhead cabinets is the same as the width of the installed downdraft vent.

When installing a 36" (91.4 cm) retractable downdraft vent with “Create-A-Cooktop” modules, the optional support must be installed on the front of the downdraft vent.

See installation steps for details.

Parts supplied for installation:

•

•2 end caps

•2 lower support legs

•2 overcounter support brackets

•2 undercounter mounting brackets

•1 bag of fasteners

•1 metal cover

•1 backdraft damper

•literature package

•optional support and two screws (36" (91.4 cm) models only

Parts needed for installation:

•2 U.L.- or C.S.A.-listed 1/2" (12.7 mm) conduit connectors (3 are required if the exterior-mounted vent motor

is used.)

•1 wall cap for interior-mounted motor

•vent system

•power supply cable

•wiring cable for optional remote blower kit.

Tools needed for installation:

•safety glasses

•gloves

•jig or keyhole saw

•drill with 1/8" drill bit

•pencil

•measuring tape

•flat-blade screwdriver

•Phillips screwdriver

•3/8" (9.5 mm) nut driver or ratchet

•level

•pliers

•metal snips

•wire stripper or utility knife

•caulking gun and weatherproof caulk

•duct tape

2

Electrical requirements

IMPORTANT: Observe all governing codes and ordinances.

It is the customer’s responsibility:

•To contact a qualified electrical installer.

•To assure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/NFPA 70

— latest edition*, or CSA Standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2 No. 0-M91 - latest edition** and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure downdraft vent is properly grounded.

Do not have a fuse in the neutral or ground circuit.

IMPORTANT: Save Installation instructions for electrical inspector’s use.

A. A 120-volt, 60-Hz, AC-only, fused electrical supply is required on a separate 15 amp circuit. A time-delay fuse or circuit breaker is recommended. The fuse must be sized per local codes in accordance with the electrical rating of the downdraft vent as specified on the model/serial rating plate located on the front of the downdraft vent above the wiring box cover.

B. The downdraft vent must be connected with copper wire only.

C. Wire sizes and connections must conform to the requirements of the National Electrical Code, ANSI/NFPA 70 — latest edition*, or CSA Standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2 No. 0-M91 - latest edition** and all local codes and ordinances.

WARNING — TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable Codes and Standards, including fire related construction. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety standards such as those published by the National Fire Protection Association (NFPA),and the American Society of Heating Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

Ducted fans must always be vented to the outdoors.

WARNING — To reduce the risk of fire, use only metal ductwork.

This unit must be grounded.

D. This downdraft vent should be connected directly to the fused disconnect (or circuit breaker) through flexible, armored or nonmetallic sheathed, copper cable. Allow some slack in the cable so the downdraft vent can be moved if servicing is ever necessary.

E. A U.L.- or C.S.A.-listed, 1/2" (12.7 mm) conduit connector must be provided at each end of the power supply cable (at the downdraft vent and at the junction box).

F. A wiring diagram is located on the downdraft vent base above the wiring box cover.

Copies of the standards listed may be obtained from:

*National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

**CSA International

8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575

3

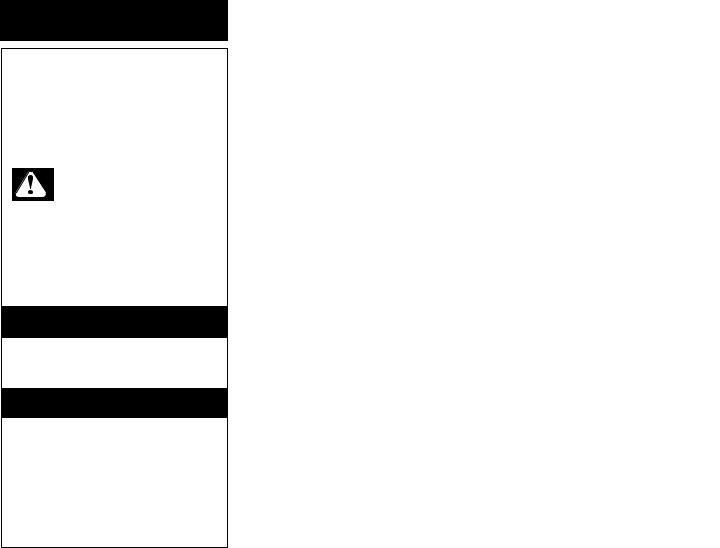

Product dimensions

top trim widths 30" vent (76.2 cm) 36" vent (91.4 cm)

8-1/4" (21 cm) retractable vent height

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-1/2" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(3.8 cm) |

|

|

16" |

|

|

|

|

|||||

|

|

27" (68.6 cm) for 30" (76.2 cm) vent |

|

|

|

|

|

|

|

|

(40.6 cm) |

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

3/8" (9.5 mm) |

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

33" (83.8 cm) for 36" (91.4 cm) vent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8" |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(20.3 cm) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26-1/8" |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(66.4 cm) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

3-1/4"x 10" |

|

|

|

|

|

|

|

|

|

|

9" (22.9 cm) Dia. |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

(8.3 cm x 25.4 cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: A 10" (2.5 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

16" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cm) round vent |

|

|||||||||

(40.6 cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

system adapter |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

collar attaches over |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

this hole. Adapter |

|

|||||||

|

|

|

|

|

|

|

|

|

5/8" |

|

|

|

|

|

|

|

|

|

collar is supplied |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

with exterior |

|

|||||||||

|

|

|

|

|

|

|

|

|

(15.9 mm) |

|

|

|

|

|

|

blower. |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

(40.6 cm) |

|

|

|

|

|

|

|

|

|

|

2-1/8” |

|

|

|

|

|

|

|

|

|

||||||

INTERNAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

(54 cm) |

|

|

|

|

|

|

|

|

|

||||||||||

BLOWER |

9-3/8" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

MOTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

(23.8 cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

4" (10.2 cm)

5/8"

(15.9 mm)

8" (20,3 cm)

16" (40.6 cm)

EXTERIOR-MOUNTED

BLOWER MOTOR

Cabinet dimensions

4-1/8"+A

(10.5 cm)

A = 1/2" (12.7 mm) min.

23-9/16"

(59.8 cm)

17-3/16"

(43.7 cm)

all cutouts are for |

3/8" |

|

3-1/4" x 10" |

(9.5 mm) |

|

(8.3 cm x 25.4 cm) |

|

|

vent system |

|

|

Locate power supply |

|

|

junction box at lower |

|

|

right hand rear corner of |

centerline of |

|

cabinet. |

||

cooktop cutout |

||

|

See cooktop manufacturer’s instructions for cooktop cutout depth and width.

Use dimensions for vent system cutout location that applies to your installation.

17-9/16"

(44.6 cm)

Vent system cutout dimensions for internal blower models only.

Exterior mounted blower systems connect with 10" (25.4 cm) round vent. The cutout locations for this vent system will depend upon your specific installation.

4

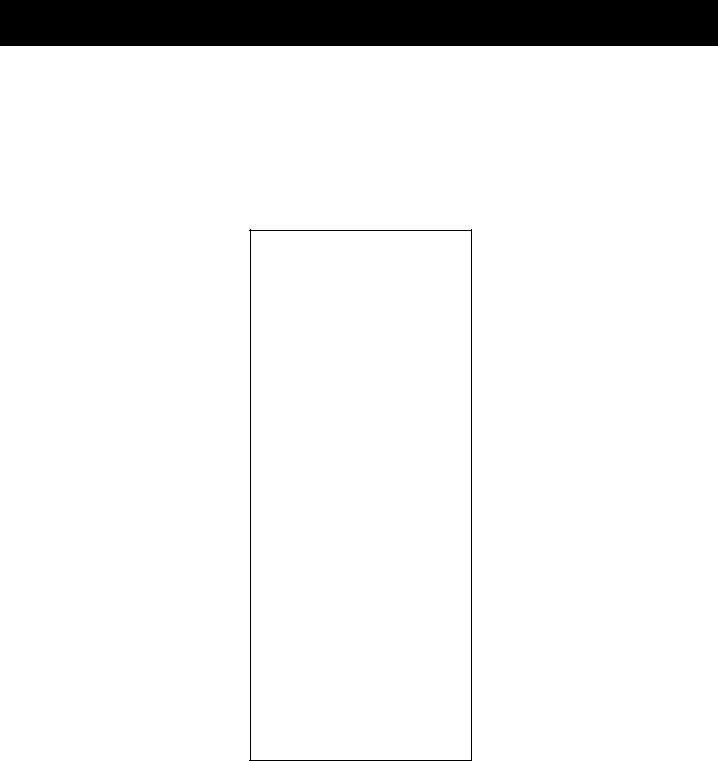

Countertop cutout dimensions

27-1/2" (69.9 cm) for 30" (76.2 cm) vent 33-1/2" (85.1 cm) for 36" (91.4 cm) vent

A = 1/2" (12.7 mm) min.

See cutout dimensions chart below.

It is recommended that the cooktop and vent cutouts be drawn on the countertop before making any cutouts to avoid mistakes.

See Cooktop Installation Instructions for complete cutout dimensions, location dimensions and installation details.

IMPORTANT: Countertops with a bullnosed front edge are not recommended for these installations. Use only the exterior-mounted blower system, KPEC992M

[900 cfm (25.5 m3/m)], with the retractable popup downdraft vent system.

|

|

|

1-7/8" |

Some models require a |

|

|

(4.8 cm) |

|

|

1/4" |

|

countertop deeper than |

|

|

|

25" (63.5 cm); see cutout |

|

|

(6.4 mm) |

dimensions chart below. |

cooktop |

|

1/2" |

|

|

||

|

|

(12.7 mm) |

|

|

|

|

|

|

|

|

min. |

|

|

|

backsplash |

|

countertop |

|

1/4" |

|

|

|

|

centerline of |

|

|

(6.4 mm) |

downdraft |

|

|

|

cooktop cutout |

|

|

|

vent |

|

|

|

|

|

|

|

3/4" (19.1 mm) max. |

|

|

1/2" (12.7 mm) |

backsplash depth |

|

|

minimum |

1/2" (12.7 mm) |

|

D |

|

minimum to |

|

Overall depth of cooktop |

|

splashguard or |

|

|

|

|

|

and downdraft vent |

|

rear wall |

|

|

|

|

|

system |

|

|

|

|

|

|

|

|

G |

|

B |

|

C |

|

A |

|

|

H

Required min. countertop depth

|

|

F |

|

|

E |

Overall width of cooktop and |

|||

downdraft vent system |

||||

|

||||

|

|

Cooktop |

Installed with |

|

|

|

|

|

|

|

|

|

Cooktop Models |

Size |

Vent System Models |

A |

B |

C |

D |

E |

F |

G |

H |

||

KGCS105G |

|

30" |

KIRD801HSS |

KIRD802HSS |

29" |

27-1/2" |

19-5/8" |

2-1/8" |

1-3/4" |

31-3/8" |

23" |

25" |

|

|

(76.2 cm) |

|

|

(73.7 cm) |

(69.9 cm) |

(49.8 cm) |

(5.4 cm) |

(4.4 cm) |

(79.7 cm) |

(58.4 cm) |

(63.5 cm) |

KECC502G* |

KECC507G* |

30" |

KIRD801HSS |

KIRD802HSS |

29-1/2" |

27-1/2" |

20-1/2" |

2-1/8" |

2" |

31-1/2" |

23-1/4" |

25-7/8" |

KECC507K* |

KECC508G* |

(76.2 cm) |

|

|

(74.9 cm) |

(69.9 cm) |

(52.1 cm) |

(5.4 cm) |

(5.1 cm) |

(80.0 cm) |

(59.1 cm) |

(65.7 cm) |

KECC508M* |

|

|

|

|

|

|

|

|

|

|

|

|

KECS100G* |

|

30" |

KIRD801HSS |

KIRD802HSS |

28-7/8" |

27-1/2" |

19" |

2-1/2" |

3-3/8" |

31-1/2" |

23" |

25-5/8" |

|

|

(76.2 cm) |

|

|

(73.3 cm) |

(69.9 cm) |

(48.3 cm) |

(6.4 cm) |

(8.6 cm) |

(80.0 cm) |

(58.4 cm) |

(65.1 cm) |

GLT3014G |

GLT3034L |

30" |

GZ7730XGS |

GZ7930XGS |

29" |

27-1/2" |

19-5/8" |

2-1/8" |

1-3/4" |

31-3/8" |

23" |

25" |

SCS3004G |

SCS3004L |

(76.2 cm) |

GZ7930XHS |

|

(73.7 cm) |

(69.9 cm) |

(49.8 cm) |

(5.4 cm) |

(4.4 cm) |

(79.7 cm) |

(58.4 cm) |

(63.5 cm |

SCS3014G |

SCS3014L |

|

|

|

|

|

|

|

|

|

|

|

RCC3024G* |

RCC3024L* |

30" |

GZ7730XGS |

GZ7930XGS |

29-1/2" |

27-1/2" |

20-1/2" |

2" |

2" |

30" |

23" |

25-3/4" |

GJC3034G* |

GJC3034L* |

(76.2 cm) |

GZ7930XHS |

|

(74.9 cm) |

(69.9 cm) |

(52.1 cm) |

(5.1 cm) |

(5.1 cm) |

(76.2 cm) |

(58.4 cm) |

(65.4 cm) |

RCS3004G* |

RCS3014L* |

30" |

GZ7730XGS |

GZ7930XGS |

28-7/8" |

27-1/2" |

19" |

2-1/2" |

3" |

31-1/2" |

23" |

25-1/2" |

RCS3014G* |

RCS3014L* |

(76.2 cm) |

GZ7930XHS |

|

(73.3 cm) |

(69.9 cm) |

(48.3 cm) |

(6.4 cm) |

(7.6 cm) |

(80.0 cm) |

(58.4 cm) |

(64.8 cm) |

YRCS3014G* YRCS3014L* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

KGCS166G |

|

36" |

KIRD861HSS |

KIRD862HSS |

35-1/4" |

33-1/2 |

19-5/8" |

2-1/8" |

1-3/4" |

37-1/2" |

23" |

25" |

|

|

(91.4 cm) |

|

|

(89.5 cm) |

(85.9 cm) |

(49.8 cm) |

(5.4 cm) |

(4.4 cm) |

(95.3 cm) |

(58.4 cm) |

(63.5 cm) |

KECC562G* |

KECC567G* |

36" |

KIRD861HSS |

KIRD862HSS |

35-1/2" |

33-1/2" |

20-1/2" |

2-1/8" |

2" |

37-1/2" |

23-1/4" |

26-7/8" |

KECC568G* |

|

(91.4 cm) |

|

|

(90.2 cm) |

(85.9 cm) |

(52.1 cm) |

(5.4 cm) |

(5.1 cm) |

(95.3 cm) |

(59.1 cm) |

(68.3 cm) |

KECS161G* |

|

36" |

KIRD861HSS |

KIRD862HSS |

35" |

33-1/2" |

19" |

2-1/2" |

3-3/8" |

37-5/8" |

23" |

25-5/8" |

|

|

(91.4 cm) |

|

|

(88.9 cm) |

(85.9 cm) |

(48.3 cm) |

(6.4 cm) |

(8.6 cm) |

(95.6 cm) |

(58.4 cm) |

(65.1 cm) |

GLT3614XG |

|

36" |

GZ7736XGS |

GZ7936XGS |

35-1/4" |

33-1/2" |

19-5/8" |

2-1/8" |

1-3/4" |

36-5/8" |

23" |

25" |

GLT3634XL |

|

(91.4 cm) |

GZ7936XHS |

|

(89.5 cm) |

(85.9 cm) |

(49.8 cm) |

(5.4 cm) |

(4.4 cm) |

(93.0 cm) |

(58.4 cm) |

(63.5 cm) |

GJC3634G* |

|

36" |

GZ7736XGS |

GZ7936XGS |

35-1/2" |

33-1/2" |

20-1/2" |

2" |

2" |

36" |

23" |

25-3/4" |

GJC3634L* |

|

(91.4 cm) |

GZ7936XHS |

|

(90.2 cm) |

(85.9 cm) |

(52.1 cm) |

(5.1 cm) |

(5.1 cm) |

(91.4 cm) |

(58.4 cm) |

(65.4 cm) |

RCS3614G* |

|

36" |

GZ7736XGS |

GZ7936XGS |

35" |

33-1/2" |

19" |

2-1/2" |

3" |

37-5/8" |

23" |

25-5/8" |

RCS3614L* |

|

(91.4 cm) |

GZ7936XHS |

|

(88.9 cm) |

(85.9 cm) |

(48.3 cm) |

(6.4 cm) |

(7.6 cm) |

(95.6 cm) |

(58.4 cm) |

(65.1 cm) |

* Installation with vent system requires countertop and base cabinet deeper than standard 25" (63.5 cm) deep countertop and 24" (61.0 cm) deep base cabinet.

5

Vent system requirements

Venting system must terminate to the outside.

Do not terminate the vent system in an attic or other enclosed area.

Do not use 4" (10.2 cm) laundrytype wall caps

Do not use plastic or metal foil vent.

Vent work needed for installation is not supplied.

Wall cap is not provided with interior-mounted motor.

Determine which venting method to use. Vent system can extend through either the wall or roof.

The length of vent system and number of elbows should be kept to a minimum to provide efficient performance.

The size of the vent should be uniform.

Do not install two elbows together.

Use duct tape to seal all joints in the vent system.

Use caulking tape to seal the exterior wall or floor opening around cap.

Do not cut joist or stud. If vent cutout falls over a joist or stud, a supporting frame must be constructed.

Flexible metal vent is not recommended. If it is used, calculate each foot of flexible vent as two feet of rigid metal vent. Flexible elbows count twice as much as standard elbows.

NOTE: Make sure there is proper clearance within the wall or floor before making exhaust vent cutouts.

Recommended vent system length: For either interior-mounted or exterior-mounted blower installations, vent system length should not exceed the maximum lengths listed in the “Maximum length of vent system” chart. (See this page for Interior-mounted vent motor; page 9 for exteriormounted vent motor.)

6

Interior-mounted vent motor

Installation requirements

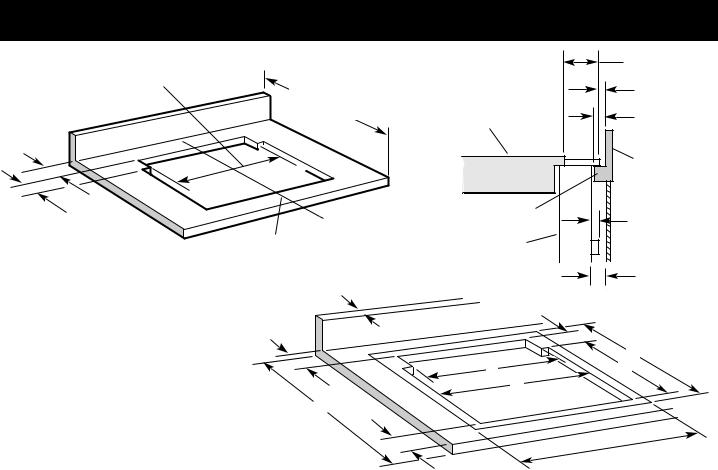

Island location

down vent

Built-in cabinet locations

down vent

rear vent

left vent

right vent

Vent system installed under a concrete slab using PVC sewer pipe.

6" (15.2 cm) round metal vent

wall |

|

|

|

|

|

|

|

|

|

6" (15.2 cm) |

transition |

||||||||

|

|

|

|

|

|

|

|

|

round PVC |

|

6" (15.2 cm) |

||||||||

cap |

|

|

|

|

|

|

|

|

|

sewer pipe |

|

round metal |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

vent |

12" (30.5 cm) |

|

|

|

|

16" (40.6 cm) |

|

6" (15.2 cm) |

||||||||||||

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

round PVC |

||||||||||||||

minimum |

|

|

|

|

maximum |

|

|||||||||||||

|

|

|

|

|

coupling |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

concrete |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

slab |

6" (15.2 cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6" (15.2 cm) |

||||

round PVC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

round PVC |

|||||

coupling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sewer pipe |

|||||

6" (15.2 cm) |

Tightly pack |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

6" (15.2 cm) |

|||||||||||||

round 90° |

gravel or sand |

|

|

round 90° |

|||||||||||||||

PVC sewer |

completely |

|

|

|

|

|

|

||||||||||||

|

|

SBCCI |

|

PVC sewer |

|||||||||||||||

pipe elbow |

around pipe. |

|

|

|

|||||||||||||||

|

|

|

pipe elbow |

||||||||||||||||

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Optional vent system installed under a concrete slab into a window well.

Do not vent a gas cooktop into a window well.

|

12" (30.5 cm) |

6" (15.2 cm) round |

transition |

|||||||||||||||

|

|

|

minimum |

|

|

PVC sewer pipe |

6" (15.2 cm) |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

concrete |

|

|

round metal vent |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

wall |

|

|

|

|

|

|

|

|

6" (15.2 cm) |

|||||||||

|

|

|

slab |

|

|

|

|

|

||||||||||

cap |

|

|

|

|

|

|

|

|

round PVC |

|||||||||

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

coupling |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6" (15.2 cm) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

round sewer |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pipe |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

6" (15.2 cm) round |

|||||

window |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

90° PVC sewer |

||||||||||||

well |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

pipe elbow |

||||||||||||

6" (15.2 cm) |

|

|

|

|

Tightly pack |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

min. |

6" (15.2 cm) gravel or sand |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

round PVC |

completely |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

coupling |

|

|

|

SBCCI |

|

|

||||

|

|

|

|

|

|

|

|

around pipe. |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Seal the space between the outside of wall cap inlet inside of PVC coupling with caulking metal.

Maximum length of vent system

Vent |

Length |

6" (15.2 cm) round |

35 feet (8.9 m) |

3-1/4" x 10" |

35 feet (8.9 m) |

(8.3 cm x 25.4 cm) |

|

For best performance, use no more than three 90° elbows. If more than one elbow is used, make sure that there is a minimum of 24" (61 cm) of straight vent between any two elbows. Do not install two elbows together. It is recommended that you use round vent instead of rectangular vent, especially if elbows are required. If rectangular vent is required, it should be transitioned to 6" (15.2 cm) round vent as soon as possible.

Determining the length of system you need:

To calculate the length of system you need, add the equivalent feet for each vent piece that will be needed. See example for 6"

(15.2 cm) round vent system.

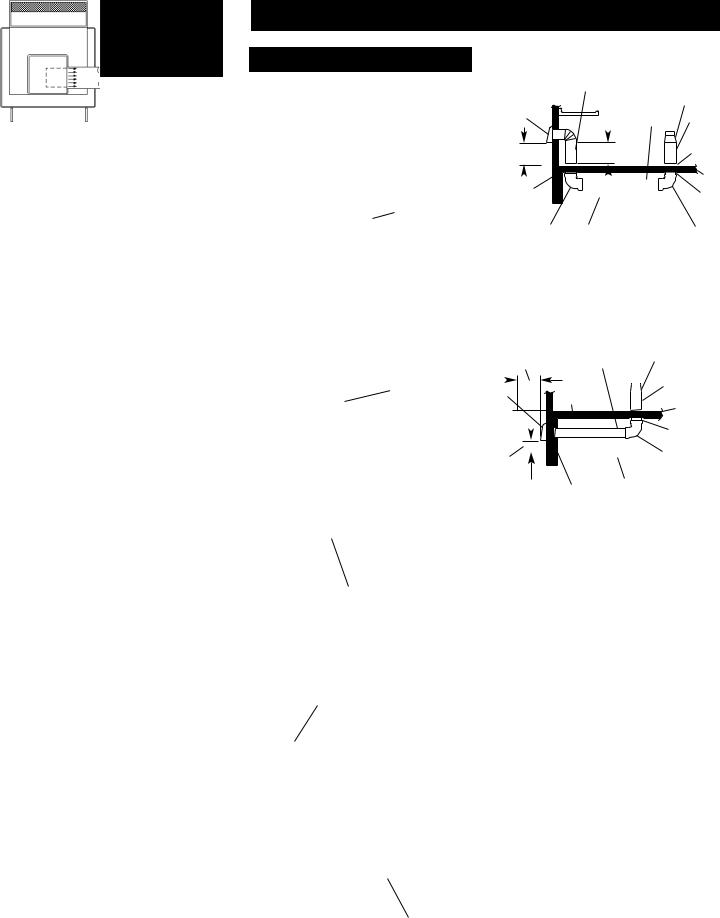

6" (15.2 cm) round vent system

90° elbows |

|

|

|

|

|

6 ft. (1.8 m) |

|

|

|

||

|

|

|

|

|

|

|

|

transition

2 ft. (0.6 m)

Maximum length = 35 ft. (8.9 m)

1 - wall cap |

|

= |

0 ft. |

|

(0 m) |

8 ft. (2.4 m) straight = |

8 ft. |

|

(2.4 m) |

||

2 - 90° elbows |

= |

10 ft. |

(3 m) |

||

Transition |

|

= |

4.5 ft. |

(1.4 m) |

|

Length of 6" |

|

|

|

|

|

(15.2 cm) system |

= |

22.5 ft. |

(6.8 m) |

||

Recommended standard |

|||||

fittings |

|

|

|

|

|

3-1/4" x 10" |

|

6" (15.2 cm) to |

|||

(8.3 cm x 25.4 cm) |

3-1/4" x 10" |

|

|||

to 6" (15.2 cm) |

(8.3 cm x 25.4 cm) |

||||

= 4.5 ft. (1.4 m) |

= 1 ft. (0.3 m) |

||||

3-1/4" x 10" |

|

6" (15.2 cm) to |

|||

(8.3 cm x 25.4 cm) |

3-1/4" x 10" |

||||

to 6" (15.2 cm) |

(8.3 cm x 25.4 cm) |

||||

90° elbow = |

|

90° elbow = |

|||

5 ft. (1.5 m) |

|

5 ft. (1.5 m) |

|||

90° elbow = |

45° elbow = |

6" wall cap = |

|||

5 ft. (1.5 m) |

2.3 ft. (0.8 m) |

0 ft. (0 m) |

|||

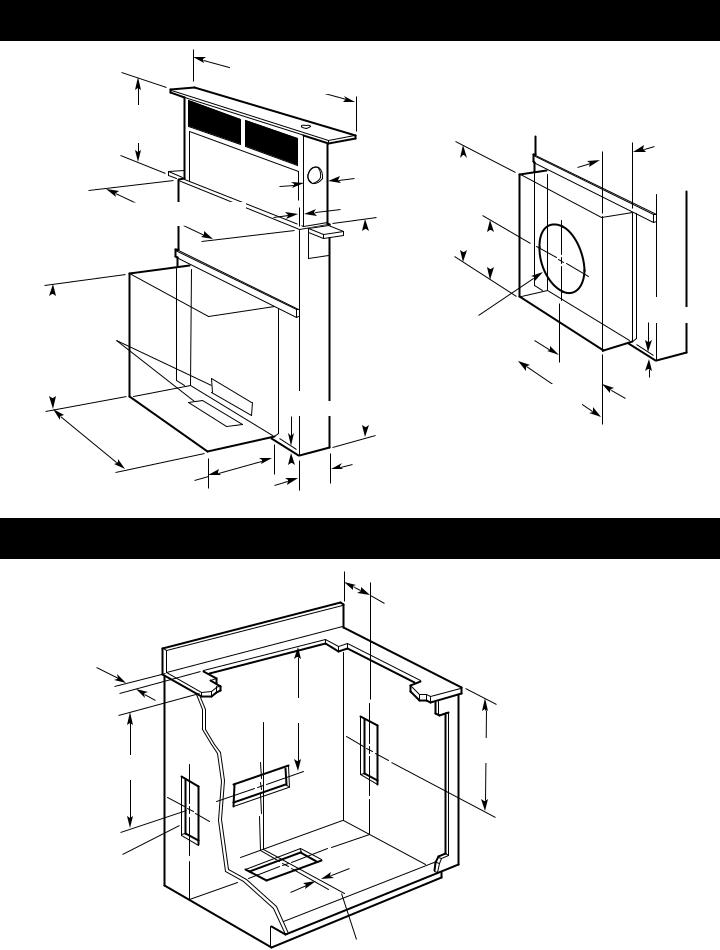

Installation steps

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install downdraft vent.

Failure to do so can result in back or other injury.

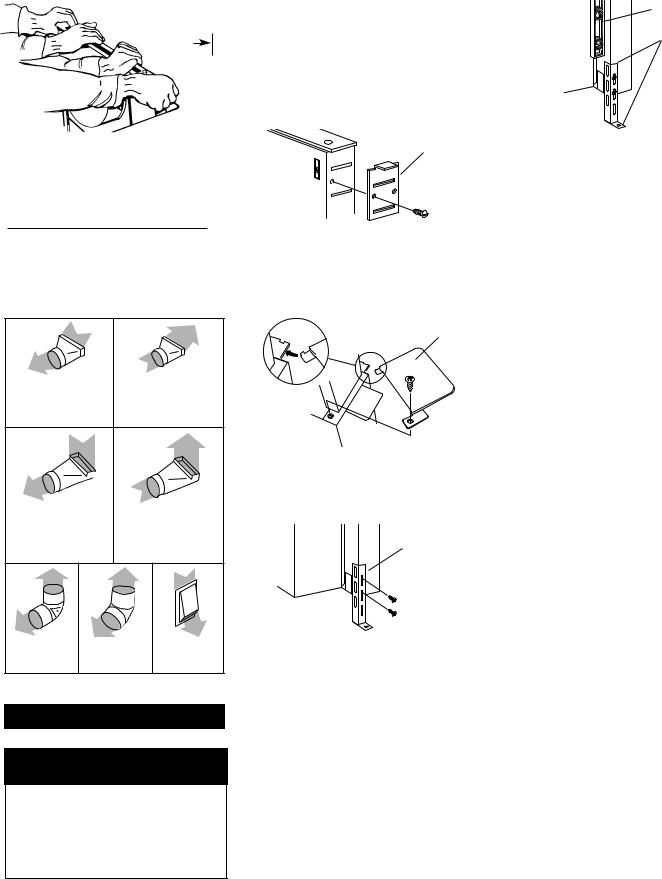

1. Put on gloves and safety glasses. Place cardboard or another form of protection on top of a flat surface where you can

easily assemble the downdraft vent system. Remove parts packages, downdraft vent and blower box from carton and set on protective surface. Remove all shipping materials, tape and protective film from downdraft vent and blower box.

over counter support arm

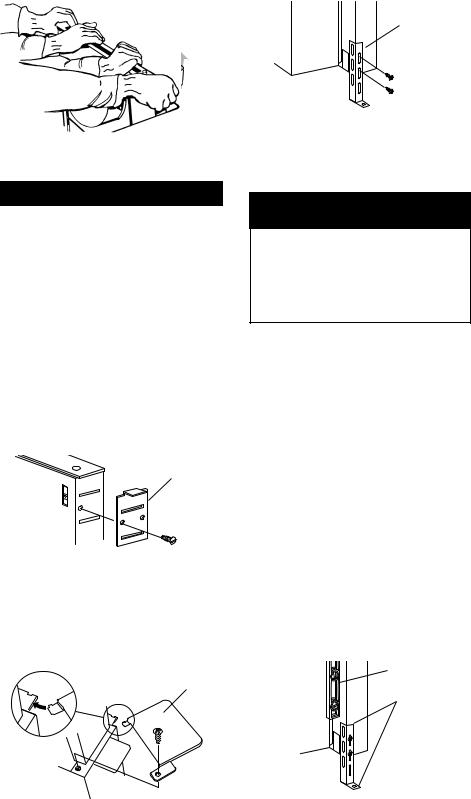

2. Attach the left side and right side overcounter support brackets to the downdraft. Use 1 screw with each bracket.

end cap

3. Attach the left side and right side end caps to the downdraft. Use 1 screw with each end cap.

support leg

4. Attach support legs to side of downdraft vent with 2 screws in each leg. Do not tighten screws.

5. Carefully insert downdraft vent into countertop cutout. Two people are recommended to support the weight of the downdraft vent during lifting. Check that downdraft vent is parallel to side of cutout and that mounting brackets overlap countertop.

level

mark

6. Move support legs down against cabinet floor. Place a level against front of downdraft vent base and adjust until downdraft vent is level vertically. Use a pencil to mark the top of each leg on downdraft vent. Then mark location of support leg mounting holes on cabinet floor. Remove downdraft vent from cutout. Drill starter holes at each mounting screw location on cabinet floor. Align top of legs with pencil marks on the face of the downdraft vent. Tighten screws in legs.

7. Determine which direction (down, rear, left, or right) vent will need to run from blower vent when installed in cabinet.

Down venting:

Downdraft vent is shipped with blower in down venting position so no modification is required. Go to Step 8.

Left or right venting:

a.Remove 4 hex nuts that attach blower box to downdraft vent base. Remove blower box.

b.Rotate blower box 90° to left or right so that vent blower is repositioned in the direction needed.

c.Reattach blower box to downdraft vent base with 4 hex nuts.

Rear venting:

a.Remove 4 hex nuts that attach blower box to downdraft vent base. Remove blower box.

b.Note how wiring cable is installed under plastic clips inside vent base. Then carefully remove wiring cable from plastic clips. Disconnect blower wiring cable.

c.Remove 6 Phillips-head screws attaching blower to blower box. Remove blower.

7

bracket for rear venting

d.Remove screws attaching brackets to each side of blower. Reposition brackets on blower as shown. Then reinstall screws.

e.Reinstall blower in blower box with mouth of blower pointing out open side of blower box.

Secure blower to blower box with 6 Phillips-head screws.

NOTE: Square metal frame attached to mouth of blower must be installed for proper operation.

f.Attach metal cover from parts bag over down-venting knockout in blower box. Remove rear knockout cover on back of vent base.

g.Reconnect blower wiring cable. Secure wiring cable in 2 black plastic clips inside vent base.The wiring cable must be properly secured in the 2 clips (see step b.) Reattach blower box to downdraft vent base with 4 hex nuts.

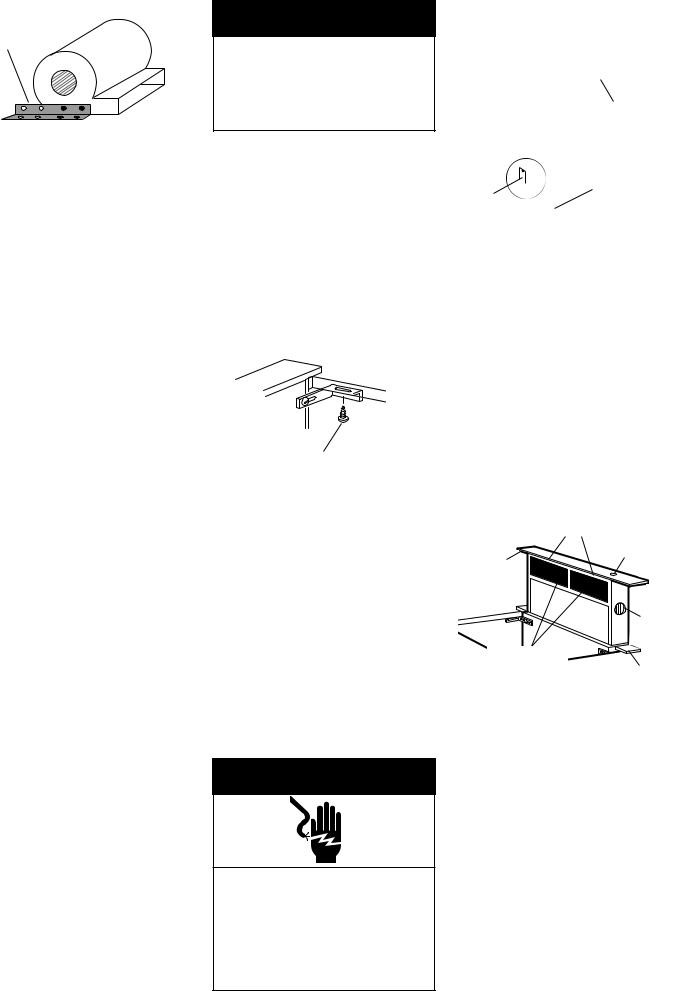

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install downdraft vent.

Failure to do so can result in back or other injury.

10. Insert downdraft vent into countertop cutout. Two people are recommended to support the weight of the downdraft vent during lifting. Position downdraft vent so it is centered in cutout and parallel to edge of cutout. Check that downdraft vent is level vertically. Then fasten lower support legs to cabinet floor with screws.

When attaching undercounter bracket to underside of countertop, make sure that the screw length will not go through countertop when tightened.

11. Attach one undercounter bracket on front upper right corner of downdraft vent with slot over vent mounting hole and flange against countertop. Attach other bracket to left side of downdraft vent. Carefully drill starter holes through undercounter mounting brackets into underside of countertop. Insert appropriate length screws into holes and tighten brackets to countertop.

8. Attach backdraft damper over blower box knockout with 2 Phillips-head screws.

9. Remove the 2 Phillips-head screws attaching the wiring box cover. Determine which direction (rear or down) electrical connection will need to run from appliance wiring box. Remove rear or bottom knockout and install conduit connector.

WARNING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Connect ground wire to green ground screw in terminal box.

Failure to do so can result in death or electrical shock.

12. Disconnect power.

green ground screw

wiring

box

conduit connector

13. Remove required knockout and install conduit connector. Feed the power supply cable through the conduit connector and into the wiring box. Connect the white wires together with a twist-on wire connector.

Connect the black wires together with a twist-on wire connector. Attach the green (or green and yellow) ground wire to eyelet with green ground screw. Tighten the conduit connector clamp screws. Replace the wiring box cover.

14. Reconnect power.

microswitches behind filters.

ON/OFF button

top trim

blower control knob

filter or filters |

|

depending on |

end cap |

model |

15.Push and hold for a few seconds the button on the top of the downdraft vent. Retractable section of downdraft vent will rise and blower will start. Position the top trim over the retractable section and snap trim into place.

8

16. Turn the control knob on side of vent to check the operation and speed of blower.

If blower does not operate:

•Check that filter or filters are pressed in as far as they will go.

•Check that circuit breaker is not tripped or house fuse blown.

•Disconnect power. Check that wire connections have been made correctly.

•Reconnect power.

17. Connect vent system to blower. Vent system must end with a wall or roof cap. Use duct tape to seal all joints.

18. Install cooktop according to manufacturer’s instructions. Check that rear of cooktop overlaps edge of retractable downdraft vent by 3/8" (9.5 mm).

To get the most efficient use from your new retractable downdraft vent, read the Use and Care Information section on page 12.

Keep Installation Instructions

and Use and Care Information close by for easy reference.

Exterior-mounted vent motor

KIRD and YKIRD

MODELS ONLY

NOTE: Exterior-mounted vent motor installations require exterior blower system, Model No. KPEC992M [900 cfm (25.5 m3/m)], available from your dealer or authorized parts supplier.

IMPORTANT: Exterior blower Model No. KPEU722M [1200 cfm (34.0 m3/3)] cannot be used with this retractable downdraft vent system.

Installation requirements

Island location

Built-in cabinet location

Roof venting

10" (25.4 cm) round vent

Maximum length of vent system

Vent |

Length |

10" (25.4 cm) round |

40 ft. (12.2 m) |

|

|

Vent length is given as a general reference only. For a longer vent run, or smaller vent system, contact a qualified and trained vent installer. Check with local codes for makeup air requirements, if any.

For best performance, use no more

than three 90° elbows. If more than Built-in cabinet location one elbow is used, make sure that

there is a minimum of 24 inches (61 cm) of straight vent between any two elbows. Do not install two elbows together.

It is recommended that you use round vent instead of rectangular vent, especially if elbows are required. If rectangular vent is required, it should be transitioned to 10" (25.4 cm) round vent as soon as possible.

Determining the length of system you need:

To calculate the length of system you need, add the equivalent feet for each duct piece that will be needed. See example for 10" (25.4 cm) round vent system.

10" (25.4 cm) round vent system

Maximum length = 40 ft. (12.2 m)

2 - 90 elbows |

= 10 |

ft. (3.05 m) |

10 ft. (3 m) straight |

= 10 |

ft. (3.05 m) |

|

|

|

Length of 10" |

|

|

(25.4 cm) system |

= 20 ft. (6.1 m) |

|

NOTE: The exterior-mounted vent motor requires a separate wiring cable that should be installed at the same time the vent work is installed.

left vent |

right vent |

9 |

Recommended standard |

|

fittings |

support leg |

90° elbow = |

45° elbow = |

4. Attach support legs to side of |

5 ft. (1.5 m) |

2.5 ft. (0.8 m) |

|

|

|

downdraft vent with two screws in |

|

|

|

|

|

each leg. Do not tighten screws. |

Installation steps

1. Put on gloves and safety glasses. Place cardboard or another form of protection on top of a flat surface where you can easily assemble the downdraft vent system. Remove parts packages, downdraft vent and blower box from carton. Remove all shipping materials, tape and protective film from downdraft vent and blower box.

over counter support arm

2. Attach the left side and right side overcounter support brackets to the downdraft. Use 1 screw with each bracket.

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install downdraft vent.

Failure to do so can result in back or other injury.

5. Carefully insert downdraft vent into countertop cutout. Two people are recommended to support the weight of the downdraft vent during lifting. Check that downdraft vent is parallel to side of cutout and that mounting brackets rest gently on countertop.

level

end cap

mark

3. Attach the left side and right side end caps to the downdraft. Use 1 screw with each end cap.

6. Move support legs down against cabinet floor. Place a level against front of downdraft vent base and adjust position of legs until downdraft is level vertically. Use a pencil to mark the top of each leg on face of downdraft vent. Then mark location of support leg mounting holes on cabinet floor. Remove downdraft vent from cutout. Drill starter holes at each mounting screw location on

cabinet floor. Align top of legs with pencil marks on face of downdraft vent. Tighten screws in legs.

7. Attach 10" (25.4 cm) round vent collar plate (supplied with exterior blower system) to front of downdraft vent using 4 hex washer nuts.

8. Remove the 2 Phillips-head screws attaching the wiring box cover and remove cover. Remove either the back or bottom knockout and install conduit connector.

NOTE: Power supply cable needed between exterior blower assembly and blower box is not provided.

9. Determine the location where the exterior blower box will be located. Cut opening in roof or wall for vent system to exterior blower. Install exterior blower according to instructions supplied with the blower kit.

Wall Installations:

•Use caulking compound between mounting flange and wall.

Roof Installations:

•Follow standard roofing procedures.

•The flashing sheet should be centered over the roof opening.

•Lower edge of flashing should lie on top of shingles and upper edge underneath shingles.

•Seal assembly between roof, fan and flashing with roofing mastic to prevent leaks.

10

Loading...

Loading...